1. Introduction

Push-fit joints are one of the most frequently used assembly methods [

1]. This is owing to the advantages of that type of joint, which include: precise alignment, the capacity to transfer high variable and impact loads, and the possibility of repeated disassembly.

Depending on the assembly method, push-fit joints may be divided into two groups. The first is shrink joints, and the other is the push-fit ones. In the case of a shrink joint, the assembly process requires a change in the temperature of one or two elements joined together in order to obtain sufficient assembly clearance. When the temperatures have become equal, suitable pressure is obtained, which makes it possible to obtain the joint. Making a push-fit joint requires the use of an appropriate force, which is determined on the basis of relevant formulae and standards. In this case, joint life depends on the value of the friction force exerted by the mutual pressure of the elements joined together. In turn, that force generates suitable surface pressures preventing joint disconnection.

Among the push-fit joint connection methods mentioned above, forced-in joints are used most often, which is undoubtedly owing to their advantages. Among these, the ease of joint making, which does not require the use of special workplaces or complicated instrumentation, and the high reliability of joint operation may be mentioned.

Despite many advantages of forced-in joints, they also have weak points, which may significantly influence the operation of that type of joint. Scratches, grooves, and surface seizures [

2,

3,

4], as well as plastic deformations resulting from the adhesive bond formation, may occur during both joint assembly and disassembly. The form and magnitude of damage to and wear of the elements depend on many factors and directly influence the cost of reworking repairs [

5,

6]. In turn, joint life is strongly influenced by the technical condition of the top layer of the elements joined together, which changes depending on the kind and magnitude of wear. Surface roughness is one of the factors which influence the rate and kind of wear of the mating elements. Extensive scientific research was conducted, which confirmed that the elements with smaller roughness are more susceptible to wear due to a larger contact area and possible adhesive wear [

7,

8,

9]. Wear is the main phenomenon that deteriorates the element’s life [

10].

In view of the advantages mentioned above, forced-in joints are used, for example, in motor vehicle power transmission systems [

11] and in some aircraft systems [

12]. Forced-in joints are also used in rail vehicles. First of all, wheel systems and, within them, the brake disc/wheelset axle assembly and the wheel/wheelset axle assembly [

13,

14] can be mentioned here. Among the examples of the use of forced-in joints, the joint between the wheel and wheelset axle of the rail vehicle deserves attention. This is the assembly which requires special attention due to its functions in the vehicle. The main task of the wheelset is to run the vehicle on the track, but the set also directly influences the safety [

15,

16] and comfort of the journey. Any damage not found on time may develop into fatigue wear and cause a railway incident, with vehicle derailing as its natural consequence. Such a situation may also involve high financial losses and cause damage to the passengers’ health. In relation to that, the wheelset is subject to strict manufacturing technology and control at both the manufacturing and operation stages.

Due to the rail vehicle wheel set operation conditions, the set is exposed to wear [

17], especially in the wheel/axle joint zone, which is quicker than the wear of other vehicle assemblies. Heavy operation conditions are due to external loads acting during the ride. These loads comprise static loads from the vehicle weight and dynamic loads from riding on the track. In these conditions, it is also appropriate to take forced-in joint assembly stresses into consideration [

18]. Such operation conditions are the cause of considerable damage to and wear of not only the wheel or axle rolling surface, as described in, for example [

19,

20,

21], but also in the wheel/axle push fit joint zone. It is precisely in that zone that the wear is least recognised, and it also poses a real threat to the safety of the journey. Fretting is one of the possible kinds of wear in the wheel/axle forced-in joint zone. In view of the complex nature of physical, chemical, and mechanical phenomena and the influence of a large number of factors on the wear process, that kind of wear has not been fully recognised yet; therefore, the unambiguous description of the mechanism of the phenomenon is yet to be given. It follows from the review of the literature that fretting may consist of several mechanisms, among which fatigue and friction wear, as well as adhesion and corrosion, may be mentioned [

22,

23].

