Full Antiferroelectric Performance and GMR Effect in Multiferroic La0.75Ba0.25Fe12O19 Ceramic

Abstract

:1. Introduction

2. Material and Methods

3. Results and Discussion

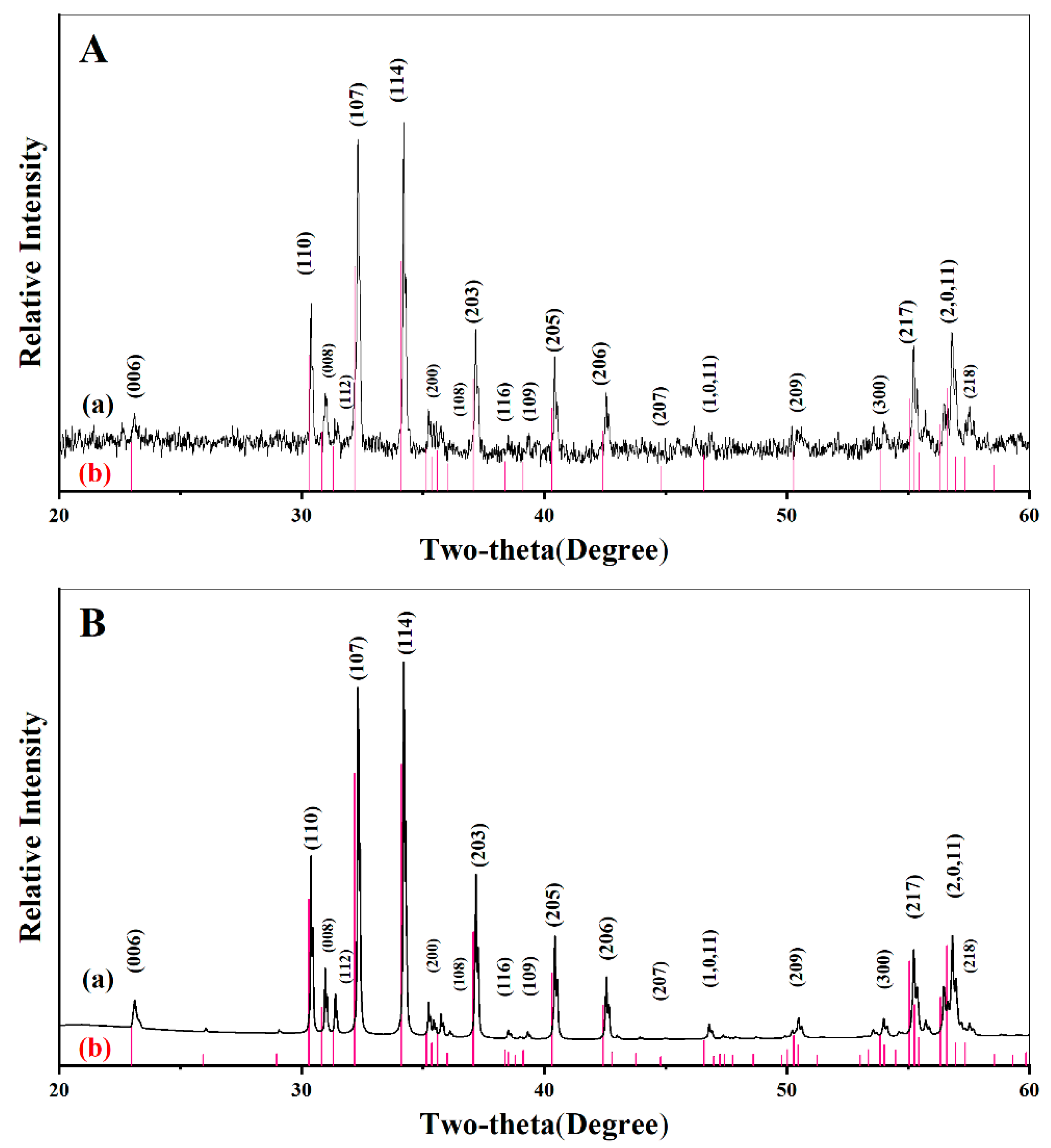

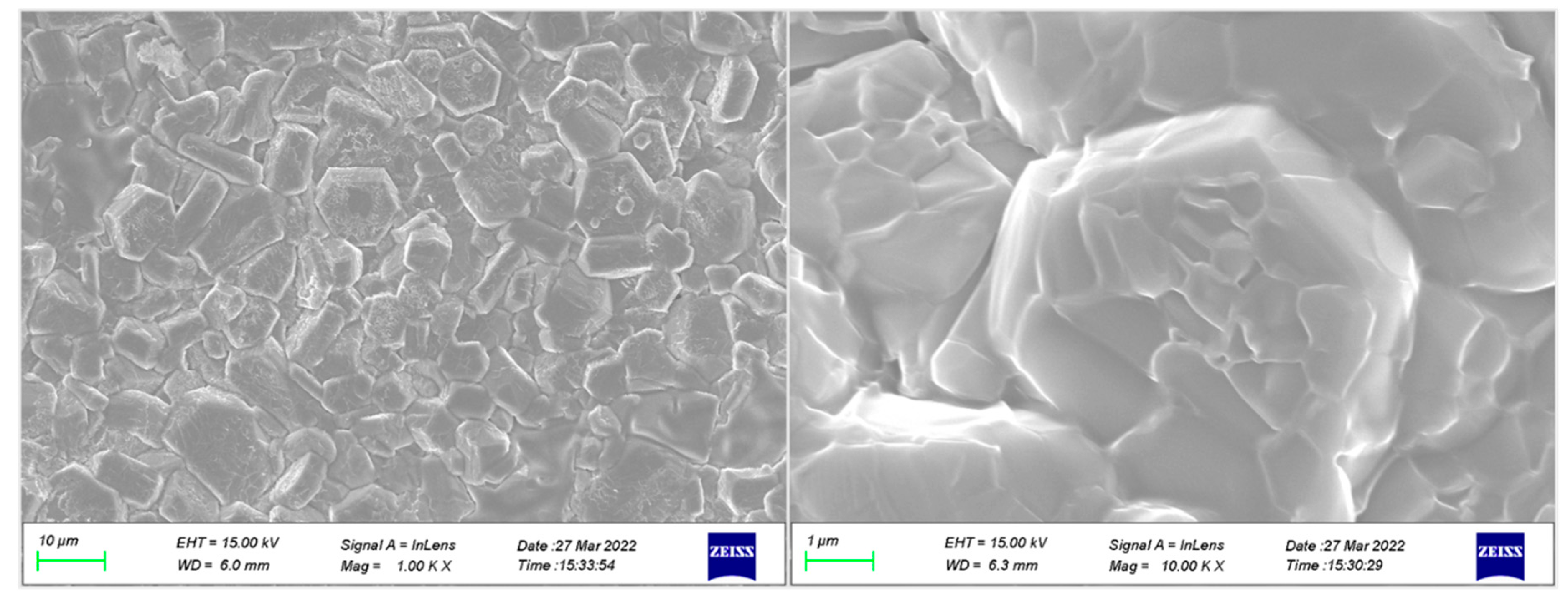

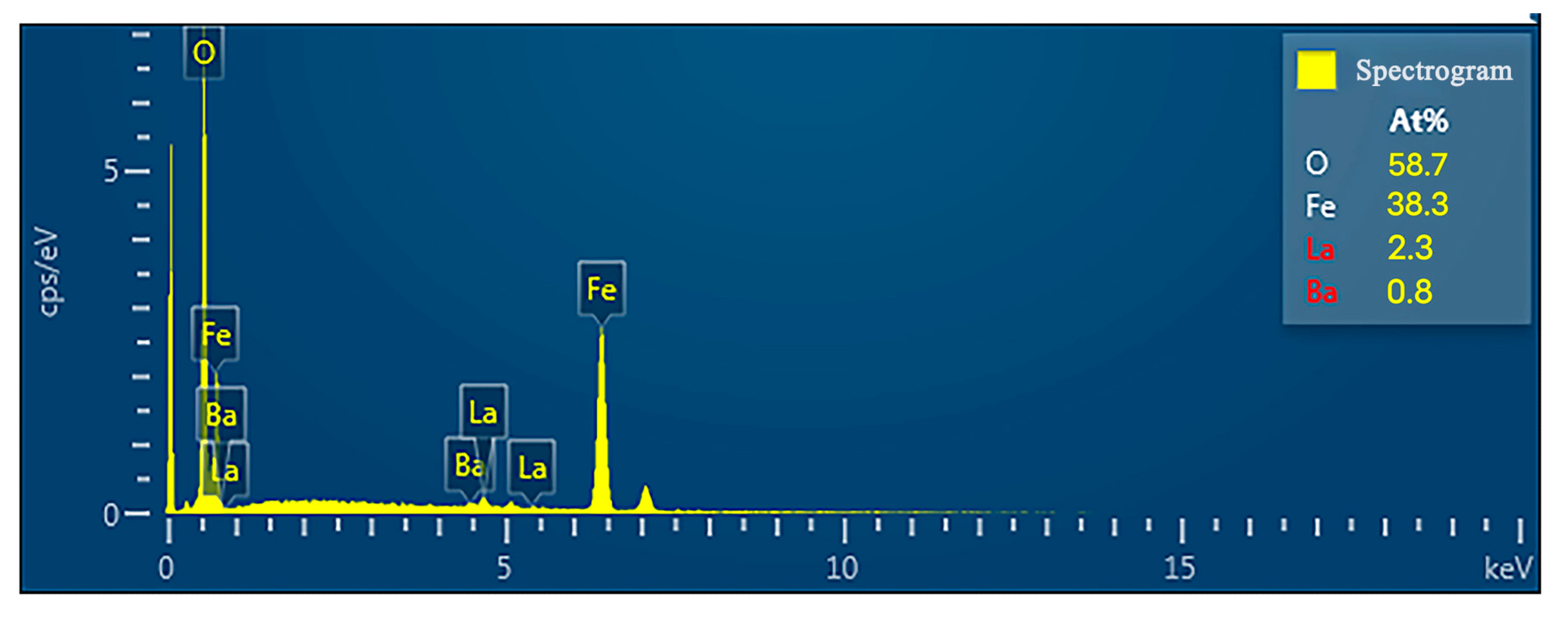

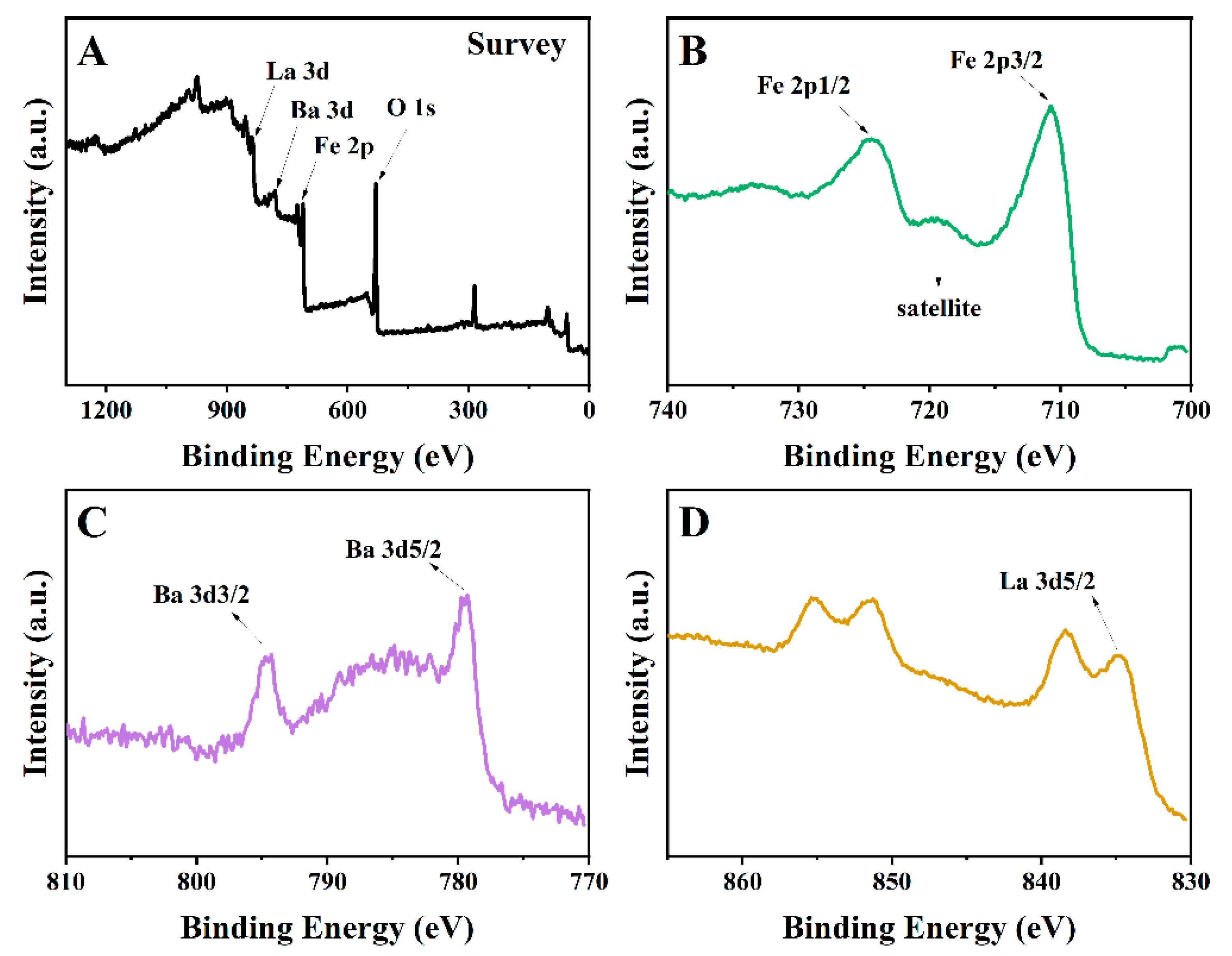

3.1. Structure Identification

3.2. Antiferroelectricity of La0.75Ba0.25Fe12O19 Ceramics

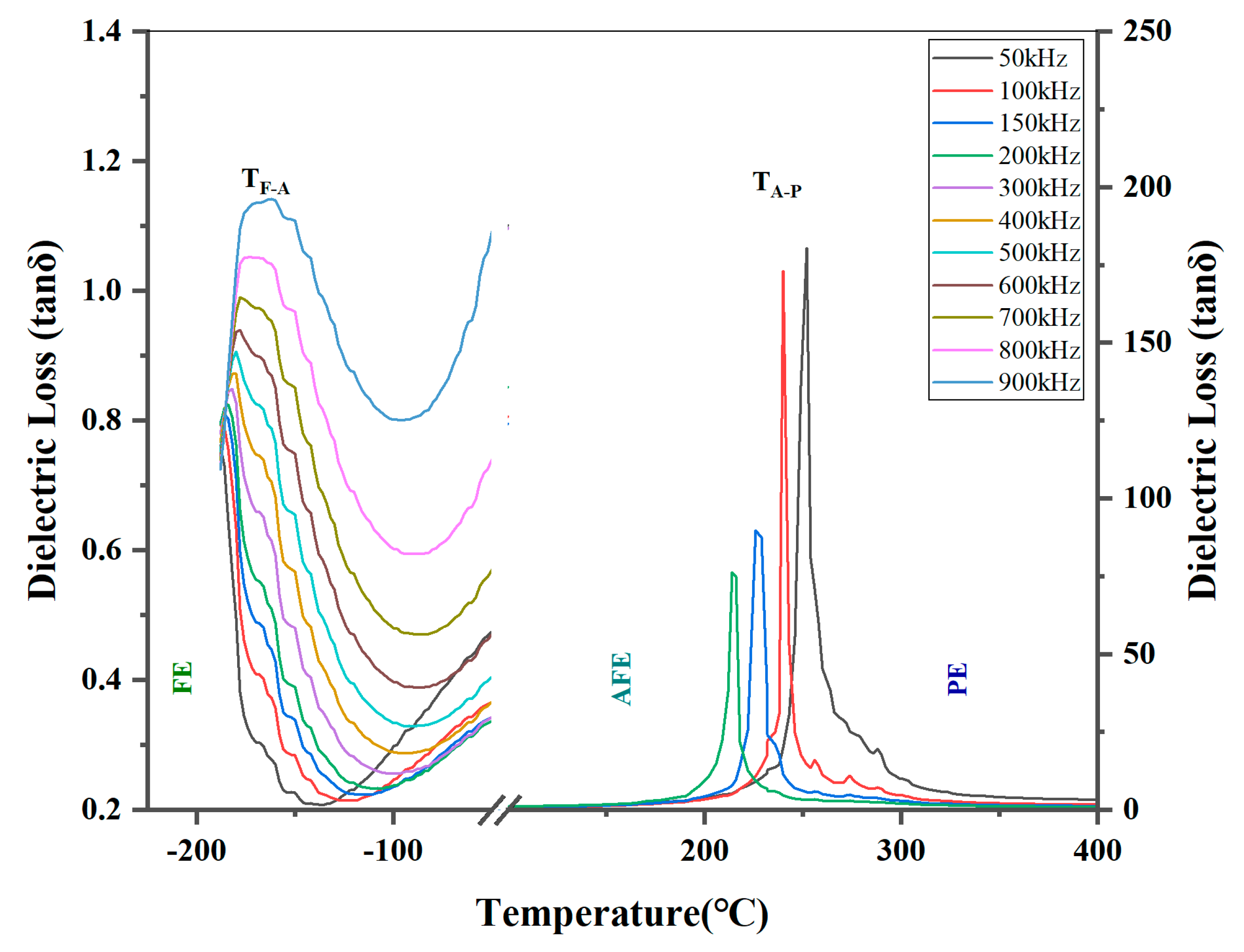

