Study of Mechanical Properties of Micron Polystyrene-Toughened Epoxy Resin

Abstract

1. Introduction

2. Experimental Program

2.1. Test Materials and Equipment

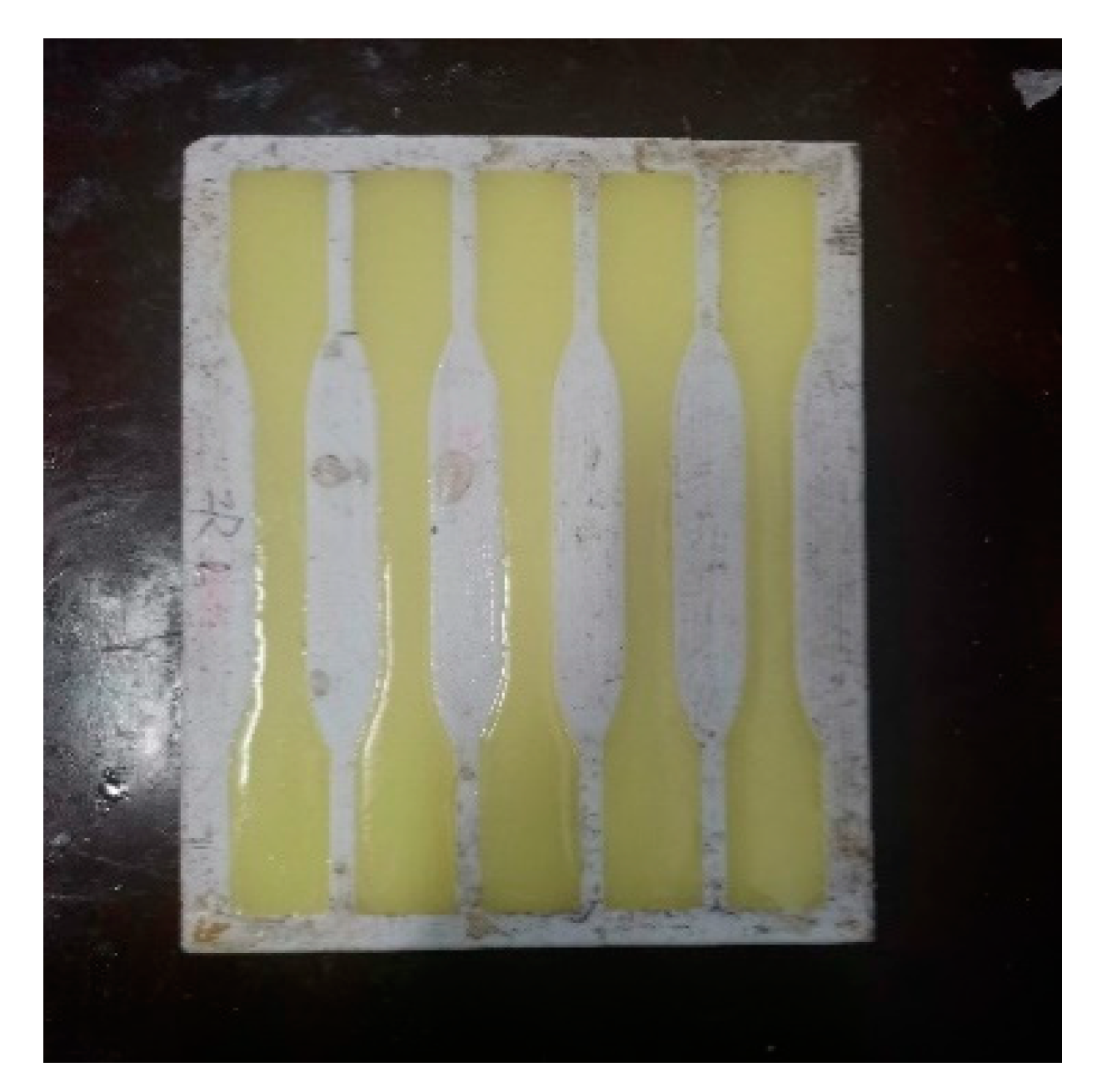

2.2. Specimen Preparation

2.3. Test Methods

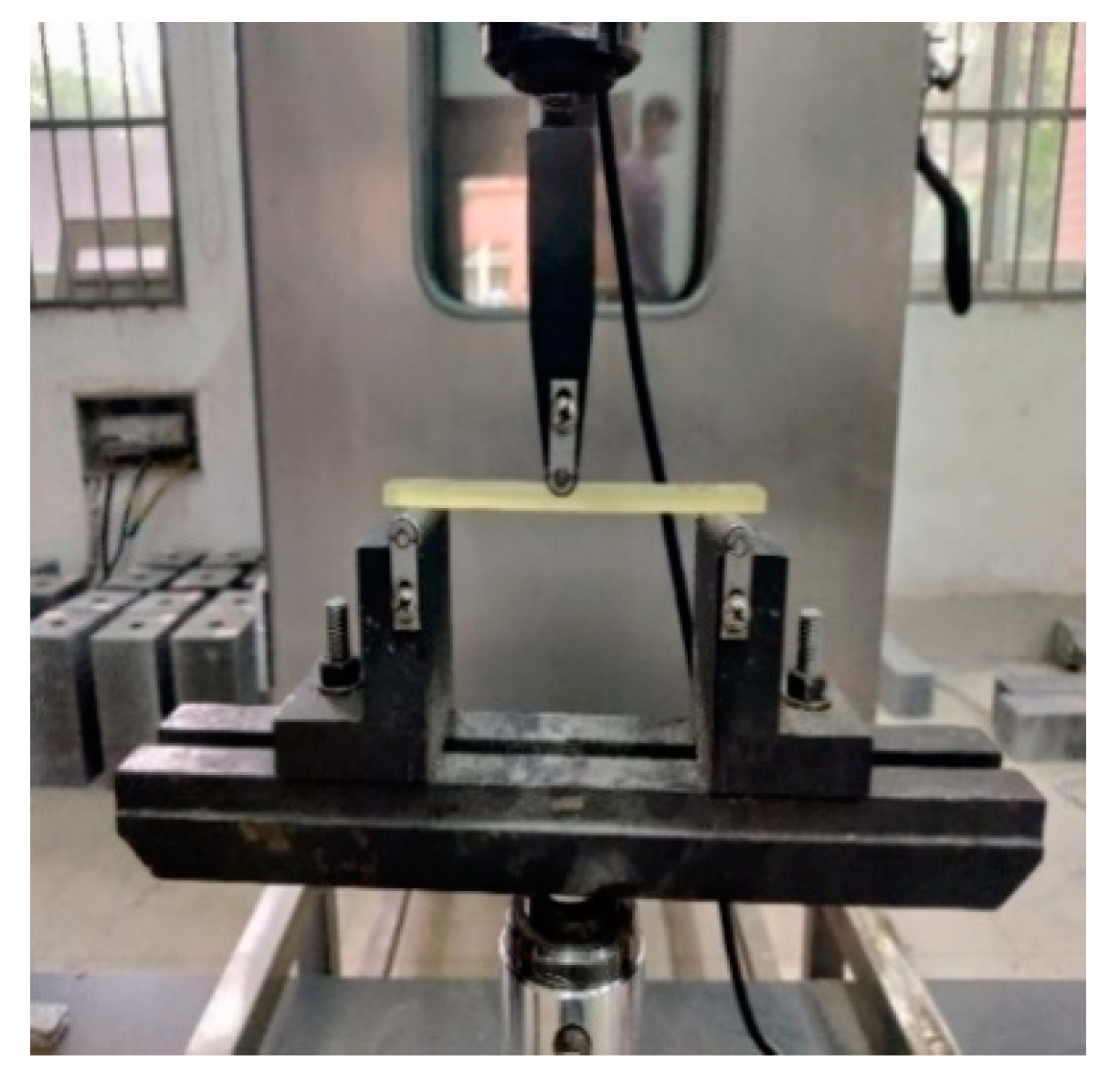

2.3.1. Tensile Test

2.3.2. Flexural Test

2.3.3. Impact Test

3. Results and Discussions

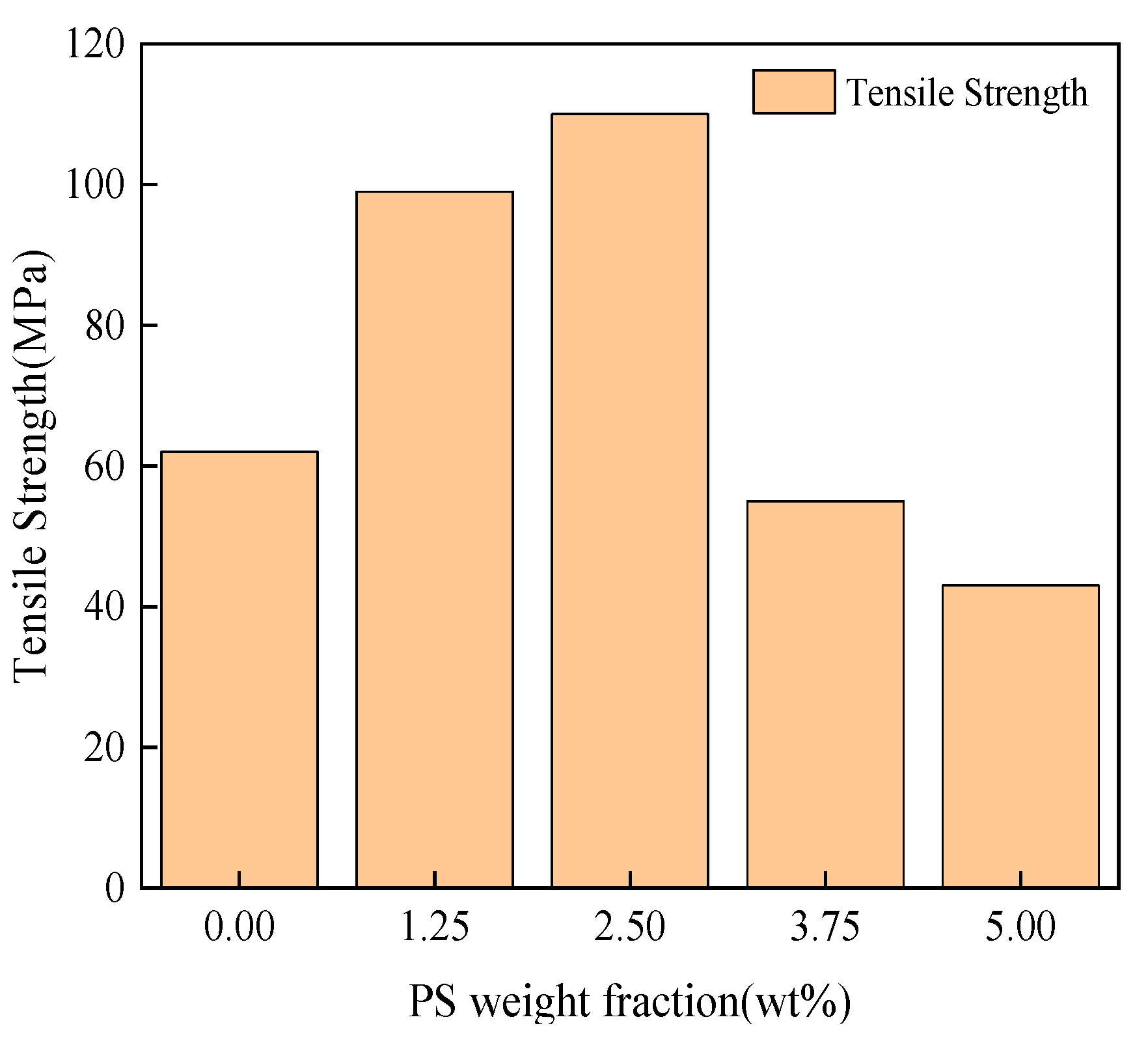

3.1. Tensile Properties of Epoxy Resins with Different PS Weight Fraction

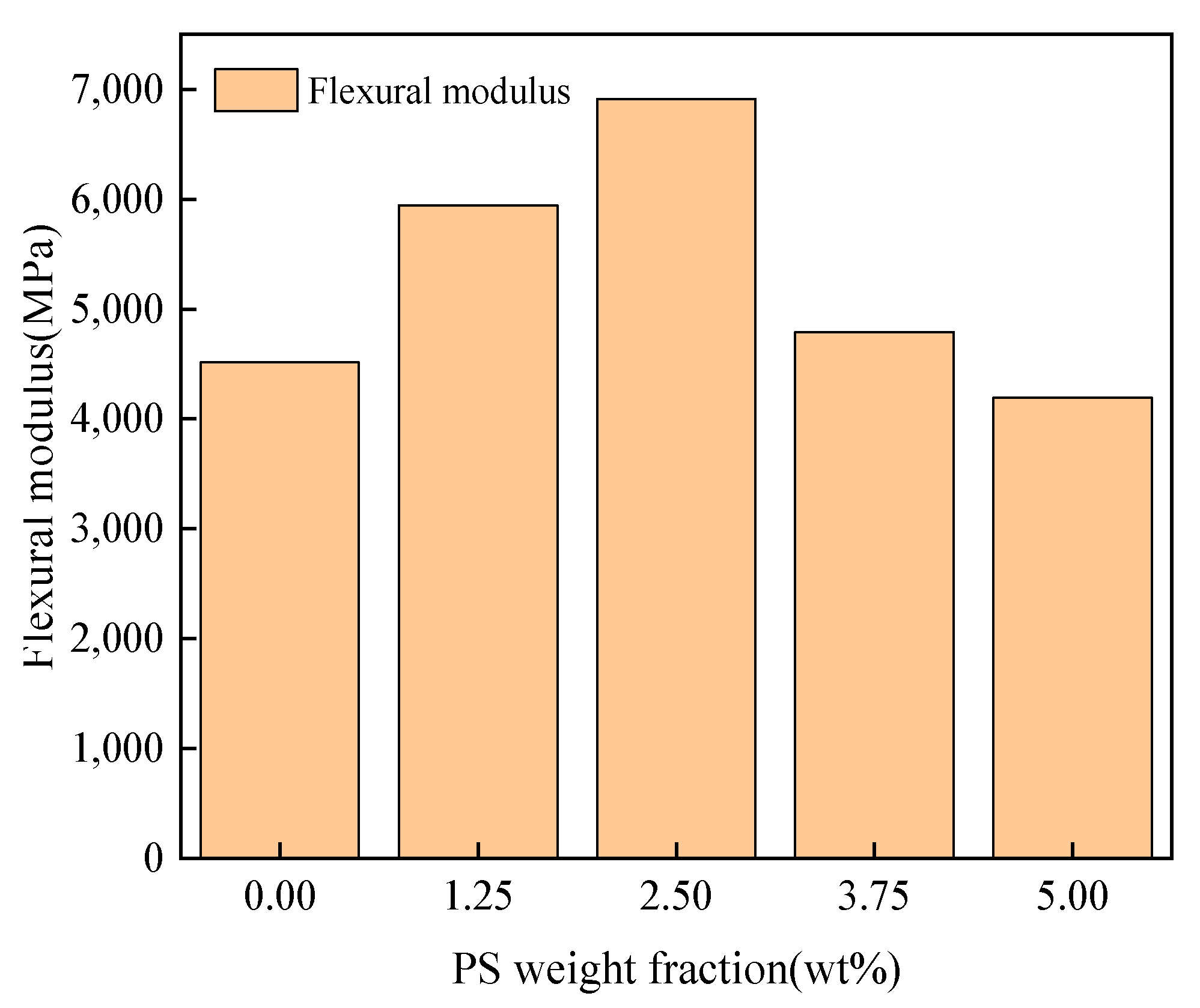

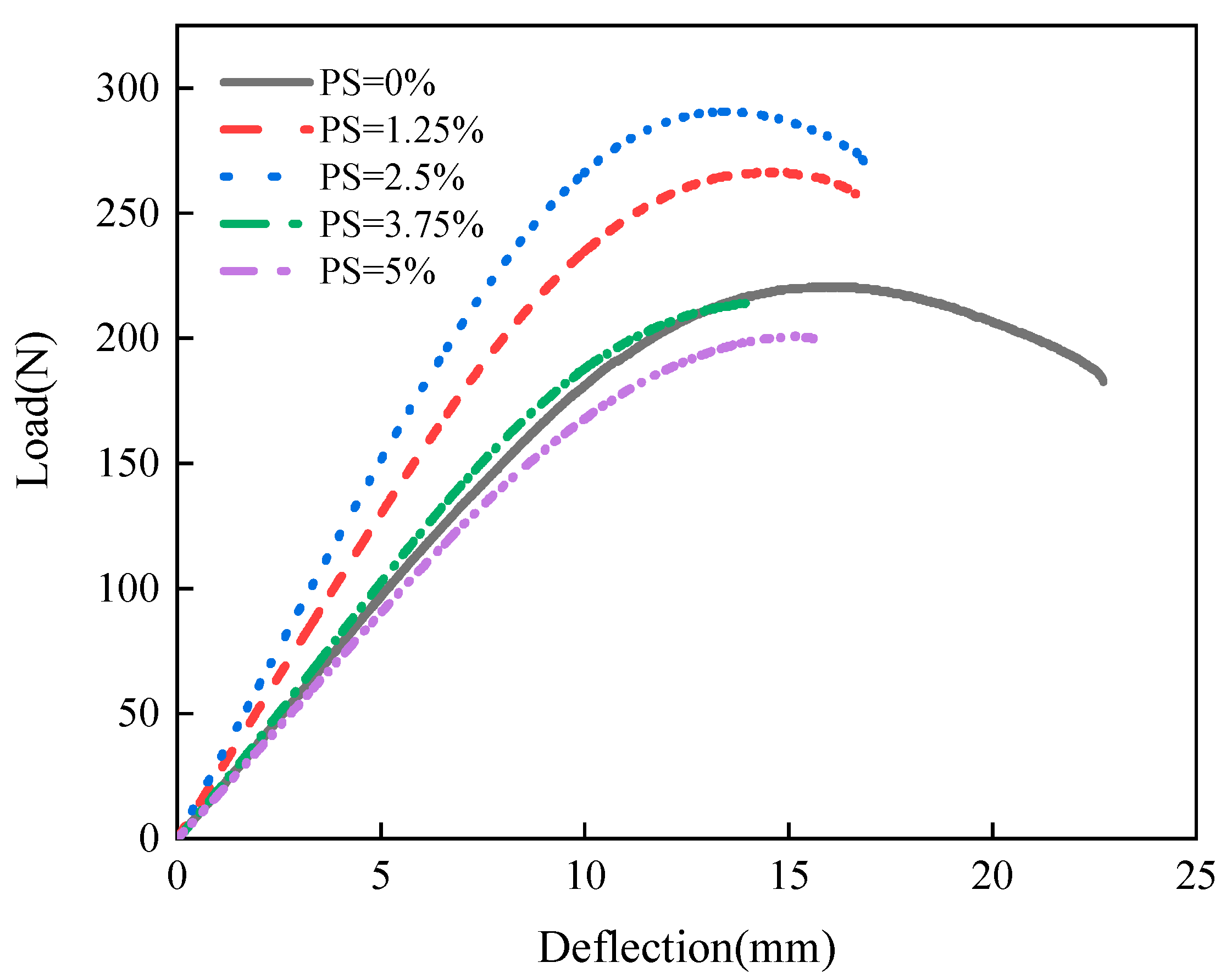

3.2. The Flexural Properties of Epoxy Resins with Different PS Weight Fraction

