Synergic Effects of Nano Additives on Mechanical Performance and Microstructure of Lightweight Cement Mortar

Abstract

:1. Introduction

2. Materials and Methods

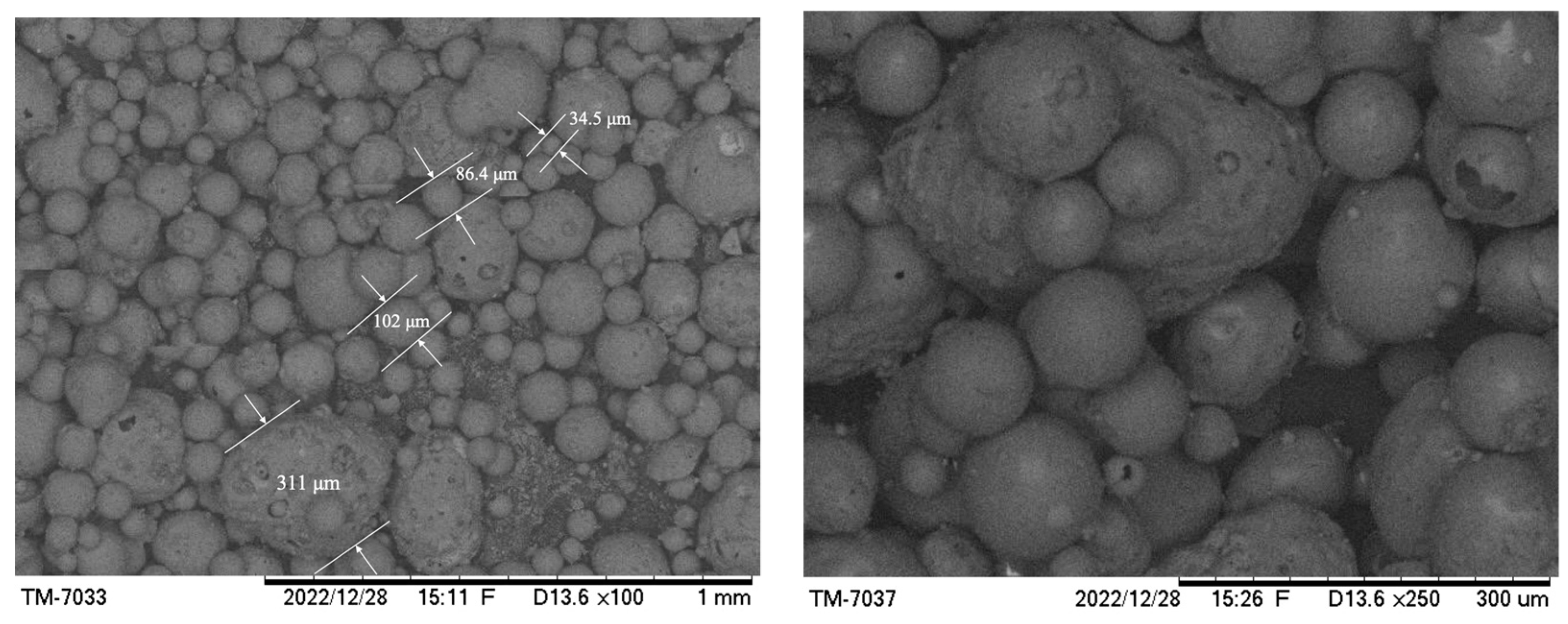

2.1. Materials

2.2. Mix Design

2.3. Dispersion of Nano Materials

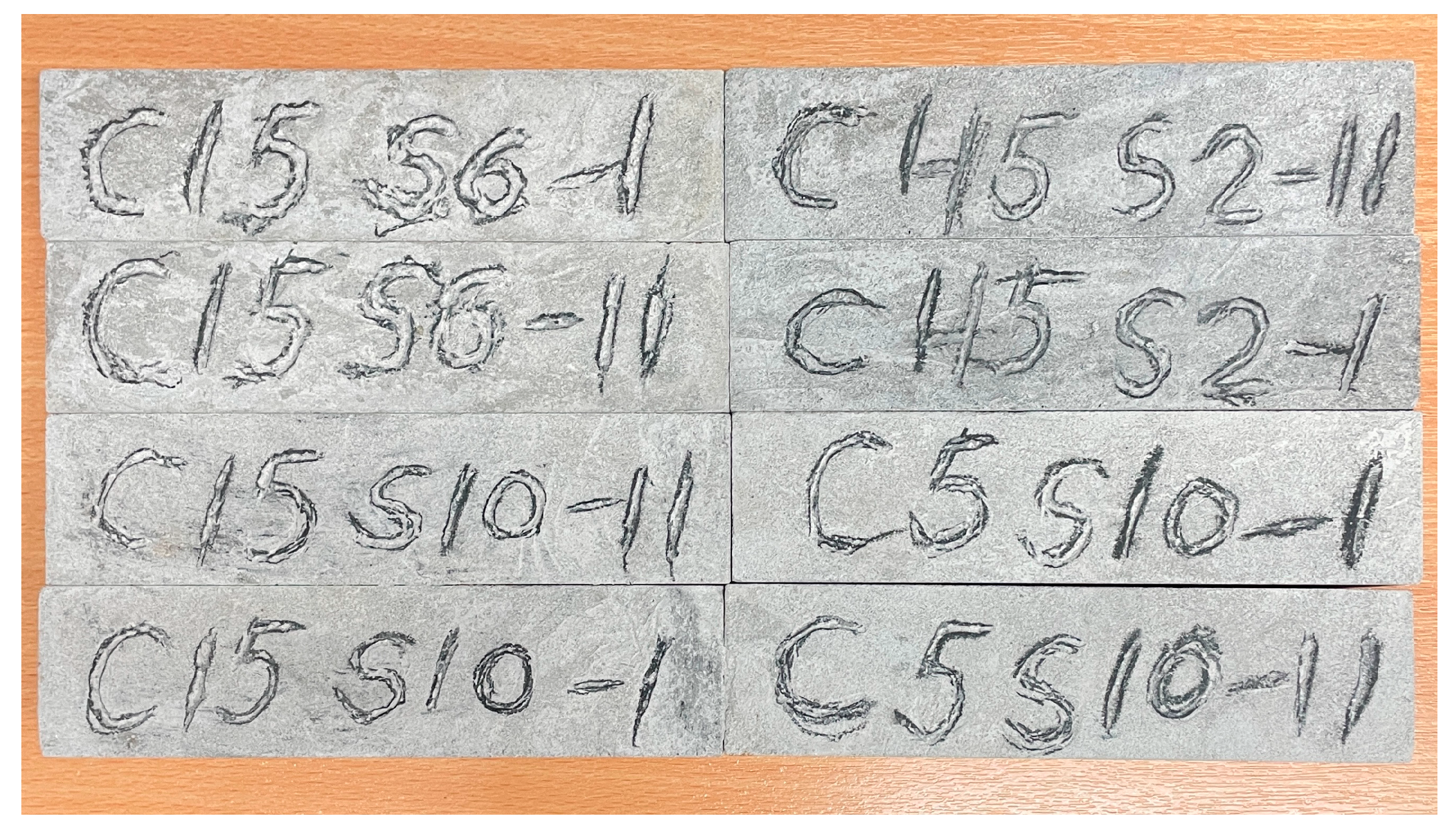

2.4. Fabrication of Samples

2.5. Testing Methods

3. Results and Discussion

3.1. Flexural Strength

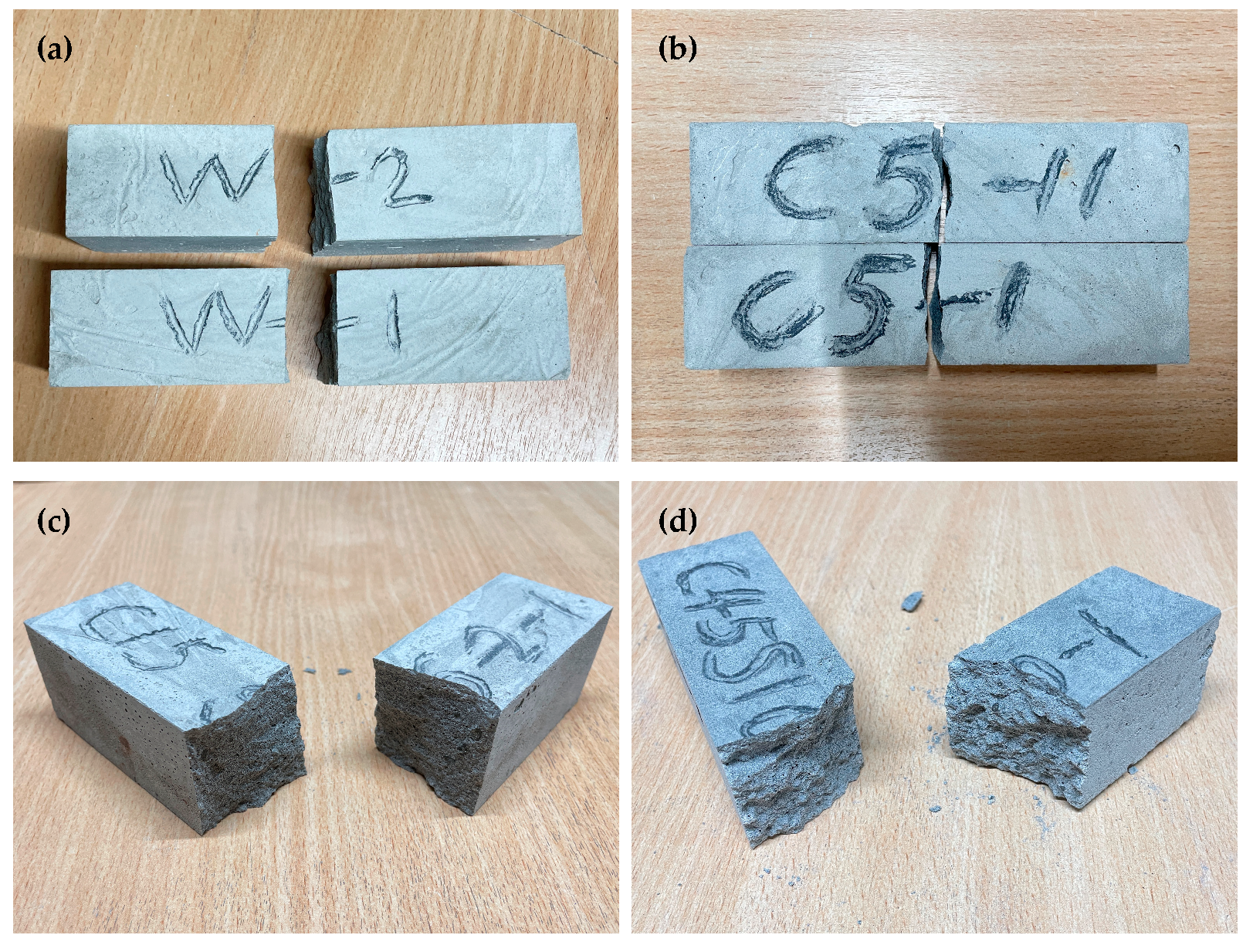

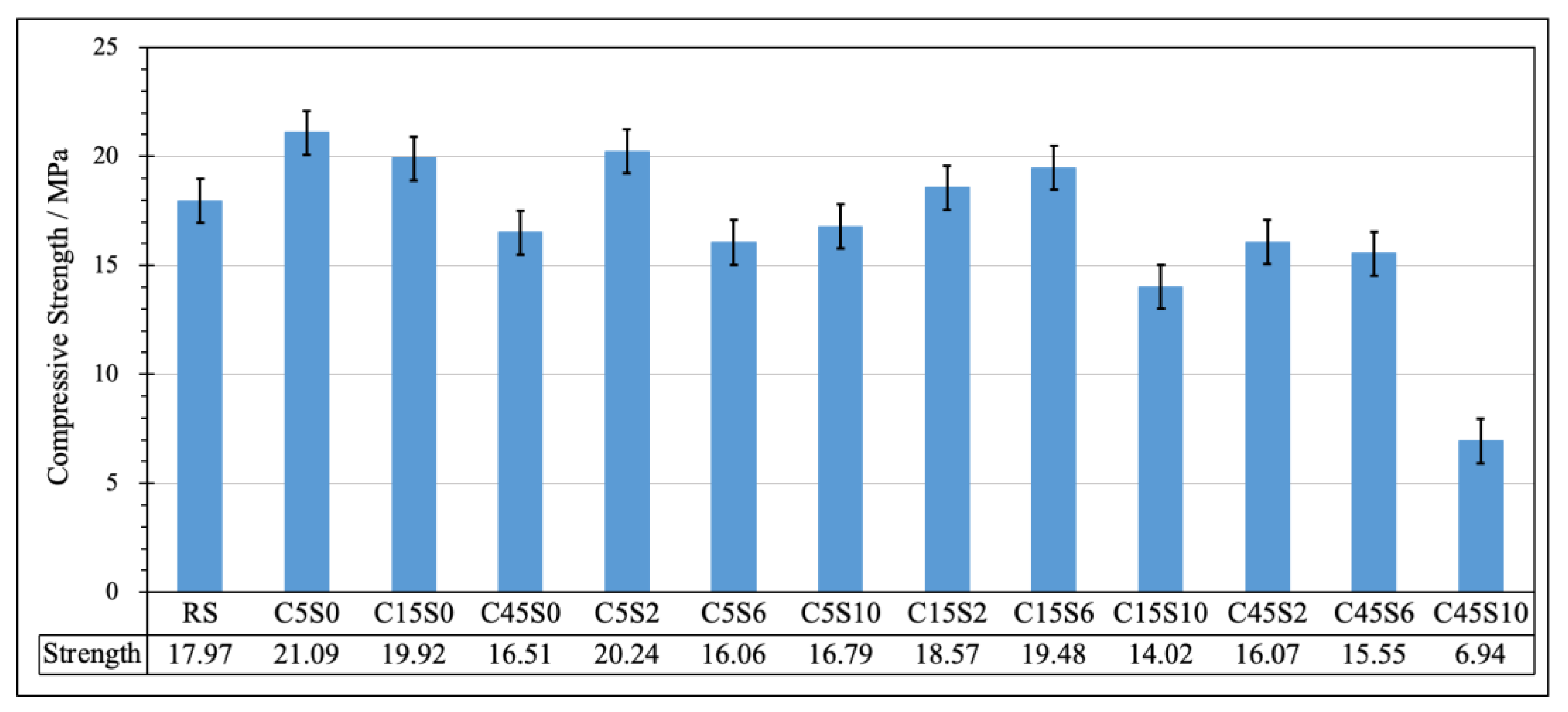

3.2. Compressive Strength

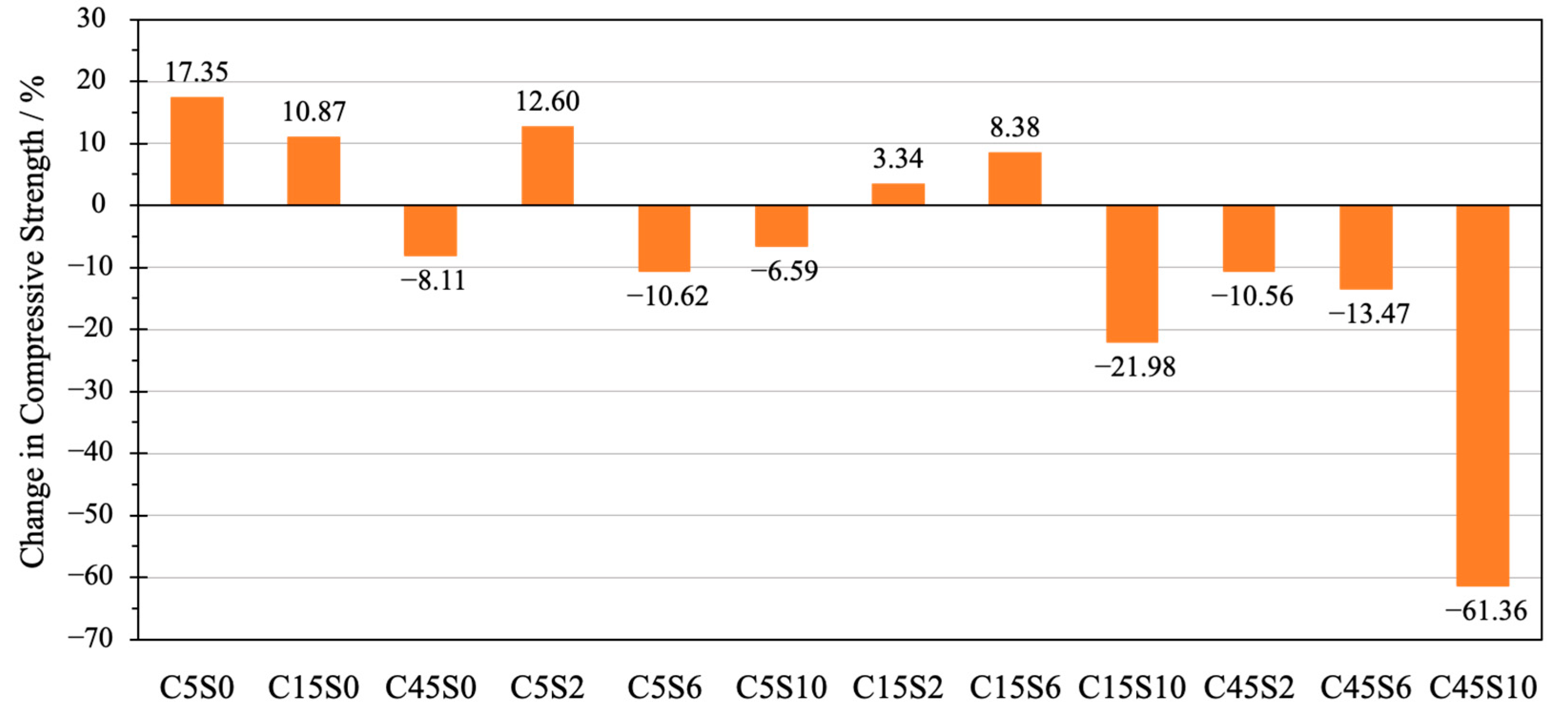

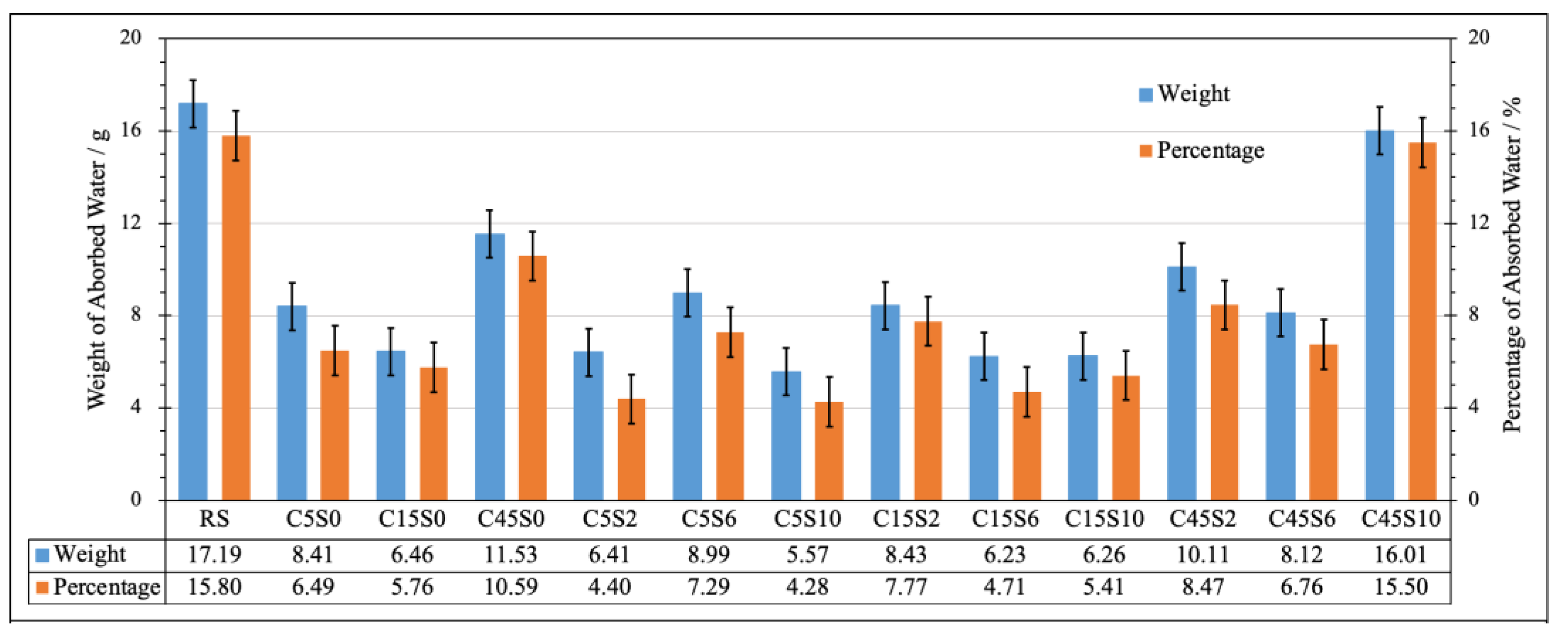

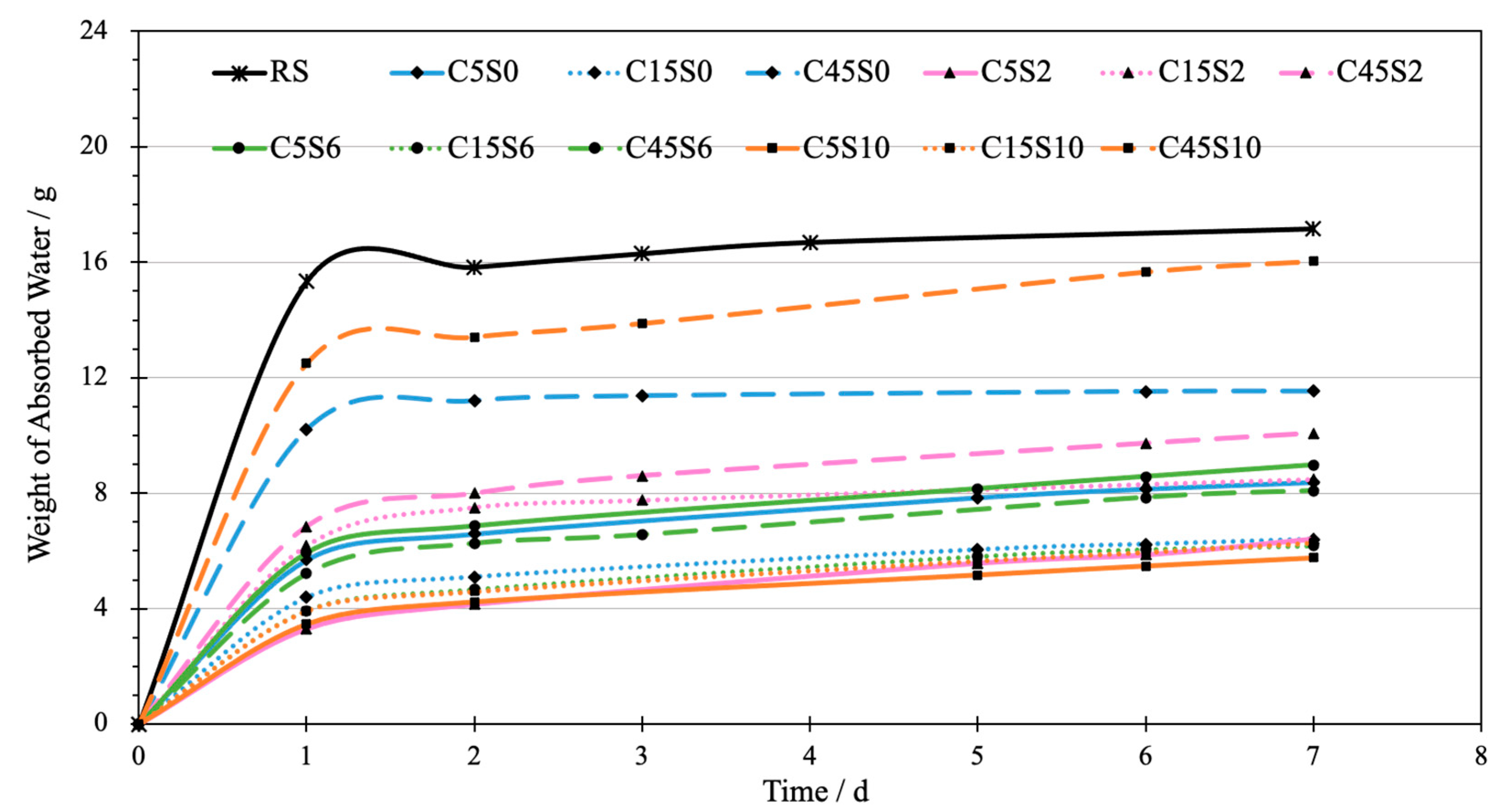

3.3. Water Absorption

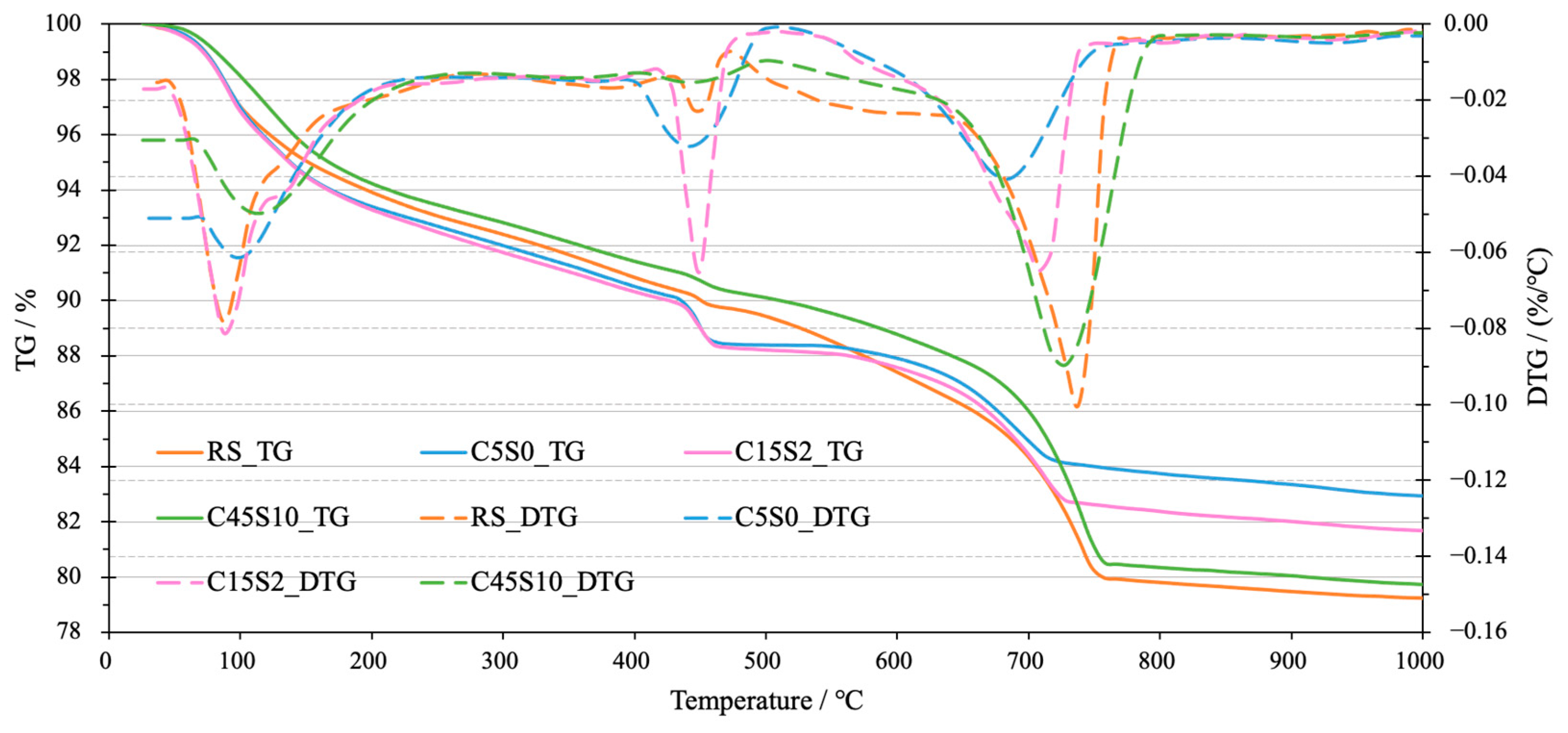

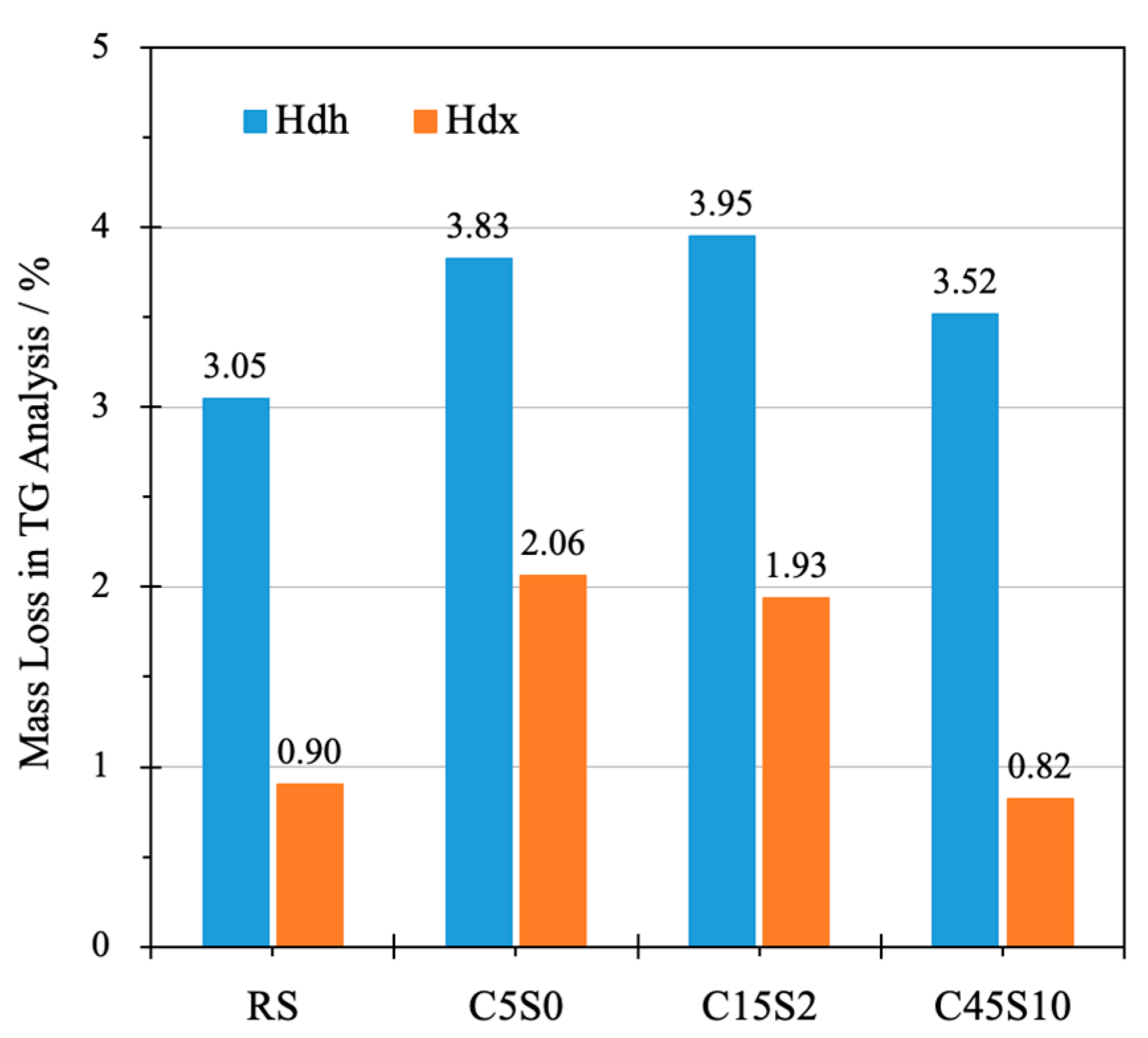

3.4. Thermalgravimetric Analysis (TG)

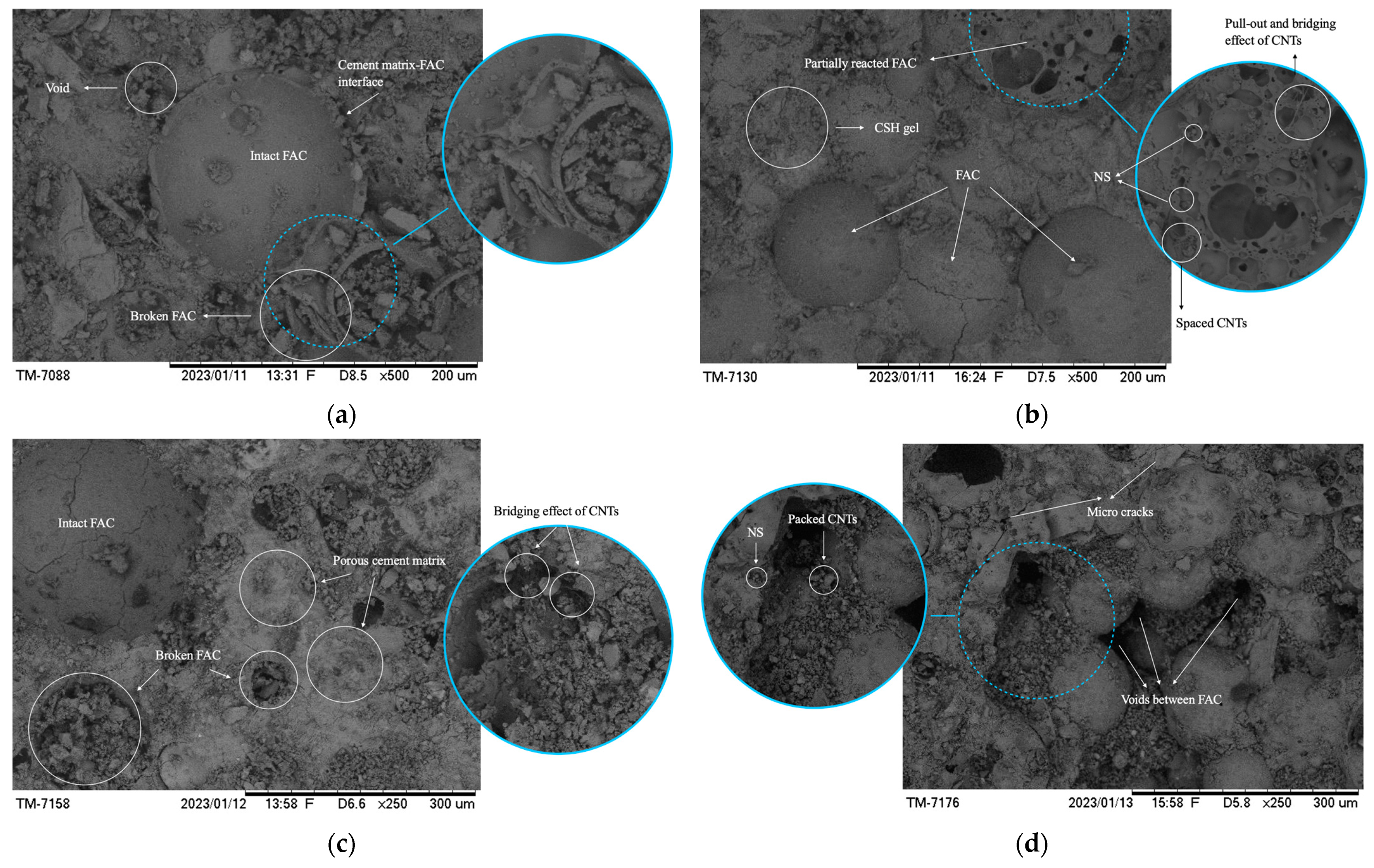

3.5. Scanning Electron Microscope (SEM)

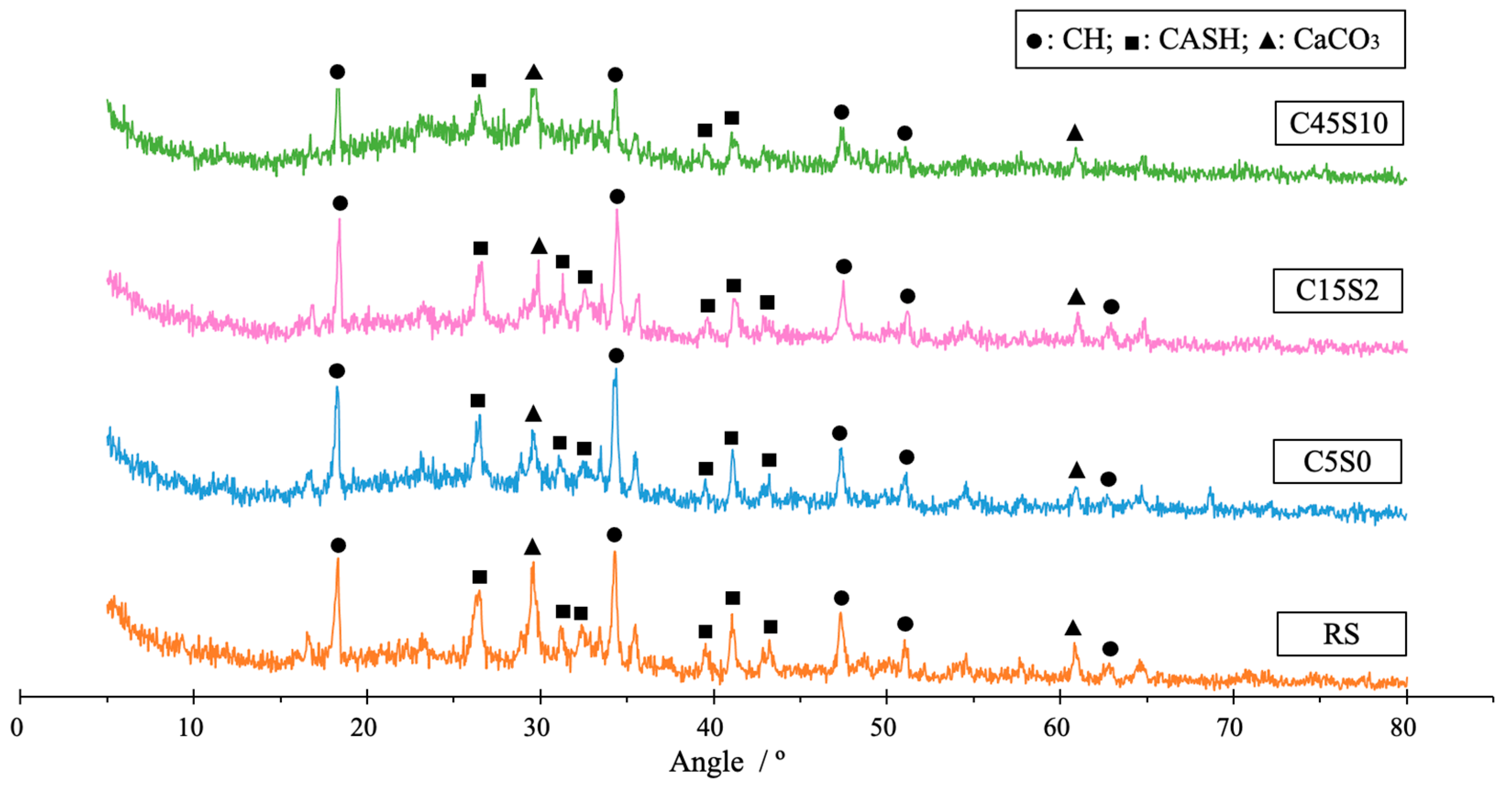

3.6. X-ray Diffraction Analysis (XRD)

4. Conclusions

