Abstract

A large percentage of musculoskeletal disorder cases occur in brewing companies. The aim of this research study is to evaluate the risk of injuries for workers in the local brewing industry by integrating the actual human motion, which was captured by the Xsens MVN Awinda motion tracking system, with the JACK Siemens ergonomics tools. This proposed fusion technology greatly overcomes the time-consuming issue in the traditionally full-body simulation and the posture sensitivity issue in the current digital human modelling (DHM) technology. In this study, the subjects performed a series of daily lifting tasks utilizing 72 kg kegs. The forces exerted on the lower back of brewery workers were fully analyzed. The maximum load applied on the hands for each of the tasks was also estimated to prevent workers from injuries. Additionally, the key factors that highly correlate to lower back injuries were emphasized. Due to the heavy load applied by the kegs, large spinal forces were exerted on the lower back of workers. Moreover, reducing trunk and hip flexion is also important to prevent workers from injuries. The results of this study can greatly improve the implementation of training techniques, environmental modifications, and assistive device design, which aim to eliminate injury risk and increase the productivity of workers within the breweries.

Keywords:

injury; prevention; brewery; digital human modelling; motion tracking; ergonomics; lower back; productivity 1. Introduction

Over one-third of workers in the U.S. labor force experienced musculoskeletal disorders (MSDs) [1]. MSDs in U.S. businesses cost USD 31 billion a year, and the highest percentage of cost is directed toward the material and stock workers [2]. According to the Pennsylvania Craft Brewers Association, there are nearly 500 breweries in Pennsylvania, and the number is increasing each year [3]. In 2020, there were over 7000 breweries in the US, and that number has grown by 300% from the last decade [4]. Therefore, breweries are fast-growing companies, and the safety of their workers is becoming a huge concern. MSDs are prevalent in the brewing industry because of the nature and type of tasks they perform within a workday [5]. From one report, more than 400 claims were identified. The lifting task (23.1%) was listed as one of the top three injury types, and the lower back (12.8%) was the most frequent anatomical area [6]. Given that the heavy lifting and repetitive tasks among the workers, including manually lifting empty half-barrel kegs, which weigh approximately 14 kg, and full kegs weighing 72 kg, directly resulted in a significant increase in work-related MSDs [2,5,7]. The constant lifting, pulling, and pushing of these heavy weights and the high frequency and awkward postures typical of some tasks can also lead to a high risk of MSDs due to the excessive strain exerted on the lower back [2,7]. Moreover, many of these breweries are small and scaled businesses; therefore, workers are facing the problem of repetitive work with no switching of activities [5]. Small businesses also have the issue of a potential deficit of materials, such as handling robotic equipment. Hence, much of the work is handled manually [7].

Numerous methods have been utilized to reduce the risks of injuries in brewery workers, such as physiotherapy, stretching, and strengthening exercises; informing workers of the postures and movements that can cause the injuries; and carrying out surveys. Physiotherapists and occupational therapists can help solve the non-neutral and awkward postures by providing education and training on correct ergonomics, such as demonstrating the proper way to lift heavy objects [8]. Free manual handling training, such as stretching and strengthening exercises, is being provided as a treatment option for reducing MSDs [9,10]. The Brewers Association has also sponsored surveys where beer workers are able to convey commonplace injuries, safety program management, and the current state of safety in the Breweries [11]. These surveys help record the number of injuries every year so the breweries will be able to understand how the safety of the workers can be improved. However, there is no study that analyzed the lower back forces of the brewery workers for risk assessment.

Digital human modeling (DHM) technology has attracted attention as it can be used to deliver realistic results to avoid injuries at workplaces [12,13,14]. The popular available DHM software packages in the market are JACK (Siemens PLM software, Plano, TX, USA) [15], SANTOS (SantosHuman Inc., Coralville, IA, USA) [16], DELMIA (Dassault Systèmes, Paris, France) [17], SAMMIE (SAMMIE CAD Limited, Loughborough, UK) [18], Anybody (Anybody Technology, Aalborg, Denmark) [19], and OpenSim (Simbios, Stanford University, Stanford, CA, USA) [20]. DHM technology has been used to recognize acceptable postures in computer-related workplaces [21], enhance the productivity of the product by reducing the risk of MSDs [22], enable end-users to develop simulations and assess the injury risk in the manufacturing sector [13,23], simulate different tasks performed at healthcare workplaces to evaluate the risk of MSDs by analysis of lower back injuries [24,25,26,27,28], evaluate the lower back compression and shear forces for materials handling tasks [29], assess the muscle activity and joint reaction force for physical strain reduction [30], and assess the joint and muscle forces by analyzing different walking speeds [31]. JACK Siemens software has been widely implemented in different research areas [32,33] due to its adequate database of human performance models and population anthropometric data. Hence, its force outputs have been extensively validated [34,35]. However, limitations also exist within DHM technology. There is no clear understanding of the principles behind human movement and posture in many software [36], and predicted human movement cannot represent real human motion due to the limited human anthropometry and posture algorithm in the model, which accounts for a different distribution of forces at the modeled joints [25,37]. Additionally, most of the studies only focused on a sequence of static poses, which cannot imitate realistic full-body human kinematic movement. Hence, some inappropriate postures during the entire task performance could be easily negligible. However, these awkward postures are the main factors that directly lead to a high risk of injuries on the lower back occurring in workplaces [24,33]. Additionally, it is a time-consuming process to generate a full-body simulation. Each anatomical joint should be manually manipulated [38,39]. Moreover, a small difference of joint angles in DHM posturing can cause a statistical difference of the spinal forces exerted on the lower back [25,32,37].

Currently, there are many studies assessing the risk of injuries by analyzing recorded motion data [40,41,42]. However, only a few integrated advanced human motion tracking systems into ergonomic biomechanics software models [34]. In ref [34], the camera-based system was used to drive the classic JACK animation for the lower back load analysis. Due to the reflective markers, which were easily blocked by the surrounding objects or the body segments, the trajectory of blocked markers needs to be predicted by the nearby markers. To overcome this limitation, we decided to use the wearable inertial sensors to record full-body human movement. Each marker is easily tracked in the acceptable wireless range.

Accordingly, to effectively analyze the worker’s lower back load by using a common task that beer workers repeatedly must undergo and to overcome the aforementioned limitations in the current DHM technology, this study focused on integrating an advanced human motion tracking system with ergonomic software to overcome the issue of posture sensitivity as individual postures do not have to be manually estimated and later merged to form one dynamic simulation [43]. This integrated approach was implemented to evaluate the postures at which the risk of injury is the highest and can provide an estimate of the maximum load of each worker’s hand, leading to the lower back force reaching an unsafe threshold. This study provides a real-time physical training opportunity on how brewery workers can avoid awkward postures in their daily handling tasks. Additionally, this study can allow for the selection of appropriate assistive devices that should be involved when the spinal force reaches the threshold limit.

2. Methods

2.1. System Setup

This study was conducted in accordance with the Declaration of Helsinki and approved by the Institutional Review Board of Gannon University for studies involving humans. It was absolutely voluntary to attend. Informed consent was obtained from all subjects involved in the study.

We recruited all three male workers from a small craft brewery. All male workers performed lifting tasks using both empty and full kegs. The anthropometric data of each subject were measured for the creation of the digital human model by using the Xsens Awinda system (Xsens 3D Motion Tracking Technology, Enschede, Netherlands) [44]. The Xsens wearable inertial sensors have accurate motion estimation as they combine the accelerometers, gyroscopes, and magnetometers, as well as a combination with a Kalman filter to continuously correct the orientation drift generated by integrating the acceleration data [45]. The parameters of each subject included the shoulder and hip widths, the lengths of upper arms, lower arms, arm span, hands, thighs, shanks, and feet [25]. The body heights and body weights of the three subjects are listed in Table 1. Each skeletal model generated in Xsens Analyze software was used to record real human motion.

Table 1.

The body heights and body weights of three subjects (S1–S3).

