Enhancing Biodegradation of Industrial Wastewater into Methane-Rich Biogas Using an Up-Flow Anaerobic Sludge Blanket Reactor

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Wastewater and Analyses

2.3. Magnetite Nanoparticles Synthesis

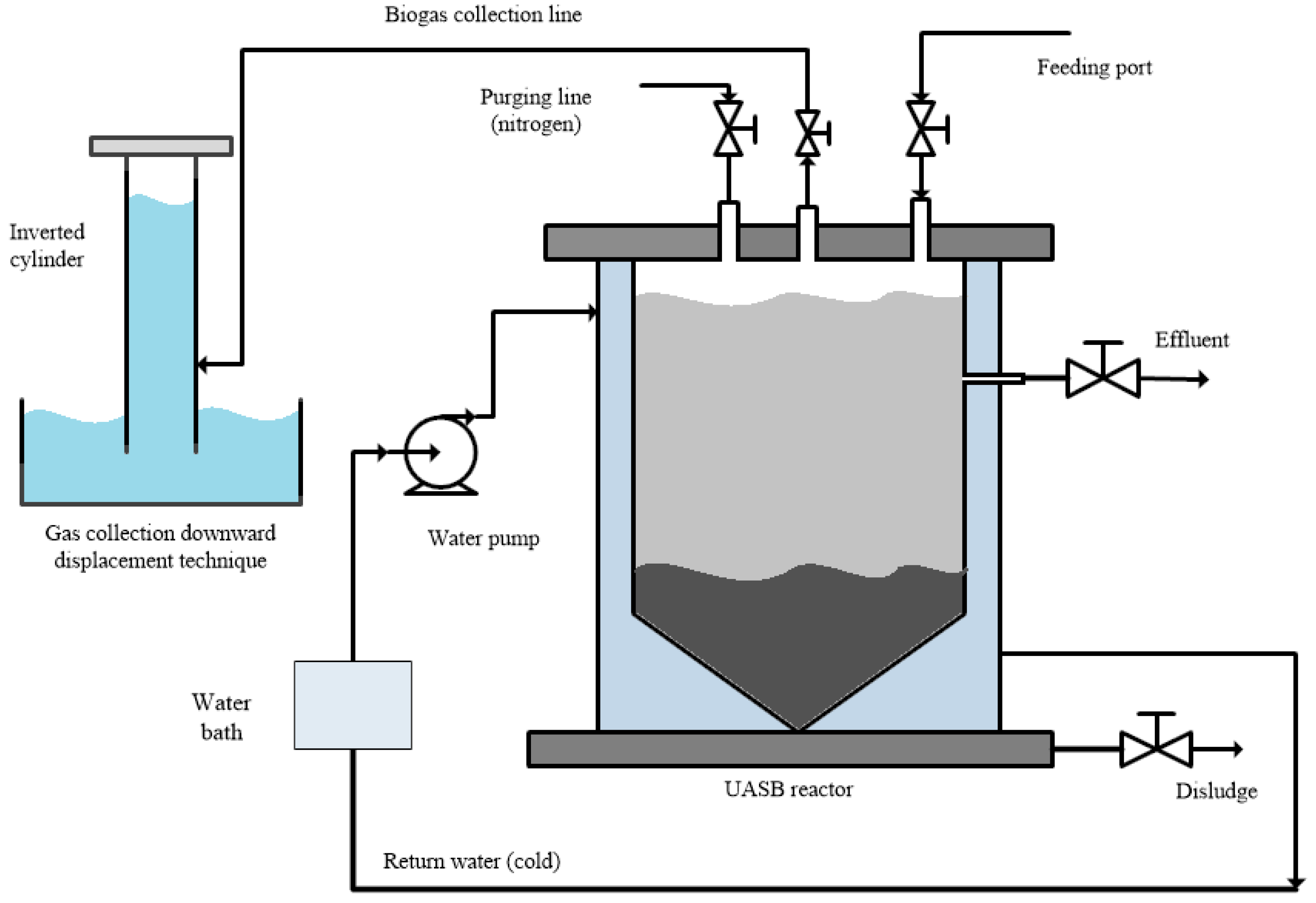

