A Review of Road Design for Wind Farms in China

Abstract

1. Introduction

2. Research on Line Selection Method Optimization

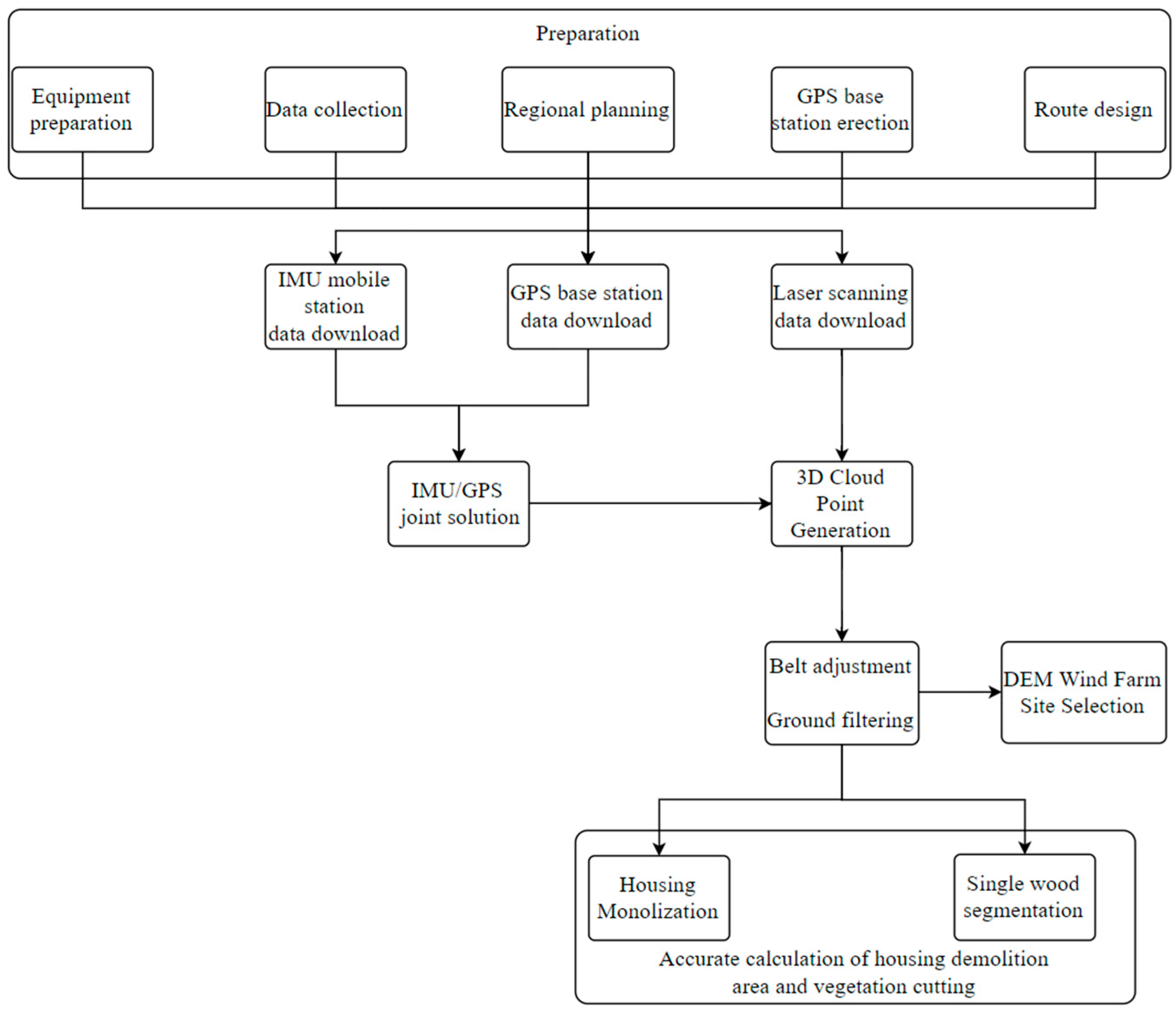

2.1. Auxiliary Survey of Aerial Surveying Equipment

2.2. Professional Software-Aided Design

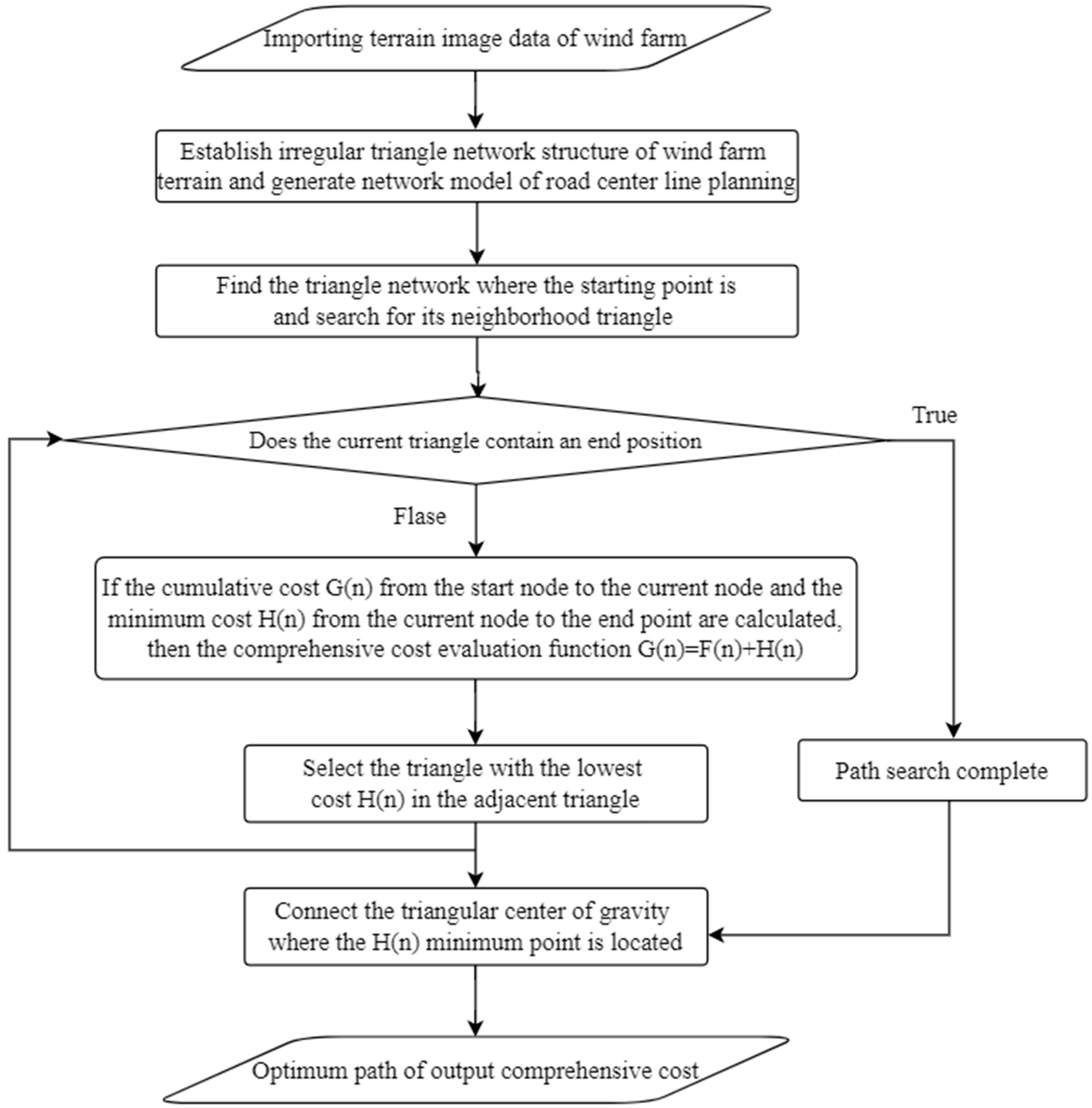

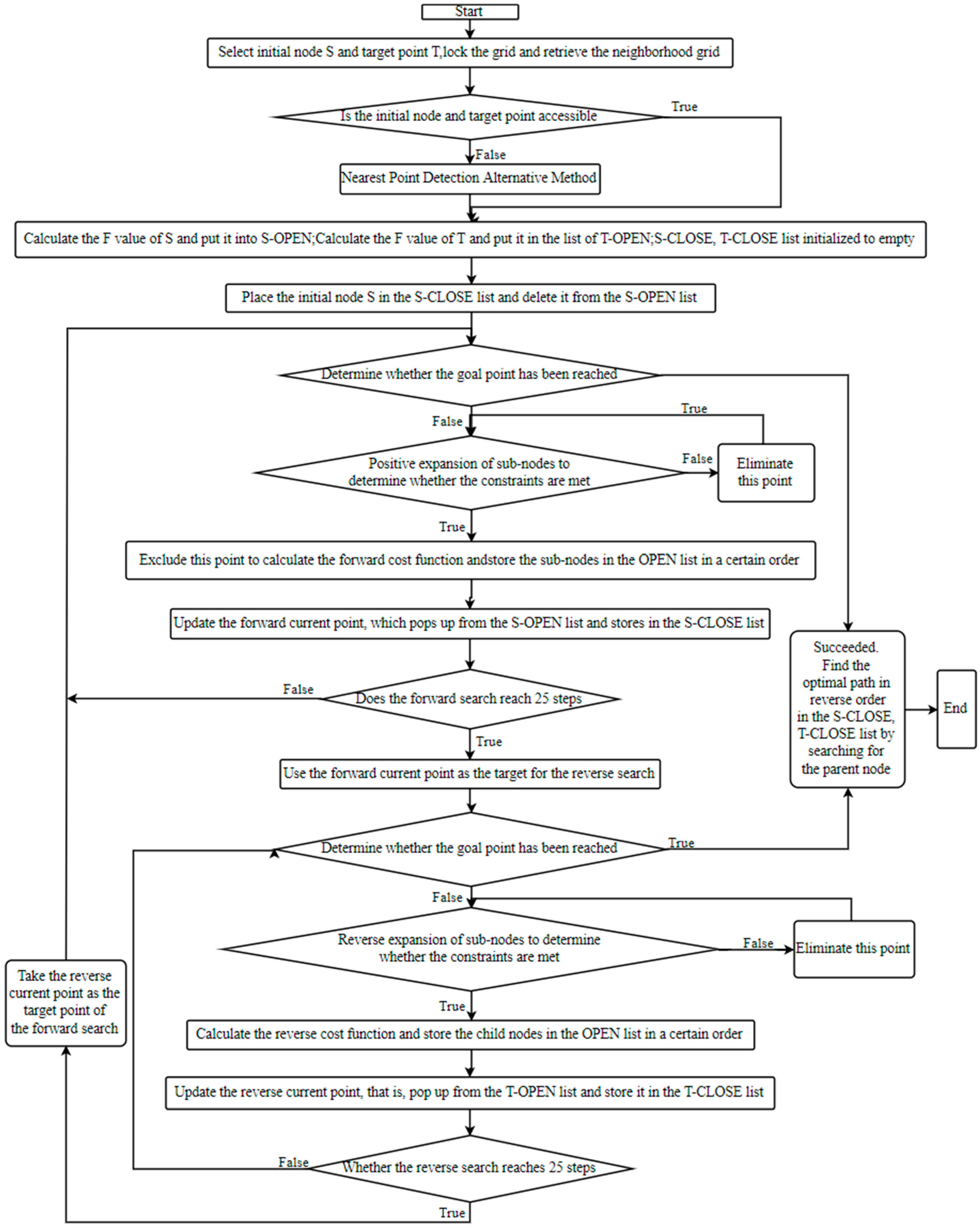