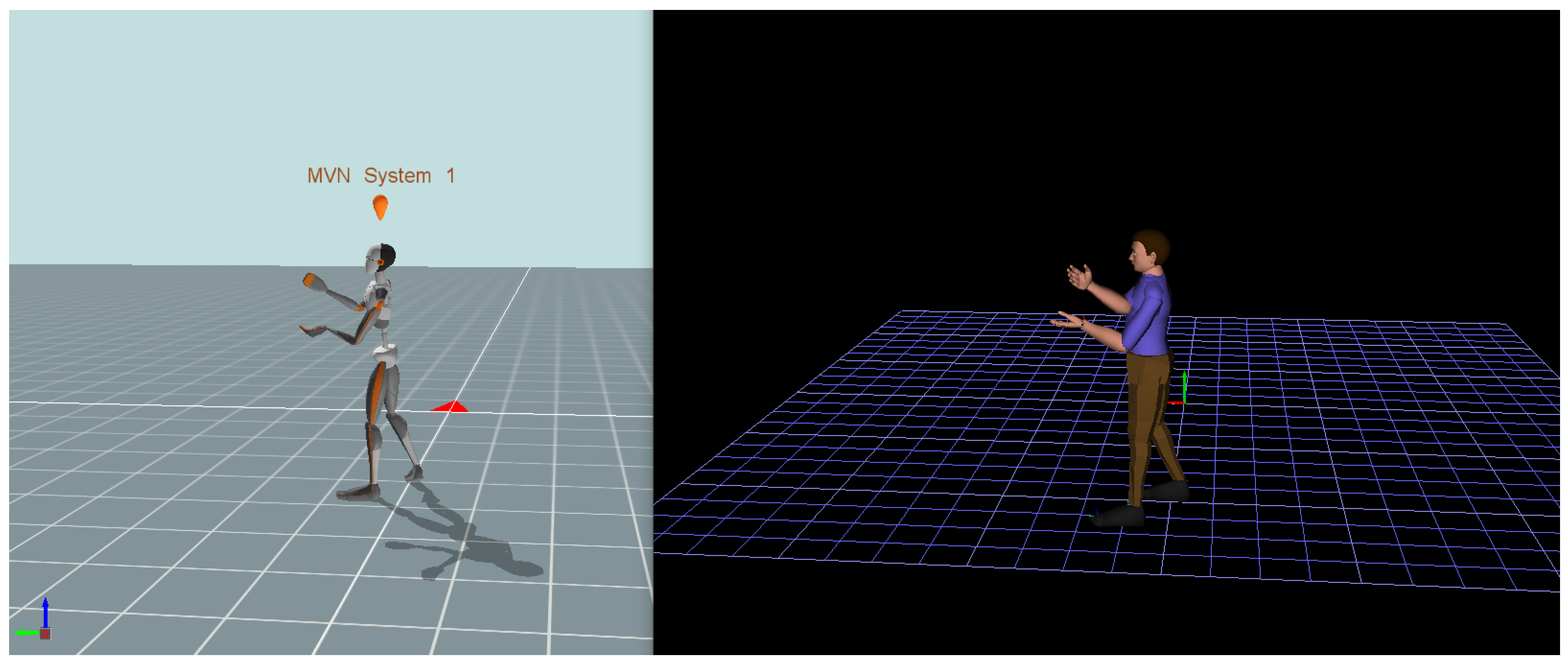

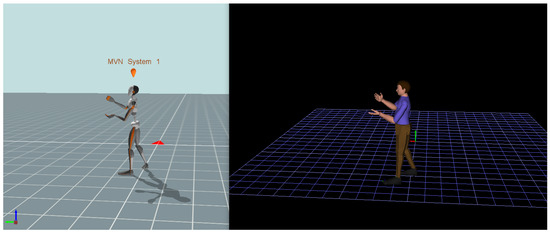

Additionally, for each subject, a second digital human model was created in JACK Siemens software to assess the injury risk. In this study, the skeletal model created by Xsens was imported into JACK software and constrained to the JACK model using the specific port number in Network Streamer. Hence, the movements performed by the JACK models follow the skeletal model on Xsens to achieve real human dynamic simulation, as shown in Figure 1.

Figure 1.

The integration of Xsens motion capture system with JACK ergonomics software. The Xsens model is on the left, which represents the recorded actual human movement, while the JACK model is on the right to represents the human dynamic simulation.

2.2. Task Performance and the Specific Poses in Each of the Tasks

All three participants performed two common daily tasks for brewery workers. Each subject was required to perform four cycles for each task. Within the whole movement, specific poses were identified as those maximizing the force acting on the lower back of each subject. The Task Analysis Toolkit in JACK was used to estimate the forces exerted on the 4th and 5th lumbar spine decomposing it into the compressive and shear anterior–posterior (A/P) force components. The spinal forces were estimated by inputting into the program the magnitude, point of application, and direction of each applied hand force using the Human Control Panel.

Task#1: An empty beer keg (0.6 m (height) by 0.4 m (width)) of approximately 14 kg was lifted from the floor using the dominant hand to be placed on the keg cleaner in front of the subjects, as shown in Figure 2. The height of the keg cleaner is approximately 1 m from the floor. As usual, there were no constraints on the standing position. Each subject just repeated their daily activities during the data collection. Two critical poses were detected as those eliciting maximal forces on the lower back. At Pose#1, the dominant hand was used to grab the handle of the keg by flexing the upper body to reach for the keg, as shown in Figure 2. To lift the empty keg, each subject must exert a vertically upwards direction force. Considering only one hand exerted the force on the 14 kg empty keg, the applied force on the dominant hand was approximately 140 N, which was calculated by the F = m × a. At Pose#2, the empty keg was placed on the keg cleaner by using the dominant hand. The magnitude and the direction of the force remained the same as the Pose#1. Although the other hand was placed on the side of the keg, considering the momentum of the keg, the force applied to the second hand is deemed negligible.

Figure 2.

Task#1: Lifting an empty beer keg from the floor and placing it on a keg cleaner: (a) Pose#1; (b) Pose#2.

Task#2: A full beer keg of approximately 72 kg was lifted from the floor using both hands to be placed on another full beer keg, as shown in Figure 3. Each subject needed to flex their knees and move their pelvis downwards to reach the keg, and both hands were used to grab the handle on both sides of the full keg. For Task#2, there were also two critical poses eliciting maximal forces acting on the lower back. At Pose#1, as the subjects flexed their upper body, the direction of applied forces was also vertically upwards to lift the full keg from the floor by using both hands. The magnitude of the overall applied force was calculated by the gravity of the full keg (72 kg × 9.8 m/s2). Hence, the magnitude of the applied force exerted on each hand was approximately 360 N. At Pose#2, each subject carried the full beer keg by bending the knees and hips to place it on top of another one. There was a tilt angle of the full beer keg, and each subject tried to use their right knee to distribute some of the load, but given that the tilt angle is small, nearly all the load of the full beer keg was applied to both hands. Hence, to estimate the force exerted on the lower back, we still used 360 N as a conservative magnitude of the applied force on each hand, assuming the direction of the application to be vertically upwards.

Figure 3.

Task#2: Lifting a full beer keg from the floor and placing it on top of another full keg: (a) Pose#1; (b) Pose#2.

2.3. Data Analysis

For each subject, the compressive and A/P shear forces acting on the lower back were determined at each of the aforementioned poses, where the corresponding joint angles for the trunk, hips, and knees were also estimated. The correlation coefficient R between said variables and the lumbar spine load was calculated to identify which variables are mostly covarying with the increase in force and thus may be an indirect indicator of a higher risk of injury in the brewery workers. Additionally, to fully understand the threshold value of lifting load applied to each hand in order to prevent workers from injury during daily activity, the maximum hand force for each subject was also predicted when the spinal forces reached the recommended safety threshold values defined as 3400 N for the compressive force [46] and 700 N for the A/P shear force [47].