The fretting damage phenomenon often appears in the interference fit assembly [

24]. Fretting wear is tribological wear, whose development is influenced by many factors, for example, operation conditions, external loads, or the material’s properties (hardness, roughness) [

25]. The variety of factors influencing the initiation and development of fretting wear and the test methodology depending on the kind of tests mean that no unambiguous definition of fretting wear has been offered until today. However, contact between two elements and oscillatory tangential displacement between them are the necessary conditions for the development of wear [

26,

27].

The typical image of fretting wear depicts corrosion traces on the surface of the elements, the increase of the surface roughness height, microcracks, micropits, as well as plastic deformations resulting from adhesive bonds. Adhesion is one of the most dangerous aspects of wear as it causes local overloading, which promotes the initiation and propagation of fretting cracks [

28,

29]. In the case of the forced-in joint, the consequences of damage mentioned above include the reduction of surface pressures, which leads to joint weakening and then disconnection.

Shafts onto which sleeves are inserted by pressing may have varying diameters. This may be related to the rise of fatigue wear, especially at the point of diameter change. That is why, in most forced-in joints, a periodic/diagnostic technical inspection plan is prepared to eliminate wear, if any. In most cases, process instructions permit the replacement of one of the joint elements. Most often, sleeves are replaced while the same shaft is left in place. That process may be repeated many times until the shaft nominal dimensions have been obtained. When these have been exceeded, hazardous situations may arise. It is economic considerations that weigh in favour of that state of affairs. Sleeve production costs are considerably lower than shaft production costs. Many users who want to reduce repair or inspection costs replace the sleeve with a new one without a detailed shaft inspection. Obviously, that situation does not concern rail vehicle wheel sets, where thorough inspections are carried out. Following such replacement, the next operation period is conducive to the development of wear, which may lead to joint destruction.

The object of the research discussed in this article was the forced-in joints because, as it follows from the review of the literature, they are more susceptible to damage and wear than shrink joints. Whereas in the case of forced-in joints, the damage or wear may arise at the joint assembly and disassembly stage and during operation, in the case of shrink joints, the damage to the elements during the assembly or disassembly process is less likely.

Considering all the information above, it was assumed that the aim of this article would be to assess the wear of the sleeve/shaft tribological kinematic pair, which operated in rotational bending moment conditions and was repeatedly disassembled from time to time. Special attention was paid to the possible occurrence of fretting wear, and the influence of contributing factors related to the joint assembly process was evaluated.

2. Materials and Methods

The object of the wear tests is the tribological kinematic pair consisting of the shaft and sleeve. As a structural material for each of the elements, C45 steel was used, whose chemical composition is presented in

Table 1 and

Table 2. These tables also present the exemplary mechanical properties of this steel.

Steel is most often used in the manufacture of moderately loaded items such as the elements of machinery and equipment. That kind of steel is distinguished by its high strength and ductility. Grinding was used as the finish treatment of both the sleeve hub and shaft axle seat, and that process guaranteed smaller initial surface roughness.

The view and dimensions of the tribological kinematic pair under investigation are shown in

Figure 1.

The test programme assumed the shaft top layer wear evaluation after fatigue tests and repeated sleeve disassembly. The fatigue tests were divided into three stages. After the first and second stages, the joint was disassembled by pulling the sleeve off the shaft by means of a press. After the third stage, the tribological kinematic pair was prepared for laboratory tests in accordance with the process procedure prepared specially for this purpose. The first stage lasted for 10,000 fatigue cycles, and the remaining two for one thousand cycles each. Each of the tested samples was subjected to the same number of fatigue cycles. The value of the maximum force needed for sleeve disassembly and assembly was recorded each time. Macrographic documentation and surface roughness measurements were also made. The testing programme permitting the assumed objective to be achieved is presented schematically in

Figure 2.