2.4. Biogas Production Up-Flow Anaerobic Sludge Blanket (UASB) Reactor Setup

3. Results and Discussion

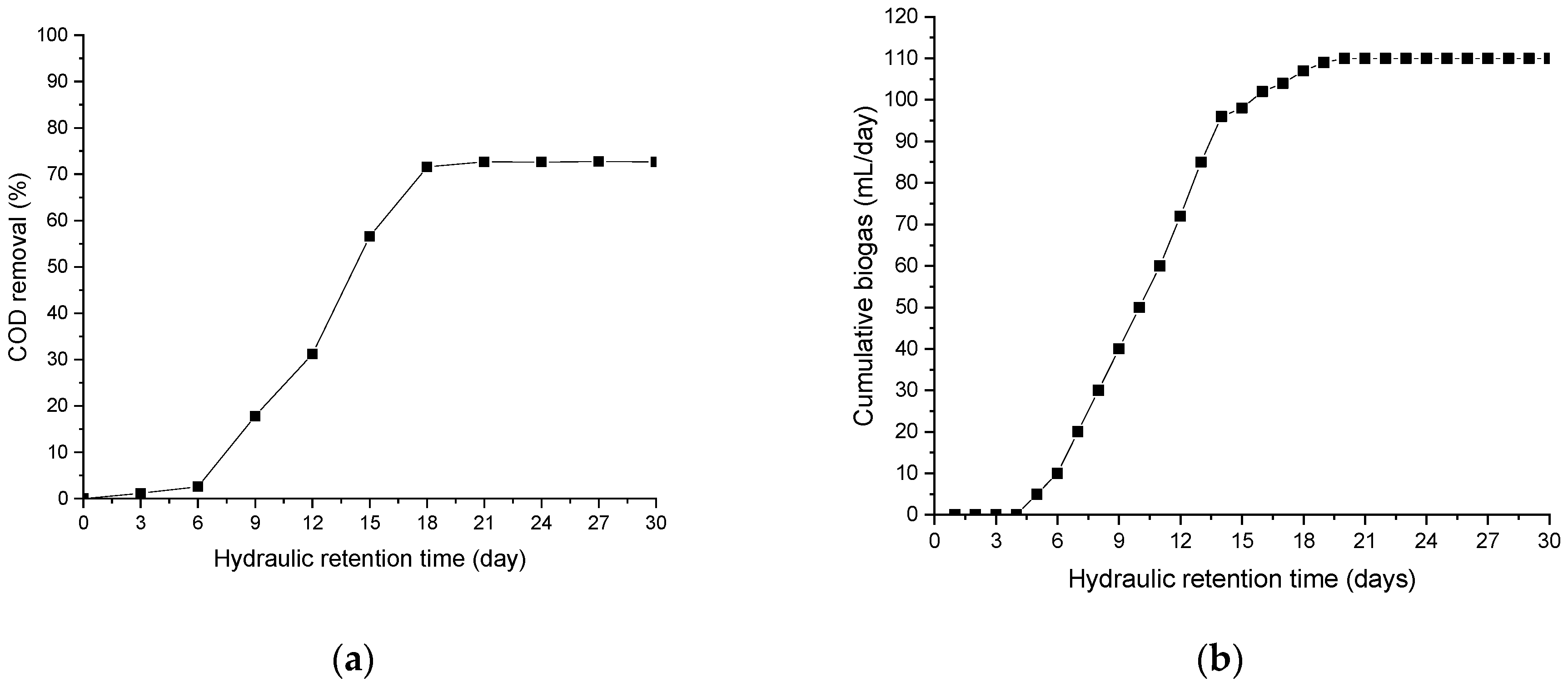

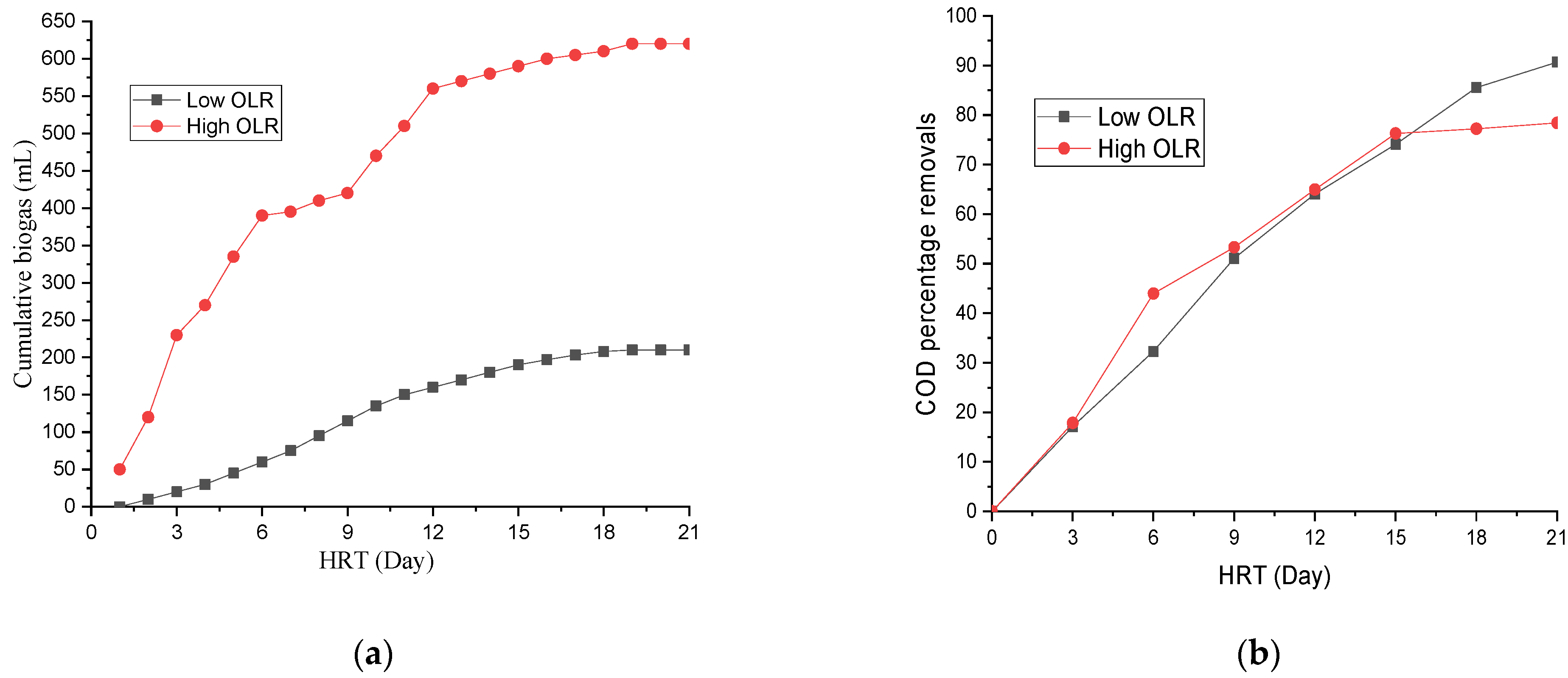

3.1. Effect of Hydraulic Retention Time on Biogas Production and COD Removal

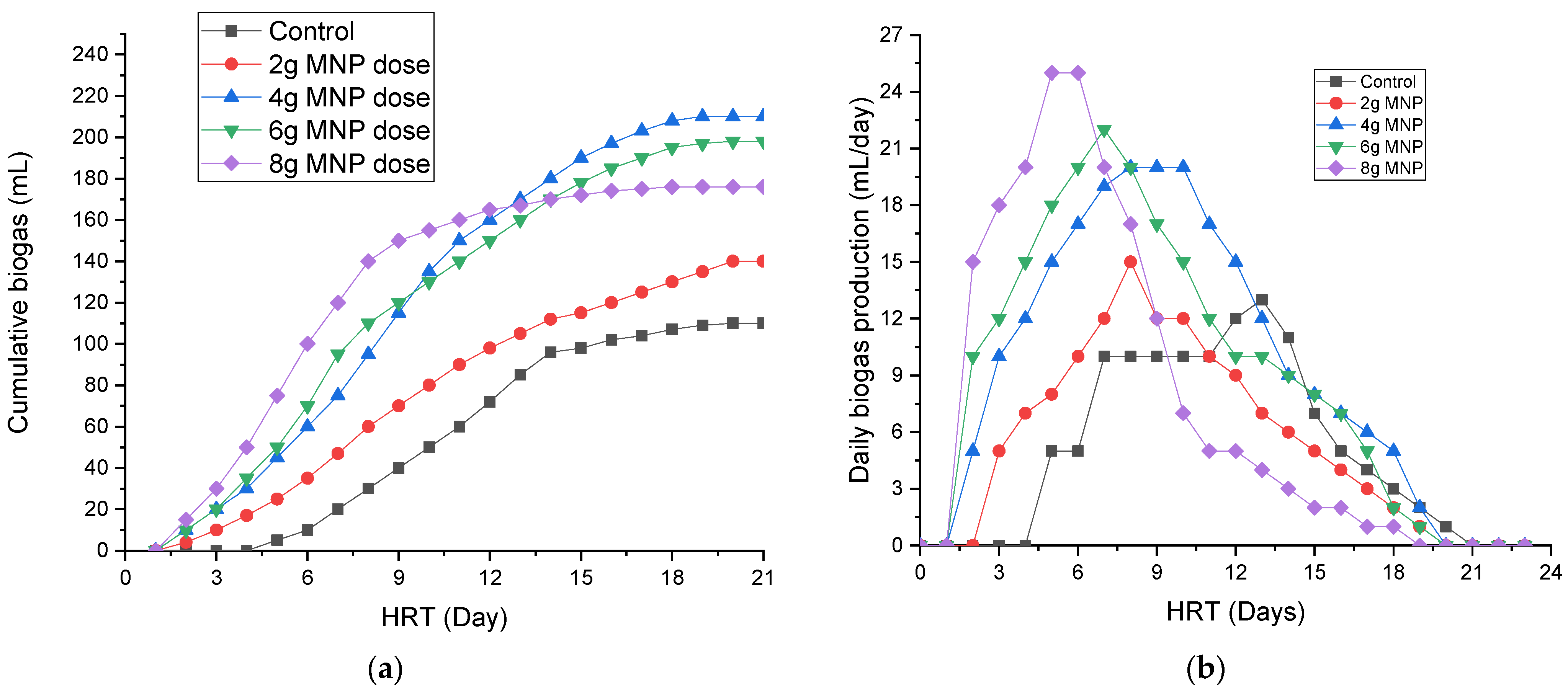