3. Results

3.1. Pose#1 in Task#1

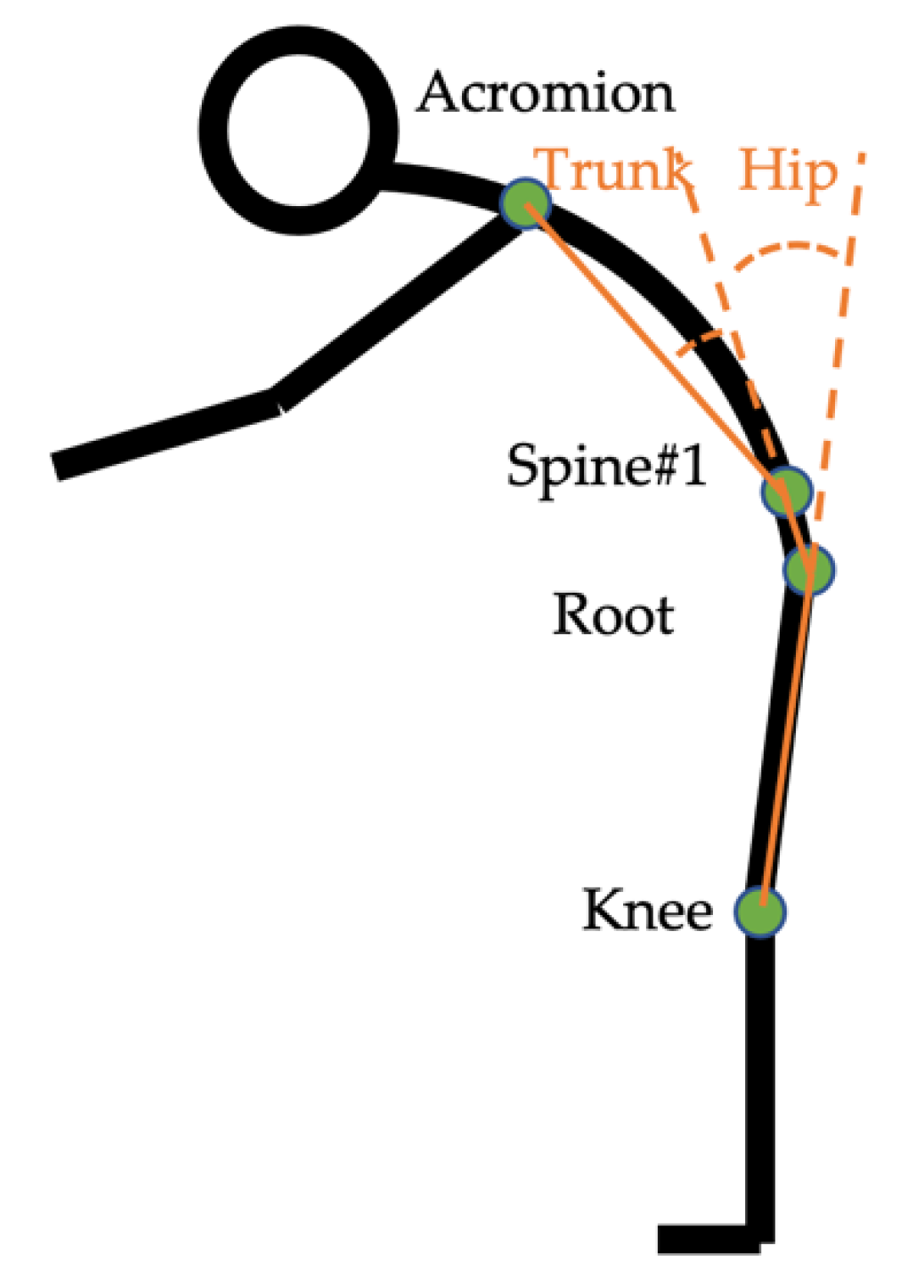

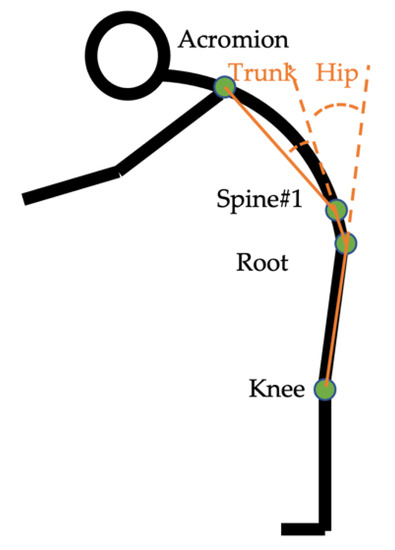

For the posture analysis, two reference joint centers were used to define the movement of the trunk and hips in the digital human model: (1) Spine#1: the center of two posterior superior iliac spines (PSIS); (2) Root: the center of two greater trochanters. Hence, the trunk angle is defined as the relative angular displacement between vector #1, (from Spine#1 to the Root) and vector #2 (from the Acromion to Spine#1). The hip angle is defined as the relative angular displacement between vector #1 (from Spine#1 to the Root) and vector #2 (from the Root to the Knee), as shown in Figure 4. The joint angle distributions of the trunk, hips, and knees among the three subjects are listed below. Assuming that the trunk and hip angles are 0° at the neural pose (when the person stands erected), the positive and negative values for the trunk, hips, and knees indicate flexion and extension, respectively.

Figure 4.

The definition of trunk and hip angles in the digital human model.

