SYSML4TA: A SysML Profile for Consistent Tolerance Analysis in a Manufacturing System Case Application

Abstract

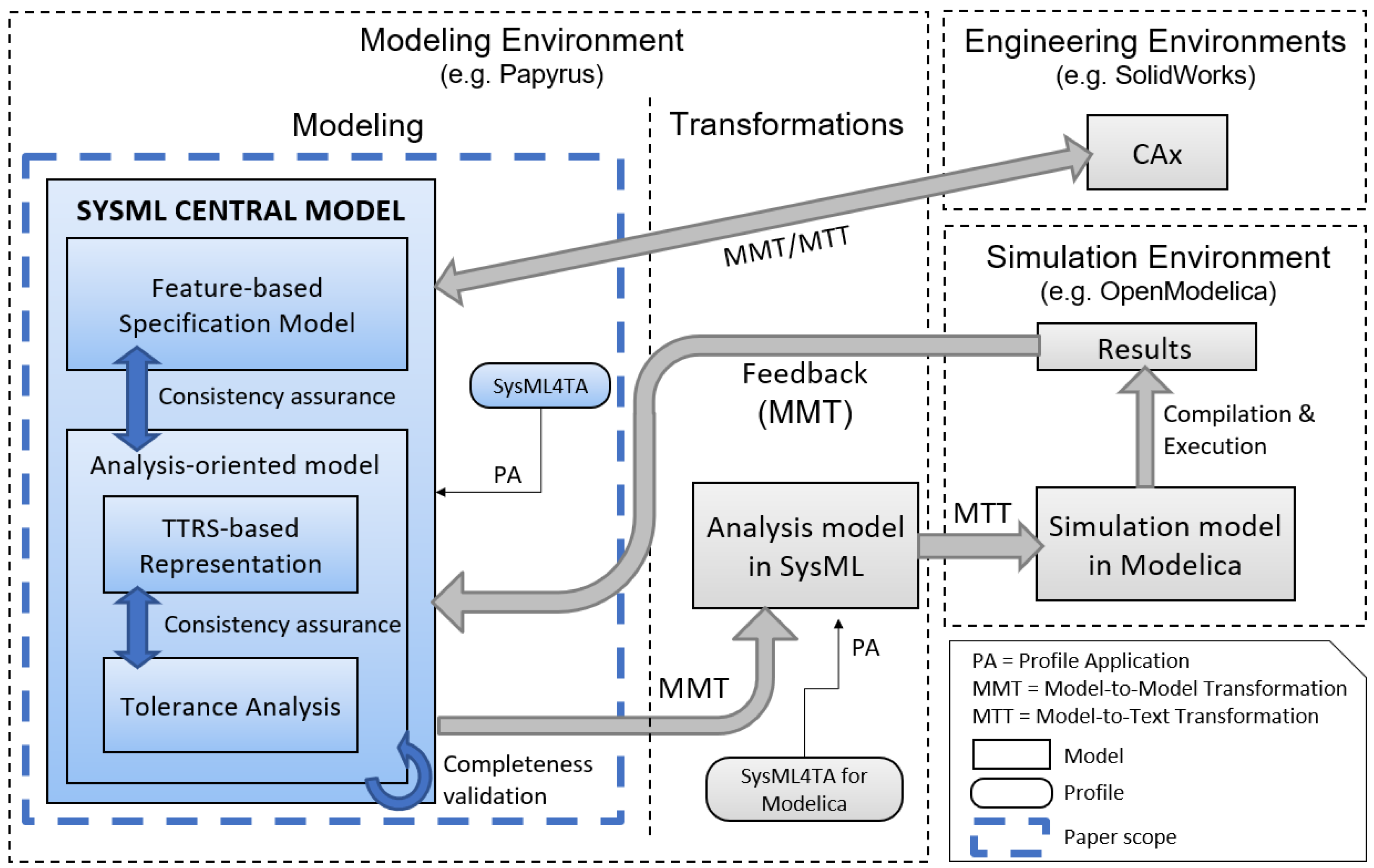

:1. Introduction

2. TTRS and Mathematical Modeling

2.1. Technologically and Topologically Related Surfaces (TTRS)

2.2. Mathematical Modeling

3. DSML-Based Methodology Proposal

3.1. SysML Profile for Tolerance Analysis (SYSML4TA)

3.1.1. Artifact Modeling Profile Package (ArtMPP)

3.1.2. Feature-Based Modeling Profile Package (FMPP)

3.1.3. TTRS-Based Modeling Profile Package (TTRS_MPP)

3.1.4. Tolerance Analysis Profile Package (TAPP)

3.2. Tolerance Analysis Library (TA_Library)

3.2.1. Feature-Based Modeling Library Package (FMLP)

3.2.2. TTRS-Based Modeling Library Package (TTRS_MLP)

3.2.3. Tolerance Specification Library Package (TSLP)

3.3. Procedure

3.3.1. Assembly Modeling

3.3.2. TTRS-Based Modeling

3.3.3. Tolerance Analysis Modeling

4. Case Study

4.1. Assembly Modeling

4.2. TTRS-Based Modeling

4.3. Tolerance Analysis Modeling

5. Discussion

6. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Stereotype | Extends to | Definitions and Constraints |

|---|---|---|

| «Artifact» | «Block» | Specification of a distinctive entity (component) in a physical system. It is an abstract stereotype whose specializations are «Part» and «Assembly». |

| «Part» | «Artifact» («Block») | Specification of an atomic Artifact that cannot be decomposed in other Artifacts, so a «Part» Block cannot contain another «Artifact» («Part» or «Assembly») Block (C1). Any «Part» Block must contain at least one «Feature» or «F_TTRS_Repr» Block (C2). |

| «Assembly» | «Artifact» («Block») | Specification of a composite Artifact that is composed of at least two «Artifact» («Part» or «Assembly») Blocks (C3). Any property typed by an «Artifact» Block must own at least one «AssemblyFeature» or «AssemblyMGRE» Port (C4) to support its assembly relationships with other Artifacts. |

| Stereotype | Extends to | Definitions and Constraints |

|---|---|---|

| «Feature» | «Block» | The specification of a shape portion of an Artifact. Every «Feature» Block must belong to an «Artifact» («Part» or «Assembly») Block (C6) to avoid orphaned features. |

| «FC_Specification» | «Block» | Specification of a Functional Condition defining the acceptable variability limits of a target feature with respect to some datum features. A «FC_Specification» Block must own a «ToleranceSize» Property and 2 to 4 «FeatureUsage» Ports (C8). |

