Hygro-Thermo-Mechanical Analysis of Brick Masonry Walls Subjected to Environmental Actions

Abstract

Featured Application

Abstract

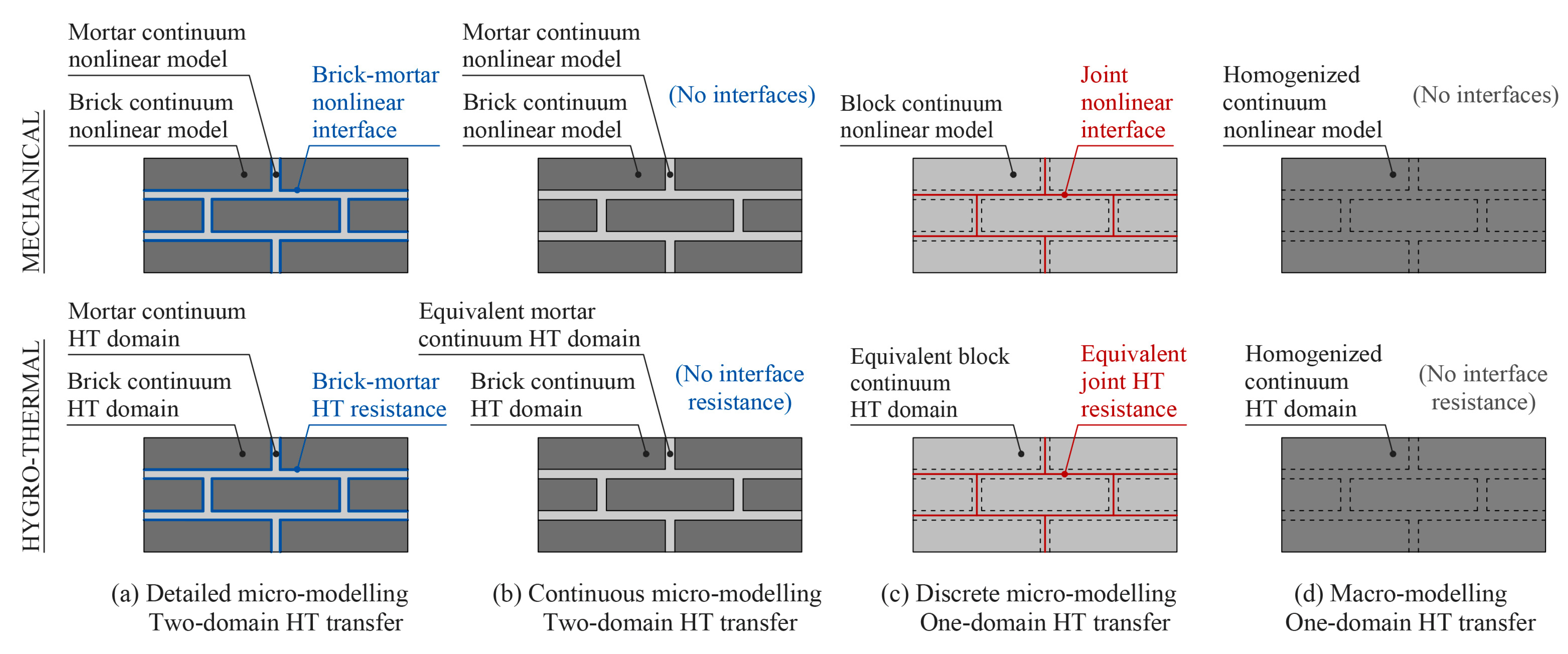

1. Introduction

2. Hygro-Thermal Model

2.1. Governing Equations

2.2. Interface Modeling

2.3. Hygro-Thermal Coupling

2.3.1. Moisture Dependency of Thermal Parameters

2.3.2. Temperature Dependency of Hygric Parameters

2.4. Initial and Boundary Conditions

3. Hygro-Thermal Simulations and Discussion

3.1. Description of the Numerical Model

| Material | Property | Symbol | Value | Units | Source |

|---|---|---|---|---|---|

| Brick | Bulk density | 1900 | kg/m3 | Ramirez et al. [18] | |

| Open porosity | 0.280 | – | |||

| Capillary moisture content | 240 | kg/m3 | |||

| Fitting parameter for sorption isotherm | 1.0070 | – | |||

| Water absorption coefficient (∥ bed face) | 0.104 | kg/(m2·s0.5) | |||

| Water absorption coefficient (⊥ bed face) | 0.075 | kg/(m2·s0.5) | |||

| Water vapor resistance factor | 34.14 | – | |||

| Specific heat capacity | 825 | J/(kg·K) | Koci et al. [62] | ||

| Thermal conductivity | 0.59 | W/(m·K) | |||

| Thermal conductivity supplement | 12.74 | – | |||

| Lime mortar (LM) | Bulk density | 2060 | kg/m3 | Ramirez et al. [18] | |

| Open porosity | 0.230 | – | |||

| Capillary moisture content | 190 | kg/m3 | |||

| Fitting parameters for adsorption isotherm | 3.80 × 10−6 | 1/Pa | |||

| 0.352 | – | ||||

| Fitting parameters for desorption isotherm | 1.19 × 10−5 | 1/Pa | |||

| 0.235 | – | ||||

| Water absorption coefficient (isotropic) | 0.080 | kg/(m2·s0.5) | |||

| Water vapor resistance factor | 15.00 | – | Prangnell [63] | ||

| Specific heat capacity | 840 | J/(kg·K) | Kumaran [64] | ||

| Thermal conductivity | 0.85 | W/(m·K) | |||

| Thermal conductivity supplement | 9.53 | – | |||

| Cement mortar (CM) | Bulk density | 2000 | kg/m3 | Ramirez et al. [18] | |

| Open porosity | 0.210 | – | |||

| Capillary moisture content | 180 | kg/m3 | |||

| Fitting parameters for adsorption isotherm | 1.43 × 10−6 | 1/Pa | |||

| 0.285 | – | ||||

| Fitting parameters for desorption isotherm | 2.51 × 10−5 | 1/Pa | |||

