Abstract

Hemp inflorescences from byproducts have been proposed as an addition to gluten-free rice bread. The scope of the research was to bake a control loaf of bread as well as bread loaves containing 1%, 2%, 3%, 4%, and 5% dried and crushed hemp inflorescence (HI). The loaves of bread were evaluated in terms of their physical and sensory properties, polyphenol and flavonoid contents, and DPPH and FRAP antioxidant activities. The study’s findings revealed that the addition of HI influenced changes in the physical properties of the bread loaves, such as increased specific volume, decreased bread hardness, increased elasticity, and chewiness of the breadcrumb, especially when the additive concentrations were greater than 3%. The addition of HI significantly increased the total amount of polyphenols, flavonoids, and antioxidant activity in the bread. The sensory evaluation revealed that gluten-free bread can be produced with a maximum of 2% HI without affecting its taste and aroma.

1. Introduction

Hemp (Cannabis sativa L.), belonging to the Cannabaceae family, is one of the world’s oldest cultivated plants. It is used for textiles, medicinal purposes, food [1,2,3,4,5,6], and for fodder purposes [7,8]. As a byproduct of hemp harvesting, hemp inflorescences are used to make niche products for the cosmetics, pharmaceutical, nutraceutical, and environmentally friendly insecticide industries [9,10]. Hemp metabolites include flavonoids, fatty acids, terpenes, amino acids, terpenophenols, and sugars, which are abundant in inflorescences, and they are gaining popularity [11]. As a result, hemp inflorescences have been identified as a potentially novel food that requires further investigation [12].

Cannabis sativa L., also known as Cannabis sativa var. spontanea, contains few psychoactive cannabinoids and is a good source of terpenoids and polyphenols, including flavonoids, as well as phenolic acids, phenolic amides, and lignoamides with significant health benefits [13,14,15]. The inflorescences of industrial hemp varieties, such as Kompolti (grown, among other things, in the Italian Alps), are particularly high in cannabidiolic acid (CBDA), which decarboxylates spontaneously to cannabidiol (CBD) under favorable environmental conditions [16].

Numerous aromatic compounds are found in cannabis inflorescences, including pinene, pinene, myrcene, terpinolene, caryophyllene, humulene, and caryophyllene. Hemp has a pleasant aroma due to the presence of volatile compounds such as terpenes, aliphatic compounds, and phenylpropanoids/benzenoids, which justifies the use of these hemp-derived aromatic compounds in the food and cosmetics industries, such as the production of essential oils as natural flavor and fragrance additives [17,18].

There are many compounds in cannabis that include terpenoids, sugars, alkaloids, stilbenoids, quinones, and cannabinoids. Due to the presence of bioactive compounds such as terpenes and cannabidiol, hemp (Cannabis sativa L.) has become widely used in a variety of industries [19]. The term “cannabinoid” refers to hemp-derived terpenophenols.

Hemp has the nutritional potential to be used in the food industry as well. It is used in the baking industry, for example, in the production of bread. Bread has previously included hemp flour, hemp protein concentrates, or hemp pomace. The addition of these raw hemp materials to bread improves its antioxidant properties (e.g., by increasing the content of polyphenols), protein content [20,21,22,23], as well as its increase its mineral content.

According to Bădărău et al. [24], the most suitable raw hemp materials for use in bread processing are 15% hemp flour, 4% hemp seed, and 8% hemp oil, all of which can be added to the dough. Aside from improving bread’s nutritional value, the benefits of using hemp products (particularly variants with 15% and 25% hemp flour) as the second auxiliary ingredient in bread include rinsing out the volume of the bread, improving the structure of the crumb and increasing the bread’s durability, providing an interesting crumb color due to the content of natural sugars, and increasing the bread’s organic acids. Furthermore, the addition of 15% hemp products has the greatest effect on the characteristics of the dough by improving the crumb quality (porosity and elasticity). As a result, the addition of hemp products can be used in baking to produce unique and highly demanded bread products.

Other research has shown that up to 10% hemp flour can be used in wheat bread [21], although too much hemp flour contributes to a decrease in the organoleptic evaluation of the bread. Furthermore, the addition of hemp flour changes the color of the crumb by raising its browning index [20]. Several studies have shown that bread with the addition of 5%, 10%, 15%, and 20% hemp flour has better nutritional properties compared to wheat bread, but the best texture was characterized by the addition of 5% hemp flour [25]. Hemp and hemp seed cakes were also tested as an addition to wheat bread. The results suggested that the addition of these hemp by-products in a proportion greater than 1% caused unfavorable changes in the quality of the bread [26].

Gluten-free bread, as a healthy alternative to wheat bread, may also include hemp flour and hemp protein concentrate, which are natural nutritional and structure-forming gluten-free bread ingredients. Hemp flour was used to make sourdough, and it was tested as an addition to gluten-free bread. The bread’s staining was reduced by using hemp sourdough. Hemp flour has improved the acceptability of gluten-free corn/rice bread [27]. In a past study, gluten-free bread with 5% hemp flour did not differ significantly from the control bread and was accepted by consumers [28].

Korus et al. [29] found that replacing some of the starch with hemp flour made bread dough weaker and more likely to deform, while a 20% share of hemp protein concentrate made bread dough stronger. The level of fiber increased from 15.2 to 61.0 g·kg−1, and the level of dietary fiber increased from 29.3 to 90.0 g·kg−1. Hemp protein supplementation improved the color of the crumb, reducing its brightness from 62.3 to 40.8 and increasing the bread volume from 633 to 878 mL. Hemp flour and hemp protein concentrate are the most commonly used ingredients in gluten-free bread production. Although various hemp products have been added to gluten-free bread, hemp inflorescence has not been added to this type of bread.

Due to the growing number of people suffering from the consumption of cereals containing gluten, there is a demand for gluten-free bread on the market. Most often, rice and corn flour are used for their production. However, consumers perceive gluten-free bread to be less appealing than traditional wheat bread due to its unsatisfactory texture and taste. Gluten-free bread also has a lower nutritional value. Various additives are used to improve the quality of gluten-free bread and they affect the physical properties, taste, and content of bioactive substances [30,31,32,33,34,35].

As previously stated, hemp inflorescence is a valuable raw material in terms of health and it has not previously been used in bread production, which is why it was proposed for inclusion in gluten-free bread. The scope of the work included determining the changes in the physical and sensory properties as well as the antioxidant potential of gluten-free bread with added hemp inflorescence. Furthermore, we aim to recommend the most nutritionally valuable and acceptable recipe for customers.

2. Materials and Methods

2.1. Materials

The ingredients for the preparation of the control bread were gluten-free rice flour (Melvit, Warsaw, Poland). The rice flour, according to the manufacturer’s declaration, contained 6 g/100 g of protein, 1.4 g/100 g of fiber, 1 g/100 g of fat, 77 g/100 g of carbohydrates, and 14.6 g/100 g moisture content. The hemp inflorescence that was used as an addition came from crops grown on a farm in the Lublin Province of Poland. The Futura hemp variety with a CBD (cannabidiol) content of 0.09% and a THC (tetrahydrocannabinol) content of 0.01% was used for the study. Salt, guar gum (NatVita, Mirków, Poland), and dry instant yeast (Instaferm, Lallemand Iberia, Setúbal Municipality, Portugal) were also used in this study to make the breads (Table A1).

