Analysis and Application of a New S-Type Bistable Generator Beam in Energy Harvester Featured in Reducing Stress Concentration

Abstract

1. Introduction

2. Design and Modeling

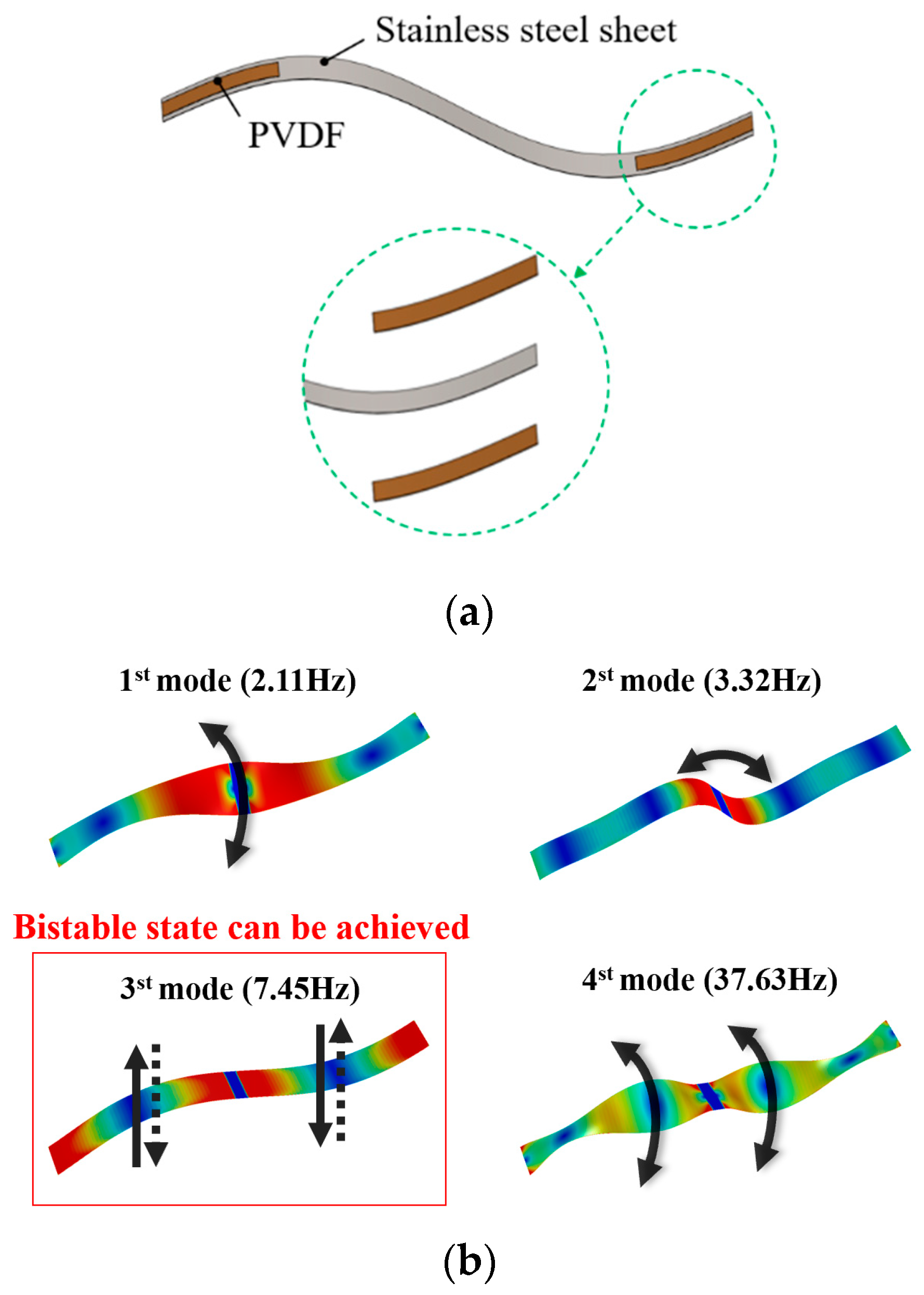

2.1. Design of “S” Type Power Generation Beam of Energy Harvester

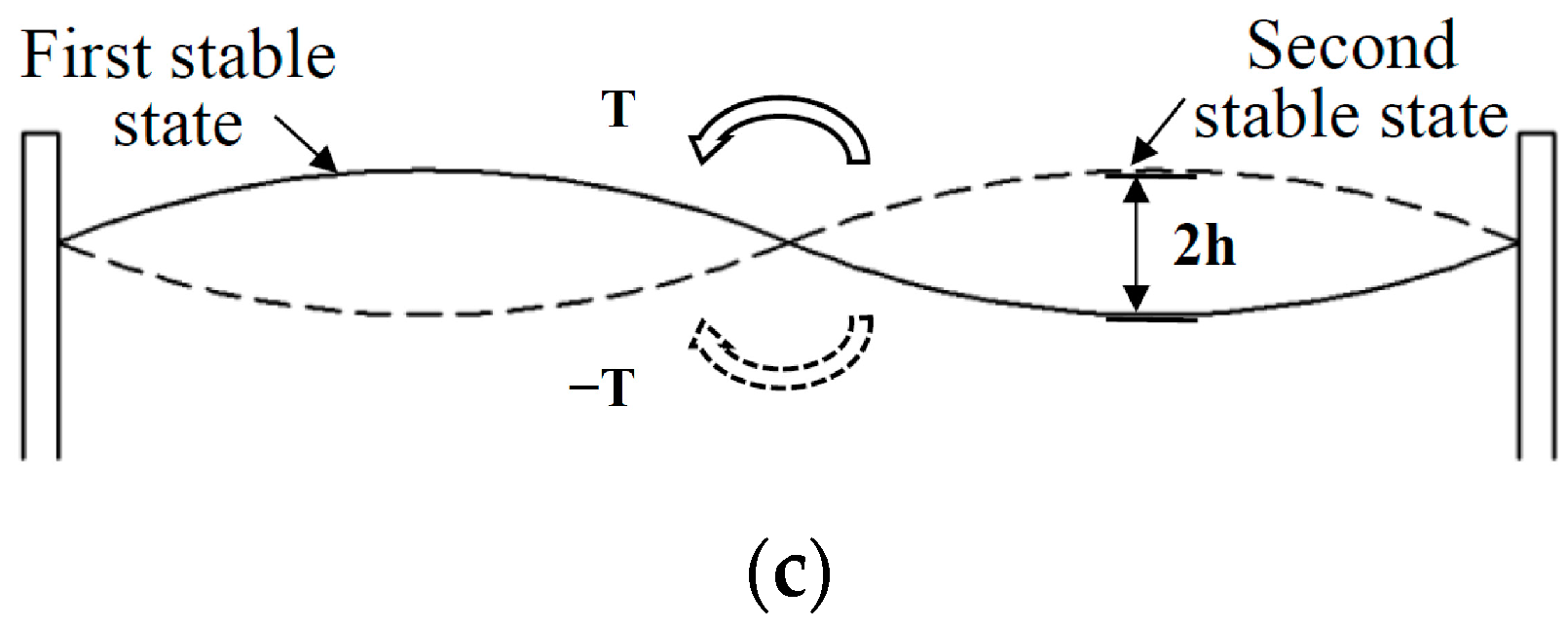

