Advanced Electronic and Optoelectronic Sensors, Applications, Modelling and Industry 5.0 Perspectives

Abstract

1. Introduction

- -

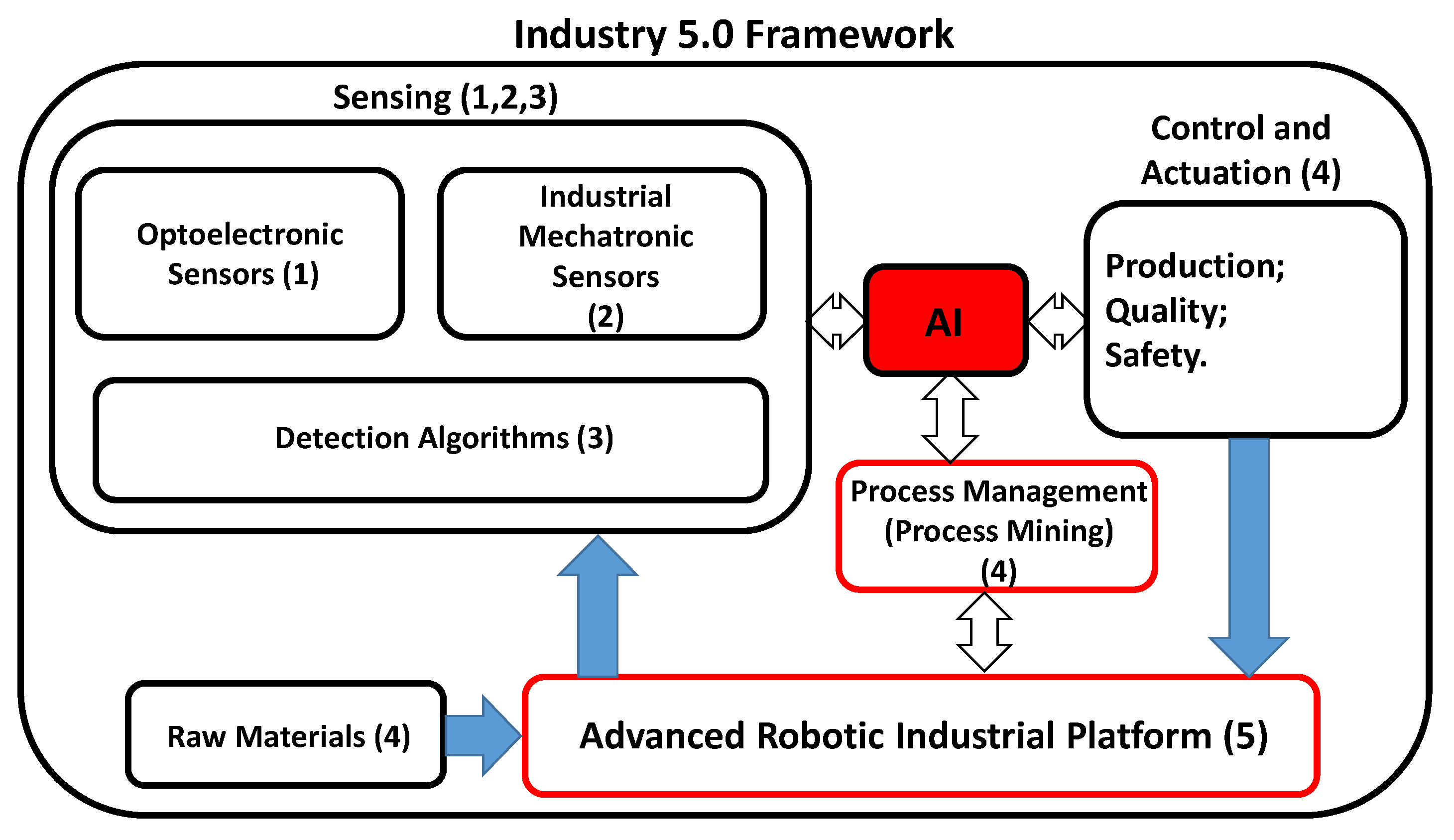

- A sensing module composed of innovative optoelectronic sensors (block 1), industrial mechatronic sensors (block 2), and detection algorithms (block 3);

- -

- Control and actuation facilities (block 4) which address production, quality, safety, process management, raw materials management, and Process Mining (PM);

- -

- An AI engine managing production line actions (blocks 1, 2, 3, 4, 5);

- -

- An Advanced robotic industrial platform (block 5).

- -

- Discussion of the adopted methodology of the searching approach of the state of the art;

- -

- Discussion of the blocks of the framework of Figure 1, which will by provide a perspective of the implementation of each framework in a future Industry 5.0 scenario for each topic;

- -

- Description of a complex model of an Industry 5.0 framework defined by the topics found in the state of the art (framework constructed by supposing possible evolutions/implementations of the analyzed technologies and by hypothesizing a production line in the manufacturing sector);

- -

- Simulation of the information flux of the designed framework by means of the estimation of the diffusion heat parameters;

- -

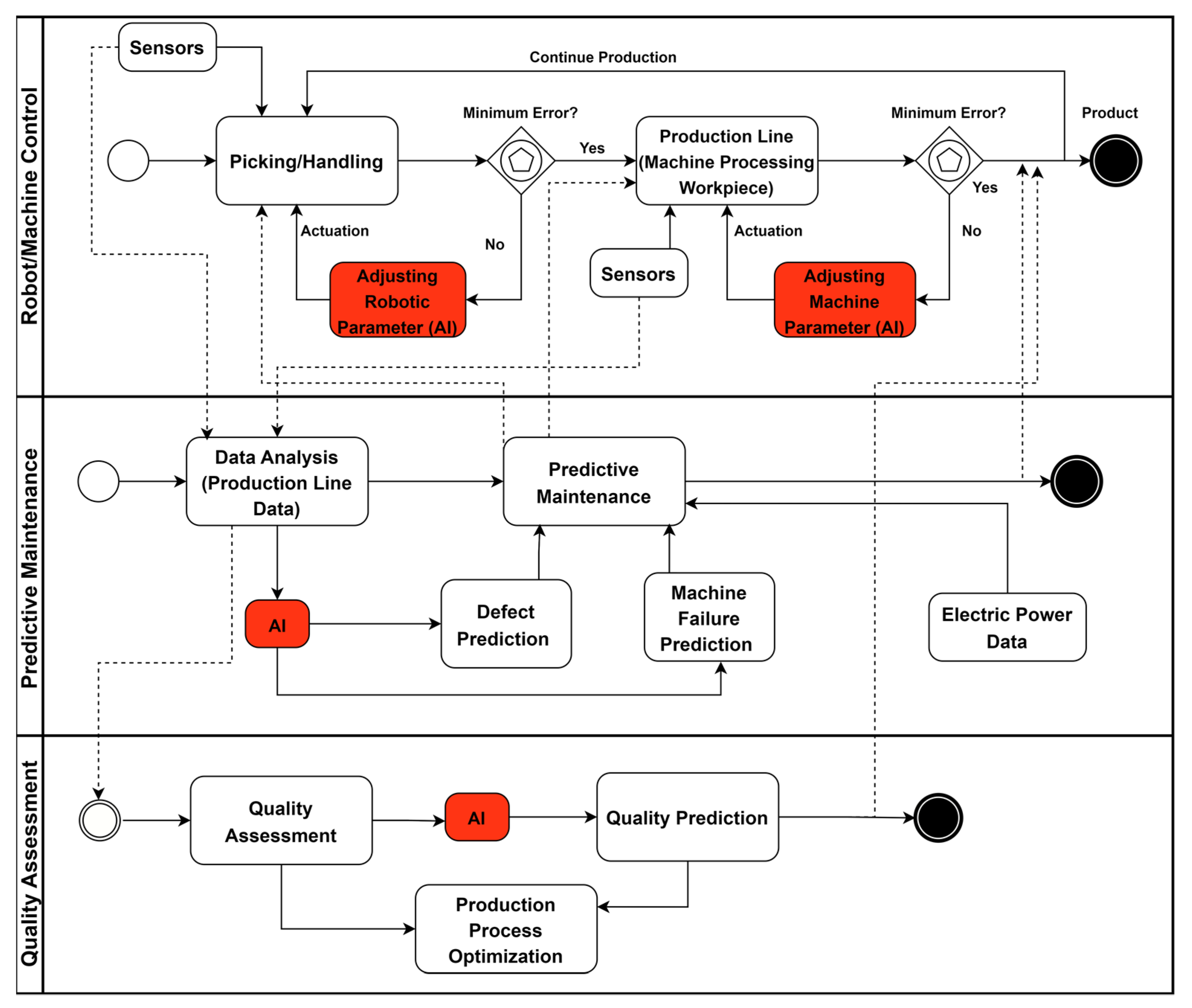

- Design of Business Process Modeling and Notation (BPMN) workflows applied to this example of the Industry 5.0 framework, which will be useful for enhancing the different technological levels that will upgrade the production;

- -

- A BPMN model explaining, with more details, the processes of the robotic and machine control exploiting predictive maintenance and quality assessment processes designed with the Industry 5.0 framework.

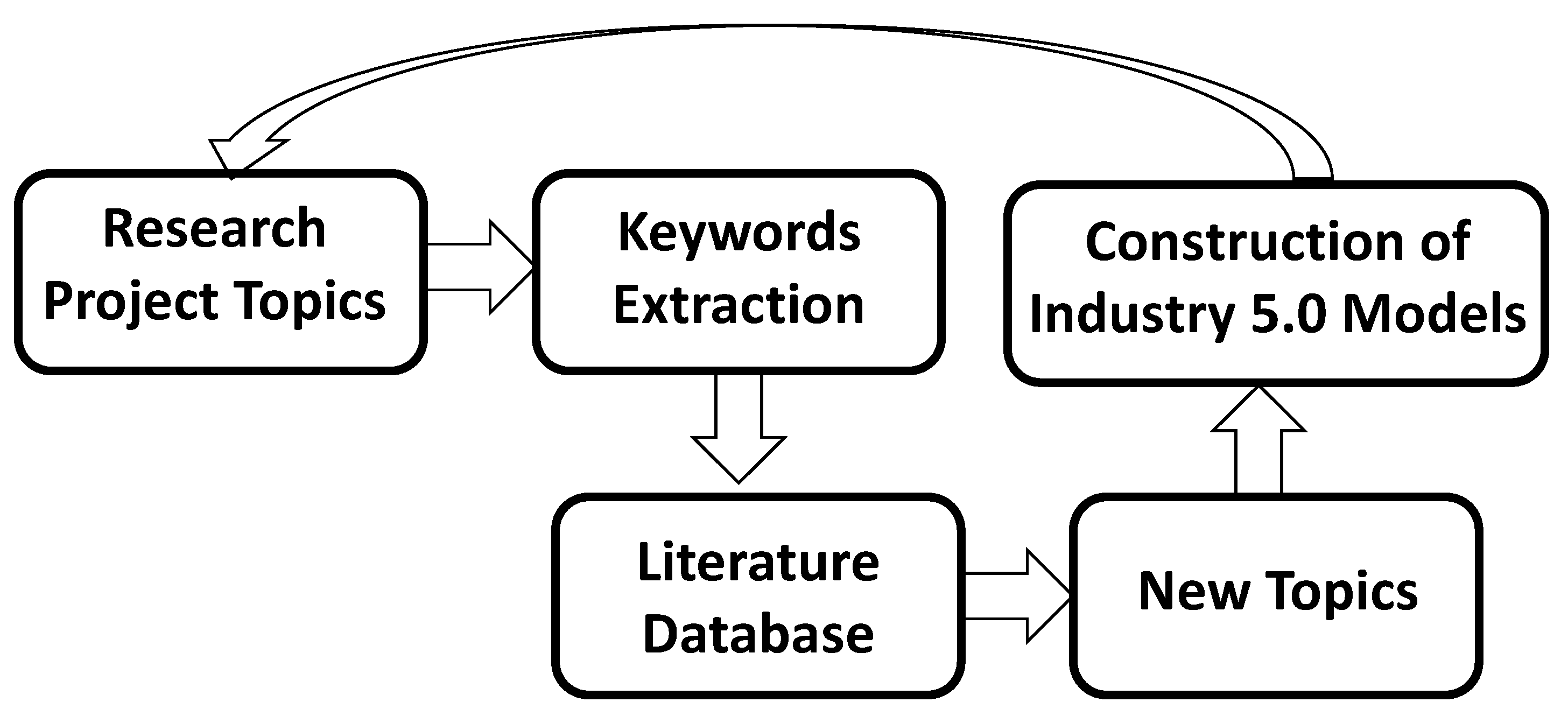

Methodology

- -

- The topics found in the literature are related to the requirements of the industry research projects (regional, national and European research topics) outlining the following macro-topics: Mechatronic Systems, Industry 4.0, Digital Transformation, Agriculture 4.0, Internet of Things (IoT), Human & Machine Interfaces (HMI), Quantum Computing, Energy, Edge Computing, Artificial Intelligence, Dynamic Business and Strategic Marketing, Additive Manufacturing, Key Enabling Technologies (KET), Photonics, Micro-Technologies, Nano-Technologies, Advanced Materials, Smart Materials, Technologies and Advanced Production Systems, Innovative Management Frameworks, Change Management, Product Quality Assessment, etc.;