| «GT_Specification» | «Block» | Specification of a geometric tolerance defining the size of the tolerance zone that represents the limits of the acceptable variability according to a type of positional/orientational imposed relationship from some datum features to a target feature. A «GT_Specification» Block must own a «ToleranceSize» Property and 2 to 4 «FeatureUsage» Ports (C9). |

| «ToleranceSize» | UML4SYSML:: «Property» | Property that specifies the size of a tolerance zone (Real value), so a «ToleranceSize» Property must be owned by a «FC_Specification» or «GT_Specification» Block and be typed by a Real (C10). |

| «FeatureUsage» | UML4SYSML:: «Port» | Port that represents a Feature participating in a geometric tolerance specification, either as datum or target. To define the role, the «FeatureUsage» stereotype has an Attribute (“role”) typed by an Enumeration with the EnumerationLiteral (datum, target). Moreover, the «FeatureUsage» stereotype has an Attribute (“order”) typed by an Enumeration that includes EnumerationLiteral (none, FirstRef, SecondRef, ThirdRef). If the «FeatureUsage» Port is a target (role = target), no order can be defined (order = none), and if the «FeatureUsage» Port is a datum (role = datum), order must be defined (order≠none) (C11). A «FeatureUsage» Port is always owned by a «GT_Specification» or «FC_Specification» Block and typed by a «Feature» Block (C12). |

| «Assembly Feature» | UML4SYSML:: «Port» | Port that represents a Feature offered by an Artifact to participate in assembly relationships. A «Assembly Feature» Port must be typed by a «Feature» Block and be owned by an «Artifact» («Part» or «Assembly») Block (C13). |

| Stereotype | Extends to | Definitions and Constraints |

|---|---|---|

| «F_TTRS_Repr» | «Block» | A TTRS-based representation of a feature, including MGREs defined with respect to the Local and the Global reference system related by a transformation. For this reason, a «F_TTRS_Repr» Block must contain (a) a «MGRE_repr» Block, representing the local definition; (b) a behavior Port typed by a «MGRE_repr» Block, representing the global definition; (c) a ConstraintBlock that supports the transformation between Local and Global reference systems; (d) a «TM_Port» behavior Port, that enables using the transformation matrix defined in the owner «Part» Block (artifact) (C14). Any Property typed by a «F_TTRS_Repr» Block always has the «Representation» Stereotype applied (C15). |