3.2. Effect of Magnetite Loading on Biogas Production and COD Removal

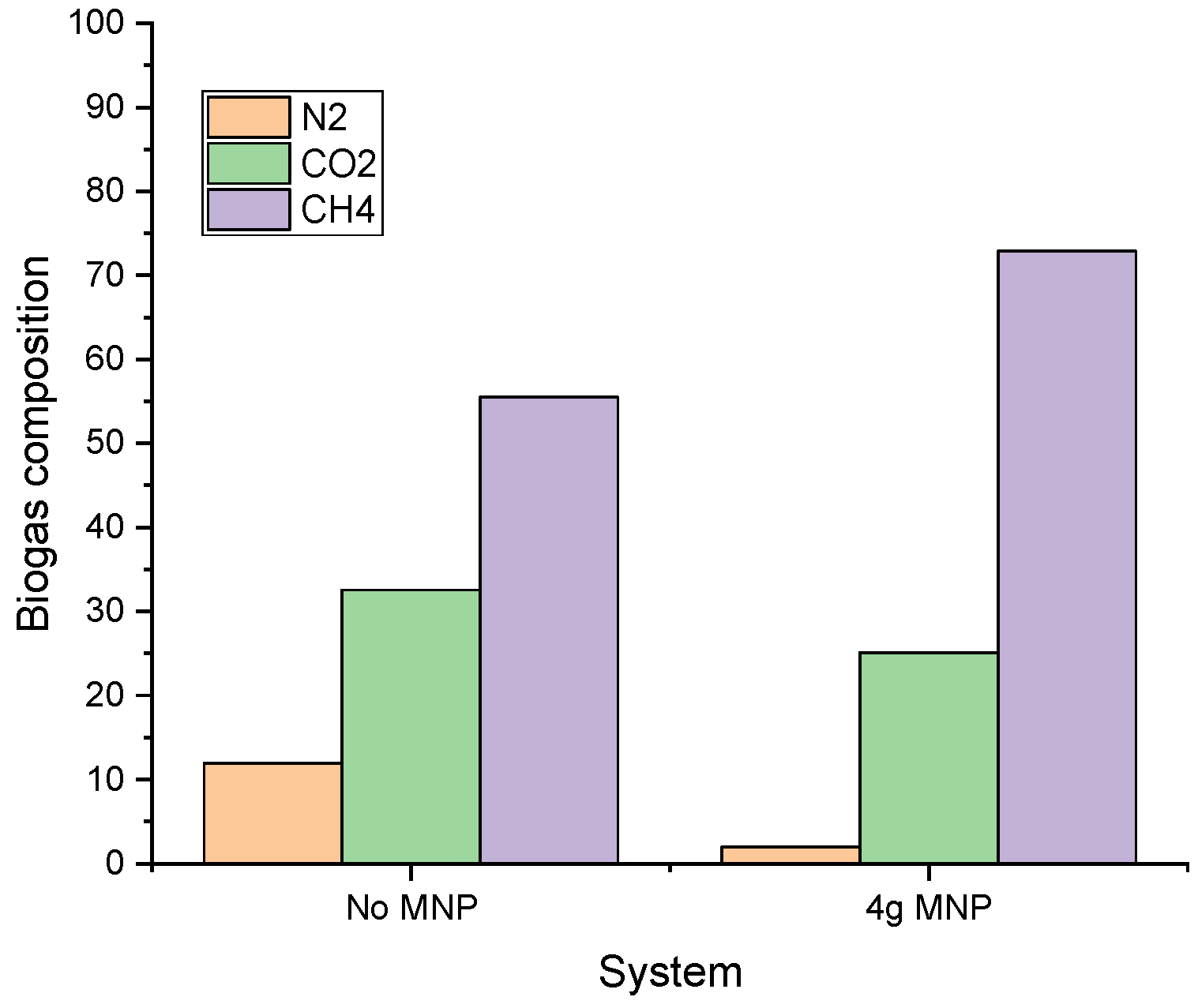

3.2.1. Biogas Quality

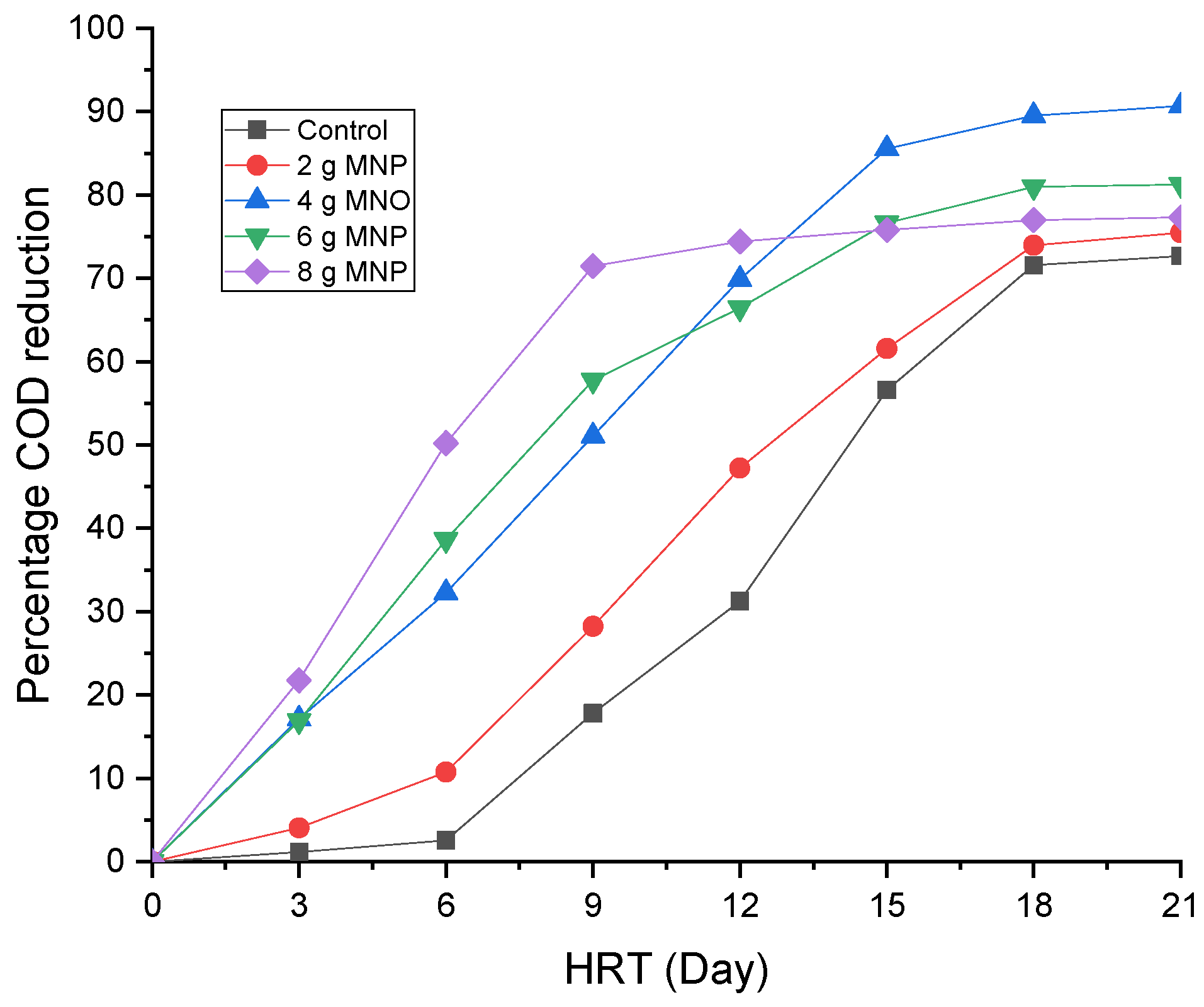

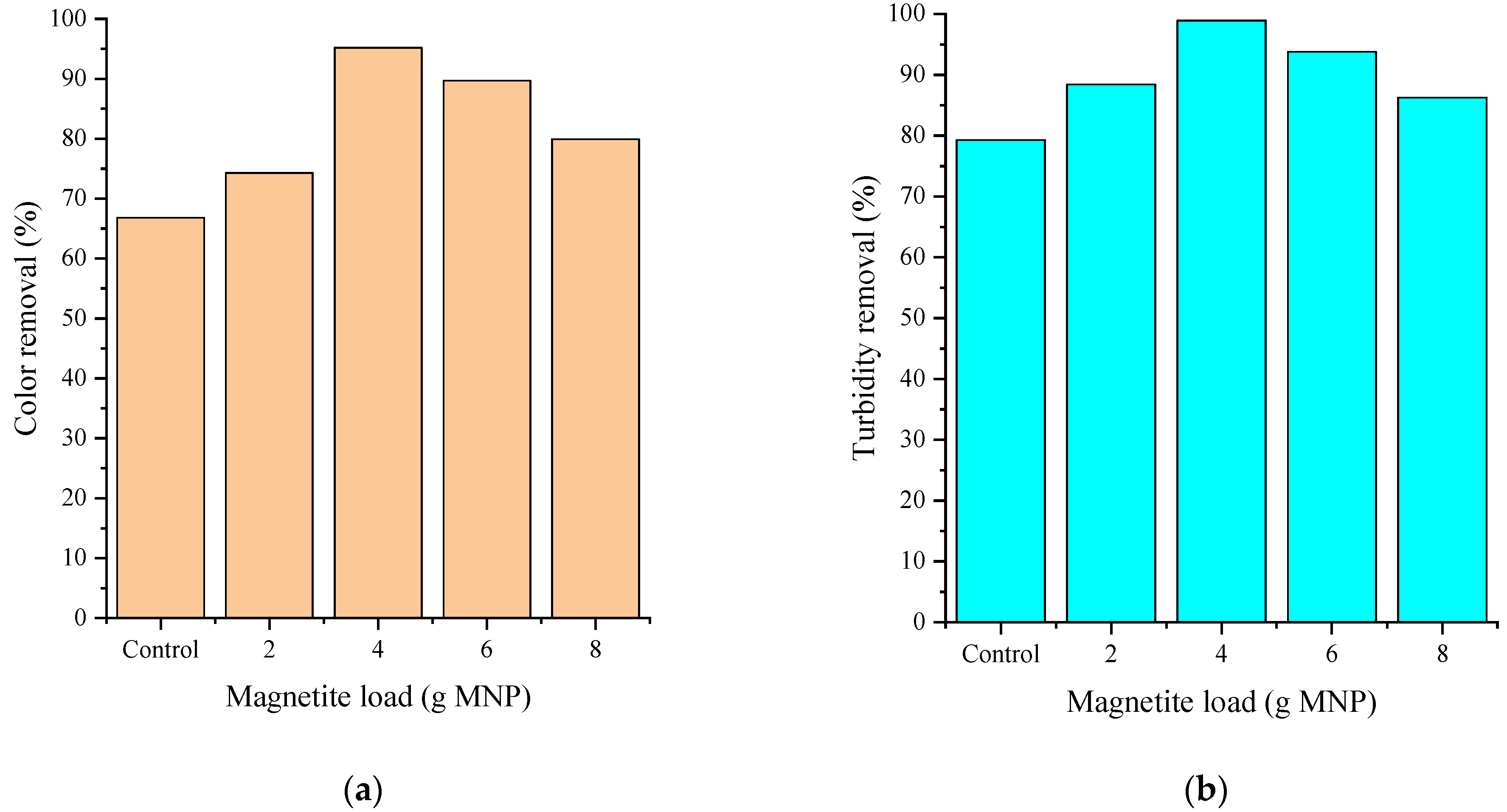

3.2.2. Effect of Magnetite on the Overall Treatability Efficiency for the UASB System