- -

- Different keywords matching with specific industrial application fields (papers found in literature) are extracted, such as: Micro-Sensors, Nano-Sensors, Optoelectronic Sensors, Image Vision Techniques, Leakage Detection, Sensing and Actuation AI Systems, Nanocomposite Sensors, Defect Detection, Defect Prediction, Embedded Electronic Devices and Systems for the Automatic Control of Assembly Processes, Embedded Microelectronics, Integrated Systems for Applications of Remote Control, Multi-Sector Environment, Soft Robotics, Infrared Thermography, Multi-Spectral Analysis, AI Control and Actuation, etc.;

- -

- New research topics following the correlations between the different extracted keywords are defined, such as: rapid prototyping, reverse engineering, Industry 5.0, process mining applied to industrial production processes and on quality assessment, electronic assisted production management, etc.;

2. Sensing Field

3. Supply Chain Processes and Advances

4. Advanced Robotic Industrial Platforms

5. Discussion: Industry 5.0 Framework and Complex Systems Simulations

5.1. Industry 5.0 Workflow Design and Process Simulation

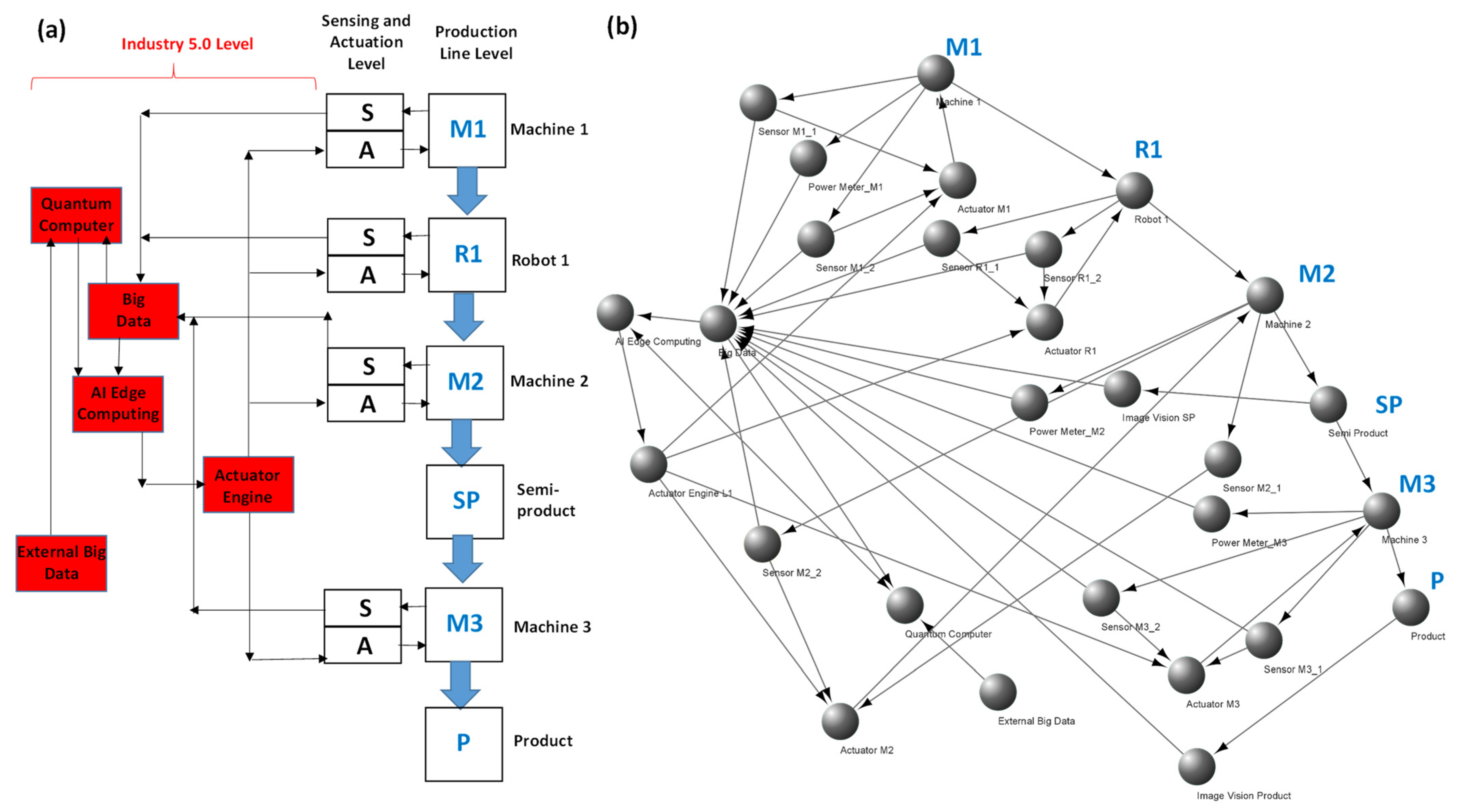

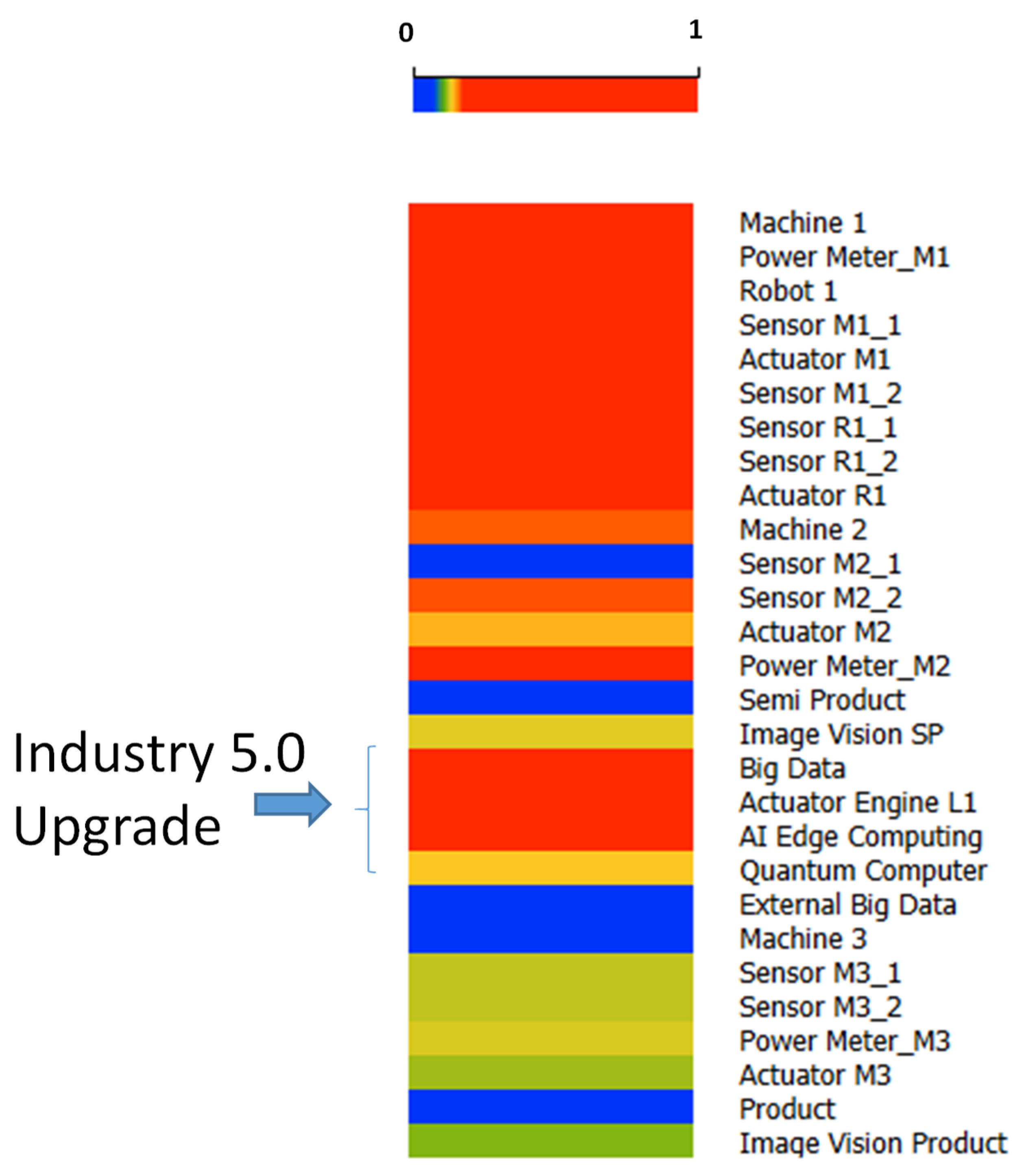

- Machine 1 (M1): the first machine, processing raw materials loaded at the input of the production line.

- Sensor M1_1: sensor monitoring Machine 1.

- Sensor M1_2: sensor monitoring Machine 1.

- Actuator M1: actuator that relays the sensing and actuation processing of from Machine 1.

- Power Meter_M1: power meter reading the electrical power of Machine 1.

- Robot 1 (R1): robot handling the workpiece processed by Machine 1.

- Sensor R1_1: first sensor monitoring Robot 1.

- Sensor R1_2: second sensor monitoring Robot 1.

- Actuator R1: actuator which relays sensing and actuation processing from Robot 1 (includes sensing of from both the sensors Sensor R1_1 and Sensor R1_2).

- Machine 2 (M2): second machine processing the workpiece after robotic manipulation.

- Sensor M2_1: sensor monitoring Machine 2.

- Sensor M2_2: sensor monitoring Machine 2.

- Actuator M2: actuator relaying sensing and actuation processing from Machine 2.

- Power Meter_M2: power meter reading the electrical power of Machine 2.

- Semi-Product (SP): semi-product output of Machine 2.

- Image Vision SP: camera implementing image vision algorithms to detect the defects of the Semi-Product.

- Machine 3 (M3): third machine processing the semi-product.

