1. Introduction

The increasing number of people, industrial production and development require more and more energy resources. Electricity is the most common type of energy used by both ordinary consumers and industries. Various resources are used to obtain electricity: fossil fuels such as oil products and gas; nuclear fuel and renewable energy sources (solar energy, wind energy, green hydrogen, etc.) [

1,

2,

3]. According to the directives of the European Union, until 2035, the production of cars with internal combustion engines will have to be completely stopped, and only cars with electric motors will be used. Hence, the demand for electricity will only increase over time [

4,

5,

6]. As the demand for electricity grows, reliable energy storage systems will become increasingly necessary. Since renewable energy often depends on weather and climate conditions, which are not stable, for this reason, power peaks appear in the general electricity transmission and distribution network, which need to be compensated. Various electrical energy storage systems consisting of high-capacity (200 MWh and more) Li–ion-based batteries are increasingly being used to level up the power imbalances. An increasing number of households are installing solar power plants, which not only supply electricity to the general distribution network but also charge electricity storage systems installed in residential houses or other private objects [

7,

8,

9,

10]. When using off-grid-type solar power plants, it is necessary to use an electrical energy storage system, which is usually made using Li–ion batteries or batteries made on the basis of lead acid. The number of life cycles of lithium–ion batteries, depending on the production technology, can reach from 2000 to 10,000 life cycles. Meanwhile, the number of life cycles of lead acid batteries is about 500–750, depending on the type of lead acid battery (deep cycle, AGM or GEL) [

11,

12,

13,

14]. Lead acid batteries have certain advantages: low cost, easy maintenance, low fire hazard, etc. [

15,

16,

17,

18]. Lead acid batteries are widely used in electrical energy storage systems, power surge smoothing systems, backup power supplies, etc. [

19,

20,

21,

22,

23]. In various power support and backup power systems, lead acid batteries are easily replaceable with new ones. In this way, money is saved, and there is no need to buy all the equipment of the power support system [

24,

25,

26]. In renewable energy systems, battery charging is uneven and chaotic. When using lead acid batteries, it is important to maintain the limits of the charging current mode of 0.1–0.3 C, because if these conditions are not met, the batteries wear out and degrade much faster. In renewable source systems, charging conditions are ensured in automatic mode using charging controllers, which are usually PWM or MPPT (maximum power point tracking) [

27,

28,

29,

30]. When using batteries in systems of renewable energy sources, it is important to monitor the amount of charging cycles and the charging level. Based on these data, the battery life can be predicted [

1,

3,

4]. There are many developed battery performance monitoring systems, but most of them usually only monitor the charge–discharge level in certain systems (such as energy storage systems, backup power systems, etc.) [

5].

After an analysis of the literature, it became clear that most of the monitoring systems of the working parameters of the batteries are of a narrow purpose (e.g., for monitoring the battery charge level). Meanwhile, monitoring systems intended not only for determining the battery charge level but also for monitoring wear and tear, the number of charge–discharge cycles and systems with advanced capabilities, which are little studied. In other words, the battery parameter monitoring systems proposed in the literature lack universality.

Taking this gap into account, the goal of the study was formulated to create an electronic monitoring system for the battery operating parameters to assess the amount of life cycles, charge level, capacity change and other parameters.