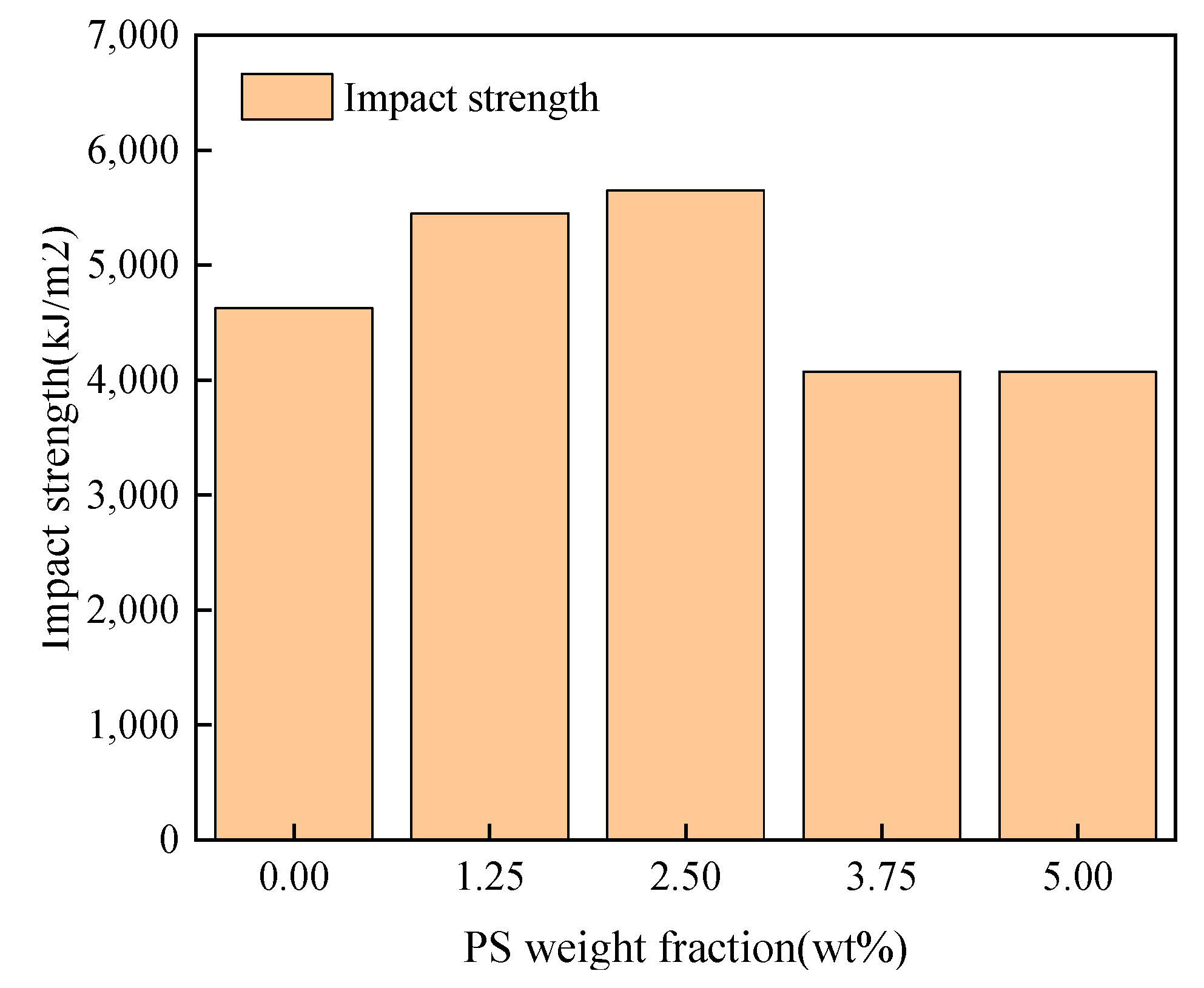

3.3. Impact Performance of Epoxy Resin with Different PS Weight Fraction

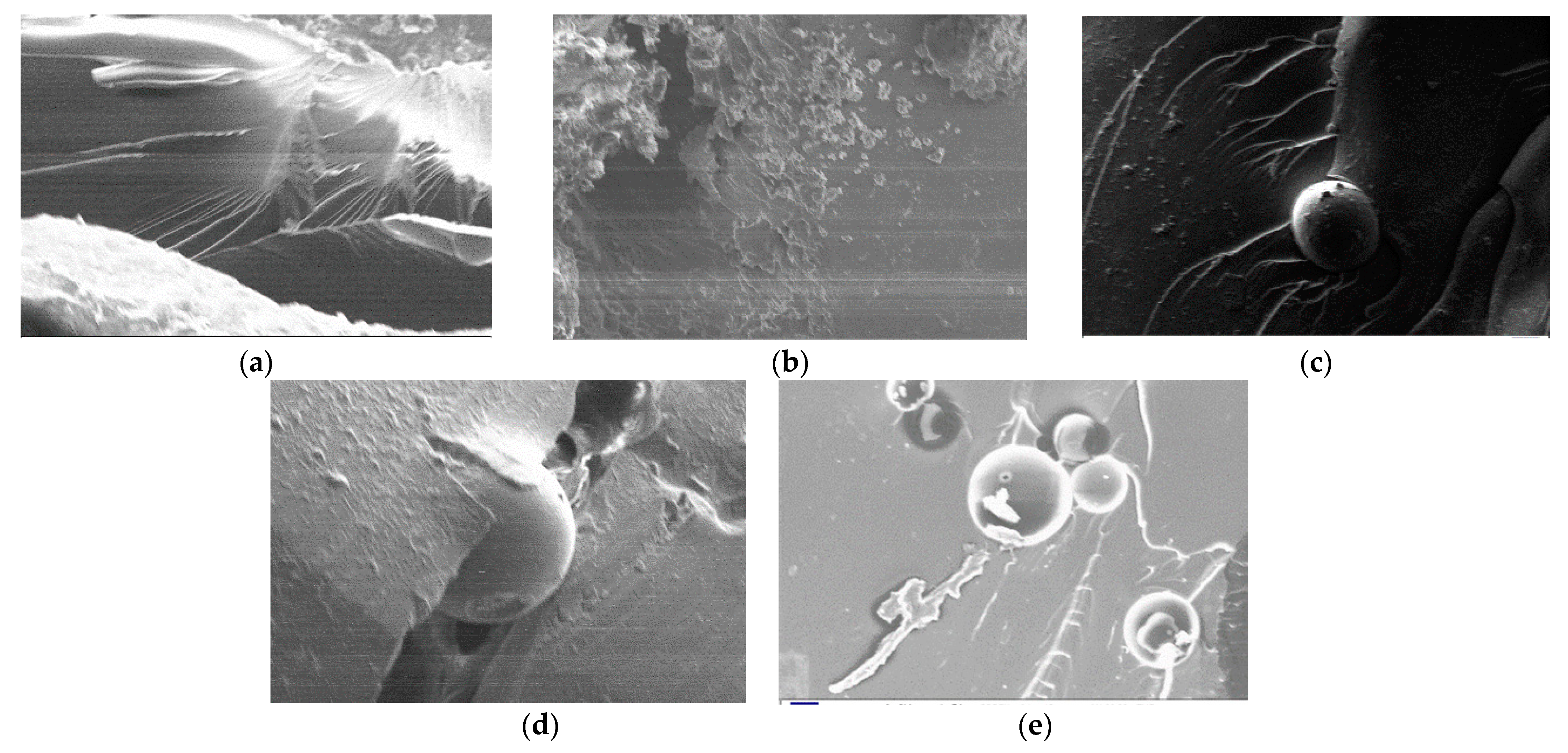

3.4. The Micromorphology of Epoxy Resin with Different PS Weight Fractions

4. Conclusions

- (1)

- The mechanical properties of the epoxy resin were significantly improved by adding the appropriate amount of micron polystyrene (PS). The tensile strength, the tensile modulus of elasticity, flexural strength, flexural modulus and impact strength of the adhesives showed a trend of increasing and then decreasing with the increase in PS incorporation; 2.5 wt% of PS