- Sensor M3_1: sensor monitoring Machine 3.

- Sensor M3_2: sensor monitoring Machine 3.

- Actuator M3: actuator relaying the sensing and actuation processing of Machine 3.

- Power Meter_M3: power meter reading electrical power of Machine 3.

- Product (P): final product of the whole production line (output of Machine 3).

- Image Vision Product: camera implementing image vision algorithms for detecting defects of in the final product;

- Big Data: internal big data collecting all production data (data from the whole production line).

- AI Edge Computing: edge computing nodes processing all data collected into the internal big data system by AI algorithms; the AI algorithms are optimized by quantum calculus (Quantum Computer).

- Quantum Computer: the quantum computer processing data collected in Big Data and External Big Data.

- External Big Data: dataset collected from the cloud by other third parties related to this specific production (external backend systems).

- Actuator Engine L1: engine synchronizing all the actuators: Actuator M1, Actuator R1, Actuator M2, Actuator M3 (with synchronization supported by the AI algorithms).

5.2. Examples of Applications Matching with Industry 5.0 Framework

6. Conclusions

Funding

Conflicts of Interest

References

- Mohammadi Estakhri, N.; Edwards, B.; Engheta, N. Inverse-Designed Metastructures That Solve Equations. Science 2019, 363, 1333–1338. [Google Scholar] [CrossRef]

- Lalegani, Z.; Seyyed Ebrahimi, S.A.; Hamawandi, B.; La Spada, L.; Batili, H.; Toprak, M.S. Targeted Dielectric Coating of Silver Nanoparticles with Silica to Manipulate Optical Properties for Metasurface Applications. Mater. Chem. Phys. 2022, 287, 126250. [Google Scholar] [CrossRef]

- Pacheco-Peña, V.; Beruete, M.; Rodríguez-Ulibarri, P.; Engheta, N. On the Performance of an ENZ-Based Sensor Using Transmission Line Theory and Effective Medium Approach. New J. Phys. 2019, 21, 043056. [Google Scholar] [CrossRef]

- Lincoln, R.L.; Scarpa, F.; Ting, V.P.; Trask, R.S. Multifunctional Composites: A Metamaterial Perspective. Multifunct. Mater. 2019, 2, 043001. [Google Scholar] [CrossRef]

- Akbari, M.; Shahbazzadeh, M.J.; La Spada, L.; Khajehzadeh, A. The Graphene Field Effect Transistor Modeling Based on an Optimized Ambipolar Virtual Source Model for DNA Detection. Appl. Sci. 2021, 11, 8114. [Google Scholar] [CrossRef]

- Greybush, N.J.; Pacheco-Peña, V.; Engheta, N.; Murray, C.B.; Kagan, C.R. Plasmonic Optical and Chiroptical Response of Self-Assembled Au Nanorod Equilateral Trimers. ACS Nano 2019, 13, 1617–1624. [Google Scholar] [CrossRef]

- Massaro, A.; Caratelli, D.; Yarovoy, A.; Cingolani, R. Analytical Approaches for Nano-Plasmonic and Micro-Millimetric Antennas. IET Microw. Antennas Propag. 2011, 5, 349. [Google Scholar] [CrossRef]

- Jamshidi, M.B.; Lalbakhsh, A.; Talla, J.; Peroutka, Z.; Roshani, S.; Matousek, V.; Roshani, S.; Mirmozafari, M.; Malek, Z.; La Spada, L.; et al. Deep Learning Techniques and COVID-19 Drug Discovery: Fundamentals, State-of-the-Art and Future Directions. In Studies in Systems, Decision and Control; Springer International Publishing: Cham, Switzerland, 2021; pp. 9–31. [Google Scholar]

- Elia, G.; Margherita, A.; Massaro, A.; Vacca, A. Adoption of Open Innovation in the COVID-19 Emergency: Developing a Process-Based Information Coordination System. Bus. Proc. Manag. J. 2022, 28, 419–441. [Google Scholar] [CrossRef]

- Wójcik, W.; Firago, V.; Smolarz, A.; Shedreyeva, I.; Yeraliyeva, B. Multispectral High Temperature Thermography. Sensors 2022, 22, 742. [Google Scholar] [CrossRef]

- Roales, J.; Moscoso, F.G.; Vargas, A.P.; Lopes-Costa, T.; Pedrosa, J.M. Colorimetric Gas Detection Using Molecular Devices and an RGB Sensor. Chemosensors 2023, 11, 92. [Google Scholar] [CrossRef]

- Ko, K.W.; Kim, D.H.; Kim, M.Y.; Kim, J.H. An Automatic Optical Inspection System for Inspection of CMOS Compact Camera Module Assembly. Int. J. Precis. Eng. Manuf. 2009, 10, 67–72. [Google Scholar] [CrossRef]

- Morganti, D.; Faro, M.J.L.; Leonardi, A.A.; Fazio, B.; Conoci, S.; Irrera, A. Luminescent Silicon Nanowires as Novel Sensor for Environmental Air Quality Control. Sensors 2022, 22, 8755. [Google Scholar] [CrossRef] [PubMed]

- Akbari-Saatlu, M.; Procek, M.; Mattsson, C.; Thungström, G.; Nilsson, H.-E.; Xiong, W.; Xu, B.; Li, Y.; Radamson, H.H. Silicon Nanowires for Gas Sensing: A Review. Nanomaterials 2020, 10, 2215. [Google Scholar] [CrossRef] [PubMed]

- Zappi, D.; Ramma, M.M.; Scognamiglio, V.; Antonacci, A.; Varani, G.; Giardi, M.T. High-Tech and Nature-Made Nanocomposites and Their Applications in the Field of Sensors and Biosensors for Gas Detection. Biosensors 2020, 10, 176. [Google Scholar] [CrossRef] [PubMed]

- Jeong, C.; Joung, C.; Lee, S.; Feng, M.Q.; Park, Y.B. Carbon nanocomposite based mechanical sensing and energy harvesting. Int. J. Precis. Eng. Manuf.-Green Technol. 2020, 7, 247–267. [Google Scholar] [CrossRef]

- Kanoun, O.; Khriji, S.; Naifar, S.; Bradai, S.; Bouattour, G.; Bouhamed, A.; El Houssaini, D.; Viehweger, C. Prospects of Wireless Energy-Aware Sensors for Smart Factories in the Industry 4.0 Era. Electronics 2021, 10, 2929. [Google Scholar] [CrossRef]

- Massaro, A.; Spano, F.; Cingolani, R.; Athanassiou, A. Experimental Optical Characterization and Polymeric Layouts of Gold PDMS Nanocomposite Sensor for Liquid Detection. IEEE Sens. J. 2011, 11, 1780–1786. [Google Scholar] [CrossRef]

- Massaro, A.; Spano, F.; Cazzato, P.; La Tegola, C.; Cingolani, R.; Athanassiou, A. Robot Tactile Sensing: Gold Nanocomposites as Highly Sensitive Real-Time Optical Pressure Sensors. IEEE Robot. Autom. Mag. 2013, 20, 82–90. [Google Scholar] [CrossRef]

- Lay-Ekuakille, A.; Massaro, A.; Singh, S.P.; Jablonski, I.; Rahman, M.Z.U.; Spano, F. Optoelectronic and Nanosensors Detection Systems: A Review. IEEE Sens. J. 2021, 21, 12645–12653. [Google Scholar] [CrossRef]

- Massaro, A.; Spano, F.; Missori, M.; Malvindi, M.A.; Cazzato, P.; Cingolani, R.; Athanassiou, A. Flexible Nanocomposites with All-Optical Tactile Sensing Capability. RSC Adv. 2013, 4, 2820–2825. [Google Scholar] [CrossRef]

- Giannoccaro, N.I.; Massaro, A.; Spedicato, L.; Lay-Ekuakille, A. Detection Analysis of Small Notches Damages Using a New Tactile Optical Device. IEEE ASME Trans. Mechatron. 2015, 20, 313–320. [Google Scholar] [CrossRef]

- Massaro, A.; Troia, M.; Spano, F.; Carbone, G. Friction in Totally Optical Robotic Finger Oriented on Shear Force Measurement. IEEE Sens. J. 2013, 13, 548–555. [Google Scholar] [CrossRef]

- Giannoccaro, N.I.; Lay-Ekuakille, A.; Spedicato, L.; Massaro, A.; Velazquez, R. An Innovative Tool for Detection of Small Notches Using a Nanocomposite Optical Sensor. IEEE Sens. J. 2016, 16, 5029–5036. [Google Scholar] [CrossRef]

- Massaro, A.; Giannoccaro, N.I.; Spedicato, L.; Lay-Ekuakille, A.; Missori, M.; Malvindi, M.A. Characterization of an Innovative Like-Eye Sensor for Feature Detection and Robot Sensing. Measurement 2014, 55, 153–167. [Google Scholar] [CrossRef]

- Moodie, D.; Costello, L.; McStay, D. Optoelectronic Leak Detection System for Monitoring Subsea Structures. In Optical Sensing and Detection; Berghmans, F., Mignani, A.G., van Hoof, C.A., Eds.; SPIE: Bellingham, WA, USA, 2010. [Google Scholar]

- McStay, D.; Shiach, G.; Nolan, A.; McAvoy, S. Optoelectronic Sensors for Subsea Oil and Gas Production. J. Phys. Conf. Ser. 2007, 76, 012065. [Google Scholar] [CrossRef]

- Ashry, I.; Mao, Y.; Wang, B.; Hveding, F.; Bukhamsin, A.; Ng, T.K.; Ooi, B.S. A Review of Distributed Fiber–Optic Sensing in the Oil and Gas Industry. J. Light. Technol. 2022, 40, 1407–1431. [Google Scholar] [CrossRef]

- Attivissimo, F.; Carducci, C.G.C.; Lanzolla, A.M.L.; Massaro, A.; Vadrucci, M.R. A Portable Optical Sensor for Sea Quality Monitoring. IEEE Sens. J. 2015, 15, 146–153. [Google Scholar] [CrossRef]

- Lay-Ekuakille, A.; Durickovic, I.; Lanzolla, A.; Morello, R.; De Capua, C.; Girão, P.S.; Postolache, O.; Massaro, A.; Van Biesen, L. Effluents, Surface and Subterranean Waters Monitoring: Review and Advances. Measurement 2019, 137, 566–579. [Google Scholar] [CrossRef]

- Prauzek, M.; Hercik, R.; Konecny, J.; Mikolajek, M.; Stankus, M.; Koziorek, J.; Martinek, R. An Optical-Based Sensor for Automotive Exhaust Gas Temperature Measurement. IEEE Trans. Instrum. Meas. 2022, 71, 1–11. [Google Scholar] [CrossRef]

- Werneck, M.M.; dos Santos, D.M.; de Carvalho, C.C.; de Nazare, F.V.B.; da Silva Barros Allil, R.C. Detection and Monitoring of Leakage Currents in Power Transmission Insulators. IEEE Sens. J. 2015, 15, 1338–1346. [Google Scholar] [CrossRef]

- Werneck, M.M.; Pinto, P.H.S.; Bellini, R.T.; Allil, R.C.S.B. Optical Sensor for Monitoring Leakage Current and Weather Conditions in a 500-KV Transmission Line. Sensors 2022, 22, 5034. [Google Scholar] [CrossRef] [PubMed]

- Raju, A.; Prakash, A.; Upadhyaya, A.M.; Sharan, P. Design and Analysis of Pipeline Leakage Detection Using Fibre Bragg Grating Sensor. In Proceedings of the 2018 3rd International Conference on Communication and Electronics Systems (ICCES), Coimbatore, India, 15–16 October 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 114–120. [Google Scholar]