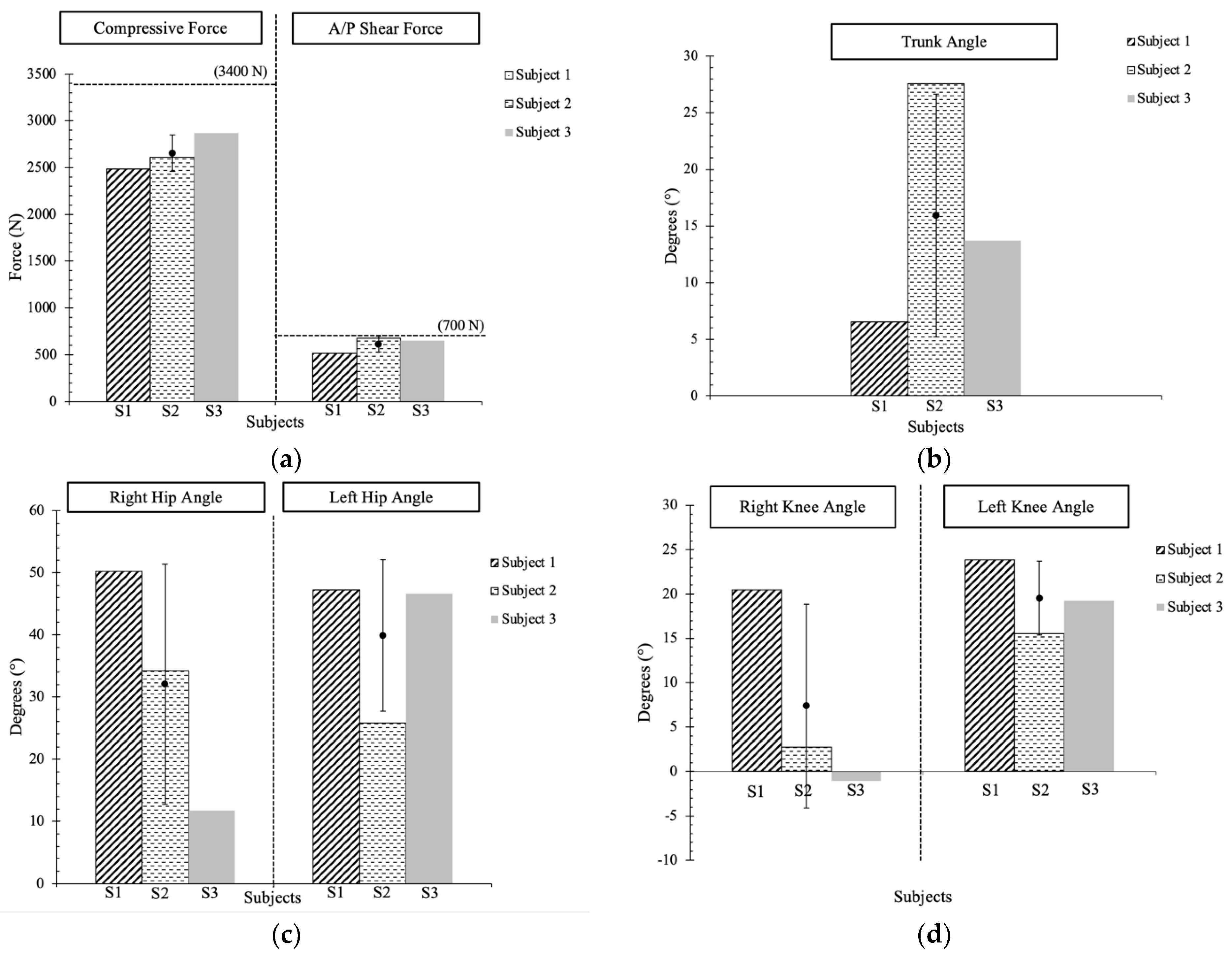

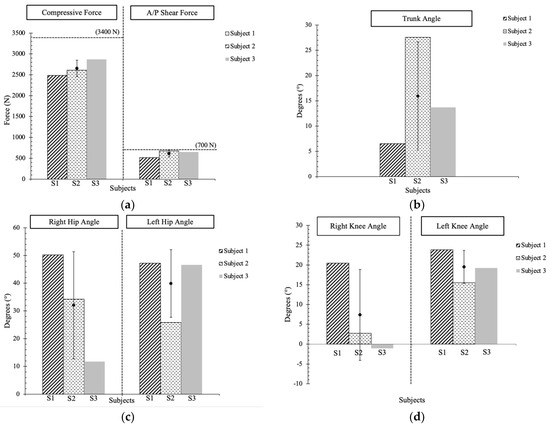

Between subjects, the range of compressive load on the lower back ranged between 2485.2 N and 2869.2 N (2654.4 ± 196.0 N), while the A/P shear forces ranged from 517.8 N to 674.0 N (613.8 ± 84.1 N), as shown in Figure 5. The predicted maximum hand load to prevent workers from injury was approximately 200 N for the spinal forces to reach the recommended safety threshold.

Figure 5.

The analyzed results at Pose#1 in Task#1: (a) the exposed spinal forces with the recommended safety threshold values; (b) the trunk angles; (c) the hip angles; (d) the knee angles.

- Trunk: range from 6.5° to 27.6° (15.9 ± 10.7°) in Figure 5b;

- Right hip: range from 11.7° to 50.2° (32.1 ± 19.3°) in Figure 5c;

- Left hip: range from 25.8° to 47.2° (39.9 ± 12.2°) in Figure 5c;

- Right knee: range from −1.1° to 20.4° (7.4 ± 11.5°) in Figure 5d;

- Left knee: range from 15.5° to 23.8° (19.5 ± 4.2°) in Figure 5d.

For the correlation coefficient analysis, the A/P shear force and trunk flexion have a strong correlation with R = 0.81. The other variables do not show a strong correlation at this specific pose.

3.2. Pose#2 in Task#1

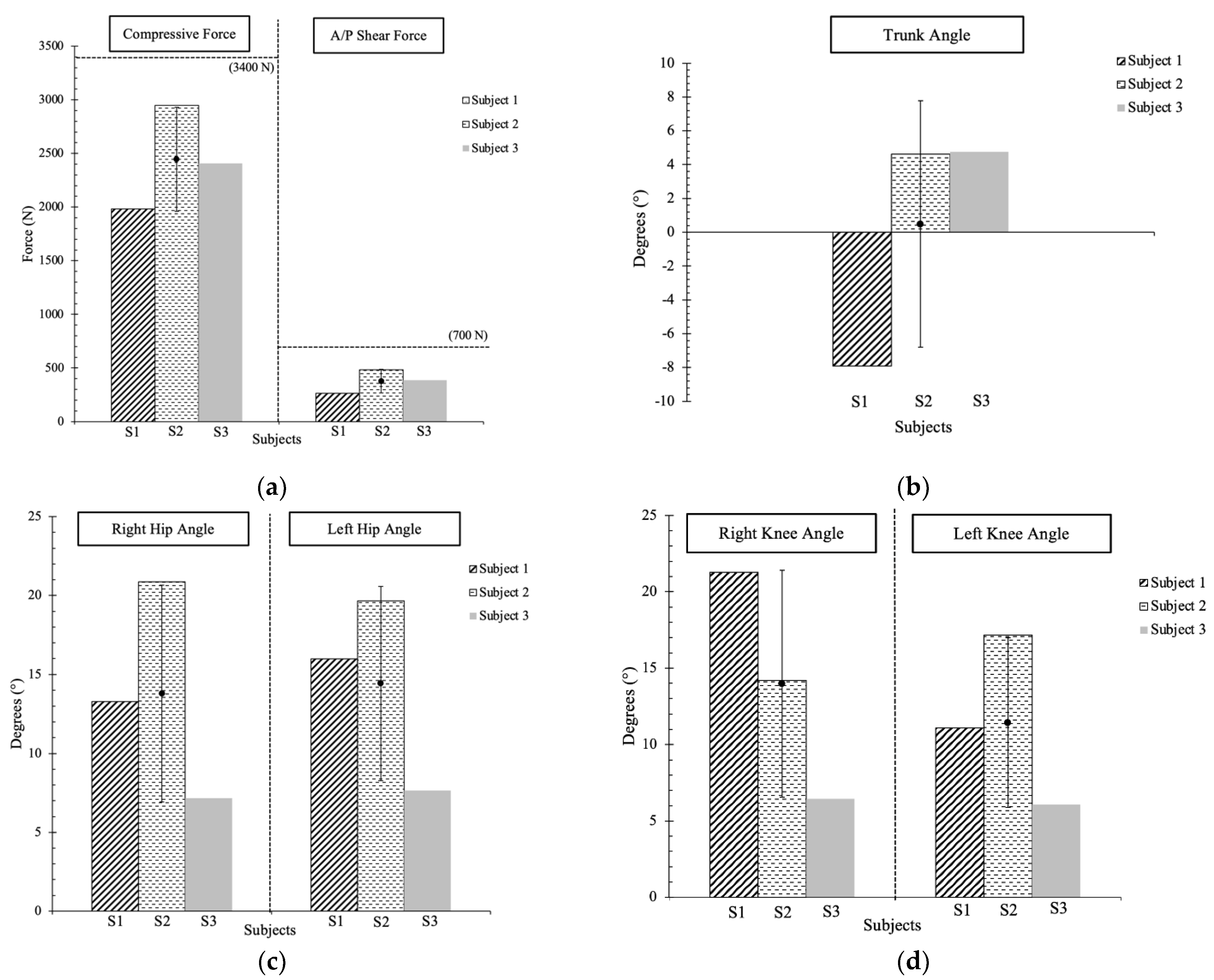

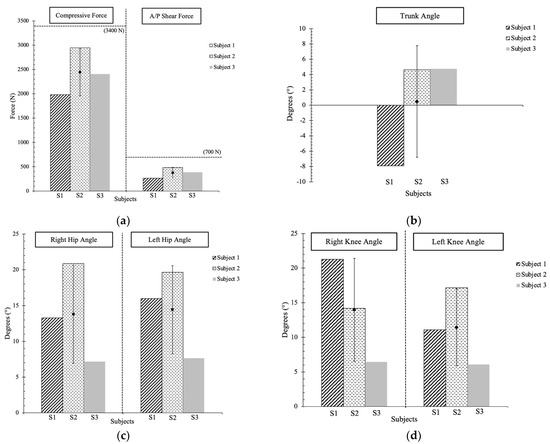

At this specific pose, the compressive forces ranged from 1982.5 N to 2947.7 N (2445.3 ± 483.8 N) for all three subjects, and the range of A/P shear forces was from 263.7 N to 482.0 N (376.7 ± 109.3 N), as shown in Figure 6. The estimated maximum hand load was approximately 240 N when the spinal loads reached the recommended safety threshold values.

