4.1. Laboratory Test—Natural Stone Specimens

Laboratory tests were conducted on the durability of six types of limestone used in the exterior cladding of high-rise buildings and structures in the coastal zone of Israel from 1997–2016. The coastal zone of Israel is characterized by high average temperatures for most of the year, combined with high humidity and strong sea breezes affecting buildings and structures. In the exterior cladding made from five types of stones analyzed in this article, there was significant wear and tear within the first 2–4 years of building construction. As a result, property owners filed lawsuits against the contractors. The authors of this article prepared expert opinions on the compliance of all stones with Israeli standard SI 2378 Part 1 and the most likely reasons for the rapid wear and tear of the stones. The sixth type of stone was chosen as a reference since the exterior cladding of a 16-story building in the coastal zone proved to be highly durable.

Three types of stones (marble, such as limestones no. 1, 2, and 6) were used as exterior cladding in pre-polished factory slabs. Three other types of stones were used as unpolished cladding stones with a rough natural texture. The physical and mechanical properties of four types of stones (three with a polished texture and one with a rough natural texture) fully complied with all requirements of Israeli standard SI 2378 Part 1. Two of the tested types of stones with a rough natural texture had water absorption exceeding the standard requirements; however, all other physical and mechanical properties fully complied with the standard requirements.

In this article, we report only the results of the qualitative mineralogical composition, determined by XRD (X-ray diffraction) analysis, and standard tests of the capillary water absorption and the resistance to immersion of the stone samples (120 × 120 × 20 mm) for 24 h in a sodium sulfate salt solution (concentration 14%, by mass), followed by drying to a constant weight in a laboratory drying oven at a temperature of 102 °C ± 2 °C. The samples were weighed on analytical scales before the start of the first cycle and at the end of each subsequent cycle. The stone test was stopped as soon as the weight of the sample decreased after drying at the end of the next cycle. Based on the changes in the sample weight, the critical content of crystallized salt causing stone crumbling was calculated. The test results are presented in

Table 3 and in

Figure 2,

Figure 3 and

Figure 4. The results of the tests clearly demonstrate that the greater the capillary water absorption coefficient of limestone, the greater the critical sulfate content causing stone crumbling. However, no relationship was established between the capillary water absorption coefficient and the number of cycles during the crystallization test before the beginning of stone crumbling. For example, Limestone #1 (Hard) and Limestone #2 (Hard) began to crumble after the first and second cycles, respectively, just like Limestone #3 and Limestone #4. Although the capillary water absorption coefficient of Limestone #3 and #4 is twice as high as the maximum value allowed by the standard, the capillary water absorption coefficient of Limestone #1 and #2 is much lower than the maximum allowed by the standard. The reference stone (Limestone #6 (Hard)), which has the minimum capillary water absorption coefficient, began to crumble after the end of three cycles of testing. Similarly, Limestone #5 (Hard), whose capillary water absorption coefficient is 1.5 times lower than the maximum allowed by the standard, but almost 8 times higher than the reference stone (Limestone #6 (Hard)), began to crumble after the third testing cycle.

Thus, the results of laboratory tests suggest that the compliance of stone with the requirements of the standard for water absorption and resistance to crystallization testing is not a guarantee of the durability of the stone when used as an exterior cladding material. Therefore, the probabilistic methods proposed in this article may be a reliable method for predicting the durability of wall cladding.

4.2. Standard and Marine Service Conditions

This stage of the empirical research was based on comprehensive fieldwork on stone cladding deterioration over time. The exterior claddings of 87 tall and high-rise (more than 4 floors) buildings were sampled by visual observations at all heights from the ground level and the roof level, as well as by analysis of 10–12 photos. The claddings were graded according to a pre-tested template [

