The Influence of Axial Compressive Stress and Internal Pressure on a Pipeline Network: A Review

Abstract

1. Introduction

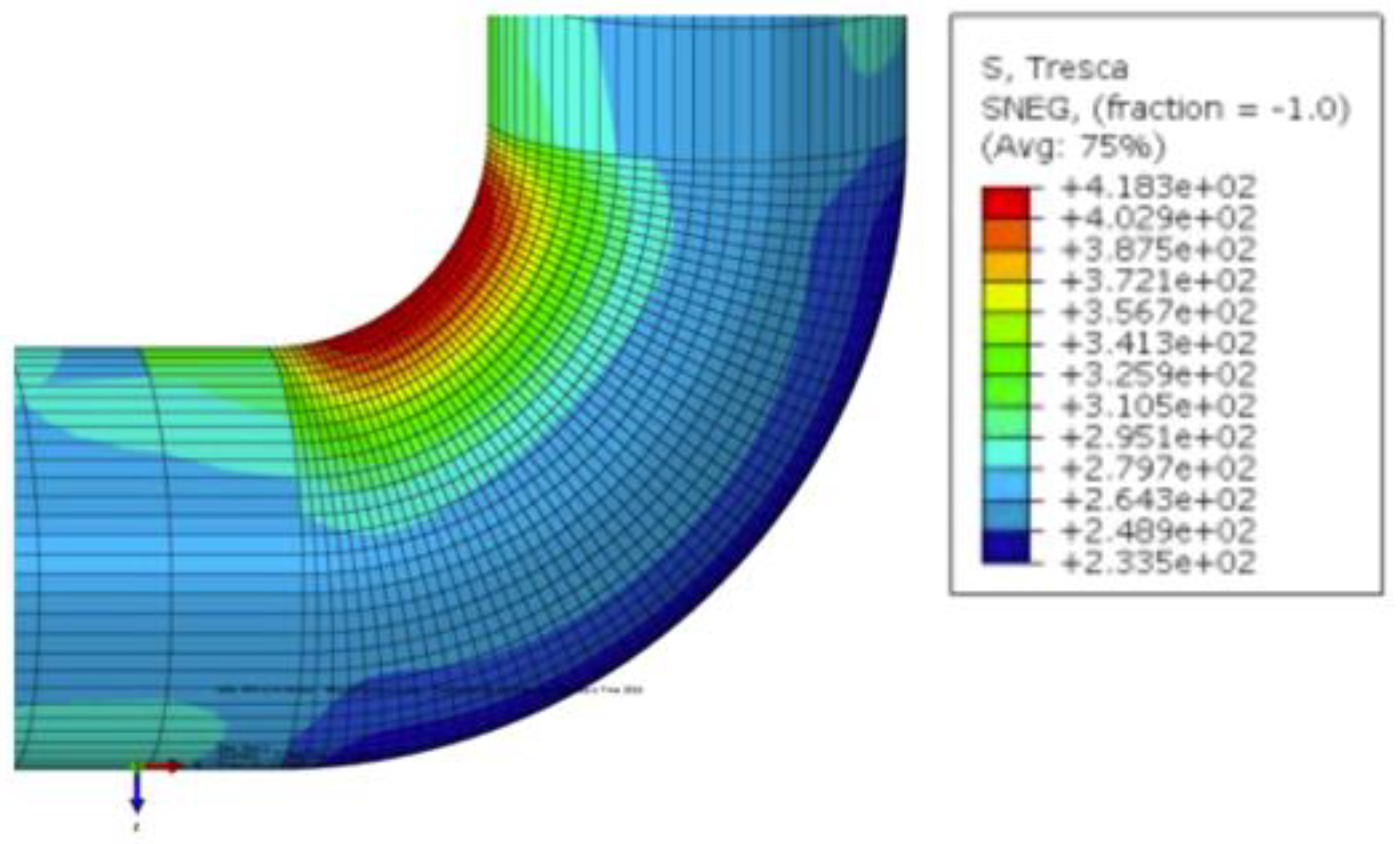

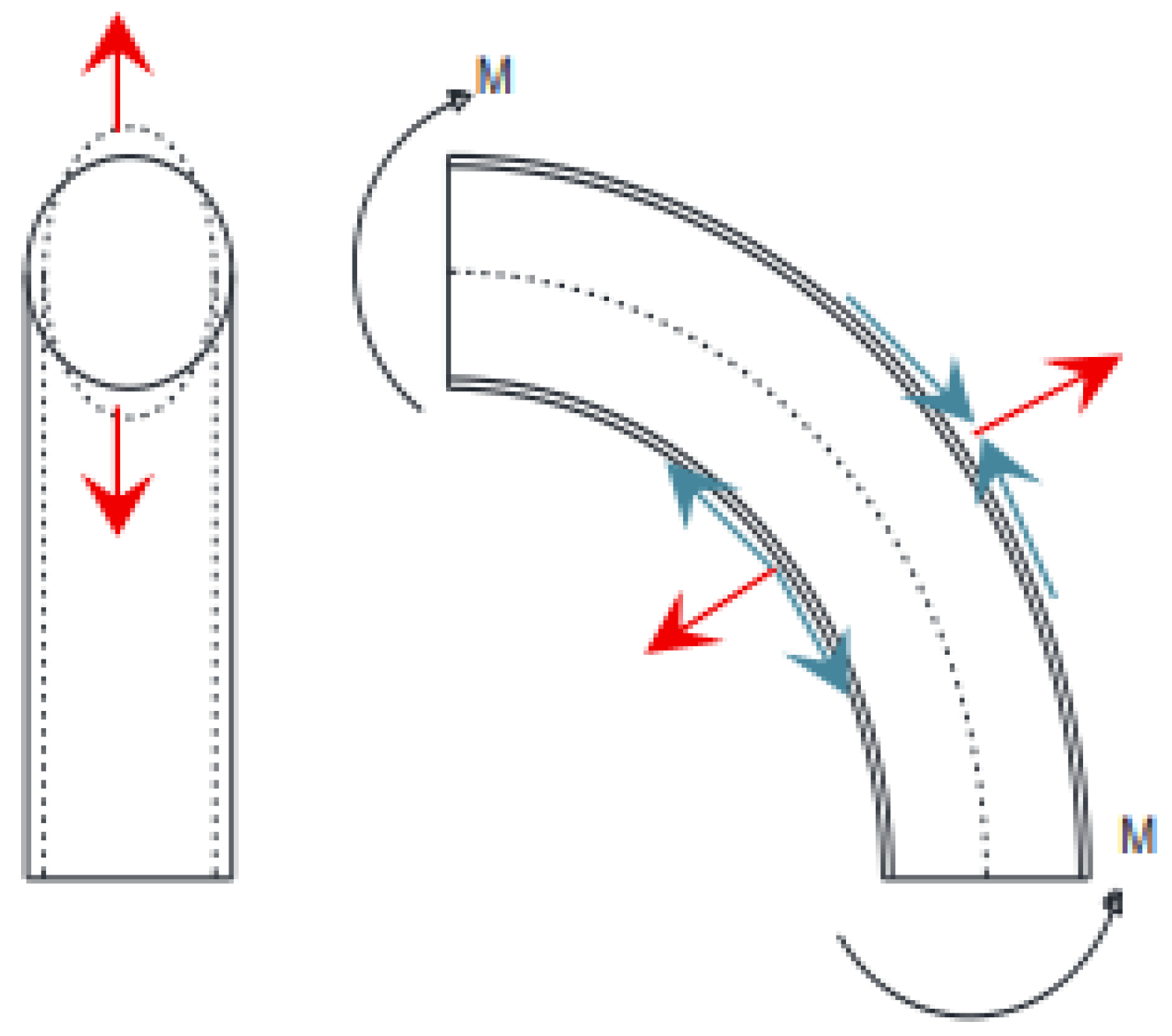

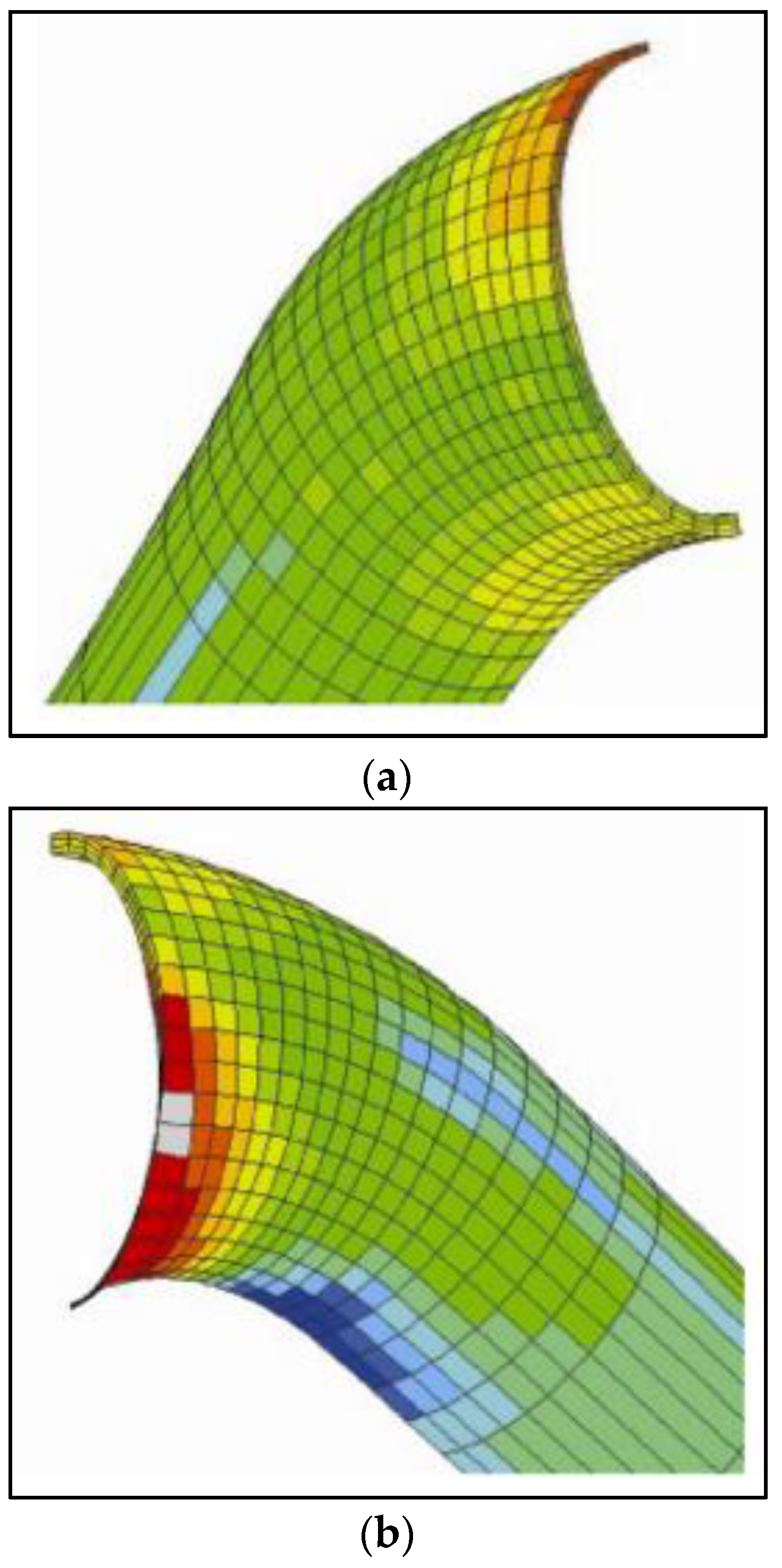

2. Axial Compressive Stress

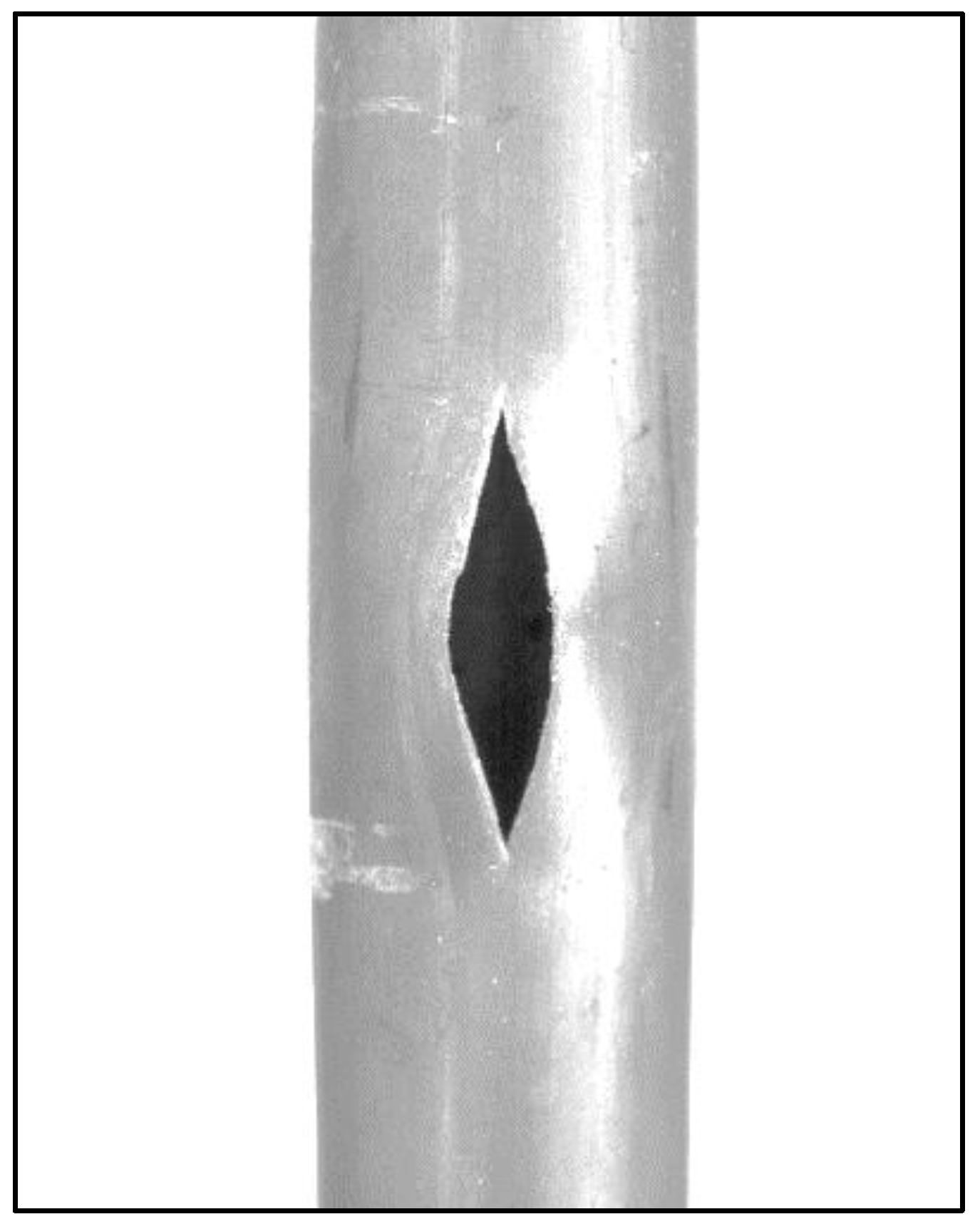

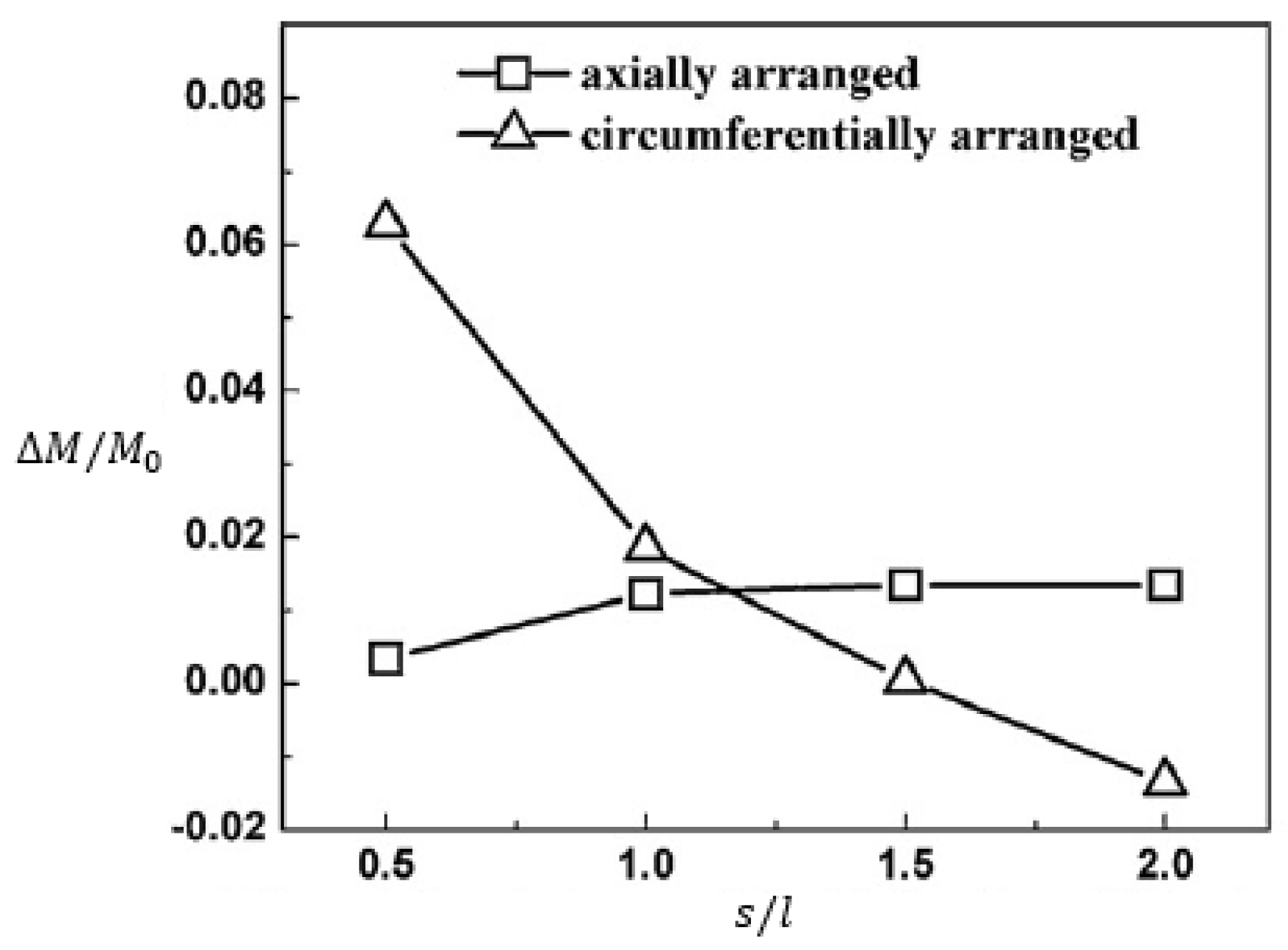

2.1. Poisson’s Effect Due to Temperature Changes

2.2. Geological Movements

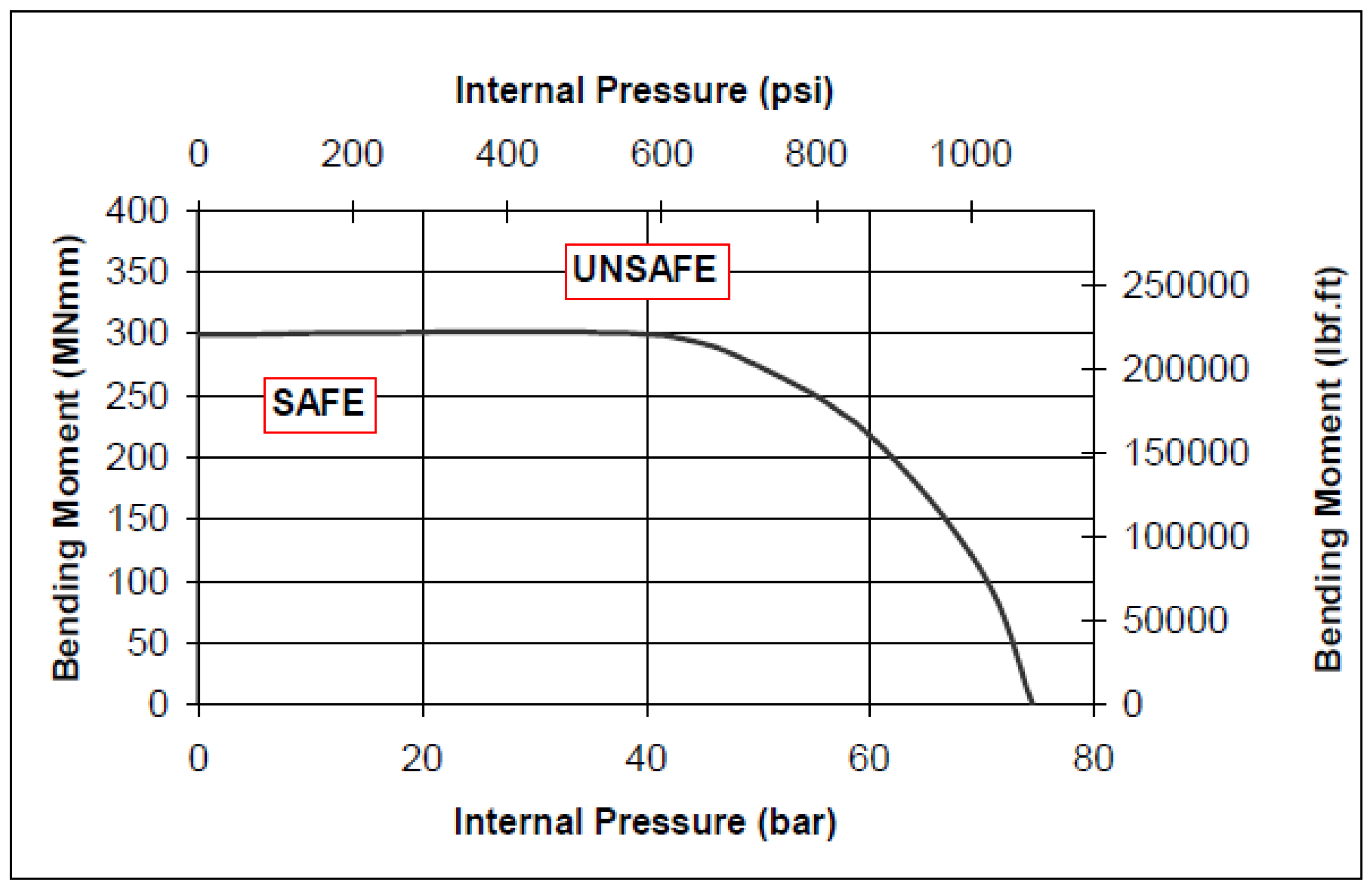

2.3. Bourdon Effect Due to Internal Pressure

3. Pipeline Residual Strength Assessment Methods

3.1. DNV-RP-F101

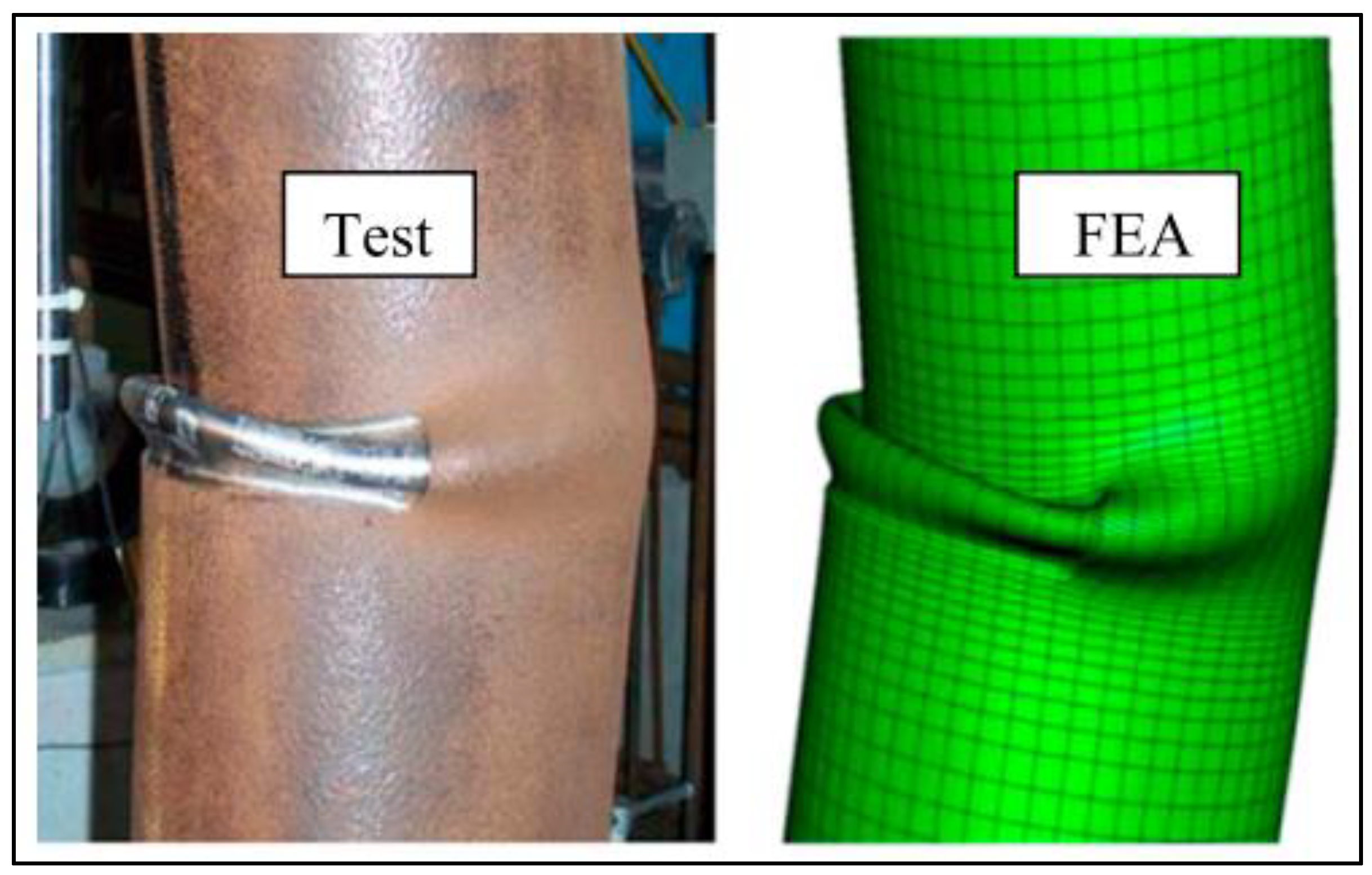

3.2. Finite Element Methods

3.3. Artificial Neural Networks

4. Effects of Axial Compressive Stress

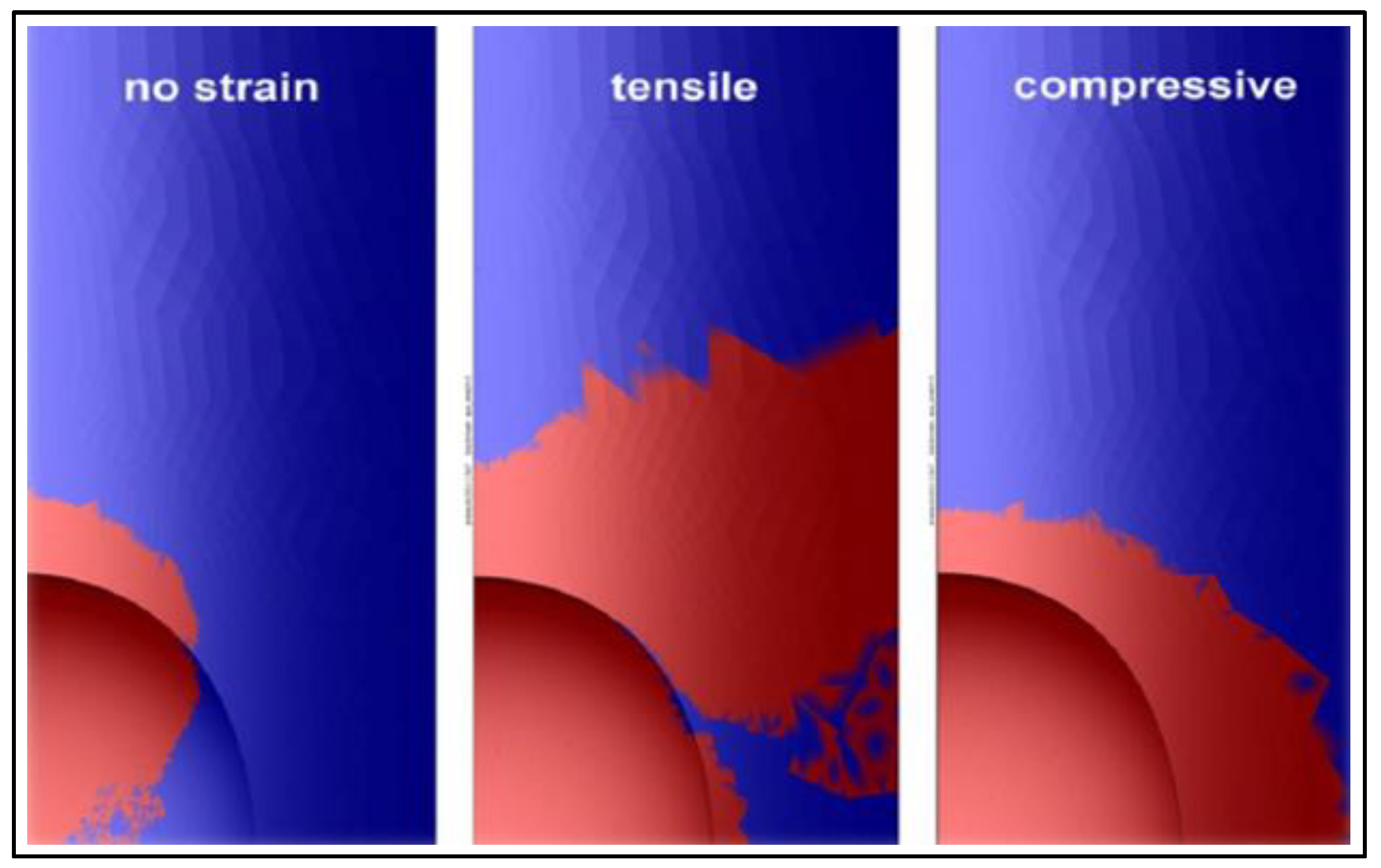

4.1. Detrimental Effects

4.2. Beneficial Effects

5. Conclusions

6. Recommendations

Funding

Conflicts of Interest

Nomenclature

| Pipe diameter | |

| Corrosion defect depth | |

| Modulus of elasticity | |

| Force acting on the pipe component | |

| Total usage factor | |

| In-plane stress intensification factor | |

| Out-of-plane stress intensification factor | |

| Pipe length | |

| Pipe geometry factor | |

| Torsional moment | |