2.2. Mechanical Model

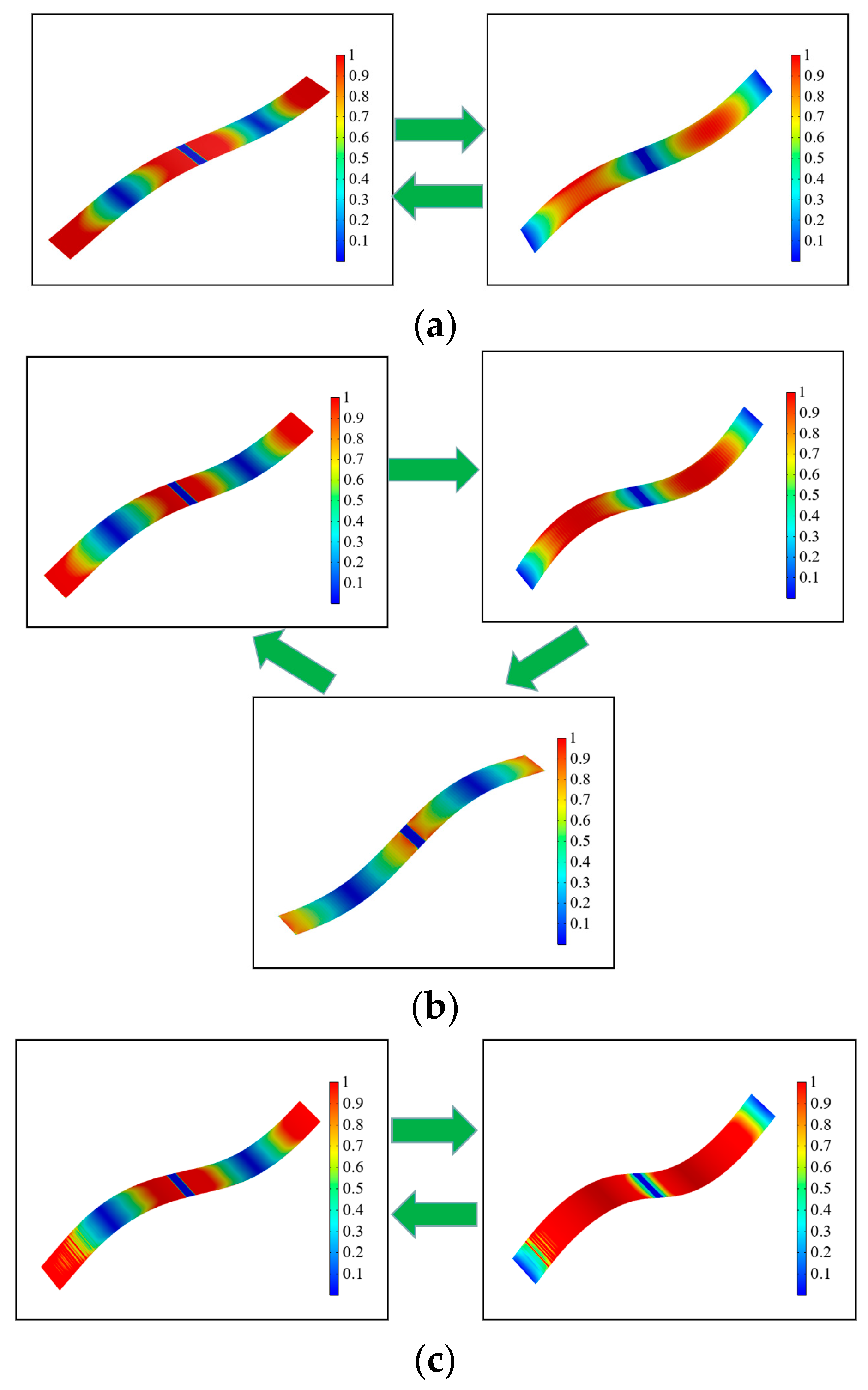

2.3. FEM Optimization Design

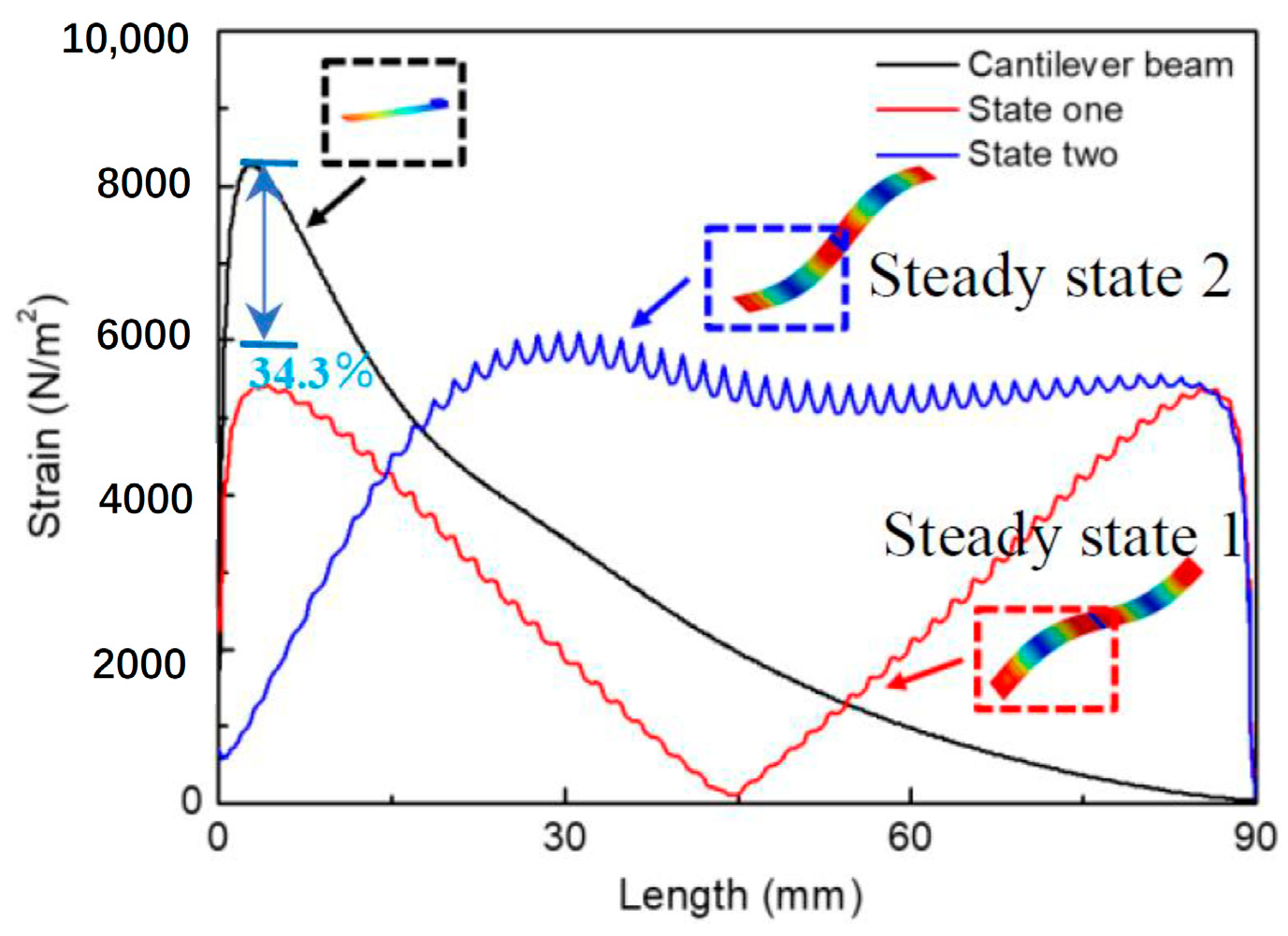

3. Relief of Stress Concentration

4. Experiments and Analysis

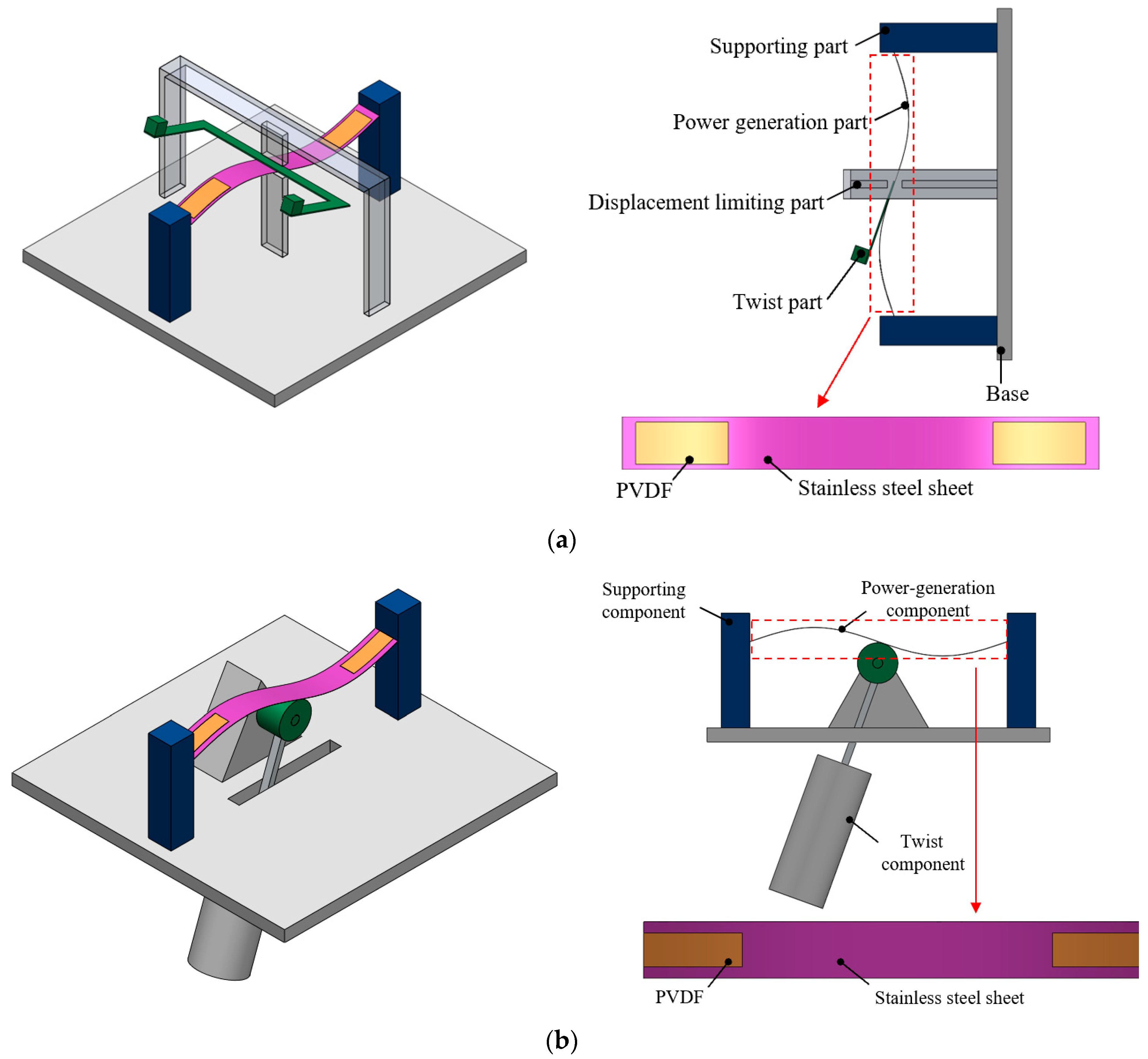

4.1. Energy Harvester Design of the S-Type Generator Beam in Different Environment

