Numerical Investigation of the Heat Transfer Characteristics and Wall Film Formation of Spray Impingement in SCR Systems

Abstract

:1. Introduction

2. Numerical Methods and Model Setup

2.1. Governing Equations of the Continuous Phase

2.2. Governing Equation of the Discrete Phase

2.3. Evaporation Model

2.4. Wall Film Model

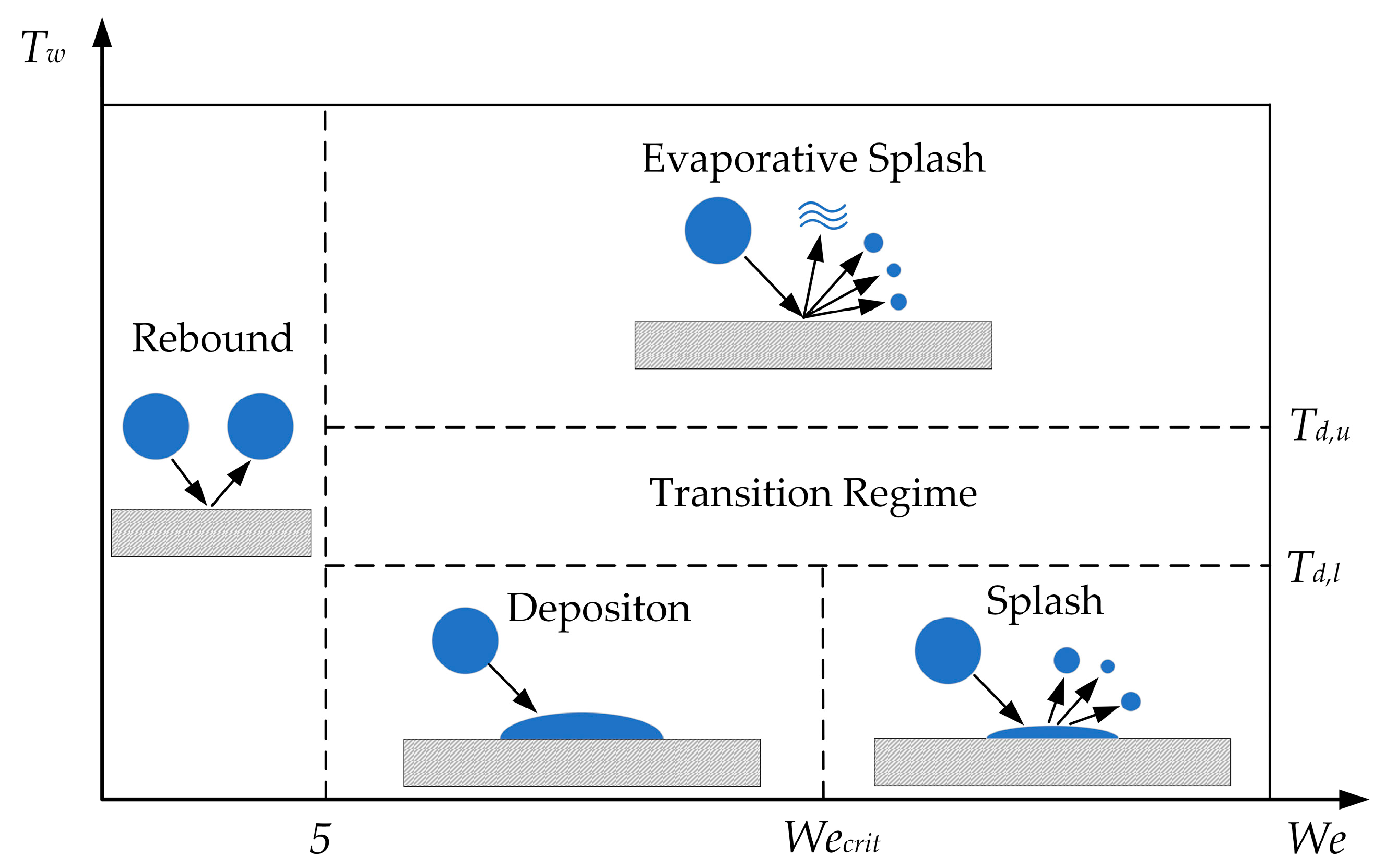

2.4.1. Spray Impingement Model

2.4.2. Governing Equations for Wall Film

2.5. Model Setup

2.6. Spray Characterization

2.6.1. Spray Pattern

2.6.2. Droplet Size Distribution

3. Results and Discussion

3.1. Model Validation and Heat Transfer Characteristics Analysis

3.2. Effect of Wall Film Model on the Estimation of Wall Film Mass

3.3. Effect of Wall Temperature on Cumulative Wall Film Mass

4. Conclusions

- The derived model contributes to quantitatively predicting the spatial distribution of the wall film and the deposits in the SCR system.

- The spray cooling effect on the wall surface is localized, and the temperature drop decreases significantly from the core region to the peripheral region along the radial direction because the mass flux in the core region of the spray impingement is larger than that in the peripheral region.

- The cooling effect of spray is instantaneous since the initial wall temperature is less than or equal to the critical transition temperature of wall film formation.

- The approximate relationship between the critical transition temperature of wall film formation and the critical heat flux temperature is clarified.

- The Stochastic Kuhnke Model was adopted as a spray/wall interaction model to improve the drawback of a sudden change in the Kuhnke Model in wall film deposition prediction.

- When the wall temperature is less than the critical transition temperature, the wall film mass is sensitive to the wall temperature and increases as the wall temperature decreases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liao, Y.; Furrer, R.; Dimopoulos Eggenschwiler, P.; Boulouchos, K. Experimental investigation of the heat transfer characteristics of spray/wall interaction in diesel selective catalytic reduction systems. Fuel 2017, 190, 163–173. [Google Scholar] [CrossRef]