- Abrar, U.; Yousaf, A.; Jaffri, N.R.; Rehman, A.U.; Ahmad, A.; Gardezi, A.A.; Naseer, S.; Shafiq, M.; Choi, J.-G. Analysis of Complex Solid-Gas Flow under the Influence of Gravity through Inclined Channel and Comparison with Real-Time Dual-Sensor System. Electronics 2021, 10, 2849. [Google Scholar] [CrossRef]

- Baroudi, U.; Al-Roubaiey, A.A.; Devendiran, A. Pipeline Leak Detection Systems and Data Fusion: A Survey. IEEE Access 2019, 7, 97426–97439. [Google Scholar] [CrossRef]

- Mohd Yussof, N.A.; Ho, H.W. Review of Water Leak Detection Methods in Smart Building Applications. Buildings 2022, 12, 1535. [Google Scholar] [CrossRef]

- Soldevila, A.; Boracchi, G.; Roveri, M.; Tornil-Sin, S.; Puig, V. Leak Detection and Localization in Water Distribution Networks by Combining Expert Knowledge and Data-Driven Models. Neural Comput. Appl. 2022, 34, 4759–4779. [Google Scholar] [CrossRef]

- Hung, S.-K.; Chung, Y.-H.; Chen, C.-L.; Chang, K.-H. Optoelectronic Angular Displacement Measurement Technology for 2-Dimensional Mirror Galvanometer. Sensors 2022, 22, 872. [Google Scholar] [CrossRef]

- Santos, J.L. Optical Sensors for Industry 4.0. IEEE J. Sel. Top. Quantum Electron. 2021, 27, 1–11. [Google Scholar] [CrossRef]

- Poprawe, R.; Hinke, C.; Meiners, W.; Eibl, F.; Zarei, O.; Voshage, M.; Ziegler, S.; Schleifenbaum, J.H.; Gasser, A.; Schopphoven, T.; et al. Digital Photonic Production along the Lines of Industry 4.0. In Laser Applications in Microelectronic and Optoelectronic Manufacturing (LAMOM) XXIII; Neuenschwander, B., Račiukaitis, G., Makimura, T., Grigoropoulos, C.P., Eds.; SPIE: Bellingham, WA, USA, 2018. [Google Scholar]

- Sioma, A.; Lenty, B. Detection of Fungal Infections on the Wood Surface Using LTM Imaging. Appl. Sci. 2022, 13, 490. [Google Scholar] [CrossRef]

- Ebayyeh, A.A.R.M.A.; Mousavi, A. A Review and Analysis of Automatic Optical Inspection and Quality Monitoring Methods in Electronics Industry. IEEE Access 2020, 8, 183192–183271. [Google Scholar] [CrossRef]

- Surdo, S.; Zunino, A.; Diaspro, A.; Duocastella, M. Acoustically Shaped Laser Light as an Enabling Technology for Industry 4.0. In Proceedings of the 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0 & IoT), Naples, Italy, 4–6 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 360–364. [Google Scholar]

- Cho, H. (Ed.) Opto-Mechatronic Systems Handbook: Techniques and Applications; The Mechanical Engineering Handbook Series; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Ley, P.-P.; Knöchelmann, M.; Wolf, A.; Lachmayer, R. Tailoring the V-Model for Optics: A Methodology for Optomechatronic Systems. Appl. Sci. 2022, 12, 7798. [Google Scholar] [CrossRef]

- Knöchelmann, M. Prozess zur Entwicklung Optomechatronischer Systeme. Ph.D. Thesis, Leibniz Universität Hannover, Hannover, Germany, 2021. (In German). [Google Scholar]

- VDI, version 2206; Development of Mechatronic and Cyber-Physical Systems. Beuth Verlag GmbH: Berlin, Germany, 2021.

- Borghetti, M.; Cantù, E.; Sardini, E.; Serpelloni, M. Future Sensors for Smart Objects by Printing Technologies in Industry 4.0 Scenario. Energies 2020, 13, 5916. [Google Scholar] [CrossRef]

- Almuslem, A.; Shaikh, S.F.; Hussain, M.M. Flexible and Stretchable Electronics for Harsh-Environmental Applications. Adv. Mater. Technol. 2019, 4, 1900145. [Google Scholar] [CrossRef]

- Verma, A.; Goos, R.; Weerdt, J.D.; Pelgrims, P.; Ferraris, E. Design, Fabrication, and Testing of a Fully 3D-Printed Pressure Sensor Using a Hybrid Printing Approach. Sensors 2022, 22, 7531. [Google Scholar] [CrossRef]

- Cruz, S.M.F.; Rocha, L.A.; Viana, J.C. Printing Technologies on Flexible Substrates for Printed Electronics. In Flexible Electronics; InTech: London, UK, 2018. [Google Scholar]

- Khajavizadeh, L.; Andersson, M. MOSFET-Based Gas Sensors for Process Industry IoT Applications. In Proceedings of the 2022 International Conference on Electrical, Computer, Communications and Mechatronics Engineering (ICECCME), Maldives, Maldives, 16–18 November 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–5. [Google Scholar]

- Di Franco, C.; Elia, A.; Spagnolo, V.; Scamarcio, G.; Lugarà, P.M.; Ieva, E.; Cioffi, N.; Torsi, L.; Bruno, G.; Losurdo, M.; et al. Optical and Electronic NO(x) Sensors for Applications in Mechatronics. Sensors 2009, 9, 3337–3356. [Google Scholar] [CrossRef]

- Shao, Y.; Li, X.; Zhang, T.; Chu, S.; Liu, X. Time-Series-Based Leakage Detection Using Multiple Pressure Sensors in Water Distribution Systems. Sensors 2019, 19, 3070. [Google Scholar] [CrossRef]

- Laiton-Bonadiez, C.; Branch-Bedoya, J.W.; Zapata-Cortes, J.; Paipa-Sanabria, E.; Arango-Serna, M. Industry 4.0 Technologies Applied to the Rail Transportation Industry: A Systematic Review. Sensors 2022, 22, 2491. [Google Scholar] [CrossRef]

- Massaro, A.; Dipierro, G.; Selicato, S.; Cannella, E.; Galiano, A.; Saponaro, A. Intelligent Inspection of Railways Infrastructure and Risks Estimation by Artificial Intelligence Applied on Noninvasive Diagnostic Systems. In Proceedings of the 2021 IEEE International Workshop on Metrology for Industry 4.0 & IoT (MetroInd4.0 & IoT), Rome, Italy, 7–9 June 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 231–236. [Google Scholar]

- Gogolák, L.; Fürstner, I. Wireless Sensor Network Aided Assembly Line Monitoring According to Expectations of Industry 4.0. Appl. Sci. 2021, 11, 25. [Google Scholar] [CrossRef]

- Kalsoom, T.; Ramzan, N.; Ahmed, S.; Ur-Rehman, M. Advances in Sensor Technologies in the Era of Smart Factory and Industry 4.0. Sensors 2020, 20, 6783. [Google Scholar] [CrossRef] [PubMed]

- Javaid, M.; Haleem, A.; Singh, R.P.; Rab, S.; Suman, R. Significance of Sensors for Industry 4.0: Roles, Capabilities, and Applications. Sens. Int. 2021, 2, 100110. [Google Scholar] [CrossRef]

- Saloko, S.; Sulastri, Y.; Murad; Rinjani, M.A. The Effects of Temperature and Roasting Time on the Quality of Ground Robusta Coffee (Coffea Rabusta) Using Gene Café Roaster. In Proceedings of the 2nd International Conference on Bioscience, Biotechnology, and Biometrics 2019, Lombok, Indonesia, 13–14 August 2019; AIP Publishing: Melville, NY, USA, 2019. [Google Scholar]

- Catelani, T.A.; Páscoa, R.N.M.J.; Santos, J.R.; Pezza, L.; Pezza, H.R.; Lima, J.L.F.C.; Lopes, J.A. A Non-Invasive Real-Time Methodology for the Quantification of Antioxidant Properties in Coffee during the Roasting Process Based on near-Infrared Spectroscopy. Food Bioprocess Technol. 2017, 10, 630–638. [Google Scholar] [CrossRef]

- Navia, J.; Mondragon, I.; Patino, D.; Colorado, J. Multispectral Mapping in Agriculture: Terrain Mosaic Using an Autonomous Quadcopter UAV. In Proceedings of the 2016 International Conference on Unmanned Aircraft Systems (ICUAS), Arlington, VA, USA, 7–10 June 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1351–1358. [Google Scholar]

- Sona, G.; Passoni, D.; Pinto, L.; Pagliari, D.; Masseroni, D.; Ortuani, B.; Facchi, A. Uav Multispectral Survey to Map Soil and Crop for Precision Farming Applications. ISPRS-Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2016, XLI-B1, 1023–1029. [Google Scholar] [CrossRef]

- Omia, E.; Bae, H.; Park, E.; Kim, M.S.; Baek, I.; Kabenge, I.; Cho, B.-K. Remote Sensing in Field Crop Monitoring: A Comprehensive Review of Sensor Systems, Data Analyses and Recent Advances. Remote Sens. 2023, 15, 354. [Google Scholar] [CrossRef]

- Ryalat, M.; ElMoaqet, H.; AlFaouri, M. Design of a Smart Factory Based on Cyber-Physical Systems and Internet of Things towards Industry 4.0. Appl. Sci. 2023, 13, 2156. [Google Scholar] [CrossRef]

- Jegorowa, A.; Kurek, J.; Antoniuk, I.; Krupa, A.; Wieczorek, G.; Świderski, B.; Bukowski, M.; Kruk, M. Automatic Estimation of Drill Wear Based on Images of Holes Drilled in Melamine Faced Chipboard with Machine Learning Algorithms. Forests 2023, 14, 205. [Google Scholar] [CrossRef]

- Massaro, A.; Galiano, A. Re-Engineering Process in a Food Factory: An Overview of Technologies and Approaches for the Design of Pasta Production Processes. Prod. Manuf. Res. 2020, 8, 80–100. [Google Scholar] [CrossRef]

- Binali, R.; Kuntoğlu, M.; Pimenov, D.Y.; Ali Usca, Ü.; Kumar Gupta, M.; Erdi Korkmaz, M. Advance Monitoring of Hole Machining Operations via Intelligent Measurement Systems: A Critical Review and Future Trends. Measurement 2022, 201, 111757. [Google Scholar] [CrossRef]

- Liang, Q.; Zhang, D.; Coppola, G.; Mao, J.; Sun, W.; Wang, Y.; Ge, Y. Design and Analysis of a Sensor System for Cutting Force Measurement in Machining Processes. Sensors 2016, 16, 70. [Google Scholar] [CrossRef]

- Kandavalli, S.R.; Khan, A.M.; Iqbal, A.; Jamil, M.; Abbas, S.; Laghari, R.A.; Cheok, Q. Application of Sophisticated Sensors to Advance the Monitoring of Machining Processes: Analysis and Holistic Review. Int. J. Adv. Manuf. Technol. 2023, 125, 989–1014. [Google Scholar] [CrossRef]

- Jafari, R.; Razvarz, S.; Vargas-Jarillo, C.; Gegov, A.; Arabikhan, F. Pipeline Leak Detection and Estimation Using Fuzzy PID Observer. Electronics 2022, 11, 152. [Google Scholar] [CrossRef]

- Spatafora, M.A.N.; Allegra, D.; Giudice, O.; Stanco, F.; Battiato, S. Natural Gas Leakage Detection: A Deep Learning Framework on IR Video Data. In Proceedings of the 2022 26th International Conference on Pattern Recognition (ICPR), Montreal, QC, Canada, 21–25 August 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 636–642. [Google Scholar]