2.2. Process of Making the Gluten-Free Bread

A single-phase method was used to produce the gluten-free bread [36]. The gluten-free rice flour used to make the control loaf was used exclusively, and the recipe also included guar gum, dry instant yeast, and salt. Hemp inflorescences, both dried and shredded, were added in various amounts to the control bread recipe (0%, 1%, 2%, 3%, 4%, and 5%). Together with the addition of the hemp inflorescence, the amount of water was increased from 120% to 136.7% [37].

A laboratory spiral mixer (Clatronic KM 3630, Clatronic International GmBh, Kempen, Germany) was used to mix the dough for 5 min at 200 rpm. The dough was then divided into 300 g pieces and placed into molds where it fermented and proved for 40 min at 30 °C with 75% humidity. A laboratory oven (Sadkiewicz Instruments, Bydgoszcz, Poland) was used to bake the bread for 40 min at 240 degrees. The baking test was repeated three times.

2.3. Determination of the Basic Physical Parameters of the Bread

After measuring the volume of the bread using the millet seed displacement method, the specific volume (bread volume divided by weight) was calculated. The pH level of the breadcrumb was determined using a pH meter (TESTO 206-ph2, Pruszków, Poland) [38]. Color measurements were taken on an L*a*b* scale (4Wave CR30-16) (Planeta, Tychy, Poland), and ΔE was calculated. The following parameters were measured: L*—lightness, a*—changes in the color from green to red, and b*—changes in the color from blue to yellow (higher values of a* and b* indicated a greater intensity of red and yellow, respectively). The total color change, ΔE, was calculated as follows:

where ΔL, Δa, and Δb are the indices of the differences in the color of the surfaces of the samples compared with the control bread. In total, three replications of the measurements of the physical characteristics of the bread were carried out [39].

2.4. Determination of the Texture and Sensory Parameters of the Bread

The textural parameters of the breadcrumbs with dimensions of 30 × 30 × 20 mm were determined using a ZWICK Z020/TN2S (ZwickRoell, Ulm, Germany) for a double compression test (TPA–texture profile analysis) to a depth of 50% at a speed of 1 mms−1. The graphs produced by the TPA test were used to compute the hardness, springiness, cohesiveness, and chewiness. In the midst of the bread’s central slices, texture measurements were made six times. A panel of 72 untrained consumers (aged 22 to 56) evaluated the bread samples’ flavors, aromas, appearances, textures, and general levels of acceptability as part of the sensory analysis. The responses were collected using a 9-point hedonic scale: 1 for extremely dislike, 2 for very dislike, 3 for rather dislike, 4 for moderately dislike, 5 for neither like nor dislike, 6 for moderately like, 7 for somewhat like, 8 for very much like, and 9 for extremely like [40].

2.5. Determination of Antioxidants

2.5.1. Preparation of the Extracts for the Chemical Analyses

To prepare the sample extract, 2 g of grinding sample was mixed with 30 mL of methanol in a 100 mL conical flask. The mixture was placed on a magnetic stirrer and heated to 30 °C. After two hours of stirring, the extract was collected into a separate flask and the raffinate was mixed with another 30 mL of methanol. After two more hours of extraction on a magnetic stirrer, the extract was collected and mixed with the previous portion of extract and centrifuged at 6500 rpm for 15 min.

2.5.2. Determination of the Total Phenolic Content (TPC)

The TPC was examined using the spectrophotometric method described by Singleton et al. [41], with the slight modification introduced by Kobus et al. [42]. Measurements were taken three times.

2.5.3. Determination of the Flavonoid Content (TFC)

The flavonoid content was determined according to the methodology described by Aryal [43], with the slight modification introduced by Kobus et al. [42]. The flavonoid content was measured in triplicate.

2.5.4. Determination of the Antioxidant Activity (DPPH and FRAP)

The antioxidant activity of the tested solutions was determined using the DPPH and FRAP reagents. It was determined according to the methodology described by Blois [44] and that by Benzie and Strain [45], with the slight modification introduced by Kobus et al. [46,47]. Measurements of the antioxidant activity were made in three repetitions.

2.6. Statistical Analysis

Statistica software version 12.0 (Statsoft, Tulsa, OK, USA) was used for the statistical analysis. The mean values were compared using analysis of variance (ANOVA) and Tukey’s test (p < 0.05). Furthermore, Dunnett’s test (p < 0.05) was also used to compare the control group to the other experimental groups.

