Abstract

In this paper, in order to help improve the information capacity of modern factories, a full connection digital factory for industrial Internet identity resolution is built, and digital technology is used to perform the digital interconnection of the production equipment. The full connection digital factory is an advanced factory with extensive connection of production units, deep integration of IT–OT, full release of data value, and improvement of the total factor productivity. This is enabled by the full integration and use of the new generation technologies represented by 5G, edge computing, and identity resolution to reach new factory level, workshop level, and production line level production scenarios. Based on the integration of infrastructure, information technology, and platform service resources, a full connection digital factory architecture is constructed. The fusion application of 5G, edge computing, and mark resolution technology in transformer discrete manufacturing digital plant is then discussed. The challenges and development trends are summarized. Finally, it is demonstrated that the full connection digital factory of identity resolution is a possible future development direction.

1. Introduction

At present, the transformation direction of the manufacturing industry is the integration and improvement of automation upgrading and the new generation of information technology. This is not only the transformation replacing the manpower with robots, but also the full utilization of production data elements. Independent decision making can then be realized and automated production lines, intelligent workshops, and unmanned factories can be fully connected and deeply integrated. With the continuous development of digital factories, the manufacturing industry is using the new generation of information technology based on 5G and identity resolution technology to break through the data barriers between all levels and systems in modern factories and closely link the managers, workers, and production equipment.

The industrial Internet identity resolution system is an important part of the industrial Internet network system, which is the nerve center supporting its interconnection. Its function is similar to the domain name resolution system (DNS) in the Internet field. Identity resolution technology denotes the process of mapping the object identity to the information required by the actual information service, such as the address, item, and spatial location. For example, by resolution the identity of an item, the address of the server where the associated information is located is stored. Identity resolution is a technical process of “information transformation” which can accurately and efficiently obtain the corresponding information of object identity in a complex network environment. By developing a unified identification system, the identity resolution technology can connect all the production factors such as equipment, machines, and materials in the industry, and connect separated data and applications through the analytical system, so as to perceive the source information, flow process, and use of data. Products, machines, workshops, and factories can be vertically connected to collect low-level identification data into scale, data sharing among information systems, and identification data analysis and application. Edge computing is an open platform integrating core capacities of network, computing, storage, and application at the side close to the object or data source to provide the nearest end service. Its applications are initiated on the edge side to produce faster network service responses that meet the industry’s basic needs in real-time business, application intelligence, security, and privacy protection.

It can horizontally connect its own upstream and downstream enterprises using identity resolution to query data on demand. Small and medium-sized businesses can be horizontally connected as a platform to share data on demand using identity resolution. From end to end, the full life cycle of design, manufacturing, logistics, and use can be opened up to perform the true full life cycle management.

Identity resolution technology will change many industries and become their preferred tracing technology in the future, especially the manufacturing industry. It is the future of industry 4.0 and intelligent manufacturing. Addressing the increased bandwidth and low latency requirements of the fully connected digital factories, the big data communication [1] generated by more connected devices, and the data application processing capacity required by the factory floor are serious challenges for the industry. The popularization of identity resolution technology, fifth-generation communication technology, and edge computing technology allows the digital factory infrastructure to have faster data transmission, lower delay, and faster calculation. The manufacturing operation management platform can basically control the workshop operation situation without delay. Deep learning and other technologies were used to model and train the historical production data and perform forward-looking adjustments for production configuration. The full connection digital factory aims at maximizing the efficiency by taking advantage of these features at all times throughout the manufacturing process and assets; it provides an understanding of the near real-time manufacturing process, as well as more comprehensive and detailed shop scheduling. With the expected growth in demand for data [2] ranging from mission-critical to large-scale machine connectivity, the deployment of 5G along with identity resolution and edge computing has raised expectations that it will open up new opportunities for novel models and applications in full connection digital factories.

1.1. Motivation

The concept of digital factory (DF) first emerged in the late 1980s, when artificial intelligence (AI) was a manufacturing tool. As an advanced intelligent application, the digital factory allows rapid and dynamic manufacturing of products in a stable manner, easily responding to the demand for customized products and optimizing the time, supply, and production network. The establishment of digital factory in most enterprises mainly relies on mature industrial digital technologies such as the manufacturing execution system (MES), Internet of Things (IoT), cyber physics system (CPS), product data management (PDM), and enterprise resource planning (ERP). However, these mature technologies cannot easily perform the fusion of different types of data between various departments of the factory, and the real-time monitoring of the current production state of the factory with low delay. In this paper, the discussion of fully connected digital factory is integrated with identity resolution, 5G, and edge computing. In addition, the previously mentioned problems are solved under the condition of maximum privacy and security protection.

1.2. Contribution

The proposed fully connected digital factory solves the following problems:

- Integration of different departments and types of data in the factory.

- Low latency real-time monitoring of current factory production status.

- Ensuring the privacy and security of all types of data.

- Full life cycle traceability of production quality.

- Intelligent operation and maintenance of production equipment.

- Factory automation.

1.3. Organization

The remainder of this paper is organized as follows. Section 2 introduces the research status of digital factory in recent years and summarizes the advantages and disadvantages of each party. Section 3 presents the proposed industrial Internet identity resolution +5G fully connected digital factory architecture, introduces its framework, and details its process. Section 4 reviews the key technologies of fully connected digital factory. In Section 5, the application of fully connected digital factory in discrete manufacturing of power transformers is presented. Section 6 summarizes the challenges and development trends. Finally, the limitation and the route of future research, as well as the contribution to theory and practice, are introduced in the conclusion in Section 7.

2. Related Work

Identity resolution technology will change many industries and become their preferred tracing technology, especially the manufacturing industry. It will also be the future of industry 4.0 and intelligent manufacturing development. Addressing the increased bandwidth and low latency requirements of fully connected digital factories, the big data communication generated by more connected devices, and the data application processing capacity required by the factory floor are serious challenges facing the industry. The popularization of identity resolution technology, fifth-generation communication technology, and edge computing technology allows the digital factory infrastructure to have faster data transmission, lower delay, and faster computation. The manufacturing operation management platform can basically control the workshop operation situation without delay. Deep learning and other technologies were used to model and train historical production data and perform forward-looking adjustments to production allocation. The fully connected digital factory aims at maximizing the efficiency by taking advantage of these features at all times throughout the manufacturing process and assets. Shop scheduling was used to provide a more comprehensive and detailed understanding of the near real-time manufacturing process. With the expected growth in demand for data ranging from mission-critical to large-scale machine connectivity, the deployment of 5G alongside identity resolution and edge computing has raised expectations that it will open up new opportunities for novel models and applications in fully connected digital factories.

2.1. Existing Studies

Many studies on digitalized factory-related technologies were conducted. For instance, Ren Yuzheng et al. [3] discussed the design objectives and key supporting technologies of the new industrial Internet identity resolution and proposed a decentralized and efficient identity resolution system scheme. Zhou Hongyu et al. [4] proposed a remote operation and maintenance system for products based on industrial Internet identity resolution. By studying the 5G technology and its advantages, Chen Xiaomin et al. [5] analyzed the technical framework of “5G+ Industrial Internet” and its application and development prospects in intelligent [6] manufacturing by combining its development process and key technologies. They showed that the development of 5G and industrial Internet can provide good solutions for intelligent manufacturing. Zhang Wei et al. [7] established a modular vertical integration scheme of intelligent manufacturing service process. They demonstrated the feasibility and superiority of the vertical integration strategy of the intelligent manufacturing service process using specific examples. Based on the requirements of sustainable intelligent manufacturing and the characteristics of 5G wireless communication, Fadwa Mahiri et al. [8] proposed a 5G system supporting the industrial Internet of Things architecture (5G-IIoT) for the sustainable intelligent manufacturing environment. In addition, the security threats and challenges of 5G-IIoT [8,9] enabling intelligent manufacturing are analyzed. Tomasz W. Nowak et al. [10] studied the impact of the application of the mobile edge computing (MEC) technology on the MEC-based business functions of 5G, while considering 12 representative vertical industries of 5G MEC [11], and introduced their basic characteristics, threats, vulnerabilities, and known attacks. Zhao Feng et al. [12] proposed an intelligent workshop fault prediction and health management system based on the 5G technology to provide technical support for preventive maintenance and effectively reduce the repair and maintenance costs. Li Xuexia et al. [13] discussed the landing scheme of the core application scenario of the 5G technology in the smart garment factory. Zhang Jie et al. [14] proposed a data-driven intelligent control system architecture for robotized textile production. Zhang Lei et al. [15] analyzed the application status and problems of the identity resolution technology in Chinese industrial Internet and explored an innovative promotion mode based on its application requirements in key links of industrial enterprises. Marko Vukovic et al. [16] retrofitted old machines with the IIoT to make them connected and able to provide data for process monitoring. The solution provided immediate results in a manufacturing environment with the ultimate goal of digital transformation of the entire factory. This study presented an implementation cycle for digital industrial broaching, supported by a recent literature analysis.