| 0.213 | – | ||||

| Water absorption coefficient (isotropic) | 0.060 | kg/(m2·s0.5) | |||

| Water vapor resistance factor | 25.00 | – | Prangnell [63] | ||

| Specific heat capacity | 932 | J/(kg·K) | Kumaran [64] | ||

| Thermal conductivity | 1.72 | W/(m·K) | |||

| Thermal conductivity supplement | 9.29 | – |

3.2. Hygro-Thermal Behavior of a Brick Masonry Wall

3.2.1. Steady-State Analysis (SS)

3.2.2. Time-Dependent Analysis with Constant Boundary Conditions (TD1)

3.2.3. Time-Dependent Analysis with Variable External Boundary Conditions (TD2)

4. Hygro-Thermo-Mechanical Model

4.1. Coupling between Heat, Moisture, and Mechanical Fields

4.2. Initial and Boundary Conditions

5. Hygro-Thermo-Mechanical Simulations and Discussion

5.1. Description of the Numerical Model and Boundary Conditions

5.2. Hygro-Thermo-Mechanical Behavior of a Brick Masonry Wall

5.3. Influence of the Initial Conditions on the Hygro-Thermo-Mechanical Response

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ghiassi, B.; Lourenço, P.B. (Eds.) Long-Term Performance and Durability of Masonry Structures: Degradation Mechanisms, Health Monitoring and Service Life Design, 1st ed.; Woodhead Publishing: Cambridge, UK, 2019; ISBN 9780081021101. [Google Scholar]

- Brooks, J.J. Moisture Movement of Clay Brick Masonry. In Concrete and Masonry Movements; Elsevier: Oxford, UK, 2015; pp. 223–253. [Google Scholar]

- Lourenço, P.B.; Milani, G.; Tralli, A.; Zucchini, A. Analysis of Masonry Structures: Review of and Recent Trends in Homogenization Techniques. Can. J. Civ. Eng. 2007, 34, 1443–1457. [Google Scholar] [CrossRef]

- Angelillo, M.; Lourenço, P.B.; Milani, G. Mechanics of Masonry Structures; Angelillo, M., Ed.; CISM International Centre for Mechanical Sciences; Elsevier: Vienna, Austria, 2014; Volume 551, ISBN 978-3-7091-1773-6. [Google Scholar]

- Lourenço, P.B. Computational Strategies for Masonry Structures: Multi-Scale Modeling, Dynamics, Engineering Applications and Other Challenges. In Proceedings of the Congress on Numerical Methods in Engineering CMN 2013, Bilbao, Spain, 25–28 July 2013; pp. 1–17. [Google Scholar]