3.3. Dielectric Relaxation Behavior of La0.75Ba0.25Fe12O19 Ceramics

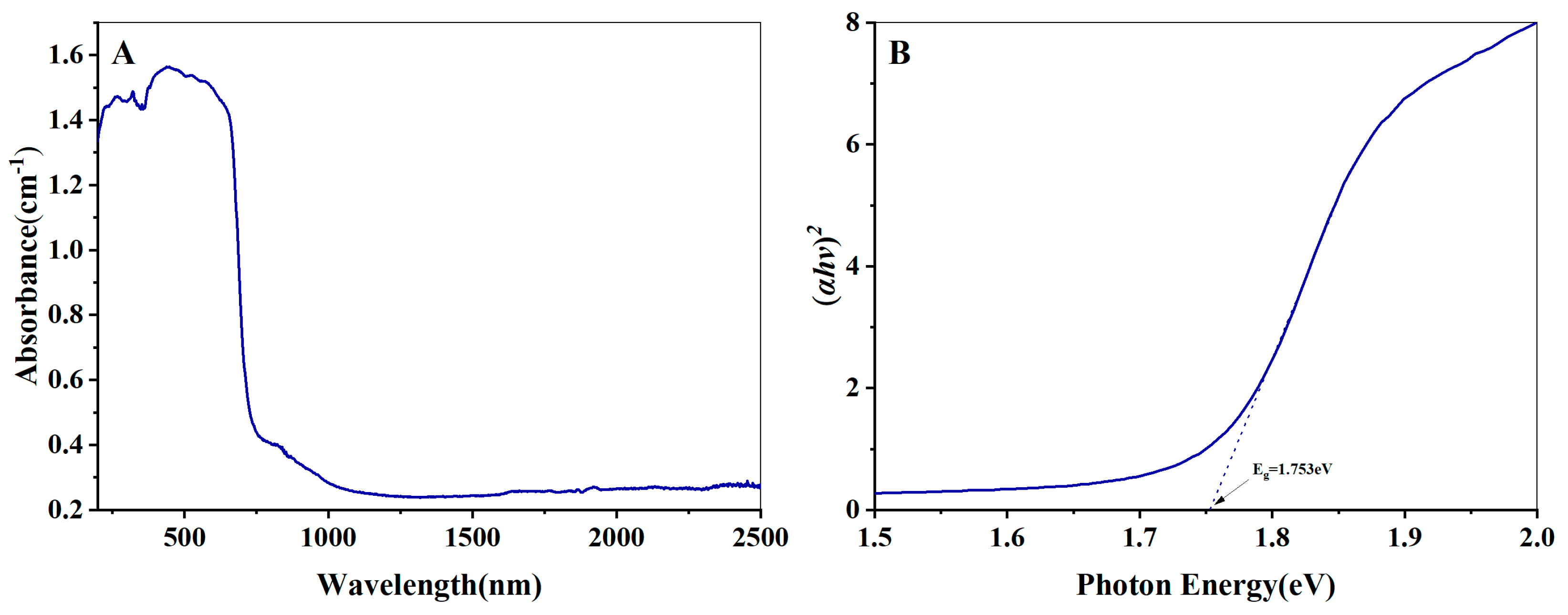

3.4. Magnetic Semiconducting Performance of La0.75Ba0.25Fe12O19 Ceramics

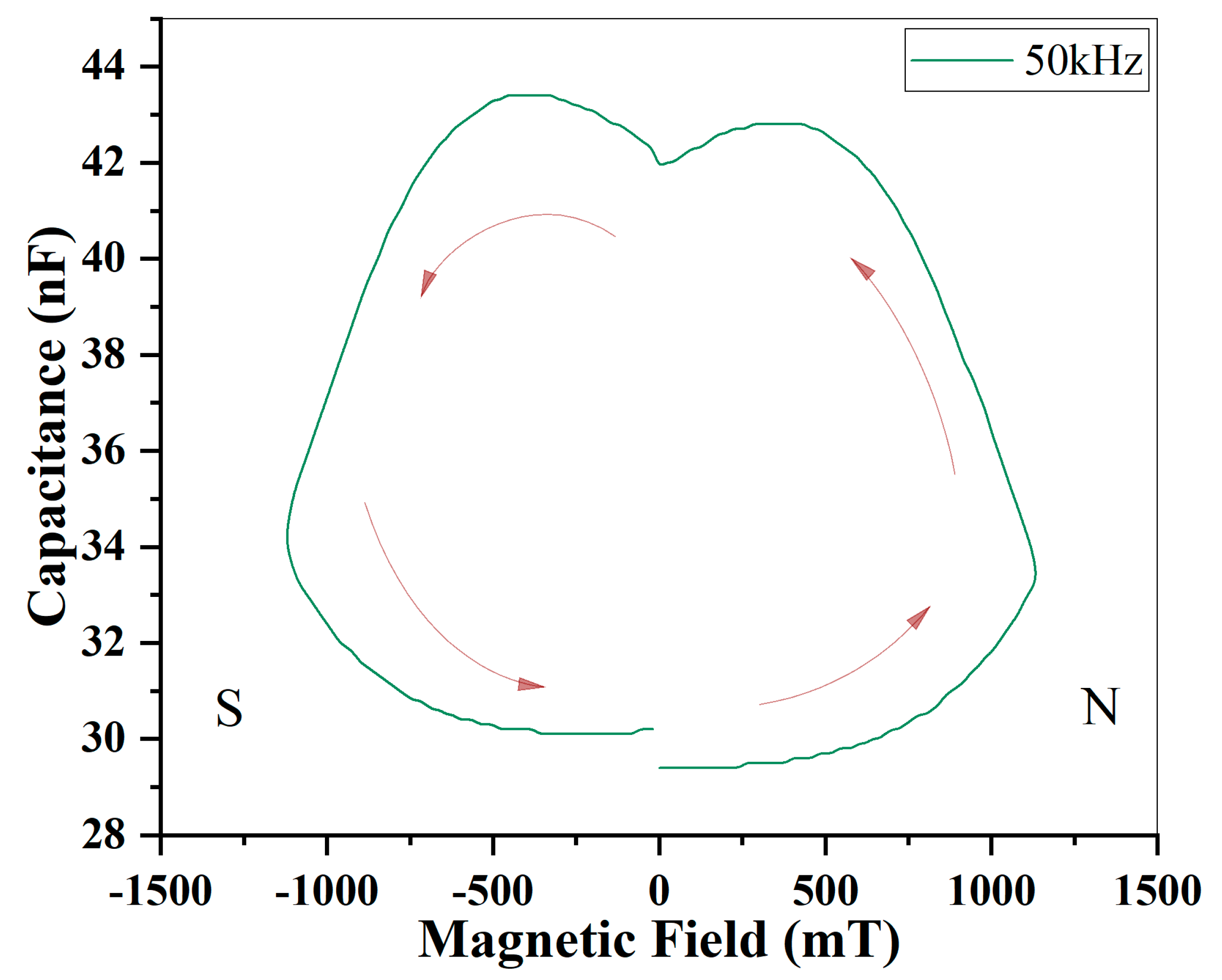

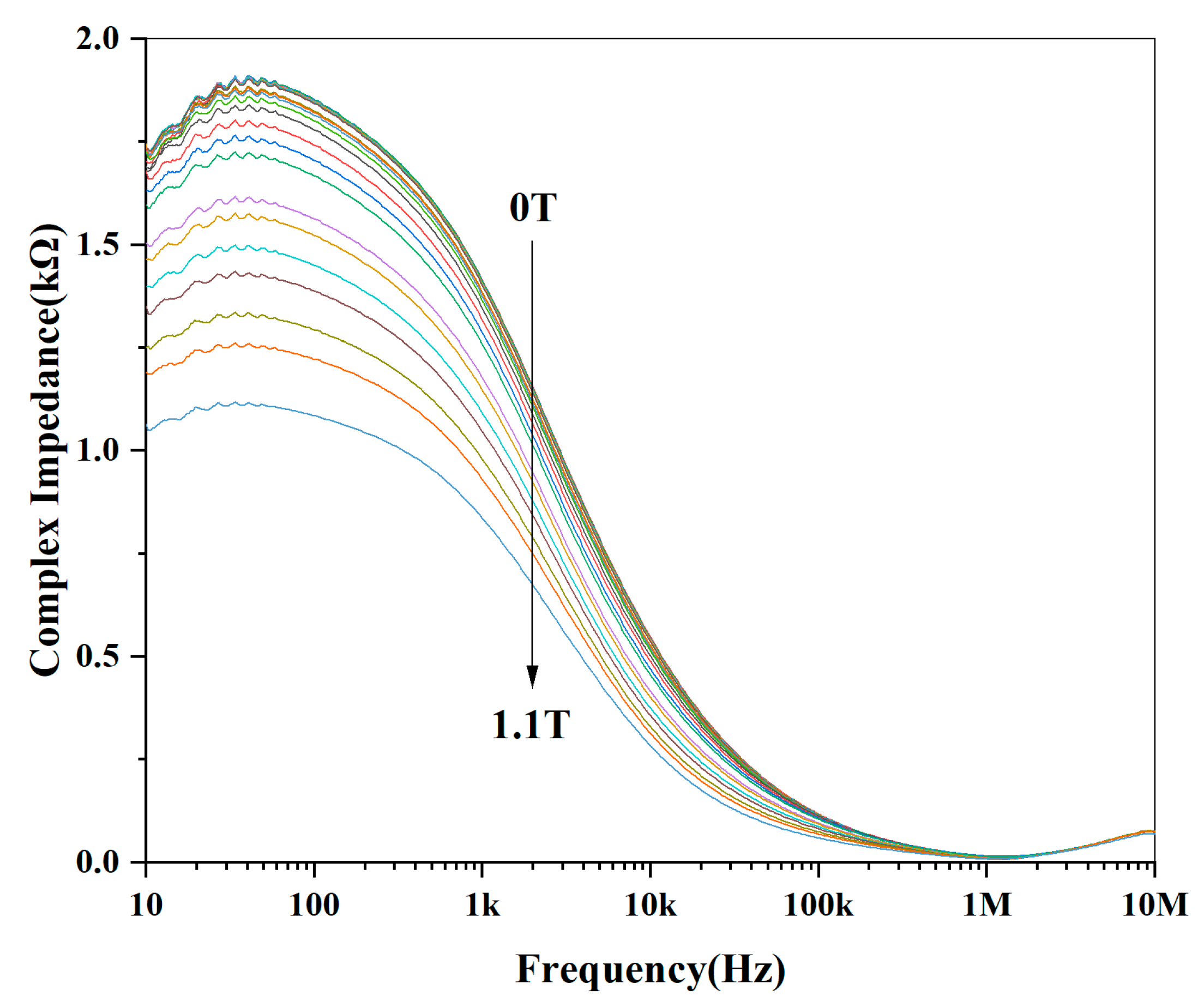

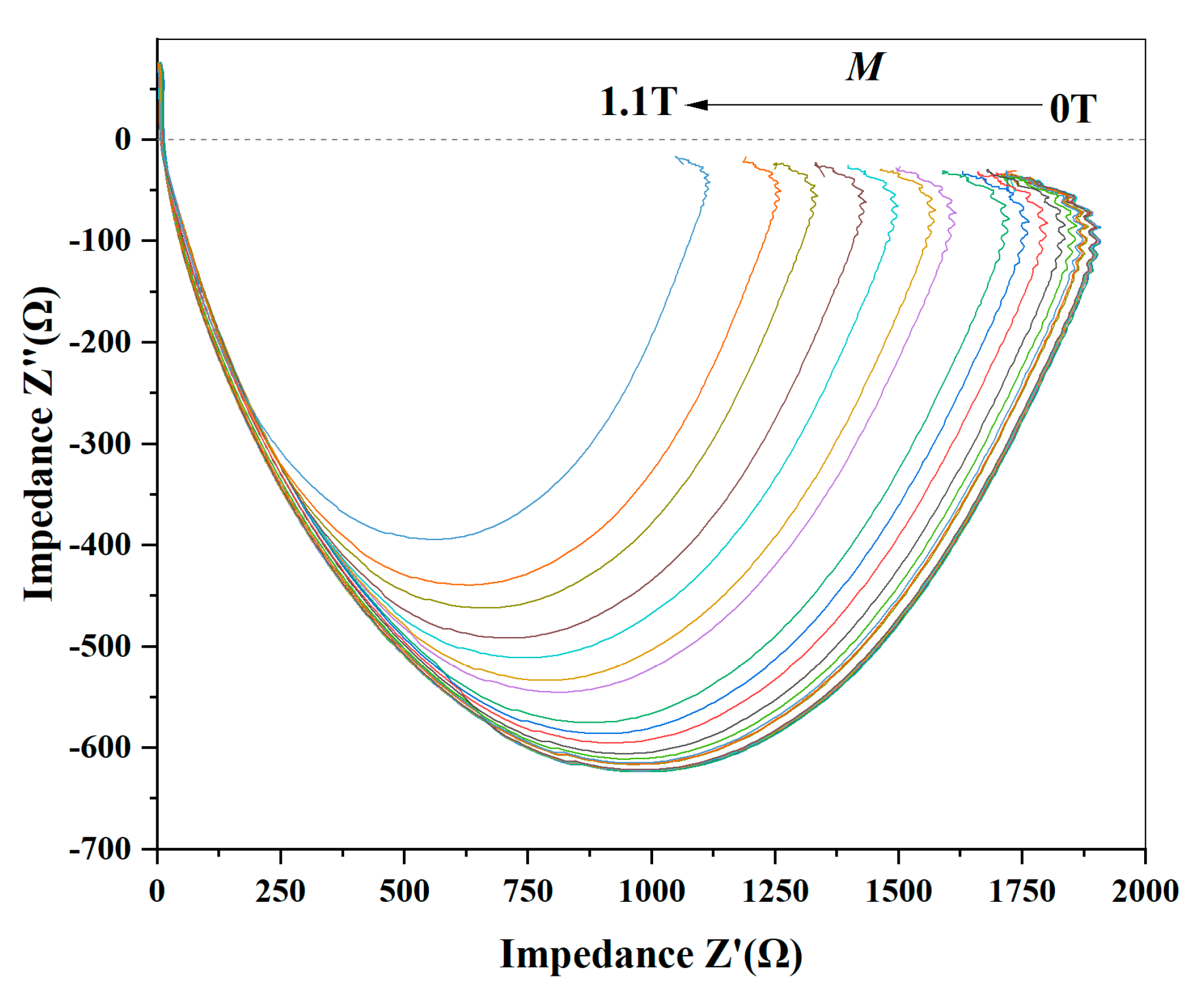

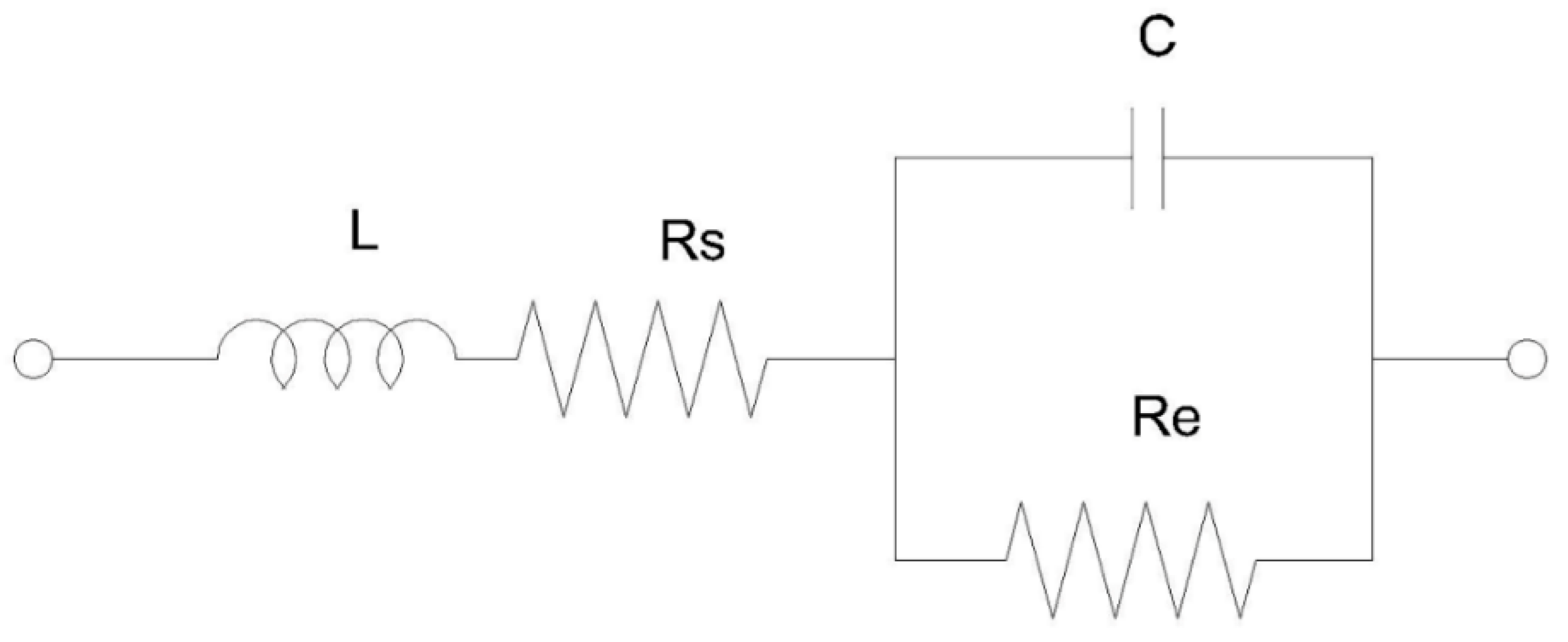

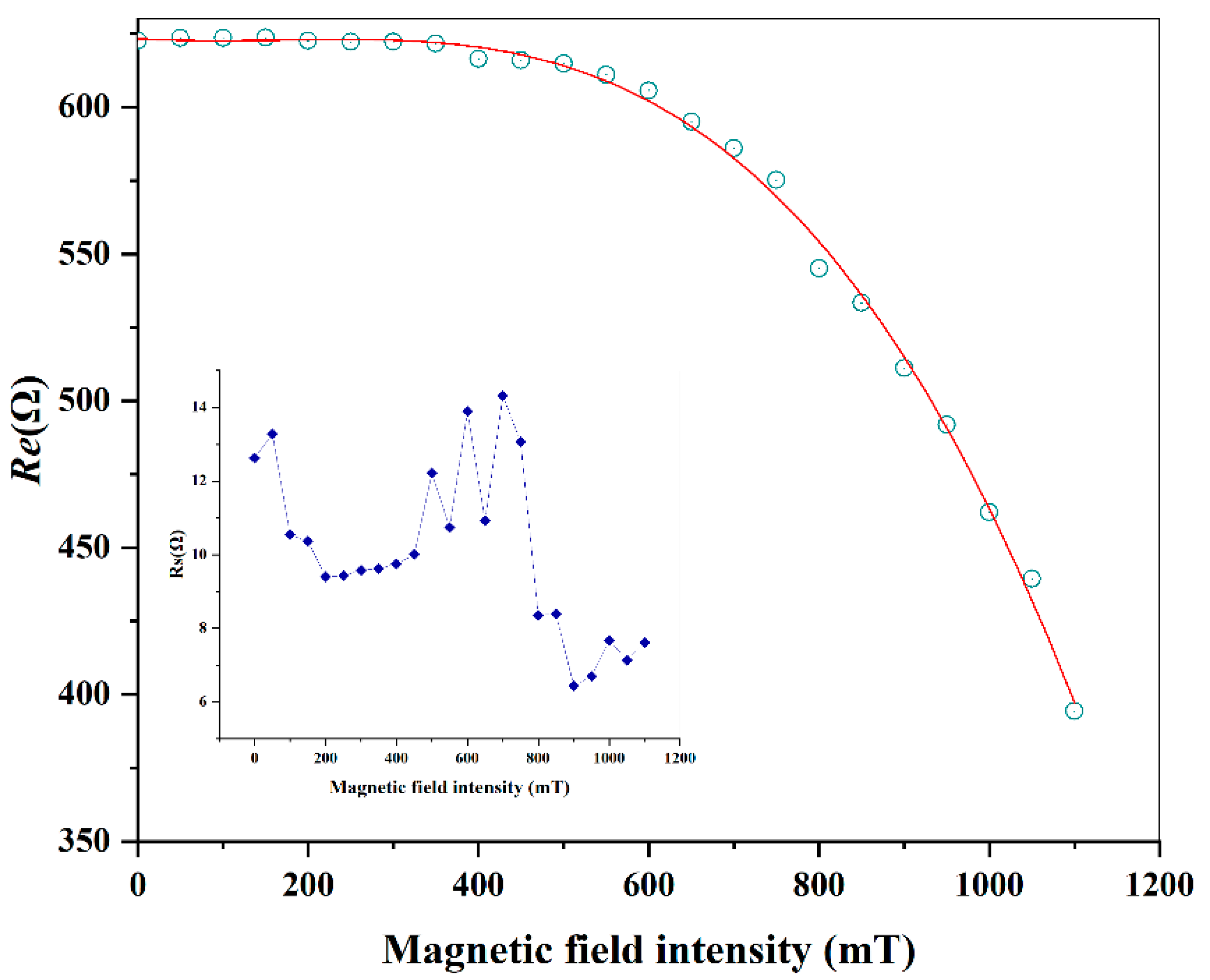

3.5. Magnetoelectric Coupling and GMR Effect of La0.75Ba0.25Fe12O19 