- Xiong, K.; Jiang, J.; Pan, Y.; Yang, Y.; Chen, X.; Yu, Z. Deep Learning Approach for Detection of Underground Natural Gas Micro-Leakage Using Infrared Thermal Images. Sensors 2022, 22, 5322. [Google Scholar] [CrossRef]

- Kopbayev, A.; Khan, F.; Yang, M.; Halim, S.Z. Gas Leakage Detection Using Spatial and Temporal Neural Network Model. Process Saf. Environ. Prot. 2022, 160, 968–975. [Google Scholar] [CrossRef]

- Zhao, Q.; Nie, X.; Luo, D.; Wang, J.; Li, Q.; Chen, W. An Effective Method for Gas-Leak Area Detection and Gas Identification with Mid-Infrared Image. Photonics 2022, 9, 992. [Google Scholar] [CrossRef]

- Massaro, A.; Panarese, A.; Galiano, A. Technological Platform for Hydrogeological Risk Computation and Water Leakage Detection Based on a Convolutional Neural Network. In Proceedings of the 2021 IEEE International Workshop on Metrology for Industry 4.0 & IoT (MetroInd4.0 & IoT), Rome, Italy, 7–9 June 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 225–230. [Google Scholar]

- Adedeji, K.; Hamam, Y.; Abe, B.; Abu-Mahfouz, A. Leakage Detection and Estimation Algorithm for Loss Reduction in Water Piping Networks. Water 2017, 9, 773. [Google Scholar] [CrossRef]

- Guo, D.; Cui, Z.; Liu, C.; Li, Y. Analysis of the Influencing Factors of the Leak Detection Method Based on the Disturbance-Reflected Signal. Energies 2023, 16, 572. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, Z.; Lu, J. Research on Leakage Location of Pipeline Based on Module Maximum Denoising. Appl. Sci. 2023, 13, 340. [Google Scholar] [CrossRef]

- Navarro-Díaz, A.; Delgado-Aguiñaga, J.A.; Santos-Ruiz, I.; Puig, V. Real-Time Leak Diagnosis in Water Distribution Systems Based on a Bank of Observers and a Genetic Algorithm. Water 2022, 14, 3289. [Google Scholar] [CrossRef]

- Xu, K.; Li, Y.; Liu, C.; Liu, X.; Hao, X.; Gao, J.; Maropoulos, P.G. Advanced Data Collection and Analysis in Data-Driven Manufacturing Process. Chin. J. Mech. Eng. 2020, 33, 43. [Google Scholar] [CrossRef]

- Jan, Z.; Ahamed, F.; Mayer, W.; Patel, N.; Grossmann, G.; Stumptner, M.; Kuusk, A. Artificial Intelligence for Industry 4.0: Systematic Review of Applications, Challenges, and Opportunities. Expert Syst. Appl. 2023, 216, 119456. [Google Scholar] [CrossRef]

- Peres, R.S.; Jia, X.; Lee, J.; Sun, K.; Colombo, A.W.; Barata, J. Industrial Artificial Intelligence in Industry 4.0—Systematic Review, Challenges and Outlook. IEEE Access 2020, 8, 220121–220139. [Google Scholar] [CrossRef]

- Janík, S.; Szabó, P.; Mĺkva, M.; Mareček-Kolibiský, M. Effective Data Utilization in the Context of Industry 4.0 Technology Integration. Appl. Sci. 2022, 12, 10517. [Google Scholar] [CrossRef]

- Gölzer, P.; Cato, P.; Amberg, M. Data Processing Requirements of Industry 4.0—Use Cases for Big Data Applications. In Proceedings of the European Conference on Information Systems, Münster, Germany, 26–29 May 2015; pp. 1–13. [Google Scholar]

- Raja Santhi, A.; Muthuswamy, P. Industry 5.0 or Industry 4.0S? Introduction to Industry 4.0 and a Peek into the Prospective Industry 5.0 Technologies. Int. J. Interact. Des. Manuf. 2023. [Google Scholar] [CrossRef]

- Bousdekis, A.; Lepenioti, K.; Apostolou, D.; Mentzas, G. Data Analytics in Quality 4.0: Literature Review and Future Research Directions. Int. J. Comput. Integr. Manuf. 2022, 1–24. [Google Scholar] [CrossRef]

- Massaro, A.; Manfredonia, I.; Galiano, A.; Pellicani, L.; Birardi, V. Sensing and Quality Monitoring Facilities Designed for Pasta Industry Including Traceability, Image Vision and Predictive Maintenance. In Proceedings of the 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0 & IoT), Naples, Italy, 4–6 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 68–72. [Google Scholar]

- del Real Torres, A.; Andreiana, D.S.; Ojeda Roldán, Á.; Hernández Bustos, A.; Acevedo Galicia, L.E. A Review of Deep Reinforcement Learning Approaches for Smart Manufacturing in Industry 4.0 and 5.0 Framework. Appl. Sci. 2022, 12, 12377. [Google Scholar] [CrossRef]

- Wahid, A.; Breslin, J.G.; Intizar, M.A. Prediction of Machine Failure in Industry 4.0: A Hybrid CNN-LSTM Framework. Appl. Sci. 2022, 12, 4221. [Google Scholar] [CrossRef]

- Massaro, A.; Dipierro, G.; Cannella, E.; Galiano, A.M. Comparative Analysis among Discrete Fourier Transform, K-Means and Artificial Neural Networks Image Processing Techniques Oriented on Quality Control of Assembled Tires. Information 2020, 11, 257. [Google Scholar] [CrossRef]

- Massaro, A.; Manfredonia, I.; Galiano, A.; Xhahysa, B. Advanced Process Defect Monitoring Model and Prediction Improvement by Artificial Neural Network in Kitchen Manufacturing Industry: A Case of Study. In Proceedings of the 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0 & IoT), Naples, Italy, 4–6 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 64–67. [Google Scholar]

- Khan, M.A.; Elmitwally, N.S.; Abbas, S.; Aftab, S.; Ahmad, M.; Fayaz, M.; Khan, F. Software Defect Prediction Using Artificial Neural Networks: A Systematic Literature Review. Sci. Program. 2022, 2022, 2117339. [Google Scholar] [CrossRef]

- Sethi, T.; Gagandeep. Improved Approach for Software Defect Prediction Using Artificial Neural Networks. In Proceedings of the 2016 5th International Conference on Reliability, Infocom Technologies and Optimization (Trends and Future Directions) (ICRITO), Noida, India, 7–9 September 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 480–485. [Google Scholar]

- Maarif, M.R.; Listyanda, R.F.; Kang, Y.-S.; Syafrudin, M. Artificial Neural Network Training Using Structural Learning with Forgetting for Parameter Analysis of Injection Molding Quality Prediction. Information 2022, 13, 488. [Google Scholar] [CrossRef]

- Tancredi, G.P.; Vignali, G.; Bottani, E. Integration of Digital Twin, Machine-Learning and Industry 4.0 Tools for Anomaly Detection: An Application to a Food Plant. Sensors 2022, 22, 4143. [Google Scholar] [CrossRef]

- Sleiti, A.K.; Kapat, J.S.; Vesely, L. Digital Twin in Energy Industry: Proposed Robust Digital Twin for Power Plant and Other Complex Capital-Intensive Large Engineering Systems. Energy Rep. 2022, 8, 3704–3726. [Google Scholar] [CrossRef]

- Paudel, H.P.; Syamlal, M.; Crawford, S.E.; Lee, Y.-L.; Shugayev, R.A.; Lu, P.; Ohodnicki, P.R.; Mollot, D.; Duan, Y. Quantum Computing and Simulations for Energy Applications: Review and Perspective. ACS Eng. Au 2022, 2, 151–196. [Google Scholar] [CrossRef]

- Ahn, J.; Kwon, H.-Y.; Ahn, B.; Park, K.; Kim, T.; Lee, M.-K.; Kim, J.; Chung, J. Toward Quantum Secured Distributed Energy Resources: Adoption of Post-Quantum Cryptography (PQC) and Quantum Key Distribution (QKD). Energies 2022, 15, 714. [Google Scholar] [CrossRef]

- Giani, A. Quantum computing opportunities in renewable energy. Nat. Comput. Sci. 2021, 1, 90–91. [Google Scholar] [CrossRef]

- Starace, G.; Tiwari, G.; Colangelo, C.; Massaro, A. Advanced Data Systems for Energy Consumption Optimization and Air Quality Control in Smart Public Buildings Using a Versatile Open Source Approach. Electronics 2022, 11, 3904. [Google Scholar] [CrossRef]

- Massaro, A.; Starace, G. Advanced and Complex Energy Systems Monitoring and Control: A Review on Available Technologies and Their Application Criteria. Sensors 2022, 22, 4929. [Google Scholar] [CrossRef]

- Toscano, G.; Maceratesi, V.; Leoni, E.; Stipa, P.; Laudadio, E.; Sabbatini, S. FTIR Spectroscopy for Determination of the Raw Materials Used in Wood Pellet Production. Fuel 2022, 313, 123017. [Google Scholar] [CrossRef]

- Rodionova, O.Y.; Sokovikov, Y.V.; Pomerantsev, A.L. Quality Control of Packed Raw Materials in Pharmaceutical Industry. Anal. Chim. Acta 2009, 642, 222–227. [Google Scholar] [CrossRef] [PubMed]

- Benabdellah, N.; Bourhaleb, M.; Nasri, M.; Benazzi, N.; Dahbi, S. Design of Temperature and Humidity Sensors for an Electronic Nose Used in Rotten Food. In Proceedings of the 2016 International Conference on Electrical and Information Technologies (ICEIT), Tangiers, Morocco, 4–7 May 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 505–509. [Google Scholar]

- Mamasadikov, Y.; Alikhonov, E.J. An Optoelectronic Device That Controls the Linear Density of Cotton Tape during Quality Processing of Cotton Raw Materials. SciEdu 2022, 3, 168–177. [Google Scholar]

- Darmawan, A.; Bahri, S.; Putra, A.T.B. Six Sigma Implementation in Quality Evaluation of Raw Material: A Case Study. IOP Conf. Ser. Mater. Sci. Eng. 2020, 875, 012065. [Google Scholar] [CrossRef]

- Strzałkowski, P. Characteristics of Waste Generated in Dimension Stone Processing. Energies 2021, 14, 7232. [Google Scholar] [CrossRef]

- You, J.; Wang, Z. Control of Raw Materials Releasing for a Manufacturing System with Product Quality Downgrade. In Proceedings of the 2021 China Automation Congress (CAC), Beijing, China, 22–24 October 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1991–1996. [Google Scholar]

- Bartnitzki, T. Mining 4.0-Importance of Industry 4.0 for the RAW Materials Sector. Artif. Intell. 2017, 2, M2M. [Google Scholar]

- Md, A.Q.; Jha, K.; Haneef, S.; Sivaraman, A.K.; Tee, K.F. A Review on Data-Driven Quality Prediction in the Production Process with Machine Learning for Industry 4.0. Processes 2022, 10, 1966. [Google Scholar] [CrossRef]

- Tercan, H.; Meisen, T. Machine Learning and Deep Learning Based Predictive Quality in Manufacturing: A Systematic Review. J. Intell. Manuf. 2022, 33, 1879–1905. [Google Scholar] [CrossRef]

- Massaro, A. Advanced Control Systems in Industry 5.0 Enabling Process Mining. Sensors 2022, 22, 8677. [Google Scholar] [CrossRef] [PubMed]

- Massaro, A. Multi-Level Decision Support System in Production and Safety Management. Knowledge 2022, 2, 682–701. [Google Scholar] [CrossRef]