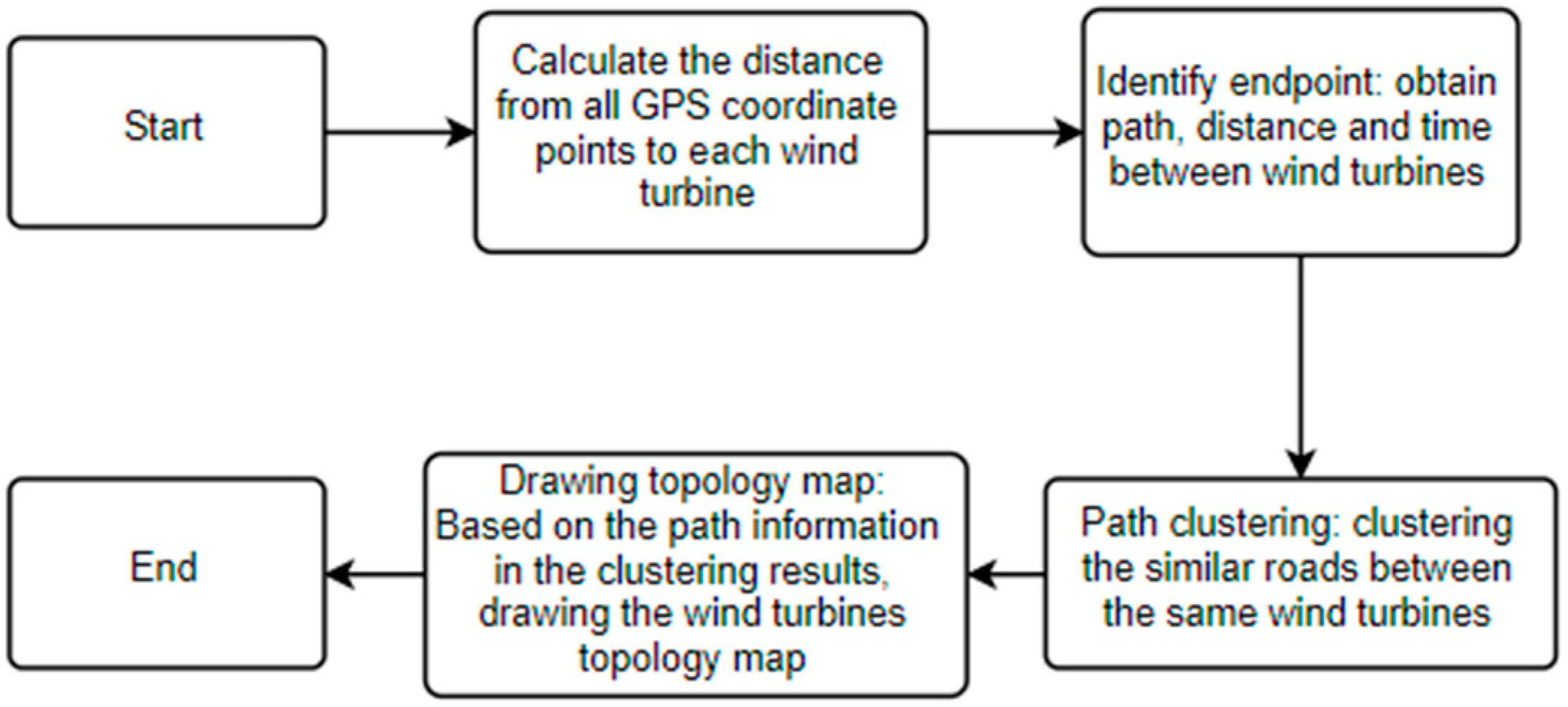

2.3. Intelligent Road Routing Model

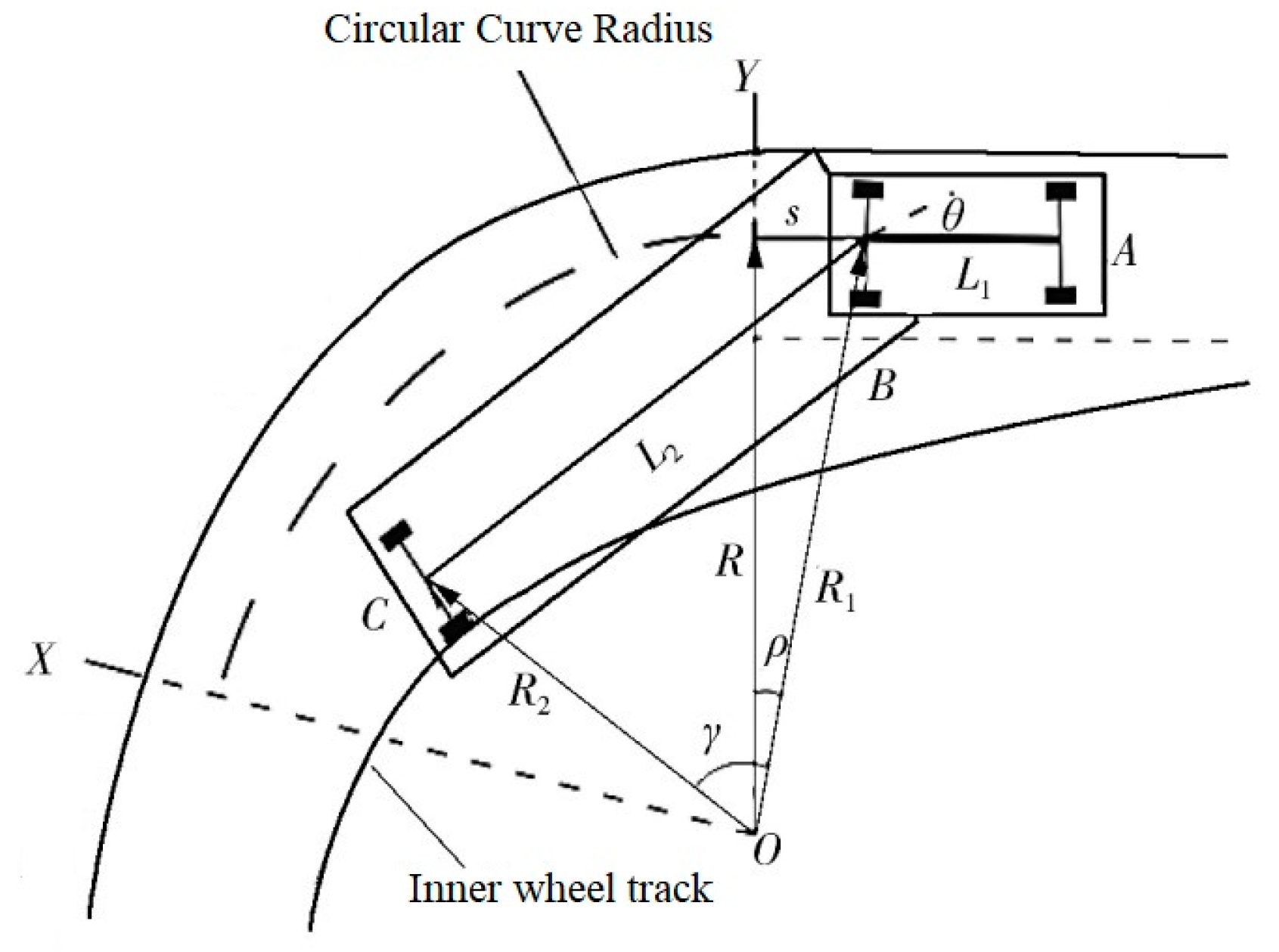

3. Research on Circular Curve Design

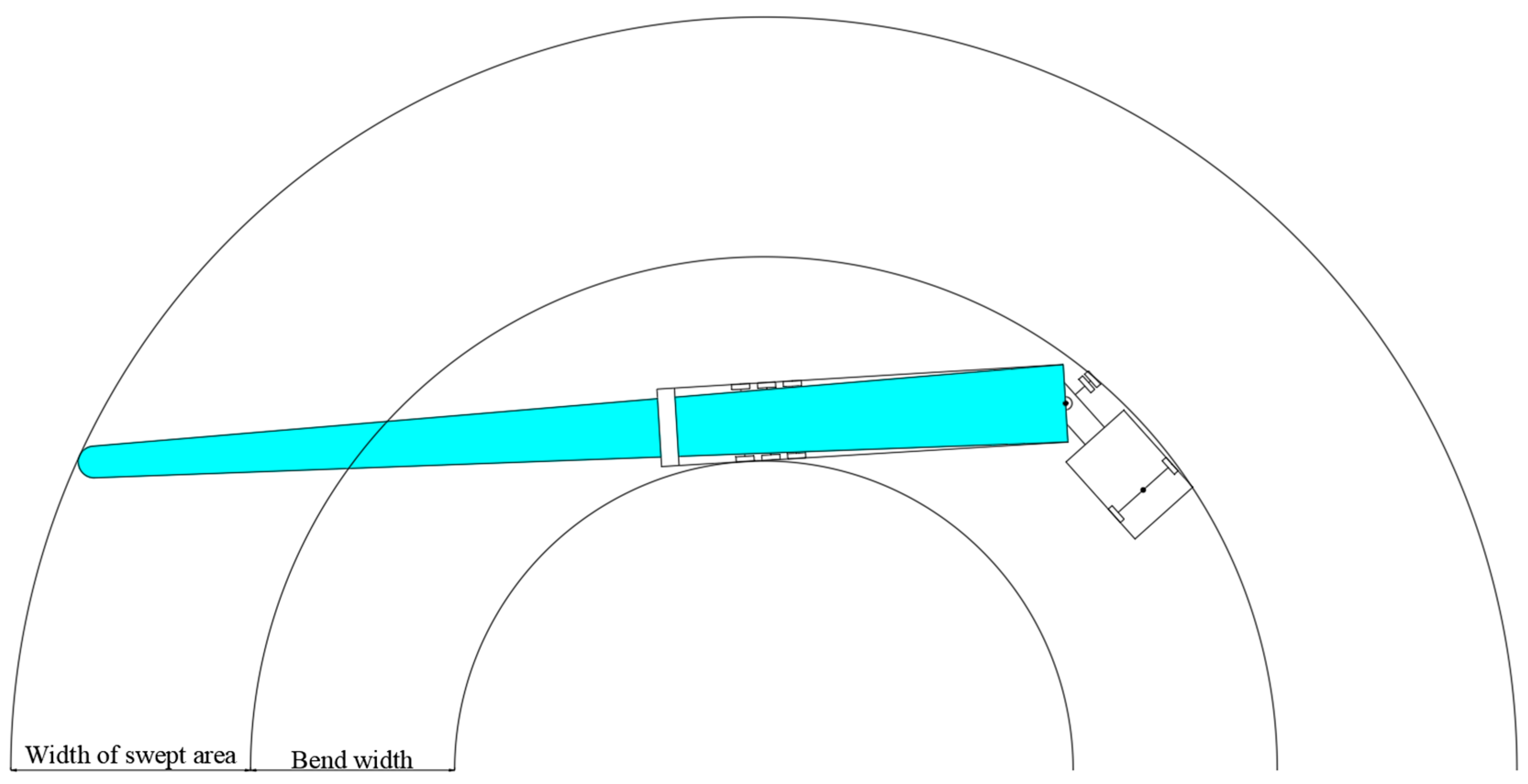

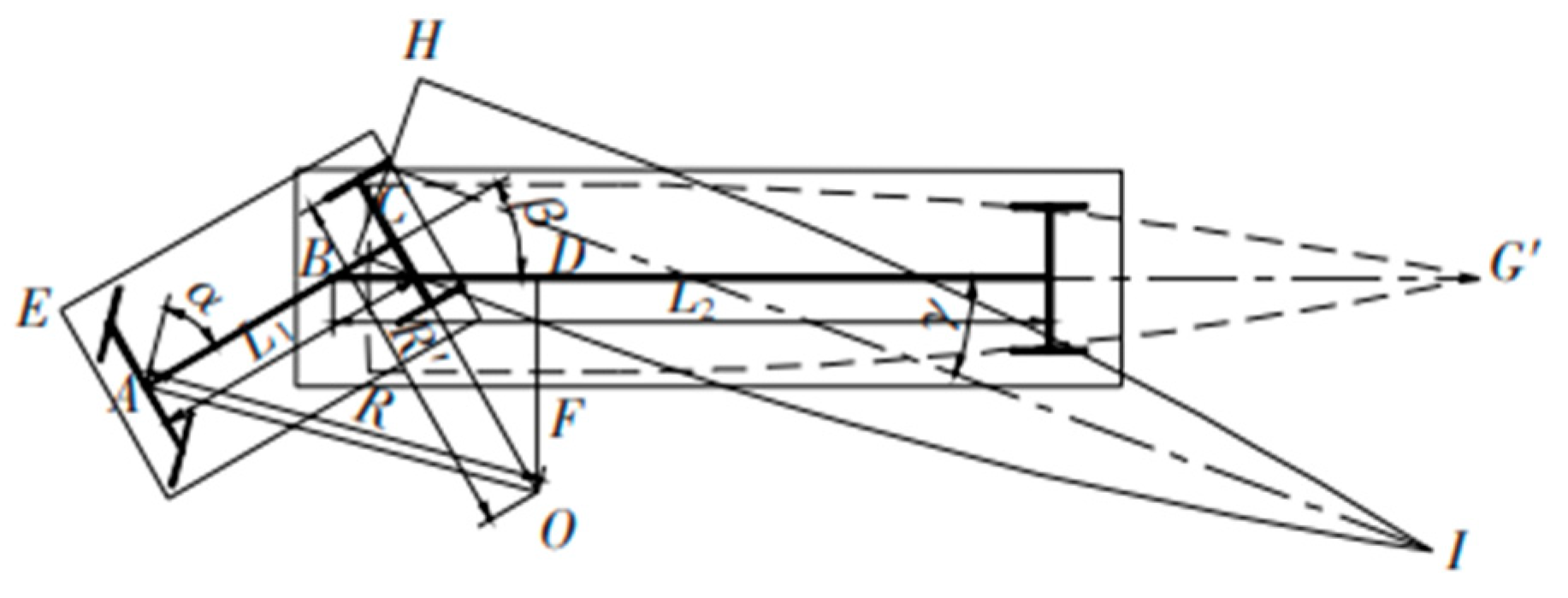

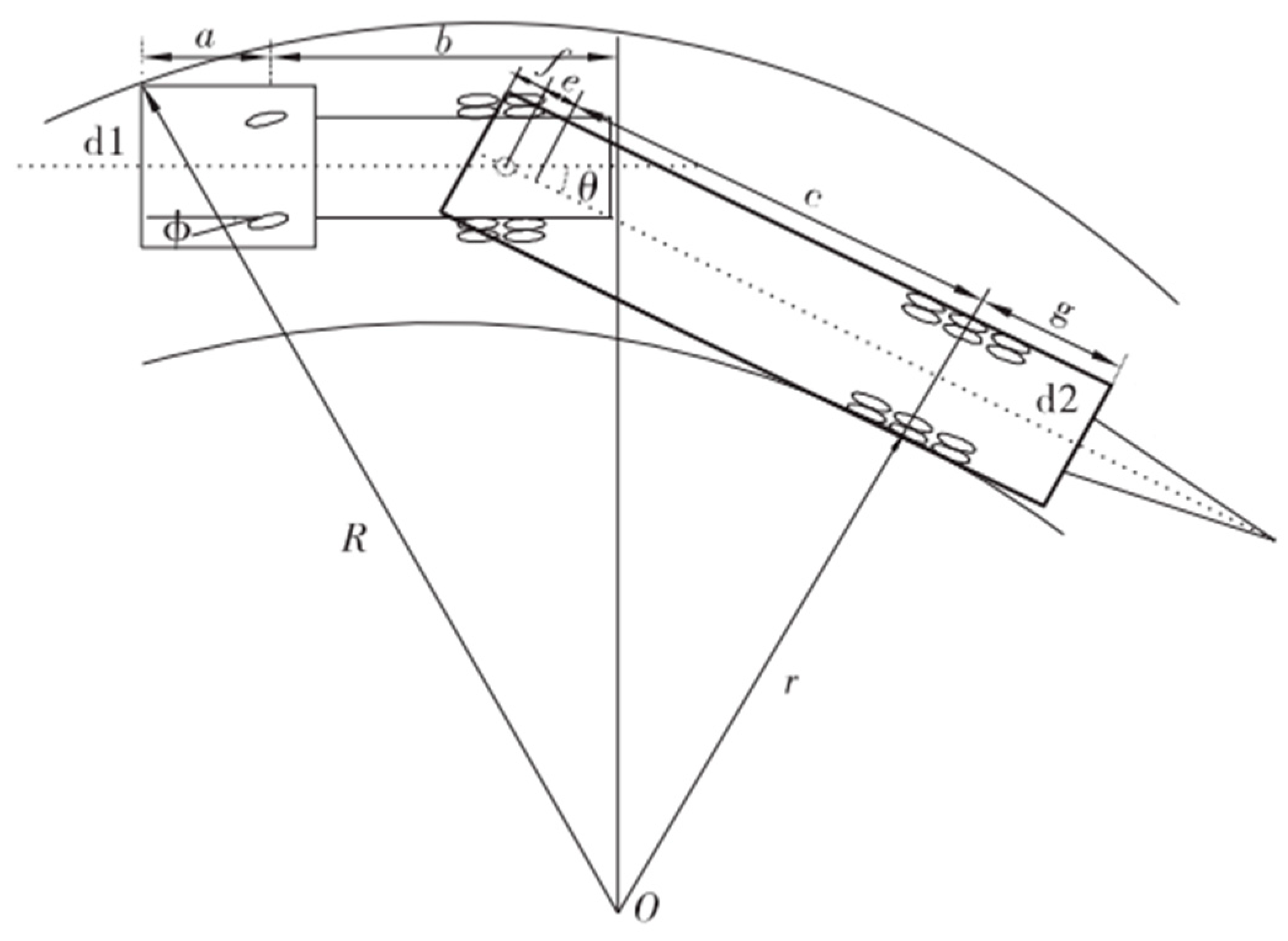

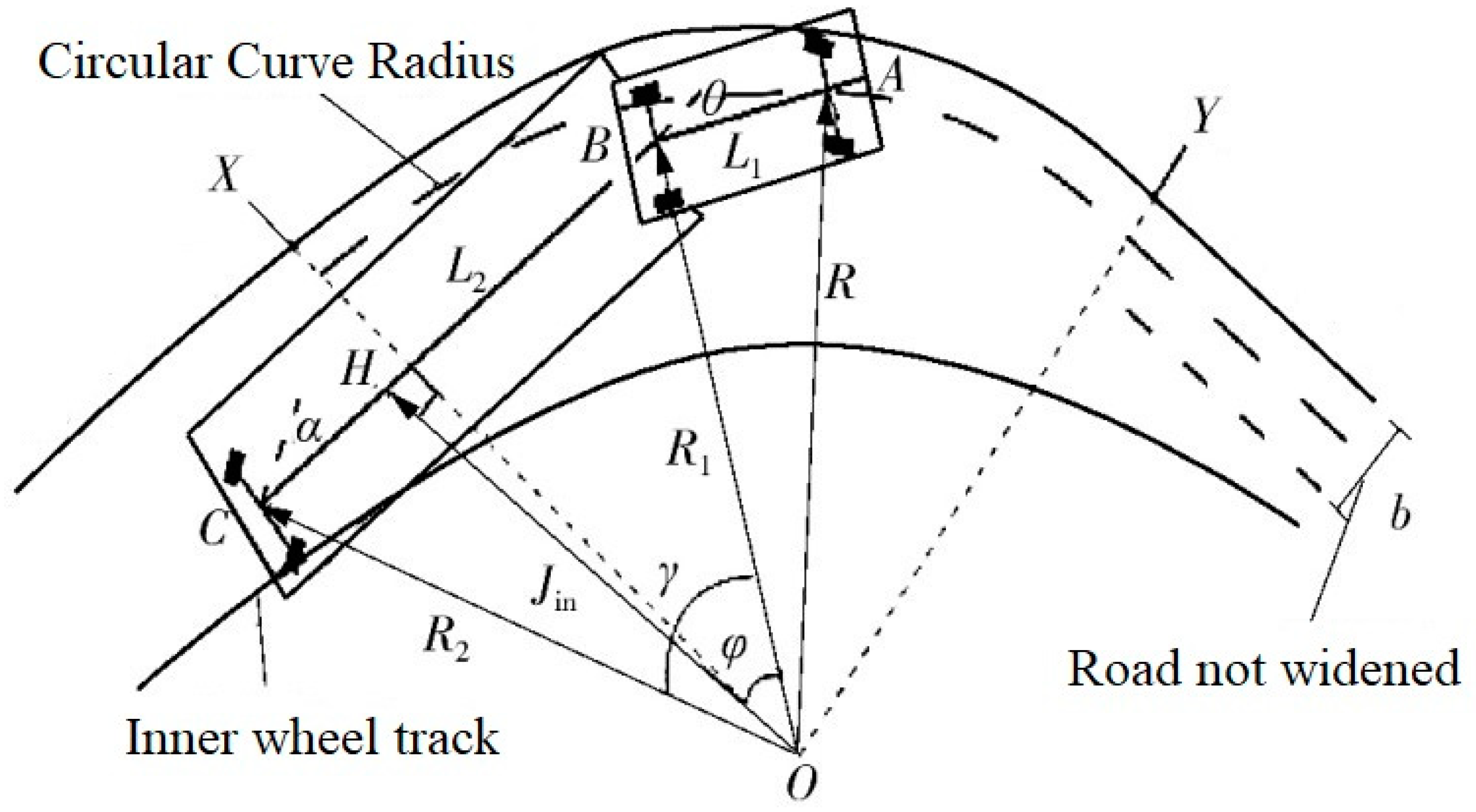

3.1. Circular Curve Widening

3.2. Radius of a Circular Curve

4. Research on Profile Design

- (1)

- Tractive force—Tractive force ;—Automobile driving wheel torque;—Engine crankshaft torque ;—Overall gear ratio;—Mechanical efficiency of the transmission system;—Wheel working radius .

- (2)

- Air resistance—air resistance ;—Air drag coefficient;—Vehicle windward area;—Air density;—Relative speed of the vehicle and air ;—Relative speed of the vehicle and air .

- (3)

- Road resistance—Road resistance ;—Rolling resistance ;—Slope resistance ;—Total vehicle gravity ;—Rolling resistance coefficient;—Slope angle of the wind farm road.

- (4)

- Inertial drag—Inertial drag ;—Inertial force coefficient;—Total vehicle gravity ;—Gravitational acceleration ;—Vehicle acceleration .