| «MGRE» | «Block» | Minimal geometric reference elements for a surface according to its invariant class. An «MGRE» Block is composed of at least one «RGE» Block and at most three «RGE» Blocks (C16). A «MGRE» Block must contain as many «RGE Constraint» ConstraintBlocks as the number of RGEs minus 1 (C17). If the «MGRE» Block contains more than one «RGE» Block, each one must be connected with at least one Parameter of an «RGE Constraint» ConstraintBlock (C18). The seven types of MGRE are defined at a library level. |

| «MGRE_repr» | «Block» | A TTRS-based representation of a feature, including both the nominal and deviated definition. For this reason, an «MGRE_repr» Block must contain a) a «MGRE_usage» behavior Port, representing the nominal definition and b) a «MGRE_usage» behavior Port, representing the deviated definition (C19). |

| «MGRE_usage» | UML4SYSML:: «Port» | Behavior Port typed by a «MGRE» Block (20), differentiating its use to support nominal or deviated definition of a geometry. The «MGRE_usage» stereotype has a Boolean Attribute (isDeviated) that distinguishes between its use to define nominal (“false”) or deviated (“true”) geometries. |

| «RGE» | «Block» | A reduced geometric element (TTRS concept) that is used to construct an MGRE. Any «RGE» Block must be owned by a «MGRE» Block (C21). An RGE can be points, planes, or lines, but these elements are defined at the library level. |

| «TTRS» | «Block» | Entity that represents a pair of related MGREs, defining constraints between them. A «TTRS» Block must own two Ports typed by «MGRE» Blocks, two Properties typed by «MGRE» Blocks, and at least one «RGE Constraint» ConstraintBlock (C22). |

| «RGE Constraint» | «ConstraintBlock» | Geometric constraint between two RGEs, corresponding to the 13 simple cases shown in Figure 2. These 13 constraints are defined at the library level. The «RGE Constraint» ConstraintBlock must own two Parameters typed by «RGE» Blocks (C23). |

| «Representation» | UML4SYSML:: «Property» | Property that represents another element of the model from a different viewpoint. The «Representation» stereotype has an Attribute (“representsTo”) to define the element it represents. The owner of a «Representation» Property must also own another Property whose name coincides with the value of the “representsTo” Attribute (C24). |

| «Assembly MGRE» | UML4SYSML:: «Port» | Port typed by a «F_TTRS_Repr» block (C25) that represents a geometry offered by an Artifact to participate in assembly relationships.An «Assembly MGRE» Port must be owned by an «Artifact» («Part» or «Assembly») Block (C26). |

| «TransformationMatrix» | UML4SYSML:: «Property» | Homogeneous matrix that supports the translation and rotation of geometry definitions to change the reference system considered. It is a Property that characterizes a Part, so every geometry owned by this Part must be transformed in the same way. For this reason, the owner «Part» Block must contain only one «TransformationMatrix» Property (C27). |

| «TM_Port» | UML4SYSML:: «Port» | Behavior Port owned by an «F_TTRS_Repr» Block that is connected with the «TransformationMatrix» Property of the Part owning the «F_TTRS_Repr» Block (C28). |

| «GT_TTRS_definition» | «Block» | Mathematical definition of a geometric tolerance between TTRS-based feature representations. Any Property typed by a «GT_TTRS_definition» Block always has the «Representation» stereotype applied (C29). A «GT_TTRS_definition» Block must own a «TZ_TTRS_definition» Block, 2 to 4 «TTRS_Repr_usage» Ports (C42), and the same quantity of Properties typed by «F_TTRS_Repr» Blocks as «TTRS_Repr_usage» Ports (C30). Moreover, a «GT_TTRS_definition» Block must own the same or higher quantity of Properties typed by «TTRS» Blocks than the double of the number of «TTRS_Repr_usage» Ports with the Attribute role = datum (C31) to relate the tolerance zone with the considered nominal and deviated data. A «GT_TTRS_definition» Block must own (direct or indirectly) two Properties typed by «SpecifValidation» and «TargetConstruction» ConstraintBlocks, respectively, that relate the tolerance zone with the target geometry and a «TargetDeviation» Property in which deviations for the target constructions are defined (C32). |

| «SpecifValidation» | «ConstraintBlock» | Validation of the specification consistency, checking that the nominal MGRE of the target coincides or is included in the nominal MGRE of the tolerance zone (constructed from the nominal MGRE of the datums). A «SpecifValidation» ConstraintBlock includes a Boolean Parameter (C33) to transfer the result of the validation. |