- Pech, M.; Vrchota, J.; Bednář, J. Predictive Maintenance and Intelligent Sensors in Smart Factory: Review. Sensors 2021, 21, 1470. [Google Scholar] [CrossRef] [PubMed]

- Angelopoulos, A.; Michailidis, E.T.; Nomikos, N.; Trakadas, P.; Hatziefremidis, A.; Voliotis, S.; Zahariadis, T. Tackling Faults in the Industry 4.0 Era-A Survey of Machine-Learning Solutions and Key Aspects. Sensors 2019, 20, 109. [Google Scholar] [CrossRef]

- Teh, H.Y.; Kempa-Liehr, A.W.; Wang, K.I.-K. Sensor Data Quality: A Systematic Review. J. Big Data 2020, 7. [Google Scholar] [CrossRef]

- Yurtay, Y. Process Mining in Manufacturing: A Literature Review. Sak. Univ. J. Comput. Inf. Sci. 2022, 5, 341–355. [Google Scholar] [CrossRef]

- Halaska, M.; Sperka, R. Process Mining—The Enhancement of Elements Industry 4.0. In Proceedings of the 2018 4th International Conference on Computer and Information Sciences (ICCOINS), Kuala Lumpur, Malaysia, 13–14 August 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–6. [Google Scholar]

- Kamala, B.; Latha, B. Process Mining and Deep Neural Network Approach for the Prediction of Business Process Outcome. In Proceedings of the 2022 International Conference on Communication, Computing and Internet of Things (IC3IoT), Chennai, India, 10–11 March 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–4. [Google Scholar]

- Xavier, M.; Dubinin, V.; Patil, S.; Vyatkin, V. Process Mining in Industrial Control Systems. In Proceedings of the 2022 IEEE 20th International Conference on Industrial Informatics (INDIN), Perth, Australia, 25–28 July 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar]

- Abonyi, J.; Dorgo, G. Process Mining in Production Systems. In Proceedings of the 2019 IEEE 23rd International Conference on Intelligent Engineering Systems (INES), Hungary, 25–27 April 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 000267–000270. [Google Scholar]

- Garcia, M.M.; Sattar, M.A.; Atmani, H.; Legendre, D.; Babout, L.; Schleicher, E.; Hampel, U.; Portela, L.M. Towards Tomography-Based Real-Time Control of Multiphase Flows: A Proof of Concept in Inline Fluid Separation. Sensors 2022, 22, 4443. [Google Scholar] [CrossRef]

- Schlicht, S.; Jaksch, A.; Drummer, D. Inline Quality Control through Optical Deep Learning-Based Porosity Determination for Powder Bed Fusion of Polymers. Polymers 2022, 14, 885. [Google Scholar] [CrossRef]

- Burmistrov, D.E.; Pavkin, D.Y.; Khakimov, A.R.; Ignatenko, D.N.; Nikitin, E.A.; Lednev, V.N.; Lobachevsky, Y.P.; Gudkov, S.V.; Zvyagin, A.V. Application of Optical Quality Control Technologies in the Dairy Industry: An Overview. Photonics 2021, 8, 551. [Google Scholar] [CrossRef]

- Sioma, A. Vision System in Product Quality Control Systems. Appl. Sci. 2023, 13, 751. [Google Scholar] [CrossRef]

- Mbodj, N.G.; Abuabiah, M.; Plapper, P.; El Kandaoui, M.; Yaacoubi, S. Modeling and Control of Layer Height in Laser Wire Additive Manufacturing. Materials 2022, 15, 4479. [Google Scholar] [CrossRef] [PubMed]

- Budzik, G.; Woźniak, J.; Paszkiewicz, A.; Przeszłowski, Ł.; Dziubek, T.; Dębski, M. Methodology for the Quality Control Process of Additive Manufacturing Products Made of Polymer Materials. Materials 2021, 14, 2202. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Park, H.J.; Chai, S.; Kim, G.R.; Yong, H.; Bae, S.J.; Kwon, D. Review on Quality Control Methods in Metal Additive Manufacturing. Appl. Sci. 2021, 11, 1966. [Google Scholar] [CrossRef]

- El-Mahdy, M.H.; Maged, S.A.; Awad, M.I. End-to-End Fault Tolerant Control of Discrete Event System Using Recurrent Neural Networks. In Proceedings of the 2022 2nd International Mobile, Intelligent, and Ubiquitous Computing Conference (MIUCC), Cairo, Egypt, 8–9 May 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 266–271. [Google Scholar]

- Karagiannis, P.; Michalos, G.; Andronas, D.; Matthaiakis, A.-S.; Giannoulis, C.; Makris, S. Cognitive Mechatronic Devices for Reconfigurable Production of Complex Parts. Appl. Sci. 2021, 11, 5034. [Google Scholar] [CrossRef]

- Low, J.H.; Khin, P.M.; Han, Q.Q.; Yao, H.; Teoh, Y.S.; Zeng, Y.; Li, S.; Liu, J.; Liu, Z.; Valdivia y Alvarado, P.; et al. Sensorized Reconfigurable Soft Robotic Gripper System for Automated Food Handling. IEEE ASME Trans. Mechatron. 2022, 27, 3232–3243. [Google Scholar] [CrossRef]

- Paul, N.; Tasgaonkar, V.; Walambe, R.; Kotecha, K. Integrating the Generative Adversarial Network for Decision Making in Reinforcement Learning for Industrial Robot Agents. Robotics 2022, 11, 150. [Google Scholar] [CrossRef]

- Chen, S.; Wen, J.T. Industrial Robot Trajectory Tracking Control Using Multi-Layer Neural Networks Trained by Iterative Learning Control. Robotics 2021, 10, 50. [Google Scholar] [CrossRef]

- Borboni, A.; Reddy, K.V.V.; Elamvazuthi, I.; AL-Quraishi, M.S.; Natarajan, E.; Azhar Ali, S.S. The Expanding Role of Artificial Intelligence in Collaborative Robots for Industrial Applications: A Systematic Review of Recent Works. Machines 2023, 11, 111. [Google Scholar] [CrossRef]

- Silva, G.; Rekik, K.; Kanso, A.; Schnitman, L. Multi-perspective human robot interaction through an augmented video interface supported by deep learning. In Proceedings of the 2022 31st IEEE International Conference on Robot and Human Interactive Communication (RO-MAN), Napoli, Italy, 29 August–2 September 2022; pp. 1168–1173. [Google Scholar]

- Buerkle, A.; Eaton, W.; Lohse, N.; Bamber, T.; Ferreira, P. EEG based arm movement intention recognition towards enhanced safety in symbiotic Human-Robot Collaboration. Robot. Comput. Integr. Manuf. 2021, 70, 102137. [Google Scholar] [CrossRef]

- Ghadirzadeh, A.; Chen, X.; Yin, W.; Yi, Z.; Bjorkman, M.; Kragic, D. Human-Centered Collaborative Robots with Deep Reinforcement Learning. IEEE Robot. Autom. Lett. 2020, 6, 566–571. [Google Scholar] [CrossRef]

- Gomes, N.M.; Martins, F.N.; Lima, J.; Wörtche, H. Reinforcement Learning for Collaborative Robots Pick-and-Place Applications: A Case Study. Automation 2022, 3, 223–241. [Google Scholar] [CrossRef]

- Koo, S. Advanced Micro-Actuator/Robot Fabrication Using Ultrafast Laser Direct Writing and Its Remote Control. Appl. Sci. 2020, 10, 8563. [Google Scholar] [CrossRef]

- Lyu, C.; Li, P.; Wang, D.; Yang, S.; Lai, Y.; Sui, C. High-Speed Optical 3D Measurement Sensor for Industrial Application. IEEE Sens. J. 2021, 21, 11253–11261. [Google Scholar] [CrossRef]

- Galdelli, A.; Pagnotta, D.P.; Mancini, A.; Freddi, A.; Monteriu, A.; Frontoni, E. Empowered Optical Inspection by Using Robotic Manipulator in Industrial Applications. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 2006–2013. [Google Scholar]

- Nabil, M.; Mahfouz, D.M.; Shehata, O.M. Development and Evaluation of a Control Architecture for Human-Collaborative Robotic Manipulator in Industrial Application. In Proceedings of the 2022 14th International Conference on Computer and Automation Engineering (ICCAE), Brisbane, Australia, 25–27 March 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 38–43. [Google Scholar]

- Wu, J.; Wang, M.; Jiang, Y.; Yi, B.; Fan, R.; Liu, M. Simultaneous Hand–Eye/Robot–World/Camera–IMU Calibration. IEEE ASME Trans. Mechatron. 2022, 27, 2278–2289. [Google Scholar] [CrossRef]

- Pizoń, J.; Gola, A. Human–Machine Relationship—Perspective and Future Roadmap for Industry 5.0 Solutions. Machines 2023, 11, 203. [Google Scholar] [CrossRef]

- Lu, Y.; Xu, X.; Wang, L. Smart manufacturing process and system automation—A critical review of the standards and envisioned scenarios. J. Manuf. Syst. 2020, 56, 312–325. [Google Scholar] [CrossRef]

- Abdelsattar, A.; Park, E.J.; Marzouk, A. An OPC UA Client/Gateway-Based Digital Twin Architecture of a SCADA System with Embedded System Connections. In Proceedings of the 2022 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Sapporo, Japan, 11–15 July 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 798–803. [Google Scholar]

- Li, W.; Fan, Y.; Liu, W.; Xin, M.; Wang, H.; Jin, Q. A Self-Adaptive Process Mining Algorithm Based on Information Entropy to Deal with Uncertain Data. IEEE Access 2019, 7, 131681–131691. [Google Scholar] [CrossRef]

- Khorasani, M.; Loy, J.; Ghasemi, A.H.; Sharabian, E.; Leary, M.; Mirafzal, H.; Cochrane, P.; Rolfe, B.; Gibson, I. A Review of Industry 4.0 and Additive Manufacturing Synergy. Rapid Prototyp. J. 2022, 28, 1462–1475. [Google Scholar] [CrossRef]

- Massaro, A.; Selicato, S.; Miraglia, R.; Panarese, A.; Calicchio, A.; Galiano, A. Production Optimization Monitoring System Implementing Artificial Intelligence and Big Data. In Proceedings of the 2020 IEEE International Workshop on Metrology for Industry 4.0 & IoT., Roma, Italy, 3–5 June 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 570–575. [Google Scholar]

- Carlin, D.E.; Demchak, B.; Pratt, D.; Sage, E.; Ideker, T. Network Propagation in the Cytoscape Cyberinfrastructure. PLoS Comput. Biol. 2017, 13, e1005598. [Google Scholar] [CrossRef] [PubMed]

- Shannon, P.; Markiel, A.; Ozier, O.; Baliga, N.S.; Wang, J.T.; Ramage, D.; Amin, N.; Schwikowski, B.; Ideker, T. Cytoscape: A Software Environment for Integrated Models of Biomolecular Interaction Networks. Genome Res. 2003, 13, 2498–2504. [Google Scholar] [CrossRef] [PubMed]

- Otasek, D.; Morris, J.H.; Bouças, J.; Pico, A.R.; Demchak, B. Cytoscape Automation: Empowering Workflow-Based Network Analysis. Genome Biol. 2019, 20. [Google Scholar] [CrossRef] [PubMed]

- ISO/IEC 19510; Information technology—Object Management Group Business Process Model and Notation. 2013. Available online: https://www.iso.org/standard/62652.html (accessed on 7 March 2023).