3. The Results and Discussion

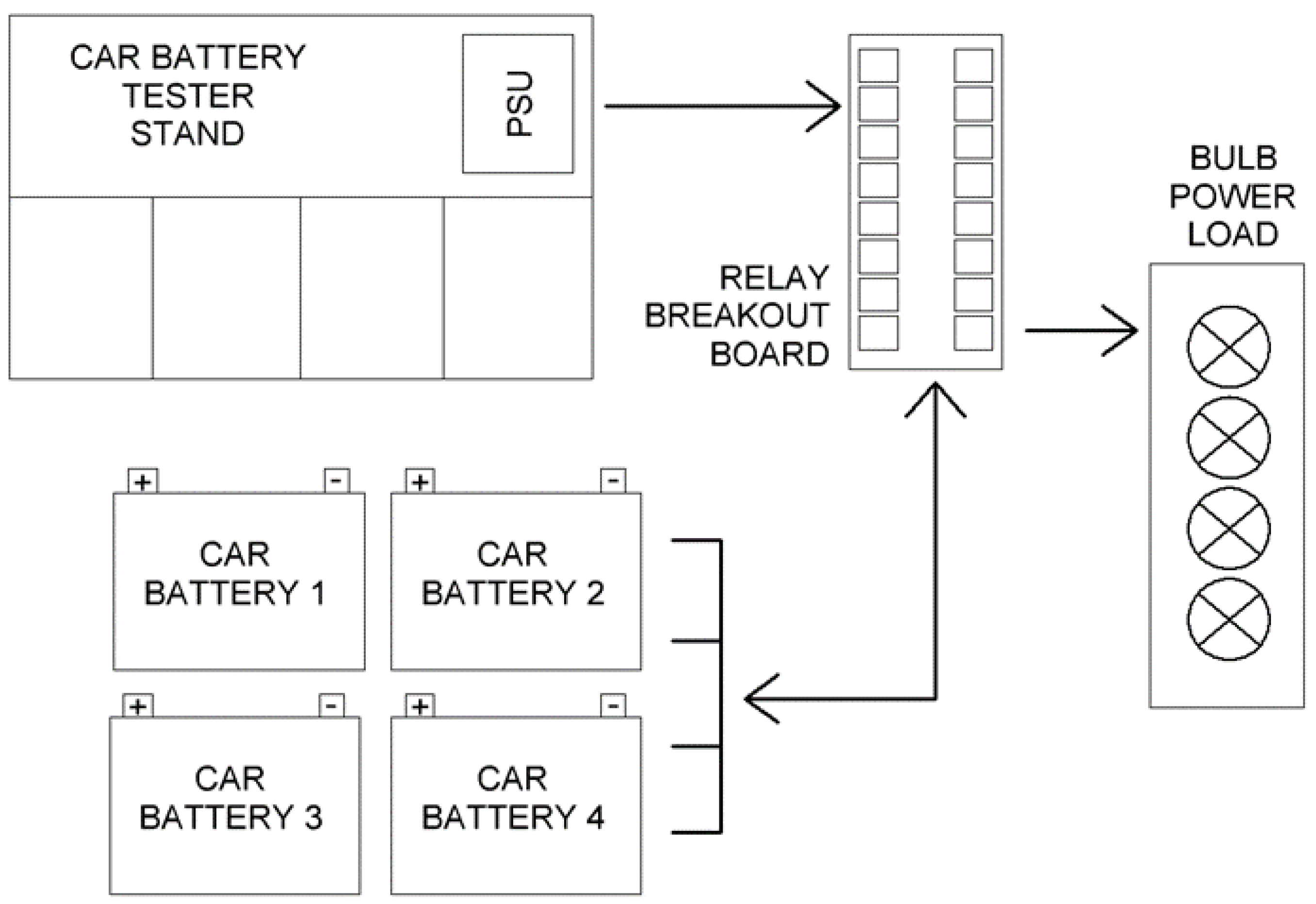

The prototype battery life cycle research and monitoring system consists of a main board and individual blocks for monitoring of the battery characteristics. The full conceptual diagram of the smart battery life cycle research and monitoring system is presented in

Figure 2. The research and measurement system consists of a main block (UPPER PCB BOARD) consisting of a control module, a communication module, information screens, voltage and current converters, measurement modules and power sources. The other part of the system consists of four separate small blocks for monitoring and measuring the electrical characteristics of different types of batteries. Hence, four batteries can be explored simultaneously using this system for set desired operating modes. These modules consist of separate control modules, RS 485 modules for communication, an information display and a module for measuring the electrical characteristics. All data are transmitted to the central computer using RS 485 communication and analyzed.

System control is ensured by the ATmega328 microcontroller. Meanwhile, in order to evaluate whether the system is working successfully, OLED-based screens are used to display the instantaneous characteristics of the working mode [

17]. The electrical diagram of the battery life cycle monitoring system is presented in

Figure 3.

This system controls the charging/discharging processes of the batteries using a relay block, which are labeled from REL1 to REL8 in

Figure 3. In the meantime, the electrical characteristics of the batteries are also measured, according to which, the charge–discharge cycles of the batteries are later graphically displayed. The previously mentioned RS485 communication is used for receiving data packets formed by the microcontroller. Using this system, four batteries can be studied at the same time. For the research process, four separate channels were designed and manufactured.