Figure 6.

The analyzed results at Pose#2 in Task#1: (a) the exposed spinal forces with the recommended safety threshold values; (b) the trunk angles; (c) the hip angles; (d) the knee angles.

For the posture analysis, the joint angles of the trunk, hips, and knees are listed below:

- Trunk: range from −7.9° to 4.8° (0.5 ± 7.3°) in Figure 6b;

- Right hip: range from 7.2° to 20.9° (13.8 ± 6.9°) in Figure 6c;

- Left hip: range from 7.7° to 19.7° (14.4 ± 6.2°) in Figure 6c;

- Right knee: range from 6.5° to 21.3° (14.0 ± 7.4°) in Figure 6d;

- Left knee: range from 6.1° to 17.2° (11.4 ± 5.5°) in Figure 6d.

For the correlation coefficient analysis, the A/P shear force and trunk flexion also have a strong correlation with R = 0.77 at this specific pose.

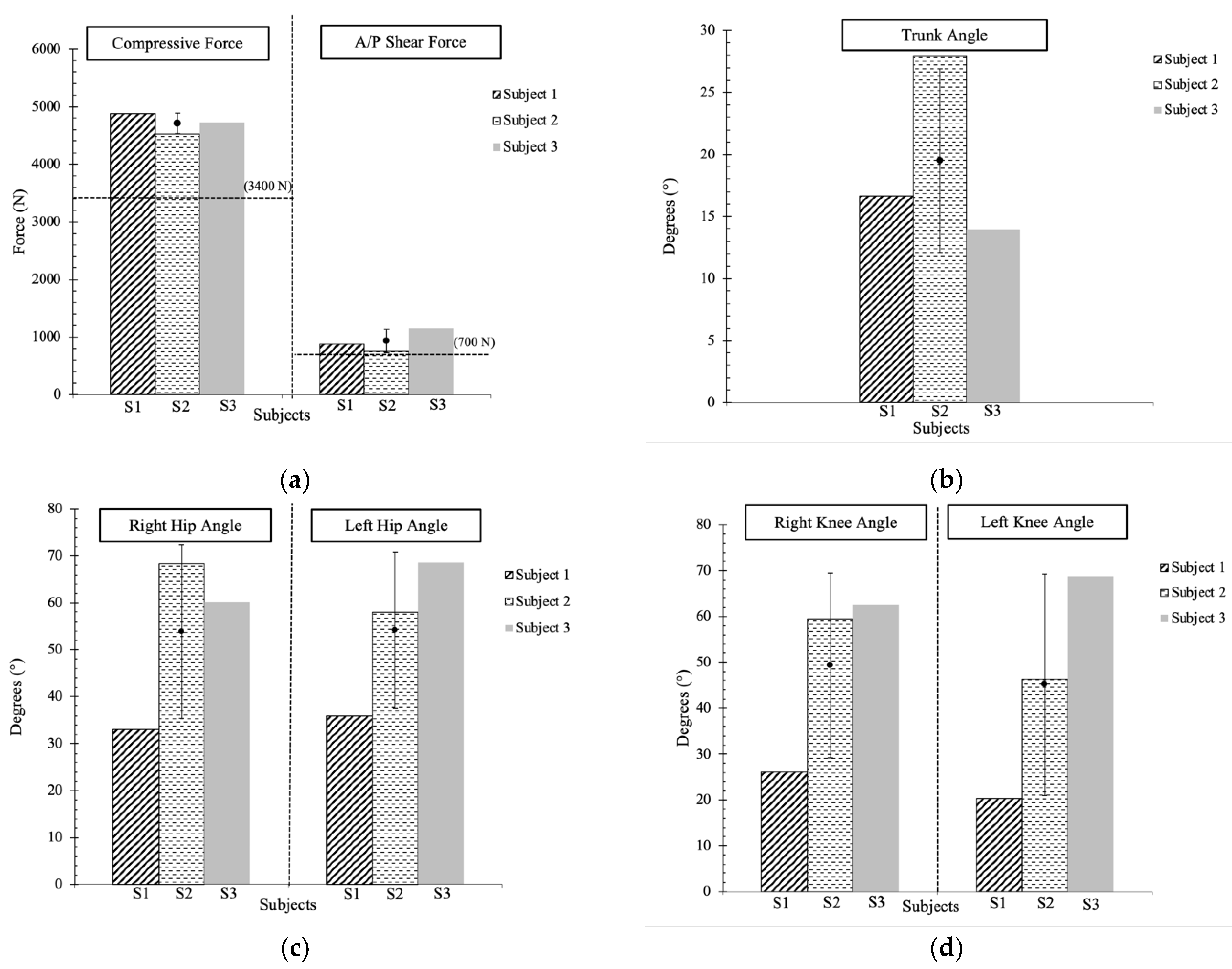

3.3. Pose#1 in Task#2

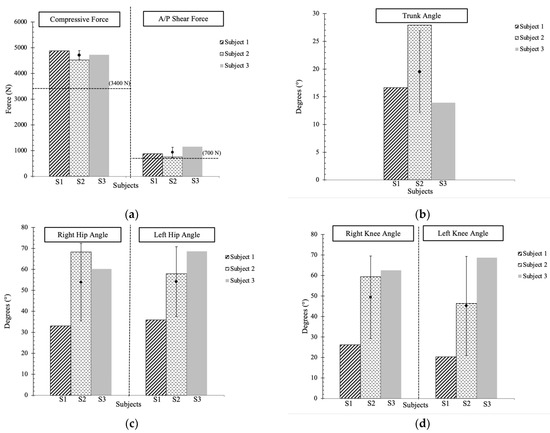

At this specific pose, the compressive forces and the A/P shear forces ranged from 4525.4 N to 4881.2 N (4709.0 ± 178.2 N) and from 754.3 N to 1153.3 N (930.1 ± 203.7 N) for all three subjects, respectively, as shown in Figure 7. The estimated maximum hand force was approximately 220 N for safety considerations.

Figure 7.

The analyzed results at Pose#1 in Task#2: (a) the exposed spinal forces with the recommended safety threshold values; (b) the trunk angles; (c) the hip angles; (d) the knee angles.

For the posture analysis, the joint angles of the trunk, hips, and knees are listed below:

- Trunk: range from 13.9° to 27.9° (19.5 ± 7.4°) in Figure 7b;

- Right hip: range from 33.1° to 68.4° (53.9 ± 18.5°) in Figure 7c;

- Left hip: range from 36.0° to 68.6° (54.2 ± 16.7°) in Figure 7c;

- Right knee: range from 26.2° to 62.6° (49.4 ± 20.2°) in Figure 7d;

- Left knee: range from 20.4° to 68.7° (45.2 ± 24.2°) in Figure 7d.