- Fernandes, J.; Reis, J.; Melão, N.; Teixeira, L.; Amorim, M. The Role of Industry 4.0 and BPMN in the Arise of Condition-Based and Predictive Maintenance: A Case Study in the Automotive Industry. Appl. Sci. 2021, 11, 3438. [Google Scholar] [CrossRef]

- Zareen, S.; Akram, A.; Ahmad Khan, S. Security Requirements Engineering Framework with BPMN 2.0.2 Extension Model for Development of Information Systems. Appl. Sci. 2020, 10, 4981. [Google Scholar] [CrossRef]

- Draw.io. Available online: https://app.diagrams.net/ (accessed on 7 March 2023).

- Cytoscape. Available online: https://cytoscape.org/ (accessed on 7 March 2023).

| Optoelectronic Technologies | Topic | Description | Reference | Possible Implementation in Industry 5.0 Proposed in This Work |

|---|---|---|---|---|

| CMOS RGB photodetectors | High-temperature detection | Acquisition of a digital images representing the temperature field | [10] | Quality check of product surface at high temperature by scanning automatically very small regions (intelligent control). |

| Colorimetric gas detection | Accurate monitoring of the color change | [11] | Integration with other sensors detecting gas leakage in industrial environment. | |

| Inspection of camera defects | Automatic inspection system for color defect check in manufacturing process | [12] | Real time checking of defect line and color defect for array of cameras working for quality check (auto-changing of camera in cases of defective cameras) | |

| Nanotechnology | Silicon nanowires | Silicon nanowires read the percentage of resistance variation in the presence of gases (laser interaction) [13], and are able to detect different gases such as CO, C6H6, NO2, etc. [14,15] | [13,14,15] | Security in air quality control in research laboratories: integration of different technologies to detect all gases characterizing a prototype or a chemical processes. |

| Carbon-based nanocomposite flexible devices | Mechanical sensing and solar energy harvesting | [16,17] | High-sensitivity pressure sensors integrating simultaneously with solar energy harvesting generators. | |

| Polymeric nanocomposite liquid sensing | High sensitivity in detecting variation of the optical transmittivity response related to different liquids | [18] | Use of this typology of sensors to measure different percentages of contaminating liquids. | |

| Polymeric pressure sensors | High-sensitivity pressure sensors detecting soft pressure forces | [19,20,21] | Implementation of hard- and soft-pressure sensors obtained by changing the chemical composition of the nanocomposite material. Both soft- and hard-pressure force sensors can be implemented into a unique controlled system that addresses the calibration of forces. | |

| Optical nanocomposite sensors contacting surfaces | Sensors detecting small notches and shear forces | [22,23,24] | Implementation of intelligent AI algorithms classifying information about the morphology of defect discontinuity on products or in general on surfaces | |

| Optical nanocomposite sensors not contacting surfaces | 3D object morphology and color detection | [25] | Implementation of intelligent algorithms scanning the object to detect by means a specific sampling pattern depending on the object morphology, and possible integration with image vision techniques to extract other object features. | |

| Leakage and pollution sensors | Oil and gas leakage of from submerged structures | Estimation of the temperature of power lines. | [26,27,28] | Application of the proposed technology for production plants working with water or in liquids. |

| Optical sensor detecting water pollution | Light-Emitting Diode (LED) source measuring turbidity [29] or an optical fiber transmitting- and receiving-system for oil spill applications [30] | [29,30] | Simultaneous use of turbidity and liquid substance detection to extract features of complex liquid pollution (use of AI algorithm for extracting information). | |

| Exhaust gas optical detection | Exhaust gas detection performed by luminescence method (automotive sector) | [31] | Integration of the technology to automate quality control in engine production | |

| High voltage leakage currents | Current leakage in 500 kV transmission lines | [32,33] | Optimization of electrical networks powering big industries linked to renewable energy sources (smart grid network balancing operations). | |

| Pipeline leakage | Fibre Bragg Grating Sensor monitoring pipeline leakage by the wavelength shift due to a variation in liquid or gas flows [34]; gas flow detection [35,36]; liquid flow detection network systems [37,38] | [34,35,36,37,38] | Integration of different technologies (capacitive based, electromagnetic, infrared thermography, acoustic or visual) optimizing flow detection and decreasing the leakage detection error. | |

| Optoelectronic sensors in manufacturing | Trajectory distortion in laser cutting operations | Measurement of mirror’s inclinations with high resolution | [39] | Application of reverse engineering methods to optimize automatically the laser cutting operations. |

| Optical Sensors improving Industry 4.0 facilities | Fiberoptic sensing in Industry 4.0 | [40,41] | Integration of automatic actuation following fiber optic sensing; adopting self-adaptive manufacturing processes by means of AI data processing. | |

| Laser and vision techniques | Quality control of wood surfaces by using Laser TriangulationMethod (LTM) | [42] | Automation of waste of wood by simultaneously processing information of infected areas and of processing defects. | |

| Optical inspection in Electronics | Check for defects in electronic devices (wafer defects, solder defects, etc.) | [43] | Automatic opticalinspection systems based on an image vision AI algorithm that classifies defects in electronic manufacturing. | |

| Acusto-OptoFluidic (AOF) system | Laser Direct-Writing (LDW) approach in additive manufacturing | [44] | Additive manufacturing control and actuation managed in real time by a powerful algorithm adjusting step-by-step precision and laser machine parameters (power, pulse signal delay, fluency, etc.) |

| Electronic and Mechatronic Technologies | Topic | Description | Reference | Possible Implementation in Industry 5.0 Proposed in This Work |

|---|---|---|---|---|

| Optomechatronic Systems | High-resolution lighting and optical models | Increase of image quality | [45,46,47,48] | Combination of more procedures and models addressing the optimization of the optomechatronic systems. |

| Printed Electronics (PE) | PE Sensors | Definition of smart active object; adding a data processing unit | [49] | PE-integrated circuit in actuation boards. |

| Flexible electronics | Adoption of stretchable electronic circuits suitable for harsh environments | [50] | Combination and simultaneous processing of data acquired from different production environments to find correlations that optimize quality. | |

| Pressure sensors on flexible substrate | Piezoresistive pressure sensors printed on a polymeric substrate | [51,52] | Adoption of the same flexible substrate for the integration of other printable circuits | |

| Electronic gas sensors | MOSFET-based gas sensors | Detection of CO and NOx gases | [53] | Reduction of gas emissions of by industrial plants by activating an automatic alerting system (sustainable production plants). |

| Gas sensor | Fabrication of quantum cascade laser-based photoacoustic (QCL-PA) detectors, Gold Nanoparticle-based Field-Effect Transistor (Au-NP-FET), and III-V semiconductor-based circuits, detecting NOx gases | [54] | Integration of different technologies based on the specific sensitivity of gas detection. | |

| Sensors systems and networks | Multiple pressure sensors monitoring fluid networks | Network monitoring system connected to SCADA units (pressure sensors monitoring water leakage); | [55] | Prediction of fluid leakage by means of AI algorithms (classification of the signals detected from different parts of the monitoring network). |

| Sensors monitoring railway infrastructures | Multiple sensors detecting temperature or mechanical anomalies of the infrastructure | [56,57] | Use of AI diagnostic algorithms to predict risks. | |

| Wireless sensor network | Wireless sensor network for assembly process monitoring and for process management. | [58] | Process mining addressing assembling processes enabled by AI decision-making engine. | |

| Smart sensor system monitoring production lines | Smart factory integrating temperature, pressure, position, force, gas, color, light, flow, nuclear, micro- (MEMS), and nano- (NEMS) sensors | [59,60] | Data processing to find correlations between more signals to build production fault prediction. | |

| Sensors in production processes | Roasting process | Temperature [61] and Near-Infrared Spectroscopy (NIRS) [62] to check food quality in roasting processes | [61,62] | Auto-calibration of temperatures ensuring a uniform roasting process (production lines made up of different ovens). |

| Agriculture 4.0 | Precision agriculture combining different technologies such as multispectral imaging, infrared thermography, and Unmanned Aerial Vehicles (UAV) | [63,64,65] | Implementation of Decision Support Systems (DSS) based on data fusion and local management of agriculture. | |

| Drilling process | Switch-activated and sensor-triggered proximity sensors detecting the arrival of the workpiece [66], and image processing [67] | [66,67] | Improvement of a reconfigurable manufacturing process by means of AI algorithms | |

| Food processing | X-rays for the detection of unknown elements in food products, thermal imaging (temperature and humidity check), volumetric sensors (check of raw materials in silos), NIR spectrometry (controlling moisture), image processing | [68] | Feedback control applied to an adaptive framework based on an AI engine optimizing the whole supply chain | |

| Hole machining process | Drilling, broaching, countersinking, and horning processes controlled by sensors detecting cutting forces, vibration, current/power, acoustic emission and temperature; and other tools such as microscopes, laser scanners, surface roughness testers, dynamometers, scanning galvanometers, profilometers, and internal micrometers | [69] | AI prediction of hole defects adjusting in real time machine parameters; predictive maintenance of machines | |

| Cutting Process | Strain gauge measuring cutting forces, cutting power | [70,71] | Auto-adaptive control predicting tool wear and tool breakage |

| Detection Algorithms/Models | Topic | Description | Reference | Possible Implementation of Processes in Industry 5.0 Frameworks (Proposed in This Work) |

|---|---|---|---|---|

| Leakage detection | Pipeline leakage detection (liquids, gases or solids suspended in a liquid) | Laguerre fuzzy proportional-integral-derivative (PID)observation system | [72] | Automated processes enabling pipeline repair interventions. |

| Natural gas leakage images | Thermal readings and images analyzed by machine learning algorithms | [73,74] | Alerting security processes enabled by AI algorithms. | |

| Gas leakages data | Spatial and temporal neural network model | [75] | Alerting security processes enabled by AI algorithms. | |

| Gas leakage images | Visual background extractor algorithm applied to mid-infrared. | [76] | Alerting security processes enabled by image vision algorithms. | |

| Water leakage | Data processing algorithms extracting information from infrared thermography and Ground Penetrating Radar (GPR) images | [77] | Data fusion processed could extract secure information about water leakage. | |

| Water/fluid leakage | Pressure data detected in whole water network | [78] | Data processing of correlations between all the measurements acquired along the whole water network (with application to a generic fluid network). | |

| Water/liquid leakage | Computational Fluid Dynamics (CFD) model | [79] | CFD simulations are included into reverse engineering processes to optimize production of pipeline network parts. | |

| Water/fluid leakage | Denoising method | [80] | Optimization process for algorithms detecting leakage. | |

| Water/fluid leakage | Genetic algorithm modelling leak nodes of the water network | [81] | Automatic data processing optimization that simultaneously considers all information extracted from all network nodes. | |

| Industry 4.0 | Data-driven manufacturing | Machine learning algorithms | [82,83,84] | Auto-calibration of machines and manufacturing processes. |

| Integration of technologies | Digital twin approach: product, asset, system, process twins | [85,86,87] | Creation of front-end Human Machine Interfaces (HMI) supporting hardware and software integration and ensuring data collection in big data systems. | |

| Algorithms processing data at different steps of levels | Pre-processing, descriptive analytics, predictive analytics and prescriptive analytics | [88] | Implementation of multi-level data processing systems managed by AI decision-making processes. | |

| Quality | Machine learning quality prediction and anomaly detection | [89] | Implementation of automated quality procedures with the goal of avoiding production failures and performing automated preventive intervention. | |

| Smart Manufacturing | Deep reinforcement learning approaches | [90] | Integration of different algorithms learning approaches for optimizing machine learning data processing. | |

| Machine failure | CNN-LSTM forecasting models | [91] | Implementation of automated predictive maintenance procedures. | |

| Defect classification | Discrete Fourier Transform (DFT), K-Means clustering and Long Short-Term Memory (LSTM) classifying tire defects | [92] | Algorithm fusion for improving defect detection. | |