The joint was assembled by pressing the sleeve onto the shaft with the use of the press recording the value of the pressing force. The constant tolerance value was assumed for all the tribological kinematic pairs, and that value was 0.02 mm. For the assumed tolerance value and the initial roughness of the mating surfaces, the average maximum force needed for pressing the sleeve onto the shaft was 3875 N.

Fatigue tests were conducted for five tribological kinematic pairs, which significantly increased the reliability of the test results obtained.

Wear tests were conducted on the fatigue testing machine permitting a rotational bending moment to be obtained. The tribological kinematic pair were loaded symmetrically with a concentrated force, and thus the bending moment pattern shown in

Figure 3 was obtained. Wear test parameters are compiled in

Table 3.

In the case of interference joints, the distribution of contact pressure (3D) is uneven. It can be determined by the finite element method, which will be the problem of the next publication.

The maximal contact slip amplitude could be evaluated from the solution for a simply supported beam under a concentrated load at the centre. This amplitude value could clarify the type of damage accumulating on the contact interface.

After the third fatigue cycle, the tribological kinematic pair was disassembled in accordance with the specific process procedure, and the samples were prepared for detailed laboratory tests. The procedure required the following steps:

As a result of the joint disassembly method described above, three different samples were obtained, and these were subjected to the following observations and tests:

Macroscopic observations of the shaft and sleeve surface, which permitted the surface condition and its geometrical structure to be assessed;

Microscopic observations of the shaft surface and joint contact surface, along with the analysis of the chemical composition of wear products. These permitted the factors conducive to the development of fretting wear to be identified;

Investigation of the surface geometrical structure, which permitted the change in surface roughness to be assessed at various sleeve assembly stages;

Shaft and sleeve surface microhardness.

The macrographic observations were conducted with the use of the NIKON COOLPIX P900 camera with a maximum of 83x magnification. The observations were performed after each fatigue cycle. The macroscopic observations were also conducted for fatigue fractures.

The microscopic observations were performed with the use of the JEOL JSM-5510LV scanning electron microscope. The investigations by means of scanning electron microscopy were performed in the backscattered electron composition (BEC), backscattered electron shadow (BES), and secondary electron image (SEI) modes with the electron beam acceleration voltage equal to 20 kV.

The quantitative and qualitative microanalysis of the chemical composition at damaged surfaces was conducted by means of the electron microscope equipped with the EDS INCA x-act Energy 350.v spectrometer. Microscopic observations and the analysis of the chemical composition were performed after the fatigue tests were completed.

The three-dimensional surface roughness analysis was created with the use of the Form Talysurf Intra device by Taylor Hobson and TalyMap Platinum 5.1 software. The analysis was performed after the end of the fatigue tests. The measurement of the basic surface roughness parameters was performed by means of the 2D technique after the end of each fatigue cycle.

The measurement of shaft surface microhardness was conducted by means of the Vickers method under a 0.05 N load. Tests were conducted for both the shaft and sleeve.

3. Research Results and Discussion

3.1. Measurement of the Shaft Sleeve Pressing and Removal Forces

The correct tolerance value is a decisive factor for the value of surface pressures, which translates into the appropriate joint strength and stability. As a result of the joint assembly or disassembly process, elastic–plastic or plastic deformations may take place in the top layer of the elements joined together. That situation will occur especially in the actual contact zone of the mating surfaces. The outcome of top-layer destruction is that the value of the actual surface pressure is smaller in relation to the structural value, which may lead to joint disconnection in the course of its operation. As indicated by the results of research undertaken by other authors, whereas joint strength clearly increases when elastic joint deformation occurs, growth strength intensity in the elastic–plastic and plastic deformation area diminishes when the tolerance grows.

The measurement of the force needed for forced-in joint assembly and disassembly demonstrated the varying values of the maximum force, depending on the fatigue cycles. The highest value of the force needed for pressing the sleeve onto the shaft was measured at the beginning of fatigue tests during the first installation of the sleeve on the shaft (for 0 fatigue cycles). After the next stages of fatigue tests, it was noted that a smaller force was needed to create a joint between the elements. It is as late as after the third fatigue cycle that the need for a greater force was noted compared to the previous test stages. The maximum value of that force did not, however, exceed the value noted during the first assembly. The detailed values of the maximum forces needed for pressing the sleeve onto the shaft and for the sleeve removal from the shaft are compiled in

Table 4, and the pattern of the shaft sleeve pressing force after each fatigue cycle is shown in

Figure 4.