- Straube, J.F.; Burnett, E.F.P. Overview of Hygrothermal (HAM) Analysis Methods. In Moisture Analysis and Condensation Control in Building Envelopes–ASTM Manual Series MNL 40; Trechsel, H.R., Ed.; American Society for Testing and Materials: West Conshohocken, PA, USA, 2001; pp. 81–89. [Google Scholar]

- Künzel, H.M.; Karagiozis, A.N.; Holm, A.H. A Hygrothermal Design Tool for Architects and Engineers (WUFI ORNL/IBD). In Moisture Analysis and Condensation Control in Building Envelopes–ASTM Manual Series MNL 40; Trechsel, H.R., Ed.; American Society for Testing and Materials: West Conshohocken, PA, USA, 2001; pp. 136–151. [Google Scholar]

- Hens, H. Modeling the Heat, Air, and Moisture Response of Building Envelopes: What Material Properties Are Needed, How Trustful Are the Predictions? J. ASTM Int. 2007, 4, 1–11. [Google Scholar] [CrossRef]

- Brocken, H.J.P. Moisture Transport in Brick Masonry: The Grey Area between Bricks. Ph.D. Thesis, Dept. Built Environment, Technische Universiteit Eindhoven, Eindhoven, The Netherlands, 1998. [Google Scholar]

- Derluyn, H.; Janssen, H.; Carmeliet, J. Influence of the Nature of Interfaces on the Capillary Transport in Layered Materials. Constr. Build. Mater. 2011, 25, 3685–3693. [Google Scholar] [CrossRef]

- Calle, K.; de Kock, T.; Cnudde, V.; van den Bossche, N. Liquid Moisture Transport in Combined Ceramic Brick and Natural Hydraulic Lime Mortar Samples: Does the Hygric Interface Resistance Dominate the Moisture Transport? J. Build. Phys. 2019, 43, 208–228. [Google Scholar] [CrossRef]

- Zhou, X.; Desmarais, G.; Vontobel, P.; Carmeliet, J.; Derome, D. Masonry Brick–Cement Mortar Interface Resistance to Water Transport Determined with Neutron Radiography and Numerical Modeling. J. Build. Phys. 2020, 44, 251–271. [Google Scholar] [CrossRef]

- Vereecken, E.; Roels, S. Hygric Performance of a Massive Masonry Wall: How Do the Mortar Joints Influence the Moisture Flux? Constr. Build. Mater. 2013, 41, 697–707. [Google Scholar] [CrossRef]

- Jensen, N.F.; Bjarløv, S.P.; Rode, C.; Møller, E.B. Hygrothermal Assessment of Four Insulation Systems for Interior Retrofitting of Solid Masonry Walls through Calibrated Numerical Simulations. Build. Environ. 2020, 180, 107031. [Google Scholar] [CrossRef]

- Soulios, V.; Jan de Place Hansen, E.; Peuhkuri, R. Hygrothermal Performance of Hydrophobized and Internally Insulated Masonry Walls–Simulating the Impact of Hydrophobization Based on Experimental Results. Build. Environ. 2021, 187, 107410. [Google Scholar] [CrossRef]

- Castellazzi, G.; de Miranda, S.; Formica, G.; Molari, L.; Ubertini, F. Coupled Hygro-Mechanical Multiscale Analysis of Masonry Walls. Eng. Struct. 2015, 84, 266–278. [Google Scholar] [CrossRef]

- Zhou, X.; Carmeliet, J.; Derome, D. Assessment of Moisture Risk of Wooden Beam Embedded in Internally Insulated Masonry Walls with 2D and 3D Models. Build. Environ. 2021, 193, 107460. [Google Scholar] [CrossRef]

- Ramirez, R.; Ghiassi, B.; Pineda, P.; Lourenço, P.B. Experimental Characterization of Moisture Transport in Brick Masonry with Natural Hydraulic Lime Mortar. Build. Environ. 2021, 205, 108256. [Google Scholar] [CrossRef]

- Conceição, J.; Faria, R.; Azenha, M. Thermo–Mechanical Analysis of an Arch Dam Monolith During Construction. In Proceedings of the Congress on Numerical Methods in Engineering CMN 2017, Valencia, Spain, 3–5 July 2017. [Google Scholar]