Ceramics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chappert, C.; Fert, A.; Van Dau, F.N. The emergence of spin electronics in data storage. Nat. Mater. 2007, 6, 813–823. [Google Scholar] [CrossRef] [PubMed]

- Heron, J.T.; Trassin, M.; Ashraf, K.; Gajek, M.; He, Q.; Yang, S.Y.; Nikonov, D.E.; Chu, Y.H.; Salahuddin, S.; Ramesh, R. Electric-Field-Induced Magnetization Reversal in a Ferromagnet-Multiferroic Heterostructure. Phys. Rev. Lett. 2011, 107, 217202. [Google Scholar] [CrossRef] [PubMed]

- Rakheja, S.; Flatté, M.E.; Kent, A.D. Voltage-Controlled Topological Spin Switch for Ultralow-Energy Computing: Performance Modeling and Benchmarking. Phys. Rev. Appl. 2019, 11, 054009. [Google Scholar] [CrossRef]

- Heron, J.T.; Chiang, T. Magnetoelectrics and multiferroics: Materials and opportunities for energy-efficient spin-based memory and logic. MRS Bull. 2021, 46, 938–945. [Google Scholar] [CrossRef]

- Schmid, H. Multi-ferroic magnetoelectrics. Ferroelectrics 1994, 162, 317. [Google Scholar] [CrossRef]

- Moskvin, A.S. Microscopic Mechanisms of Magnetoelectric Coupling in 3d Oxides. Solid State Phenom. 2011, 168–169, 445–452. [Google Scholar]

- Chang, C.M.; Mani, B.K.; Lisenkov, S.; Ponomareva, I. Thermally Mediated Mechanism to Enhance Magnetoelectric Coupling in Multiferroics. Phys. Rev. Lett. 2015, 114, 177205. [Google Scholar] [CrossRef]