DF-related newest studies are presented in Table 1.

Table 1.

Summary of existing research.

2.2. Key Considerations for Full Connection Digital Factory

The following factors should be considered in the establishment of a fully connected digital factory:

2.2.1. Data Security

This is a problem that both the owner and the user of data are very concerned about. It involves legal, ethical, and computer systems. These factors can be divided into two categories: the external conditions that are not directly related to the database system itself and the database system defense ability. As far as external conditions are concerned, it includes a series of appropriate management policies and security measures such as classification of data by secret level, control of who has access to the data, data testing, etc. It also includes computer physical damage, equipment security, and radiation protection. The defense ability of the database system is reflected by the measures it provides for data security:

It provides an authorized means for administrators to control access to the database.

It allows the users to be classified and granted different access rights.

It sets a password and other methods when the user enters the system security check.

It uses view and other methods to conceal and encrypt the data.

The security of a database system can be measured in terms of its integrity, flexibility, extra cost of the security checks, and robustness of the security mechanism.

2.2.2. Equipment Compatibility

It includes the device and application compatibilities. However, the application developer only takes into consideration the application compatibility, while he should check if his application is compatible with each potential device configuration. The system has different versions, and it runs on different devices. Therefore, the application should be tailored to his own needs. For example, if the core component of the application should be supported by sensors, then devices equipped with sensors should be selected.

2.2.3. Scalability

Many heterogeneous nodes exist in the IIoT. The number of nodes in the network may increase with the increase of the work schedule, even exceeding the load capacity of the network. Therefore, the data types and data processing platform should be continuously expanded, even if the increase of the data volume should not cause too much impact on the operation of the whole system. A complete network system should be able to resist this problem.

2.2.4. Stability

The overall operation of the fully connected factory system is stable, and all kinds of equipment can continuously and stably run, which is very important for the long-term stable operation of the factory.

2.2.5. Integrity

Any unauthorized third-party manipulation or modification of data is a key challenge for IIoT.

2.2.6. Interchangeability

Many IIoT devices are based on real-time communication connections and operations. In a distributed network, even if one node (server or device) fails, the processes on the other nodes should be able to continue running.

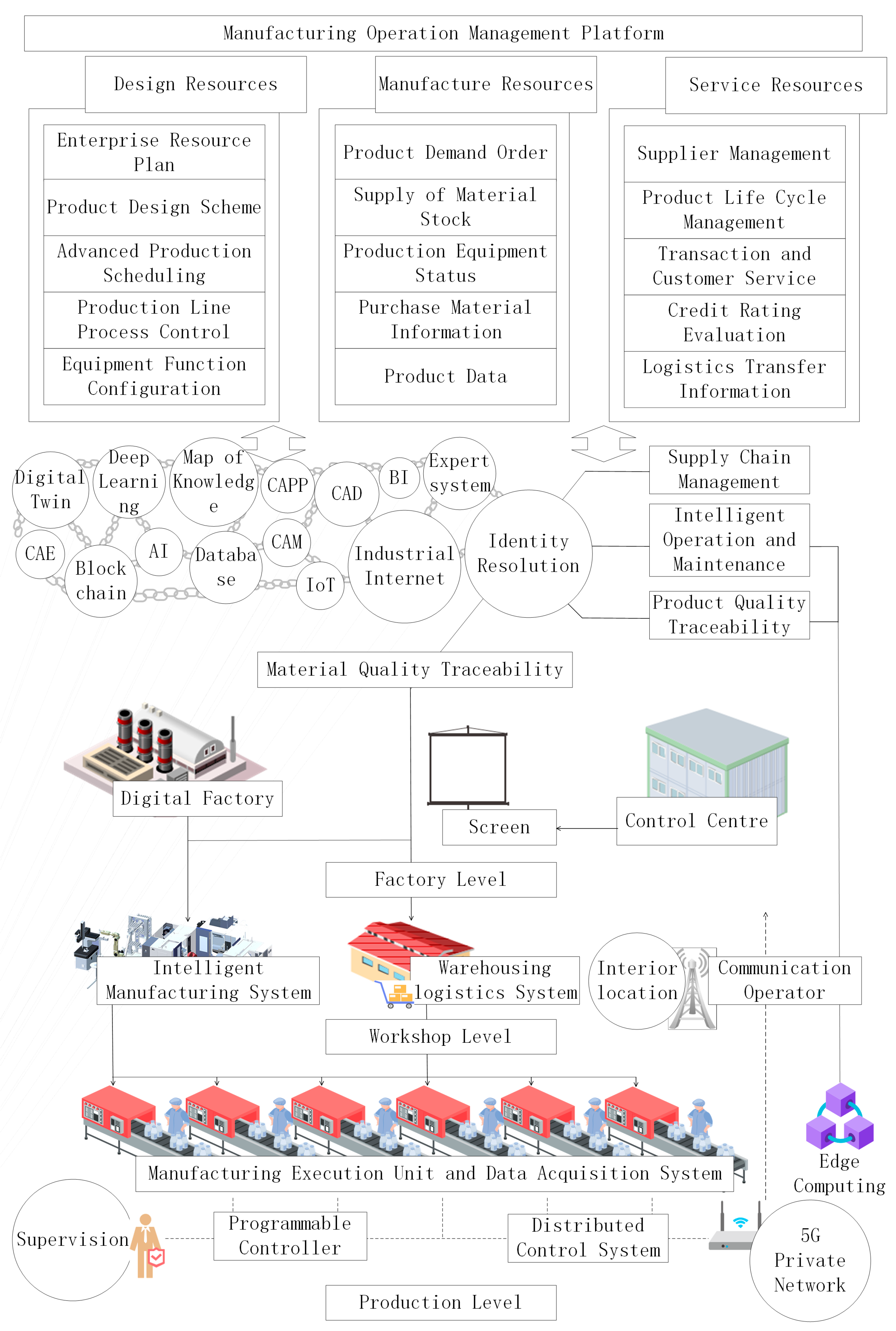

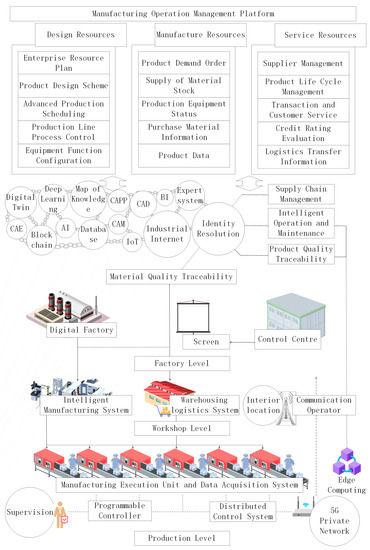

3. Full Connection Digital Factory Architecture

A full connection digital factory architecture comprises infrastructure, information technology, and platform service resources. The infrastructure resources are divided into three parts: production line level, workshop level, and factory level. The production line level manufacturing execution unit and data acquisition system communicate with the programmable controller and distributed control system through the 5G industrial private network provided by the communication operator and build the production line level edge computing platform. A workshop level intelligent manufacturing system and a warehousing and logistics system are used to perform the overall control of workshop production, warehousing, and logistics. The factory-level digital intelligent control center classifies and regresses the production data at the production line level and workshop level, integrates information technology resources and platform service resources to further process the data, and then projects them onto the information screen of the digital intelligent control center.

The identity resolution technology is throughout the level of information technology resources, due to the integration of the identity resolution technology with indoor positioning, deep learning, expert system, and other technologies. The traceability of materials consists of the traceability of the whole process from the upstream supply chain manufacturer and workshop level warehousing logistics to the workpiece output. It mainly tackles the production personnel, process plan, and manufacturing process at the production line level. The traceability of the production process and material quality ensures the high quality of the products. In addition, at the production line level, each part of the production equipment in the workshop is coded and the digital model of the production equipment is developed by using data mining technology. Quality traceability is performed for the whole life cycle of the production equipment parts at the level of operation and maintenance.