3. Results and Discussion

3.1. Basic Physical Properties of the Gluten-Free Bread with the Addition of Hemp Inflorescence

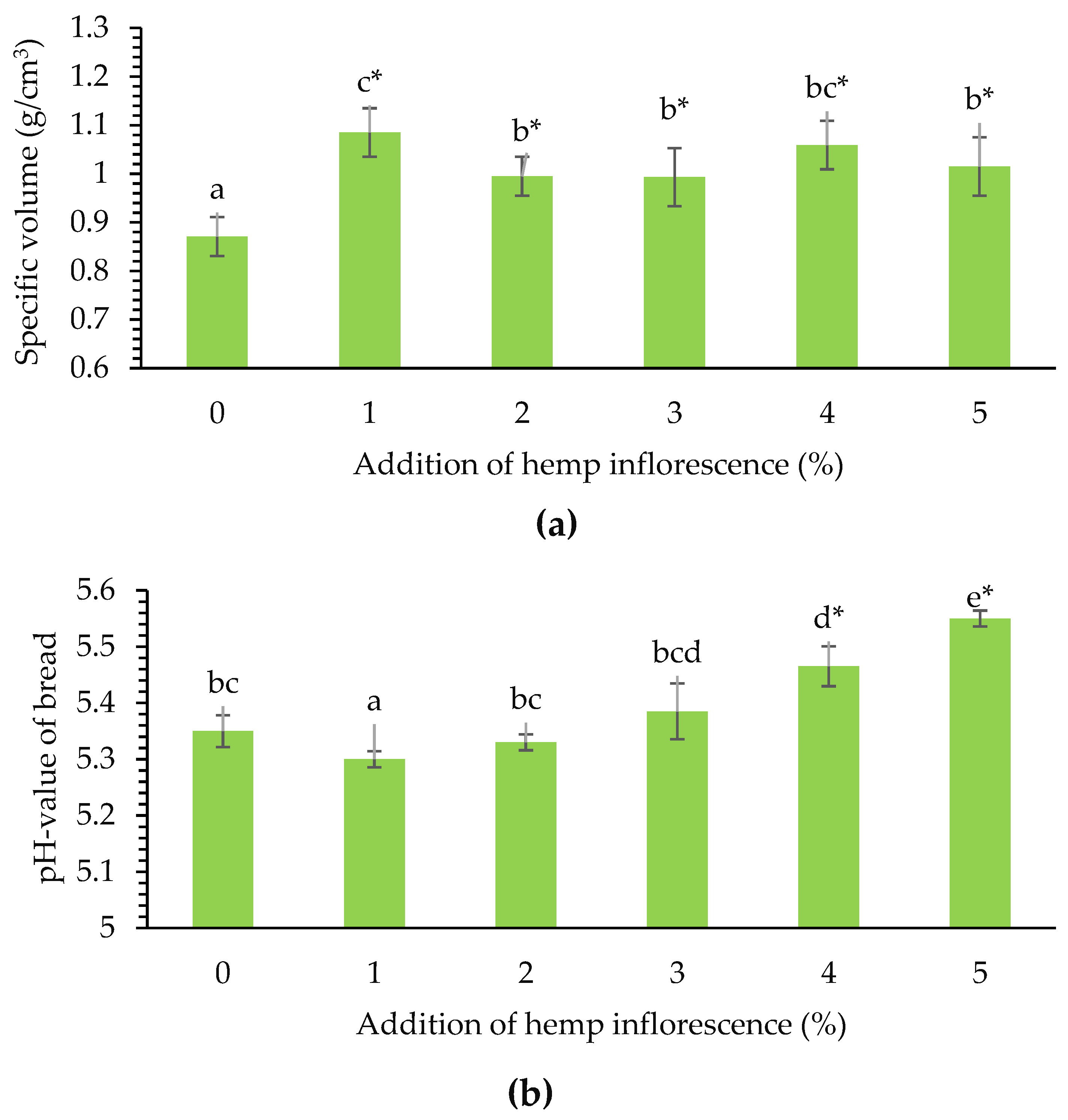

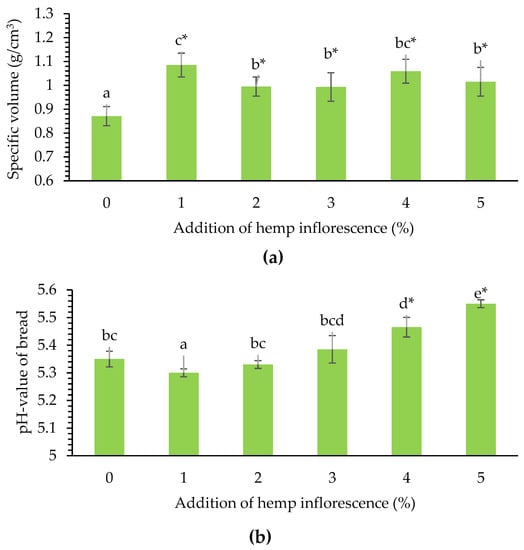

The results indicated that gluten-free bread with added hemp inflorescence had an increased specific volume (Figure 1a). Bread containing 1% and 4% hemp inflorescence had higher volumes than the control gluten-free bread. The increase in specific volume was approximately 24% in the case of the bread with 1% HI. A higher share of HI (2–5%) caused volume changes of 13% to 20%. There were no significant differences between the volumes of the breads with the addition of 2%, 3%, 4%, and 5% hemp inflorescence. As shown in Figure 1b, a clear increase in pH value was observed as the percentage of hemp inflorescence addition increased from 1% to 5%. The highest pH value was 5.55 for the 5% hemp addition, while the lowest value was 5.3 for the 1% hemp inflorescence addition. pH changes in the control sample were observed only in the case of 4% and 5% HI addition, and they were in the range of 2–3.7%.

Figure 1.

Basic physical properties of gluten-free bread with the addition of hemp inflorescence: (a) specific volumes of the breads and (b) pH values of the breadcrumbs. The mean values in the same figure marked with different letters were significantly (p < 0.05) different, as determined by the Tukey test. The means followed by an asterisk (*) differed from the control sample, as determined by the Dunnett’s test (p < 0.05).

Thus far, no research has been conducted on the addition of hemp inflorescence to bread; however, other authors have used hemp flour [21,22,23,48] and discovered that the addition of hemp flour increased the specific volume of bread. Bread with 15% extruded hemp–rice flour had a higher specific volume, lower hardness, and larger pores in the crumb structure according to Wang et al. [49]. Pojic et al. [50] discovered that regardless of the level of substitution, hemp flour affected the water absorption and development time of the dough, and thus, it affected the bread volume, color, and structural and textural properties of the crumb. Hrušková and Švec [48] discovered that the addition of hemp flour reduced the specific volume of wheat bread while increasing the crumb pore density. According to these authors, hemp proteins are primarily composed of low-molecular-weight globulin, and this may have contributed to the volume reduction in the wheat bread.