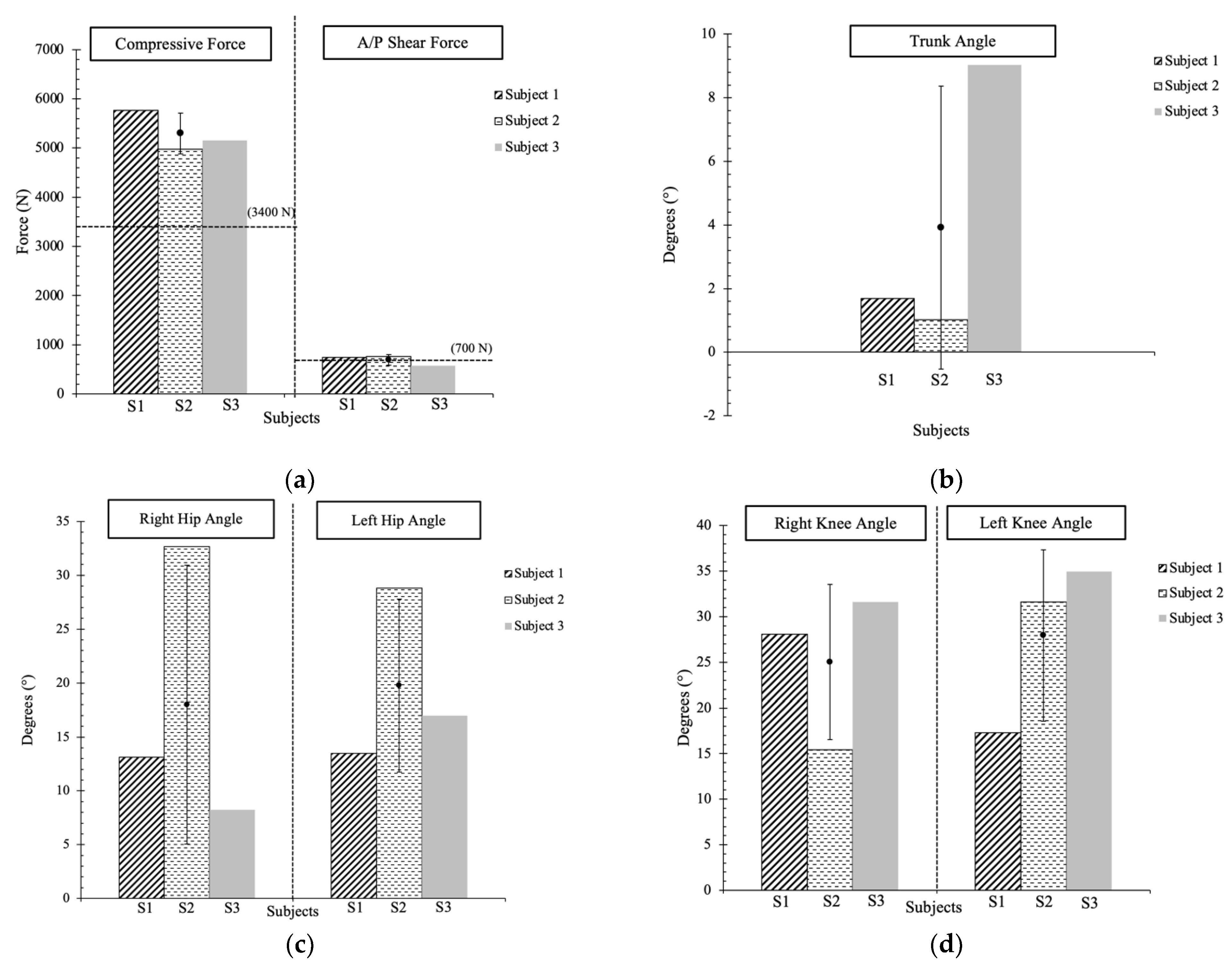

3.4. Pose#2 in Task#2

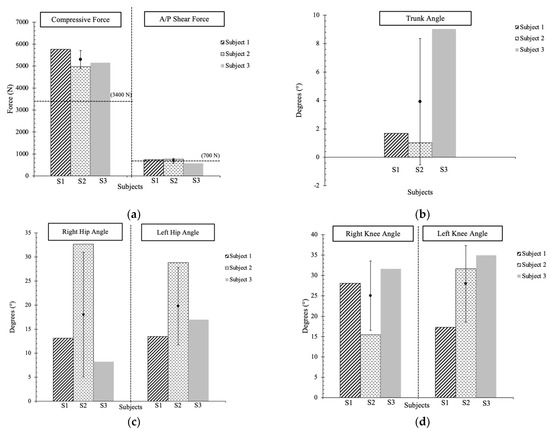

At this specific pose, the compressive forces and the A/P shear forces ranged from 4973.9 N to 5762.1 N (5297.1 ± 412.8 N) and from 572.1 N to 766.2 N (695.8 ± 107.5 N) for all three subjects, respectively, as shown in Figure 8. Moreover, the estimated maximum hand force was approximately 215 N for safety considerations.

Figure 8.

The analyzed results at Pose#2 in Task#2: (a) the exposed spinal forces with the recommended safety threshold values; (b) the trunk angles; (c) the hip angles; (d) the knee angles.

For the posture analysis, the joint angles of the trunk, hips, and knees are listed below.

- Trunk: range from 1.0° to 9.0° (3.9 ± 4.4°) in Figure 8b;

- Right hip: range from 8.2° to 32.7° (18.0 ± 12.9°) in Figure 8c;

- Left hip: range from 13.5° to 28.8° (19.8 ± 8.0°) in Figure 8c;

- Right knee: range from 15.4° to 31.6° (25.0 ± 8.5°) in Figure 8d;

- Left knee: range from 17.3° to 34.9° (28.0 ± 9.4°) in Figure 8d.

4. Discussion

This study provided one of the first digital ergonomics analyses for brewery workers. The maximum compressive and A/P shear forces were estimated during two common tasks the workers perform daily. Such tasks consist of placing an empty keg on a cleaning platform and lifting a full keg from the ground, and placing it on top of a second keg. The corresponding anatomical joint angles were monitored during the movements. The correlation coefficient between joints and spinal loads determines the key factors affecting the transmission of forces from the hands to the lower back.

In Task#1 at Pose#1, the subjects lifted the empty keg from the floor, and the A/P shear force and trunk angular displacement show a strong correlation, which is consistent with the results obtained from previous studies [48,49] that considered lifting movements. The compressive force was increased with the increase in trunk flexion angle. In [25], a high correlation between compressive force and trunk movement was revealed. Our results reaffirmed this conclusion. The literature shows that a small trunk flexion in parallel with a relatively large hip flexion will result in a less compressive force acting on the lower back than a large trunk flexion with a small hip flexion. However, following this model, as subject#3 flexed his trunk to 13.7° compared to subject#2 (27.6°), the latter is supposed to have a larger exerted spinal force than subject#3, but the compressive force estimated on subject#3 was the higher. In this case, we posit that the additional asymmetric hip flexion (right hip: 11.7°, left hip: 46.6°) is an additional cause for high risk. Furthermore, as the average A/P shear force among the three subjects for this pose was more than 600 N, the workers should be aware that if there is any beer left in the empty keg, the load on the lower back will easily reach the recommended safety threshold limit of 700 N.

At Pose#2 in Task#1, as the subjects placed the empty keg on the keg holder, there still is a high correlation between the A/P shear force and trunk flexion. The average A/P shear force exerted on the lower back was greatly reduced at this pose compared with the force at Pose#1 due to the greatly reduced trunk flexion. Additionally, subject#1 extended his trunk to place the empty keg on the holder, while subject#2 flexed his trunk, which directly led to an approximately 1000 N difference in the compressive force acting on their lower back. The result is also consistent with one previous study [25]. However, the difference in compressive force between subject#2 and subject#3 was approximately 500 N, even though the trunk flexion of both subjects was approximately 5°. The hip flexion (20° vs. 7°) might play an important role, as it did at Pose#1.

For Task#1, if we compare the body height and body weight among these three subjects, subject#2 is the tallest and thinnest, which may cause him to bend the upper body more than the others if the position of the object is constrained, which is consistent with the result in [24]. A previous study [50,51] emphasized that the proper lifting postures should be with the knees bent, as the upper body is kept straight, inducing the subject to use the strength of the lower body to lift the load. In our population, subject#1 seemed to follow the proper lifting techniques very well.

In Task#2, at Pose#1, the subjects lifted the full kegs from the floor. The full kegs are quite heavy, inducing a force applied on the lower back that is much higher than the recommended safety threshold limits for both compressive and A/P shear forces. This is despite all three subjects having adopted a large knee flexion to avoid more upper-body bending. To avoid workers from becoming injured, the maximum applied force to each hand cannot exceed 200 N (approximately a full load of 41 kg) at this specific pose. Hence, an assistive device ought to be adopted to help reduce the weight of the full keg.