resulted in the optimum mechanical properties, which were improved by 77%, 147.7%, 71%, 35% and 22%, respectively, compared with the pure epoxy resin.

- (2)

- The influence of PS admixture on the elongation at break and bending deflection of the adhesive was significant; the elongation at break and bending deflection of the adhesive were maximum when the PS admixture was 0. With the increase in PS mass fraction, the elongation at break and flexural deflection of the adhesive increased, but still less than the pure resin.

- (3)

- Correlations between the microscopic morphology and the mechanical properties of the adhesive were obtained using SEM techniques. The PS particles produce large deformation to absorb energy when the matrix fractures, and crack expansion needs to bypass or shear the PS particles, thus inhibiting the crack expansion and achieving toughening. When the PS weight fraction increases to 5%, PS particles in the resin appear to adhere to the agglomeration phenomenon, resulting in a decrease in the mechanical properties of the adhesive.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, C.X.; Ke, L.; Chen, Z.Y.; He, J.; Guo, L.C.; Yang, J. Fatigue performance of orthotropic anisotropic steel bridge panels with curved cutouts and their CFRP reinforcement. Chin. J. Highw. 2021, 34, 63–75. [Google Scholar]

- Wang, Y.; Li, J.; Deng, J.; Li, S. Bond behavior of CFRP/steel strap joints exposed to overloading fatigue and wetting/drying cycles. Eng. Struct. 2018, 172, 1–12. [Google Scholar] [CrossRef]

- Ghafoori, E.; Motavalli, M.; Nussbaumer, A.; Herwig, A.; Prinz, G.S.; Fontana, M. Determination of minimum CFRP pre-stress levels for fatigue crack prevention in retrofitted metallic beams. Eng. Struct. 2015, 84, 29–41. [Google Scholar] [CrossRef]

- Wu, C.; Zhao, X.L.; Chiu, W.K.; Al-Mahaidi, R.; Duan, W.H. Effect of fatigue loading on the bond behavior between UHM CFRP plates and steel plates. Compos. Part B 2013, 50, 344–353. [Google Scholar] [CrossRef]

- Tavakkolizadeh, M.; Saadatmanesh, H. Fatigue Strength of Steel Girders Strengthened with Carbon Fiber Reinforced Polymer Patch. J. Struct. Eng. 2003, 129, 186–196. [Google Scholar] [CrossRef]

- Benachour, A.; Benyoucef, S.; Tounsi, A.; Bedia, E.A. Interfacial stress analysis of steel beams reinforced with bonded prestressed FRP plate. Eng. Struct. 2008, 30, 3305–3315. [Google Scholar] [CrossRef]

- Kotełko, M.; Lis, P.; Macdonald, M. Load capacity probabilistic sensitivity analysis of thin-walled beams. Thin-Walled Struct. 2017, 115, 142–153. [Google Scholar] [CrossRef]