- Ponce-Farfán, C.; Santillán, D.; Toledo, M.Á. Thermal Simulation of Rolled Concrete Dams: Influence of the Hydration Model and the Environmental Actions on the Thermal Field. Water 2020, 12, 858. [Google Scholar] [CrossRef]

- Oliveira, R.G.; Rodrigues, J.P.C.; Pereira, J.M.; Lourenço, P.B.; Lopes, R.F.R. Experimental and Numerical Analysis on the Structural Fire Behaviour of Three–Cell Hollowed Concrete Masonry Walls. Eng. Struct. 2021, 228, 111439. [Google Scholar] [CrossRef]

- Prakash, P.R.; Azenha, M.; Pereira, J.M.; Lourenço, P.B. Finite Element Based Micro Modelling of Masonry Walls Subjected to Fire Exposure: Framework Validation and Structural Implications. Eng. Struct. 2020, 213, 110545. [Google Scholar] [CrossRef]

- Khoshbakht, M.; Lin, M.W. A Finite Element Model for Hygro-Thermo-Mechanical Analysis of Masonry Walls with FRP Reinforcement. Finite Elem. Anal. Des. 2010, 46, 783–791. [Google Scholar] [CrossRef]

- Ramézani, H.; Jeong, J. Environmentally Motivated Modeling of Hygro-Thermally Induced Stresses in the Layered Limestone Masonry Structures: Physical Motivation and Numerical Modeling. Acta Mech. 2011, 220, 107–137. [Google Scholar] [CrossRef]

- Castellazzi, G.; Colla, C.; de Miranda, S.; Formica, G.; Gabrielli, E.; Molari, L.; Ubertini, F. A Coupled Multiphase Model for Hygrothermal Analysis of Masonry Structures and Prediction of Stress Induced by Salt Crystallization. Constr. Build. Mater. 2013, 41, 717–731. [Google Scholar] [CrossRef]

- Koniorczyk, M.; Gawin, D. Modelling of Salt Crystallization in Building Materials with Microstructure–Poromechanical Approach. Constr. Build. Mater. 2012, 36, 860–873. [Google Scholar] [CrossRef]

- Derluyn, H.; Moonen, P.; Carmeliet, J. Deformation and Damage Due to Drying-Induced Salt Crystallization in Porous Limestone. J. Mech. Phys. Solids 2014, 63, 242–255. [Google Scholar] [CrossRef]

- Choo, J.; Sun, W. Cracking and Damage from Crystallization in Pores: Coupled Chemo-Hydro-Mechanics and Phase-Field Modeling. Comput. Methods Appl. Mech. Eng. 2018, 335, 347–379. [Google Scholar] [CrossRef]

- Castellazzi, G.; de Miranda, S.; Grementieri, L.; Molari, L.; Ubertini, F. Multiphase Model for Hygrothermal Analysis of Porous Media with Salt Crystallization and Hydration. Mater. Struct. 2016, 49, 1039–1063. [Google Scholar] [CrossRef]

- Grementieri, L.; Daghia, F.; Molari, L.; Castellazzi, G.; Derluyn, H.; Cnudde, V.; de Miranda, S. A Multi-Scale Approach for the Analysis of the Mechanical Effects of Salt Crystallisation in Porous Media. Int. J. Solids Struct. 2017, 126–127, 225–239. [Google Scholar] [CrossRef]

- de Miranda, S.; D’Altri, A.M.; Castellazzi, G. Modeling Environmental Ageing in Masonry Strengthened with Composites. Eng. Struct. 2019, 201, 109773. [Google Scholar] [CrossRef]

- Mertens, S. Hysteresis, Damage and Moisture Effects in Quasi-Brittle Porous Materials. Ph.D. Thesis, Katholieke Universiteit Leuven, Leuven, Belgium, 2009. [Google Scholar]

- Carmeliet, J. Influence of Damage and Moisture on the Nonlinear Hysteretic Behavior of Quasi-Brittle Materials. In Nonlinear Elasticity and Hysteresis: Fluid-Solid Coupling in Porous Media; Kim, A.H., Guyer, R.A., Eds.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2015; pp. 81–104. ISBN 9783527665068. [Google Scholar]