| «TargetConstruction» | «ConstraintBlock» | Construction of the deviated MGRE for the target geometry, using a «DeviationVector» Parameter (C34) according to the limits imposed by the tolerance zone MGRE and its size. |

| «TZ_TTRS_definition» | «Block» | A geometrical space used to control/define the position/orientation of a target geometry. This geometrical space is characterized by a size, specified in a geometric tolerance specification, so a «TZ_TTRS_definition» Block owns an AdjunctProperty that points to the «ToleranceSize» Property of a Property typed by a «GT_Specification» Block (35). A «TZ_definition» Block also owns two «MGRE» Blocks, one of them with the Attribute “isNominal = true” and another with the Attribute “isNominal = false” (C36). |

| «TTRS_Repr_usage» | UML4SYSML:: «Port» | TTRS-based representation used as a reference (datum) or target element in the definition of a geometric tolerance. Any «TTRS_Repr_usage» Port is always owned by a «GT_Specification» or «FC_Specification» Block and typed by an «F_TTRS_Repr» Block (C37).The «TTRS_Repr_usage» stereotype has an Attribute (“role”) typed by an Enumeration with EnumerationLiterals (datum, target), and an Attribute (“order”) typed by an Enumeration with EnumerationLiterals (none, FirstRef, SecondRef, ThirdRef). If the «TTRS_Repr_usage» Port is a target (role = target), no order can be defined (order = none), and if the «TTRS_Repr_usage» Port is a datum (role = datum), order must be defined (order ≠ none) (C38). |

| «TargetDeviation» | UML4SYSML:: «Property» | Property that expresses the displacements (deviations) in the variant DoFs of the target MGRE. Any «TargetDeviation» Property must be owned by a «GT_TTRS_definition» or «GT_TTRS_deviation» Block and must be typed by a «DeviationVector» DataType (C39). |

| «DeviationVector» | UML4SYSML:: «DataType» | DataType that is defined to express the small displacements of a deviated MGRE with respect to the nominal position. All the DataValues considered must be typed by a Real primitive (C40). |

| Stereotype | Extends to | Definition and Constraints |

|---|---|---|

| «TolAnalysisModel» | «Block» | Block that includes analysis of different Functional Chains. Any «TolAnalysisModel» Block is composed of at least one «Chain Analysis» Blocks (C41). A «TolAnalysisModel» Block must aggregate the «Artifact» («Part» or «Assembly») Block to be analyzed (C42). |

| «ChainAnalysis» | «Block» | Block that contains the tolerance analysis of a Functional Chain. It must contain a «ChainConstruction» Block and at least one «AnalysisSpecification» Block (43). |

| «ChainConstruction» | «Block» | The definition of the Functional Chain to be analyzed, including the Functional Condition, the links and nodes involved, and other additional constraints to define the configuration, if necessary. Any «ChainConstruction» Block must include a «Functional Condition» Block, at least two «TTRS_Link» AdjunctProperties, and at least three «TTRS_Node» AdjunctProperties (C44). All owned «TTRS_Link» or «TTRS_Node» Blocks must point to constructions with a common parent «Artifact» Block (C45). Moreover, it is necessary to ensure that the chain is closed (C46). |

| «Analysis Specification» | «Block» | Specification of an analysis for a Functional Chain, where input Parameters are defined according to the tolerance stacking method. To establish the input Parameters, an «AnalysisSpecification» Block must own at least one «AnalysisParameter» Property and a «ParamAssignment» ConstraintBlock (C47) to assign those Parameters to Properties of each link. Moreover, an «AnalysisSpecification» Block must own an «FC_Value» Property and an «FC_Requirement» AdjunctProperty, as well as an «FC_Compliance» ConstraintBlock in which both values are compared (C48). |

| «Functional Condition» | UML4SYSML:: «Property» | A Functional Condition under analysis, generally defined in the specification model (feature-based representation). A «FunctionalCondition» Property must have also applied the «Representation» stereotype (C49). Structurally, a Functional Condition is equivalent to a geometric tolerance where deviations are not defined, but calculated by the rest of the Functional Chain, so a «FunctionalCondition» Property must be typed by a «GT_TTRS_deviation» Block (C50). |

| «FC_Value» | «AdjunctProperty» | AdjunctProperty owned by a «ChainAnalysis» Block (C51) to store the accumulated deviation of the Functional Condition. An «FC_Value» AdjunctProperty must point to a property of the «TZ_TTRS_definition» Block owned by the «Functional Condition» Block (C52). |