In the case of joint disassembly, varying maximum values of the forces needed to remove the sleeve from the shaft are also noted. The lowest value was recorded after the first fatigue cycle. After the successive fatigue cycles, greater forces were required to disconnect the joint. However, the difference between the maximum forces in the second and third fatigue cycles is insignificant and amounts to 0.2 kN only. Diagrams showing the shaft sleeve removal forces are presented in

Figure 5.

The process of forcing the sleeve onto the shaft results in shearing and crushing the microirregularities present on the surface of the elements joined together. Shearing intensity on those irregularities depends mainly on the tolerance value and the physical and chemical properties of the materials joined together. Adhesion-related damage may also arise. The greatest deformation occurs at the contact surfaces at the beginning of the hub and at the end of the axle seat. This results in uneven contact over the joint length and in the related uneven distribution of surface pressures.

Based on the information above and on the results of the measurements presented in this work, it may be concluded that the maximum force needed to press the sleeve onto the shaft and to remove the sleeve from the shaft strongly depends on surface roughness and on the presence of wear products between the surfaces joined together.

The greatest maximum pressing force was necessary to assemble the joint for the first time because the joint surfaces have low initial roughness. Hence, during joining, adhesive bonds arise, which generate friction forces requiring the use of considerable force.

The small shaft sleeve removal force after the first fatigue cycle is due to the presence of wear products between the surfaces. These products prevent the formation of adhesive bonds during joint disassembly.

The next joint assembly, before the start of the second fatigue cycle, requires the use of the maximum pressing force of 2370 kN. That force has a value smaller than the pressing force during the first assembly and higher than the removal force. This situation is due to the fact that wear products occurring between the mating surfaces were partly removed, which permits the re-formation of adhesive bonds. In addition to the shearing of surface irregularities, these bonds may also cause plastic deformations to arise on the surfaces joined together.

The higher value of the shaft sleeve removal force after the second fatigue cycle In relation to the previous values is due to surface smoothing. Wear products migrating during assembly and fatigue tests fill the microirregularities on both surfaces and create areas with very low roughness. This is where the need to use a greater removal force comes from. The maximum values of the forces at the successive stages of wear tests can be explained in a similar way.

3.2. Measurement of the Coefficient of Friction

Figure 6 presents a change in the coefficient of friction depending on the number of fatigue cycles. In the tribological kinematic pair under analysis, the change of the coefficient of friction is strongly influenced by the condition of the surface of the mating elements, which follows from the destruction of the top layer as a result of developing wear. The coefficient of friction measured was 0.764 before the wear tests. After the first fatigue cycle, the coefficient increased insignificantly to 0.773. That increase may be due to the intensive shearing of surface microirregularities on the mating surfaces during joint assembly and then during operation in rotational bending moment conditions. The movement of the torn-off microirregularities takes place at that time, and the microholes occurring on the shaft and sleeve surfaces are filled, and thus, the surfaces become “smoother”. In this case, smoothing will create the surface area of the mating elements larger, and thus the value of the coefficient of friction will increase. After the next fatigue cycle, the decrease in the value of the coefficient of friction is noted. That phenomenon should be explained by the partial removal of the wear products, which had filled the microholes until that time, and by the creation of build-ups on the surface of the elements. Then the contact surface area of the mating elements decreases, and there is a smaller risk of the creation of adhesive bonds. Therefore, the value of the coefficient of friction diminishes. The smallest value of the coefficient of friction was noted after the last fatigue cycle. As a result of the repeated loading of the tribological kinematic pair with the rotational bending moment and of the next joint disassembly and assembly, the process of creating wear products generates more build-ups on the surface or the increase of the volume of the existing build-ups becomes more intensive. Moreover, as a result of shaft bending during fatigue tests and of the occurrence of microvibrations, some wear products are removed to the outside of the contact surface area [

30].