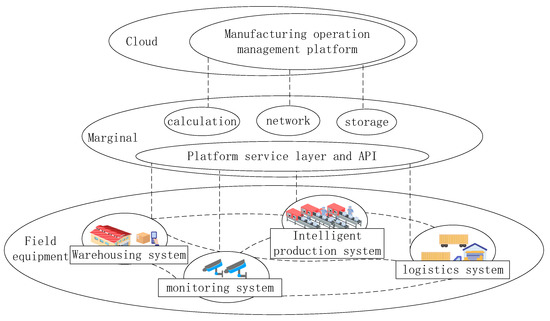

At the service level of the platform, the design [27], manufacturing resources, and service resources of the manufacturing operation management are integrated to connect the design, manufacturing, and service links in product life cycle. This allows to transform the closed series into open parallel links in order to form close collaboration and synchronous linkage among all the links, fully transfer and apply the data flow, effectively allocate resources, quickly respond to the market, and enhance the competitiveness of the product. More precisely, it includes the unified standard and coordination synchronization of the design, manufacturing resource, and service resource coordination. The architecture of the full connection digital factory is shown in Figure 1.

Figure 1.

Architecture of the full connection digital factory.

4. Key Technologies and Applications

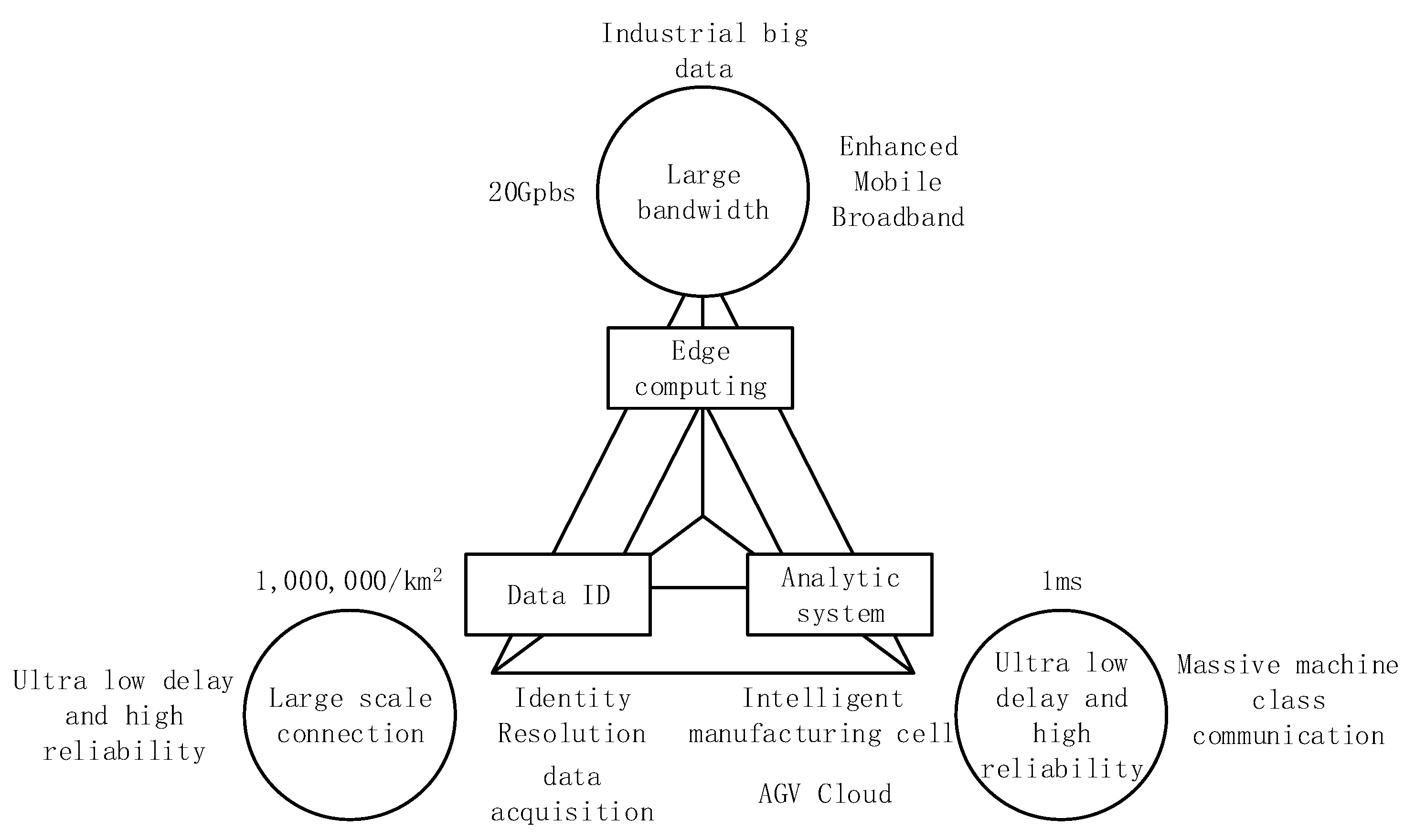

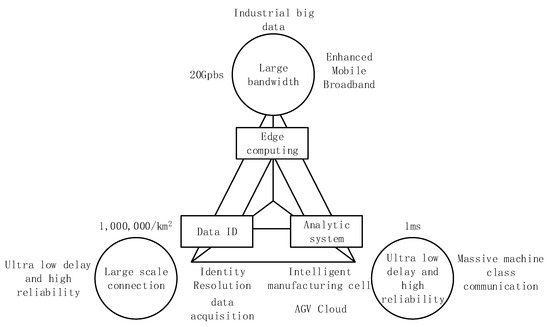

4.1. 5G Full Connection Digital Factory

Many industries realized the potential of 5G as the new generation of communication technology. Thus, it is promoted in vertical markets such as agriculture, energy, healthcare, logistics, and electronic information. Smart manufacturing devices using 5G wireless control have been recently used in digital factories, which will allow the machines to use their computing power in combination with the cloud storage, cloud computing [28,29], and other information technologies to control the manufacturing process in real time, without being restrained by physical wires. 5G integrates many features of 4G while solving its shortcomings. 5G has higher bandwidth and lower latency than Wi-Fi and 4G LTE, and it can support higher density of device links within the same area. One of the main differences between 5G and the previous generations of networks is that 5G adopts high concentration of machine-like communications (MTC) and IoT. In addition, it expands the mobile broadband capacities, where the data rates are growing. In addition, it provides advanced wireless connectivity for vertical industries such as the manufacturing industry. 5G supports the following basic communication types: enhanced mobile broadband (eMBB), massive type communication (MTC), and ultra-reliable low-latency communication (URLLC). eMBB provides extensive enhanced coverage and extremely high data rates, far exceeding 4G. MTC provides ubiquitous connectivity with low hardware and software device requirements while enabling battery saving through low-power operations. The URLLC application execution is highly critical and very demanding in terms of end-to-end low latency [30], reliability, and availability. A concrete example of these applications in manufacturing is the industrial automation and control requiring high performance connectivity. 5G will become an essential networking technology in the intelligent manufacturing environment driven by big data [31]. With its higher speed, low delay, large-capacity connected devices, and massive IoT connections [32], the system can reliably, safely, and continuously connect more devices to heterogeneous manufacturing resources for large-scale communication. This will improve the real-time operational control and decision-making capacity, flexibility, versatility, usability, and efficiency of the sustainable intelligent manufacturing system for future sustainable smart factories. With the increasing deployment of 5G communication base stations, all the data of digital factories will be collected and analyzed to provide detailed analysis for each service item of the factory operation management. The three key features of 5G technology are shown in Figure 2.

Figure 2.

Three key features of 5G technology.

In the field of digital factory, the application of 5G is divided into mobile network and fixed network. The 5G mobile network is used for communication between mobile devices in the workshop. The 5G fixed network is also known as the industrial 5G private network technology and industry optical ring (IOR). The integration of industrial 5G private network and IIoT [3] equipment edge computing [33] in workshops will transfer massive real-time production data of workshops without loss, in an ordered and fast manner, and assist the manufacturing operation platform to make analyses and decisions. The workshop level and production line level real-time intelligent control can then be realized. The industrial 5G private network adopts a ring structure to improve the network reliability. The industrial halo network consists of three parts: the head end equipment, terminal equipment, and passive halo network equipment. Using the SA network, the UPF of the user device is deployed in the enterprise park to implement MEC edge computing [34] and UPF sinking, providing enterprise users with exclusive network services such as edge computing, data retention, and ultra-low latency communication. The industrial 5G private network provides unified access to the factory security monitoring network. Industry Optical Ring is considered as the backbone of the digital factory, staff location and 5G network. It can perform microsecond low delay and provide high-precision clock synchronization and service isolation functions for 5G bearer. The indoor baseband processing unit of the 5G can be directly connected to the terminal equipment of the halo network.