| «FC_Requirement» | «AdjunctProperty» | AdjunctProperty owned by a «ChainAnalysis» Block (C53) to store the limits imposed by the Functional Condition specification, so the «FC_Requirement» AdjunctProperty must point to a «ToleranceSize» Property of an «FC_Specification» Block (C54). |

| «FC_Compliance» | «ConstraintBlock» | ConstraintBlock owned by a «ChainAnalysis» Block (C55) to prove with an inequation if the calculated deviation is lower than the requirement. One Parameter of the «FC_Compliance» ConstraintBlock must be connected with an «FC_Value» AdjunctProperty and another to the «FC_Requirement» AdjunctProperty (C56). |

| «TTRS_Link» | «AdjunctProperty» | A link of the Functional Chain, that is, one of the TTRS-based definitions of geometric tolerances that participates in the constructed chain. A «TTRS_Link» AdjunctProperty must be owned by a «ChainAnalysis» Block, and its Principal Attribute must point to a «GT_TTRS_deviation» Block (C57). |

| «TTRS_Node» | «AdjunctProperty» | A node of the Functional Chain, that is, one of the TTRS-based feature representations that participates in the constructed chain. A «TTRS_Node» AdjunctProperty must be owned by a «ChainAnalysis» Block and point to an «F_TTRS_Repr» Block (C58). Each «TTRS_Node» AdjunctProperty must be connected with a «TTRS_Link» AdjunctProperty or a «Functional Condition» Block through their Ports (C59). |

| «AnalysisParameter» | UML4SYSML:: «Property» | Property owned by a «ChainAnalysis» Block and typed by a to a «DeviationVector» DataType (C60) to state the values of deviations considered depending on the tolerance stacking method (worst case, statistical, Monte Carlo simulation, etc.). |

Appendix B

| Rule | OCL Expression |

|---|---|

| C1 | self.base_Class.allAttributes()->select(a|a.type.oclIsKindOf(UML::Class)).type.oclAsType (UML::Class).getAppliedStereotypes().allParents()->select(b|b.name = ‘Artifact’)->isEmpty() |

| C4 | self.base_Class.allAttributes()->select(a|a.type.oclIsKindOf(UML::Class)).type.oclAsType(UML::Class) ->select(b|b.getAppliedStereotypes().allParents()->select(c|c.name = ‘Artifact’)->notEmpty())-> forAll(d|d.ownedPort.getAppliedStereotypes()->select(e|e.name = ‘AssemblyFeature’ or e.name = ‘AssemblyMGRE’)->notEmpty()) |

| C46 | self.base_Class.allAttributes()->select(b|b.type.oclIsKindOf(UML::Class))->select(c|c. getAppliedStereotypes()->select(d|d.name = TTRS_)->notEmpty()) ->forAll(node|self. base_Class.allFeatures()->select(f|f.oclIsKindOf(UML::Connector)). oclAsType(UML::Connector).ownedElement->select(g|g.oclIsKindOf(UML::ConnectorEnd)). oclAsType(ConnectorEnd).role->select(h|h.oclType() = UML::Property)->select(i|i = node)->size() = 2) and self.base_Class.allAttributes()->select(j|j.type.oclIsKindOf(UML::Class))->select(k|k. getAppliedStereotypes()->select(l|l.name = ‘TTRS_Link’)->notEmpty())->forAll(link|self. base_Class.allFeatures()->select(n|n.oclIsKindOf(UML::Connector)) .oclAsType(UML::Connector).ownedElement->select(o|o.oclIsKindOf(UML::ConnectorEnd)). oclAsType(UML::ConnectorEnd).partWithPort->select(p|p = link)->size() = 2) and let C:Integer = self.base_Class.allFeatures()->select(a|a.oclIsKindOf(UML::Connector))->size() in C>0 and let N:Integer = self.base_Class.allAttributes()->select(b|b.type.oclIsKindOf(UML::Class)). getAppliedStereotypes()->select(c|c.name = ‘TTRS_Node’)->size() in C=2*N and let L:Integer = self.base_Class. allAttributes()->select(b|b.type.oclIsKindOf(UML::Class)).getAppliedStereotypes()->select(c|c. name=‘TTRS_Link’)->size() in N = L |

References

- Akundi, A.; Lopez, V. A Review on Application of Model Based Systems Engineering to Manufacturing and Production Engineering Systems. Procedia Comput. Sci. 2021, 185, 101–108. [Google Scholar] [CrossRef]