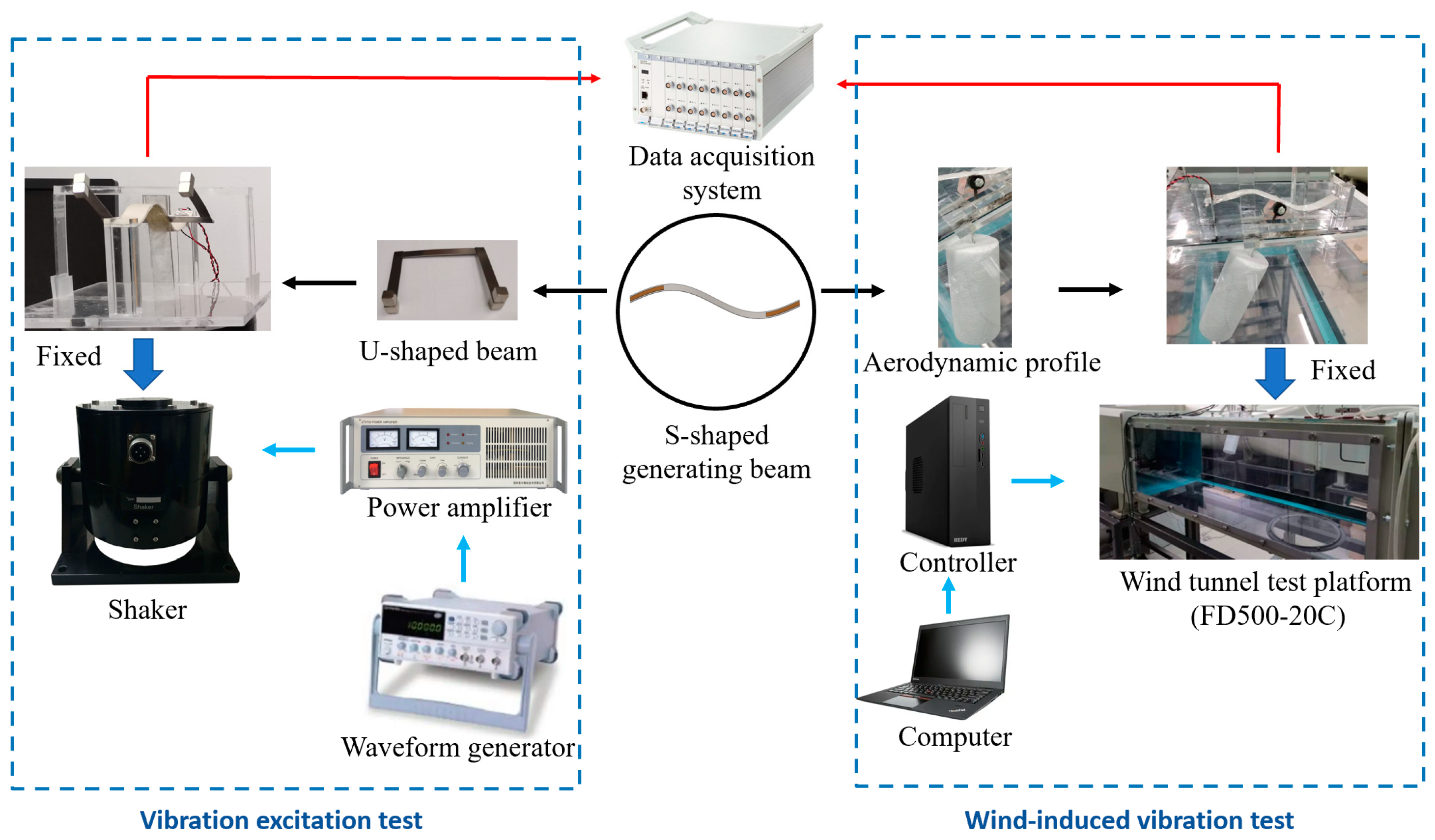

4.2. Prototype Fabrication and Experimental Setup

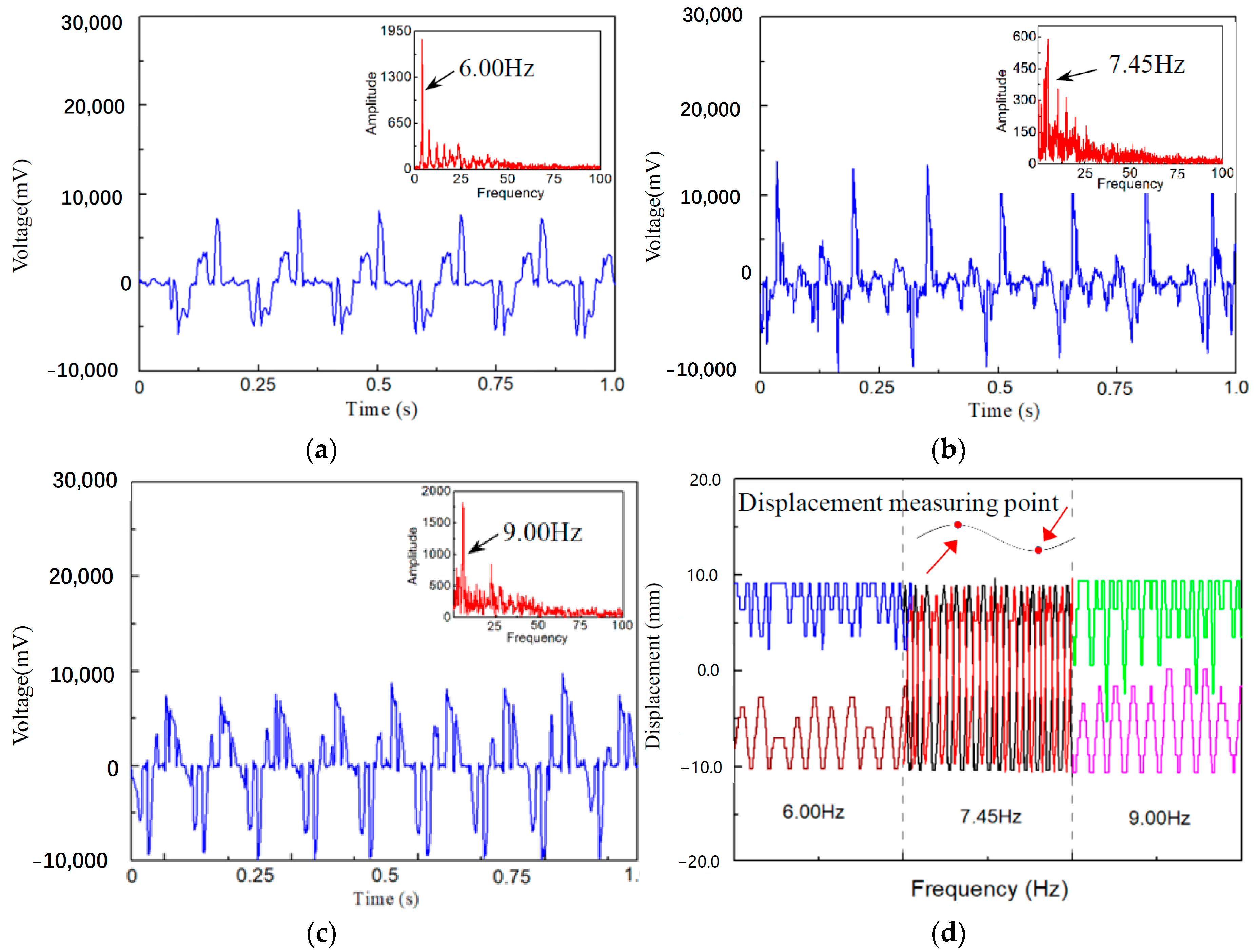

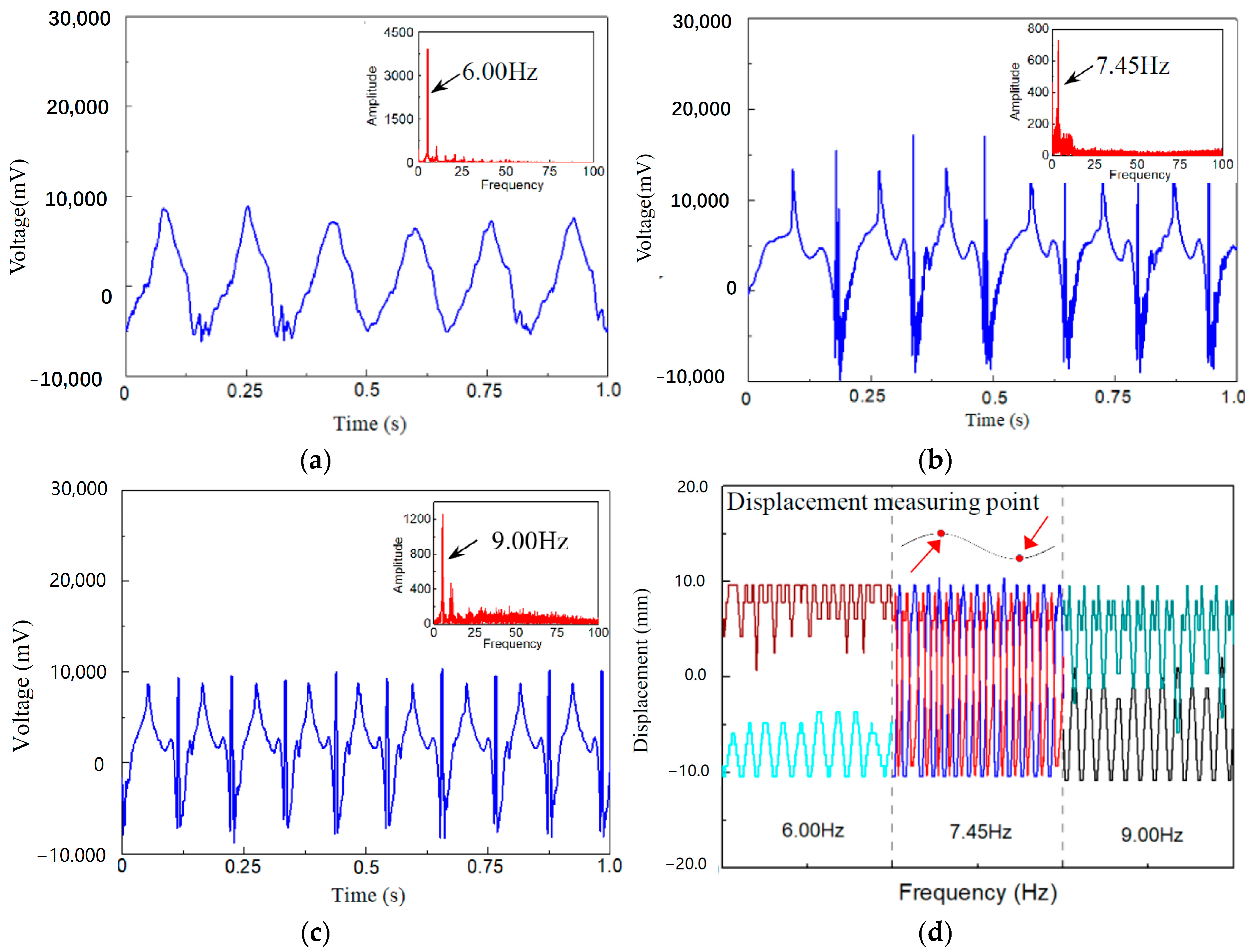

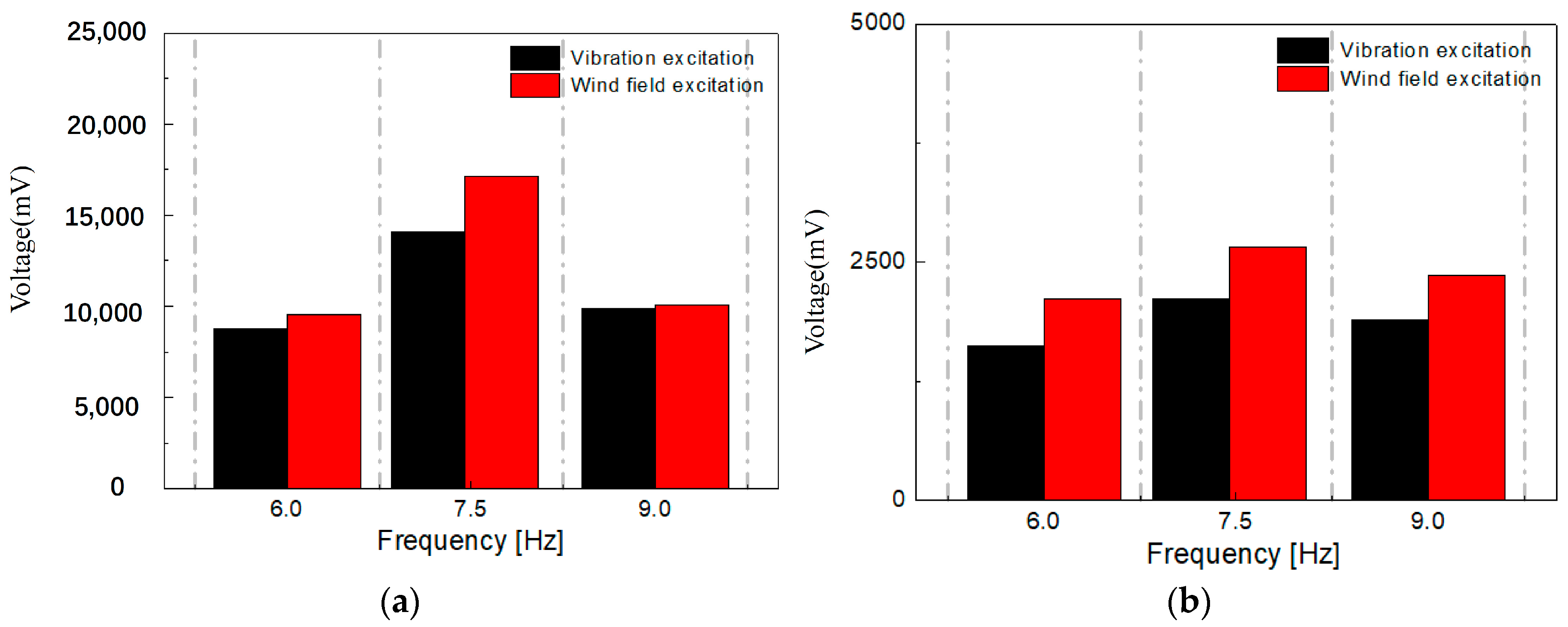

4.3. Voltage Frequency Response Analysis

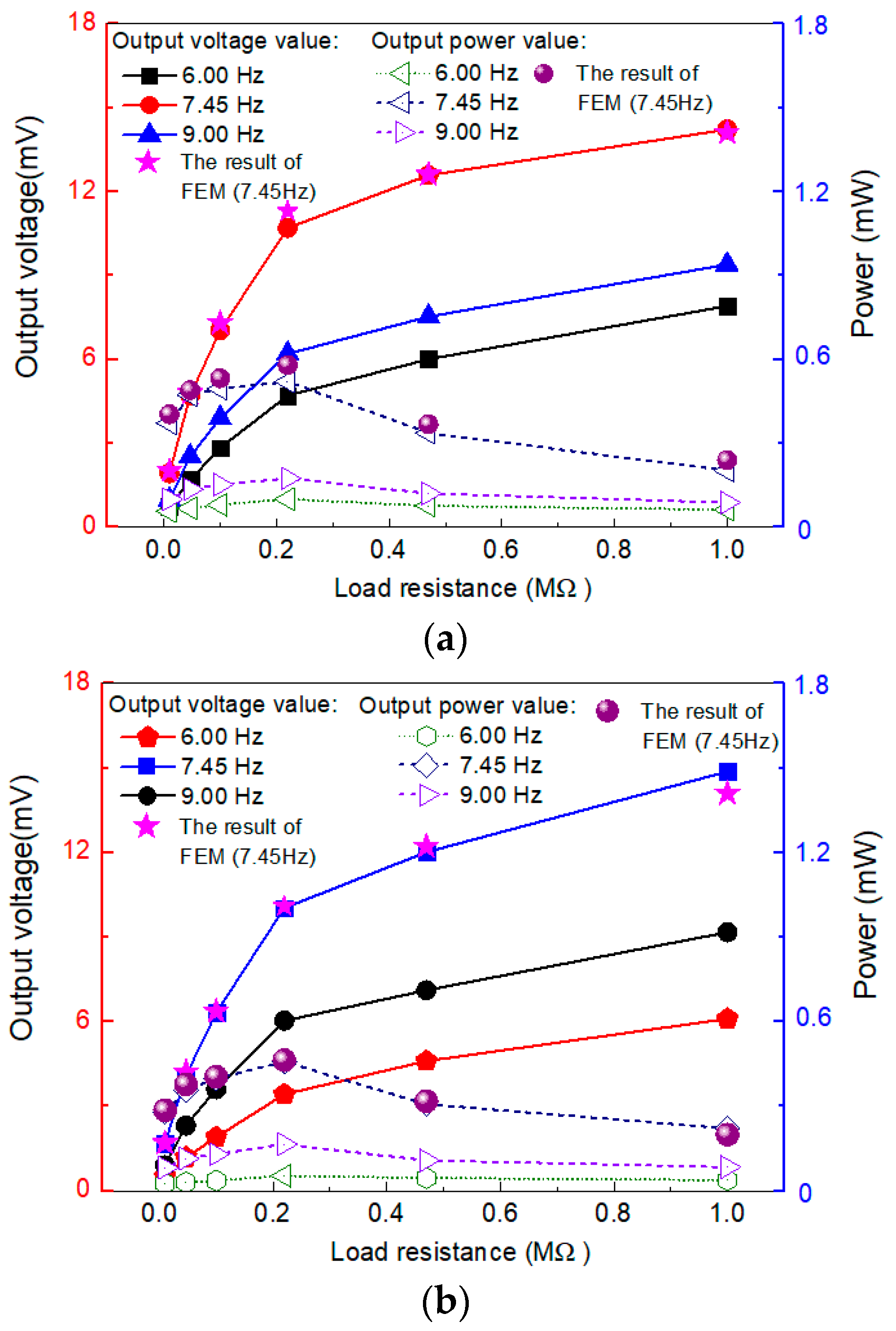

4.4. Output Performance of Two Kinds of Harvester in Different Environments

5. Conclusions

- This research paper proposes an S-type generator beam which can fully utilize materials and avoid premature fatigue failure caused by stress concentration. Under the same excitation conditions, the peak stress of the S-type generator beam is 34.3% lower than that of the cantilever beam (in the optimal working condition), indicating the advanced technology of the S-type generator beam in improving material fatigue failure.

- The S-type generator beam has good energy capture performance in low-frequency environments. A collector using S-type bistable generator beam was tested in two typical environments. When the environmental excitation frequency rises to the third natural frequency (the third mode, 7.45 Hz) of the generator beam, the motion process of the beam breaks through the potential energy barrier and produces intrawell motion (penetration). The peak output voltage in the two environments is 14,350 mV and 17,630 mV, respectively.

