Study on Preparation and Rheological Properties of 3D Printed Pre-Foaming Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Design and Preparation of Pastes

2.3. 3D Printing Concrete

2.4. Experimental Methods of Fresh Foam Mortar

2.4.1. Mini-Slump and Fluidity

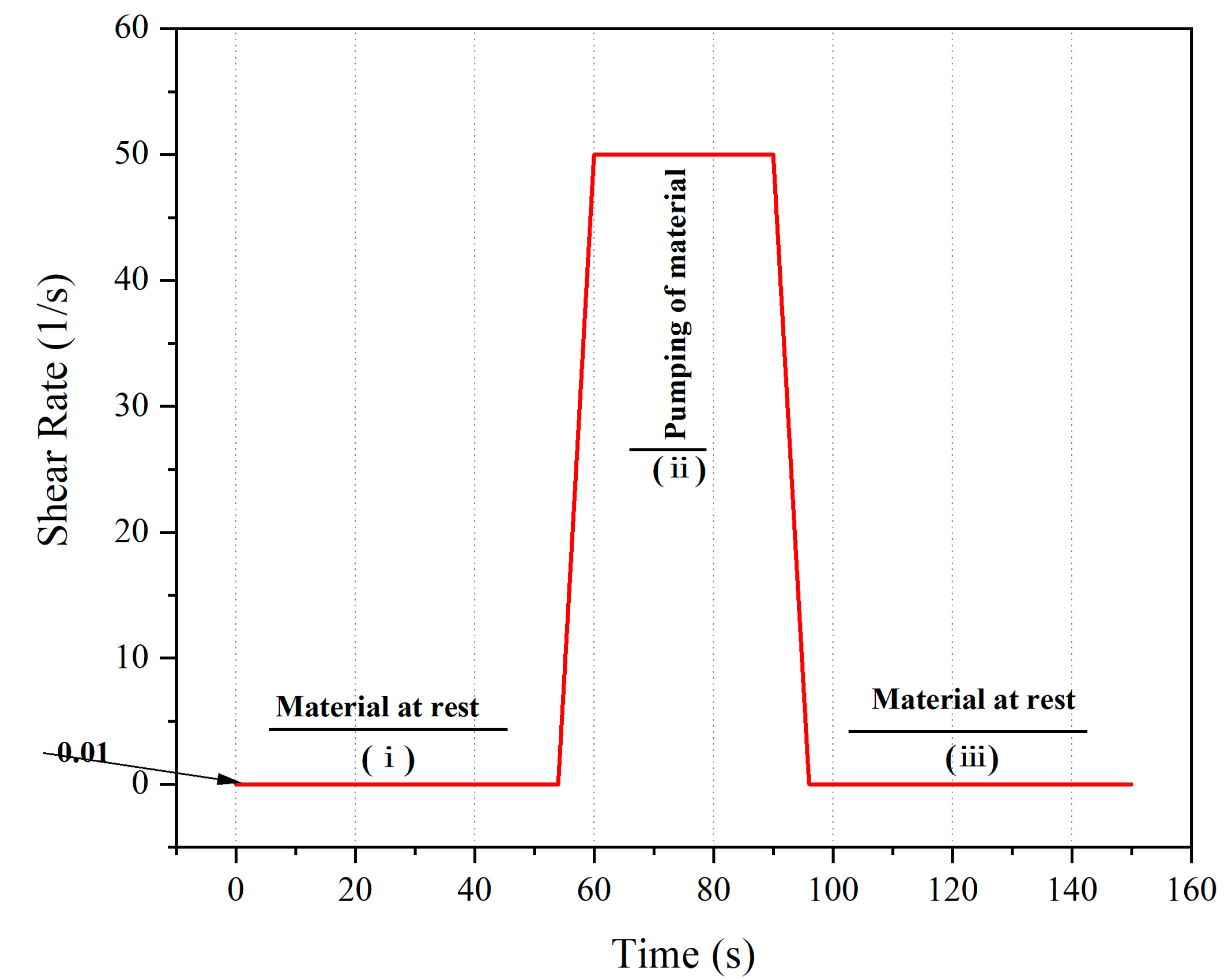

2.4.2. Rheology

2.5. Experimental Methods of Hardened Foam Mortar

2.5.1. Compressive Strength and Volume Density

2.5.2. Mercury Intrusion Porosimetry

2.5.3. Scanning Electron Microscopy

2.5.4. Thermal Conductivity

3. Results and Discussion

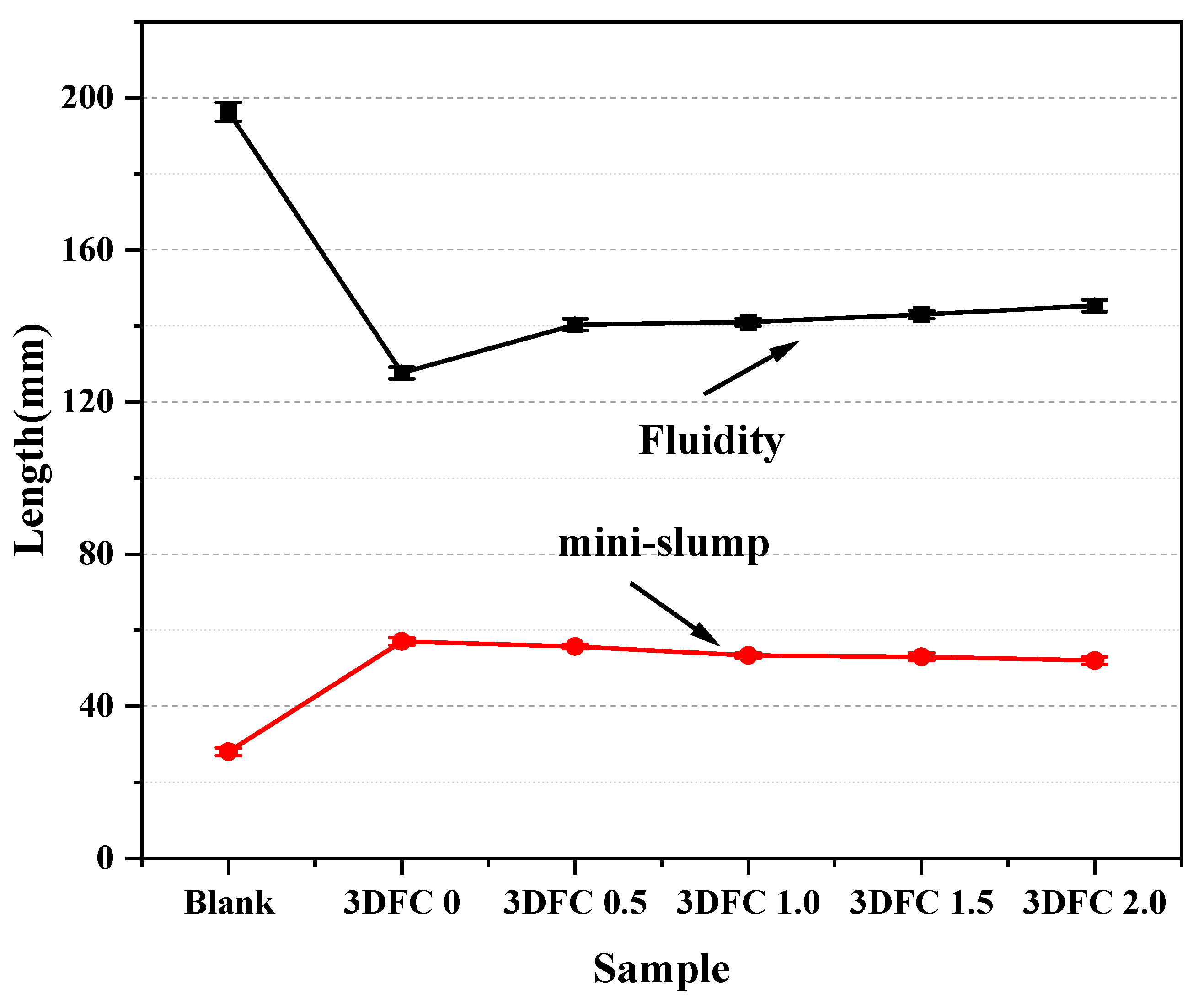

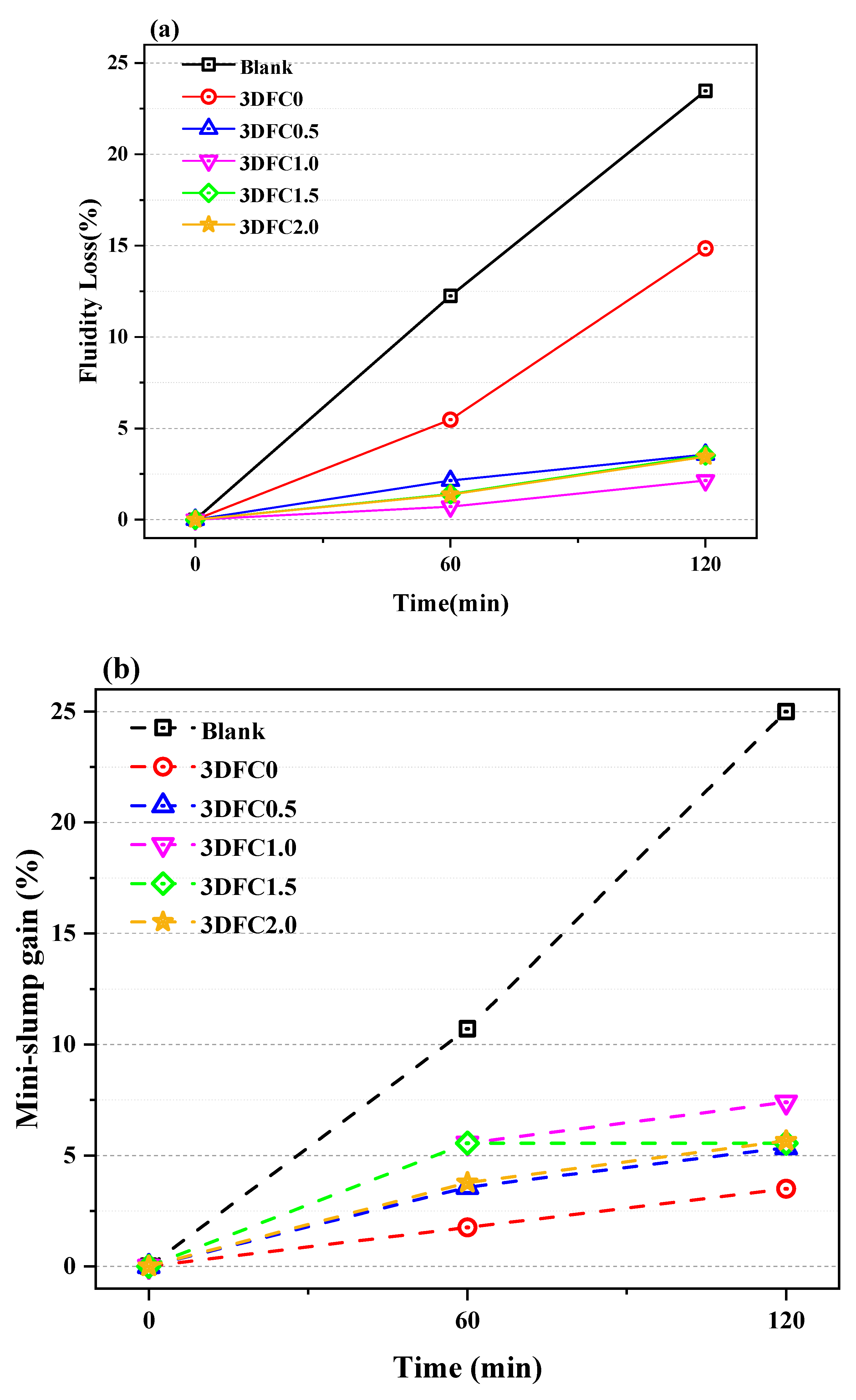

3.1. Mini-Slump and Fluidity

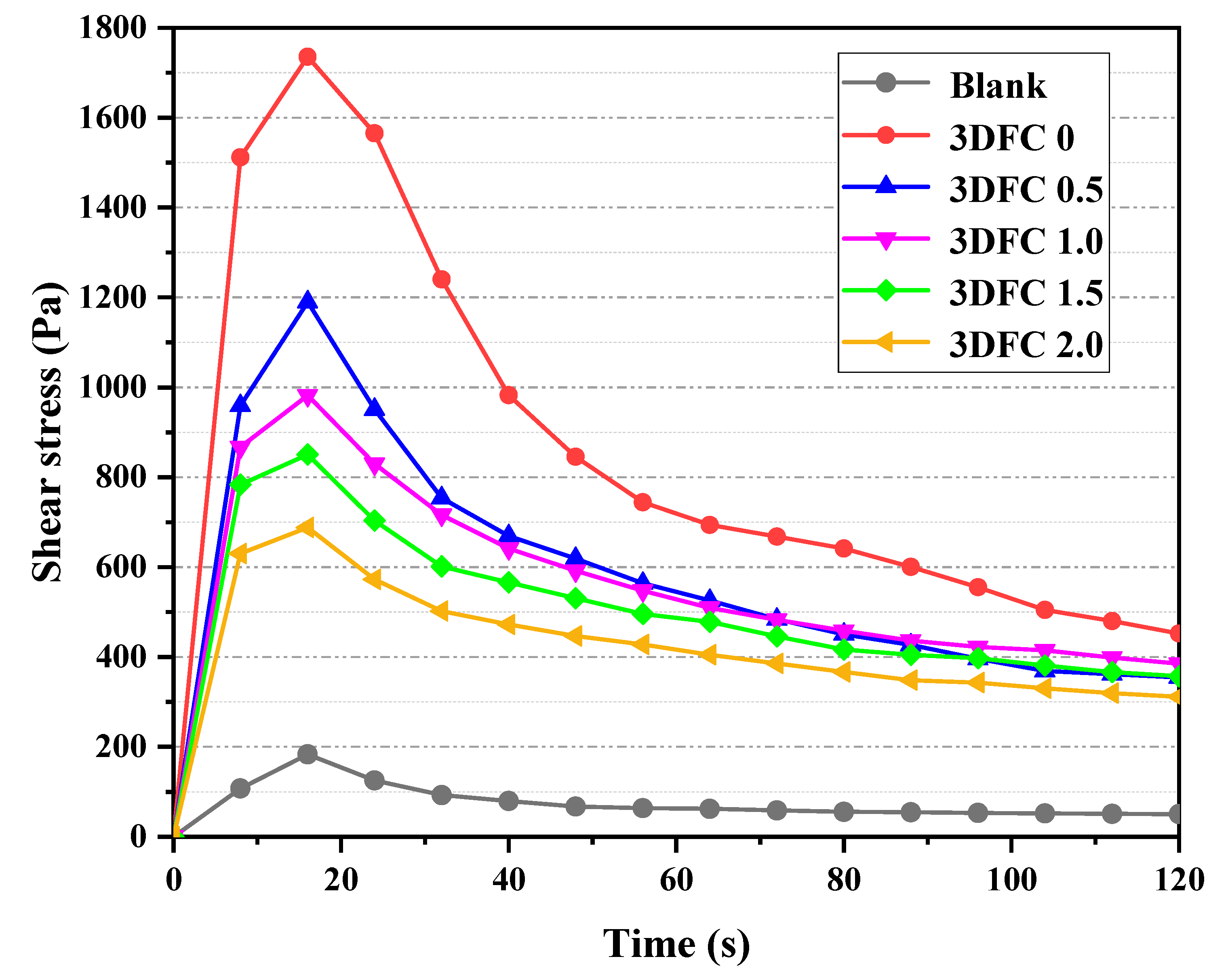

3.2. Static Yield Stress

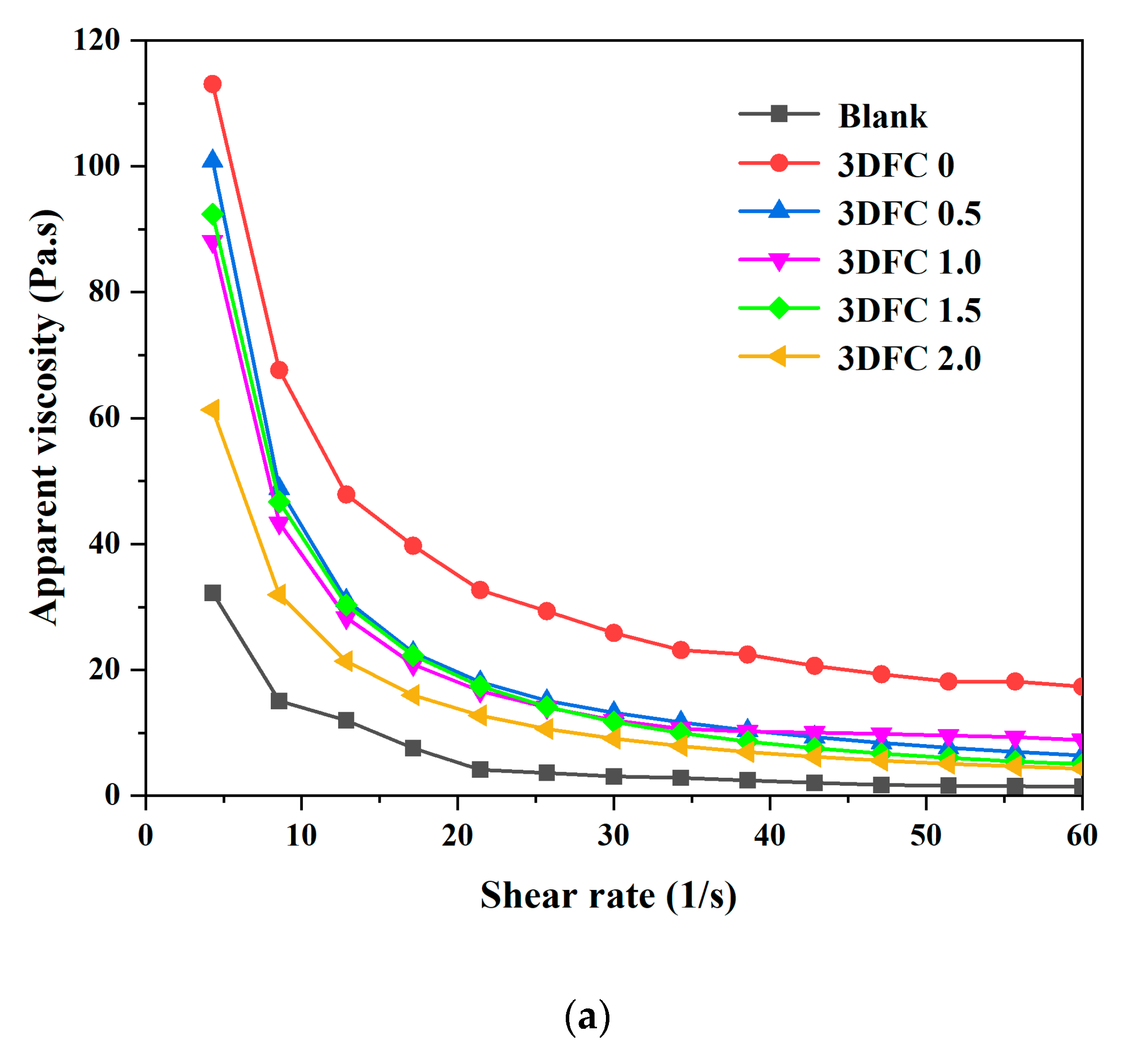

3.3. Apparent Viscosity