| Out-of-plane member bending moment | |

| Failure pressure of pipe | |

| Safe working pressure of the corroded pipe | |

| Internal pressure that results in yielding of a pristine pipe | |

| Length correction factor | |

| Bending stress | |

| Equivalent tensile stress | |

| Hoop stress due to fluid pressure | |

| Longitudinal stress in the pipe | |

| Standard deviation | |

| Fluid temperature | |

| Pipe thickness | |

| Section modulus of pipe | |

| Linear coefficient of thermal expansion | |

| Strain | |

| Factor for defining a fractile value for the corrosion depth | |

| Partial safety factor for corrosion depth | |

| Partial safety factor for longitudinal corrosion model prediction | |

| Poisson’s ratio | |

| Angular width of the defect | |

| Ultimate tensile strength pipe in the circumferential direction | |

| Load-line displacement | |

| Net free expansion | |

| Abbreviations | |

| ANN | Artificial neural network |

| BPNN | Back-propagation neural network |

| DNV | DNV-RP-F101 assessment code |

| FEA | Finite element analysis |

| FEM | Finite element method |

| HSS | High-strength steel |

| SVM | Support vector machine |

References

- Bhardwaj, U.; Teixeira, A.P.; Soares, C.G. Burst strength assessment of X100 to X120 ultra-high strength corroded pipes. Ocean Eng. 2021, 241, 110004. [Google Scholar] [CrossRef]

- Kumar, S.D.V.; Lo, M.; Karuppanan, S.; Ovinis, M. Failure Pressure Prediction of Medium to High Toughness Pipe with Circumferential Interacting Corrosion Defects Subjected to Combined Loadings Using Artificial Neural Network. Appl. Sci. 2022, 12, 4120. [Google Scholar] [CrossRef]

- Kumar, S.D.V.; Lo, M.; Arumugam, T.; Karuppanan, S. A review of finite element analysis and artificial neural networks as failure pressure prediction tools for corroded pipelines. Materials 2021, 14, 6135. [Google Scholar] [CrossRef]

- Lo, M.; Kumar, S.D.V.; Karuppanan, S.; Ovinis, M. An Artificial Neural Network-Based Equation for Predicting the Remaining Strength of Mid-to-High Strength Pipelines with a Single Corrosion Defect. Appl. Sci. 2022, 12, 1722. [Google Scholar] [CrossRef]

- Shuai, Y.; Zhou, D.-C.; Wang, X.-H.; Yin, H.-G.; Zhu, S.; Li, J.; Cheng, Y.F. Local buckling failure analysis of high strength pipelines containing a plain dent under bending moment. J. Nat. Gas Sci. Eng. 2019, 77, 103266. [Google Scholar] [CrossRef]