3.3. Measurement of Surface Hardness

Figure 7 presents a change in the surface hardness as a function of the number of fatigue cycles. Hardness is an important parameter in the evaluation of the functional strength of steel components.

The initial hardness of both the sleeve and shaft was 187 HV. As the number of fatigue cycles increases, the decrease in surface hardness in the area affected by wear is noted. When the fatigue tests were completed, shaft hardness equal to 184 HV and sleeve hardness equal to 183 HV was measured. Thus, hardness change by 3–4 units in relation to the initial parameters was recorded. Lower hardness values may be due to the abrasion of the top layer of the elements. That phenomenon occurs when wear products travel, first during the joint assembly process and, second, during wear tests, as a result of microvibrations appearing in the tribological kinematic pair. Wear products from the fatigue tests considerably influence the “abrasion” of the surface because, due to those products’ oxidation, they are harder than the remaining wear products and even harder than the surface on which they occur.

In relation to the above, the steel hardness decrease may be the cause of the reduced resistance of an element to friction wear and plastic deformations, which are conducive to adhesion processes. Those factors create a suitable environment for the development of fretting wear, whose consequence is the development of fatigue wear and the cracking of the element.

3.4. Roughness Measurement

Surface roughness is one of the significant factors determining forced-in joint quality. Surface roughness considerably influences the values of the force needed for joint assembly and disassembly, as it was explained in detail in the previous point.

As part of this article, the basic parameters of the roughness of the shaft axle seat and sleeve hub were measured after each completed fatigue cycle. The change in the Ra and Rz roughness parameters after the successive fatigue cycles are presented in

Figure 8.

Figure 9 shows the sample roughness profiles recorded on the shaft surface.

The results of Ra and Rz roughness parameter measurements on the shaft axle seat and sleeve hub indicate an increase in the value of those parameters along with the increase in the number of fatigue cycles in comparison to roughness before the first pressing process. It should be noted, however, that the measurements performed after the third fatigue cycle, that is, after 1,000,000 cycles, indicate that the values of the roughness parameters decreased compared to the value of those parameters after each previously completed fatigue cycle.

The registration of the shaft surface roughness profile demonstrated that the profile is diversified depending on the number of fatigue cycles. After the first fatigue cycle, it was noted that the surface was smoothed and the microholes filled with wear products.

After the next fatigue cycle (100,000 cycles), the shaft surface profile changed its shape significantly. The change is due to wear products, which move along the joint and create microbuild-ups and, occasionally, adhesive bonds. The roughness profile image, such as the one presented in the figure for 100,000 cycles, confirms fretting wear development.

The shaft surface profile after the third fatigue cycle, at 1,000,000 cycles, suggests fully developed fretting wear. That wear comprises, for example, plastic deformations on the shaft surface, chippings, and numerous build-ups of the material.

The shaft surface profile after the end of the third fatigue cycle is presented in

Figure 10, and the sample values of roughness parameters measured in accordance with ISO 25178 are also shown there.

Both in the profile diagram and in the 3D image, a change in the surface structure as a result of fretting wear development can be noted. Contrary to the surface affected by fretting wear, uniform traces of the finish treatment and randomly spaced scratches resulting from the joint assembly process can be seen on the surface not affected by that wear. Part of the shaft surface, which is affected by fretting wear, has a diversified structure at which alternating single summit and cavity peaks can be seen. This confirms the formation of material build-ups on the shaft surface on the one hand and the presence of cavities on the other.

During the analysis of the parameter values for the surface not affected by wear, it may be noticed that the maximum surface height Sz is 9.416 μm, and the arithmetic mean surface height Sa = 1.021 μm.