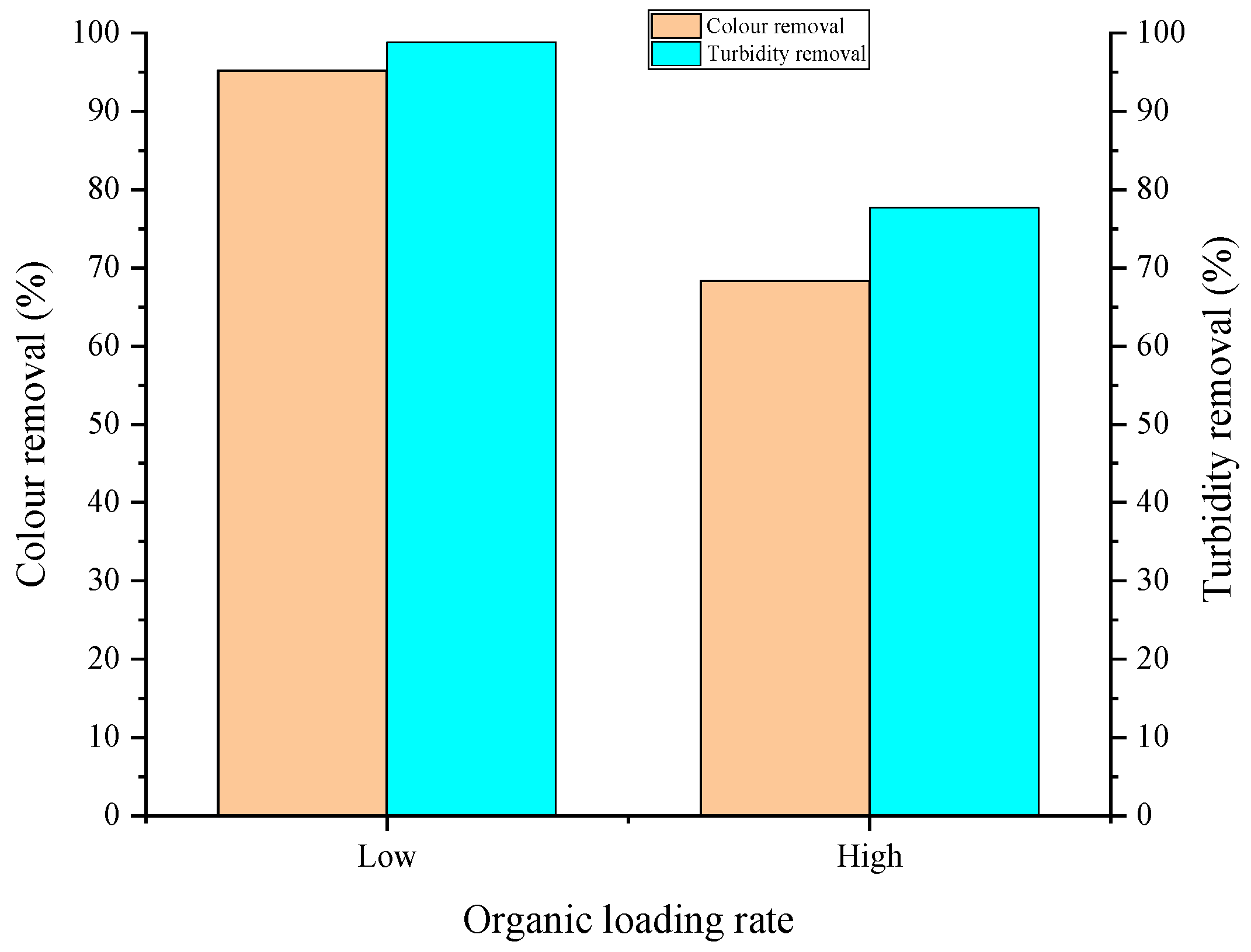

3.3. Effect of Organic Content on Biogas Production and COD Removal

Effect of Organic Content in the Treatability Efficiency for the Digester

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lin, B.; Wesseh, P.K., Jr. Energy consumption and economic growth in South Africa reexamined: A nonparametric testing apporach. Renew. Sustain. Energy Rev. 2014, 40, 840–850. [Google Scholar] [CrossRef]

- Achinas, S.; Achinas, V.; Euverink, G.J.W. Microbiology and biochemistry of anaerobic digesters: An overview. Bioreactors 2020, 12, 17–26. [Google Scholar]

- Calise, F.; Cappiello, F.L.; Cimmino, L.; d’Accadia, M.D.; Vicidomini, M. Dynamic analysis and investigation of the thermal transient effects in a CSTR reactor producing biogas. Energy 2023, 263, 126010. [Google Scholar] [CrossRef]