At Pose#2 in Task#2, as the subjects placed the full keg on top of another one, the forces exerted on the lower back of all three subjects were much greater than the recommended safety thresholds, even though they maintained a relatively neutral position. This is due to the extended arms of each subject that are paralleled with the trunk flexion, resulting in a load of full keg applied fully to the spinal discs. At this specific pose, the maximum estimated force applied to each hand was approximately 210 N (approximately a full load of 43 kg), resulting in the exerted spinal forces reaching the recommended safety thresholds.

Hence, for Task#2, to lift a full keg from the floor, even all three subjects with a large variety of body weight and body height, who followed the proper lifting techniques, the load of the keg was too heavy, and it must be reduced by adding an assistive device so that the risk of becoming injured for workers could be effectively eliminated. Alternatively, training to implement a two-person lift should be implemented, which may need to be further studied.

5. Conclusions

The local brewery workers are at high risk during their daily activities, such as lifting kegs. This study successfully evaluated the risk of injuries for workers in the local brewing industry by implementing the proposed fusion technology. It greatly overcomes the time-consuming issue in the traditionally full-body simulation and the posture sensitivity issue in the current DHM technology. From this study, the extremely large spinal forces exerted on their lower back were mainly due to the heavy load applied by the objects. Adding an assistive device seems mandatory for the worker’s safety considerations if they are to move the loads alone. Moreover, proper training to adopt a neutral posture is also important for workers to reduce trunk and hip flexion, which highly affects the magnitude of the compressive force as they lift the load.

Author Contributions

Conceptualization, X.J., N.L.L. and D.P.; Methodology, X.J.; Software, X.J., R.O.H. and A.L.E.L.; Validation, D.P.; Formal analysis, X.J.; Investigation, X.J.; Resources, X.J. and N.L.L.; Data curation, X.J., R.O.H. and A.L.E.L.; Writing—original draft, X.J., R.O.H. and A.L.E.L.; Writing—review & editing, N.L.L. and D.P. All authors have read and agreed to the published version of the manuscript.

Funding

Manufacturing PA Innovation Program: 1060170-457922.

Institutional Review Board Statement

This study was conducted in accordance with the Declaration of Helsinki, and approved by the Institutional Review Board of Gannon University (protocol code: GUIRB-2021-10-6803, and date of approval: November 2021) for studies involving humans.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Not applicable.

Acknowledgments

This work was partially funded by the Manufacturing PA Innovation Program.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Statistics, B.O.L. The Economics Daily: Back Injuries Prominent in Work-Related Musculoskeletal Disorder Cases in 2016. U.S. Department of Labor. Available online: https://www.bls.gov/opub/ted/2018/back-injuries-prominent-in-work-related-musculoskeletal-disorder-cases-in-2016.htm (accessed on 8 October 2022).

- Post, J.L. Five Workplace Safety Tips on Tap: How Craft Breweries Can Keep Workers Injury-Free. Craft Brewing Business. Retrieved September 6, 2022. Available online: https://www.craftbrewingbusiness.com/featured/five-workplace-safety-tips-on-tap-how-craft-breweries-can-keep-workers-injury-free/ (accessed on 26 September 2022).

- B.A. Pennsylvania’s Craft Beer Sales & Production Statistics, 2021. Available online: https://www.brewersassociation.org/statistics-and-data/state-craft-beer-stats/?state=PA (accessed on 22 January 2023).

- Association, B. State Craft Beer Sales & Production Statistics. Available online: https://www.brewersassociation.org/statistics/by-state/ (accessed on 15 September 2022).

- Lavery, N. Occupational Health and Breweries: A Collaborative Approach. Master Brew. Assoc. Am. 2021, 58, 34–36. [Google Scholar]

- Brents, C.; Rosecrance, J. Work-Related injuries among craft brewery workers in Colorado, 2015–2018. In Proceedings of the Human Factors Society Conference, Seattle, WA, USA, 28 October–1 November 2019; p. 129. [Google Scholar]

- Xsens. Measuring Low Back Biomechanics during Beer Keg Handling. Available online: https://www.xsens.com/cases/measuring-low-back-biomechanics-beer-keg-handling (accessed on 8 October 2022).

- De Beer, A.; Cordier, W. Spinal revival: The management of lower back pain. S. Afr. Gen. Pract. 2022, 3, 19–21. [Google Scholar] [CrossRef]

- Finnie, S. Brewers Association. The Ergonomics of Brewing: Avoiding Injury and Staying the Course in the Brewery. Available online: https://www.brewersassociation.org/seminars/the-ergonomics-of-brewing-avoiding-injury-and-staying-the-course-in-the-brewery/ (accessed on 15 September 2022).

- Finnie, S.; Lavery, N. Brewers Association. Brewery Ergonomics: How to Stay Safe and Healthy in Your Brewery. Available online: https://www.brewersassociation.org/seminars/brewery-ergonomics-how-to-stay-safe-and-healthy-in-your-brewery/ (accessed on 23 January 2023).

- Embry, E.; Stinchfield, M. Brewers Association. Praise and Paradox: What We Learned from the Brewers Association Safety and Injury Survey. Available online: https://www.brewersassociation.org/seminars/praise-and-paradox-what-we-learned-from-the-brewers-association-safety-and-injury-survey/ (accessed on 15 September 2022).

- Hussain, M.M.; Qutubuddin, S.; Kumar, K.P.R.; Reddy, C.K. Digital human modeling in ergonomic risk assessment of working postures using RULA. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Bangkok, Thailand, 5–7 March 2019; pp. 5–7. [Google Scholar]

- Cao, W. Ergonomic Assessment of Sonography Workplace and Posture Parameters Using Digital Human Modeling; State University of New York at Binghamton: Binghamton, NY, USA, 2011. [Google Scholar]

- Maurya, C.M.; Karmakar, S.; Das, A.K. Digital human modeling (DHM) for improving work environment for specially-abled and elderly. SN Appl. Sci. 2019, 1, 1–9. [Google Scholar] [CrossRef]

- Siemens. Human Factor and Ergonomics. Available online: https://www.plm.automation.siemens.com/global/en/products/manufacturing-planning/human-factors-ergonomics.html (accessed on 2 February 2023).

- Santoshuman. Products for Human-Centric Design. Available online: https://www.santoshumaninc.com/products/ (accessed on 2 February 2023).

- DASSAULT Systems. DELMIA Products. Available online: https://www.3ds.com/products-services/delmia/ (accessed on 2 February 2023).

- Sammie. The SAMMIE DHM SYSTEM. Available online: https://www.lboro.ac.uk/microsites/lds/sammie/dhm.html (accessed on 2 February 2023).

- AnyBody. AnyBody Technology. Available online: https://www.anybodytech.com (accessed on 21 February 2023).

- OpenSim. Simbios. Available online: https://opensim.stanford.edu (accessed on 21 February 2023).