- Batteux, M.; Prosvirnova, T.; Rauzy, A. Model Synchronization: A Formal Framework for the Management of Heterogeneous Models. In Model-Based Safety and Assessment; Papadopoulos, Y., Aslansefat, K., Katsaros, P., Bozzano, M., Eds.; Springer: Cham, Switzerland, 2019; Volume 11842. [Google Scholar] [CrossRef] [Green Version]

- Torres, W.; van den Brand, M.G.J.; Serebrenik, A. A systematic literature review of cross-domain model consistency checking by model management tools. Softw. Syst. Model. 2021, 20, 897–916. [Google Scholar] [CrossRef]

- Feldmann, S.; Kernschmidt, K.; Wimmer, M.; Vogel-Heuser, B. Managing inter-model inconsistencies in model-based systems engineering: Application in automated production systems engineering. J. Syst. Softw. 2019, 153, 105–134. [Google Scholar] [CrossRef]

- Qamar, A.; Paredis, C.J.J.; Wikander, J.; During, C. Dependency Modeling and Model Management in Mechatronic Design. J. Comput. Inf. Sci. Eng. 2012, 12, 041009. [Google Scholar] [CrossRef] [Green Version]

- Höpfner, G.; Jacobs, G.; Zerwas, T.; Drave, I.; Berroth, J.; Guist, C.; Rumpe, B.; Kohl, J. Model-Based Design Workflows for Cyber-Physical Systems Applied to an Electric-Mechanical Coolant Pump. In Proceedings of the 19th Drive Train Technology Conference (ATK 2021), Aachen, Germany, 9–11 March 2021. [Google Scholar] [CrossRef]

- Wagner, H.; Zuccaro, C. Collaboration between System Architect and Simulation Expert. In Proceedings of the IEEE International Symposium on Systems Engineering, Vienna, Austria, 24–26 October 2022. [Google Scholar] [CrossRef]

- Benavent Nácher, S.; Rosado Castellano, P.; Romero Subirón, F.; Abellán-Nebot, J.V. Multidomain Simulation Model for Analysis of Geometric Variation and Productivity in Multi-Stage Assembly Systems. Appl. Sci. 2020, 10, 6606. [Google Scholar] [CrossRef]

- Abellan-Nebot, J.V.; Liu, J.; Romero, F. Design of multi-station manufacturing processes by integrating the stream-of-variation model and shop-floor data. J. Manuf. Syst. 2011, 30, 70–82. [Google Scholar] [CrossRef]

- OMG Systems Modeling Language (SysML) v. 1.6. Available online: https://sysml.org/.res/docs/specs/OMGSysML-v1.6-19-11-01.pdf (accessed on 13 January 2023).

- OMG Object Constraint Language (OCL), v. 2.4. Available online: https://www.omg.org/spec/OCL/ (accessed on 13 January 2023).

- Moeser, G. Integration of a visually supported Function-Embodiment-Synthesis into the Concepts of Model Based Systems Engineering (MBSE). In Proceedings of the 3rd International Spring School on Systems Engineering, Paderborn, Germany, 4–8 May 2015. [Google Scholar]

- Jagla, P.; Jacobs, G.; Siebrecht, J.; Wischmann, S.; Sprehe, J. Using SysML to Support Impact Analysis on Structural Dynamics Simulation Models. Procedia CIRP 2021, 100, 91–96. [Google Scholar] [CrossRef]

- Brahmi, R.; Hammadi, M.; Aifaoui, N.; Choley, J.Y. Interoperability of CAD models and SysML specifications for the automated checking of design requirements. Procedia CIRP 2021, 100, 259–264. [Google Scholar] [CrossRef]

- Berriche, A.; Mhenni, F.; Mlika, A.; Choley, J.-Y. Towards Model Synchronization for Consistency Management of Mechatronic Systems. Appl. Sci. 2020, 10, 3577. [Google Scholar] [CrossRef]

- Kernschmidt, K.; Vogel-Heuser, B. An interdisciplinary SysML based modeling approach for analyzing change influences in production plants to support the engineering. In Proceedings of the IEEE International Conference on Automation Science and Engineering (CASE), Madison, WI, USA, 17–20 August 2013. [Google Scholar] [CrossRef]