Separate channels were used for the measurements of battery charging/discharging and electrical characteristics. The conceptual electrical diagram of one such channel is presented in

Figure 4. The battery is charged using a 230 V AC power source, which gives a 24 V DC voltage at the output. A 24 V DC to 13.6 V DC converter was used to obtain the correct charging voltage for the battery. A load module was used for the battery discharge process. Meanwhile, relays were used to start and finish the charge and discharge process, and digital measuring modules were used to measure the electrical characteristics. The batteries were charged using an 8 A direct current while discharged with an 8 A current through the load module.

The electrical diagram for measuring of the electrical characteristics of one battery is presented in

Figure 5. The circuit for measuring the electrical characteristics consists of pressed contacts to which the ends of the cable are attached. The main part of this subsystem is the electrical characteristics measurement module that performs level measurements of the battery charge and charge cycles and transmits the data to the microcontroller.

As mentioned earlier, the battery monitoring and testing system is fully automatic, the operation of which is ensured by a microcontroller. The program code for the microcontroller was written using the C programming language, and the scheme characterizing the algorithm scenario of the program is presented in

Figure 6.

The program running on the microcontroller is started by the Start program command. During the next step, the battery voltage levels are measured. The charging mode is determined according to the voltage values. During the next step, the relay block activates or deactivates the charging or discharging modes. Later, the electric current is measured. After performing the necessary measurements, a data packet is formed and transmitted to the central computer. Subsequently, the following process is performed related to battery discharge: the relay unit switches the battery terminals to the discharge mode through the load. The electrical values are measured, and a data packet is formed and transmitted to the central computer. The last stage is data storage and processing.

To ensure the data transmission, RS485 modules connected by a twisted pair of wires were used. The conceptual diagram of data packet transmission is shown in

Figure 7. The received data is stored in the memory of the central computer. Using this method, the communication between system nodes is also ensured, and the necessary commands are sent according to the algorithm script.

In order to realize the battery research and parameter monitoring system and to make its prototype, printed circuit boards were designed, the general view of which is presented in

Figure 8.

The printed circuit board tracks are made of a copper layer. In addition to the microcontroller, the printed circuit board has designed spaces for active SMD elements such as capacitors, diodes, etc. In order to obtain a PCB with the smallest possible dimensions, the optimization of the PCB design was carried out, allowing to reduce the number of tracks and make them as short as possible. A special dialectic layer is used to protect PCB active tracks from environmental influences, which is characterized by protection from both environmental factors and mechanical track damage. Main parts, such as microcontrollers, data transfer modules, power supplies, etc., were installed on the printed circuit board. Modules for measuring the electrical parameters of the batteries were also installed.

The general view of the manufactured system is presented in

Figure 9. Aluminum profiles and quick fastening parts were used to assemble the individual parts of the system into one common stand. Some of the plastic parts for mounting were obtained using a 3D printer. The measuring stand itself is compact and can be easily transported from one place to another if needed.

A computer application running on the Win 10 operating system was created for the process of battery monitoring, analysis and display of the working characteristics and data storage. This application is able to receive data, evaluate them, save them in the database and inform the system operator about the progress of the process and possible and existing deviations from the norms. Both the monitoring system itself and the application can operate in the fully automatic mode for a long time without additional operator intervention. The computer application was developed using the programming language Delphi. Meanwhile, the algorithm of the application software code is presented in

Figure 10.

As it can be seen from the algorithm script that the application program starts with the Start PC command. Next, whether the data and command package are received from the battery research and monitoring system stand is checked. If the data has been received successfully, the received package is analyzed and stored in the database. The main parameters obtained after receiving and storing the data package are displayed on the screen. In the last stage, the evaluation of the data and the process is carried out programmatically according to the experimental conditions set in advance. If the application notices certain deviations from the norm, a message and suggestions to enter certain corrections are displayed for the operator on the screen.