- Estrada, J.E.; Vea, L.A. Modelling and Simulation of Spine in Sitting Posture in a Computer-Related Workplace. IJCSMC 2018, 7, 121–135. [Google Scholar]

- Iriondo Pascual, A.; Högberg, D.; Syberfeldt, A.; Brolin, E.; Perez Luque, E.; Hanson, L.; Lämkull, D. Multi-objective optimization of ergonomics and productivity by using an optimization framework. In Proceedings of the Congress of the International Ergonomics Association, online, 13–18 June 2021; pp. 374–378. [Google Scholar]

- Fletcher, S.R.; Johnson, T.L.; Thrower, J. A study to trial the use of inertial non-optical motion capture for ergonomic analysis of manufacturing work. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 90–98. [Google Scholar] [CrossRef]

- Ji, X.; Piovesan, D.; Conley, K. The Effect of Pulling Effort on Lumbar Spine via Applying Digital Human Modeling Technology. In Proceedings of the Institute of Industrial and Systems Engineers (IISE) Annual Conference, Seattle, WA, USA, 21–24 May 2022; pp. 21–24. [Google Scholar]

- Ji, X.; Piovesan, D.; Arenas, M.; Liu, H. Analysis of Healthcare Push and Pull Task via JACK: Predicted Joint Accuracy during Full-Body Simulation. Appl. Sci. 2022, 12, 6450. [Google Scholar] [CrossRef]

- Quintero-Duran, M.; Paul, G. Ergonomic assessment of a physical task using two different digital human modelling systems: A case study. Int. J. Hum. Factors Model. Simul. 2018, 6, 298–313. [Google Scholar] [CrossRef]

- Paul, G.; Quintero-Duran, M. Ergonomic Assessment of Hospital Bed Moving Using DHM Siemens JACK. In Proceedings of the 19th Triennial Congress of the International Ergonomics Association, Melbourne, VIC, Australia, 9–14 August 2015. [Google Scholar]

- Cao, W.; Jiang, M.; Han, Y.; Khasawneh, M.T. Ergonomic assessment of patient barrow lifting technique using digital human modeling. In Proceedings of the Digital Human Modeling and Applications in Health, Safety, Ergonomics, and Risk Management. Human Body Modeling and Ergonomics: 4th International Conference, DHM 2013, Held as Part of HCI International 2013, Las Vegas, NV, USA, 21–26 July 2013; Proceedings, Part II 4, 2013. pp. 20–29. [Google Scholar]

- Wagner, D.W.; Reed, M.P.; Rasmussen, J. Assessing the importance of motion dynamics for ergonomic analysis of manual materials handling tasks using the AnyBody Modeling System. SAE Trans. 2007, 116, 2092–2101. [Google Scholar]

- Fritzsche, L.; Galibarov, P.E.; Gärtner, C.; Bornmann, J.; Damsgaard, M.; Wall, R.; Schirrmeister, B.; Gonzalez-Vargas, J.; Pucci, D.; Maurice, P. Assessing the efficiency of exoskeletons in physical strain reduction by biomechanical simulation with AnyBody Modeling System. Wearable Technol. 2021, 2, e6. [Google Scholar] [CrossRef]

- Alexander, N.; Schwameder, H.; Baker, R.; Trinler, U. Effect of different walking speeds on joint and muscle force estimation using AnyBody and OpenSim. Gait Posture 2021, 90, 197–203. [Google Scholar] [CrossRef] [PubMed]

- Chaffin, D.B. Improving digital human modelling for proactive ergonomics in design. Ergonomics 2005, 48, 478–491. [Google Scholar] [CrossRef]

- Ji, X.; Littman, A.; Hettiarachchige, R.O.; Piovesan, D. The Effect of Key Anthropometric and Biomechanics Variables Affecting the Lower Back Forces of Healthcare Workers. Sensors 2023, 23, 658. [Google Scholar] [CrossRef]

- Cutler, B.; Merritt, T.; Eger, T.; Godwin, A. Using Peak Vicon data to drive Classic JACK animation for the comparison of low back loads experienced during para-rowing. Int. J. Hum. Factors Model. Simul. 2015, 5, 99–112. [Google Scholar] [CrossRef]

- Qi, Z.; Chen, Y. Investigation of Ergonomics in Photocuring 3D Printing Post-Processing Using Jack. In Proceedings of the 2020 IEEE 7th International Conference on Industrial Engineering and Applications (ICIEA), Bangkok, Thailand, 16–21 April 2020; pp. 326–329. [Google Scholar]

- Lad, U. Comparing the Kinematic and Kinetic Outputs from Digital Human Modeling Tools to a Lab-Based Rigid-Link Model for the Investigation of Musculoskeletal Disorder Hazards During Patient Handling; University of Waterloo: Waterloo, ON, Canada, 2018. [Google Scholar]

- Ji, X.; Tiari, S. Posture evaluation for the full-body dynamic simulation in JACK Siemens PLM. Int. J. Hum. Factors Ergon. 2022, 9, 261–281. [Google Scholar] [CrossRef]

- Rhén, I.-M.; Forsman, M.; Örtengren, R.; Högberg, D.; Keyvani, A.; Lämkull, D.; Hanson, L. Ergonomic risk assessment in DHM tools employing motion data-exposure calculation and comparison to epidemiological reference data. Int. J. Hum. Factors Model. Simul. 2018, 6, 31–64. [Google Scholar] [CrossRef]

- Wegner, D.; Chiang, J.; Kemmer, B.; Lämkull, D.; Roll, R. Digital Human Modeling Requirements and Standardization; SAE Technical Paper 0148-7191; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Haggag, H.; Hossny, M.; Nahavandi, S.; Creighton, D. Real time ergonomic assessment for assembly operations using kinect. In Proceedings of the 2013 UKSim 15th International Conference on Computer Modelling and Simulation, Cambridge, UK, 10–12 April 2013; pp. 495–500. [Google Scholar]

- Caputo, F.; Greco, A.; D ‘Amato, E.; Notaro, I.; Spada, S. Imu-based motion capture wearable system for ergonomic assessment in industrial environment. In Proceedings of the Advances in Human Factors in Wearable Technologies and Game Design: Proceedings of the AHFE 2018 International Conferences on Human Factors and Wearable Technologies, and Human Factors in Game Design and Virtual Environments, Orlando, FL, USA, 21–25 July 2018; pp. 215–225. [Google Scholar]

- Bortolini, M.; Faccio, M.; Gamberi, M.; Pilati, F. Motion Analysis System (MAS) for production and ergonomics assessment in the manufacturing processes. Comput. Ind. Eng. 2020, 139, 105485. [Google Scholar] [CrossRef]

- Constantinescu, C.; Todorovic, O.; Ippolito, D. Comprehensive modelling and simulation towards the identification of critical parameters for evaluation of exoskeleton-centred workplaces. Procedia CIRP 2019, 79, 176–179. [Google Scholar] [CrossRef]

- Movella. MVN Awinda. Available online: https://www.movella.com/products/motion-capture/xsens-mvn-awinda (accessed on 2 February 2023).

- Roetenberg, D.; Luinge, H.; Slycke, P. Xsens MVN: Full 6DOF human motion tracking using miniature inertial sensors. Xsens Motion Technol. BV Tech. Rep. 2009, 1, 1–7. [Google Scholar]

- Waters, T.R.; Putz-Anderson, V.; Garg, A.; Fine, L.J. Revised NIOSH equation for the design and evaluation of manual lifting tasks. Ergonomics 1993, 36, 749–776. [Google Scholar] [CrossRef]

- Gallagher, S.; Marras, W.S. Tolerance of the lumbar spine to shear: A review and recommended exposure limits. Clin. Biomech. 2012, 27, 973–978. [Google Scholar] [CrossRef]

- Cavaguchi, A.M.; Oliveira, M.R.; Macedo, C.G.; Souza, P.E.d.; Aguiar, A.F.; Dallaire, M.; Ngomo, S.; Silva, R.A.d. Impact of lifting of two types of barrels on postural control, trunk muscle recruitment, and kinematic measures in manual workers. Int. J. Environ. Res. Public Health 2019, 16, 2183. [Google Scholar] [CrossRef] [PubMed]

- Rohlmann, A.; Bauer, L.; Zander, T.; Bergmann, G.; Wilke, H.-J. Determination of trunk muscle forces for flexion and extension by using a validated finite element model of the lumbar spine and measured in vivo data. J. Biomech. 2006, 39, 981–989. [Google Scholar] [CrossRef] [PubMed]

- Schoenfeld, B.J. Squatting kinematics and kinetics and their application to exercise performance. J. Strength Cond. Res. 2010, 24, 3497–3506. [Google Scholar] [CrossRef] [PubMed]

- UNC. Environment, Health and Safety. Lifting and Material Handling. Available online: https://ehs.unc.edu/topics/ergonomics/lifting-and-material-handling/ (accessed on 3 November 2021).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).