- Lourenço, P.B. Computational Strategies for Masonry Structures. Ph.D. Thesis, Delft University, Delft, The Netherlands, 1996. [Google Scholar]

- D’Altri, A.M.; de Miranda, S.; Castellazzi, G.; Sarhosis, V. A 3D Detailed Micro–Model for the in–Plane and out–of–Plane Numerical Analysis of Masonry Panels. Comput. Struct. 2018, 206, 18–30. [Google Scholar] [CrossRef]

- Petracca, M.; Pelà, L.; Rossi, R.; Zaghi, S.; Camata, G.; Spacone, E. Micro–Scale Continuous and Discrete Numerical Models for Nonlinear Analysis of Masonry Shear Walls. Constr. Build. Mater. 2017, 149, 296–314. [Google Scholar] [CrossRef]

- Ramirez, R.; Ghiassi, B.; Pineda, P.; Lourenço, P.B. Simulation of Moisture Transport in Fired-Clay Brick Masonry Structures Accounting for Interfacial Phenomena. Build. Environ. 2023, 228, 109838. [Google Scholar] [CrossRef]

- Künzel, H.M. Simultaneous Heat and Moisture Transport in Building Components: One– and Two–Dimensional Calculation Using Simple Parameters. Ph.D. Thesis, Fraunhofer Institute for Building Physics, Stuttgart, Germany, 1995. [Google Scholar]

- Bergman, T.L.; Lavine, A.S. Fundamentals of Heat and Mass Transfer, 8th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2017; ISBN 978-1-119-32042-5. [Google Scholar]

- Cammerer, W.F. Wärme- Und Kälteschutz Im Bauwesen Und in Der Industrie, 5th ed.; Springer: Berlin/Heidelberg, Germany, 1995; ISBN 978-3-642-78636-5. [Google Scholar]

- HAMSTAD Reports: Hagentoft, C.E.; Adan, O.; Adl-Zarrabi, B.; Becker, R.; Brocken, H.; Carmeliet, J.; Djebbar, R.; Funk, M.; Grunewald, J.; Hens, H.; et al. HAMSTAD Work Package 2: Final Report—Benchmark Package; Chalmers University of Technology: Gothenburg, Sweden, 2003. [Google Scholar]

- Janssen, H.; Blocken, B.; Carmeliet, J. Conservative Modelling of the Moisture and Heat Transfer in Building Components under Atmospheric Excitation. Int. J. Heat. Mass. Transf. 2007, 50, 1128–1140. [Google Scholar] [CrossRef]

- Defraeye, T.; Blocken, B.; Carmeliet, J. Influence of Uncertainty in Heat–Moisture Transport Properties on Convective Drying of Porous Materials by Numerical Modelling. Chem. Eng. Res. Des. 2013, 91, 36–42. [Google Scholar] [CrossRef]

- Feng, C.; Janssen, H. Hygric Properties of Porous Building Materials (II): Analysis of Temperature Influence. Build. Environ. 2016, 99, 107–118. [Google Scholar] [CrossRef]

- Salager, S.; Youssoufi, M.S.E.; Saix, C. Influence of Temperature on the Water Retention Curve of Soils. Modelling and Experiments. In Experimental Unsaturated Soil Mechanics; Schanz, T., Ed.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 251–258. [Google Scholar]

- Kell, G.S. Density, Thermal Expansivity, and Compressibility of Liquid Water from 0° to 150°: Correlations and Tables for Atmospheric Pressure and Saturation Reviewed and Expressed on 1968 Temperature Scale. J. Chem. Eng. Data 1975, 20, 97–105. [Google Scholar] [CrossRef]

- Hansen, K.K. Sorption Isotherms. A Catalogue; Technical University of Denmark (DTU): Lyngby, Denmark, 1986. [Google Scholar]

- Pavlík, Z.; Žumár, J.; Medved, I.; Černý, R. Water Vapor Adsorption in Porous Building Materials: Experimental Measurement and Theoretical Analysis. Transp. Porous Media 2012, 91, 939–954. [Google Scholar] [CrossRef]

- Castellazzi, G.; de Miranda, S.; Grementieri, L.; Molari, L.; Ubertini, F. Modelling of Non-Isothermal Salt Transport and Crystallization in Historic Masonry. Key Eng. Mater. 2014, 624, 222–229. [Google Scholar] [CrossRef]