- Bowman, G.; Ayed, L.; Burg, V. Material and energy flows of industrial biogas plants in Switzerland in the context of the circular economy. Bioresour. Technol. Rep. 2022, 20, 101273. [Google Scholar] [CrossRef]

- Weiland, P. Biogas production: Current state and perspectives. Appl. Microbiol. Biotechnol. 2010, 85, 849–860. [Google Scholar] [CrossRef] [PubMed]

- Arif, S.; Liaquat, R.; Adil, M. Applications of materials as additives in anaerobic digestion technology. Renew. Sustain. Energy Rev. 2018, 97, 354–366. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, Y.; Li, K.; Zhou, H. Effects of increasing organic loading rate on performance and microbial community shift of an up-flow anaerobic sludge blanket reactor treating diluted pharmaceutical wastewater. J. Biosci. Bioeng. 2014, 118, 284–288. [Google Scholar] [CrossRef]

- Siegert, I.; Banks, C. The effect of volatile fatty acid additions on the anaerobic digestion of cellulose and glucose in batch reactors. Process Biochem. 2005, 40, 3412–3418. [Google Scholar] [CrossRef]

- Chen, J.L.; Ortiz, R.; Steele, T.W.; Stuckey, D.C. Toxicants inhibiting anaerobic digestion: A review. Biotechnol. Adv. 2014, 32, 1523–1534. [Google Scholar] [CrossRef]

- Cheng, Q.; Huang, W.; Jiang, M.; Xu, C.; Fan, G.; Yan, J.; Chai, B.; Zhang, Y.; Zhang, Y.; Zhang, S. Challenges of anaerobic digestion in China. Int. J. Environ. Sci. Technol. 2021, 18, 3685–3696. [Google Scholar] [CrossRef]

- Pramanik, S.K.; Suja, F.B.; Zain, S.M.; Pramanik, B.K. The anaerobic digestion process of biogas production from food waste: Prospects and constraints. Bioresour. Technol. Rep. 2019, 8, 100310. [Google Scholar] [CrossRef]

- Karim, K.; Hoffmann, R.; Klasson, K.T.; Al-Dahhan, M. Anaerobic digestion of animal waste: Effect of mode of mixing. Water Res. 2005, 39, 3597–3606. [Google Scholar] [CrossRef]

- Ratanatamskul, C.; Saleart, T. Effects of sludge recirculation rate and mixing time on performance of a prototype single-stage anaerobic digester for conversion of food wastes to biogas and energy recovery. Environ. Sci. Pollut. Res. 2016, 23, 7092–7098. [Google Scholar] [CrossRef] [PubMed]

- Poh, P.E.; Tan, D.T.; Chan, E.-S.; Tey, B.T. Current advances of biogas production via anaerobic digestion of industrial wastewater. In Advances in Bioprocess Technology; Springer: Berlin/Heidelberg, Germany, 2015; pp. 149–163. [Google Scholar]

- Rajeshwari, K.; Balakrishnan, M.; Kansal, A.; Lata, K.; Kishore, V. State-of-the-art of anaerobic digestion technology for industrial wastewater treatment. Renew. Sustain. Energy Rev. 2000, 4, 135–156. [Google Scholar] [CrossRef]

- Zhang, L.; Loh, K.-C.; Zhang, J. Enhanced biogas production from anaerobic digestion of solid organic wastes: Current status and prospects. Bioresour. Technol. Rep. 2019, 5, 280–296. [Google Scholar] [CrossRef]

- Abdelsalam, E.; Samer, M.; Attia, Y.; Abdel-Hadi, M.; Hassan, H.; Badr, Y. Influence of zero valent iron nanoparticles and magnetic iron oxide nanoparticles on biogas and methane production from anaerobic digestion of manure. Energy 2017, 120, 842–853. [Google Scholar] [CrossRef]

- Ajay, C.; Mohan, S.; Dinesha, P.; Rosen, M.A. Review of impact of nanoparticle additives on anaerobic digestion and methane generation. Fuel 2020, 277, 118234. [Google Scholar] [CrossRef]

- Amo-Duodu, G.; Tetteh, E.K.; Rathilal, S.; Chollom, M.N. Application of metallic nanoparticles for biogas enhancement using the biomethane potential test. Sci. Afr. 2021, 12, e00728. [Google Scholar] [CrossRef]

- Ahmadi-pirlou, M.; Mesri Gundoshmian, T.; Rasekh, M. Effects of different concentrations of zero valent iron nanoparticles on biogas production from co-digestion of municipal solid waste and sewage sludge. J. Environ. Sci. Stud. 2023, 8, 5910–5921. [Google Scholar]

- Ganzoury, M.A.; Allam, N.K. Impact of nanotechnology on biogas production: A mini-review. Renew. Sustain. Energy Rev. 2015, 50, 1392–1404. [Google Scholar] [CrossRef]

- Khumalo, S.M.; Bakare, B.F.; Rathilal, S.; Tetteh, E.K. Characterization of South African Brewery Wastewater: Oxidation-Reduction Potential Variation. Water 2022, 14, 1604. [Google Scholar] [CrossRef]