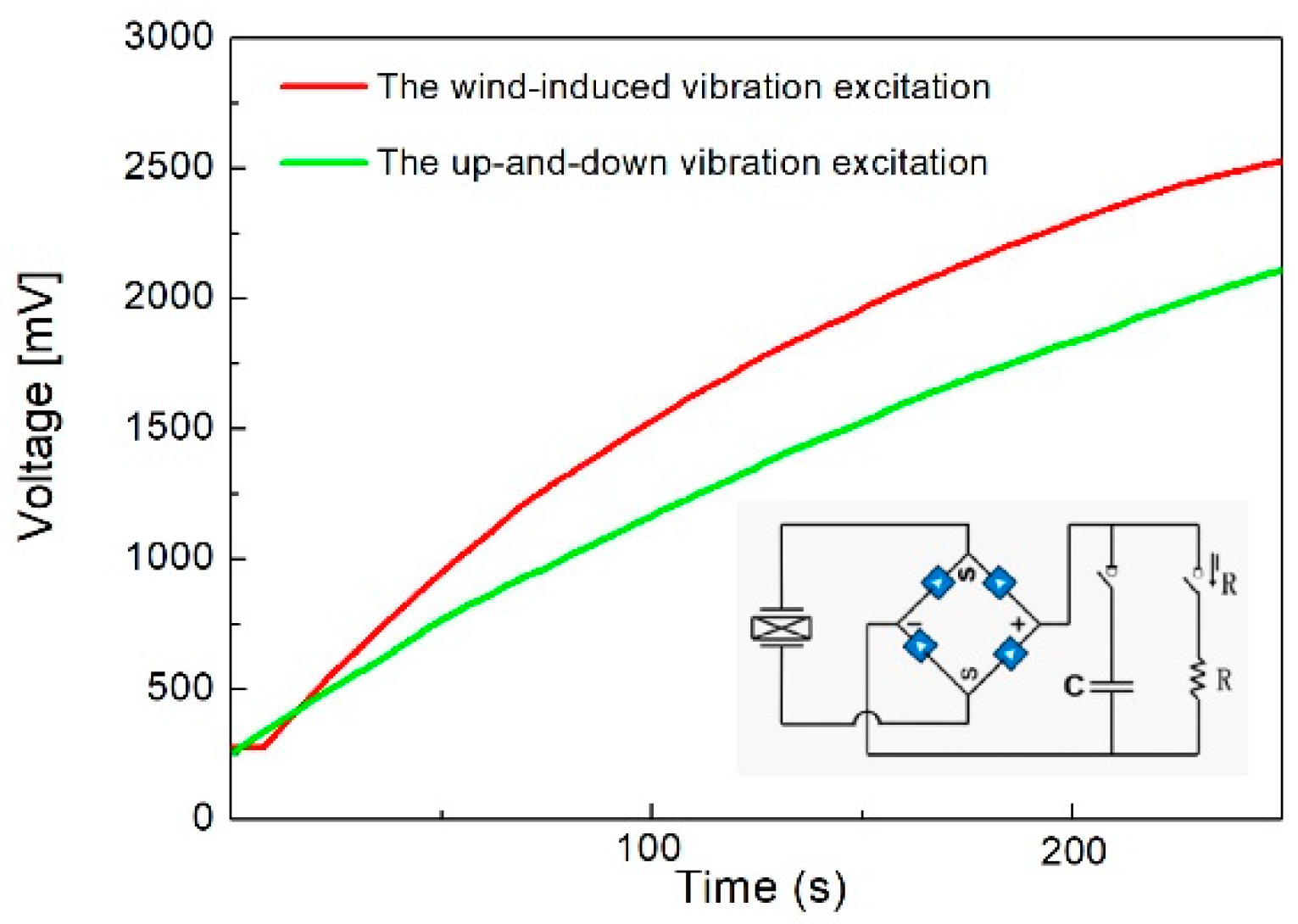

- The S-type generator beam has a high energy capture efficiency. Within the experimental range, when the external resistance of the circuit is 22 kΩ, the energy collector in both environments reaches the optimal power output state, which is 0.534 mW and 0.545 mW, respectively. At this time, the AC-to-DC bridge circuit sends power to a 470 μF capacitor, and the energy collector is better in the wind environment than in the up-down vibration environment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shaikh, F.K.; Zeadally, S. Energy harvesting in wireless sensor networks: Acomprehensive review, Renew. Sustain. Energy Rev. 2016, 55, 1041–1054. [Google Scholar] [CrossRef]

- Harne, R.L.; Wang, K.W. A review of the recent research on vibration energy harvesting via bistable systems. Smart Mater. Struct. 2013, 22, 023001. [Google Scholar] [CrossRef]

- Priya, S.; Song, H.-C.; Zhou, Y.; Varghese, R.; Chopra, A.; Kim, S.-G.; Kanno, I.; Wu, L.; Ha, D.S.; Ryu, J.; et al. A review on piezoelectric energy harvesting: Materials, methods, and circuits. Energy Harvest. Syst. 2019, 4, 3–39. [Google Scholar] [CrossRef]

- Yang, B.; Lee, C.; Xiang, W.; Xie, J.; He, J.H.; Kotlanka, R.K.; Low, S.P.; Feng, H. Electromagnetic energy harvesting from vibrations of multiple frequencies. J. Micromech. Microeng. 2009, 19, 035001. [Google Scholar] [CrossRef]

- Crovetto, A.; Wang, F.; Hansen, O. Modeling and optimization of an electrostatic energy harvesting device. J. Microelectromech. Syst. 2014, 23, 1141–1155. [Google Scholar] [CrossRef]

- Wang, Z.L.; Chen, J.; Lin, L. Progress in triboelectric nanogenerators as a new energy technology and self-powered sensors. Energy Environ. Sci. 2015, 8, 2250–2282. [Google Scholar] [CrossRef]

- Bowen, C.R.; Kim, H.A.; Weaver, P.M.; Dunn, S. Piezoelectric and ferroelectric materials and structures for energy harvesting applications. Energy Environ. Sci. 2013, 7, 25–44. [Google Scholar] [CrossRef]

- Farhangdoust, S.; Mehrabi, A.; Younesian, D. Bistable wind-induced vibration energy harvester for self-powered wireless sensors in smart bridge monitoring systems. In Proceedings of the Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, Civil Infrastructure, and Transportation XIII, Denver, CO, USA, 4–7 March 2019. [Google Scholar] [CrossRef]

- Kan, J.; Liao, W.; Wang, J.; Wang, S.; Yan, M.; Jiang, Y.; Zhang, Z. Enhanced piezoelectric wind-induced vibration energy harvester via the interplay between cylindrical shell and diamond-shaped baffle. Nano Energy 2021, 89, 106466. [Google Scholar] [CrossRef]

- Wu, N.; He, Y.; Fu, J.; Liao, P. Performance of a bistable flow-energy harvester based on vortex-induced vibration. J. Wind Eng. Ind. Aerodyn. 2021, 217, 104733. [Google Scholar] [CrossRef]

- Zhou, J.; Zhao, X.; Wang, K.; Chang, Y.; Xu, D.; Wen, G. Bio-inspired bistable piezoelectric vibration energy harvester: Design and experimental investigation. Energy 2021, 228, 120595. [Google Scholar] [CrossRef]

- Peng, Y.; Xu, Z.; Wang, M.; Li, Z.; Peng, J.; Luo, J.; Xie, S.; Pu, H.; Yang, Z. Investigation of frequency-up conversion effect on the performance improvement of stack-based piezoelectric generators. Renew. Energy 2021, 172, 551–563. [Google Scholar] [CrossRef]

- Nan, W.; Yuncheng, H.; Jiyang, F. Bistable energy harvester using easy snap-through performance to increase output power. Energy 2021, 226, 120414. [Google Scholar] [CrossRef]

- Umeda, M.; Nakamura, K.; Ueha, S. Analysis of the Transformation of Mechanical Impact Energy to Electric Energy Using Piezoelectric Vibrator. Jpn. J. Appl. Phys. 1996, 35, 3267. [Google Scholar] [CrossRef]

- Fu, H.; Sharif-Khodaei, Z.; Aliabadi, F. A bio-inspired host-parasite structure for broadband vibration energy harvesting from low-frequency random sources. Appl. Phys. Lett. 2019, 114, 143901. [Google Scholar] [CrossRef]

- Shin, Y.-H.; Choi, J.; Kim, S.J.; Kim, S.; Maurya, D.; Sung, T.-H.; Priya, S.; Kang, C.-Y.; Song, H.-C. Automatic resonance tuning mechanism for ultra-wide bandwidth mechanical energy harvesting. Nano Energy 2020, 77, 104986. [Google Scholar] [CrossRef]

- Kouritem, S.A.; Bani-Hani, M.A.; Beshir, M.; Elshabasy, M.M.Y.B.; Altabey, W.A. Automatic Resonance Tuning Technique for an Ultra-Broadband Piezoelectric Energy Harvester. Energies 2022, 15, 7271. [Google Scholar] [CrossRef]

- Rezaei, M.; Talebitooti, R.; Liao, W.-H. Investigations on Magnetic Bistable PZT-Based Absorber for Concurrent Energy Harvesting and Vibration Mitigation: Numerical and Analytical Approaches. Energy 2022, 239, 122376. [Google Scholar] [CrossRef]

- Saint-Martin, C.; Morel, A.; Charleux, L.; Roux, E.; Benhemou, A.; Badel, A. Power Expectation as a Unified Metric for the Evaluation of Vibration Energy Harvesters. Mech. Syst. Signal Process. 2022, 181, 109482. [Google Scholar] [CrossRef]

- Chiacchiari, S.; Romeo, F.; McFarland, D.M.; Bergman, L.A.; Vakakis, A.F. Vibration Energy Harvesting from Impulsive Excitations via a Bistable Nonlinear Attachment—Experimental Study. Mech. Syst. Signal Process. 2019, 125, 185–201. [Google Scholar] [CrossRef]