The distribution of the data for the local summits is the normal distribution with high kurtosis Sku = 8.93 and insignificant negative skewness Ssk = 0.816, which points out to the surface with a plateau shape. The surface not affected by wear has a random isotropic structure.

In the case of the surface affected by fretting wear, all the amplitude parameters even doubled in value compared to the unaffected surface. The Sa parameter, whose decrease is noted, is an exception. That surface is also distinguished by a random isotropic structure. The parameters pertaining to the distribution of local summit peak levels indicate the surface with a pointed shape.

The surface affected by wear is distinguished by a greater core fluid retention index (Sci) and diminishing valley fluid retention index (Svi), with a growing bearing index compared to the unaffected surface. In this case, the liquid is the wear products in the form of iron oxides, Fe2O3.

Based on the quoted data and the review of the literature [

31,

32,

33], it is appropriate to think that higher surface roughness reduces surface resistance to wear as a result of the greater actual contact area between the elements. For that reason, the biggest influence on fretting wear intensity is exerted by high surface roughness parameters and the radius of curvature of microirregularity pits.

3.5. Macroscopic Observations

The macroscopic observations of the shaft surface were conducted at each stage of the wear tests. The results of those observations are included in

Table 5. Surfaces are distinguished by their diversity and intensity of wear and damage depending on the number of fatigue cycles. Traces of damage, mainly due to the shaft sleeve forcing in and removal process, are noted on shafts which operated for 10,000 cycles. These are insignificant surface seizures occurring over the entire axle seat circumference, especially at the end from which sleeve installation on the shaft began. It should be emphasised that the joint was “dry”-assembled, which could enhance the development of surface friction wear as a result of the shearing and movement of irregularities occurring at the surfaces of the elements joined together. It is the microirregularities migrating during the forcing process which were the cause of surface scratching and grooving. In addition to the traces of surface seizing, scratches of insignificant dimensions were also noted in places on the shaft surface.

On the surfaces of shafts which operated for 100,000 fatigue cycles, micro-size plastic deformations were noted, and these are most probably the result of the local occurrence of adhesive bonds. Insignificant fretting wear traces also appear. The wear occurring on the shaft surface is due to the successive assembly and disassembly process and to the fatigue operation of the joint in rotational bending conditions.

Moving wear products originating from the shearing of microprojections on the surface of the mating elements tightly fill the microholes and create a bigger surface area of the joint between the mating elements. That situation translates into the need to apply greater forces to remove the sleeve from the shaft and contributes to the formation of adhesive bonds, causing plastic deformation.

Local chippings of the top layer and plastic deformations are noted on the surface of the shafts, which operated for 1,000,000 fatigue cycles. Fretting wear traces are, however, the prevailing kind of damage visible on all the surfaces under investigation. When that number of cycles was exceeded, quickly progressing fatigue wear also occurred, which resulted in shaft fracture.