- Schirmer, R. Die Diffusionswiderstandszahl von Wasserdampf-Luftgemischen Und Die Verdampfungsgeschwindigkeit. VDI Beih. Verfahr. 1938, 6, 170–177. [Google Scholar]

- Murray, F.W. On the Computation of Saturation Vapor Pressure. J. Appl. Meteorol. 1967, 6, 203–204. [Google Scholar] [CrossRef]

- Monteith, J.L.; Shatleworth, M.H. Principles of Environmental Physics, 4th ed.; Elsevier Ltd.: London, UK, 2013; ISBN 9780123869937. [Google Scholar]

- Gummerson, R.J.; Hall, C.; Hoff, W.D. Water Movement in Porous Building Materials II. Hydraulic Suction and Sorptivity of Brick and Other Masonry Materials. Build. Environ. 1980, 15, 101–108. [Google Scholar] [CrossRef]

- Guizzardi, M.; Derome, D.; Carmeliet, J. Water Uptake in Clay Brick at Different Temperatures: Experiments and Numerical Simulations. J. Build. Phys. 2016, 39, 373–389. [Google Scholar] [CrossRef]

- Feng, C.; Janssen, H. The Influence of Temperature on the Capillary Absorption Coefficient-A Confrontation of Two Recent Papers in Building and Environment. Build. Environ. 2017, 116, 257–258. [Google Scholar] [CrossRef]

- Hanumanthu, K.; Sarkar, K. Statistical Quantification of the Effect of Temperature on Capillary Water Absorption in Some Porous Building Materials. Build. Environ. 2021, 198, 107889. [Google Scholar] [CrossRef]

- Washburn, E.W. The Dynamics of Capillary Flow. Phys. Rev. 1921, 17, 273–283. [Google Scholar] [CrossRef]

- Karagiannis, N.; Karoglou, M.; Bakolas, A.; Moropoulou, A. Building Materials Capillary Rise Coefficient: Concepts, Determination and Parameters Involved. In New Approaches to Building Pathology and Durability. Building Pathology and Rehabilitation; Delgado, J.M.P.Q., Ed.; Springer: Singapore, 2016; Volume 6, pp. 27–44. [Google Scholar]

- COMSOL COMSOL Multiphysics®, 6th ed.; COMSOL AB: Stockholm, Sweden, 2021.

- Climate and Average Weather Year–Round in Guimarães, Portugal. Available online: https://weatherspark.com/y/32437/Average-Weather-in-Guimar%C3%A3es-Portugal-Year-Round (accessed on 1 October 2022).

- Hagentoft, C.E.; Kalagasidis, A.S.; Adl-Zarrabi, B.; Roels, S.; Carmeliet, J.; Hens, H.; Grunewald, J.; Funk, M.; Becker, R.; Shamir, D.; et al. Assessment Method of Numerical Prediction Models for Combined Heat, Air and Moisture Transfer in Building Components: Benchmarks for One-Dimensional Cases. J. Therm. Envel. Build. Sci. 2004, 27, 327–352. [Google Scholar] [CrossRef]

- Kočí, V.; Čáchová, M.; Koňáková, D.; Vejmelková, E.; Jerman, M.; Keppert, M.; Maděra, J.; Černý, R. Heat and Moisture Transport and Storage Parameters of Bricks Affected by the Environment. Int. J. Thermophys. 2018, 39, 63. [Google Scholar] [CrossRef]

- Prangnell, R.D. The Water Vapour Resistivity of Building Materials: A Literature Survey. Matériaux Constr. 1971, 4, 399–405. [Google Scholar] [CrossRef]

- Kumaran, K. IEA Annex 24: Heat, Air and Moisture Transfer in Insulated Envelope Parts. Final Report, Volume 3, Taks 3: Material Properties; Katholieke Universiteit Leuven: Leuven, Belgium, 1996. [Google Scholar]

- Szekeres, A. Thermo-Hygro-Elasticity (THE). In Encyclopedia of Thermal Stresses; Hetnarski, R.B., Ed.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 5918–5924. ISBN 978-94-007-2738-0. [Google Scholar]

- Carmeliet, J.; Derome, D.; Dressler, M.; Guyer, R.A. Nonlinear Poro-Elastic Model for Unsaturated Porous Solids. J. Appl. Mech. 2013, 80, 020909. [Google Scholar] [CrossRef]