30] (see

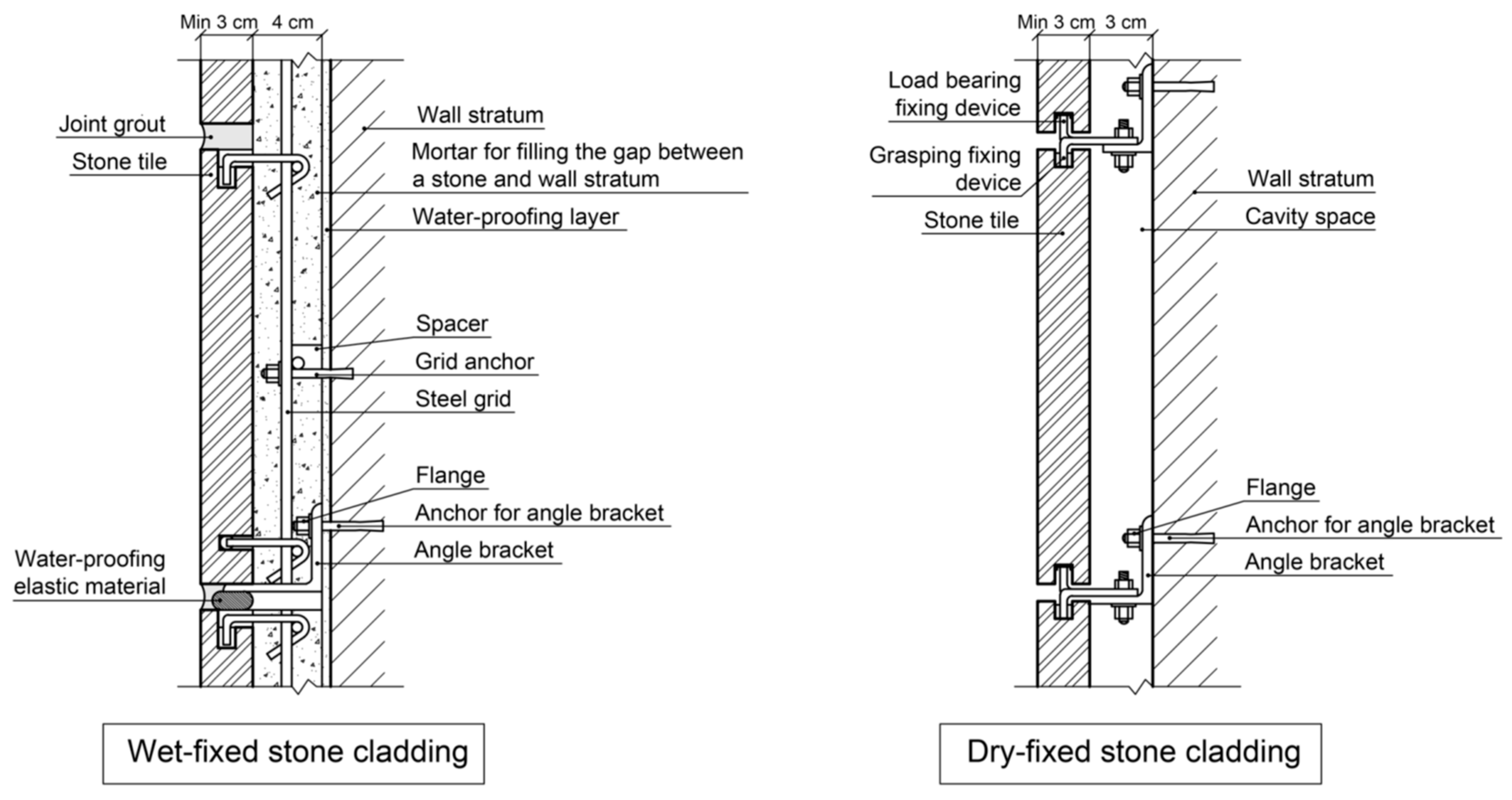

Appendix A). Degradation sources, such as marine environment, air-polluted environment, poor details (e.g., lack of joints and expansion joints, poor fixing details, and poor materials), were rigorously considered. The data gathering referred to factors such as the wind direction, the orientation of the large facade towards the wind direction, and the size of the natural stone panels. Observations with an evident failure degradation mechanism were excluded from the survey. The sample was further categorized according to the fixing method of the stone and the exterior service conditions.

Table 4 and

Table 5 delineate examples of various physical and visual degradation levels in three wet- and dry-fixed stone claddings taken from the sample inspected. Three different scatter diagrams were prepared from the results, where standard conditions reflect the normal conditions for which the building was designed, constructed, and maintained, and a marine environment reflects harsh environmental conditions: (1) dry-fixing exterior stone cladding under standard service conditions, (2) dry-fixing exterior stone cladding exposed to marine environment service conditions, and (3) wet fixing exposed to a marine environment. The buildings in the sample exposed to marine conditions were located in close proximity to the seashore (less than 400 m) on the central coast-line trip of Israel, considering the exposure to local sea water breeze regime conditions. This region is characterized by a mild rain regime (annual rain fall of 400–700 mm), 30–60 annual rain days, and a light wind regime (mainly south–west). The orientation of the large façade was found to be west in the majority of the sample, exposing the façade to the effects of the south–west wind regime. The dry-fixed stone cladding sample was limited to claddings aged up to 35 years, as this cladding is a relatively new method for exterior finishing in Israel and has only been implemented on a large scale since approximately 1985. The performance grading indicated that as a result of all facades, in a marine environment where the wind regime is dominantly a west wind, deterioration appears mainly in western facades (facing the seashore). Observations were taken at all height levels by observations at a roof level and a ground level, and by analysis of 10–12 photos.

As discussed above, the predicted life expectancy of a component is determined by the typical deterioration path intersection with the MRCP. Two threshold levels of minimum required component performance were considered [

10,

11,

12,

30], as follows:

(1) MRCP = 60%, for a high service standard of CP, for instance, in public or corporate buildings.