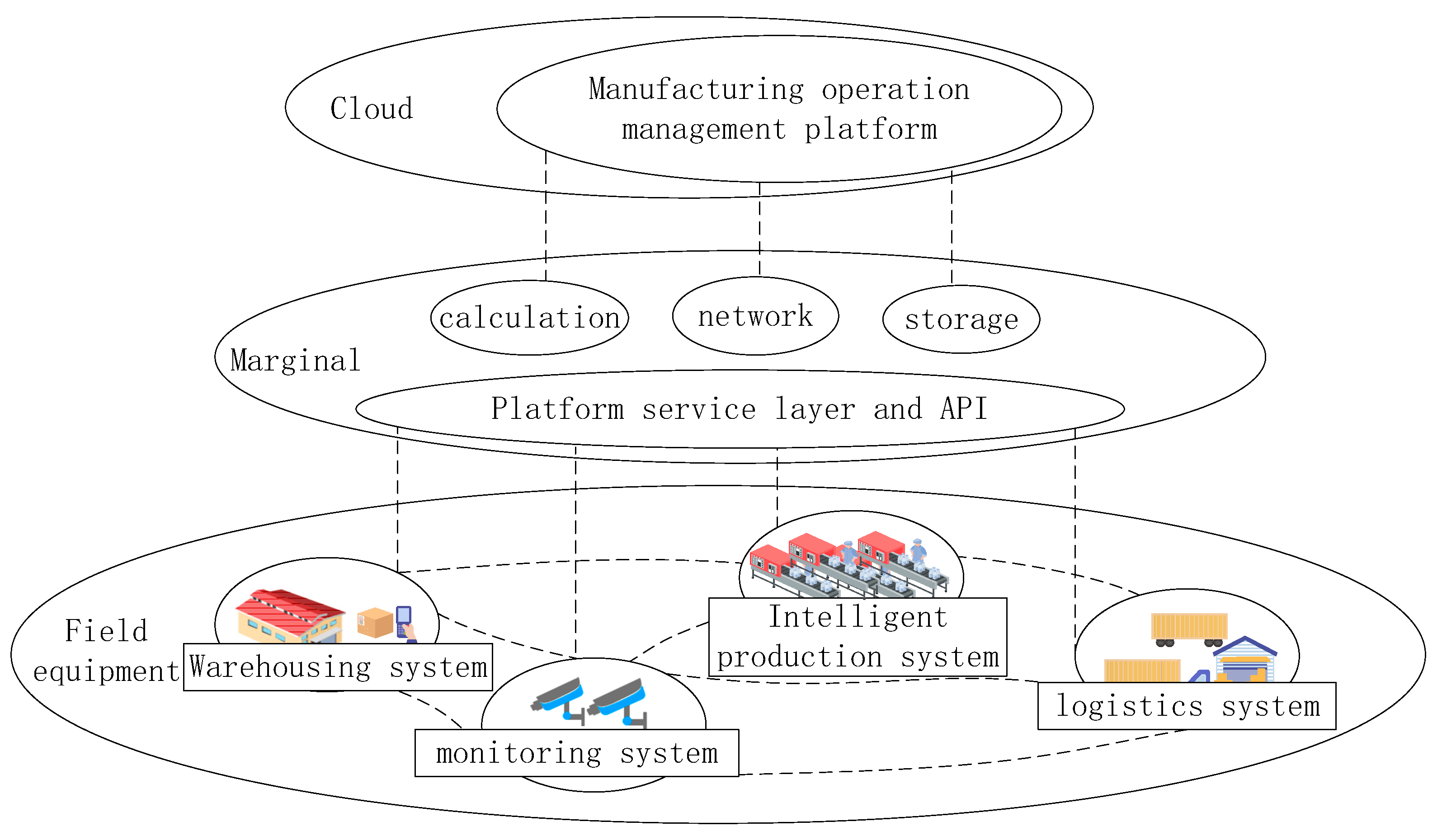

4.2. Edge Computing Full Connection Digital Factory

The collaborative interaction between the digital intelligent control center and the field equipment is performed through “cloud-edge-end” edge computing, where the “end” is responsible for the connection of the production line equipment, supports a variety of several heterogeneous network interfaces, and integrates the equipment and information system into a whole through communication. It also performs the hardware collection and interconnection of PLC control, machine tool system, cutting, welding, logistics and testing equipment, and configures the corresponding acquisition module and protocol according to the actual interface type. “Edge” performs data classification and identification processing of equipment status and algorithm. The edge management accepts sensor perception data and task instruction execution results from the production equipment of digital factory and performs cleaning, coding, mining, analysis, and fusion for the collected at the device end. In addition, the control instructions are sent to the welding, cutting, logistics, machine tool system, and others through the interface of the equipment end to the real-time monitoring of the production line level equipment status. The manufacturing operations management platform is responsible for further data analysis and report presentation. It supports the mainstream standard data interface and data sharing of the business application system. It receives the data uploaded from the edge side, stores it in the cloud computing center, transmits the real-time data to the cloud computing center for model training, and stores the time-stamped data as historical data for cloud computing model call. The edge computing architecture based on the concept of “cloud-edge-end” is of great significance for full connection digital factories. With the breakthrough of the edge computing technology in practical application, and the rapid development of the new generation communication technology and embedded hardware technology, more computing can be performed by relying on the computing power of the intelligent devices on the “end” side. This allows to avoid unnecessary data transmission to the cloud. That is, decision screening of the terminal device data on the device side is performed. This will make full use of the physical resources of the digital factory, filter and analyze at the edge nodes [35], save energy and time, and reduce the possibility of delay caused by data transmission. Only the required content will be sent to the cloud computing server through the communication network for data processing. It greatly improves the efficiency of data processing and decision making and reduces the cloud server pressure. Therefore, the edge computing concept based on 5G and other advanced network technologies provides a new solution for the problems of bandwidth competition and serious time delay when large-scale data are accessed by the industrial Internet. Edge computing can enable data connection, data optimization, and intelligent decision making in the case of real-time security, so that the data can really play a crucial role in ensuring the industrial site quality, cost, efficiency, and safety, and solve other critical problems. The continuous development of edge computing accelerates the deep integration of information technology resources and platform service resources and has a significant role in the industrial Internet era.

Edge computing is an open platform that can provide computing, storage, and other functions. It provides faster services and stronger computing power for mobile networks. It is compatible with 5G technology, it has high reliability and low time delay, and thus it will help the deployment of the Internet of Things and the construction of the edge computing network of full connection digital factories in the future. The edge computing architecture composed of field devices, edge end, and cloud is shown in Figure 3.

Figure 3.

Edge computing architecture.