- Shuai, Y.; Zhang, X.; Huang, H.; Feng, C.; Cheng, Y.F. Development of an empirical model to predict the burst pressure of corroded elbows of pipelines by finite element modelling. Int. J. Press. Vessel. Pip. 2022, 195, 104602. [Google Scholar] [CrossRef]

- Zhang, Y.; Shuai, J.; Ren, W.; Lv, Z. Investigation of the tensile strain response of the girth weld of high-strength steel pipeline. J. Constr. Steel Res. 2021, 188, 107047. [Google Scholar] [CrossRef]

- Liu, X.; Xia, M.; Bolati, D.; Liu, J.; Zheng, Q.; Zhang, H. An ANN-based failure pressure prediction method for buried high-strength pipes with stray current corrosion defect. Energy Sci. Eng. 2020, 8, 248–259. [Google Scholar] [CrossRef]

- Kumar, S.D.V.; Karuppanan, S.; Ovinis, M. Artificial Neural Network-Based Failure Pressure Prediction of API 5L X80 Pipeline with Circumferentially Aligned Interacting Corrosion Defects Subjected to Combined Loadings. Materials 2022, 15, 2259. [Google Scholar] [CrossRef]

- Arumugam, T.; Karuppanan, S.; Ovinis, M. Finite element analyses of corroded pipeline with single defect subjected to internal pressure and axial compressive stress. Mar. Struct. 2020, 72, 102746. [Google Scholar] [CrossRef]