- In contrast with the reference sample, specimens with nano additives presented development in flexural strength at various extents, but the binary effects of CNTs and NS cannot always guarantee greater flexural behaviour than that of specimens with only CNTs. The most remarkable flexural strength was measured for specimen C15S2, with an 89.02% increment observed, whereas specimen C45S10 exhibited the lowest improvement in flexural strength with only an increase of 7.53%;

- In comparison to the control specimen, enhancement and reduction in compressive strength were both measured. Regardless of the NS content, the presence of 0.45% CNTs always accounted for a decline of strength, owing to the increasing difficulty of dispersion and agglomeration of CNTs. Similarly, despite the changes in CNT content, samples with 1.0% NS presented decreases in compressive strength. The most impressive improvement was measured for the sample C5S0, with a growth of 17.35% to 21.09 MPa;

- Compared to the compressive strength of samples with only CNTs, the synergic addition of NS cannot further improve the strength. The greatest value of LWCM under the synergic use of CNTs and NS was measured for specimen C5S2, with the value increasing by 12.60%. Overall, the binary usage of NS and CNTs was more effective to improve flexural behaviour than compression. This can be attributed to the bridging effect of CNTs, which is more dominant than the filling and nucleation effects of CNTs and NS on the enhancement of mechanical characteristics;

- The incorporation of nano additives accounted for the reduction of absorbed water of modified specimens. Sample C5S2 showed the greatest decrease in the percentage of absorbed water, viz., 11.40%. This can be related to the increasingly dense and homogeneous microstructure. Sample C45S10 showed the lowest reduction of absorbed water, with only a decrease of 0.30%. For all the samples, the capacity of absorbing water reached saturation at an early stage within 24 h, after which the increment of water absorbed was very limited;