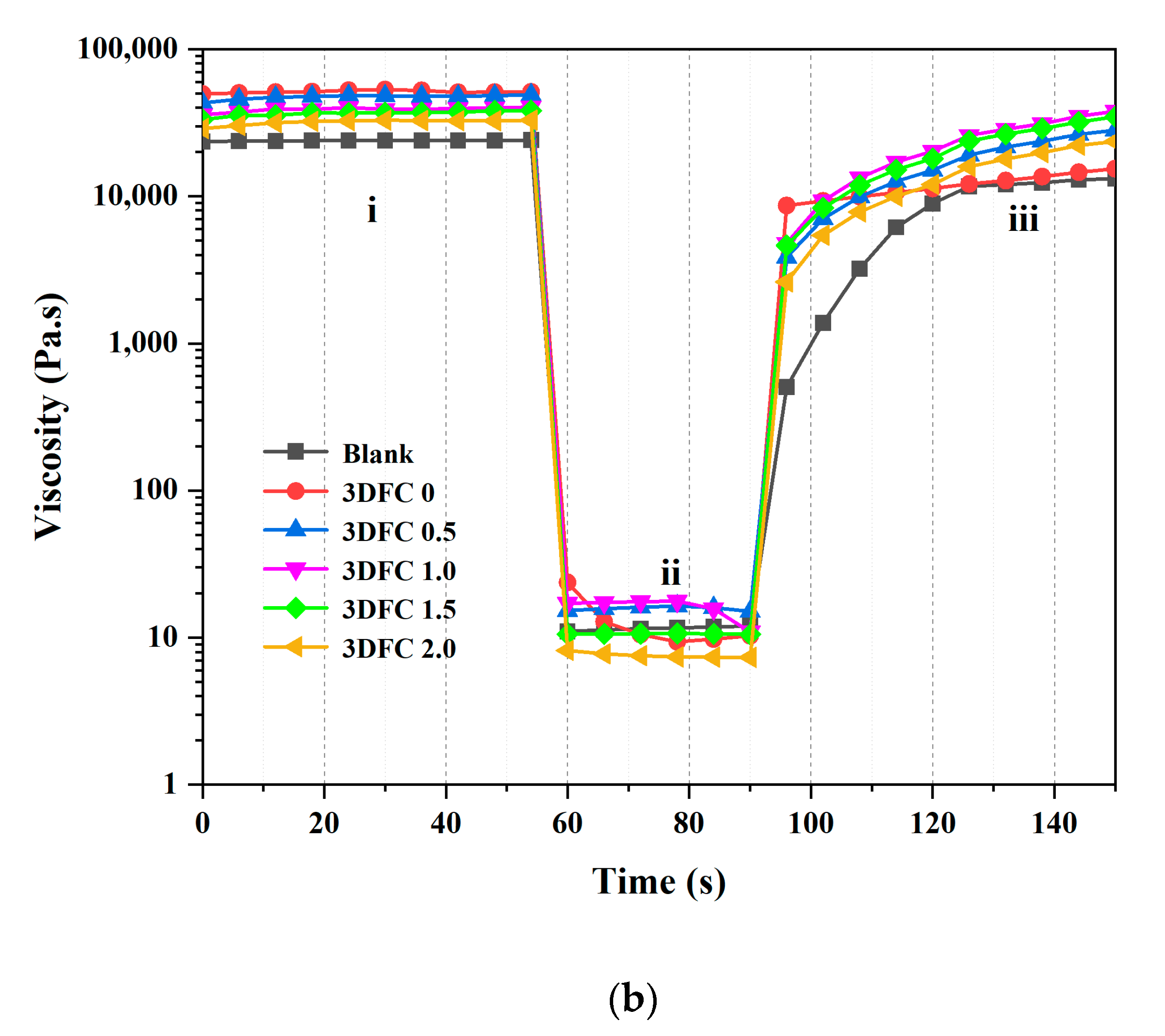

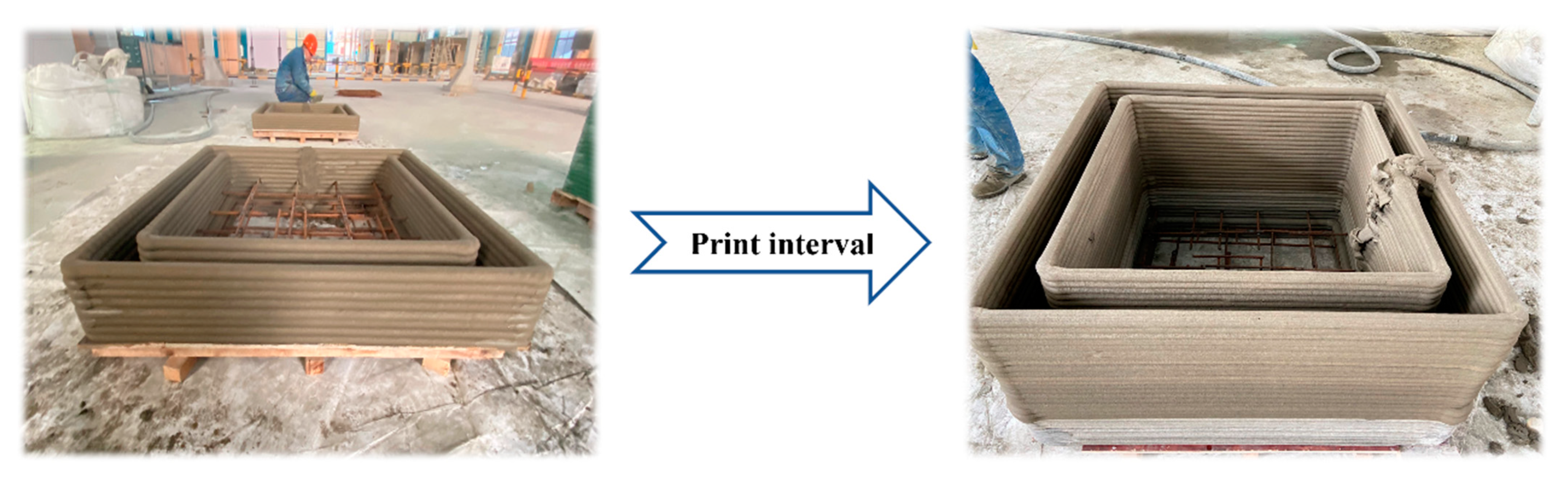

3.4. Buildability

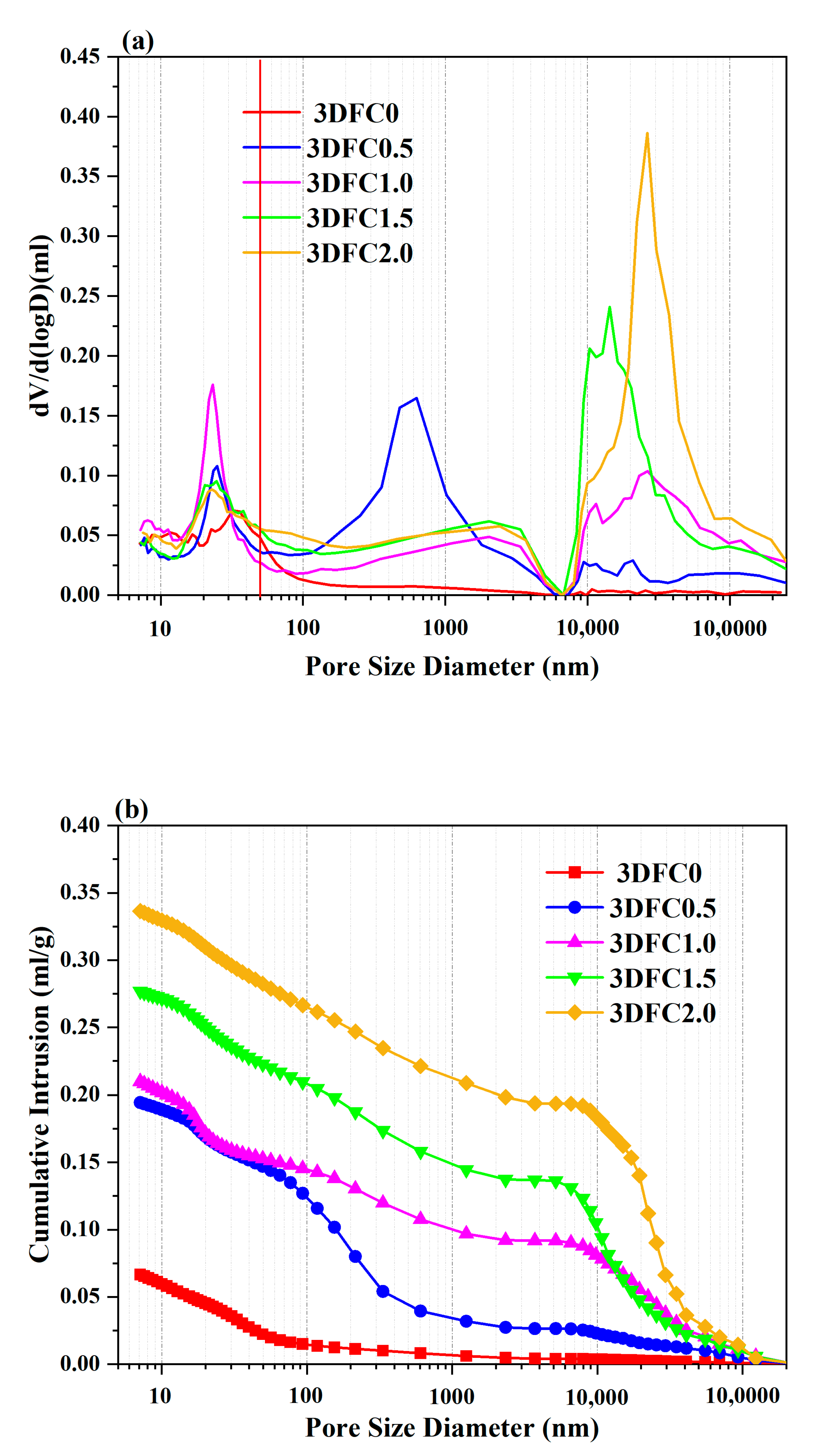

3.5. Pore Structure

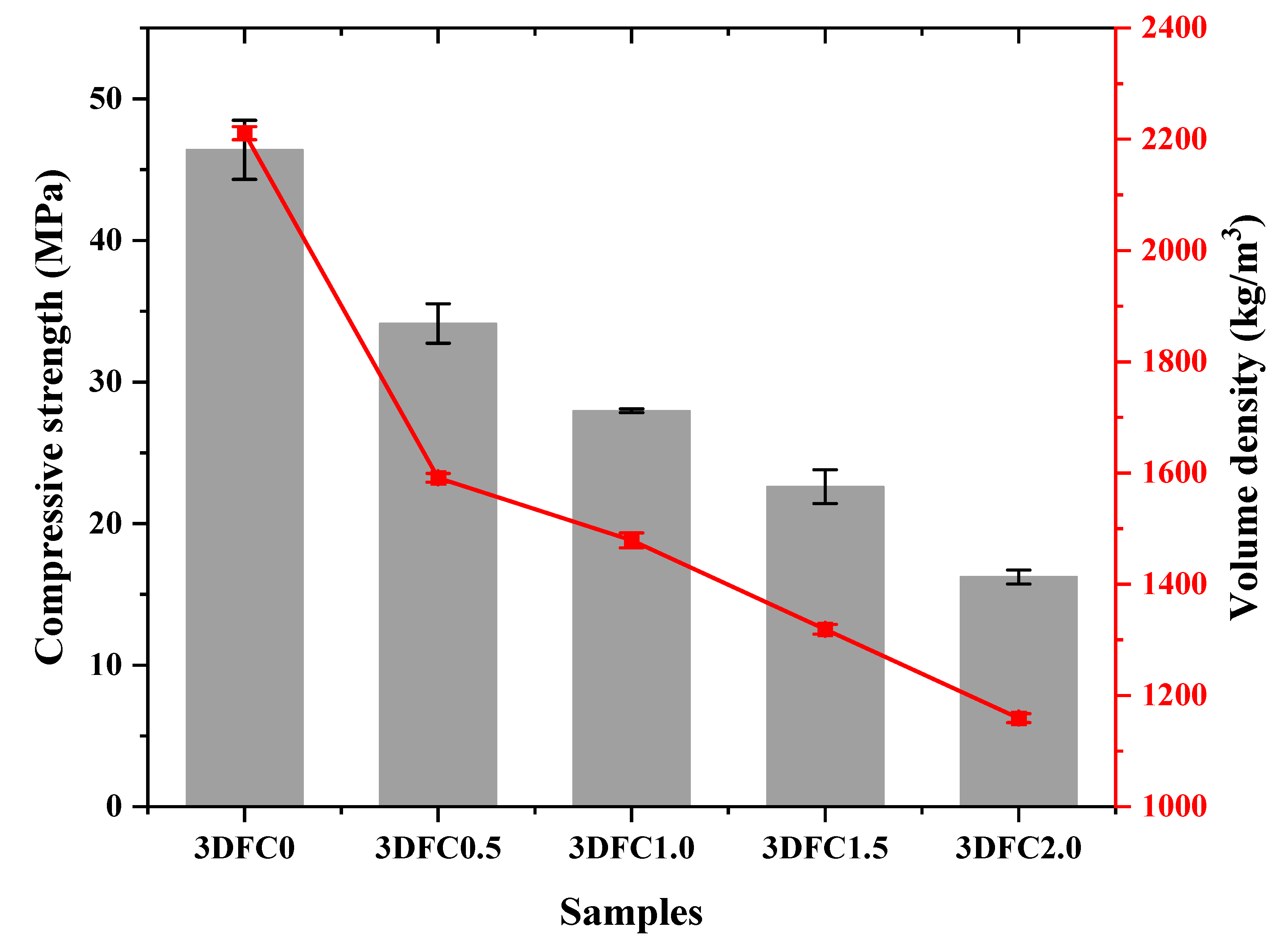

3.6. Compressive Strength, Volume Density

3.7. Thermal Conductivity

4. Discussion

5. Conclusions

- The addition of 0.1 wt.% HPMC to 3DFCs increases the static yield stress and apparent viscosity (especially at low shear rate), thus enhancing the buildability. Although the fluidity of 3DFCs is reduced, its loose and porous internal structure reduces the resistance to pumping, which is suitable for printability.

- The buildability of 3DFCs containing various dosages of surfactant is evaluated via the static yield stress development, apparent viscosity and viscosity recovery