- Hu, J.M.; Duan, C.G.; Nan, C.W.; Chen, L.Q. Understanding and designing magnetoelectric heterostructures guided by computation: Progresses, remaining questions, and perspectives. NPJ Comput. Mater. 2017, 3, 18. [Google Scholar] [CrossRef]

- Yu, B.; Hu, Z.Q.; Cheng, Y.X.; Peng, B.; Zhou, Z.Y.; Liu, M. Recent progress of multiferroic magnetoelectric devices. Acta Phys. Sin. 2018, 67, 157507. [Google Scholar]

- Li, J.; Zhao, D.P.; Bai, H.; Yuan, Z.; Zhou, Z.X. Low magnetic-field induced high temperature dynamic magnetoelectric coupling performances in Z-type Sr3Co2Fe24O41. J. Phys. Condens. Matter 2021, 34, 105803. [Google Scholar] [CrossRef]

- De Sousa, R.; Moore, J.E. Multiferroic Materials for Spin-Based Logic Devices. J. Nanoelectron. Optoelectron. 2008, 3, 77–81. [Google Scholar] [CrossRef]

- De Sousa, R.; Allen, M.; Cazayous, M. Theory of Spin-Orbit Enhanced Electric-Field Control of Magnetism in Multiferroic BiFeO3. Phys. Rev. Lett. 2013, 110, 267202. [Google Scholar] [CrossRef] [PubMed]