- Schmidt, A.; Bonarens, M.; Roisman, I.V.; Nishad, K.; Sadiki, A.; Dreizler, A.; Hussong, J.; Wagner, S. Experimental Investigation of AdBlue Film Formation in a Generic SCR Test Bench and Numerical Analysis Using LES. Appl. Sci. 2021, 11, 6907. [Google Scholar] [CrossRef]

- He, L.; Hu, J.; Zhang, S.; Wu, Y.; Guo, X.; Guo, X.; Song, J.; Zu, L.; Zheng, X.; Bao, X. Investigating Real-World Emissions of China’s Heavy-Duty Diesel Trucks: Can SCR Effectively Mitigate NOx Emissions for Highway Trucks? Aerosol Air Qual. Res. 2017, 17, 2585–2594. [Google Scholar] [CrossRef]

- Martinovic, F.; Castoldi, L.; Deorsola, F.A. Aftertreatment Technologies for Diesel Engines: An Overview of the Combined Systems. Catalysts 2021, 11, 653. [Google Scholar] [CrossRef]

- Forzatti, P. Present status and perspectives in de-NOx SCR catalysis. Appl. Catal. A Gen. 2001, 222, 221–236. [Google Scholar] [CrossRef]

- Koebel, M.; Elsener, M.; Kleemann, M. Urea-SCR: A promising technique to reduce NOx emissions from automotive diesel engines. Catal. Today 2000, 59, 335–345. [Google Scholar] [CrossRef]

- Birkhold, F.; Meingast, U.; Wassermann, P.; Deutschmann, O. Modeling and simulation of the injection of urea-water-solution for automotive SCR DeNOx-systems. Appl. Catal. B Environ. 2007, 70, 119–127. [Google Scholar] [CrossRef]

- Spiteri, A.; Dimopoulos Eggenschwiler, P.; Liao, Y.; Wigley, G.; Michalow-Mauke, K.A.; Elsener, M.; Kröcher, O.; Boulouchos, K. Comparative analysis on the performance of pressure and air-assisted urea injection for selective catalytic reduction of NOx. Fuel 2015, 161, 269–277. [Google Scholar] [CrossRef]

- McKinley, T.L.; Alleyne, A.G.; Lee, C.-F. Mixture Non-Uniformity in SCR Systems: Modeling and Uniformity Index Requirements for Steady-State and Transient Operation. SAE Int. J. Fuels Lubr. 2010, 3, 486–499. [Google Scholar] [CrossRef]