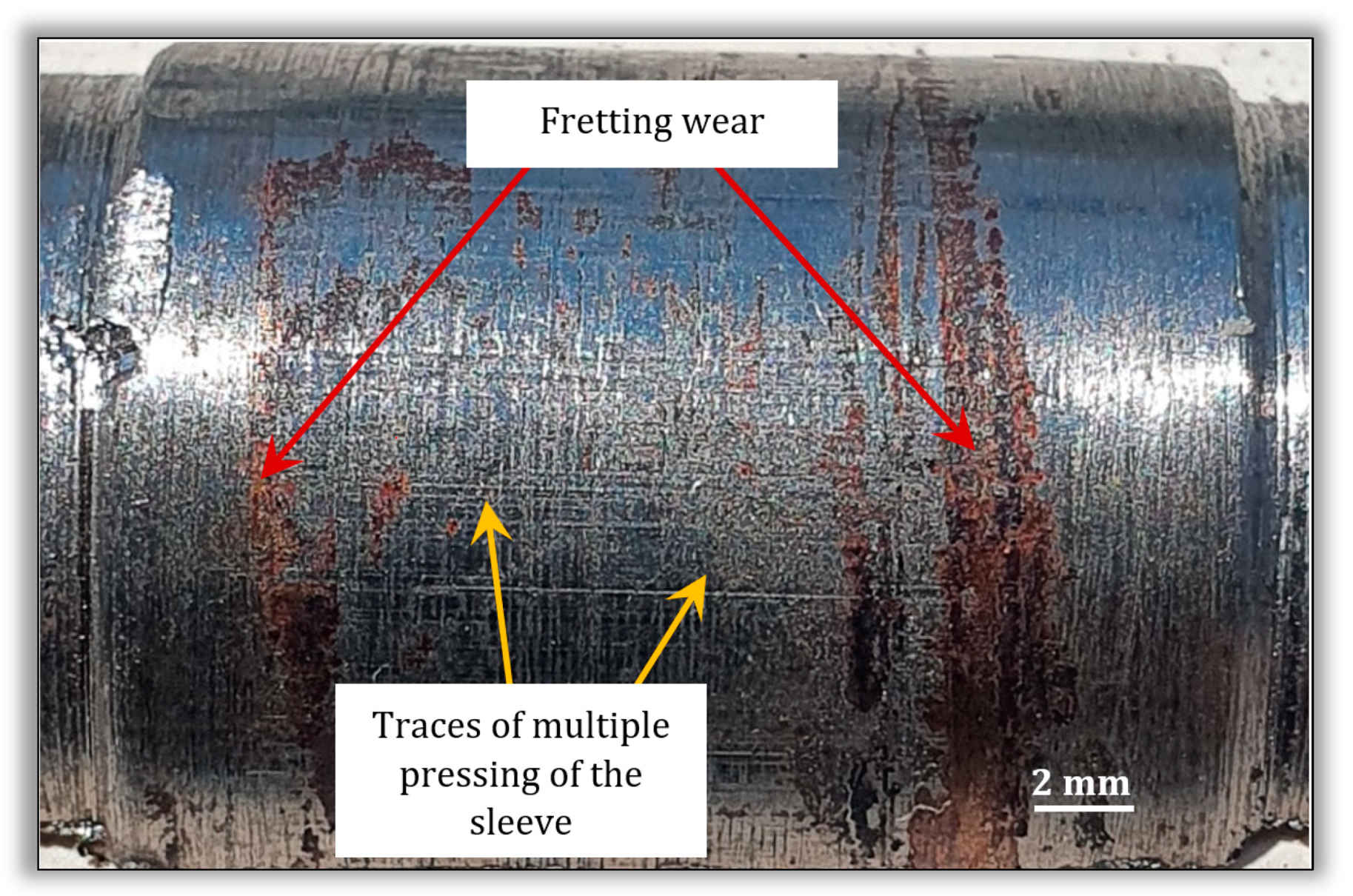

The surface of the shaft, which operated for 1,000,000 fatigue cycles, is shown in

Figure 11. Visible are forcing traces in the form of scratches and skinning of the material, which do not significantly affect the life of the shaft/sleeve forced-in joint. On the shaft surface, fretting wear traces are also noted, which may cause fatigue wear development or surface pressure reduction leading to joint disconnection.

Fretting wear traces are located on either side of the shaft axle seat and occur close to the edges of the joint with the sleeve. The movement of wear towards the deeper area of the joint is noticeable in places. What is conspicuous is that, on one side, the wear comprises the entire circumference of the shaft axle seat. The width of the wear ring in its widest place is approximately 4 mm, and the width in its narrowest place is 1 mm. On the other side of the axle seat, however, the wear is spaced randomly on the entire axle seat circumference. This situation concerns all the samples tested. The wear ring occurs each time on the opposite side in relation to the one from which forcing was performed.

Fretting wear traces are distinguished by their grey and dark brown colour, which may prove surface oxidation.

3.6. Wear Volume Measurement

Quantification of wear data is represented by specific wear rate data [

34].