- Li, C.X.; Ke, L.; Chen, Z.Y.; He, J.; Luo, N.H. Experimental and numerical simulation of bonding performance of CFRP-steel interface. J. Compos. 2018, 35, 3534–3546. [Google Scholar]

- Xu, B.S.; Qian, Y.J.; Tang, J.S.; Ma, M.; Li, X.B. Sensitivity analysis of stress parameters at CFRP-steel interface based on viscoelastic principal structure. Highw. Transp. Technol. 2017, 34, 57–63. [Google Scholar]

- Chen, Z.Y.; Peng, Y.Z.; Li, C.X.; Guo, J. Mechanical properties of double-lap steel-CFRP plate adhesive interface at high temperature. J. Compos. 2021, 38, 449–460. [Google Scholar]

- Li, C.X.; Li, Y.; He, J.; Liu, Y.M.; Peng, Y.Z. Effect of curing agent on the interfacial properties of room temperature glued CFRP sheets/steel plates. J. Constr. Mater. 2021, 24, 339–347. [Google Scholar]

- Yang, Y.; Biscaia, H.; Chastre, C.; Silva, M.A. Bond characteristics of CFRP-to-steel joints. J. Constr. Steel Res. 2017, 138, 401–419. [Google Scholar] [CrossRef]

- He, J.; Xian, G. Debonding of CFRP-to-steel joints with CFRP delamination. Compos. Struct. 2016, 153, 12–20. [Google Scholar] [CrossRef]

- Yuan, Z.W.; Niu, Y.P.; Wang, S.W.; Du, S.M. Toughening mechanism and research progress of epoxy resin. Resins 2019, 34, 65–70. [Google Scholar]

- Chen, F.; Wang, S.X.; Zhai, J.M.; Guo, J.J. Study on toughened bisphenol A epoxy resin modified by vinyl ester resin. Compos. Sci. Eng. 2020, 12, 92–99. [Google Scholar]

- Mishra, K.; Singh, R.P. Effect of APTMS modification on multiwall carbon nanotube reinforced epoxy nanocomposites. Compos. Part B 2019, 162, 425–432. [Google Scholar] [CrossRef]

- Li, H.W.; Yu, X.H.; Xia, Y. Synthesis of bisphenol S epoxy resin and development of its adhesive. China Adhes. 2021, 30, 1–4. [Google Scholar]

- Al-Mosawe, A.; Al-Mahaidi, R.; Zhao, X.L. Effect of CFRP properties, on the bond characteristics between steel and CFRP laminate under quasi-static loading. Constr. Build. Mater. 2015, 98, 489–501. [Google Scholar] [CrossRef]

- Biscaia, H.C.; Chastre, C. Theoretical analysis of fracture in double overlap bonded joints with FRP composites and thin steel plates. Eng. Fract. Mech. 2018, 190, 435–460. [Google Scholar] [CrossRef]

- Wang, J.J.; Zhang, X.Z.; Su, Y.L. Study on the toughening modification of epoxy resins. Resins 2020, 35, 55–59. [Google Scholar]

- Pinto, D.; Bernardo, L.F.; Amaro, A.; Lopes, S. Mechanical Properties of Epoxy Nanocomposites Using Alumina as Reinforcement—A Review. J. Nano Res. 2015, 30, 9–38. [Google Scholar] [CrossRef]

- Wazalwar, R.; Tripathi, N.; Raichur, A.M. Mechanical and curing behavior of epoxy composites reinforced with polystyrene-graphene oxide (PS-GO) core-shell particles. Compos. Part C Open Access 2021, 5, 100128. [Google Scholar] [CrossRef]

- Korayem, A.H.; Li, C.Y.; Zhang, Q.H.; Zhao, X.L.; Duan, W.H. Effect of carbon nanotube modified epoxy adhesive on CFRP-to-steel interface. Compos. Part B 2015, 79, 95–104. [Google Scholar] [CrossRef]

- Omrani, A.; Simon, L.C.; Rostami, A.A. The effects of alumina nanoparticle on the properties of an epoxy resin system. Mater. Chem. Phys. 2008, 114, 145–150. [Google Scholar] [CrossRef]

- Serin, H.; Yıldızhan, Ş. Tensile properties and cost-property efficiency analyses of expanded polystyrene/chopped glass fiber/epoxy novel composite. J. Mech. Sci. Technol. 2021, 35, 145–151. [Google Scholar] [CrossRef]

- Hu, Z.F.; Duan, H.J.; Tang, Y.S.; Chen, X.S.; Zhang, L. End-epoxy-based polystyrene oligomers toughened modified epoxy resins. Resins 2016, 31, 49–53. [Google Scholar]

- Mirmohseni, A.; Zavareh, S. Modeling and optimization of a new impact-toughened epoxy nanocomposite using response surface methodology. J. Polym. Res. 2011, 18, 509–517. [Google Scholar] [CrossRef]

- GBT 2567-2008; Test Method of Resin Casting Body Properties. General Administration of Quality Supervision, Inspection and Quarantine: Beijing, China, 2008.