- Three morphologies of FAC were observed in the micrographs via microscope: intact spherical FAC, broken FAC, and partially reacted FAC. The existence of FAC led to the loose and highly porous microstructure. The agglomeration of FAC promoted the propagation of large voids and cracks. The filler effects of NS and CNTs were observed for the modified samples, which effectively filled up the voids in LWCM, forming a denser microstructure. The bridging and pull-out effects of CNTs were identified in the micrographs, which effectively restrained the propagation of microcracks, benefiting the development of flexural strength.

- TG analysis demonstrated that CNTs can effectively improve the hydration degree in LWCM, and the synergic use of NS further enhanced this positive effect, owing to the nucleation effects of nano additives. Sample C15S2 showed the highest amount of CSH formed during hydration process, and specimen C5S0 had the greatest amount of CH. This is associated with the influence of NS which participates in the reaction, consuming CH and producing CSH.

- XRD analysis proved the positive effects of CNTs and NS on promoting cement hydration, but the degree was limited. Combined with the results from TG and SEM, it can be inferred that the physical interaction of CNTs and NS in the cement matrix is greater than the chemical reaction.

- Based on this study, it is suggested to further experiment at a smaller content gradient of CNTs varying from 0.05% to 0.15%, and NS around 0.2% bcw, to identify the optimal content for synergic use. The usage of FAC and nano additives in cement materials are regarded as sustainable and economical. Further attempts can be made to compare environmental impacts and economic viability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Sample | Flexural Strength | Average Strength | Standard Deviation | ||||