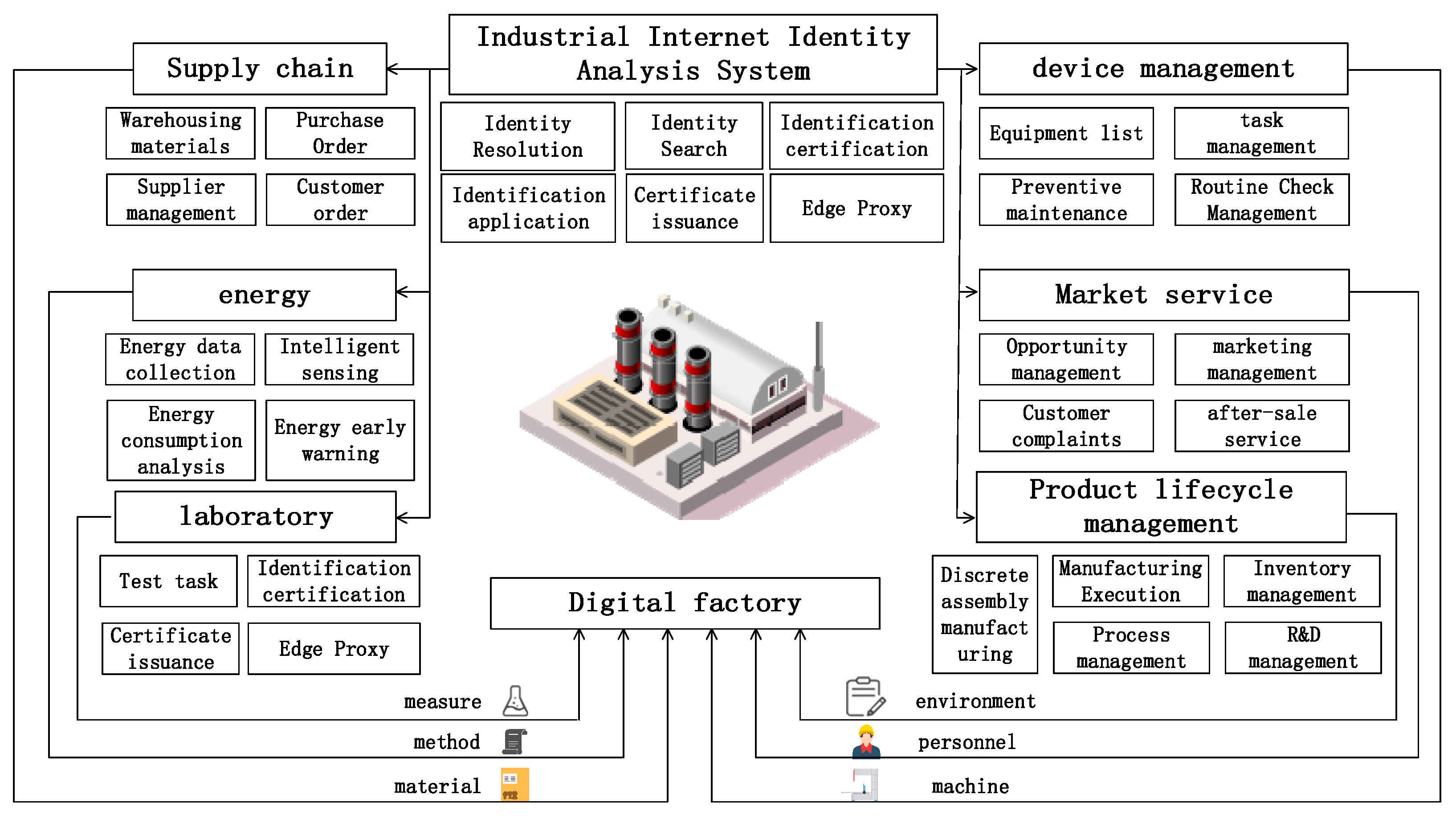

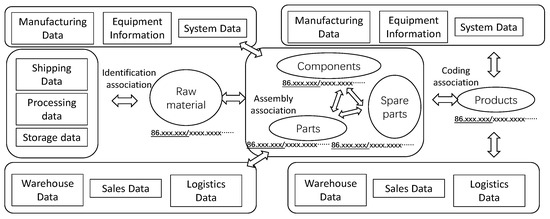

4.3. Identity Resolution Full Connection Digital Factory

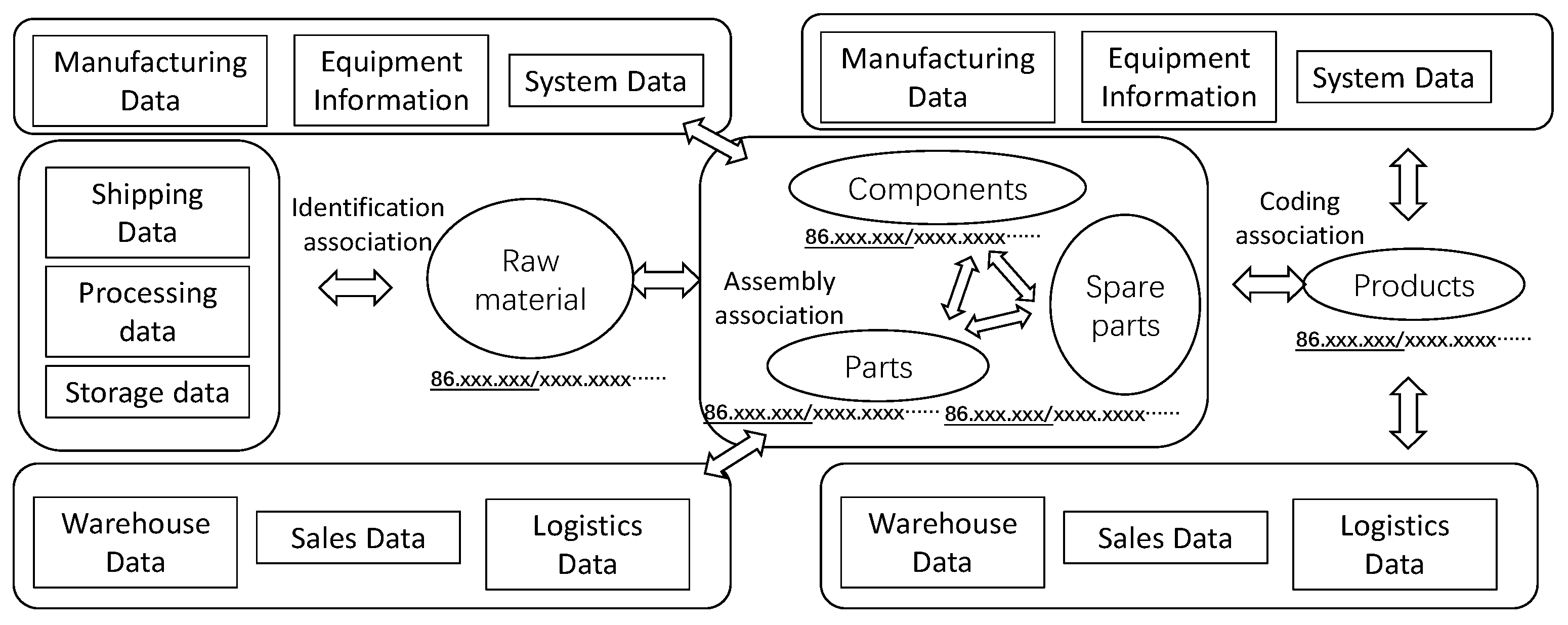

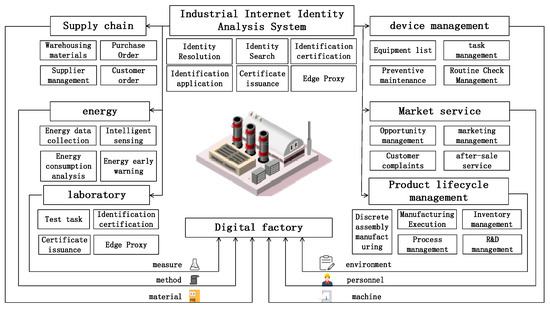

The industrial Internet identity resolution technology is one of the key technologies to perform data sharing between the upstream and downstream of the industrial chain [36] and the information systems within the enterprise. The full connection digital factory focuses on the production, processing, transportation, product testing, and other links. The scanning of the product identification code, automatic acquisition of raw materials, parts, and products, finished product process parameters, and other information allows to achieve more efficient, flexible, intelligent, and accurate parameter configuration. It is also efficient for equipment control, process association, problem analysis, and other applications. In network collaboration, information correlation is established through the identity resolution in production processing, supply chain, and other links. Thus, the enterprises can share production capacity, inventory, logistics capacity, and other information in real time, so as to perform the design, (external) production, online sharing of manufacturing capacity, and accurate management of supply chain. The servitization extension focuses on the production, logistics, maintenance, and other links. By scanning the product identification code, the relevant information of raw materials, parts, and products can be automatically obtained from upstream and downstream enterprises. Using data governance, the identification application of product traceability, predictive maintenance, and spare parts management can be realized. In digital management, due to the complexity of the product circulation links, it focuses on exploring the product code allocation and identity resolution [37] to open up the data links of different upstream and downstream enterprises in product circulation, perform the data linking covering production and manufacturing, as well as the whole-life cycle management and supply chain, improve the decision-making efficiency, and allow more accurate and transparent management. The application of full connection digital factories with identity resolution is shown in Figure 4.

Figure 4.

Identity resolution for full connection digital factory applications.

The identity resolution is used to perform the whole data management process of the product. It performs data connection between raw materials and production, production and storage, and storage and logistics. It also reduces the storage costs, improves the turnover rate, performs the two-way interaction and dynamic update of AGV and facility information based on the active identification technology, instantly and safely matches the user needs, automatically matches the production process in intelligent production scenarios, improves efficiency, reduces the trial-and-error costs, and increases the yield. The active identification carrier is used to determine the process parameters and perform two-way monitoring. It facilitates the transparent manufacturing process of the production line and promotes an efficient collaboration between the upstream and downstream of the supply chain. In addition, it provides a supply for the production and circulation process, reduces the production and operation costs, and improves the production efficiency and user experience.