- Koebel, M.; Strutz, E.O. Thermal and Hydrolytic Decomposition of Urea for Automotive Selective Catalytic Reduction Systems: Thermochemical and Practical Aspects. Ind. Eng. Chem. Res. 2003, 42, 2093–2100. [Google Scholar] [CrossRef]

- Scott Sluder, C.; Storey, J.M.E.; Lewis, S.A.; Lewis, L.A. Low Temperature Urea Decomposition and SCR Performance. SAE Trans. 2005, 114, 669–677. [Google Scholar]

- Eichelbaum, M.; Farrauto, R.J.; Castaldi, M.J. The impact of urea on the performance of metal exchanged zeolites for the selective catalytic reduction of NOxPart I. Pyrolysis and hydrolysis of urea over zeolite catalysts. Appl. Catal. B Environ. 2010, 97, 90–97. [Google Scholar] [CrossRef]

- Sebelius, S.; Le, T.T.; Pettersson, L.J.; Lind, H. Identification of urea decomposition from an SCR perspective; A combination of experimental work and molecular modeling. Chem. Eng. J. 2013, 231, 220–226. [Google Scholar] [CrossRef]

- Musa, S.N.A.; Saito, M.; Furuhata, T.; Arai, M. Evaporation characteristics of a single aqueous urea solution droplet. In Proceedings of the ICLASS-2006, Kyoto, Japan, 27 August 2006. [Google Scholar]

- Wang, T.J.; Baek, S.W.; Lee, S.Y.; Kang, D.H.; Yeo, G.K. Experimental investigation on evaporation of urea-water-solution droplet for SCR applications. AIChE J. 2009, 55, 3267–3276. [Google Scholar] [CrossRef]

- Kuhnke, D. Spray/Wall-Interaction Modelling by Dimensionless Data Analysis. Ph.D. Thesis, Technische Universität Darmstadt, Aachen, Germany, 2004. [Google Scholar]

- Grout, S.; Blaisot, J.-B.; Pajot, K.; Osbat, G. Experimental investigation on the injection of an urea–water solution in hot air stream for the SCR application: Evaporation and spray/wall interaction. Fuel 2013, 106, 166–177. [Google Scholar] [CrossRef]

- Ravikumar, S.V.; Jha, J.M.; Tiara, A.M.; Pal, S.K.; Chakraborty, S. Experimental investigation of air-atomized spray with aqueous polymer additive for high heat flux applications. Int. J. Heat Mass Transf. 2014, 72, 362–377. [Google Scholar] [CrossRef]

- Fu, T.L.; Wang, Z.D.; Deng, X.T.; Liu, G.H.; Wang, G.D. The influence of spray inclination angle on the ultra fast cooling of steel plate in spray cooling condition. Appl. Therm. Eng. 2015, 78, 500–506. [Google Scholar] [CrossRef]

- Nayak, S.K.; Mishra, P.C.; Parashar, S.K.S. Influence of spray characteristics on heat flux in dual phase spray impingement cooling of hot surface. Alex. Eng. J. 2016, 55, 1995–2004. [Google Scholar] [CrossRef]

- Farshchian, B.; Pierce, J.; Beheshti, M.S.; Park, S.; Kim, N. Droplet Impinging Behavior on Surfaces with Wettability Contrasts. Microelectron. Eng. 2018, 195, 50–56. [Google Scholar] [CrossRef]

- Wang, J.; Fu, H.; Hu, Y.; Cai, Y.; Chen, K. Experiment investigation on the effects of air assisted SCR spray impingement on wall temperature evolution. Energy 2020, 204, 117943. [Google Scholar] [CrossRef]

- Birkhold, F.; Meingast, U.; Wassermann, P. Analysis of the Injection of Urea-Water-Solution for Automotive SCR DeNOx-Systems: Modeling of Two-Phase Flow and Spray/Wall-Interaction. In Proceedings of the SAE 2006 World Congress & Exhibition, Detroit, MI, USA, 3–6 April 2006. [Google Scholar]