5. Research on Water and Soil Loss

5.1. Influencing Factors of Water and Soil Loss of Wind Power

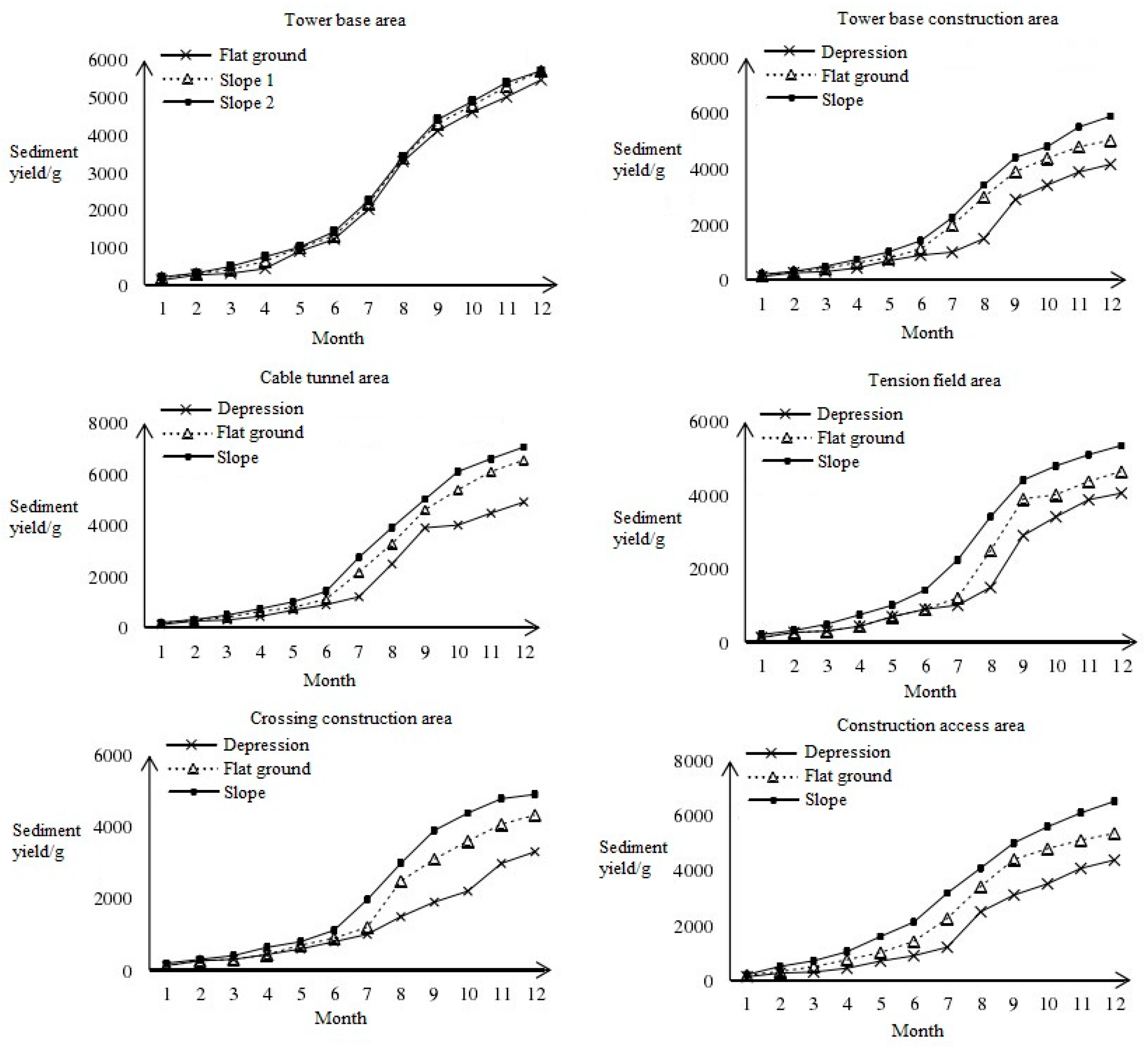

5.2. Characteristics of Water and Soil Loss in the Wind Farm

5.2.1. Diversity of Erosion Forms

5.2.2. Nonuniformity of Time Distribution

5.2.3. Spatial Distribution Nonuniformity

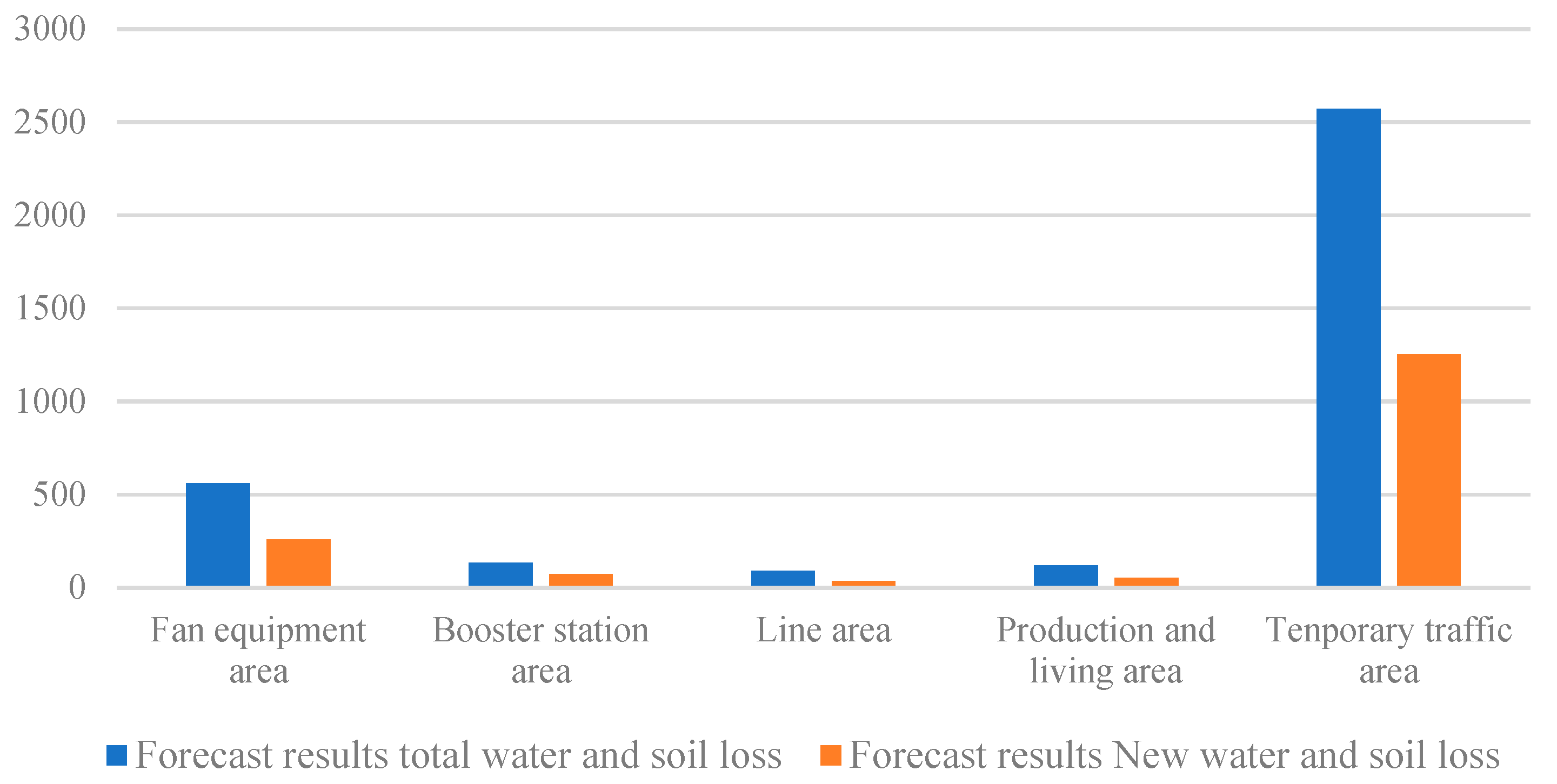

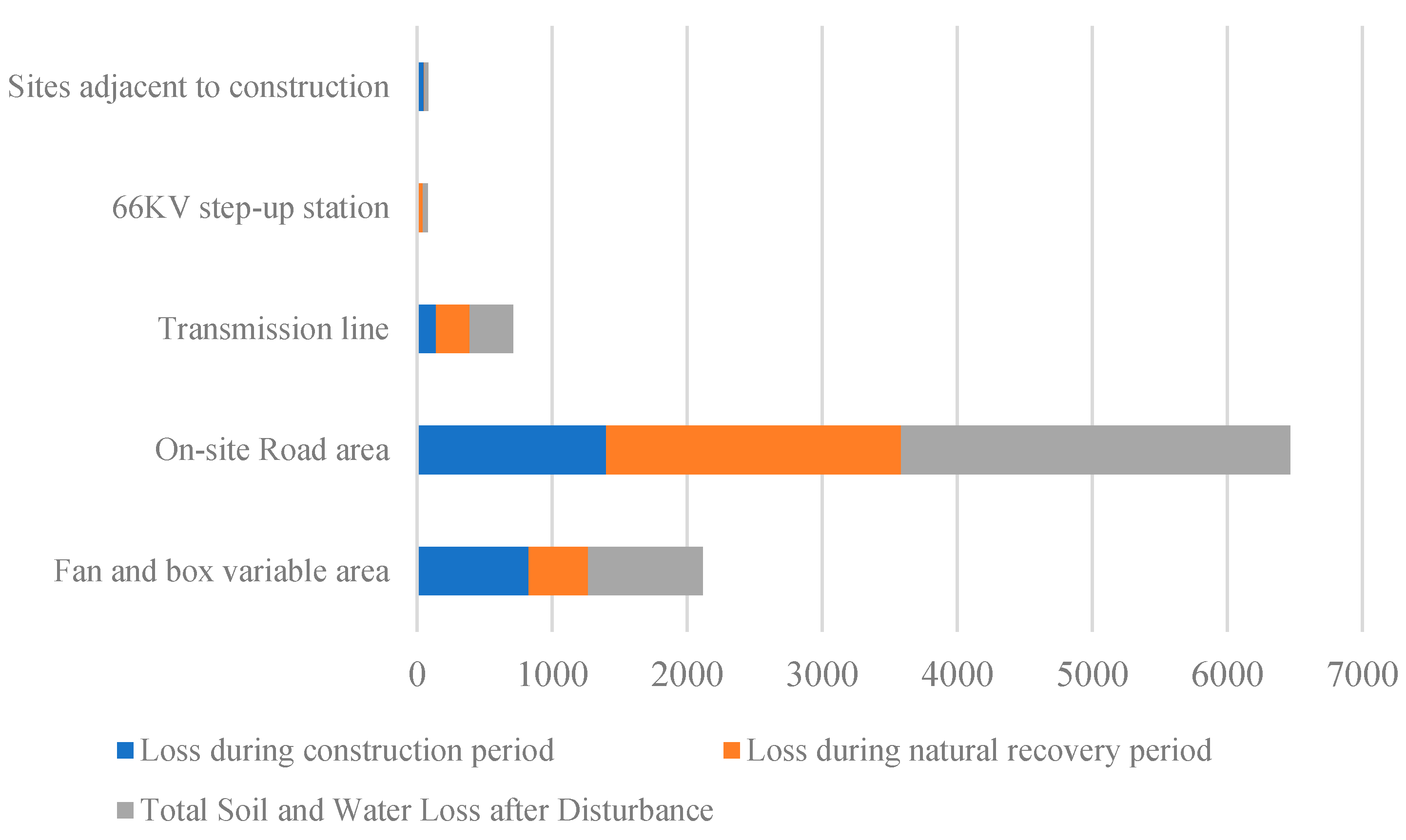

5.3. Prediction of Water and Soil Loss Intensity of the Wind Farm

5.3.1. Division of Water and Soil Loss Prediction Units

5.3.2. Prediction of Water and Soil Loss Intensity

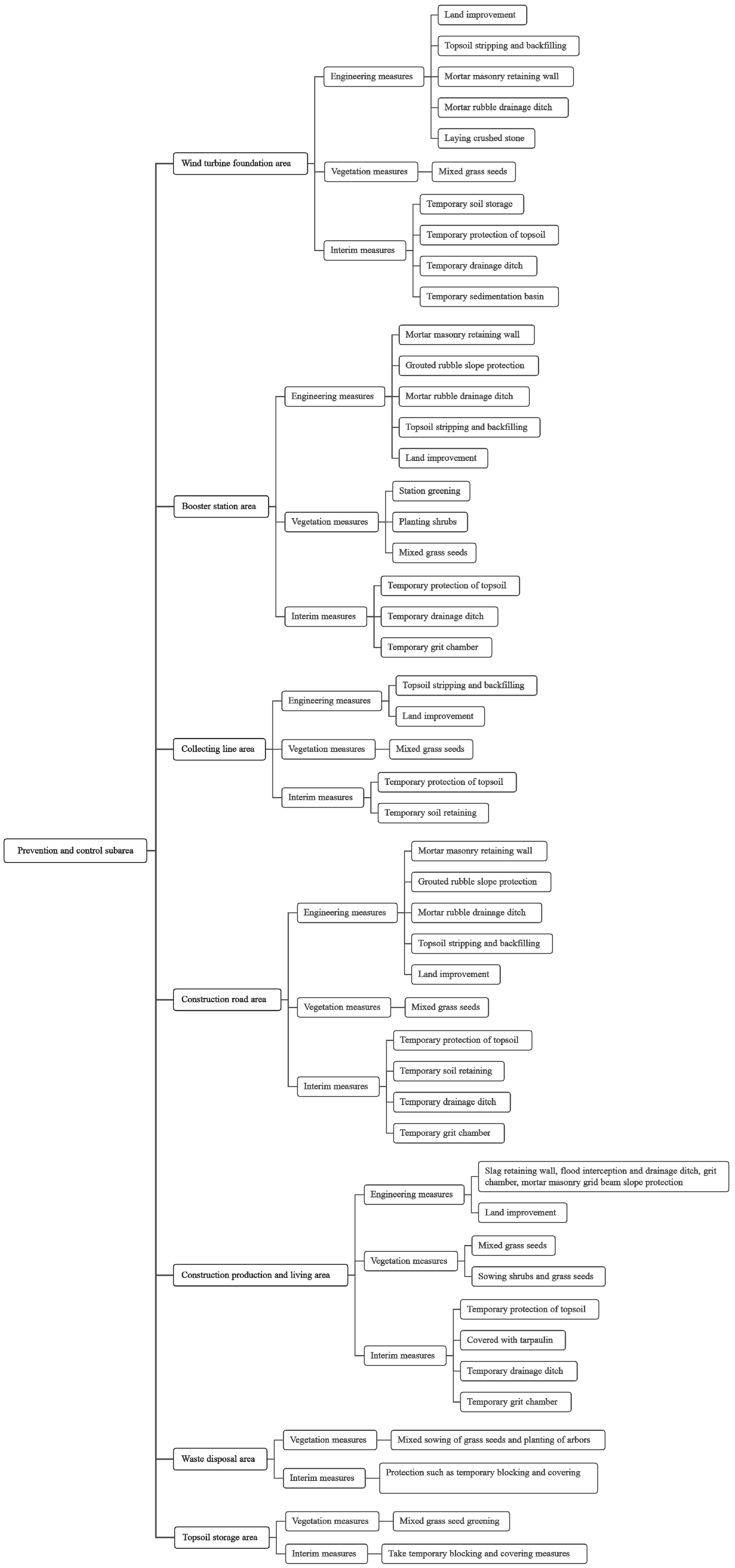

5.4. Prevention and Control Measures for Water and Soil Loss

6. Problems in Road Design of Wind Farms

6.1. Unclear Constraints of Intelligent Line Selection Models

6.2. The Variety of Design Vehicles Used in Circular Curve Design Index Research Is Relatively Single

6.3. The Incomplete Forecasting Model of Soil and Water Loss Intensity

7. Outlook of Road Design for Wind Farm

7.1. Intelligent Wind Power Road Design

7.2. Eco-Environmental Assessment and Ecological Restoration in Wind Farms

7.3. Diversified Transportation Modes of Wind Turbine Blades

8. Conclusions

- (1)

- Wind farm route selection is a comprehensive evaluation method based on field reconnaissance and back-office multi-view CAD-aided mapping technology. Although it can realize the automation of transportation road design to a certain extent, it is difficult to meet the road demand of complex macro-transportation environment of wind farms due to the lack of abstraction of view split projection and overall expression ability of multi-dimensional space. Therefore, it is necessary to improve and optimize the route selection method. According to the existing experience of road construction in wind farms and combined with advanced survey technology and algorithms, an intelligent route selection model for wind farm roads is obtained. By comparing the route selection optimization methods, it is concluded that the intelligent route selection model is the best method for route selection optimization.

- (2)

- The road route design of wind farms is mainly faced with complicated and changeable terrain conditions. Fan units have special requirements for roads due to their oversize and overweight features. Relevant standards and codes are not perfect in these three aspects. Several calculation models for the widening of wind farm roads, minimum radius values under different restrictions, calculation models, and values for longitudinal slope and the vertical curve index are listed in this paper, and a comparative analysis is made. It is concluded that the method for selecting the radius of a circular curve with widening as a restriction condition is more suitable for wind farm roads.

- (3)

- Soil and water losses in wind farms are characterized by the diversity of erosion, which is characterized by the combination of point erosion, line erosion, and area erosion. The time and space distribution of water and soil losses are uneven. The period of water and soil losses mainly concentrates on the construction period, and the period of severe water and soil losses mainly occurs in the concentration period of rainfall each year. Water and soil losses mainly occur in the fan equipment area and road engineering area. Because most inland wind farms are built in mountainous areas, the climate in mountainous areas is complex and changeable, and the local microclimate characteristics are obvious. Meteorological factors, such as rainfall and air temperature, do not have regularity. Therefore, comprehensive zoning of wind farm water and soil loss risk should be carried out by taking meteorology, geography, soil, vegetation, and other factors into consideration. Based on the previous scholar’s prevention measures, the water and soil loss prevention measures system should be put forward.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, W.; Zhu, R. Application of UAV aerial photogrammetry technology in wind farm survey and design. Inn. Mong. Power Technol. 2013, 31, 75–79. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, J. Research on the Application of UAV LiDAR in Road Survey and Design of Wind Farm. Wind. Energy 2019, 03, 66–71. (In Chinese) [Google Scholar]