test. Result demonstrates that the incorporation of surfactants reduces the static yield stress and apparent viscosity, but the viscosity recovery rate of all 3DFCs is similar.

- The MIP test results show that the number of macropores (10–100 μm) and total pores in hardened foam mortar increase obviously with the increase of surfactant. In addition, SEM images show that when the foam content in 3DFCs increases, the pore size and the number of large pores (100–500 μm) in 3DFCs will also increase.

- The presence of surfactant can effectively reduce the volume density of 3DFCs from 2211 to 1159 kg/m3 but also weaken the compressive strength of 3DFCs. This is due to the generation of more pores with the addition of surfactant and consequently to the decrease of compressive strength and density. Moreover, the thermal conductivity of 3DFCs decreases slightly from 0.288 to 0.255 W/(m·K), with the gradual increase of surfactant dosage, which is also related to the development of pore structure.

Author Contributions

Funding

Conflicts of Interest

References

- Paolini, A.; Kollmannsberger, S.; Rank, E. Additive manufacturing in construction: A review on processes, applications, and digital planning methods. Addit. Manuf. 2019, 30, 100894. [Google Scholar] [CrossRef]

- Bester, F.; van den Heever, M.; Kruger, J.; van Zijl, G. Reinforcing digitally fabricated concrete: A systems approach review. Addit. Manuf. 2021, 37, 101737. [Google Scholar] [CrossRef]

- Panda, B.; Tan, M.J. Experimental study on mix proportion and fresh properties of fly ash based geopolymer for 3D concrete printing. Ceram. Int. 2018, 44, 10258–10265. [Google Scholar] [CrossRef]