- Rostamiyan, Y.; Mashhadzadeh, A.H.; SalmanKhani, A. Optimization of mechanical properties of epoxy-based hybrid nanocomposite: Effect of using nano silica and high-impact polystyrene by mixture design approach. Mater. Des. 2013, 56, 1068–1077. [Google Scholar] [CrossRef]

- Fereidoon, A.; Mashhadzadeh, A.H.; Rostamiyan, Y. Experimental, modeling and optimization study on the mechanical properties of epoxy/high- impact polystyrene/multi-walled carbon nanotube ternary nanocomposite using artificial neural network and genetic algorithm. Sci. Eng. Compos. Mater. 2013, 20, 265–276. [Google Scholar] [CrossRef]

- Ma, Q.L.; Zhang, C.X.; Wang, H.; Jiang, J.; Lv, W.B. Effect of temperature on the shear strength of carbon nanotube fiber/epoxy resin interface. J. Shanghai Univ. (Nat. Sci. Ed.) 2018, 24, 961–967. [Google Scholar]

- Sun, T.; Wu, Z.; Zhuo, Q.; Liu, X.; Wang, Z.; Fan, H. Microstructure and mechanical properties of aminated polystyrene spheres/epoxy polymer blends. Compos. Part A 2014, 66, 58–64. [Google Scholar] [CrossRef]

- Sha, Y.; Kramer, E.; Hahn, S.; Berglund, C.; Hui, C. Fracture Toughness and Failure Mechanisms of Epoxy/Rubber-Modified Polystyrene (HIPS) Interfaces Reinforced by Grafted Chains. Macromolecules 1996, 29, 4728–4736. [Google Scholar] [CrossRef]

- Gu, H.; Ma, C.; Liang, C.; Meng, X.; Gu, J.; Guo, Z. A low loading of grafted thermoplastic polystyrene strengthens and toughens transparent epoxy composites. J. Mater. Chem. C 2017, 5, 4275–4285. [Google Scholar] [CrossRef]

- Amaro, A.M.; Bernardo, L.; Pinto, D.G.; Lopes, S.; Rodrigues, J. The influence of curing agents in the impact properties of epoxy resin nanocomposites. Compos. Struct. 2017, 174, 26–32. [Google Scholar] [CrossRef]

| Material Symbol | Material Name | Based on E51 |

|---|---|---|

| 1 | Bisphenol A type epoxy resin (E51) | 1 |

| 2 | Epoxy resin thinner | 10 wt% |

| 3 | Fatty amines (triethylenetetramine) | 15 wt% |

| 4 | Polyether amines | 30 wt% |

| 5 | Trifunctional epoxy resin | 10 wt% |

| Symbol | PS Weight Fraction (wt%) | Tensile Strength (MPa) | Modulus of Elasticity (MPa) | Elongation at Break (%) |

|---|---|---|---|---|

| 1 | 0 | 62 | 12,088 | 0.6037 |

| 2 | 1.25 | 99 | 29,641 | 0.3378 |

| 3 | 2.50 | 110 | 29,945 | 0.4097 |

| 4 | 3.75 | 55 | 12,763 | 0.5494 |

| 5 | 5 | 43 | 11,069 | 0.39415 |

| Symbol | PS Weight Fraction (wt%) | Flexural Strength (MPa) | Flexural Modulus (MPa) | Deflection (mm) |

|---|---|---|---|---|

| 1 | 0 | 105 | 4515 | 22.722 |

| 2 | 1.25 | 127 | 5944 | 16.6787 |

| 3 | 2.50 | 178 | 6912 | 16.9621 |

| 4 | 3.75 | 102 | 4792 | 14.1701 |

| 5 | 5 | 96 | 4193 | 15.7122 |

| Symbol | PS Weight Fraction (wt%) | Absorbed Work (J) | Toughness (J/m3) | Impact Strength (KJ/m2) |

|---|---|---|---|---|

| 1 | 0 | 0.185 | 0.207 | 4625 |

| 2 | 1.25 | 0.218 | 5.450 | 5405 |

| 3 | 2.50 | 0.226 | 5.649 | 5650 |

| 4 | 3.75 | 0.163 | 4.075 | 4075 |

| 5 | 5 | 0.163 | 4.075 | 4075 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Liu, Y.; Chen, Z. Study of Mechanical Properties of Micron Polystyrene-Toughened Epoxy Resin. Appl. Sci. 2023, 13, 3981. https://doi.org/10.3390/app13063981

Li C, Liu Y, Chen Z. Study of Mechanical Properties of Micron Polystyrene-Toughened Epoxy Resin. Applied Sciences. 2023; 13(6):3981. https://doi.org/10.3390/app13063981

Chicago/Turabian StyleLi, Chunxu, Yan Liu, and Zhuoyi Chen. 2023. "Study of Mechanical Properties of Micron Polystyrene-Toughened Epoxy Resin" Applied Sciences 13, no. 6: 3981. https://doi.org/10.3390/app13063981

APA StyleLi, C., Liu, Y., & Chen, Z. (2023). Study of Mechanical Properties of Micron Polystyrene-Toughened Epoxy Resin. Applied Sciences, 13(6), 3981. https://doi.org/10.3390/app13063981