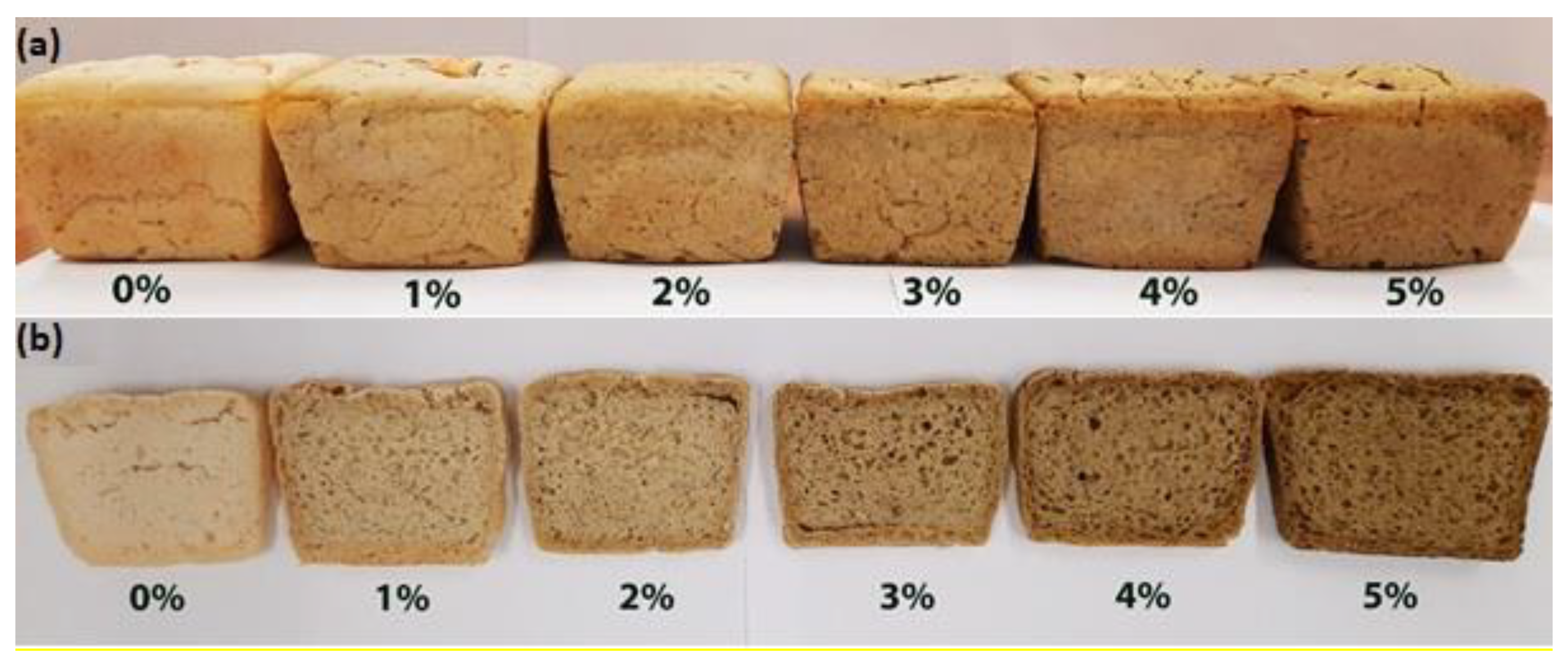

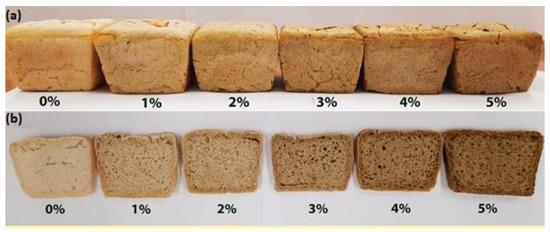

The addition of HI reduced the crumb lightness significantly, from 75.17 for the control bread to 51.53 for the bread with the highest (5%) share of hemp inflorescence (Table 1). Each amount of HI additive caused a significant change in the lightness of the bread. With a 1% HI addition, the brightness decreased by approximately 13%, and with a 5% HI addition, the brightness decreased by as much as 32%. There were no significant differences in the lightness levels of the breads with 1% and 2% hemp inflorescence additions, and there was a decrease, and then no significant differences, in the lightness levels of the breads with 3% and 4% hemp inflorescence additions. As with the L* index values, the a*, b*, and C* values increased as the amount of HI added to the bread increased. The a-index was significantly different for each HI supplement compared to the control. An addition of 5% increased the value of a* by more than 200%. There were no statistically significant differences between the a* samples containing 1%, 2%, and 4% HI. The control b* value increased by 108% for the 5% hemp bread sample. Figure 2 shows the external appearances and cross-sections of the breads with different hemp inflorescence contents.

Table 1.

The colors of the gluten-free breadcrumbs with the addition of hemp inflorescence.

Figure 2.

External appearances (a) and cross-sections (b) of the breads with different hemp inflorescence contents.

The addition of HI to bread reduced the ho value. It was equal to 90.10 for the control sample and 85.66 for the sample containing 5% HI.

The absolute color difference (ΔE) criterion was also used in the results’ elaboration. The ΔE for all the tested samples with HI additions exceeded five, indicating a significant color deviation. All the color parameters changed significantly owing to a significant difference in the color of the hemp inflorescence addition from the rice flour that was used as the main raw material in the recipe. The dried hemp inflorescence had a green-brown color, which influenced the color of the bread significantly. Significant changes and darkening of the bread color were observed in other studies where hemp seed cake and hemp seed grit were used as bread additives (with only 1% of the addition) [26].

When cookies with hemp flour were tested, similar results were obtained [51]. The L* value decreased significantly when the ratio of raw and roasted hemp flour was increased from 0% to 20%.

The crusts and crumb colors of the breads made with extruded hemp–rice flour were significantly darker than the control bread [49]. According to other authors [24], the addition of a hemp product (particularly 15% and 25% hemp flour) as the second auxiliary ingredient of bread results in an interesting color of the crumb due to the content of natural sugars and organic acids.

3.2. Texture and Sensory Analysis of Gluten-Free Bread with the Addition of Hemp Inflorescence

The addition of HI to gluten-free bread slightly affected the hardness of the crumb. A significant reduction in hardness was observed for only the 1–2% of hemp inflorescence (Table 2). Bread hardness is frequently related to the distribution of pores in the bread. The porosity of the crumb increased and the hardness decreased with a smaller addition, i.e., 1–2%; with a larger addition, the bread was more compact and had a hardness similar to the control bread. Overall, the addition of hemp inflorescence may have increased the amount of simple sugars, allowing the yeast to produce more carbon dioxide by creating more pores. A more compact and hard structure was formed with a higher addition of 3–5% hemp inflorescence, which was difficult to overcome by the forming gas bubbles. Compounds found in hemp inflorescence, such as fiber, could bind to rice starch and cause a decrease in hardness once more. The gluten-free bread springiness ranged from 0.74 (for 1% HI addition) to 0.84 (for 4% HI addition). A significant difference from the control sample was only observed for the 4–5% HI addition. In this case, the breadcrumbs’ springiness increased by approximately 10%. Bread samples with 1–4% HI added had lower cohesiveness than the control sample; only the addition of 5% HI increased cohesiveness. The addition of 3–4% HI to the control sample increased the chewiness by approximately 7–8%.

Table 2.

The textures of the gluten-free breadcrumbs with hemp inflorescence additions.

The addition of hemp inflorescence to bread has not been investigated in previous studies. However, when hemp flour was added to wheat bread in the range of 5–20%, a decrease in bread elasticity was observed [25]. The addition of hemp and hemp seed cakes in a proportion greater than 1% caused an increase in hardness and a decrease in elasticity [26].

According to Ertaş and Aslan’s research [51], the addition of raw and roasted hemp flour significantly reduced the hardness and softness of wheat biscuits. Other authors [24] have claimed that using a hemp product (especially 15% and 25% hemp flour) as the second auxiliary ingredient of bread improves the structure of the crumb and increases the bread’s durability, as well as provides an interesting color of the crumb due to the content of natural sugars and organic acids. Furthermore, the addition of 15% hemp products had the greatest effect on the dough’s characteristics, improving crumb quality (porosity and elasticity).