|---|---|---|---|---|---|---|---|

| A | B | C | D | E | |||

| RS | 1.127 | 0.792 * | 1.140 | 1.115 | 1.124 | 1.13 | 0.01 |

| C5S0 | 1.304 | 1.307 | 1.301 | 1.310 | 1.306 | 1.31 | 0.01 |

| C15S0 | 1.425 | 1.448 | 1.463 | 1.371 | 1.399 | 1.42 | 0.04 |

| C45S0 | 1.298 | 1.286 | 1.341 | 1.249 | 1.307 | 1.30 | 0.03 |

| C5S2 | 1.566 | 1.586 | 1.560 | 1.578 | 1.574 | 1.57 | 0.01 |

| C5S6 | 1.194 | 1.247 | 1.184 | 1.275 | 1.207 | 1.22 | 0.04 |

| C5S10 | 1.385 | 1.347 | 1.249 | 1.463 | 1.379 | 1.36 | 0.08 |

| C15S2 | 2.130 | 2.099 | 2.072 | 2.198 | 2.147 | 2.13 | 0.05 |

| C15S6 | 1.587 | 1.610 | 1.590 | 1.609 | 1.647 | 1.61 | 0.02 |

| C15S10 | 1.640 | 1.647 | 1.659 | 1.662 | 1.706 | 1.66 | 0.03 |

| C45S2 | 1.249 * | 1.524 | 1.563 | 1.636 | 1.710 | 1.61 | 0.08 |

| C45S6 | 1.310 * | 1.654 | 1.561 | 1.684 | 1.605 | 1.63 | 0.05 |

| C45S10 | 1.179 | 1.261 | 1.251 | 1.156 | 1.209 | 1.21 | 0.05 |

| Weighting factor/% | 20 | 20 | 20 | 20 | 20 | - | - |

| T-Test | A, B | A, C | A, D | A, E | B, C | B, D | B, E | C, D | C, E | D, E |

|---|---|---|---|---|---|---|---|---|---|---|

| Value | 0.97 | 0.94 | 0.90 | 0.92 | 0.86 | 0.89 | 0.89 | 0.79 | 0.78 | 0.99 |

| Sample | Compressive Strength | Average Strength | Standard Deviation | |||||

|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | |||

| RS | 18.14 | 19.15 * | 17.79 | 17.86 | 17.99 | 18.07 | 17.97 | 0.14 |

| C5S0 | 21.38 | 20.88 | 21.04 | 21.13 | 20.95 | 21.15 | 21.09 | 0.18 |

| C15S0 | 19.88 | 20.02 | 19.87 | 19.93 | 19.96 | 19.88 | 19.92 | 0.06 |

| C45S0 | 16.41 | 16.53 | 16.68 | 16.49 | 16.37 | 16.60 | 16.51 | 0.12 |

| C5S2 | 20.06 | 20.48 | 20.06 | 20.25 | 20.37 | 20.19 | 20.24 | 0.17 |

| C5S6 | 15.86 | 16.10 | 16.24 | 16.09 | 15.91 | 16.17 | 16.06 | 0.15 |

| C5S10 | 16.82 | 16.68 | 16.86 | 16.90 | 16.71 | 16.74 | 16.79 | 0.09 |

| C15S2 | 18.62 | 18.70 | 18.43 | 18.51 | 18.64 | 18.52 | 18.57 | 0.10 |

| C15S6 | 19.08 | 19.80 | 19.22 | 19.58 | 19.41 | 19.76 | 19.48 | 0.29 |

| C15S10 | 14.00 | 14.03 | 14.02 | 14.06 | 14.01 | 14.00 | 14.02 | 0.02 |

| C45S2 | 15.88 | 16.30 | 16.23 | 16.13 | 15.92 | 15.97 | 16.07 | 0.17 |

| C45S6 | 14.52 * | 15.48 | 15.61 | 15.57 | 15.53 | 15.56 | 15.55 | 0.05 |

| C45S10 | 6.98 | 6.88 | 7.91 * | 7.01 | 6.85 | 7.00 | 6.94 | 0.14 |

| Weighting factor/% | 17 | 17 | 17 | 17 | 17 | 17 | - | - |

| T-Test | A, B | A, C | A, D | A, E | A, F | B, C | B, D | B, E | B, F | C, D | C, E | C, F | D, E | D, F | E, F |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Value | 0.88 | 0.98 | 0.94 | 0.99 | 0.93 | 0.95 | 0.99 | 0.95 | 0.99 | 0.97 | 0.99 | 0.96 | 0.96 | 1.00 | 0.96 |

| Sample | Weight of Absorbed Water | Average Weight | Standard Deviation | |||

|---|---|---|---|---|---|---|

| A | B | C | D | |||

| RS | 17.16 | 17.35 | 17.02 | 17.21 | 17.19 | 0.14 |

| C5S0 | 8.38 | 8.71 | 8.53 | 8.02 | 8.41 | 0.29 |

| C15S0 | 6.40 | 6.09 | 6.81 | 6.52 | 6.46 | 0.30 |

| C45S0 | 11.53 | 11.89 | 11.02 | 11.68 | 11.53 | 0.37 |

| C5S2 | 6.42 | 6.91 | 6.32 | 6.00 | 6.41 | 0.38 |

| C5S6 | 8.97 | 9.21 | 8.75 | 9.03 | 8.99 | 0.19 |

| C5S10 | 5.76 | 6.12 | 5.28 | 5.11 | 5.57 | 0.46 |

| C15S2 | 8.47 | 8.59 | 8.26 | 8.41 | 8.43 | 0.14 |

| C15S6 | 6.17 | 5.77 | 6.45 | 6.53 | 6.23 | 0.34 |

| C15S10 | 6.28 | 5.66 | 6.34 | 6.75 | 6.26 | 0.45 |

| C45S2 | 10.07 | 10.16 | 9.81 | 10.39 | 10.11 | 0.24 |

| C45S6 | 8.08 | 8.67 | 7.52 | 8.21 | 8.12 | 0.47 |

| C45S10 | 16.03 | 16.05 | 15.82 | 16.14 | 16.01 | 0.14 |

| Weighting factor/% | 25 | 25 | 25 | 25 | - | - |

| Sample | Percentage of Absorbed Water | Average Weight | Standard Deviation | |||

|---|---|---|---|---|---|---|

| A | B | C | D | |||

| RS | 15.61 | 15.58 | 16.43 | 15.57 | 15.80 | 0.42 |

| C5S0 | 6.47 | 6.49 | 6.48 | 6.53 | 6.49 | 0.02 |

| C15S0 | 5.80 | 6.09 | 4.69 | 6.46 | 5.76 | 0.76 |

| C45S0 | 10.65 | 10.34 | 11.12 | 10.26 | 10.59 | 0.39 |

| C5S2 | 4.14 | 4.07 | 4.60 | 4.77 | 4.40 | 0.34 |

| C5S6 | 7.42 | 7.05 | 7.49 | 7.20 | 7.29 | 0.20 |

| C5S10 | 4.36 | 4.13 | 4.16 | 4.45 | 4.28 | 0.16 |

| C15S2 | 7.83 | 7.43 | 8.15 | 7.66 | 7.77 | 0.30 |

| C15S6 | 4.83 | 4.95 | 4.63 | 4.42 | 4.71 | 0.24 |

| C15S10 | 5.56 | 5.73 | 5.24 | 5.09 | 5.41 | 0.29 |

| C45S2 | 8.54 | 8.01 | 9.07 | 8.27 | 8.47 | 0.45 |

| C45S6 | 6.78 | 6.32 | 7.60 | 6.34 | 6.76 | 0.60 |

| C45S10 | 15.59 | 15.27 | 15.99 | 15.17 | 15.50 | 0.37 |

| Weighting factor/% | 25 | 25 | 25 | 25 | - | - |

| T-Test | A, B | A, C | A, D | B, C | B, D | C, D |

|---|---|---|---|---|---|---|

| Weight of absorbed water | 0.94 | 0.92 | 0.99 | 0.86 | 0.95 | 0.91 |

| Percentage of absorbed water | 0.91 | 0.92 | 0.94 | 0.84 | 0.97 | 0.86 |

References

- Satpathy, H.; Patel, S.; Nayak, A. Development of sustainable lightweight concrete using fly ash cenosphere and sintered fly ash aggregate. Constr. Build. Mater. 2019, 202, 636–655. [Google Scholar] [CrossRef]

- Hanif, A.; Lu, Z.; Li, Z. Utilization of fly ash cenosphere as lightweight filler in cement-based composites—A review. Constr. Build. Mater. 2017, 144, 373–384. [Google Scholar] [CrossRef]

- Shannag, M. Characteristics of lightweight concrete containing mineral admixtures. Constr. Build. Mater. 2011, 25, 658–662. [Google Scholar] [CrossRef]

- Junaid, M.F.; ur Rehman, Z.; Kuruc, M.; Medveď, I.; Bačinskas, D.; Čurpek, J.; Čekon, M.; Ijaz, N.; Ansari, W.S. Lightweight concrete from a perspective of sustainable reuse of waste byproducts. Constr. Build. Mater. 2022, 319, 126061. [Google Scholar] [CrossRef]

- Alqamish, H.; Al-Tamimi, A. Development and evaluation of nano-silica sustainable concrete. Appl. Sci. 2021, 11, 3041. [Google Scholar] [CrossRef]

- Kan, A.; Demirboğa, R. A novel material for lightweight concrete production. Cem. Concr. Compos. 2009, 31, 489–495. [Google Scholar] [CrossRef]

- Uysal, H.; Demirboğa, R.; Şahin, R.; Gül, R. The effects of different cement dosages, slumps, and pumice aggregate ratios on the thermal conductivity and density of concrete. Cem. Concr. Res. 2004, 34, 845–848. [Google Scholar] [CrossRef]

- Aslam, M.; Shafigh, P.; Jumaat, M. Oil-palm by-products as lightweight aggregate in concrete mixture: A review. J. Clean. Prod. 2016, 126, 56–73. [Google Scholar] [CrossRef]

- Muthusamy, K.; Nordin, N.; Vesuvapateran, G.; Ali, M.; Annual, N.M.; Harun, H.; Ullap, H. Exploratory study of rubber seed shell as partial coarse aggregate replacement in concrete. Res. J. Appl. Sci. Eng. Technol. 2014, 7, 1013–1016. [Google Scholar] [CrossRef]

- De Castro, S.; De Brito, J. Evaluation of the durability of concrete made with crushed glass aggregates. J. Clean. Prod. 2013, 41, 7–14. [Google Scholar] [CrossRef]

- Danish, A.; Mosaberpanah, M.A.; Tuladhar, R.; Salim, M.U.; Yaqub, M.A.; Ahmad, N. Effect of cenospheres on the engineering properties of lightweight cementitious composites: A comprehensive review. J. Build. Eng. 2022, 49, 104016. [Google Scholar] [CrossRef]

- Blanco, F.; García, P.; Mateos, P.; Ayala, J. Characteristics and properties of lightweight concrete manufactured with cenospheres. Cem. Concr. Res. 2000, 30, 1715–1722. [Google Scholar] [CrossRef]

- Dixit, M.K.; Fernández-Solís, J.L.; Lavy, S.; Culp, C.H. Identification of parameters for embodied energy measurement: A literature review. Energy Build. 2010, 42, 1238–1247. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, W.; Wang, J.; Wang, Y.; Xu, Y.; Xiao, J. A review of life cycle assessment of recycled aggregate concrete. Constr. Build. Mater. 2019, 209, 115–125. [Google Scholar] [CrossRef]

- Oyebisi, S.; Alomayri, T. Cement-based concrete modified with Vitellaria Paradoxa ash: A lifecycle assessment. Constr. Build. Mater. 2022, 342, 127906. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, J.Y.; Monteiro, P.J.; Zhang, M.H. Development of ultra-lightweight cement composites with low thermal conductivity and high specific strength for energy efficient buildings. Constr. Build. Mater. 2015, 87, 100–112. [Google Scholar] [CrossRef]

- Huang, X.; Ranade, R.; Zhang, Q.; Ni, W.; Li, V.C. Mechanical and thermal properties of green lightweight engineered cementitious composites. Constr. Build. Mater. 2013, 48, 954–960. [Google Scholar] [CrossRef]