(2) MRCP = 40%, for moderated or low service standards, where the owner prefers to minimize maintenance costs while compromising the service standard of the exterior cladding.

Thus, the LE for MRCP 60 and 40 may be derived from the intercepts between the typical deterioration path curve and the 60 and 40 lines of performance levels, respectively. The confidence limit of the service life prediction was established at 80%, as recommended by ISO 15686 (2011) [

13].

The standard life expectancy (SLE) for wet-fixed stone cladding under standard service conditions was previously discussed by Shohet and Paciuk et.al. [

12], who reported values for MRCP

60% and MRCP

40% of 44 and 64 years, respectively. In this study, the reference service life of exterior dry-fixed stone cladding under standard service conditions was investigated in order to compare the values to the standard life expectancy of wet-fixed stone cladding. In addition, the typical deterioration patterns of both cladding methods in marine environmental conditions were examined in order to estimate the LELC.

The typical deterioration curve for dry-fixed cladding under standard service conditions is shown in

Figure 5. It expresses the regression analysis of 24 data points in a linear degradation process. The moderate decline in cladding performance reaches MRCP

60% and MRCP

40% levels after 59.5 and 88 years, respectively. It should be emphasized once more that the service life cycle expectancy at MRCP

40% is marginal with respect to the component performance of exterior stone cladding and involves inherent hazardous defects, i.e., delamination of stone plates, cracks in cladding, and detachment of complete stone plates.

Figure 6 shows the typical deterioration progression for wet-fixed stone claddings subjected to a marine environment. The life expectancies (LEFCs) for MRCP60% and MRCP40% were found to be 35 and 54 years, respectively. Calculating the life expectancy limited coefficient according to Equation (1) gave LELC = 0.79–0.84, indicating the strong impact of marine environment service conditions on the service life expectancy of the wet-fixed exterior stone cladding.

Table 6 summarizes the typical service life expectancy of wet-fixed exterior stone claddings exposed to the various service conditions. These findings are valid if no differences in the weather conditions occurred, compared to the characteristics at the time of analysis or if a constant increase of the sunny days number occurs, or the temperature, or the number of freeze–thaw cycles per year—and the weathering conditions, such as the salinity of water, increase (and accordingly the salinity of the air and thus the degree of influence on the anchorage system of the exterior stone cladding wall). It should be emphasized that the predicted service life intervals, MRCP

60% and MRCP

40%, were deduced by extrapolation of the linear regression lines of the predicted life expectancy, as well as the lower and upper prediction intervals lines. Therefore, further research with an extended range of service life is recommended in order to validate the results.

Finally, the typical deterioration pattern for dry-fixed stone cladding exposed to marine environment is presented in

Figure 4. The relatively moderate gradient of the average regression line yields life expectancies (LEFC) of 55 and 85 years for MRCP

60% and MRCP

40%, respectively. In this case, calculation of the life expectancy limited coefficient according to Equation (1) gave values for the LELC = 0.94–0.97, indicating the moderate impact of the marine environment service regime on the service life expectancy of dry fixed exterior stone cladding.

The service life expectancy of dry-fixed stone claddings subjected to standard conditions and marine environment are summarized in

Table 7.

The LELCs express the effects of the marine environment service conditions on the reference service life of wet- and dry-fixed stone claddings are presented in

Table 8. These findings reveal the main differences in the impact of marine environment on the performance of the two fixing techniques under discussion, i.e., the dry-fixed stone cladding method is less vulnerable to the marine environment service conditions. This conclusion is derived from the finding that the LE of Dry-fixed cladding in marine environment (for MRCP = 60) is 55, whereas the wet-fixed stone cladding is 35, and the prediction intervals of the at probability of 0.8 are distinctive (47–63 years for dry-fixed stone and 30–40 years for wet fixed stone—see

Figure 6 and

Figure 7 and

Table 6 and

Table 7). Nevertheless, the durability of the dry-fixed cladding is highly dependent on the performance of the stone and the fixing details and, therefore is highly dependent on the adherence of the design and construction to the technical parameters of the cladding systems, such as anchors resistance, suitability between the stone and joints materials and boundary details, such as the façade cornice and drip-edge).

Based on the data in

Table 7, the degradation impact due to the exposure to marine environment conditions can be calculated according to Equation (3):

where,

EFA−B—Coefficient expressing environmental conditions impact for alternative exterior cladding fixing techniques A (Wet-fixed) and B (Dry-fixed);

LELC

A and LELC

B—Coefficients expressing the Life Expectancy Limiting ratio for Wet and Dry fixed stone claddings, respectively. From values presented in

Table 7, EI

A−B for MRCP60% and MRCP40% can be calculated as 3.50 and 5.33, respectively. These findings reveal that the impact of marine environment service conditions on the deterioration of wet-fixed stone cladding is 3.5 to 5 times higher than on dry-fixed stone cladding.