- El Masry, M.; Nassar, K.; Osman, H. Simulating the Effect of Access Road Route Selection on Wind Farm Construction. Comput. Civ. Eng. 2011. [Google Scholar] [CrossRef]

- Ma, F.; Li, K.; Meng, X. Research on the Application of Satellite Images and Digital Topographic Maps in Wind Power Plants. Wind. Energy 2014, 03, 66–69. (In Chinese) [Google Scholar] [CrossRef]

- Xiao, J.; Cong, O.; Hao, H.; Wang, H. Development and application of BIM technology in wind farm construction. Life Sci. J. 2018, 02, 56–59. (In Chinese) [Google Scholar]

- Chen, K.; Wang, Y. Research on 3D Digital Design System of Wind Farm Based on GIS + BIM. Energy Technol. 2021, 19, 50–53. (In Chinese) [Google Scholar]

- Zeng, S.; Xie, X.; Zhang, Y.; Zeng, H.; Zhu, Q.; Cao, Z. Multi Dimensional Terrain Environment and Fan Parameter Constraint Wind Farm Road Optimal Design Method. Geogr. Inf. World 2018, 25, 54–59. (In Chinese) [Google Scholar] [CrossRef]

- Zhou, T.; Zhu, Q.; Zeng, H.; Xie, X.; Ding, Y.L. Wind Farm Road Optimization Design Method Based on Multiple Linear Programming Model. Geogr. Inf. World 2019, 26, 61–65. (In Chinese) [Google Scholar]

- Wang, Y. Intelligent Route Selection Method of Wind Farm Road in the Mountain Based on Improved A* Algorithm. Master’s Thesis, Shijiazhuang Railway University, Shijiazhuang, China, 2021. (In Chinese) [Google Scholar] [CrossRef]

- Kotb, M.; Elhelloty, A.; Shaaban, M. Selecting Optimal Access Roads for Mobile Crane in Wind Farm Project. Life Sci. J. 2019, 16, 28–31. [Google Scholar] [CrossRef]

- Wang, L.; Liu, J. Route Optimization of Wind Turbines Based On Vehicle Gps Data. In 2020 Global Reliability and Prognostics and Health Management (PHM-Shanghai); IEEE: New York, NY, USA, 2020. [Google Scholar]

- Yang, K.; Du, H.; Wang, Q.; Liu, P. Research and Application of Optimal Road Design Algorithm for Wind Farm. Distrib. Energy 2022, 7, 56–62. (In Chinese) [Google Scholar] [CrossRef]

- Guo, Y.; Liu, Y.; Liu, H.; Xu, H.; Tang, W. Analysis on Turning Radius and Road Occupation of Mountain Transport Vehicles with Fan Blades. Highw. Automob. Transp. 2013, 04, 11–14. (In Chinese) [Google Scholar] [CrossRef]

- Yao, X. Research on Road Design of Wind Farm. Master’s Thesis, Zhejiang University, Hangzhou, China, 2013. (In Chinese). [Google Scholar]

- Chen, K.; Li, X. Road Route Design and Key Points Analysis of Wind Farm in Hilly Areas. Sol. Energy 2013, 24, 57–60. (In Chinese) [Google Scholar]

- Du, J.; Qi, J. Design of Widening the Turning Radius of Wind Farm Roads. Low Carbon World 2014, 23, 57–60. (In Chinese) [Google Scholar]

- Yang, Y.; Chen, Z.; Wang, X.; Mao, G. Study of Highway Horizontal Curve Radius for Large Air Blower Transportation in Wind Farm. Highw. Eng. 2014, 39, 73–75. (In Chinese) [Google Scholar] [CrossRef]

- Ji, M. Selection of road parameters and paths for wind farms. Wind. Energy 2016, 03, 52–54. (In Chinese) [Google Scholar] [CrossRef]

- Chen, K. Research on the road horizontal curve of mountain wind farms. Sol. Energy 2017, 03, 55–57. (In Chinese) [Google Scholar] [CrossRef]

- Zhao, Y. Study on Design Index of Circle Curve Radius and Pavement Width in Mountain Wind Farm. Highw. Eng. 2018, 43, 124–128. (In Chinese) [Google Scholar]

- Yang, Y.; Deng, Z. Study on Horizontal Curve Index Satisfying the Safe Passing of Articulated Train. J. South China Univ. Technol. (Nat. Sci. Ed.) 2019, 47, 87–93. (In Chinese) [Google Scholar] [CrossRef]

- Ren, L.; Xu, N.; Chai, L. Application of AutoTURN in Road Design of Southwest Mountain Wind Farm. Hydropower Stn. Des. 2019, 35, 23–25. (In Chinese) [Google Scholar] [CrossRef]

- NB/T 10209-2019; Wind Farm Engineering Road Design Specifications. National Energy Administration: Beijing, China, 2019. (In Chinese)