- Panda, B.; Unluer, C.; Tan, M.J. Extrusion and rheology characterization of geopolymer nanocomposites used in 3D printing. Compos. Part B Eng. 2019, 176, 107290. [Google Scholar] [CrossRef]

- Panda, B.; Unluer, C.; Tan, M.J. Investigation of the rheology and strength of geopolymer mixtures for extrusion-based 3D printing. Cem. Concr. Compos. 2018, 94, 307–314. [Google Scholar] [CrossRef]

- Jiao, D.; De Schryver, R.; Shi, C.; De Schutter, G. Thixotropic structural build-up of cement-based materials: A state-of-the-art review. Cem. Concr. Compos. 2021, 122, 104152. [Google Scholar] [CrossRef]

- Cho, S.; Kruger, J.; van Rooyen, A.; van Zijl, G. Rheology and application of buoyant foam concrete for digital fabrication. Compos. Part B Eng. 2021, 215, 108800. [Google Scholar] [CrossRef]

- Lv, Q.; Yang, J.; Sun, X.; Tang, H.; Wang, L. Preparation of highly efficient thermal insulating halloysite nanotubes/polyvinyl alcohol composite aerogel based on a simple freeze-drying strategy. Polym. Compos. 2022, 44, 1648–1657. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, J.; Wu, H.; Fu, P.; Liu, Y.; Yang, W. Dynamic thermal performance of ultra-light and thermal-insulative aerogel foamed concrete for building energy efficiency. Sol. Energy 2020, 204, 569–576. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Mechanical, thermal insulation, thermal resistance and acoustic absorption properties of geopolymer foam concrete. Cem. Concr. Compos. 2015, 62, 97–105. [Google Scholar] [CrossRef]