- Drave, I.; Rumpe, B.; Wortmann, A.; Berroth, J.; Hoepfner, G.; Jacobs, G.; Spuetz, K.; Zerwas, T.; Guist, C.; Kohl, J. Modeling mechanical functional architectures in SysML. In Proceedings of the 23rd ACM/IEEE International Conference on Model Driven Engineering Languages and Systems, Virtual Event, Canada, 16–23 October 2020. [Google Scholar] [CrossRef]

- Barbedienne, R.; Penas, O.; Choley, J.Y.; Rivière, A.; Warniez, A.; Della Monica, F. Introduction of geometrical constraints modeling in SysML for mechatronic design. 10th France-Japan Congress. In Proceedings of the 10th France-Japan/ 8th Europe-Asia Congress on Mecatronics (MECATRONICS2014-Tokyo), Tokyo, Japan, 27–30 November 2014. [Google Scholar] [CrossRef]

- Albers, A.; Zingel, C. Interdisciplinary Systems Modeling using the Contact & Channel-Model for SysML. In Proceedings of the 18th International Conference on Engineering Design (ICED 11), Lyngby/Copenhagen, Denmark, 15–19 August 2011. [Google Scholar]

- Albert, A.; Zingel, C. Extending SysML for Engineering Designers by Integration of the Contact & Channel—Approach (C&C2-A) for Function-Based Modeling of Technical Systems. Procedia Comput. Sci. 2013, 16, 353–362. [Google Scholar] [CrossRef] [Green Version]

- Fenves, S.J.; Foufou, S.; Bock, C.; Sriram, R.D. CPM: A core model for product data. JCISE 2008, 5, 014501. [Google Scholar] [CrossRef]

- Baysal, M.M.; Roy, U.; Sudarsan, R.; Sriram, R.D.; Lyons, K.W. The Open Assembly Model for the Exchange of Assembly and Tolerance Information: Overview and Example. In Proceedings of the DETC, Salt Lake City, UT, USA, 28 September 2004. [Google Scholar] [CrossRef] [Green Version]

- Baysal, M.M. Functional and Behavioral Product Information Representation and Consistency Validation for Collaboration in Product Lifecycle Activities. Doctoral Thesis, Syracuse University, Syracuse, NY, USA, 2012. [Google Scholar]

- Grauberger, P.; Wessels, H.; Gladysz, B.; Bursac, N.; Matthiesen, S.; Albers, A. The contact and channel approach—20 years of application experience in product engineering. J. Eng. Des. 2020, 31, 241–265. [Google Scholar] [CrossRef]

- Riveire, A.; Clément, A.; Valade, C. The TTRS: 13 oriented constraints for dimensioning, tolerancing and inspection. Adv. Math. Appl. Sci. 1997, 45, 24–42. [Google Scholar] [CrossRef]

- Peng, H.; Peng, Z.; Zhou, Z. Manufacturing variation modeling and process evaluation based on small displacement torsors and functional tolerance requirements. J. Adv. Mech. Des. Syst. Manuf. 2021, 15, 3. [Google Scholar] [CrossRef]

- Cao, Y.; Liu, Y.; Mao, J.; Yang, J. 3DTS: A 3D tolerancing system based on mathematical definition. J. Zhejiang Univ. Sci. 2006, 7, 1810–1818. [Google Scholar] [CrossRef]

- ASME. Dimensioning and Tolerancing Y14.5—2018; ASME: New York, NY, USA, 2018; pp. 1–344. ISBN 9780791872192. [Google Scholar]

- Eclipse Papyrus Modeling Environment. Available online: https://www.eclipse.org/papyrus/ (accessed on 16 January 2023).

- Grauberger, P.; Goetz, S.; Schleich, B.; Gwosch, T.; Matthiesen, S.; Wartzack, S. A Conceptual Model Combination for the Unification of Design and Tolerancing in Robust Design. In Proceedings of the Design Society: DESIGN Conference, Cavtat, Croatia, 26–29 October 2020. [Google Scholar] [CrossRef]

- Aguilella, D.; Rosado, P.; Benavent, S. A Modelica library to simulate geometrical and dimensional deviations in process assemblies. In Proceedings of the MESIC 2023, Sevilla, Spain, 28–30 June 2023. Abstract accepted by the Scientific Committee. [Google Scholar]

| Package | Description | Some Constructions |

|---|---|---|

| Features | Blocks stereotyped as «Feature». Each Feature can also contain Attributes (Value Properties) related to geometry (diameter of an axis, for example) and necessary information for the analysis. | PlanarFeature CylindricalFeature … |