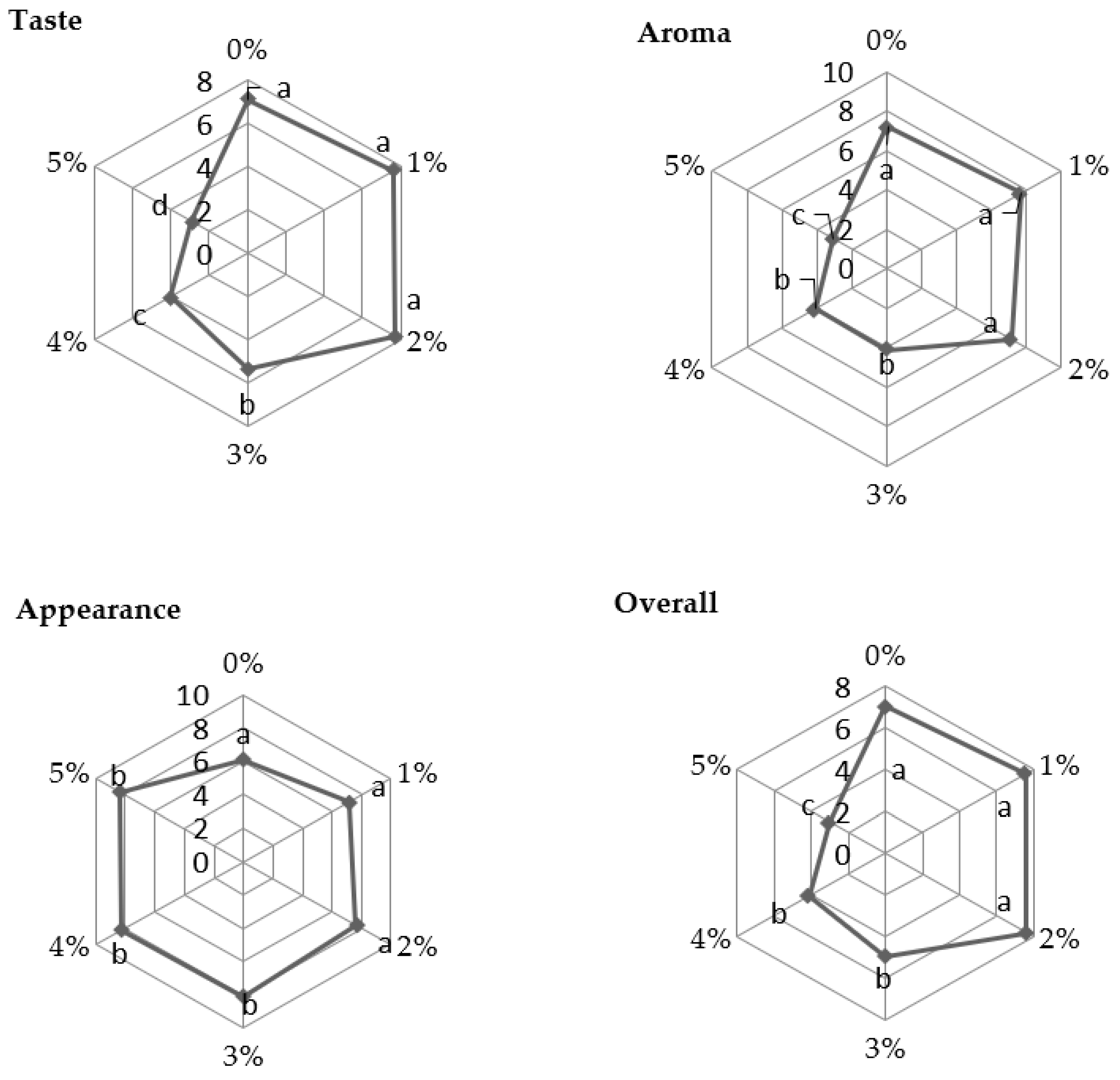

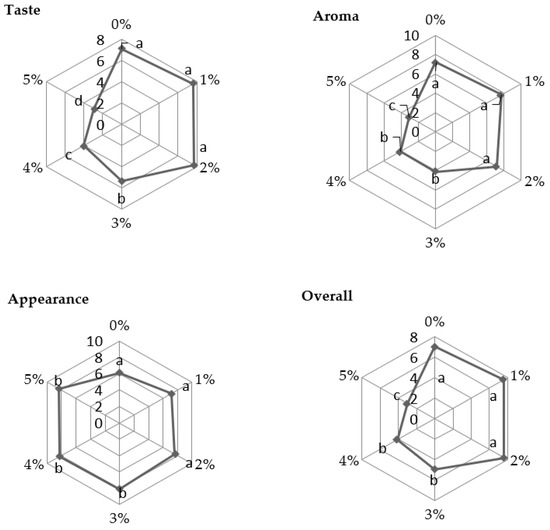

The additions of hemp at 1% and 2% did not significantly alter the taste of the bread, and consumers rated them as the best (Figure 3). The addition of hemp ranging from 3% to 5% significantly reduced the flavor of the gluten-free bread. The bread with 5% hemp added had the worst flavor, leaving a bitter aftertaste when swallowed. The addition of 1% hemp to gluten-free bread improved the taste and smell slightly.

Figure 3.

Sensory evaluations of the gluten-free breads with the additions of hemp inflorescence. The mean values in the same figure marked with different letters were significantly different (α = 0.05).

The addition of 2% to 5% hemp resulted in a significant deterioration of the bread’s aroma. All the hemp-infused bread samples had a better appearance compared to the control sample according to the consumers. In general, the consumers thought that the breads with 1% and 2% hemp were the best; the lower hardness and chewiness of these breads may have influenced the ratings. A lower overall consumer rating was obtained for the bread with the additions of 3%, 4%, and 5% hemp.

Other studies [23] have shown that sensory evaluations of hemp–wheat breads are poor due to the savory flavor and fatty aftertaste. According to Wang et al. [49], adding hemp-rice flour to bread reduced its hardness during storage. However, in the sensory evaluation of biscuits containing up to 20% raw hemp flour and up to 15% roasted hemp flour, they were found to be more desirable by consumers in terms of overall acceptability due to their softness [51]. Wheat flour for bread production can be enriched with functional ingredients by adding partially defatted hemp seed flour. The addition of 5% and 10% partially defatted hemp seed flour resulted in superior sensory and physicochemical values, which were comparable to white wheat bread. The quality of bread obtained with 15% and 20% partially defatted hemp seed flour from P4 and P5 mixture samples (15% and 20% partially defatted hemp seed flour) was comparable to wholegrain bread [52]. The addition of 10% hemp flour improved the sensory properties of sourdough bread, and the authors concluded that the addition of up to 20% hemp flour could be used for bakery products to create an improved nutritional profile [48].

3.3. The Bioactive Compound Content of Gluten-Free Bread with Hemp Inflorescence Addition

The amount of polyphenols in the tested samples was affected by the addition of hemp inflorescence (HI). The polyphenol content increased from 36 to 195% with HI addition in the 1% to 4% tested range of addition (Table 3). There was no statistically significant difference in the polyphenol content when 2% and 3% hemp were added. Similarly, the flavonoid content in the bread with hemp additions compared to the control bread increased from 100% for 1% HI addition to 433% for 5% HI addition (Table 3). All the tested bread samples had statistically significant differences in flavonoid contents. There are numerous studies in the literature on the polyphenol content of hemp. However, a majority of them have focused on the contents of these compounds in seeds, oils, and flours [53,54,55,56,57]. The polyphenol content of the leaves, for example, ranges from 0.09 to 0.56 [54], that of the inflorescences ranges from 3.02 to 9.35 mg QE∙g−1 [58], while for the seeds it is 51.6 mg GAE·g−1 [53,55,56]. According to Izzo’s research [14], the inflorescence contains significantly more polyphenols than other parts of the plant (10.5–48.9 mg GAE·g−1) depending on the variety. The polyphenol content in flour ranges between 0.74 and 1.71 mg GAE·g−1 [57].

Table 3.

The polyphenols, flavonoids, and antioxidant activities of the gluten-free breads with hemp inflorescences added.