The identification coding technology includes the identification carrier, laser marking, and identification reading technologies. The enterprises choose one of the mainstream identity resolution systems according to their needs. Product coding is a premise of the product quality traceability. The two-dimensional code is favored by the enterprises due to its low cost, large data storage, high fault tolerance rate, and its ability to perform web page jump. The product identification code and web address are stored together in the two-dimensional code, which is attached to the minimum package or even the product by spraying or coding. According to the product flow direction, the key quality information and data generated in the links of procurement, production, circulation, and sales are digitally correlated. The workflow of the product quality traceability system is shown in Figure 5. Currently, in the process of product quality traceability, product anti-counterfeiting and anti-channeling are two major problems. It is important to mention that the high energy density laser marking technology is used to make the surface of the metal products have a chemical reaction of color change, leaving a permanent mark number on the product to ensure its uniqueness.

Figure 5.

Workflow of the product quality traceability system.

5. Full Connection Power Transformers for Digital Factory Applications

In the power transformer discrete assembly manufacturing enterprises, the establishment of full connection digital factory has greatly improved its production efficiency. The manufacturing execution unit and the data acquisition system integrate the physical and network data resources of production line and shop level [38] into the edge computing and cloud manufacturing operation management server. The data generated by the manufacturing activities will be systematically modeled through big data analysis, cloud computing processing, and deep learning, while relying on the advanced data sensing and 5G communication technology. Real-time and high-fidelity manufacturing process synchronization between the workshop and Manufacturing Operation Management Platform. In this process, edge computing will provide some computing power and take some data processing tasks. In addition, the manufacturing operation management platform coordinates design resources and manufacturing resources to split product demand orders, reasonably allocates personnel and materials, and controls the manufacturing process in real time. The whole life cycle of the product and the follow-up delivery logistics are traced using identity resolution technology.

The deployment of power transformer discrete assembly and manufacturing full connection digital factory is divided into three parts: automatic production, product quality assurance, and intelligent operation and maintenance of workshop equipment. The production resources of the digital factory are synchronized and coordinated by the manufacturing operation management platform. The intelligent production equipment at the workshop level and production line level has the decision-making authority for some production tasks, such as the planning of AGV material distribution path and the temporary material scheduling in the storage system.

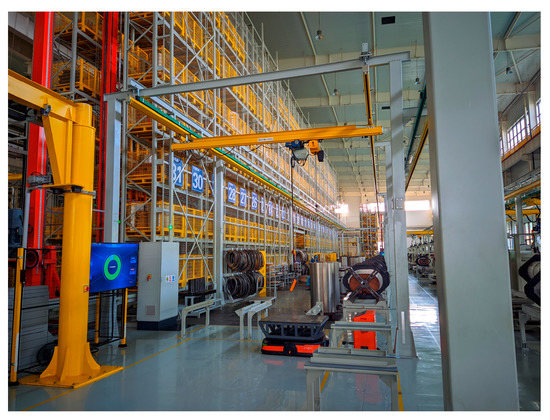

At the automatic production level, according to the current order, the digital technology is used for the design of resources and process plan, production team personnel arrangement, work order of each production line, production material allocation, coil process plan, semi-finished products storage, as well as transportation and discrete assembly, finished products delivery, and order delivery to ensure a normal, orderly, and automatic production. The 5G communication base station deployed in the workshop is combined with the workshop positioning technology to perceive the position state depth of AGV. Moreover, cloud computing [39] is combined with the edge computing technology to specifically split the material distribution tasks of each station and rationally subcontract the types and quantities of the materials required by the station and the distribution path of AGV. The AGV equipped with an artificial vision camera can then identify the obstacles on the path. The workshop monitoring system and edge computing platform were combined to avoid obstacles, and the distribution rhythm was adjusted according to the production rhythm. The intelligent warehousing logistics of multiple stations and various materials in the whole distribution process are realized, as shown in Figure 6.

Figure 6.

Intelligent warehousing logistics transportation.

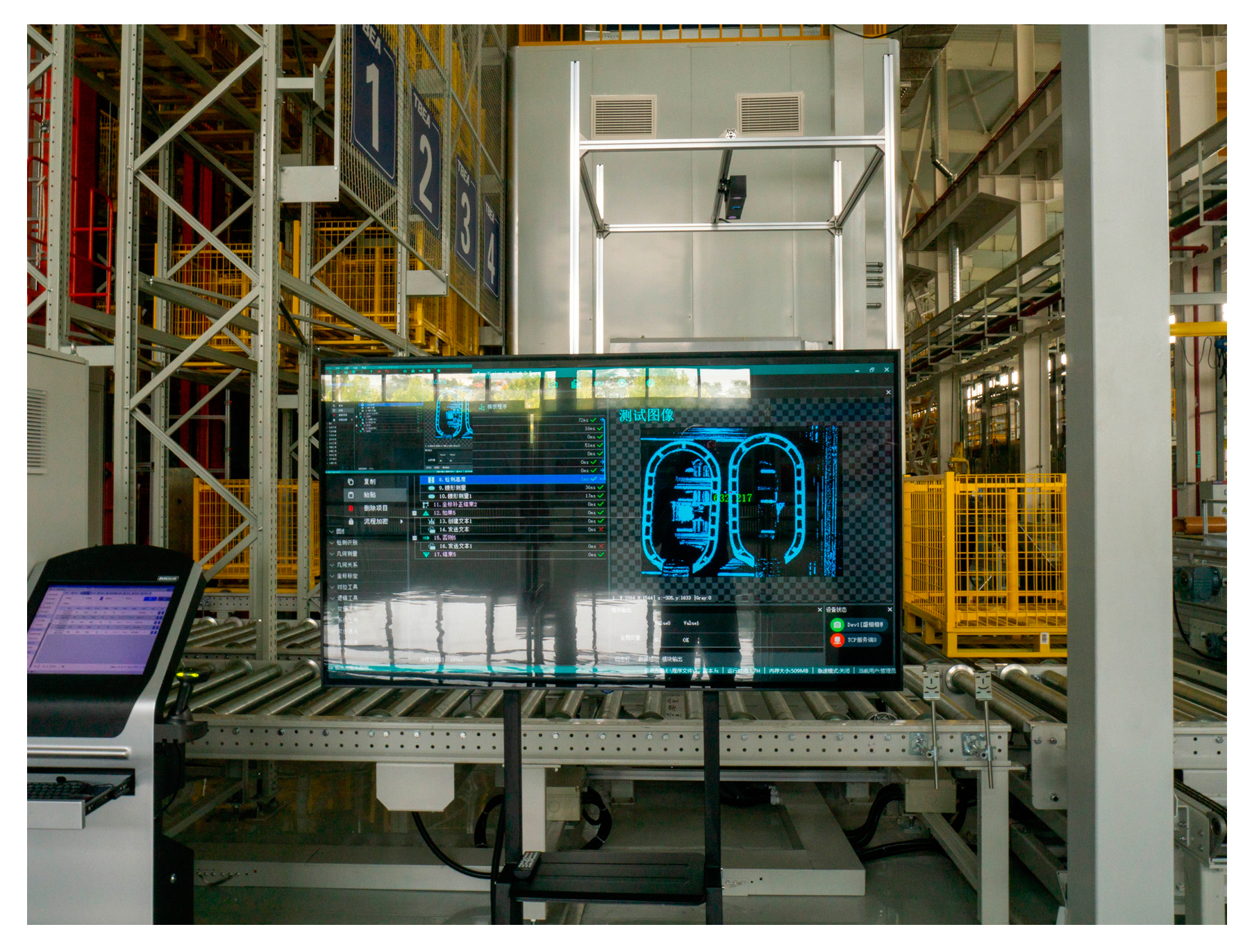

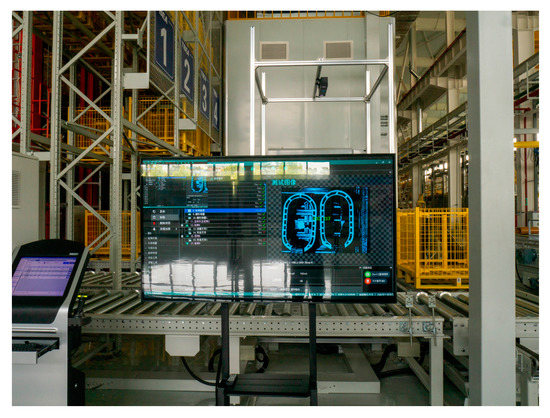

In product quality assurance, material quality is closely related to product quality. Using the identity resolution technology, the whole process of the production of product parts, assembly of components, and assembly and delivery of finished products, from the supply from the upstream chain manufacturers to the warehousing and discharging of materials, is assigned to the cloud. The specifications, production date, quality rating, and other information on the materials, as well as the parts and finished products, are input in each flow link to perform the quality traceability of the whole life cycle of the products. To control the cost, a classification is performed for the production materials having different qualities and costs, corresponding to orders of different production specifications, without reducing the quality of the finished product. The identification codes should be scanned to record the information of each node in the process of material discharging, loading, and delivery to the station, including the number of the warehouse location, number of the operator, number of AGV, and distribution time. In the factory, the ground identification codes should be scanned to record the distribution information when the AGV arrives at each location point, and the AGV path and material destination should be synchronized and traced. The AI+ machine vision combined with the edge computing technology was used to detect the transformer coil drying from the drying tank. To ensure that its basic process requirements, dimensions, and other parameters are in line with the requirements of the process drawings, and according to the test results, warehouse locations are allocated in the three-dimensional warehouse for the classified storage for the next process. The machine vision quality inspection is shown in Figure 7.