- Ma, K.; Zhou, X. Research on the Road Route Design of the Wind Farm in Mountainous Area. South. Energy Constr. 2018, 5, 172–176. (In Chinese) [Google Scholar] [CrossRef]

- Rybak, J. Foundations of wind power plants-challenges in designing and execution of construction work. J. Phys. Con-Ference Ser. 2020, 1706, 012130. [Google Scholar] [CrossRef]

- Zhao, Y. Application of Latitude 3D Road Auxiliary System in the Design of Hoisting Platform for Mountainous Wind Power Plants. Hongshuihe 2012, 31, 15–18. (In Chinese) [Google Scholar]

- Guan, Y. Highway design and points analysis of wind-power farm in desert region. Shanxi Archit. 2014, 40, 156–158. (In Chinese) [Google Scholar] [CrossRef]

- Zheng, R.; Wang, M.; Hua, X. Research on Digital Design of Gaoshan Wind Farm Roads. Sci. Technol. Inf. 2019, 17, 79–80. (In Chinese) [Google Scholar] [CrossRef]

- Yao, X. Research on the maximum longitudinal slope of wind farm road. Highw. Automob. Transp. 2015, 04, 77–79. (In Chinese) [Google Scholar] [CrossRef]

- Du, J.; Qi, J. Road Design of Mountain Wind Farm. Low Carbon World 2015, 01, 307–308. (In Chinese) [Google Scholar]

- Yang, Y.; Hou, H.; Chen, X.; Zhou, X. Investigation into Minimum Vertical Curve Radius and Length of Highway in Mountainous Wind Farm. J. South China Univ. Technol. (Nat. Sci. Ed.) 2015, 43, 85–90. (In Chinese) [Google Scholar] [CrossRef]

- Yang, W.; Chen, K.; Zhao, Y. Internal Road Design in Taohuashan Wind Power Farm. Hydropower New Energy 2016, 02, 76–78. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, S.; Chen, L. Summary of the Road Design for the Project of Wind Farm with Mountain Terrain. Appl. Energy Technol. 2016, 11, 56–59. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, L.; Fan, L.; Ma, C.; Liu, J.; Zhou, Y.; Chen, Z.; Wu, J. Influence of mountain wind farm construction on soil properties and vegetation cover:A case study of Jiangjunshan wind farm in Yunnan Province. J. Ecol. 2022, 41, 2397–2405. (In Chinese) [Google Scholar] [CrossRef]

- Li, G.; Zhang, C.; Zhang, L. Wind farm effect on grassland vegetation due to its influence on the range, intensity and variation of wind direction. IEEE Int. Symp. Geosci. Remote Sens. IGARSS 2016. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, T.; Wang, C.; Liu, J. Comparison of vegetation composition and soil fertility quality inside and outside the wind farm. J. Inn. Mong. Agric. Univ. (Nat. Sci. Ed.) 2020, 41, 30–36. (In Chinese) [Google Scholar]

- Meng, X. Study on the Law of Water and Soil Loss and Its Prevention and Control Technology in Wind Farm Project. Master’s Thesis, Chinese Academy of Agricultural Sciences, Beijing, China, 2010. (In Chinese). [Google Scholar]

- Xun, H. Water and soil loss characteristics and prevention measures of wind farm project. Master’s Thesis, Nanchang University, Nanchang, China, 2017. [Google Scholar]

- Sun, K. Characteristics of Water and Soil Loss in Mountainous Wind Farm and Prevention Measures. Sci. Technol. Innov. Appl. 2021, 11, 99–101. (In Chinese) [Google Scholar]

- Yi, Z.; Chen, X.; Wei, L.; Zhang, X.; Zhao, J. Research on the maximum longitudinal slope of wind farm road. Preliminary Study on the Characteristics and Prevention Techniques of Water and Soil Loss of Guizhou High Altitude Mountain Wind Farm Project. Appl. Technol. Soil Water Conserv. 2013, 05, 30–32. (In Chinese) [Google Scholar] [CrossRef]

- Mo, L. Characteristics and Prevention Measures of Water and Soil Loss of Wind Farm Project in Middle and Low Mountainous and Hilly Areas in Northeast Guangxi. Enterp. Sci. Technol. Dev. 2014, 20, 27–28. (In Chinese) [Google Scholar] [CrossRef]

- Yin, X. Discussion on Water and Soil Conservation Measures in Traffic Road Prevention Area of Wind Farm Project. China Water Soil Conserv. 2015, 07, 32–33. (In Chinese) [Google Scholar] [CrossRef]

- Tang, Q. Discussion on Prevention and Control Measures for Key Prevention and Control Areas of Water and Soil Conservation of Hunan Mountainous Wind Farm Project. Hunan Water Resour. Hydropower 2016, 04, 86–88. (In Chinese) [Google Scholar] [CrossRef]

- Cao, B. Characteristics of water and soil loss of wind power generation projects in Anhui Province and prevention and control measures. Jianghuai Water Conserv. Sci. Technol. 2017, 02, 5–6. (In Chinese) [Google Scholar]

- Jia, Z.; Li, J. Preliminary study on the design of water and soil conservation measures for wind farm projects in coastal areas. Hebei Water Conserv. 2017, 12, 28–29. (In Chinese) [Google Scholar]

- Sun, J. Research on the Impact of Jiuquan Ten Million Kilowatt Wind Power Base Project on the Ecological Environment. Master’s Thesis, Lanzhou University, Lanzhou, China, 2011. (In Chinese). [Google Scholar]

- Chen, W.; Shi, Y.; Liu, G.; Yu, J. Research on the maximum longitudinal slope of wind farm road. Analysis on Water and Soil Loss and Study on Conservation Scheme of 49.5MW Wind Farm in Hubei Province. J. Green Sci. Technol. 2014, 01, 9–11. (In Chinese) [Google Scholar] [CrossRef]

- Wei, Z. Design of Water and Soil Conservation Measures for Anchaba Wind Farm Project in Lichuan. Master’s Thesis, Northwest University of Agriculture and Forestry Science and Technology, Xianyang, China, 2014. (In Chinese). [Google Scholar]

- Zhao, X. Water and Soil Conservation Design of Wangyunshan Wind Farm in Central Hunan. Master’s Thesis, Northwest University of Agriculture and Forestry Science and Technology, Xianyang, China, 2014. (In Chinese). [Google Scholar]

- Chen, A. Monitoring and Evaluation of Water and Soil Loss of Wind Farms in Piedmont Alluvial Plain Area. Master’s Thesis, Shanxi Agricultural University, Taiyuan, China, 2019. (In Chinese) [Google Scholar] [CrossRef]

- Guo, S. Research on the Environmental Impact of Wind Farm Construction in Ecologically Fragile Areas and the Prevention and Control of Water and Soil Loss. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2018. [Google Scholar]

- Chen, J.; Wen, Y. Characteristics of water and soil loss in mountain wind farms and prevention measures. Soil Water Conserv. Subtrop. 2016, 28, 51–53. (In Chinese) [Google Scholar] [CrossRef]

- Wang, K. Impacts of Wind Farm Construction on the Surrounding Environment and Restoration Measures. Sci. Environ. Prot. 2015, 41, 105–108. (In Chinese) [Google Scholar] [CrossRef]

- Li, W.; Li, S.; Lv, G.; Wang, D. Ecological impact of wind power plant construction under different terrain conditions in northwest Liaoning and its prevention and control measures. Environ. Prot. Circ. Econ. 2015, 35, 52–54. (In Chinese) [Google Scholar] [CrossRef]

- Colonna, P.; Berloco, N.; Intini, P.; Ranieri, V. The method of the friction diagram: New developments and possible applications. Transp. Infrastruct. Syst. 2017, 8, 309–316. [Google Scholar] [CrossRef]

- Duan, Y.; Duan, H. Vegetation Protectionand Restoration Strategies of the Wind Power Plant Area in Subalpine Regions in the Northwest of Yunnan Province. Environ. Sci. Guide 2016, 35, 6–7. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Y.; Ying, F.; Qian, A.; Lin, L. Water and soil loss prevention experience of Zhejiang coastal mountain wind farm project. China Water Soil Conserv. 2015, 04, 19–21. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Y. Water and soil conservation measures and effect evaluation of roads in typical mountain wind farms. Yunnan Hydropower 2020, 36, 8–11. (In Chinese) [Google Scholar]

- Cong, R.; Yang, M. Overview of Water and Soil Conservation Measures for Wind Farm Construction Project. For. Surv. Des. Inn. Mong. 2017, 40, 5–6. (In Chinese) [Google Scholar] [CrossRef]

- Xia, Y.; Zhang, S.; Liu, R. Discussion on Soil and Water Loss Prevention of Road Engineering of Mountain Wind Farm Project. Anhui Agric. Bull. 2019, 25, 119–120. (In Chinese) [Google Scholar] [CrossRef]

- Xu, H.; Zhao, X. Brief Discussion on Water and Soil Conservation Measures of Wind Farm Project. West. Sci. Technol. China 2014, 13, 55–57. (In Chinese) [Google Scholar] [CrossRef]

- Hao, Z. Analysis on main causes and countermeasures of water and soil loss in wind power projects in southern hilly areas. Sci. Technol. Innov. Her. 2015, 12, 177. (In Chinese) [Google Scholar] [CrossRef]

- Li, L.; Han, X.; Du, Z.; Zhang, J. EIA Technical Points of Mountatinous Wind Power farm. Energy Energy Conserv. 2009, 05, 43–45. (In Chinese) [Google Scholar] [CrossRef]

- Gu, Z. Main Environmental Problems of Wind Power Generation Projects and the Possible Solution Countermeasures. Environ. Prot. Sci. 2010, 36, 89–91. (In Chinese) [Google Scholar] [CrossRef]