- Baleta, J.; Vujanović, M.; Pachler, K.; Duić, N. Numerical modeling of urea water based selective catalytic reduction for mitigation of NOx from transport sector. J. Clean. Prod. 2015, 88, 280–288. [Google Scholar] [CrossRef]

- Rogóż, R.; Kapusta, Ł.J.; Bachanek, J.; Vankan, J.; Teodorczyk, A. Improved urea-water solution spray model for simulations of selective catalytic reduction systems. Renew. Sustain. Energy Rev. 2020, 120, 109616. [Google Scholar] [CrossRef]

- Abramzon, B.; Sirignano, W.A. Droplet vaporization model for spray combustion calculations. Int. J. Heat Mass Transf. 1989, 32, 1605–1618. [Google Scholar] [CrossRef]

- Miller, R.S.; Harstad, K.; Bellan, J. Evaluation of equilibrium and non-equilibrium evaporation models for many-droplet gas-liquid flow simulations. Int. J. Multiph. Flow 1998, 24, 1025–1055. [Google Scholar] [CrossRef]

- Sazhin, S.S. Advanced models of fuel droplet heating and evaporation. Prog. Energy Combust. Sci. 2006, 32, 162–214. [Google Scholar] [CrossRef]

- Ranz, W.E.; Marshall, W.R. Evaporation from drops, part I. Chem. Eng. Prog. 1952, 48, 141–146. [Google Scholar]

- Ranz, W.E.; Marshall, W.R. Evaporation from drops, part II. Chem. Eng. Prog. 1952, 48, 173–180. [Google Scholar]

- Bracho, G.; Postrioti, L.; Moreno, A.; Brizi, G. Experimental study of the droplet characteristics of a SCR injector spray through optical techniques. Int. J. Multiph. Flow 2021, 135, 103531. [Google Scholar] [CrossRef]

- Bai, C.X.; Liu, K.; Zhao, T.; Liu, J.J. Study on Spray Characteristics and Breakup Mechanism of an SCR Injector. Appl. Sci. 2022, 12, 9387. [Google Scholar] [CrossRef]

- Spiteri, A.; Dimopoulos Eggenschwiler, P. Experimental Fluid Dynamic Investigation of Urea–Water Sprays for Diesel Selective Catalytic Reduction–DeNOx Applications. Ind. Eng. Chem. Res. 2014, 53, 3047–3055. [Google Scholar] [CrossRef]

- Mascarenhas, N.; Mudawar, I. Analytical and computational methodology for modeling spray quenching of solid alloy cylinders. Int. J. Heat Mass Transf. 2010, 53, 5871–5883. [Google Scholar] [CrossRef]

| Case | Min Cell Length [mm] | Max Cell Length [mm] | Total Cells |

|---|---|---|---|

| 1 | 1.5 | 3 | 155,731 |

| 2 | 1 | 2 | 308,344 |

| 3 | 0.5 | 1 | 986,487 |

| 4 | 0.4 | 0.8 | 1,449,546 |

| Parameters | Value |

|---|---|

| Number of spray plumes | 3 (evenly distributed) |

| Hole center diameter | 1.9 mm |

| Inclination angle | 9° |

| Cone angle of a jet | 11° |

| Mass flow rate | 1.2 g/s |

| Initial velocity | 32 m/s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, C.; Liu, K.; Zhao, T.; Liu, J. Numerical Investigation of the Heat Transfer Characteristics and Wall Film Formation of Spray Impingement in SCR Systems. Appl. Sci. 2023, 13, 5353. https://doi.org/10.3390/app13095353

Bai C, Liu K, Zhao T, Liu J. Numerical Investigation of the Heat Transfer Characteristics and Wall Film Formation of Spray Impingement in SCR Systems. Applied Sciences. 2023; 13(9):5353. https://doi.org/10.3390/app13095353

Chicago/Turabian StyleBai, Chuanxin, Kai Liu, Tong Zhao, and Jinjin Liu. 2023. "Numerical Investigation of the Heat Transfer Characteristics and Wall Film Formation of Spray Impingement in SCR Systems" Applied Sciences 13, no. 9: 5353. https://doi.org/10.3390/app13095353