- Wang, J.Y.; Chia, K.S.; Liew, J.Y.R.; Zhang, M.H. Flexural performance of fiber-reinforced ultra lightweight cement composites with low fiber content. Cem. Concr. Compos. 2013, 43, 39–47. [Google Scholar] [CrossRef]

- Khan, K.; Ahmad, W.; Amin, M.N.; Nazar, S. Nano-silica-modified concrete: A bibliographic analysis and comprehensive review of material properties. Nanomaterials 2022, 12, 1989. [Google Scholar] [CrossRef] [PubMed]

- Parveen, S.; Rana, S.; Fangueiro, R.; Paiva, M.C. Microstructure and mechanical properties of carbon nanotube reinforced cementitious composites developed using a novel dispersion technique. Cem. Concr. Res. 2015, 73, 215–227. [Google Scholar] [CrossRef]

- Hawreen, A.; Bogas, J.A.; Dias, A.P.S. On the mechanical and shrinkage behavior of cement mortars reinforced with carbon nanotubes. Constr. Build. Mater. 2018, 168, 459–470. [Google Scholar] [CrossRef]

- Silvestro, L.; Gleize, P.J.P. Effect of carbon nanotubes on compressive, flexural and tensile strengths of Portland cement-based materials: A systematic literature review. Constr. Build. Mater. 2020, 264, 120237. [Google Scholar] [CrossRef]

- Singh, A.P.; Gupta, B.K.; Mishra, M.; Chandra, A.; Mathur, R.B.; Dhawan, S.K. Multiwalled carbon nanotube/cement composites with exceptional electromagnetic interference shielding properties. Carbon 2013, 56, 86–96. [Google Scholar] [CrossRef]

- Balapour, M.; Joshaghani, A.; Althoey, F. Nano-SiO2 contribution to mechanical, durability, fresh and microstructural characteristics of concrete: A review. Constr. Build. Mater. 2018, 181, 27–41. [Google Scholar] [CrossRef]

- Ayad, A.; Said, A. Using colloidal nano silica to enhance the performance of cementitious mortars. Open J. Civ. Eng. 2018, 8, 82–90. [Google Scholar] [CrossRef]

- Tarbozagh, A.S.; Rezaifar, O.; Gholhaki, M.; Abavisani, I. Magnetic enhancement of carbon nanotube concrete compressive behavior. Constr. Build. Mater. 2020, 262, 120772. [Google Scholar] [CrossRef]

- Szeląg, M. Mechano-physical properties and microstructure of carbon nanotube reinforced cement paste after thermal load. Nanomaterials 2017, 7, 267. [Google Scholar] [CrossRef]

- Tarangini, D.; Sravana, P.; Rao, P.S. Effect of nano silica on frost resistance of pervious concrete. Mater. Today Proc. 2022, 51, 2185–2189. [Google Scholar] [CrossRef]

- Turkmenoglu, H.N.; Atahan, H.N. Deformation Properties of Nano-Silica Modified Concrete Mixtures under Uniaxial Compression Loading. Arab. J. Sci. Eng. 2021, 46, 11009–11025. [Google Scholar] [CrossRef]

- Rostami, M.R.; Abbassi-Sourki, F.; Bouhendi, H. Synergistic effect of branched polymer/nano silica on the microstructures of cement paste and their rheological behaviors. Constr. Build. Mater. 2019, 201, 159–170. [Google Scholar] [CrossRef]

- Gupta, M.; Kumar, M. Effect of nano silica and coir fiber on compressive strength and abrasion resistance of concrete. Constr. Build. Mater. 2019, 226, 44–50. [Google Scholar] [CrossRef]

- Abna, A.; Mazloom, M. Flexural properties of fiber reinforced concrete containing silica fume and nano-silica. Mater. Lett. 2022, 316, 132003. [Google Scholar] [CrossRef]

- Mowlaei, R.; Lin, J.; de Souza, F.B.; Fouladi, A.; Korayem, A.H.; Shamsaei, E.; Duan, W. The effects of graphene oxide-silica nanohybrids on the workability, hydration, and mechanical properties of Portland cement paste. Constr. Build. Mater. 2021, 266, 121016. [Google Scholar] [CrossRef]

- Mohammadyan-Yasouj, S.E.; Ghaderi, A. Experimental investigation of waste glass powder, basalt fibre, and carbon nanotube on the mechanical properties of concrete. Constr. Build. Mater. 2020, 252, 119115. [Google Scholar] [CrossRef]

- Du, Y.; Yang, J.; Thomas, B.S.; Li, L.; Li, H.; Nazar, S. Hybrid graphene oxide/carbon nanotubes reinforced cement paste: An investigation on hybrid ratio. Constr. Build. Mater. 2020, 261, 119815. [Google Scholar] [CrossRef]

- Sikora, P.; Abd Elrahman, M.; Chung, S.Y.; Cendrowski, K.; Mijowska, E.; Stephan, D. Mechanical and microstructural properties of cement pastes containing carbon nanotubes and carbon nanotube-silica core-shell structures, exposed to elevated temperature. Cem. Concr. Compos. 2019, 95, 193–204. [Google Scholar] [CrossRef]

- Karakouzian, M.; Farhangi, V.; Farani, M.R.; Joshaghani, A.; Zadehmohamad, M.; Ahmadzadeh, M. Mechanical characteristics of cement paste in the presence of carbon nanotubes and silica oxide nanoparticles: An experimental study. Materials 2021, 14, 1347. [Google Scholar] [CrossRef]

- Narasimman, K.; Jassam, T.M.; Velayutham, T.S.; Yaseer, M.M.M.; Ruzaimah, R. The synergic influence of carbon nanotube and nanosilica on the compressive strength of lightweight concrete. J. Build. Eng. 2020, 32, 101719. [Google Scholar] [CrossRef]

- Garg, M.; Das, C.S. Use of silica particles to improve dispersion of-COOH CNTs/carbon fibers to produce HyFRCC. Constr. Build. Mater. 2020, 250, 118777. [Google Scholar] [CrossRef]

- Aydın, A.C.; Nasl, V.J.; Kotan, T. The synergic influence of nano-silica and carbon nano tube on self-compacting concrete. J. Build. Eng. 2018, 20, 467–475. [Google Scholar] [CrossRef]

- Xi, B.; Zhou, Y.; Yu, K.; Hu, B.; Huang, X.; Sui, L.; Xing, F. Use of nano-SiO2 to develop a high performance green lightweight engineered cementitious composites containing fly ash cenospheres. J. Clean. Prod. 2020, 262, 121274. [Google Scholar] [CrossRef]

- Hanif, A.; Parthasarathy, P.; Ma, H.; Fan, T.; Li, Z. Properties improvement of fly ash cenosphere modified cement pastes using nano silica. Cem. Concr. Compos. 2017, 81, 35–48. [Google Scholar] [CrossRef]

- Najeeb, Z.; Mosaberpanah, M.A. Mechanical and durability properties of modified High-Performance mortar by using cenospheres and Nano-Silica. Constr. Build. Mater. 2023, 362, 129782. [Google Scholar] [CrossRef]

- Manzur, T.; Yazdani, N. Optimum mix ratio for carbon nanotubes in cement mortar. KSCE J. Civ. Eng. 2015, 19, 1405–1412. [Google Scholar] [CrossRef]

- Kowsalya, M.; Sindhu Nachiar, S.; Sekar, A.; Ravichandran, P.T. Study on mechanical and microstructural properties of concrete with fly ash cenosphere as fine aggregate—A sustainable approach. Buildings 2022, 12, 1679. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S. Microstructural, thermal, physical and mechanical behavior of the self compacting concrete containing SiO2 nanoparticles. Mater. Sci. Eng. A 2010, 527, 7663–7672. [Google Scholar] [CrossRef]

- Li, H.; Zhang, M.H.; Ou, J.P. Abrasion resistance of concrete containing nano-particles for pavement. Wear 2006, 260, 1262–1266. [Google Scholar] [CrossRef]

- Ji, T. Preliminary study on the water permeability and microstructure of concrete incorporating nano-SiO2. Cem. Concr. Res. 2005, 35, 1943–1947. [Google Scholar] [CrossRef]

- Mohsen, M.O.; Taha, R.; Taqa, A.A.; Shaat, A. Optimum carbon nanotubes’ content for improving flexural and compressive strength of cement paste. Constr. Build. Mater. 2017, 150, 395–403. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Pressure-sensitive properties and microstructure of carbon nanotube reinforced cement composites. Cem. Concr. Compos. 2007, 29, 377–382. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Mechanical behavior and microstructure of cement composites incorporating surface-treated multi-walled carbon nanotubes. Carbon 2005, 43, 1239–1245. [Google Scholar] [CrossRef]

- Bagheri, A.; Parhizkar, T.; Madani, H.; Raisghasemi, A.M. The influence of different preparation methods on the aggregation status of pyrogenic nanosilicas used in concrete. Mater. Struct. 2013, 46, 135–143. [Google Scholar] [CrossRef]

- Song, S.; Niu, Y.; Zhong, X. Study on dynamic mechanical properties of carbon nanotubes reinforced concrete subjected to freeze–thaw cycles. Struct. Concr. 2022, 23, 3221–3233. [Google Scholar] [CrossRef]

- Yao, Y.; Lu, H. Mechanical properties and failure mechanism of carbon nanotube concrete at high temperatures. Constr. Build. Mater. 2021, 297, 123782. [Google Scholar] [CrossRef]