- Huguet, T.; Badel, A.; Druet, O.; Lallart, M. Drastic Bandwidth Enhancement of Bistable Energy Harvesters: Study of Subharmonic Behaviors and Their Stability Robustness. Appl. Energy 2018, 226, 607–617. [Google Scholar] [CrossRef]

- Andó, B.; Baglio, S.; Maiorca, F.; Trigona, C. Two Dimensional Bistable Vibration Energy Harvester. Procedia Eng. 2012, 47, 1061–1064. [Google Scholar] [CrossRef]

- Harne, R.L.; Zhang, C.; Li, B.; Wang, K.W. An Analytical Approach for Predicting the Energy Capture and Conversion by Impulsively-Excited Bistable Vibration Energy Harvesters. J. Sound Vib. 2016, 373, 205–222. [Google Scholar] [CrossRef]

- Syta, A.; Bowen, C.R.; Kim, H.A.; Rysak, A.; Litak, G. Responses of Bistable Piezoelectric-Composite Energy Harvester by Means of Recurrences. Mech. Syst. Signal Process. 2016, 76–77, 823–832. [Google Scholar] [CrossRef]

- Derakhshani, M.; Momenzadeh, N.; Berfield, T.A. Analytical and Experimental Study of a Clamped-Clamped, Bistable Buckled Beam Low-Frequency PVDF Vibration Energy Harvester. J. Sound Vib. 2021, 497, 115937. [Google Scholar] [CrossRef]

- Sosna, P.; Rubeš, O.; Hadaš, Z. Verification and Analysis of Advanced Tuneable Nonlinear Vibration Energy Harvester. Mech. Syst. Signal Process. 2023, 189, 110096. [Google Scholar] [CrossRef]

- Andò, B.; Baglio, S.; Maiorca, F.; Trigona, C. Analysis of Two Dimensional, Wide-Band, Bistable Vibration Energy Harvester. Sens. Actuators A Phys. 2013, 202, 176–182. [Google Scholar] [CrossRef]

- Tan, D.; Zhou, J.; Wang, K.; Ouyang, H.; Zhao, H.; Xu, D. Sliding-Impact Bistable Triboelectric Nanogenerator for Enhancing Energy Harvesting from Low-Frequency Intrawell Oscillation. Mech. Syst. Signal Process. 2023, 184, 109731. [Google Scholar] [CrossRef]

- Naseer, R.; Abdelkefi, A. Nonlinear Modeling and Efficacy of VIV-Based Energy Harvesters: Monostable and Bistable Designs. Mech. Syst. Signal Process. 2022, 169, 108775. [Google Scholar] [CrossRef]

- Huguet, T.; Lallart, M.; Badel, A. Orbit Jump in Bistable Energy Harvesters through Buckling Level Modification. Mech. Syst. Signal Process. 2019, 128, 202–215. [Google Scholar] [CrossRef]

- Cao, D.-X.; Lu, Y.-M.; Lai, S.-K.; Mao, J.-J.; Guo, X.-Y.; Shen, Y.-J. A novel soft encapsulated multi-directional and multi-modal piezoelectric vibration energy harvester. Energy 2022, 254, 124309. [Google Scholar] [CrossRef]

- Song, J.; Xia, C.; Shan, G.; Wang, Z.; Ono, T.; Wang, D.F. Widening frequency bandwidth with parametric coupling in a wings-inspired low frequency MEMS energy harvester. Energy Convers. Manag. 2022, 267, 115924. [Google Scholar] [CrossRef]

- Wang, J.; Liao, W.-H.; Cao, J. Power enhancement of a monostable energy harvester by orbit jumps. J. Intell. Mater. Syst. Struct. 2021, 32, 2601–2614. [Google Scholar] [CrossRef]

- Hou, C.; Zhang, X.; Yu, H.; Shan, X.; Sui, G.; Xie, T. Ori-inspired bistable piezoelectric energy harvester for scavenging human shaking energy: Design, modeling, and experiments. Energy Convers. Manag. 2022, 271, 116309. [Google Scholar] [CrossRef]

- Qian, F.; Hajj, M.R.; Zuo, L. Bio-inspired bi-stable piezoelectric harvester for broadband vibration energy harvesting. Energy Convers. Manag. 2020, 222, 113174. [Google Scholar] [CrossRef]

- Zhou, Z.; Qin, W.; Zhu, P.; Shang, S. Scavenging wind energy by a Y-shaped bi-stable energy harvester with curved wings. Energy. 2018, 153, 400–412. [Google Scholar] [CrossRef]

- Usman, M.; Hanif, A.; Kim, I.-H.; Jung, H.-J. Experimental validation of a novel piezoelectric energy harvesting system employing wake galloping phenomenon for a broad wind spectrum. Energy. 2018, 153, 882–889. [Google Scholar] [CrossRef]

- Wu, R.; Zhou, C. Design and Experimental Study of Two-Stage Flexible Flapping Wing Air Vehiicle. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2019. [Google Scholar] [CrossRef]

- Li, H.; Ding, H.; Chen, L. Chaotic dynamics of a bi-stable energy harvesting system with asymmetric potential well characteristics. J. Vib. Shock. 2020, 39, 54–59+69. [Google Scholar] [CrossRef]

- Avvari, P.V.; Yang, Y.; Soh, C.K. Long-term fatigue behavior of a cantilever piezoelectric energy harvester. J. Intell. Mater. Syst. Struct. 2017, 28, 1188–1210. [Google Scholar] [CrossRef]

- Yi, Z.; Hu, Y.; Ji, B.; Liu, J.; Yang, B. Broad bandwidth piezoelectric energy harvester by a flexible buckled bridge. Appl. Phys. Lett. 2018, 113, 183901. [Google Scholar] [CrossRef]

- Zhang, L.B.; Dai, H.L.; Abdelkefi, A.; Wang, L. Experimental investigation of aerodynamic energy harvester with different interference cylinder cross-sections. Energy 2019, 167, 970–981. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, N.; Fu, J.; Xiong, C. Analysis and Application of a New S-Type Bistable Generator Beam in Energy Harvester Featured in Reducing Stress Concentration. Appl. Sci. 2023, 13, 5258. https://doi.org/10.3390/app13095258

Wu N, Fu J, Xiong C. Analysis and Application of a New S-Type Bistable Generator Beam in Energy Harvester Featured in Reducing Stress Concentration. Applied Sciences. 2023; 13(9):5258. https://doi.org/10.3390/app13095258

Chicago/Turabian StyleWu, Nan, Jiyang Fu, and Chao Xiong. 2023. "Analysis and Application of a New S-Type Bistable Generator Beam in Energy Harvester Featured in Reducing Stress Concentration" Applied Sciences 13, no. 9: 5258. https://doi.org/10.3390/app13095258

APA StyleWu, N., Fu, J., & Xiong, C. (2023). Analysis and Application of a New S-Type Bistable Generator Beam in Energy Harvester Featured in Reducing Stress Concentration. Applied Sciences, 13(9), 5258. https://doi.org/10.3390/app13095258