Due to the high polyphenol content of hemp flour, its addition to various types of bakery products helps to strengthen the antioxidant properties of these products. In comparison to the control samples, the addition of raw or roasted hemp flour to wheat flour cookies increased the total phenol content (0.559–1.634 mg GAE·g−1) and antioxidant activity (34.41–40.88%). The TPC values increased with the addition of raw and roasted hemp flour, with the greatest increase in TPC observed for the biscuit samples containing 20% roasted hemp flour (4.03-fold increase in TPC compared to the control sample) [51].

The antioxidant activity in the tested samples, as measured by DPPH and FRAP, increased as the hemp addition increased. The DPPH ranged from 1.66 µM TE·g−1 d.m. for 1% hemp addition to 3.23 µM TE·g−1 d.m. for 5% hemp addition. Compared to the control sample, with 1% of the additive, there was a 48% increase in the DPPH value, and with 5%, the increase was 188%.

With the addition of 1% and 5% hemp, the antioxidant activity, expressed as FRAP, ranged from 1.25 to 3.00 µM TE·g−1 d.m, and so for the highest addition, the value increased by 140%. The antioxidant activity measured by the FRAP test in the bread without the addition of hemp was 1.25 µM TE·g−1 d.m (Table 3). There was no statistically significant difference in the antioxidant activity of FRAP between the control bread and the bread with the addition of 1% hemp, as well as between the samples with the additions of 3% and 4% hemp.

4. Conclusions

This study found that hemp inflorescence can be a valuable addition to gluten-free bread made with rice flour. The additive, which was used at concentrations of 1–4%, caused significant changes in the physical properties of the bread. After using 1% of the additive, the volume of the bread increased significantly and the color of the breadcrumb changed significantly. The changes in crumb texture were less clear. Based on the organoleptic evaluation, gluten-free bread with a maximum of 2% HI addition is the most recommended; however, with a higher proportion of hemp inflorescence, the bread has a bitter aftertaste. The addition of hemp inflorescence in the acceptable amount of 2% increased the biological activity of the bread significantly. With this amount of addition, the polyphenol content increased by 86%, the flavonoid content increased by 167%, and the antioxidant activity measured with DPPH increased by 86%, while the activity measured with FRAP increased by 28%.

Author Contributions

Conceptualization, R.R. and A.P.; methodology, R.R. and Z.K.; software, R.R.; validation, R.R. and A.P.; formal analysis, R.R., A.P. and A.B.; investigation, A.P., A.B. and R.R.; resources, A.B.; writing—original draft preparation, A.P., A.B. and R.R; writing—review and editing, A.P., A.B. and R.R; visualization, A.P.; supervision, R.R.; project administration, A.P.; funding acquisition, R.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Model of experimental parameters.

Table A1.

Model of experimental parameters.

| Ingredients | 0 | 1% | 2% | 3% | 4% | 5% |

|---|---|---|---|---|---|---|

| Rice flour (g) | 300 | 297 | 294 | 291 | 288 | 285 |

| Hemp inflorescence (g) | 0 | 3 | 6 | 9 | 12 | 15 |

| Water (mL) | 360 | 370 | 380 | 390 | 400 | 410 |

| Guar gum (g) | 6 | 6 | 6 | 6 | 6 | 6 |

| Dry instant yeast (g) | 4 | 4 | 4 | 4 | 4 | 4 |

| Salt (g) | 6 | 6 | 6 | 6 | 6 | 6 |

References

- Rupasinghe, H.P.V.; Davis, A.; Kumar, S.K.; Murray, B.; Zheljazkov, V.D. Industrial Hemp (Cannabis sativa subsp. sativa) as an Emerging Source for Value-Added Functional Food Ingredients and Nutraceuticals. Molecules 2020, 25, 4078. [Google Scholar] [CrossRef] [PubMed]

- Spano, M.; Di Matteo, G.; Ingallina, C.; Botta, B.; Quaglio, D.; Ghirga, F.; Balducci, S.; Cammarone, S.; Campiglia, E.; Giusti, A.M.; et al. A Multimethodological Characterization of Cannabis sativa L. Inflorescences from Seven Dioecious Cultivars Grown in Italy: The Effect of Different Harvesting Stages. Molecules 2021, 26, 2912. [Google Scholar] [CrossRef]

- Iftikhar, A.; Zafar, U.; Ahmed, W.; Shabbir, M.A.; Sameen, A.; Sahar, A.; Bhat, Z.F.; Kowalczewski, P.Ł.; Jarzębski, M.; Aadil, R.M. Applications of Cannabis Sativa L. in Food and Its Therapeutic Potential: From a Prohibited Drug to a Nutritional Supplement. Molecules 2021, 26, 7699. [Google Scholar] [CrossRef] [PubMed]

- Ranalli, P.M.; Di Candilo, G.; Mandolino, G.; Grassi, A.; Carboni. Hemp for sustainable agricultural systems. Agro-Food Ind. Hi-Tech. 1999, 2, 33–3899. [Google Scholar]

- Nissen, L.; Casciano, F.; Babini, E.; Gianotti, A. Chapter 10—Industrial Hemp Foods and Beverages and Product Properties; Industrial Hemp; Academic Press: Cambridge, MA, USA, 2022; pp. 219–246. [Google Scholar]

- Callaway, J.C. Hempseed as a nutritional resource: An overview. Euphytica 1999, 140, 65–72. [Google Scholar] [CrossRef]

- Ranalli, P.; Venturi, G. Hemp as a raw material for industrial applications. Euphytica 2004, 140, 1–5. [Google Scholar] [CrossRef]

- Crini, G.; Lichtfouse, E.; Chanet, G.; Morin-Crini, N. Applications of hemp in textiles, paper industry, insulation and building materials, horticulture, animal nutrition, food and beverages, nutraceuticals, cosmetics and hygiene, medicine, agrochemistry, energy production and environment: A review. Environ Chem. Lett. 2020, 18, 1451–1476. [Google Scholar] [CrossRef]

- Lewis-Bakker, M.M.; Yang, Y.; Vyawahare, R.; Kotra, L.P. Extractions of Medical Cannabis Cultivars and the Role of Decarboxylation in Optimal Receptor Responses. Cannabis Cannabinoid Res. 2019, 4, 183–194. [Google Scholar] [CrossRef]

- Fiorini, D.; Molle, A.; Nabissi, M.; Santini, G.; Benelli, G.; Maggi, F. Valorizing industrial hemp (Cannabis sativa L.) by-products: Cannabidiol enrichment in the inflorescence essential oil optimizing sample pre-treatment prior to distillation. Ind. Crops Prod. 2019, 128, 581–589. [Google Scholar] [CrossRef]

- Jin, D.; Dai, K.; Xie, Z.; Chen, J. Secondary Metabolites Profiled in Cannabis Inflorescences, Leaves, Stem Barks, and Roots for Medicinal Purposes. Sci. Rep. 2020, 10, 3309. [Google Scholar] [CrossRef]