- Chin, K.T.; Arumugam, T.; Karuppanan, S.; Ovinis, M. Failure pressure prediction of pipeline with single corrosion defect using artificial neural network. Pipeline Sci. Technol. 2020, 4, 10–17. [Google Scholar] [CrossRef]

- Kumar, S.D.V.; Karuppanan, S.; Ovinis, M. Failure Pressure Prediction of High Toughness Pipeline with a Single Corrosion Defect Subjected to Combined Loadings Using Artificial Neural Network (ANN). Metals 2021, 11, 373. [Google Scholar] [CrossRef]

- Cosham, A.; Palmer, A.; Hopkins, P. The Assessment of Corrosion in Pipeline-Guidance in The Pipeline Defect Assessment Manual (PDAM). In Proceedings of the Pipeline Pigging and Integrity Management Conference, Amsterdam, The Netherlands, 17–18 May 2004; pp. 1–18. [Google Scholar]

- Belachew, C.T.; Ismail, M.C.; Karuppanan, S. Burst strength analysis of corroded pipelines by finite element method. J. Appl. Sci. 2011, 11, 1845–1850. [Google Scholar] [CrossRef]

- Schweitzer, P.A. Fundamentals of Corrosion: Mechanisms, Causes, and Preventative Methods; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Cosham, A.; Hopkins, P.; Macdonald, K.A. Best practice for the assessment of defects in pipelines—Corrosion. Eng. Fail. Anal. 2007, 14, 1245–1265. [Google Scholar] [CrossRef]