- Sedaghatdoost, A.; Behfarnia, K. Mechanical properties of Portland cement mortar containing multi-walled carbon nanotubes at elevated temperatures. Constr. Build. Mater. 2018, 176, 482–489. [Google Scholar] [CrossRef]

- Baloch, W.L.; Khushnood, R.A.; Khaliq, W. Influence of multi-walled carbon nanotubes on the residual performance of concrete exposed to high temperatures. Constr. Build. Mater. 2018, 185, 44–56. [Google Scholar] [CrossRef]

- Zhou, C.; Li, F.; Hu, J.; Ren, M.; Wei, J.; Yu, Q. Enhanced mechanical properties of cement paste by hybrid graphene oxide/carbon nanotubes. Constr. Build. Mater. 2017, 134, 336–345. [Google Scholar] [CrossRef]

- Cwirzen, A.; Habermehl-Cwirzen, K.; Nasibulin, A.G.; Kaupinen, E.I.; Mudimela, P.R.; Penttala, V. SEM/AFM studies of cementitious binder modified by MWCNT and nano-sized Fe needles. Mater. Charact. 2009, 60, 735–740. [Google Scholar] [CrossRef]

- Beigi, M.H.; Berenjian, J.; Omran, O.L.; Nik, A.S.; Nikbin, I.M. An experimental survey on combined effects of fibers and nanosilica on the mechanical, rheological, and durability properties of self-compacting concrete. Mater. Des. 2013, 50, 1019–1029. [Google Scholar] [CrossRef]

- Ghazy, A.; Bassuoni, M.T.; Shalaby, A. Nano-modified fly ash concrete: A repair option for concrete pavements. ACI Mater. J. 2016, 113, 231–242. [Google Scholar] [CrossRef]

- Wang, Z.; Yu, J.; Li, G.; Zhang, M.; Leung, C.K. Corrosion behavior of steel rebar embedded in hybrid CNTs-OH/polyvinyl alcohol modified concrete under accelerated chloride attack. Cem. Concr. Compos. 2019, 100, 120–129. [Google Scholar] [CrossRef]

- Ganesh, P.; Ramachandra Murthy, A.; Sundar Kumar, S.; Mohammed Saffiq Reheman, M.; Iyer, N.R. Effect of nanosilica on durability and mechanical properties of high-strength concrete. Mag. Concr. Res. 2016, 68, 229–236. [Google Scholar] [CrossRef]

- Pachideh, G.; Gholhaki, M. Effect of pozzolanic materials on mechanical properties and water absorption of autoclaved aerated concrete. J. Build. Eng. 2019, 26, 100856. [Google Scholar] [CrossRef]

- Zhang, R.; Panesar, D.K. Water absorption of carbonated reactive MgO concrete and its correlation with the pore structure. J. CO2 Util. 2018, 24, 350–360. [Google Scholar] [CrossRef]

- Jung, S.H.; Oh, S.; Kim, S.W.; Moon, J.H. Effects of CNT dosages in cement composites on the mechanical properties and hydration reaction with low water-to-binder ratio. Appl. Sci. 2019, 9, 4630. [Google Scholar] [CrossRef]

- Carriço, A.; Bogas, J.A.; Hawreen, A.; Guedes, M. Durability of multi-walled carbon nanotube reinforced concrete. Constr. Build. Mater. 2018, 164, 121–133. [Google Scholar] [CrossRef]

- Karpova, E. Influence of Carbon Nanotubes on the Effectiveness of Plasticizers, Hydration and Structure of Cement-based Materials. Ph.D. Thesis, Vilnius Gediminas Technical University, Vilnius, Lithuania, 2020. [Google Scholar] [CrossRef]

- Alarcon-Ruiz, L.; Platret, G.; Massieu, E.; Ehrlacher, A. The use of thermal analysis in assessing the effect of temperature on a cement paste. Cem. Concr. Res. 2005, 35, 609–613. [Google Scholar] [CrossRef]

- Hanif, A.; Lu, Z.; Diao, S.; Zeng, X.; Li, Z. Properties investigation of fiber reinforced cement-based composites incorporating cenosphere fillers. Constr. Build. Mater. 2017, 140, 139–149. [Google Scholar] [CrossRef]

- Liew, K.M.; Kai, M.F.; Zhang, L.W. Carbon nanotube reinforced cementitious composites: An overview. Compos. A Appl. Sci. Manuf. 2016, 91, 301–323. [Google Scholar] [CrossRef]

- Huang, X.; Jiang, M.; Zhao, X.; Tang, C. Mechanical properties and hydration mechanisms of high-strength fluorogypsum-blast furnace slag-based hydraulic cementitious binder. Constr. Build. Mater. 2016, 127, 137–143. [Google Scholar] [CrossRef]

- Gopinath, S.; Mouli, P.C.; Murthy, A.R.; Iyer, N.R.; Maheswaran, S. Effect of nano silica on mechanical properties and durability of normal strength concrete. Arch. Civ. Eng. 2012, 433–444. [Google Scholar] [CrossRef]

- Zhang, Y.; Fan, Z.; Sun, X.; Zhu, X. Utilization of surface-modified fly ash cenosphere waste as an internal curing material to intensify concrete performance. J. Clean. Prod. 2022, 358, 132042. [Google Scholar] [CrossRef]

| Material Property | Values |

|---|---|

| Initial setting time/min | >60 |

| Loss on ignition/% | <5.0 |

| Bulk density/(g/cm3) | 0.9–1.5 |

| Sulphate content/% | <3.5 |

| Chloride content/% | <0.1 |

| Early compressive strength (2 days)/MPa | >10.0 |

| Standard compressive strength (28 days)/MPa | 42.5–62.5 |

| Material Property | Values |

|---|---|

| Size/micron | 40–300 |

| pH value | 7–8 |

| Bulk density/(g/cm3) | 0.37–0.40 |

| True density/(g/cm3) | 0.6–0.7 |

| Thermal conductivity/(w/mk) | 0.036–0.060 |

| Compressive strength/MPa | 20–40 |

| Sample | OPC | Water | Fine Aggregate FAC | Melment F10 | CNTs | NS | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| kg/m3 | kg/m3 | % | kg/m3 | % | kg/m3 | % | kg/m3 | % | kg/m3 | % | |

| RS | 527.34 | 295.31 | 56 | 386.72 | 73.33 | - | - | - | - | - | - |

| C5S0 | 527.34 | 295.31 | 56 | 386.72 | 73.33 | 2.66 | 0.50 | 0.27 | 0.05 | - | - |

| C15S0 | 527.34 | 295.31 | 56 | 386.72 | 73.33 | 2.66 | 0.50 | 0.78 | 0.15 | - | - |

| C45S0 | 527.34 | 295.31 | 56 | 386.72 | 73.33 | 2.66 | 0.50 | 2.38 | 0.45 | - | - |

| C5S2 | 527.34 | 295.31 | 56 | 386.72 | 73.33 | 2.66 | 0.50 | 0.27 | 0.05 | 1.05 | 0.20 |

| C15S2 | 527.34 | 295.31 | 56 | 386.72 | 73.33 | 2.66 | 0.50 | 0.78 | 0.15 | 1.05 | 0.20 |

| C45S2 | 527.34 | 295.31 | 56 | 386.72 | 73.33 | 2.66 | 0.50 | 2.38 | 0.45 | 1.05 | 0.20 |

| C5S6 | 527.34 | 295.31 | 56 | 386.72 | 73.33 | 2.66 | 0.50 | 0.27 | 0.05 | 0.60 | |

| C15S6 | 527.34 | 295.31 | 56 | 386.72 | 73.33 | 2.66 | 0.50 | 0.78 | 0.15 | 0.60 | |

| C45S6 | 527.34 | 295.31 | 56 | 386.72 | 73.33 | 2.66 | 0.50 | 2.38 | 0.45 | 0.60 | |

| C5S10 | 527.34 | 295.31 | 56 | 386.72 | 73.33 | 2.66 | 0.50 | 0.27 | 0.05 | 5.27 | 1.00 |

| C15S10 | 527.34 | 295.31 | 56 | 386.72 | 73.33 | 2.66 | 0.50 | 0.78 | 0.15 | 5.27 | 1.00 |

| C45S10 | 527.34 | 295.31 | 56 | 386.72 | 73.33 | 2.66 | 0.50 | 2.38 | 0.45 | 5.27 | 1.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, Y.; Korjakins, A. Synergic Effects of Nano Additives on Mechanical Performance and Microstructure of Lightweight Cement Mortar. Appl. Sci. 2023, 13, 5130. https://doi.org/10.3390/app13085130

Du Y, Korjakins A. Synergic Effects of Nano Additives on Mechanical Performance and Microstructure of Lightweight Cement Mortar. Applied Sciences. 2023; 13(8):5130. https://doi.org/10.3390/app13085130

Chicago/Turabian StyleDu, Yiying, and Aleksandrs Korjakins. 2023. "Synergic Effects of Nano Additives on Mechanical Performance and Microstructure of Lightweight Cement Mortar" Applied Sciences 13, no. 8: 5130. https://doi.org/10.3390/app13085130

APA StyleDu, Y., & Korjakins, A. (2023). Synergic Effects of Nano Additives on Mechanical Performance and Microstructure of Lightweight Cement Mortar. Applied Sciences, 13(8), 5130. https://doi.org/10.3390/app13085130