In the case of the working mode of the monitoring and research system, the general picture that the system operator can see is presented in

Figure 11. In this case, if the process is proceeding properly and there are no deviations from the experimental conditions, the screen simply shows the currents and voltages of each charging or discharging battery. In order to change or stop the research process in the application, the operator has to perform certain actions using the system settings. The developed application is smart and able to independently evaluate the data received from the stand, and in the case of deviations, the reason for their occurrence is shown. At the same time, in the case of deviations from the norm (such as exceeding the number of battery life cycles, etc.), the computer application is able to offer the operator possible scenarios for solving the problem.

The charging and discharging modes of the batteries are determined using a certain software subsystem in the application, the general view of which is presented in

Figure 12. Using this digital tool, the system operator can enter the parameters of the experiment. In this way, it is possible to change the battery charging voltage and current, depending on the type of batteries and recommendations of manufacturers. After completing the settings, the planned experiment and data monitoring process begins.

After creating a prototype system for the research and analysis of the working parameters of batteries, various types of lead-based batteries were tested. A 12 V voltage and 40 Ah batteries were chosen for the research. Four types of batteries were studied: (1) shallow cycle batteries, (2) deep cycle batteries, (3) AGM-type batteries and (4) GEL-type batteries. The dependence of the charging voltage on the charge level is presented in

Figure 13.

The batteries were charged in the voltage range of 11.9–12.7 V using a DC source. The battery charging mode was selected using 0.2 C (which corresponds to a charging current of 8 A). Usually, the manufacturer recommends using a charge mode in the range of 0.1–0.3 C in order to keep the battery intact [

1,

5]. As we can see from the results, the charging curves of all the analyzed types of batteries coincide within the limits of measurement error. This meant that the battery charging speed does not depend on the type of battery in this case. The fastest charging was observed up to 80% of the charge level. Between 80 and 100%, the charging speed of the batteries slowed down a bit.

During the testing of the developed battery research system, the level of battery degradation was also evaluated. The level of battery degradation was assessed by measuring the dependence of the battery capacity on the number of life cycles. It is worth noting that the life cycle is considered the process when, according to the manufacturer’s recommendations, the battery is fully charged and discharged. The dependence of the battery capacity on the number of life cycles is presented in

Figure 14. In this case, the shallow cycle batteries were not examined, because they are not suitable for a deep multicycle charge/discharge process.

Examining the results, it was found that deep cycle batteries with liquid electrolytes are the most likely to degrade faster. As it can be seen from the results, this type of battery can withstand about 500 charge/discharge cycles. Later, their capacity drops down to 4 Ah. AGM-type batteries which electrolytes are made on the basis of glass fibers serve approximately 600 charge/discharge cycles when the capacity decreases to 5 Ah. Meanwhile, GEL-type batteries (batteries which electrolytes resemble jelly) withstand about 700–750 charge–discharge cycles. The battery tests were performed at a room temperature of 20 °C. During the tests, the system worked in the fully automatic mode when four batteries were tested simultaneously. Analyzing the system work and the obtained research results, no significant deviations from the given experimental conditions were observed.

When using electricity storage systems made up of batteries, it is important to predict the service life of the batteries.

Figure 15 shows the dependence of the predicted service life of batteries on the length of the charge–discharge cycle. In this case, the expected lifetime of deep cycle, AGM- and GEL-type batteries is analyzed, and their lifetime is analyzed when the charge–discharge cycle is full. The batteries are charged and discharged at 0.3 C. As we can see, GEL-type batteries have the longest expected service life, which is about 11,000 h. However, it is worth noting that, when using the battery throughout its life, its capacity may decrease to a minimum, which may not be sufficient to ensure the supply of electric current to the powered system (e.g., household electrical appliances, etc.). In order for the electricity storage system to function reliably, it is recommended to use the batteries for half of their predicted service life.

Various types of lead acid batteries were chosen for testing the system, but in virtual applications of use, it is possible to choose other types of batteries, such as Li–ion, Ni-MH, etc. The system software provides protection, because the user must select a specific battery type before testing the batteries. In this way, battery protection is ensured due to an improper charge–discharge voltage. The system application provides an opportunity to explore an unknown type of battery (e.g., newly developed in the laboratory) by selecting the necessary conditions. The system can be equipped together with renewable electricity sources when the charging–discharging process is chaotic. During the testing, it was not noticed that the system was influenced by extraneous factors.