- Kweinor Tetteh, E.; Rathilal, S. Kinetics and Nanoparticle Catalytic Enhancement of Biogas Production from Wastewater Using a Magnetized Biochemical Methane Potential (MBMP) System. Catalysts 2020, 10, 1200. [Google Scholar] [CrossRef]

- Amo-Duodu, G.; Tetteh, E.K.; Rathilal, S.; Armah, E.K.; Adedeji, J.; Chollom, M.N.; Chetty, M. Effect of Engineered Biomaterials and Magnetite on Wastewater Treatment: Biogas and Kinetic Evaluation. Polymers 2021, 13, 4323. [Google Scholar] [CrossRef]

- Tetteh, E.K.; Rathilal, S. Response Surface Optimization of Biophotocatalytic Degradation of Industrial Wastewater for Bioenergy Recovery. Bioengeering 2022, 9, 95. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.K.; Oh, B.R.; Chun, Y.N.; Kim, S.W. Effects of temperature and hydraulic retention time on anaerobic digestion of food waste. J. Biosci. Bioeng. 2006, 102, 328–332. [Google Scholar] [CrossRef] [PubMed]

- Zwietering, M.; Rombouts, F.; Riet, K.v.t. Comparison of definitions of the lag phase and the exponential phase in bacterial growth. J. Appl. Bacteriol. 1992, 72, 139–145. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Guo, R.; Shi, X.; Wang, C.; Wang, L.; Dai, M. Magnetite nanoparticles enable a rapid conversion of volatile fatty acids to methane. RSC Adv. 2016, 6, 25662–25668. [Google Scholar] [CrossRef]

- Mainardis, M.; Buttazzoni, M.; Goi, D. Up-Flow Anaerobic Sludge Blanket (UASB) Technology for Energy Recovery: A Review on State-of-the-Art and Recent Technological Advances. Bioengineering 2020, 7, 43. [Google Scholar] [CrossRef]

- Casals, E.; Barrena, R.; García, A.; González, E.; Delgado, L.; Busquets-Fité, M.; Font, X.; Arbiol, J.; Glatzel, P.; Kvashnina, K. Programmed iron oxide nanoparticles disintegration in anaerobic digesters boosts biogas production. Small 2014, 10, 2801–2808. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Zhang, P.; Hu, Z.; Qi, Q.; He, Y.; Zhang, J. New insight on Fe-bioavailability: Bio-uptake, utilization and induce in optimizing methane production in anaerobic digestion. Chem. Eng. J. 2022, 441, 136099. [Google Scholar] [CrossRef]

- Wijekoon, K.C.; Visvanathan, C.; Abeynayaka, A. Effect of organic loading rate on VFA production, organic matter removal and microbial activity of a two-stage thermophilic anaerobic membrane bioreactor. Bioresour. Technol. 2011, 102, 5353–5360. [Google Scholar] [CrossRef] [PubMed]

- Boe, K.; Batstone, D.J.; Steyer, J.-P.; Angelidaki, I. State indicators for monitoring the anaerobic digestion process. Water Res. 2010, 44, 5973–5980. [Google Scholar] [CrossRef] [PubMed]

| Containments | Stream 1 | Stream 2 |

|---|---|---|

| COD (mg COD/L) | 4320 ± 12 | 9590 ± 58 |

| TOC (mg TOC/L) | 18.2 ± 2 | 200.6 ± 2 |

| TDS (ppt) | 3.07 ± 2 | 15.69 ± 0.7 |

| Turbidity (NTU) | 1480 ± 16 | 3590 ± 14 |

| Color (Pt-Co) | 2725 ± 24 | 22,100 ± 60 |

| Phosphorus (mg PO4/L) | 3.2 ± 0.2 | 52.1 ± 0.2 |

| Nitrates (mg NO3/L) | 65 ± 1.1 | 512 ± 0.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ngema, L.; Sathiyah, D.; Tetteh, E.K.; Rathilal, S. Enhancing Biodegradation of Industrial Wastewater into Methane-Rich Biogas Using an Up-Flow Anaerobic Sludge Blanket Reactor. Appl. Sci. 2023, 13, 4181. https://doi.org/10.3390/app13074181

Ngema L, Sathiyah D, Tetteh EK, Rathilal S. Enhancing Biodegradation of Industrial Wastewater into Methane-Rich Biogas Using an Up-Flow Anaerobic Sludge Blanket Reactor. Applied Sciences. 2023; 13(7):4181. https://doi.org/10.3390/app13074181

Chicago/Turabian StyleNgema, Lindokuhle, Devona Sathiyah, Emmanuel Kweinor Tetteh, and Sudesh Rathilal. 2023. "Enhancing Biodegradation of Industrial Wastewater into Methane-Rich Biogas Using an Up-Flow Anaerobic Sludge Blanket Reactor" Applied Sciences 13, no. 7: 4181. https://doi.org/10.3390/app13074181

APA StyleNgema, L., Sathiyah, D., Tetteh, E. K., & Rathilal, S. (2023). Enhancing Biodegradation of Industrial Wastewater into Methane-Rich Biogas Using an Up-Flow Anaerobic Sludge Blanket Reactor. Applied Sciences, 13(7), 4181. https://doi.org/10.3390/app13074181