- Ghiassi, B.; Oliveira, D.V.; Lourenço, P.B.; Marcari, G. Numerical Study of the Role of Mortar Joints in the Bond Behavior of FRP-Strengthened Masonry. Compos. B Eng. 2013, 46, 21–30. [Google Scholar] [CrossRef]

- Penas, F.; Veiga, R.; Gomes, A. Hydraulic Lime Mortars to Use in Old Buildings: Advantages and Drawbacks. In Proceedings of the HMC08—1st Historical Mortars Conference 2008: Characterization, Diagnosis, Conservation, Repair and Compatibility, Lisbon, Portugal, 24–26 September 2008; Laboratório Nacional de Engenharia Civil (LNEC): Lisbon, Portugal, 2008. [Google Scholar]

| Analysis | Initial Conditions | Exterior Boundary Conditions | Interior Boundary Conditions | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

[°C] | [–] | [°C] | [W/(m2·K)] | [–] | [s/m] | [°C] | [W/(m2·K)] | [–] | [s/m] | |

| SS | 13.5 | 0.74 | 13.5 | 25 | 0.74 | 2.0 × 10−7 | 20.0 | 8 | 0.50 | 3.0 × 10−8 |

| TD1 | 13.5 | 0.74 | 13.5 | 25 | 0.74 | 2.0 × 10−7 | 20.0 | 8 | 0.50 | 3.0 × 10−8 |

| TD2 | SS results 1 | SS results 1 | Equation (20) | 25 | Equation (21) | 2.0 × 10−7 | 20.0 | 8 | 0.50 | 3.0 × 10−8 |

| Material | Property | Symbol | Value/Expression | Units | Source |

|---|---|---|---|---|---|

| Brick | Young’s modulus | 5580 | MPa | Ghiassi et al. [67] | |

| Poisson’s ratio | 0.20 | – | |||

| Compressive strength | 19.80 | MPa | |||

| Tensile strength | 2.00 | MPa | |||

| Coefficient of thermal expansion | 2.56 × 10−6 | 1/°C | Ramirez et al. [18] | ||

| Coefficient of hygric expansion | – | ||||

| Lime mortar (LM) | Young’s modulus | 3330 | MPa | Penas et al. [68] | |

| Poisson’s ratio | 0.20 | – | |||

| Compressive strength | 1.10 | MPa | |||

| Tensile strength | 0.40 | MPa | |||

| Coefficient of thermal expansion | 3.04 × 10−6 | 1/°C | Ramirez et al. [18] | ||

| Coefficient of hygric expansion | – | ||||

| Cement mortar (CM) | Young’s modulus | 2370 | MPa | D’Altri et al. [35] | |

| Poisson’s ratio | 0.20 | – | |||

| Compressive strength | 8.20 | MPa | |||

| Tensile strength | 1.50 | MPa | |||

| Coefficient of thermal expansion | 7.38 × 10−6 | 1/°C | Ramirez et al. [18] | ||

| Coefficient of hygric expansion | – |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramirez, R.; Ghiassi, B.; Pineda, P.; Lourenço, P.B. Hygro-Thermo-Mechanical Analysis of Brick Masonry Walls Subjected to Environmental Actions. Appl. Sci. 2023, 13, 4514. https://doi.org/10.3390/app13074514

Ramirez R, Ghiassi B, Pineda P, Lourenço PB. Hygro-Thermo-Mechanical Analysis of Brick Masonry Walls Subjected to Environmental Actions. Applied Sciences. 2023; 13(7):4514. https://doi.org/10.3390/app13074514

Chicago/Turabian StyleRamirez, Rafael, Bahman Ghiassi, Paloma Pineda, and Paulo B. Lourenço. 2023. "Hygro-Thermo-Mechanical Analysis of Brick Masonry Walls Subjected to Environmental Actions" Applied Sciences 13, no. 7: 4514. https://doi.org/10.3390/app13074514

APA StyleRamirez, R., Ghiassi, B., Pineda, P., & Lourenço, P. B. (2023). Hygro-Thermo-Mechanical Analysis of Brick Masonry Walls Subjected to Environmental Actions. Applied Sciences, 13(7), 4514. https://doi.org/10.3390/app13074514