- De Andrade, E.Q.; Benjamin, A.C.; Machado, P.R.S.; Pereira, L.C.; Jacob, B.; Carneiro, E.G.; Guerreiro, J.N.C.; Silva, R.C.C.; Noronha, D.B. Finite element modeling of the failure behavior of pipelines containing interacting corrosion defects. In International Conference on Offshore Mechanics and Arctic Engineering—OMAE; ASME: New York, NY, USA, 2006; Volume 2006. [Google Scholar] [CrossRef]

- Bjørnøy, O.; Fu, B.; Sigurdsson, G.; Cramer, E.; Ritchie, D. Introduction and Background to DNV-RP-F101 Corroded Pipelines. In Proceedings of the Ninth International Offshore and Polar Engineering Conference, Brest, France, 30 May–4 June 1999. [Google Scholar]

- Peng, L.C. Stress analysis methods for underground pipelines. Pipe Line Ind. 1978, 47, 65–74. [Google Scholar]

- Soares, E.; Bruère, V.M.; Afonso, S.M.B.; Willmersdorf, R.B.; Lyra, P.R.M.; Bouchonneau, N. Structural integrity analysis of pipelines with interacting corrosion defects by multiphysics modelling. Eng. Fail. Anal. 2019, 97, 91–102. [Google Scholar] [CrossRef]

- Dewanbabee, H.; Das, S. Structural Behavior of Corroded Steel Pipes Subject to Axial Compression and Internal Pressure: Experimental Study. J. Struct. Eng. 2013, 139, 57–65. [Google Scholar] [CrossRef]

- Lee, E.; Audibert, J.; Hengesh, J.; Nyman, G. Landslide-Related Ruptures of the Camisea Pipeline System, Peru; Geological Society of London: London, UK, 2009; Volume 42, pp. 251–259. [Google Scholar]

- Chou, Z.; Cheng, J.; Zhou, J. Monitoring and prediction of pipe wrinkling using distributed strain sensors. In Proceedings of the 2006 International Pipeline Conference, Calgary, AB, Canada, 25–29 September 2006; pp. 307–315. [Google Scholar]

- Liu, B.; Liu, X.; Zhang, H. The Response of Buried Pipeli Ne Subjected to Landslides. In Proceedings of the Nineteenth International Offshore and Polar Engineering Conference, Osaka, Japan, 21–26 June 2009. [Google Scholar]

- Murray, S. Local buckling, strain localization, wrinkling and postbuckling response of line pipe. Eng. Struct. 1997, 19, 360–371. [Google Scholar] [CrossRef]

- Palmer, A.; Tebboth, L.; Miles, D.; Calladine, C. Instability of Pipelines on Slopes; ASME: New York, NY, USA, 1999. [Google Scholar]

- Oswell, J.; Hanna, A.; Doblanko, R.; Wilkie, S.J.O. Instrumentation yields geotechnical picture of slope movements along northern Canadian pipeline. Oils Gas J. 2001, 99, 62–67. [Google Scholar]

- Abdulhameed, D.; Adeeb, S.; Cheng, R.; Martens, M. The Influence of the Bourdon Effect on Pipe Elbow. In Proceedings of the 2016 International Pipeline Conference, Calgary, AB, Canada, 26–30 September 2016. [Google Scholar] [CrossRef]

- Abdulhameed, D.; Cheng, R.; Martens, M. The Influence of Bourdon Effect and Ovalization Effect on The Stress Distribution on Pipe Elbows. In Proceedings of the 2016 Pipeline Technology Conference, Calgary, AB, Canada, 25–27 September 2016; pp. 1–17. [Google Scholar]

- Vitali, L.; Bruschi, R.; Mork, K.J.; Levold, E.; Verley, R. Hotpipe project: Capacity of pipes subject to internal pressure, axial force and bending moment. In Proceedings of the Ninth International Offshore and Polar Engineering Conference, Brest, France, 30 May–4 June 1999. [Google Scholar]

- Roy, S.; Grigory, S.; Smith, M.; Kanninen, M.; Anderson, M. Numerical Simulations of Full-Scale Corroded Pipe Tests with Combined Loading; ASME: New York, NY, USA, 1997. [Google Scholar]

- Spangler, M.G.; Handy, R.L. Soil Engineering; HarperCollins: New York, NY, USA, 1982. [Google Scholar]

- Moser, A.P.; Folkman, S.L. Buried Pipe Design; McGraw-Hill: New York, NY, USA, 2001. [Google Scholar]

- Xu, L.; Lin, M. Analysis of buried pipelines subjected to reverse fault motion using the vector form intrinsic finite element method. J. Soil Dyn. Earthq. Eng. 2017, 93, 61–83. [Google Scholar] [CrossRef]

- Nicolella, D.P.; Smith, M.Q. Non-linear finite element prediction of wrinkling in corroded pipe. In Proceedings of the Seventh International Offshore and Polar Engineering Conference, Honolulu, HI, USA, 25–30 May 1997. [Google Scholar]

- Pipeline Report—P977H0024: Natural Gas Pipeline Rupture. 1997. Available online: https://www.tsb.gc.ca/eng/rapports-reports/pipeline (accessed on 29 December 2022).

- Guo, X.; Cao, Y.; Ma, H.; Xiao, C.; Wen, B. Dynamic analysis of an L-shaped liquid-filled pipe with interval uncertainty. Int. J. Mech. Sci. 2022, 217, 107040. [Google Scholar] [CrossRef]

- Kim, J.W.; Na, M.G.; Park, C.Y. Effect of local wall thinning on the collapse behavior of pipe elbows subjected to a combined internal pressure and in-plane bending load. Nucl. Eng. Des. 2008, 238, 1275–1285. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Z.; Qian, H.; Fan, F. Effect of local corrosion on the axial compression behavior of circular steel tubes. Eng. Struct. 2020, 224, 111205. [Google Scholar] [CrossRef]

- Chen, Y.F.; Zhang, J.; Zhang, H.; Liu, X.B.; Li, X.; Zhou, J.; Cao, J. Ultimate load capacity of offshore pipeline with arbitrary shape corrosion defects. China Ocean Eng. 2015, 29, 241–252. [Google Scholar] [CrossRef]

- Chouchaoui, B.; Pick, R. Behaviour of circumferentially aligned corrosion pits. Int. J. Press. Vessel. Pip. 1994, 57, 187–200. [Google Scholar] [CrossRef]

- Li, F.; Wang, W.; Xu, J.; Yi, J.; Wang, Q. Comparative study on vulnerability assessment for urban buried gas pipeline network based on SVM and ANN methods. Process Saf. Environ. Prot. 2019, 122, 23–32. [Google Scholar] [CrossRef]

- Kumar, S.D.V.; Lo, M.; Karuppanan, S.; Ovinis, M. Empirical Failure Pressure Prediction Equations for Pipelines with Longitudinal Interacting Corrosion Defects Based on Artificial Neural Network. J. Mar. Sci. Eng. 2022, 10, 764. [Google Scholar] [CrossRef]

- Kumar, S.D.V.; Karuppanan, S.; Ovinis, M. An empirical equation for failure pressure prediction of high toughness pipeline with interacting corrosion defects subjected to combined loadings based on artificial neural network. Mathematics 2021, 9, 2582. [Google Scholar] [CrossRef]