| Defect mapping and prediction | p-charts mapping defect trends and Artificial Neural Network (ANN) predicting defects | [93,94,95,96] | Integration of traditional processes for mapping and controlling defects with AI algorithms. | |

| Energy and production | Digital Twin | Machine learning detecting anomalies [97], and predicting a system’s dynamic behavior with data-driven methods [98] | [97,98] | Improvement of flexible and auto-adaptive powerplant optimization, ensuring high product quality. |

| Quantum computing | Renewable energy and energy source management by quantum computing approaches | [99,100,101] | Large-scale energy-balancing approach optimizing energy for production districts. | |

| Smart energy systems and Key Performance Indicators | Long Short-Term Memory (LSTM) [102] and Artificial Neural Network (ANN) energy forecasting [103] | [102,103] | Simulations of complex energy systems (theory of complex systems) based on AI energy-forecasting to optimize energy in production plants and buildings. |

| Raw Material Management Models, Process Mining and Control & Actuation Improvements | Topic | Description | Reference | Possible Improvements of Processes in Industry 5.0 Frameworks (Proposed in This Work) |

|---|---|---|---|---|

| Raw materials check and management | Quality check of raw wood pellet materials | Fourier Transform InfraRed (ATR-FTIR) spectroscopy applied to the analysis of chemical composition of wood pellets | [104] | Automated processes for managing raw materials and product quality assessment. |

| Raw materials in pharmaceutics | Use of technology such as Near-Infrared (NIR) spectroscopy and fiberoptic probes for quality control | [105] | Data fusion techniques and AI algorithms to process optical signals. | |

| Raw material check in food industry | Temperature and humidity check | [106] | Continuous process monitoring of raw materials in all the phases of the supply chain by enabling automated waste. | |

| Optoelectronic sensor checking linear density of raw materials | Checking of linear density of cotton | [107] | Fast and accurate quality processes applied to raw materials. | |

| Estimation of the quality level of raw materials | Application of the Six Sigma methodology | [108] | Integration of traditional management processes with AI decision-making engines. | |

| Management and reduction of stone waste | Finding of technologies for reducing waste | [109] | Implementation of automatic sustainable processes based on waste control and reuse. | |

| Mathematical model controlling raw material releasing | Control of quality levels in manufacturing | [110] | Ideation of new algorithms as alternatives to AI ones to control raw materials in the whole supply chain. | |

| Raw materials management | Process management of raw materials | [111] | Process mining applied to raw materials. | |

| Processes mining | Quality prediction | Machine learning algorithms applied to quality processes | [112,113] | Auto-calibration of quality processes by means of AI quality predictions. |

| Decision Support Systems (DSSs) enabling process mining | Automated improvement of processes concerning product quality, worker security, and machine parameter setting | [114,115] | Production, security, quality and organizational processes enabled automatically by AI algorithms. | |

| Predictive maintenance process | Automated predictive maintenance by machine learning matched with Industry 4.0 technologies | [116,117] | Predictive maintenance procedures enable automatic interventions, which completely avoids the risk of machine failure. | |

| Data quality | Internet of Things (IoT), data processing and methods to correct errors | [118] | Implementation of data pre-processing algorithms automatically cleaning the production dataset by ensuring good performance of the AI training models (use of big data systems). | |

| Process mining manufacturing | Process mining focused on advanced business models | [119,120,121] | Dynamic adaptation of production to customer needs and markets in real time. | |

| Industry control | Model to extract information for detection of anomalies [122] and alarms [122,123] | [122,123] | Integrated alarm systems applied for different types of alarms and worked into a multi-level risk-alerting system. | |

| Control and actuation improving production, quality and safety | Realtime control of fluid flow process | Tomography technique analyzing distribution of phases | [124] | Integration of tomography technique into a sensor network (finding correlations between different parameters). |

| Inline quality control | Deep learning applied to a porosity check of polymers | [125] | Inline automated systems could check quality and synchronize successive machines (actuators are synchronized with all machines of the production line). | |

| Quality control in diary industry | Infrared spectroscopy improving quality control | [126] | Integration of the tomography technique into a sensor network. (Finding correlations between different parameters). | |

| Image vision in quality control | Imaging techniques in industry | [127] | Integration of image vision techniques into a sensor network (finding correlations between different parameters). | |

| Additive manufacturing | Control of laser parameters [128], three-staged control approach [129], and quality control in metal processing [130] | [128,129,130] | Control and actuation processes driven by AI. | |

| Fault-tolerant control in manufacturing | Recurrent neural network-driven control reconfiguration | [131] | Reconfiguration of the whole supply line according to the data processing of all working robots and machines. | |

| Mechatronics in reconfigurable production systems | Actuation in manipulation, assembly and packaging processes | [132] | Reconfiguration of the whole supply line according to the data processing of all working robots and machines. |

| Advanced Robotic Industrial Platform Facilities | Topic | Description | Reference | Possible Improvements of Processes in Industry 5.0 Frameworks (Proposed in This Work) |

|---|---|---|---|---|

| Robotics | Soft robotics in automated food handling | Sensors improving gripper processing | [133] | Robot data read by sensors could be used to synchronized production-line velocity and machine parameters. |

| Industrial robot agents | Reinforcement learning of robot | [134] | Improvement of reinforcement learning as an approach to optimizing the self-adaptive processes of robots | |

| Robot trajectory tracking | Neural networks improving control | [135] | Self-adaptive robot control systems could adjust real time trajectories. | |

| Collaborative robot (Cobot) | Artificial Intelligence applied in industrial Cobots | [136,137,138,139,140] | AI edge computing approaches optimized by quantum computers could optimize the Cobot’s processes. | |

| 3D writing robotic systems | Two-photon polymerization (TPP) process | [141] | Integration of innovative laser techniques in precision manufacturing. | |

| Optical sensors implementable in robotics | 3D measurement approach [142] and optical inspection [143] | [142,143] | Complex operation in the 3D space improved by multiple optical sensor 3D systems (high-precision manipulation). | |

| Advanced platforms | Robotic manipulator | Motion tracking algorithms and dynamic models [144], and calibration systems [145] | [144,145] | Intelligent manipulations by AI control. |

| From Industry 4.0 to Industry 5.0 scenario | Improvement of human-machine relationships | [146] | Reconfiguration of HMI according to specific processing programs. | |

| Personalized production | Manufacturing of a personalized product | [147] | The possibility of personalizing the product according to real-time market needs, customer segmentation, and sales predictions. | |

| Digital twin platform architecture | Digital twin platform connecting sensors and actuators with a Supervisory Control and Data Acquisition (SCADA) system | [148] | Digital twin model assisting and optimizing the production. | |

| Data quality | Adaptive algorithm removing uncertain data | [149] | Automatic selection of data processing optimizers (optimization of AI choice and of related hyper-parameters based on the cleaned dataset). | |

| Additive manufacturing platform | Integration of data driven approaches | [150] | Implementation of a precise feedback system automatically optimizing the additive manufacturing process by fast data processing engines. | |

| Information infrastructure | Enterprise Service Bus (ESB) system interfacing different information systems including big data | [151] | Integration of edge computing approaches to accelerate partial data processing. |

| Parameter | Value |

|---|---|

| Number of nodes | 28 |

| Number of edges | 51 |

| Avg. number of neighbors | 3.643 |

| Network diameter | 5 |

| Network radius | 3 |

| Characteristic path length | 2.370 |

| Clustering coefficient | 0.215 |

| Network density | 0.135 |

| Network heterogeneity | 0.645 |

| Network centralization | 0.413 |

| Analysis time t (s) | 0.038 |

| Limitations | Perspectives |

|---|---|

| Use of a unique informatics infrastructure integrating all data protocols (different technologies use different protocols and infrastructures). | Design of ESB-based information networks integrating all data protocols and managing synchronization. |

| Synchronization of all robots and machines (the different sampling times of sensors could generate problems around the efficiency of synchronization of all robots and machines of a production line). | Development of codes managing the sampling time and time machines according to sensor technologies and production velocity. |

| Computational cost for real-time data processing (a large number of sensors provide a big quantity of data to be processed at the same time, thus incurring a high computational cost). | Cloud computing could be inappropriate for the real time data processing and big data analytics, but an edge computing approach could be a good alternative. |

| The gap between the velocities of production machines and high-velocity optical system detecting data. | Production machines that integrate all opto-electronic systems (fully optical sensing and actuation systems). |

| Efficiency of quantum computing (standalone qubit processor could be not appropriate for the data processing of industrial datasets). | Combined use of AI algorithms executed by edge computing methods and a quantum computer optimizing AI hyperparameters. |

| Application Fields | Device Typology | Industry 5.0 Framework |

|---|---|---|

| Telemedicine | Platform based on software enabling communication between doctors and patients | The telemedicine platform integrates different datasets performing data fusion operations, improving the homecare process. |

| Medical diagnostics | Wearable systems and medical images for diagnostics | An AI-based Point of Care (POC) platform computes different variables to provide a diagnosis with a low probabilistic error (high accuracy and precision). |

| Biomedicine | Molecular microscope | Systems of microscopes linked to provide in new pharmacological solutions in short times (precision medicine). |

| Nanomedicine | Biocompatible nanoparticles | Adoption of innovative automated tools focused on the execution of measurements in nanomedicine. |

| Smart Cities | Sensors detecting electrical power and environmental pollution | Integrated sensor complex systems automatically enable public management procedures. |

| Telecommunications | Wireless systems | A reconfigurable wireless network improves transmission security between different nodes (AI-based algorithms define network configuration). |

| Industrial Measurements Protocols | Industrial IoT devices | Adoption of innovative automated tools focused on the execution of measurements of production quality using AI automation. |

| Nanoelectronics | Smart circuits | Arrays of driven microcircuits providing punctual data on a micrometer scale (very accurate measurements). |

| Automotive | Sensors improving driving security | An AI system linked to the car motion control improves security. |

| Agriculture | Field sensors detecting hydric stress | Data fusion of spectral data and field data automate fertigation processes. |

| High Tech Manufacturing | Optical and laser-based devices | Production lines controlled by a unique platform which synchronizes production machines (see example in Section 5.1). |

| Renewable energy | Sensors reading electric power | An AI-based network that correctly balances the energy in grid connections. |

| Industrial Robotics | Sensors enabling control and actuation | AI-supervised and -unsupervised algorithms could improve robotic control and synchronization. |

| Logistics (services) | GPS sensors | AI based platform predicts fleet maintenance and security by optimizing logistics services (efficiency in transportation times, decrease of fuel consumption, flux optimization based on predictions, etc.). |

| Learning | E-learning platforms | AI based E-learning platform automatically optimizes the learning process. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Massaro, A. Advanced Electronic and Optoelectronic Sensors, Applications, Modelling and Industry 5.0 Perspectives. Appl. Sci. 2023, 13, 4582. https://doi.org/10.3390/app13074582

Massaro A. Advanced Electronic and Optoelectronic Sensors, Applications, Modelling and Industry 5.0 Perspectives. Applied Sciences. 2023; 13(7):4582. https://doi.org/10.3390/app13074582

Chicago/Turabian StyleMassaro, Alessandro. 2023. "Advanced Electronic and Optoelectronic Sensors, Applications, Modelling and Industry 5.0 Perspectives" Applied Sciences 13, no. 7: 4582. https://doi.org/10.3390/app13074582

APA StyleMassaro, A. (2023). Advanced Electronic and Optoelectronic Sensors, Applications, Modelling and Industry 5.0 Perspectives. Applied Sciences, 13(7), 4582. https://doi.org/10.3390/app13074582