- Shah, S.N.; Mo, K.H.; Yap, S.P.; Yang, J.; Ling, T.-C. Lightweight foamed concrete as a promising avenue for incorporating waste materials: A review. Resour. Conserv. Recycl. 2021, 164, 105103. [Google Scholar] [CrossRef]

- Dhasindrakrishna, K.; Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. Progress, current thinking and challenges in geopolymer foam concrete technology. Cem. Concr. Compos. 2021, 116, 103886. [Google Scholar] [CrossRef]

- Li, T.; Huang, F.; Zhu, J.; Tang, J.; Liu, J. Effect of foaming gas and cement type on the thermal conductivity of foamed concrete. Constr. Build. Mater. 2020, 231, 117197. [Google Scholar] [CrossRef]

- Furet, B.; Poullain, P.; Garnier, S. 3D printing for construction based on a complex wall of polymer-foam and concrete. Addit. Manuf. 2019, 28, 58–64. [Google Scholar] [CrossRef]

- Othuman, M.A.; Wang, Y.C. Elevated-temperature thermal properties of lightweight foamed concrete. Constr. Build. Mater. 2011, 25, 705–716. [Google Scholar] [CrossRef]

- Yang, S.; Wi, S.; Park, J.H.; Cho, H.M.; Kim, S. Novel proposal to overcome insulation limitations due to nonlinear structures using 3D printing: Hybrid heat-storage system. Energy Build. 2019, 197, 177–187. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Ramakrishnan, S.; Sanjayan, J. Technologies for improving buildability in 3D concrete printing. Cem. Concr. Compos. 2021, 122, 104144. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, Y.; Pan, T.; Yin, K. The Synergistic Effect of Ester-Ether Copolymerization Thixo-Tropic Superplasticizer and Nano-Clay on the Buildability of 3D Printable Cementitious Materials. Materials 2021, 14, 4622. [Google Scholar] [CrossRef]

- Zhang, C.; Deng, Z.; Chen, C.; Zhang, Y.; Mechtcherine, V.; Sun, Z. Predicting the static yield stress of 3D printable concrete based on flowability of paste and thickness of excess paste layer. Cem. Concr. Compos. 2022, 129, 104494. [Google Scholar] [CrossRef]

- Alghamdi, H.; Neithalath, N. Synthesis and characterization of 3D-printable geopolymeric foams for thermally efficient building envelope materials. Cem. Concr. Compos. 2019, 104, 103377. [Google Scholar] [CrossRef]

- Falliano, D.; De Domenico, D.; Ricciardi, G.; Gugliandolo, E. 3D-printable lightweight foamed concrete and comparison with classical foamed concrete in terms of fresh state properties and mechanical strength. Constr. Build. Mater. 2020, 254, 119271. [Google Scholar] [CrossRef]

- Gu, G.; Xu, F.; Huang, X.; Ruan, S.; Peng, C.; Lin, J. Foamed geopolymer: The relationship between rheological properties of geopolymer paste and pore-formation mechanism. J. Clean. Prod. 2020, 277, 123238. [Google Scholar] [CrossRef]

- Feneuil, B.; Pitois, O.; Roussel, N. Effect of surfactants on the yield stress of cement paste. Cem. Concr. Res. 2017, 100, 32–39. [Google Scholar] [CrossRef]

- Luan, X.; Li, J.; Liu, L.; Yang, Z. Preparation and characteristics of porous magnesium phosphate cement modified by diatomite. Mater. Chem. Phys. 2019, 235, 121742. [Google Scholar] [CrossRef]

- Panda, B.; Sonat, C.; Yang, E.-H.; Tan, M.J.; Unluer, C. Use of magnesium-silicate-hydrate (M-S-H) cement mixes in 3D printing applications. Cem. Concr. Compos. 2021, 117, 103901. [Google Scholar] [CrossRef]

- ASTM C1437-15; Standard Test Method for Flow of Hydraulic Cement Mortar. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- Jiang, J.; Lu, Z.; Niu, Y.; Li, J.; Zhang, Y. Investigation of the properties of high-porosity cement foams based on ternary Portland cement–metakaolin–silica fume blends. Constr. Build. Mater. 2016, 107, 181–190. [Google Scholar] [CrossRef]

- Panda, B.; Tan, M.J. Rheological behavior of high volume fly ash mixtures containing micro silica for digital construction application. Mater. Lett. 2019, 237, 348–351. [Google Scholar] [CrossRef]

- Qian, H.; Hua, S.; Gao, Y.; Qian, L.; Ren, X. Synergistic effect of EVA copolymer and sodium desulfurization ash on the printing performance of high volume blast furnace slag mixtures. Addit. Manuf. 2021, 46, 102183. [Google Scholar] [CrossRef]

- Panda, B.; Ruan, S.; Unluer, C.; Tan, M.J. Improving the 3D printability of high volume fly ash mixtures via the use of nano attapulgite clay. Compos. Part B Eng. 2019, 165, 75–83. [Google Scholar] [CrossRef]

- Lim, J.H.; Panda, B.; Pham, Q.-C. Improving flexural characteristics of 3D printed geopolymer composites with in-process steel cable reinforcement. Constr. Build. Mater. 2018, 178, 32–41. [Google Scholar] [CrossRef]

- ASTM C349-18; Standard Test Method for Compressive Strength of Hydraulic-Cement Mortars. American Society for Testing and Materials: West Conshohocken, PA, USA, 2018.