Figure 7.

Machine vision quality inspection.

In terms of intelligent operation and maintenance of workshop equipment, various production data of workshop production equipment are collected, processed by edge computing analysis and manufacturing operation management platform, and displayed on the production line screen of the digital intelligent control center. Workshop production managers follow up on the data on the screen and resolve the unexpected production anomalies. Through 3D modeling, the 3D model corresponds to the workshop entity one by one. According to the equipment operation instructions, the maintenance time of each part can be marked on the 3D model. When the maintenance period is approaching, it will be reminded on the screen to assign code binding to each part. Scanning the corresponding two-dimensional code before the operation and maintenance of the workshop equipment parts allows to record their specific situation. The data will be synchronized on the screen of the production line. In addition, the operation and maintenance personnel of the production equipment and the implementation of the operation and maintenance technology of the workshop will be traced. The production situation of the workshop and the situation of each equipment will be displayed on the screen of the production line. The main page of the visual equipment management platform has modules such as the production line introduction, planned output, production trend, qualified rate of production line, abnormal safety light, and on-hours statistics, as shown in Figure 8.

Figure 8.

Production line operation analysis screen.

6. Challenges and Development Trends

6.1. 5G Application Layer

Due to the fact that 5G can achieve high speed, low time delay, ubiquitous network, low power consumption, and Internet of Everything, it is widely used in the construction of digital factories. Thus, it is necessary to consider the frequency band interference and avoid the use of low-frequency signal equipment. However, the penetration of high-frequency signals is poor. In order to ensure the high transmission quality of signals, more 5G base stations should be built in areas with complex obstacles. This will affect the digital factory network smoothness. 5G is the top priority for a full connection digital factory communication network. However, it still should be combined with other communication technologies to build a digital factory for solving the low latency and high-rate network communication between fixed and mobile devices. Therefore, the coexistence mechanism between the 5G communication technology and other wireless communication technologies that may conflict with its spectrum is still a matter to be discussed. In addition, the risk assessment method and private network design technology should be used to ensure the production line and workshop communication security. This provides a communication guarantee for the construction of a full connection digital factory.

6.2. Edge Computational Plane

Digital assets, such as the industrial core data, key technology patents, and enterprise user data, have become the core assets of enterprises. As the primary guarantee of production, data security has always been the most concerned issue of the enterprises. In the production workshop, there will be more intelligent production equipment connected to the edge computing platform in the future. Besides the rigid standards for communication technology, security issues are also important. If a large number of devices in an edge computing cluster are attacked, data are maliciously written, or critical data are stolen, which leads to serious losses. To avoid this kind of situation, a challenge for the future development of edge computing consists in establishing a unified and compatible standardized secure communication protocol and a stable and secure software operating ecosystem.

6.3. Identity Resolution Layer

The industrial Internet identity resolution system has been widely used in several application domains such as intelligent production and network collaboration in manufacturing factories. It has become an important infrastructure to support industrial digital transformation and build full connection digital factories. The industrial Internet identity resolution system is an important part of the industrial internet network system. In addition, the sign system is an important pillar for the development of full connection digital factory data integration and interconnection to break the data barriers of all workshops and production lines. It is important to mention that the actual role of identity resolution is closely related to the wide range of identified objects and the range and accuracy of data. By allowing more upstream and downstream enterprises of the supply chain to access the identity resolution platform of various industries and allowing more production equipment and parts to use the identity resolution technology, the co-construction and sharing of the industrial Internet identity resolution system of the whole industrial chain can be formed. Thus, the full connection digital factory equipment operation and maintenance, as well as the and quality traceability system, can be improved.

7. Conclusions

With the application and promotion of 5G, edge computing, and identity resolution technology in the whole industrial scene, the full connection digital factory will become the target of construction and transformation of more manufacturing enterprises. Starting from the core support of the digital factory, this paper integrates platform service, information technology, and infrastructure resources to build the architecture of the full connection digital factory. It also discusses the development of 5G, edge computing, and identity resolution technology and their practical applications in power transformer discrete manufacturing plants. The challenges and prospects are then summarized from three aspects: 5G full connection, edge computing, and industrial internet identity resolution. The core support of the identity resolution technology, 5G, and edge computing fully integrates new generation information and communication technologies such as big data, cloud computing, artificial intelligence, edge collaboration, blockchain [40], and digital twinning. This is helpful to comprehensive integration of human, machine, material, method, environment, product life cycle, technology, business, resources, finally achieve the full connection digital factory. The fundamental goal of building a full connection digital factory is to achieve the rational utilization and integrated management of factory resources from the perspective of the whole industrial chain, process, and factors.

Author Contributions

Conceptualization, R.J. and W.S.; methodology, D.W.; software, X.Z.; validation, D.W., R.J. and Y.Z.; formal analysis, C.L.; investigation, D.W.; resources, D.W.; data curation, X.Z.; writing—original draft preparation, D.W. and R.J.; writing—review and editing, R.J.; visualization, X.Z. and Y.Z.; supervision, W.S.; project administration, W.S.; funding acquisition, D.W. and W.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the 2021 Industrial Internet Innovation and Development Project-Industrial Internet Identity Resolution All Element Integration Platform Project, grant number TC210A02E.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ren, J.; He, Y.; Yu, G.; Li, G.Y. Joint Communication and Computation Resource Allocation for Cloud-Edge Collaborative System. In Proceedings of the 2019 IEEE Wireless Communications and Networking Conference (WCNC), Austin, TX, USA, 10–13 April 2022. [Google Scholar]

- Wang, H.; Wang, B.; Han, S.; Cui, J. Multi-source data sharing of electrical equipment based on handle system identity resolution technology for Internet of things in electric industry. In Proceedings of the 2021 International Conference on Intelligent Computing, Automation and Systems (ICICAS), Chongqing, China, 29–31 December 2021; pp. 181–186. [Google Scholar]

- Ren, Y.; Xie, R.; Yu, F.R.; Huang, T.; Liu, Y. Potential Identity Resolution Systems for the Industrial Internet of Things: A Survey. Commun. Surv. Tutor. 2021, 23, 391–430. [Google Scholar] [CrossRef]

- Zhou, H.; Zhou, B.; Li, J.; Ma, C.; Wei, Y.; Bai, Y.; Wu, J.; Chen, Z.; Xu, H.; Wang, J.; et al. Cloud Edge Collaborative System Based on 5G Industrial Internet Identification and Collaborative Method. CN 112163821 A, 1 January 2021. [Google Scholar]

- Chen, X.; Zhao, T.; Yuan, X.; Liu, X. Intelligent Manufacturing of High-End Equipment in the Era of “5G+Industrial Internet”. J. Nantong Univ. 2021, 20, 1–12. [Google Scholar]

- Wang, T.; Luo, H.; Jia, W.; Liu, A.; Xie, M. MTES: An Intelligent Trust Evaluation Scheme in Sensor-Cloud-Enabled Industrial Internet of Things. IEEE Trans. Ind. Inform. 2020, 16, 2054–2062. [Google Scholar] [CrossRef]

- Zhang, W.; Zhu, X.; Nurjamal, M.; Gu, X.; He, X.; Ma, J.; Xu, W. Intelligent manufacturing service flow vertical integration in industrial internet environment. Syst. Eng.—Theory Pract. 2021, 41, 1761–1770. [Google Scholar]

- Mahiri, F.; Najoua, A.; Ben Souda, S. 5G-Enabled IIoT Framework Architecture towards Sustainable Smart Manufacturing. Int. J. Online Biomed. Eng. 2022, 18, 4–20. [Google Scholar] [CrossRef]