- Spano, M.; Di Matteo, G.; Ingallina, C.; Sobolev, A.P.; Giusti, A.M.; Vinci, G.; Cammarone, S.; Tortora, C.; Lamelza, L.; Prencipe, S.A.; et al. Industrial Hemp (Cannabis sativa L.) Inflorescences as Novel Food: The Effect of Different Agronomical Practices on Chemical Profile. Foods 2022, 11, 3658. [Google Scholar] [CrossRef]

- Nagy, D.U.; Cianfaglione, K.; Maggi, F.; Sut, S.; Dall’Acqua, S. Chemical Characterization of Leaves, Male and Female Flowers from Spontaneous Cannabis (Cannabis sativa L.) Growing in Hungary. Chem Biodivers 2019, 9, 90. [Google Scholar]

- Izzo, L.; Castaldo, L.; Narváez, A.; Graziani, G.; Gaspari, A.; Rodríguez-Carrasco, Y.; Ritieni, A. Analysis of Phenolic Compounds in Commercial Cannabis sativa L. Inflorescences Using UHPLC-Q-Orbitrap HRMS. Molecules 2020, 25, 631. [Google Scholar] [CrossRef] [PubMed]

- Giupponi, L.; Leoni, V.; Pavlovic, R.; Giorgi, A. Influence of Altitude on Phytochemical Composition of Hemp Inflorescence: A Metabolomic Approach. Molecules 2020, 25, 1381. [Google Scholar] [CrossRef] [PubMed]

- Hanuš, L.O.; Meyer, S.M.; Muñoz, E.; Taglialatela-Scafati, O.; Appendino, G. Phytocannabinoids: A unified critical inventory. Nat. Prod. Rep. 2016, 33, 1357–1392. [Google Scholar] [CrossRef]

- Da Porto, C.; Decorti, D.; Natolino, A. Separation of aroma compounds from industrial hemp inflorescences (Cannabis sativa L.) by supercritical CO2 extraction and on-line fractionation. Ind. Crops Prod. 2014, 58, 99–103. [Google Scholar] [CrossRef]

- Bertoli, A.; Tozzi, S.; Pistelli, L.; Angelini, L.G. Fibre hemp inflorescences: From crop-residues to essential oil production. Ind. Crops Prod. 2010, 32, 329–337. [Google Scholar] [CrossRef]

- Bakro, F.; Jedryczka, M.; Wielgusz, K.; Sgorbini, B.; Inchingolo, R.; Cardenia, V. Simultaneous determination of terpenes and cannabidiol in hemp (Cannabis sativa L.) by fast gas chromatography with flame ionization detection. J. Sep. Sci. 2020, 43, 2817–2826. [Google Scholar] [CrossRef]

- Mikulec, A.; Kowalski, S.; Sabat, R.; Skoczylas, Ł.; Tabaszewska, M.; Wywrocka-Gurgul, A. Hemp flour as a valuable component for enriching physicochemical and antioxidant properties of wheat bread. LWT 2019, 102, 64–172. [Google Scholar] [CrossRef]

- Švec, I.; Hrušková, M. Properties and nutritional value of wheat bread enriched by hemp products. Potravin. Slovak J. Food Sci. 2015, 9, 304–308. [Google Scholar] [CrossRef]

- Švec, I.; Hrušková, M.; Jurinová, I. Technological and nutritional aspect of different hemp types addition: Comparison of flour and whole meal effect. Croat. J. Food Sci. Technol. 2015, 7, 68–75. [Google Scholar] [CrossRef]

- Hrušková, M.; Švec, I.; Jurinová, I. Composite Flours-Characteristics of Wheat/Hemp and Wheat/Teff Models. Food Sci. Nutr. 2012, 3, 1484–1490. [Google Scholar] [CrossRef]

- Bădărău, C.L.; Apostol, L.; Mihăilă, L. Effects of Hemp Flour, Seeds and Oil Additions on Bread Quality. Int. J. Eng. Res. Appl. 2018, 8, 73–78. [Google Scholar]

- Rusu, I.E.; Marc (Vlaic), R.A.; Mureşan, C.C.; Mureşan, A.E.; Mureşan, V.; Pop, C.R.; Chiş, M.S.; Man, S.M.; Filip, M.R.; Onica, B.-M.; et al. Hemp (Cannabis sativa L.) Flour-Based Wheat Bread as Fortified Bakery Product. Plants 2021, 10, 1558. [Google Scholar] [CrossRef] [PubMed]

- Wiedemair, V.; Gruber, K.; Knöpfle, N.; Bach, K.E. Technological Changes in Wheat-Based Breads Enriched with Hemp Seed Press Cakes and Hemp Seed Grit. Molecules 2022, 27, 1840. [Google Scholar] [CrossRef] [PubMed]

- Jagelaviciute, J.; Cizeikiene, D. The influence of non-traditional sourdough made with quinoa, hemp and chia flour on the characteristics of gluten-free maize/rice bread. LWT 2021, 137, 110457. [Google Scholar] [CrossRef]

- Hayward, L.; McSweeney, M.B. Acceptability of bread made with hemp (Cannabis sativa subsp. sativa) flour evaluated fresh and following a partial bake method. J. Food Sci 2020, 85, 2915–2922. [Google Scholar] [CrossRef]

- Korus, J.; Witczak, M.; Ziobro, R.; Juszczak, L. Hemp (Cannabis sativa subsp. sativa) flour and protein preparation as natural nutrients and structure forming agents in starch based gluten-free bread. LWT 2017, 84, 143–150. [Google Scholar] [CrossRef]

- Bugarín, R.; Gómez, M. Can Citrus Fiber Improve the Quality of Gluten-Free Breads? Foods 2023, 12, 1357. [Google Scholar] [CrossRef]

- Aguiar, E.V.; Santos, F.G.; Krupa-Kozak, U.; Capriles, V.D. Nutritional facts regarding commercially available gluten-free bread worldwide: Recent advances and future challenges. Crit. Rev. Food Sci. Nutr. 2023, 63, 693–705. [Google Scholar] [CrossRef] [PubMed]

- Łopusiewicz, Ł.; Kowalczewski, P.Ł.; Baranowska, H.M.; Masewicz, Ł.; Amarowicz, R.; Krupa-Kozak, U. Effect of Flaxseed Oil Cake Extract on the Microbial Quality, Texture and Shelf Life of Gluten-Free Bread. Foods 2023, 12, 595. [Google Scholar] [CrossRef] [PubMed]

- Rybicka, I.; Doba, K.; Bińczak, O. Improving the sensory and nutritional value of gluten-free bread. Int. J. Food Sci. Technol. 2019, 54, 2661–2667. [Google Scholar] [CrossRef]

- Cantero, L.; Salmerón, J.; Miranda, J.; Larretxi, I.; Fernández-Gil, M.d.P.; Bustamante, M.Á.; Matias, S.; Navarro, V.; Simón, E.; Martínez, O. Performance of Apple Pomace for Gluten-Free Bread Manufacture: Effect on Physicochemical Characteristics and Nutritional Value. Appl. Sci. 2022, 12, 5934. [Google Scholar] [CrossRef]