- Ducloué, L.; Pitois, O.; Tocquer, L.; Goyon, J.; Ovarlez, G. Yielding and flow of foamed metakaolin pastes. Colloids Surf. A: Physicochem. Eng. Asp. 2017, 513, 87–94. [Google Scholar] [CrossRef]

- Ducloué, L.; Pitois, O.; Goyon, J.; Chateau, X.; Ovarlez, G. Rheological behaviour of suspensions of bubbles in yield stress fluids. J. Non-Newton. Fluid Mech. 2015, 215, 31–39. [Google Scholar] [CrossRef]

- Qian, H.; Hua, S.; Yue, H.; Feng, G.; Qian, L.; Jiang, W.; Zhang, L. Utilization of recycled construction powder in 3D concrete printable materials through particle packing optimization. J. Build. Eng. 2022, 61, 105236. [Google Scholar] [CrossRef]

- Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. Enhancing the properties of foam concrete 3D printing using porous aggregates. Cem. Concr. Compos. 2022, 133, 104687. [Google Scholar] [CrossRef]

- Cheng, C.; Hong, S.; Zhang, Y.; He, J. Effect of expanded polystyrene on the flexural behavior of lightweight glass fiber reinforced cement. Constr. Build. Mater. 2020, 265, 120328. [Google Scholar] [CrossRef]

- Yavuz Bayraktar, O.; Kaplan, G.; Gencel, O.; Benli, A.; Sutcu, M. Physico-mechanical, durability and thermal properties of basalt fiber reinforced foamed concrete containing waste marble powder and slag. Constr. Build. Mater. 2021, 288, 123128. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, Y.; Wang, W.; Zhang, Y.; Wang, Z.; Jiang, L. A study on heat transfer performance of recycled aggregate thermal insulation concrete. J. Build. Eng. 2020, 32, 101797. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, X. Thermal Conductivity Analysis of High Porosity Structures with Open and Closed Pores. Int. J. Heat Mass Transf. 2022, 183, 122089. [Google Scholar] [CrossRef]

- Raj, A.; Sathyan, D.; Mini, K.M. Physical and functional characteristics of foam concrete: A review. Constr. Build. Mater. 2019, 221, 787–799. [Google Scholar] [CrossRef]

- Cho, S.; van Rooyen, A.; Kearsley, E.; van Zijl, G. Foam stability of 3D printable foamed concrete. J. Build. Eng. 2022, 47, 103884. [Google Scholar] [CrossRef]

- Liu, C.; Chen, Y.; Xiong, Y.; Jia, L.; Ma, L.; Wang, X.; Chen, C.; Banthia, N.; Zhang, Y. Influence of HPMC and SF on buildability of 3D printing foam concrete: From water state and flocculation point of view. Compos. Part B Eng. 2022, 242, 110075. [Google Scholar] [CrossRef]

- Dai, S.; Zhu, H.; Zhai, M.; Wu, Q.; Yin, Z.; Qian, H.; Hua, S. Stability of steel slag as fine aggregate and its application in 3D printing materials. Constr. Build. Mater. 2021, 299, 123938. [Google Scholar] [CrossRef]

- Nambiar, E.K.K.; Ramamurthy, K. Air-void characterisation of foam concrete. Cem. Concr. Res. 2007, 37, 221–230. [Google Scholar] [CrossRef]

- Tripathi, A.; Nair, S.A.O.; Neithalath, N. A comprehensive analysis of buildability of 3D-printed concrete and the use of bi-linear stress-strain criterion-based failure curves towards their prediction. Cem. Concr. Compos. 2022, 128, 104424. [Google Scholar] [CrossRef]

- Othman, R.; Jaya, R.P.; Muthusamy, K.; Sulaiman, M.; Duraisamy, Y.; Abdullah, M.; Przybyl, A.; Sochacki, W.; Skrzypczak, T.; Vizureanu, P.; et al. Relation between Density and Compressive Strength of Foamed Concrete. Materials 2021, 14, 2967. [Google Scholar] [CrossRef]

- Li, P.; Wu, H.; Liu, Y.; Yang, J.; Fang, Z.; Lin, B. Preparation and optimization of ultra-light and thermal insulative aerogel foam concrete. Constr. Build. Mater. 2019, 205, 529–542. [Google Scholar] [CrossRef]

- Zhang, D.; Ding, S.; Ma, Y.; Yang, Q. Preparation and Properties of Foam Concrete Incorporating Fly Ash. Materials 2022, 15, 6287. [Google Scholar] [CrossRef]

| SiO2 | Al2O3 | Fe2O3 | TiO2 | CaO | MgO | SO3 | K2O | Na2O | MnO | P2O5 | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 22.84 | 7.14 | 3.76 | 0.38 | 56.24 | 2.07 | 2.03 | 0.74 | 0.13 | 0.17 | 0.099 | 4.14 |

| Mix | Cement | Admixture | Surfactant (%) | Water-Binder Ratio | SAND-Binder Ratio | |

|---|---|---|---|---|---|---|

| HPMC(%) | PP(%) | |||||

| Blank | 100 | 0 | 0.2 | 0.5 | 0.4 | 1.1 |

| 3DFC0 | 100 | 0.1 | 0.2 | 0 | 0.4 | 1.1 |

| 3DFC0.5 | 100 | 0.1 | 0.2 | 0.5 | 0.4 | 1.1 |

| 3DFC1.0 | 100 | 0.1 | 0.2 | 1.0 | 0.4 | 1.1 |

| 3DFC1.5 | 100 | 0.1 | 0.2 | 1.5 | 0.4 | 1.1 |

| 3DFC2.0 | 100 | 0.1 | 0.2 | 2.0 | 0.4 | 1.1 |

| No. | 3DFC0 | 3DFC0.5 | 3DFC1 | 3DFC1.5 | 3DFC2 |

|---|---|---|---|---|---|

| 14.76% | 31.49% | 32.45% | 38.00% | 43.07% | |

| (0) | 0.993 | 0.965 | 0.963 | 0.947 | 0.93 |

| Samples | 3DFC0.5 | 3DFC1.0 | 3DFC1.5 | 3DFC2.0 |

|---|---|---|---|---|

| Volume density (kg/m3) | 1600 | 1480 | 1320 | 1160 |

| Thermal conductivity (W/m·K) | 0.288 | 0.287 | 0.249 | 0.225 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Hua, S.; Yue, H. Study on Preparation and Rheological Properties of 3D Printed Pre-Foaming Concrete. Appl. Sci. 2023, 13, 5303. https://doi.org/10.3390/app13095303

Gao Y, Hua S, Yue H. Study on Preparation and Rheological Properties of 3D Printed Pre-Foaming Concrete. Applied Sciences. 2023; 13(9):5303. https://doi.org/10.3390/app13095303

Chicago/Turabian StyleGao, Yanan, Sudong Hua, and Hongfei Yue. 2023. "Study on Preparation and Rheological Properties of 3D Printed Pre-Foaming Concrete" Applied Sciences 13, no. 9: 5303. https://doi.org/10.3390/app13095303

APA StyleGao, Y., Hua, S., & Yue, H. (2023). Study on Preparation and Rheological Properties of 3D Printed Pre-Foaming Concrete. Applied Sciences, 13(9), 5303. https://doi.org/10.3390/app13095303