- Tohidi, S.; Sharifi, Y.; Shari, Y. Thin-Walled Structures Load-carrying capacity of locally corroded steel plate girder ends using artificial neural network. Thin-Walled Struct. 2016, 100, 48–61. [Google Scholar] [CrossRef]

- Netto, T.; Ferraz, U.; Estefen, S. The effect of corrosion defects on the burst pressure of pipelines. J. Constr. Steel Res. 2005, 61, 1185–1204. [Google Scholar] [CrossRef]

- Timoshenko, S.P.; Gere, J.M. Theory of Elastic Stability; Courier Corporation: Chelmsford, MA, USA, 2009. [Google Scholar]

- Bai, Y.; Hauch, S.; Jensen, J.C. Local buckling and plastic collapse of corroded pipes with yield anisotropy. In Proceedings of the Ninth International Offshore and Polar Engineering Conference, Brest, France, 30 May–4 June 1999. [Google Scholar]

- Smith, M.Q.; Nicolella, D.P.; Waldhart, C.J. Full-scale wrinkling tests and analyses of large diameter corroded pipes. In Proceedings of the 2nd International Pipeline Conference, Calgary, AB, Canada, 7–11 June 1998; pp. 543–551. [Google Scholar]

- Gurney, K. An Introduction to Neural Networks; UCL Press: London, UK, 1997. [Google Scholar]

- Lo, M.; Karuppanan, S.; Ovinis, M. Failure Pressure Prediction of a Corroded Pipeline with Longitudinally Interacting Corrosion Defects Subjected to Combined Loadings Using FEM and ANN. J. Mater. Sci. Eng. 2021, 9, 281. [Google Scholar] [CrossRef]

- Dewanbabee, H. Behaviour of Corroded X46 Steel Pipe under Internal Pressure and Axial Load; University of Windsor: Windsor, ON, Canada, 2009; pp. 1–274. [Google Scholar]

- BjØrnoy, O.; Sigurdsson, G.; Marley, M. Background and Development of DNV-RP-F101 Corroded Pipelines. In Proceedings of the Eleventh International Offshore and Polar Engineering Conference, Stavanger, Norway, 17–22 June 2001. [Google Scholar]

- Yoosef-Ghodsi, N. Behavior of Girth-Welded Line Pipe; University of Alberta: Edmonton, AT, Canada, 1995. [Google Scholar]

- Smith, M.Q.; Grigory, S.C. New procedures for the residual strength assessment of corroded pipe subjected to combined loads. In Proceedings of the 1st International Pipeline Conference, Calgary, AB, Canada, 7–11 June 1996; pp. 387–400. [Google Scholar]

- Takahashi, K.; Ando, K.; Hisatsune, M.; Hasegawa, K. Failure behavior of carbon steel pipe with local wall thinning near orifice. Nucl. Eng. Des. 2007, 237, 335–341. [Google Scholar] [CrossRef]

- Chauhan, V.; Swankie, T.D.; Espiner, R.; Wood, I. Developments in Methods for Assessing the Remaining Strength of Corroded Pipelines. In Proceedings of the NACE Corrosion 2009 Conference Expo, Houston, TX, USA, 22–26 March 2009; pp. 1–29. [Google Scholar]