- Różańska, M.B.; Kokolus, P.; Królak, J.; Jankowska, P.; Osoś, A.; Romanowska, M.; Szala, Ł.; Kowalczewski, P.Ł.; Lewandowicz, J.; Masewicz, Ł.; et al. Insight into the Gluten-Free Dough and Bread Properties Obtained from Extruded Rice Flour: Physicochemical, Mechanical, and Molecular Studies. Appl. Sci. 2023, 13, 4033. [Google Scholar] [CrossRef]

- Różyło, R.; Rudy, S.; Krzykowski, A.; Dziki, D. Novel Application of Freeze-Dried Amaranth Sourdough in Gluten-Free Bread Production. J. Food Process Eng. 2015, 38, 135–143. [Google Scholar] [CrossRef]

- Ziemichód, A.; Wójcik, M.; Różyło, R. Seeds of Plantago psyllium and Plantago ovata: Mineral composition, grinding, and use for gluten-free bread as substitutes for hydrocolloids. J. Food Process Eng. 2019, 42, e12931. [Google Scholar] [CrossRef]

- Różyło, R.; Piekut, J.; Wójcik, M.; Kozłowicz, K.; Smolewska, M.; Krajewska, M.; Szmigielski, M.; Bourekoua, H. Black cumin pressing waste material as a functional additive for starch bread. Materials 2021, 14, 4560. [Google Scholar] [CrossRef]

- Różyło, R.; Wójcik, M.; Dziki, D.; Biernacka, B.; Cacak-Pietrzak, G.; Gawłowski, S.; Zdybel, A. Freeze-dried elderberry and chokeberry as natural colorants for gluten-free wafer sheets. Int. Agroph. 2019, 33, 217–225. [Google Scholar] [CrossRef]

- Lim, H.S.; Park, S.H.; Ghafoor, K.; Hwang, S.Y.; Park, J. Quality and antioxidant properties of bread containing turmeric (Curcuma longa L.) cultivated in South Korea. Food Chem. 2011, 124, 1577–1582. [Google Scholar] [CrossRef]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzymol. 1999, 299, 152–178. [Google Scholar]

- Kobus, Z.; Krzywicka, M.; Pecyna, A.; Buczaj, A. Process efficiency and energy consumption during the ultrasound-assisted extraction of bioactive substances from hawthorn berries. Energies 2021, 14, 7638. [Google Scholar] [CrossRef]

- Aryal, S.; Baniya, M.K.; Danekhu, K.; Kunwar, P.; Gurung, R.; Koirala, N. Total Phenolic Content, Flavonoid Content and Antioxidant Potential of Wild Vegetables from Western Nepal. Plants 2019, 8, 96. [Google Scholar] [CrossRef] [PubMed]

- Blois, M.S. Antioxidant determinations by the use of a stable free radical. Nature 1958, 181, 1199–1200. [Google Scholar] [CrossRef]

- Benzie, I.; Strain, J. The ferric reducing ability of plasma (FRAP) as a measure of “Antioxidant Power: The FRAP Assay”. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef]

- Kobus, Z.; Buczaj, A.; Pecyna, A.; Kapica, J.; Findura, P.; Kocira, S. Application of Response Surface Method in Pulsed Ultrasound-Assisted Extraction of Complex Plant Materials—A Case Study on Cannabis sativa L. Appl. Sci. 2023, 13, 760. [Google Scholar] [CrossRef]

- Kobus, Z.; Krzywicka, M.; Starek-Wójcicka, A.; Sagan, A. Effect of the duty cycle of the ultrasonic processor on the efficiency of extraction of phenolic compounds from Sorbus intermedia. Sci. Rep. 2022, 12, 8311. [Google Scholar] [CrossRef]

- Hrušková, M.; Švec, I. Hemp products for food and medicine using. In Proceedings of the 8th International Congress FLOUR-BREAD 2015—10th Croatian Congress of Cereal Technologists, Opatija, Croatia, 28–30 October 2015; pp. 106–112. [Google Scholar]

- Wang, Y.Y.; Norajit, K.; Ryu, G.H. Influence of Extruded Hemp-Rice Flour Addition on the Physical Properties of Wheat Bread. Prev. Nutr. Food Sci. 2011, 16, 62–66. [Google Scholar] [CrossRef]

- Pojić, M.; Dapčević Hadnađev, T.; Hadnađev, M.; Rakita, S.; Brlek, T. Hemp Seed Cake in Bread Making. J. Food Qual. 2015, 38, 431–440. [Google Scholar] [CrossRef]

- Ertaş, N.; Aslan, M. Antioxidant and physicochemical properties of cookies containing raw and roasted hemp flour. Acta Sci. Pol. Technol. Aliment. 2020, 19, 177–184. [Google Scholar]

- Apostol, L.; Popa, M.; Mustatea, G. Cannabis sativa L. partially skimmed flour as source of bio-compounds in the bakery industry. Rom. Biotechnol. Lett. 2015, 20, 10835–10844. [Google Scholar]

- Frassinetti, S.; Moccia, E.; Caltavuturo, L.; Gabriele, M.; Longo, V.; Bellani, L.; Giorgi, G.; Giorgetti, L. Nutraceutical potential of hemp (Cannabis sativa L.) seeds and sprouts. Food Chem. 2018, 262, 56–66. [Google Scholar] [CrossRef] [PubMed]

- Mkpenie, V.; Essien, E.; Udoh, I. Effect of extraction conditions on total polyphenol contents, antioxidant and antimicrobial activities of Cannabis sativa L. Electron. J. Environ. Agric. Food Chem. 2012, 11, 300–307. [Google Scholar]

- Siano, F.; Moccia, S.; Picariello, G.; Russo, G.L.; Sorrentino, G.; Di Stasio, M.; La Cara, F.; Volpe, M.G. Comparative Study of Chemical, Biochemical Characteristic and ATR-FTIR Analysis of Seeds, Oil and Flour of the Edible Fedora Cultivar Hemp (Cannabis sativa L.). Molecules 2018, 24, 83. [Google Scholar] [CrossRef]

- Vonapartis, E.; Aubin, M.-P.; Seguin, P.; Mustafa, A.F.; Charron, J.-B. Seed composition of ten industrial hemp cultivars approved for production in Canada. J. Food Compos. Anal. 2015, 39, 8–12. [Google Scholar] [CrossRef]

- Moccia, S.; Siano, F.; Russo, G.L.; Volpe, M.G.; La Cara, F.; Pacifico, S.; Piccolella, S.; Picariello, G. Antiproliferative and antioxidant effect of polar hemp extracts (Cannabis sativa L., Fedora cv.) in human colorectal cell lines. Int. J. Food Sci. Nutr. 2020, 71, 410–423. [Google Scholar] [CrossRef] [PubMed]

- Kobus, Z.; Pecyna, A.; Buczaj, A.; Krzywicka, M.; Przywara, A.; Nadulski, R. Optimization of the Ultrasound-Assisted Extraction of Bioactive Compounds from Cannabis sativa L. Leaves and Inflorescences Using Response Surface Methodology. Appl. Sci. 2022, 12, 6747. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).