- Zhao, Z.; Wu, Z.; Zhou, J.; Zhou, B.; Zhang, X. Impact of wind farm construction on water and soil loss in Hexi Corridor and its prevention and control measures. Soil Water Conserv. China 2011, 08, 17–18. (In Chinese) [Google Scholar] [CrossRef]

- Wang, W.; Jiao, J.; Ma, L. Changes in erosion and sand production intensity in different erosion types of the Loess Plateau and their management objectives. Soil Water Conserv. Bull. 2012, 32, 1–7. (In Chinese) [Google Scholar]

- Wang, W.; Jiao, J. Temporal and Spatial Variation Features of Sediment Yield Intensity on Loess Plateau. Acta Geogr. Sin. 2002, 57, 210–217. (In Chinese) [Google Scholar] [CrossRef]

- Hang, Z.; Bo, B.; Chen, L. Soil and Water Loss Differentiation of Different Slopes, Land Use Types and Precipitation Changes in Loess Hilly Area. Sci. Soil Water Conserv. 2005, 3, 11–18. (In Chinese) [Google Scholar] [CrossRef]

- Cyr, L.; Ferdinand, B.; Alain, P. Vegetation indices derived from remote sensing for an estimation of soil protection against water erosion. Ecol. Model. 1995, 79, 277–285. [Google Scholar] [CrossRef]

- Jain, S.K.; Goel, M.K. Assessing the vulnerability to soil erosion of the Ukai Dam catchments using remote sensing and GIS. Int. Assoc. Sci. Hydrol. 2002, 47, 31–40. [Google Scholar] [CrossRef]

- Zhong, H.; Wang, H. Analysis on Spatio-temporal Change Characteristics of Normalized Vegetation Index in Hubei Province from 2007 to 2016. J. Cent. China Norm. Univ. (Nat. Sci.) 2018, 52, 582–588. (In Chinese) [Google Scholar] [CrossRef]

- Guo, J.; Hu, Y.; Xiong, Z. Spatio-temporal changes of NDVI during vegetation growth season in permafrost region of Northeast China and its response to climate change. Chin. J. Appl. Ecol. 2017, 28, 2413–2422. (In Chinese) [Google Scholar] [CrossRef]

- Liu, X.; Yang, Q.; Tang, G. Extraction and Application of Relief of China Based on DEM and GIS Method. Bull. Soil Water Conserv. 2001, 21, 57–62. (In Chinese) [Google Scholar] [CrossRef]

- Peeters, M.; Santo, G.; Degroote, J.; Van Paepegem, W. The Concept of Segmented Wind T urbine Blades: A Review. Energies 2017, 10, 1112. [Google Scholar] [CrossRef]

- Jensen, J. A Method for the Transport of a Long Windmill Wing and a Vehicle for the Transport Thereof. W.O. Patent 2,006,000,230(A1), 5 January 2006. [Google Scholar]

- Wobben, A. Transport Vehicle for a Rotor Blade of a Wind-Energy Turbine. W.O. Patent 03,057,528(A1), 17 July 2003. [Google Scholar]

- Kawada, M. Transporting Method and Transporter of Irregular Shaped Elongated Article. J.P. 2,004,243,805 (A), 2 September 2004. [Google Scholar]

- Nies, J. Transport Device for an Elongate Object Such as a Rotor Blade for a Wind Turbine or the Like. U.S. Patent 8,226,342(B2), 24 July 2012. [Google Scholar]

- Pedersen, G. A Vehicle for Transporting a Wind Turbine Blade, a Control System and a Method for Transporting a Wind Turbine Blade. W.O. Patent 2,007,147,413(A1), 27 December 2007. [Google Scholar]

- Mikhail, A. Low Wind Speed Turbine Development Project Report; Technical Report NREL/SR-500-43743; National Renewable Energy Laboratory: Golden, CO, USA, 2009. [Google Scholar]

- Wobben, A. Rotor Blade for a Wind Power Installation. W.O. Patent 02,051,730(A3), 7 November 2002. [Google Scholar]

- Vronsky, T.; Hancock, M. Segmented Rotor Blade Extension Portion. W.O. Patent 2,010,013,025(A3), 4 November 2010. [Google Scholar]

- Siegfriedsen, S. Rotor Blade for Wind Power Installations. W.O. Patent 0,146,582(A2), 28 June 2001. [Google Scholar]

- Judge, P.W. Segmented Wind Turbine Blade. U.S. Patent 7,854,594(B2), 21 December 2010. [Google Scholar]

- Broome, P.; Hayden, P. An Aerodynamic Fairing for a Wind Turbine and a Method of Connecting Adjacent Parts of Such a Fairing. W.O. Patent 2,011,064,553(A3), 5 January 2012. [Google Scholar]

- Van Wingerde, A.M.; van Delft, D.R.V.; Molenveld, K.; Bos, H.L.; Bulder, B.H.; de Bonte, H. BLADECO Eindrapport; Technical Report BLDPV1-05; Knowledge Centre WMC: Wieringerwerf, The Netherlands, 2002. [Google Scholar]

- De La Rua, I.A.; Pascual, E.S.; Collado, S.A. Blade Insert. U.S. Patent 8,388,316, 5 March 2013. [Google Scholar]

- Mark, H. Modular Wind Turbine Blade with Both Spar and Foil Sections Forming Aerodynamic Profile. G.B. Patent 2,488,099(A), 22 August 2012. [Google Scholar]

| Speed/(km·h−1) | General Minimum Radius/m | Ultimate Minimum Radius/m |

|---|---|---|

| 10 | 40 | 30 |

| 12 | 60 | 35 |

| 15 | 90 | 45 |

| 18 | 130 | 60 |

| 20 | 160 | 80 |

| 22 | 190 | 100 |

| 25 | 250 | 120 |

| Fan Unit | Internal Curvature | Camber | ||

|---|---|---|---|---|

| Minimum Radius | No Widening Minimum Radius | Minimum Radius | No Widening Minimum Radius | |

| 750 kW | 15 | 60 | 15 | 45 |

| 1500 kW | 25 | 110 | 20 | 85 |

| 2500 kW | 35 | 135 | 30 | 110 |

| Wind Farm Altitude/m | ||||||

|---|---|---|---|---|---|---|

| 1500 kW | 2000 kW | 3000 kW | 1500 kW | 2000 kW | 3000 kW | |

| 0~500 | 8.749 | 5.537 | 3.31 | 15.4 | 9.7 | 5.8 |

| 500~1000 | 8.054 | 5.037 | 2.943 | 14.2 | 8.8 | 5.1 |

| 1000~1500 | 7.395 | 4.562 | 2.595 | 13.0 | 8.0 | 4.5 |

| 1500~2000 | 6.768 | 4.111 | 2.264 | 11.9 | 7.2 | 4.0 |

| 2000~2500 | 6.174 | 3.683 | 1.950 | 10.8 | 6.4 | 3.4 |

| 2500~3000 | 5.611 | 3.276 | 1.651 | 9.8 | 5.7 | 2.9 |

| Design Speed/(km/h) | Minimum Radius of Concave Curve | Minimum Radius of Convex Curve/m | Minimum Length of vertical Curve/m | |

|---|---|---|---|---|

| Recommended Value | Slope Difference/% | |||

| 5 | 200 | 4 ≤ w ≤ 10 | 100 | 10 |

| 10 | 200 | 6 ≤ w ≤ 10 | 100 | 12 |

| 15 | 200 | 8 ≤ w ≤ 10 | 100 | 16 |

| 20 | 250 | 8 ≤ w ≤ 30 | 150 | 20 |

| 25 | 250 | 10 ≤ w ≤ 30 | 200 | 25 |

| 30 | 300 | 10 ≤ w ≤ 30 | 250 | 30 |

| Serial No. | Water and Soil Conservation Zoning | Area Covered/hm2 | Proportion/% |

|---|---|---|---|

| 1 | Fan unit area | 8.7 | 13.84 |

| 2 | Collecting line area | 0.94 | 1.49 |

| 3 | Booster station area | 0.94 | 1.53 |

| 4 | Road works area | 37.56 | 59.73 |

| 5 | Waste disposal area | 13.15 | 20.91 |

| 6 | Construction production and living area | 1.57 | 2.50 |

| Partition | Project Construction Area | Directly Affected Area | Total |

|---|---|---|---|

| Fan and box transformer area | 3.53 | 0.60 | 4.13 |

| On-site road | 14.98 | 9.32 | 24.30 |

| Transmission line | 1.17 | 2.53 | 3.70 |

| 66 kV booster station | 0.54 | 0.00 | 0.54 |

| Temporary construction site | 0.81 | 0.07 | 0.88 |

| Total | 21.3 | 12.52 | 33.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.-d.; Yin, F.-k.; Shen, L.; Wu, C.-z. A Review of Road Design for Wind Farms in China. Appl. Sci. 2023, 13, 4075. https://doi.org/10.3390/app13074075

Wang Y-d, Yin F-k, Shen L, Wu C-z. A Review of Road Design for Wind Farms in China. Applied Sciences. 2023; 13(7):4075. https://doi.org/10.3390/app13074075

Chicago/Turabian StyleWang, Yu-dong, Fu-kun Yin, Lu Shen, and Cheng-zhi Wu. 2023. "A Review of Road Design for Wind Farms in China" Applied Sciences 13, no. 7: 4075. https://doi.org/10.3390/app13074075

APA StyleWang, Y.-d., Yin, F.-k., Shen, L., & Wu, C.-z. (2023). A Review of Road Design for Wind Farms in China. Applied Sciences, 13(7), 4075. https://doi.org/10.3390/app13074075