- Huang, J.; Kong, L.; Chen, G.; Wu, M.Y.; Liu, X.; Zeng, P. Towards Secure Industrial IoT: Blockchain System with Credit-Based Consensus Mechanism. IEEE Trans. Ind. Inform. 2019, 15, 3680–3689. [Google Scholar] [CrossRef]

- Nowak, T.W.; Sepczuk, M.; Kotulski, Z.; Niewolski, W.; Artych, R.; Bocianiak, K.; Osko, T.; Wary, J.-P. Verticals in 5G MEC-use cases and security challenges. IEEE Access 2021, 9, 87251–87298. [Google Scholar] [CrossRef]

- Jung, S.; Kim, D.; Shin, N. Success Factors of the Adoption of Smart Factory Transformation: An Examination of Korean Manufacturing SMEs. IEEE Access 2023, 11, 2239–2249. [Google Scholar] [CrossRef]

- Zhao, F.; Zhu, S.; Lv, Z. Intelligent workshop fault prediction and health management system based on 5G technology. Pract. Electron. 2020, 15, 34–35. [Google Scholar]

- Li, X.; Zhang, Z.; Chu, J. Research on the application of 5G technology in intelligent garment factory. Wool Text. J. 2021, 49, 104–109. [Google Scholar]

- Zhang, J.; Liu, W. Construction of cotton information tracing platform based on Internet of Things technology. China Cotton Processing 2017, 6, 19–21. [Google Scholar]

- Zhang, L.; Den, Y.; Den, S.; Yang, T. Industrial Internet identification analysis experiential promotion model Exploration and practice. Cyber Secur. 2021, 7, 39–41. [Google Scholar]

- Vukovi´c, M.; Jorg, O.; Hosseinifard, M.; Fantoni, G. Low-Cost Digitalization Solution through Scalable IIoT Prototypes. Appl. Sci. 2022, 12, 8571. [Google Scholar] [CrossRef]

- Bondin, A.; Zammit, J.P. A New Age for Plant Maintenance: Making use of Augmented Reality to Improve Maintenance of Production Assets. In Proceedings of the 2022 IEEE International Conference on Technology Management, Operations and Decisions (ICTMOD), Marrakech, Morocco, 23–25 November 2022; pp. 1–6. [Google Scholar]

- Basu, D.; Ghosh, U.; Datta, R. 6G for Industry 5.0 and Smart CPS: A Journey from Challenging Hindrance to Opportunistic Future. In Proceedings of the 2022 IEEE Silchar Subsection Conference (SILCON), Silchar, India, 4–6 November 2022; pp. 1–6. [Google Scholar]

- Xia, Y.; Guo, X. Intelligent Manufacturing Line Design Based on Parallel Collaboration. In Proceedings of the 2022 5th World Conference on Mechanical Engineering and Intelligent Manufacturing (WCMEIM), Ma’anshan, China, 18–20 November 2022; pp. 1149–1152. [Google Scholar]

- Lichtenstern, I.; Kerber, F. Data-Based Digital Twin of an Automated Guided Vehicle System. In Proceedings of the 2022 Winter Simulation Conference (WSC), Singapore, 11–14 December 2022; pp. 2936–2946. [Google Scholar]

- Kwon, Y.-K. Optimal Digital Twin Model-based CPS (Cyber Physical System) Design for Smart Factory. In Proceedings of the 2022 22nd International Conference on Control, Automation and Systems (ICCAS), Busan, Republic of Korea, 27–30 November 2022; pp. 752–754. [Google Scholar]

- Zhu, H.; Ebel, H.; Scheinert, D.; Schmidt, F.; Altenkirch, J.; Kao, O. Scalable and Data-driven Decision Support in the Maintenance, Repair, and Overhaul Process. In Proceedings of the 2022 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Kuala Lumpur, Malaysia, 7–10 December 2022; pp. 0344–0348. [Google Scholar]

- Mohan, T.R.; Roselyn, J.P.; Uthra, R.A. Digital Smart Kaizen To Improve Quality Rate Through Total Productive Maintenance Implemented Industry 4.0. In Proceedings of the 2022 IEEE 3rd Global Conference for Advancement in Technology (GCAT), Bangalore, India, 7–9 October 2022; pp. 1–6. [Google Scholar]

- Chakroun, A.; Hani, Y.; Elmhamedi, A.; Masmoudi, F. Digital Transformation Process of a Mechanical Parts Production workshop to fulfil the Requirements of Industry 4.0. In Proceedings of the 2022 14th International Colloquium of Logistics and Supply Chain Management (LOGISTIQUA), El Jadida, Morocco, 25–27 May 2022; pp. 1–6. [Google Scholar]

- Haricha, K.; Khiat, A.; Issaoui, Y.; Bahnasse, A.; Ouajji, H. Recent technological progress to empower Smart Manufacturing: Review and Potential Guidelines. IEEE Access 2023. [Google Scholar] [CrossRef]

- Chen, H.; Jeremiah, S.R.; Lee, C.; Park, J.H. A Digital Twin-Based Heuristic Multi-Cooperation Scheduling Framework for Smart Manufacturing in IIoT Environment. Appl. Sci. 2023, 13, 1440. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Cheng, G. Design and Implementation of an SDN-Enabled DNS Security Framework. China Commun. 2019, 16, 13. [Google Scholar]

- Goldin, E.; Feldman, D.; Georgoulas, G.; Castano, M.; Nikolakopoulos, G. Cloud computing for big data analytics in the Process Control Industry. In Proceedings of the 2017 25th Mediterranean Conference on Control and Automation (MED), Valletta, Malta, 3–6 July 2017; pp. 1373–1378. [Google Scholar]

- Ning, F.; Zhou, W.; Zhang, F.; Yin, Q.; Ni, X. The architecture of cloud manufacturing and its key technologies research. In Proceedings of the 2011 IEEE International Conference on Cloud Computing and Intelligence Systems, Beijing, China, 15–17 September 2011; pp. 259–263. [Google Scholar] [CrossRef]

- Ren, J.; Yu, G.; He, Y.; Li, Y. Collaborative Cloud and Edge Computing for Latency Minimization. IEEE Trans. Veh. Technol. 2019, 68, 5031–5044. [Google Scholar] [CrossRef]

- Rehman, M.H.U.; Ahmed, E.; Yaqoob, I.; Hashem, I.A.T.; Imran, M.; Ahmad, S. Big Data Analytics in Industrial IoT Using a Concentric Computing Model. IEEE Commun. Mag. 2018, 56, 37–43. [Google Scholar] [CrossRef]

- Sisinni, E.; Saifullah, A.; Han, S.; Jennehag, U.; Gidlund, M. Industrial Internet of Things: Challenges, Opportunities, and Directions. IEEE Trans. Ind. Inform. 2018, 14, 4724–4734. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, X.; Qin, Y. A survey of mobile edge computing in the industrial internet. In Proceedings of the 2019 7th International Conference on Information, Communication and Networks (ICICN), Macau, China, 23–26 April 2019; pp. 94–98. [Google Scholar]

- Cai, S.; Zhu, Y.; Wang, T.; Xu, G.; Liu, X. Data Collection in Underwater Sensor Networks based on Mobile Edge Computing. IEEE Access 2019, 7, 65357–65367. [Google Scholar] [CrossRef]

- Baas, J. Combining Node Embeddings with Domain Knowledge for Identity Resolution. Graphs Netw. Humanit. 2021, 6. [Google Scholar]

- Cui, J.; Wang, H.; Xue, W.; Wang, B. Application of identity resolution and blockchain technology in the whole industrial chain management of electrical equipment. J. Phys. Conf. Ser. 2021, 1800, 012011. [Google Scholar] [CrossRef]

- Xie, R.; Wang, Z.; Yu, F.R.; Huang, T.; Liu, Y. A novel identity resolution system design based on Dual-Chord algorithm for industrial Internet of Things. China Commun. 2021, 64, 14. [Google Scholar] [CrossRef]

- Lu, H.; Li, X.; Xie, R.; Feng, W. Integrated Architecture for Networking and Industrial Internet Identity. ZTE Commun. 2020, 18, 24–35. [Google Scholar]

- Ding, C.; Zhou, A.; Liu, Y.; Chang, R.; Wang, S. A Cloud-Edge Collaboration Framework for Cognitive Service. IEEE Trans. Cloud Comput. 2020, 10, 1489–1499. [Google Scholar] [CrossRef]

- Ali, M.S.; Vecchio, M.; Pincheira, M.; Dolui, K.; Antonelli, F.; Rehmani, M.H. Applications of Blockchains in the Internet of Things: A Comprehensive Survey. Commun. Surv. Tutor. IEEE 2018, 21, 1676–1717. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).