Figure 12 presents shaft wear intensity after successive fatigue cycles. Macroscopic observations demonstrated the presence of wear traces on either side of the shaft axle seat, which is why the wear intensity measurement was conducted separately for each shaft side. Shaft axle seat wear intensity on the left side is considerably lower than on the right side, which was also noted during macroscopic observations. The left side of the sample corresponds to the side from which the joint assembly started. In the case of the left side of the axle seat, the increase in wear stability is steady, and it grows evenly with the number of fatigue cycles. The situation on the right side of the sample is different. In the first two fatigue cycles, wear increases steadily, but a sudden increase in wear intensity is noted in the third fatigue cycle. The magnitude of wear is influenced by both joint assembly processes and fatigue loads. Therefore, that situation should be explained in terms of the mechanism of fretting wear development in forced-in joints. In the case of that type of joint, roughness is particularly important in terms of the actual contact between the surfaces and, consequently, for initiating the development of fretting wear. Joining the shaft with the sleeve—whose bondable surfaces have a similar roughness profile—will cause a situation where, as a result of the operation of the tangent force, first of all, the mutual shearing of the microirregularities on both surfaces will occur. In view of the gap shape, wear products on the right side of the shaft axle seat will be removed more easily, and therefore, a greater contact area between the first bodies will come into being. The right side of the joint is wider than the left one, and this can be seen in

Figure 13.

The direct contact between the first bodies and the occurrence of microvibrations at the same time will be conducive to the creation of adhesive bonds, which will then become broken, thus creating microprojections, micropullouts, and material build-ups. In turn, relative slips, with the highest amplitude in this area, will initiate plastic deformation processes. This is the way in which greater wear intensity at the right side of the shaft axle seat should be explained when compared to the left side of the axle seat.

3.7. Microscopic Observations with the EDS Analysis of the Chemical Composition of Wear Products

Following the completion of the macroscopic observations, microscopic observations of the shaft surfaces were conducted, in particular at the place of changes caused by fretting wear. Sample scanning images of shaft axle seat surfaces after the forcing process and at the place of fretting wear are presented in

Figure 14.

The observations of the shaft axle seat surfaces confirmed the results of the surface roughness tests. Mainly surface smoothing caused by the sleeve forcing process is visible. It is also noted that microholes are filled with moving wear products (

Figure 14a). Both the smoothed surface and the wear products in microholes create the contact area between the mating elements bigger. In turn, this may promote the formation of adhesive bonds, initiating fretting wear.

Those we\ar products which did not fill the microholes but migrate during assembly or wear tests stick to the surface and create material build-ups (

Figure 14c). Those build-ups plasticise under the influence of cyclic tangential displacements between the mating surfaces, which can be seen in

Figure 14b.

Migrating wear product particles not only cause the kinds of damage mentioned above but also contribute to the formation of pits and surface abrasion in places. The initial surface roughness of the elements joined together is of significant importance in this case. Noticeable are also surface microcracks (

Figure 14d) which become larger with the number of wear cycles and move deeper into the material. Thus, these microcracks contribute to the initiation and development of fatigue wear, which causes shaft fracture.

The surface of the shafts at which wear products are located was subjected to the analysis of the chemical composition by means of the EDS technique. The results of this analysis are shown in

Figure 15.

The analysis also demonstrated the presence of iron and oxygen atoms. This confirms wear product oxidation, which would explain the grey and dark brown colour of the shaft surface in the fretting wear zone, as noted during the macroscopic observations. As a result of wear product oxidation, there forms a liquid in the form of a powder, that being iron trioxide, Fe2O3. This is distinguished by lower density and, thus, by greater volume.

Oxidised wear products are distinguished by much higher hardness compared to that of the shaft and sleeve surface. Thus, wear products migrating along the joint are responsible for the rise of damage such as scratches, plastic deformation, and surface abrasion.

It follows from the observations that only those fragments of the shaft surface oxidised at which damage in the form of build-ups and pits has arisen and at which loose wear products have formed.