| Feature Associations | Blocks stereotyped as «FeaturesAssociation» to support different types of associations between Features, both intra-part specifications (relative position, relative orientation, etc.) and inter-parts relationships to support assembly contacts and fittings (planar contact, hole–axis fitting, etc.). | Distance_parallell_planes PlanesPerpendicularity PlanarContact Hole-Axis_fitting … |

| Package | Description | Some Constructions |

|---|---|---|

| TTRS_F_repr | Repository of Blocks that support TTRS-based representations for the different features, including two MGRE_repr to support the local and deviated definition, and the corresponding transformation. | PlanarF_repr CylindricalF_repr … |

| MGREs | Blocks stereotyped as «MGRE». The TTRS theory identifies 7 different MGREs, corresponding to the 7 invariance classes, but the MGRE associated with the helicoidal invariance class has not been considered in this library. | MGRE_spherical MGRE_planar MGRE_cylindrical … |

| MGRE_repr | Repository of Blocks that contains nominal and deviated MGREs to represent a surface according to its invariance class. | MGRE_spherical_repr MGRE_planar_repr … |

| TTRS | Blocks defined to support the association between MGREs considered in the previous package. These constructions are stereotyped as «TTRS», and based on the TTRS theory, 35 types of TTRS were defined, excluding cases with helicoidal MGREs (see Figure 2). Each TTRS contains at least one RGE Constraint. | Case1 Case2 … Case44 |

| RGEs | Blocks stereotyped as «RGE» to support the reduced geometric elements. Based on the TTRS theory, three types of RGEs have been defined (point, plane, line). | PointRGE PlaneRGE LineRGE |

| RGE Constraints | ConstraintBlocks, stereotyped as «RGE_Constraint», with almost two RGE Parameters. Based on the TTRS theory, 13 constraints were defined, aggregating some additional ConstraintBlocks from the next package. | C1 C2 … C13 |

| Basic Mathematical Constraints | Additional ConstraintBlocks to support geometric operations between points, vectors, or matrices, for example. | Perpendicular_vectors Point_Contained_in_line … |

| Package | Description | Some Constructions |

|---|---|---|

| GT4PlanarTarget | Package containing geometric tolerances for which the target element is a planar geometry. The unique possible TZ in this case is the planar tolerance zone, because it is the only zone type capable of controlling the position and/or orientation of a plane. | Plane-Plane_Distance_specif Plane-Plane_Perpendicularity_specif Plane-Plane_Distance_cons Plane-Plane_Perpendicularity_cons … |

| GT4AxialTarget | Package containing geometric tolerances for which the target element is a cylindrical geometry. These GT can use different tolerance zones, such as planar, cylindrical, or prismatic TZ, according to the number of references. | Plane-Axis_Distance_specif Axis-Axis_Coaxiality_specif Plane-Axis_Distance_cons Axis-Axis_Coaxiality_cons … |

| GT4PunctualTarget | Package containing geometric tolerances for which the target element is a punctual geometry. These GT can use different tolerance zones, such as planar or spherical TZ, according to the type and number of references. | Plane-Point_Distance_specif Axis-Point_Distance_specif Axis-Point_Distance_cons … |

| Simple Tolerance Zones | Package containing simple tolerance zones, each one being characterized by a MGRE and a size. | TZ_Planar TZ_cylindrical … |

| V&C blocks | Package containing blocks that relate the target element with the tolerance zone, containing the necessary constraints to support the validation of the specification correctness and the constructions of the deviated target. | Plane_in_planarTZ Cylinder_in_planarTZ Cylinder_in_cylindricalTZ … |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benavent-Nácher, S.; Rosado Castellano, P.; Romero Subirón, F.; Abellán-Nebot, J.V. SYSML4TA: A SysML Profile for Consistent Tolerance Analysis in a Manufacturing System Case Application. Appl. Sci. 2023, 13, 3794. https://doi.org/10.3390/app13063794

Benavent-Nácher S, Rosado Castellano P, Romero Subirón F, Abellán-Nebot JV. SYSML4TA: A SysML Profile for Consistent Tolerance Analysis in a Manufacturing System Case Application. Applied Sciences. 2023; 13(6):3794. https://doi.org/10.3390/app13063794

Chicago/Turabian StyleBenavent-Nácher, Sergio, Pedro Rosado Castellano, Fernando Romero Subirón, and José Vicente Abellán-Nebot. 2023. "SYSML4TA: A SysML Profile for Consistent Tolerance Analysis in a Manufacturing System Case Application" Applied Sciences 13, no. 6: 3794. https://doi.org/10.3390/app13063794