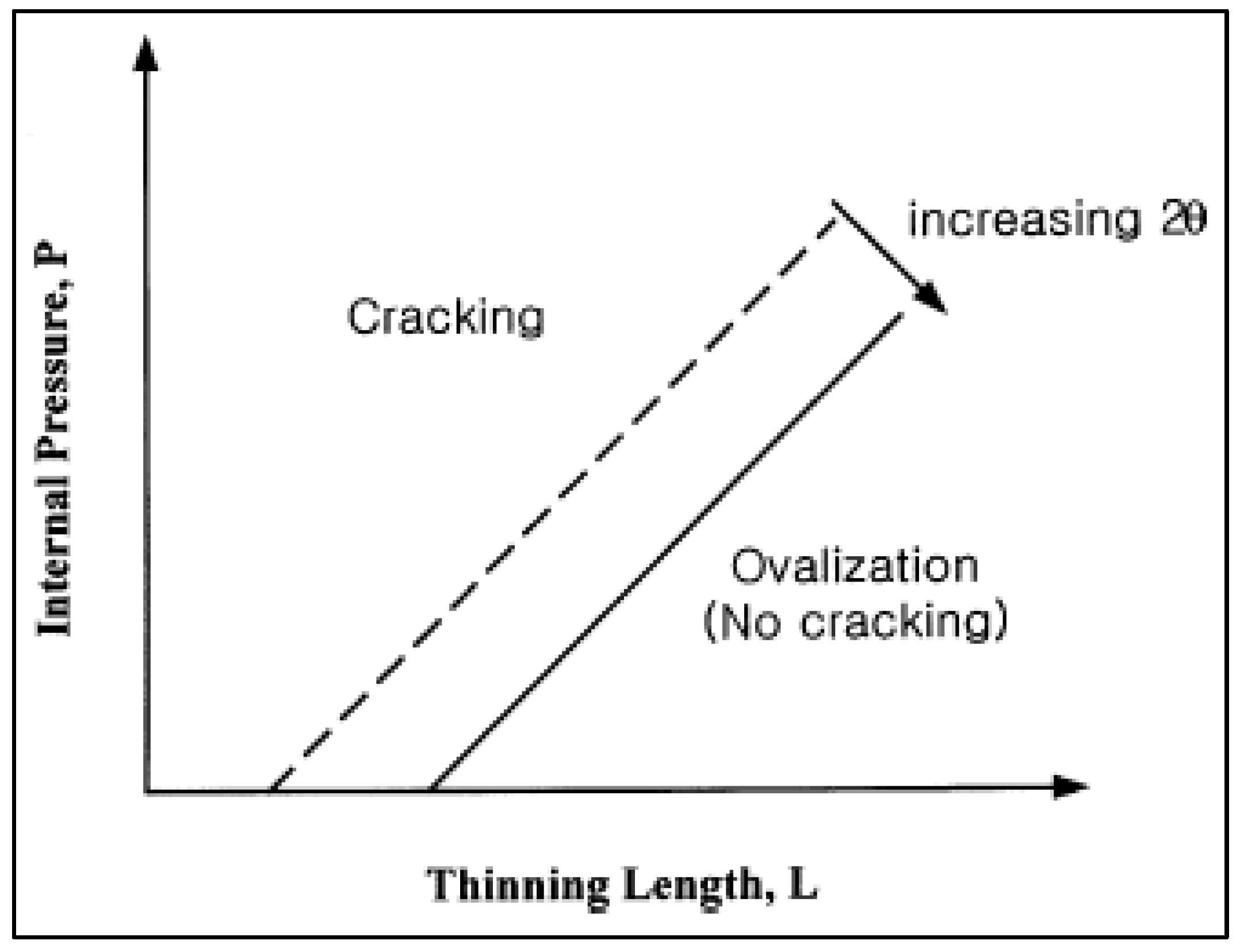

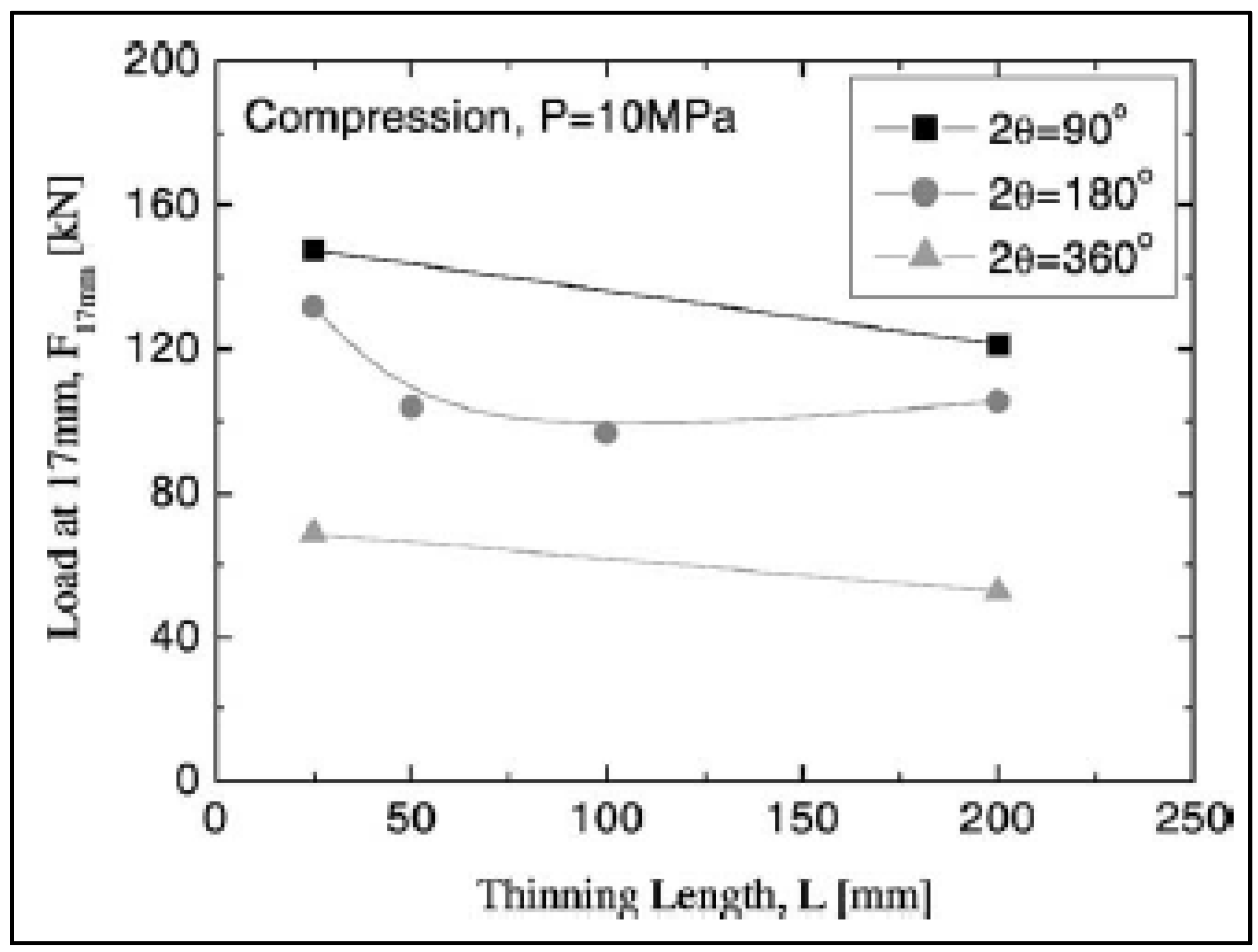

- Kim, J.W.; Park, C.Y. Effect of length of thinning area on the failure behavior of carbon steel pipe containing a defect of wall thinning. Nucl. Eng. Des. 2003, 220, 274–284. [Google Scholar] [CrossRef]

- Blake, A.C. 20, Uniform Cantilever Beams. In Practical Stress Analysis in Engineering Design; CRC Press: New York, NY, USA, 1990; pp. 211–222. ISBN 082478152X. [Google Scholar]

- Peng, J.; Zhou, C.; Xue, J.; Dai, Q.; He, X. Safety assessment of pipes with multiple local wall thinning defects under pressure and bending moment. Nucl. Eng. Des. 2011, 241, 2758–2765. [Google Scholar]

- Oh, C.; Kim, Y.; Park, C. Effects of local wall thinning on net-section limit loads for pipes under combined pressure and bending. Nucl. Eng. Des. 2009, 239, 261–273. [Google Scholar] [CrossRef]

- LXu, Y.; Cheng, Y.F. Reliability and failure pressure prediction of various grades of pipeline steel in the presence of corrosion defects and pre-strain. Int. J. Press. Vessel. Pip. 2012, 89, 75–84. [Google Scholar] [CrossRef]

- Bjørnsen, T.; Hagen, Ø.; Mørk, K.J. Reliability Based Pipeline Design And Integrity Assessment: Pipeline Industry On the Verge. In Proceedings of the Fifth International Offshore and Polar Engineering Conference, The Hague, The Netherlands, 11–16 June 1995. [Google Scholar]

- Hohl, G.; Vogt, I. Allowable strains for high strength linepipe. 3 R Int. 1992, 31, 696. [Google Scholar]

- Kirkwood, M.; Fu, B.; Vu, D.; Batte, A. Assessing the Integrity of Corroded Linepipe-An Industry Initiative. In Aspect’96: Advances in Subsea Pipeline Engineering and Technology; OnePetro: Richardson, TX, USA, 1996. [Google Scholar]

- Bjørnøy, O.H.; Sigurdsson, G.; Cramer, E. Residual Strength of Corroded Pipelines, DNV Test Results. In Proceedings of the Tenth (2000) International Offshore and Polar Engineering Conference, Seattle, WA, USA, 28 May–2 June 2000; Volume II, pp. 1–7. [Google Scholar]

- Chouchaoui, B.A.; Pick, R.J. Behaviour of longitudinally aligned corrosion pits. Int. J. Press. Vessel. Pip. 1996, 67, 17–35. [Google Scholar] [CrossRef]

- Shuai, Y.; Shuai, J.; Xu, K. Probabilistic analysis of corroded pipelines based on a new failure pressure model. Eng. Fail. Anal. 2017, 81, 216–233. [Google Scholar] [CrossRef]

- Mokhtari, M.; Melchers, R.E. A new approach to assess the remaining strength of corroded steel pipes. Eng. Fail. Anal. 2018, 93, 144–156. [Google Scholar] [CrossRef]

- Shuai, Y.; Shuai, J.; Liu, C. Research on the reliability methods of corroded pipeline. Pet. Sci. Bull. 2017, 2, 288–297. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arumugam, T.; Vijaya Kumar, S.D.; Karuppanan, S.; Ovinis, M. The Influence of Axial Compressive Stress and Internal Pressure on a Pipeline Network: A Review. Appl. Sci. 2023, 13, 3799. https://doi.org/10.3390/app13063799

Arumugam T, Vijaya Kumar SD, Karuppanan S, Ovinis M. The Influence of Axial Compressive Stress and Internal Pressure on a Pipeline Network: A Review. Applied Sciences. 2023; 13(6):3799. https://doi.org/10.3390/app13063799

Chicago/Turabian StyleArumugam, Thibankumar, Suria Devi Vijaya Kumar, Saravanan Karuppanan, and Mark Ovinis. 2023. "The Influence of Axial Compressive Stress and Internal Pressure on a Pipeline Network: A Review" Applied Sciences 13, no. 6: 3799. https://doi.org/10.3390/app13063799

APA StyleArumugam, T., Vijaya Kumar, S. D., Karuppanan, S., & Ovinis, M. (2023). The Influence of Axial Compressive Stress and Internal Pressure on a Pipeline Network: A Review. Applied Sciences, 13(6), 3799. https://doi.org/10.3390/app13063799