- Gopman, D.B.; Chen, P.; Lau, J.W.; Chavez, A.C.; Carman, G.P.; Finkel, P.; Staruch, M.; Shull, R.D. Large Interfacial Magnetostriction in (Co/Ni)4/Pb(Mg1/3Nb2/3)O3–PbTiO3 Multiferroic Heterostructures. ACS Appl. Mater. Interfaces 2018, 10, 24725–24732. [Google Scholar] [CrossRef]

- Li, X.; Casamento, J.; Dang, P.; Zhang, Z.; Afuye, O.; Mei, A.B.; Apsel, A.B.; Schlom, D.G.; Jena, D.; Ralph, D.C.; et al. Spin–orbit torque field-effect transistor (SOTFET): Proposal for a magnetoelectric memory. Appl. Phys. Lett. 2020, 116, 242405. [Google Scholar] [CrossRef]

- Vopson, M.M. Fundamentals of Multiferroic Materials and Their Possible Applications. Crit. Rev. Solid State Mater. Sci. 2015, 40, 223–250. [Google Scholar] [CrossRef]

- Mudinepalli, V.R.; Feng, L.; Lin, W.-C.; Murty, B.S. Effect of grain size on dielectric and ferroelectric properties of nanostructured Ba0.8Sr0.2TiO3 ceramics. J. Adv. Ceram. 2015, 4, 46–53. [Google Scholar] [CrossRef]

- Clabel, H.J.L.; Ferri, F.A.; Zabotto, F.L.; Rivera, V.A.G.; Nogueira, I.C.; Garcia, D.; de Lima, O.F.; Leite, E.R.; Pereira-da-Silva, M.A.; Cardoso, C.A. Grain size and interfacial interdiffusion influence on the magnetic and dielectric properties of magnetoelectric La0.7Ba0.3MnO3–BaTiO3 composites. J. Magn. Magn. Mater. 2016, 407, 160–166. [Google Scholar] [CrossRef]

- Zhang, Q.W.; Zhai, J.W.; Shen, B.; Zhang, H.J.; Yao, X. Grain size effects on dielectric properties of barium strontium titanate composite ceramics. Mater. Res. Bull. 2013, 48, 973–977. [Google Scholar] [CrossRef]

- Han, T.-C.; Hsu, W.-L.; Lee, W.-D. Grain size-dependent magnetic and electric properties in nanosized YMnO3 multiferroic ceramics. Nanoscale Res. Lett. 2011, 6, 201. [Google Scholar] [CrossRef]

- Clabel, H.J.L.; Zabotto, F.L.; Nogueira, I.C.; Schio, P.; Garcia, D.; de Lima, O.F.; Leite, E.R.; Moreira, F.M.A.; Cardoso, C.A. Magnetoelectric properties of laminated La0.7Ba0.3MnO3–BaTiO3 ceramic composites. J. Magn. Magn. Mater. 2014, 364, 18–23. [Google Scholar] [CrossRef]

- Huamán, J.L.C.; Rivera, V.A.G.; Pinto, A.H.; Marega, E. 11—Multiferroic perovskite ceramics: Properties and applications. In Perovskite Ceramics; Huamán, J.L.C., Rivera, V.A.G., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 339–381. [Google Scholar]

- Teague, J.R.; Gerson, R.; James, W.J. Dielectric hysteresis in single crystal BiFeO3. Solid State Commun. 1970, 8, 1073. [Google Scholar] [CrossRef]

- Kimura, T.; Goto, T.; Shintani, H.; Ishizaka, K.; Arima, T.; Tokura, Y. Magnetic control of ferroelectric polarization. Nature 2003, 426, 55–58. [Google Scholar] [CrossRef] [PubMed]

- Tokunaga, Y.; Kaneko, Y.; Okuyama, D.; Ishiwata, S.; Arima, T.; Wakimoto, S.; Kakurai, K.; Taguchi, Y.; Tokura, Y. Multiferroic M-type hexaferrites with a room-temperature conical state and magnetically controllable spin helicity. Phys. Rev. Lett. 2010, 105, 257201. [Google Scholar] [CrossRef] [PubMed]

- Tan, G.L.; Wang, M. Multiferroic PbFe12O19 ceramics. J. Electroceramics 2011, 26, 170. [Google Scholar] [CrossRef]

- Wang, L.; Wang, D.; Cao, Q.; Zheng, Y.; Xuan, H.; Gao, J.; Du, Y. Electric control of magnetism at room temperature. Sci. Rep. 2012, 2, 223. [Google Scholar] [CrossRef]

- Zhou, W.P.; Wang, L.Y.; Song, Y.Q.; Fang, Y.; Wang, D.H.; Cao, Q.Q.; Du, Y.W. Magnetoelectric effect in PbCoTiFe10O19 multiferroic ceramic. Ceram. Int. 2014, 40 Pt A, 15737–15742. [Google Scholar] [CrossRef]

- Li, X.; Tan, G.L. Multiferroic and magnetoelectronic polarizations in BaFe12O19 system. J. Alloys Compd. 2021, 858, 157722. [Google Scholar] [CrossRef]

- Sharma, V.; Kumari, S.; Kuanr, B.K. Rare earth doped M-type hexaferrites; ferromagnetic resonance and magnetization dynamics. AIP Adv. 2018, 8, 056232. [Google Scholar] [CrossRef]

- Yousaf, M.; Nazir, S.; Hayat, Q.; Akhtar, M.N.; Akbar, M.; Lu, Y.; Noor, A.; Zhang, J.M.; Shah, M.A.K.Y.; Wang, B. Magneto-optical properties and physical characteristics of M-type hexagonal ferrite (Ba1-xCaxFe11.4Al0.6O19) nanoparticles (NPs). Ceram. Int. 2021, 47, 11668–11676. [Google Scholar] [CrossRef]

- Guerra, J.D.S.; Betal, S.; Pal, M.; Garcia, J.E.; Oliveira, A.J.A.; M’Peko, J.C.; Hernandes, A.C.; Guo, R.Y.; Bhalla, A.S. Magnetoelectric Response in (1-x)PbZr0.65Ti0.35O3-xBaFe12O19 Multiferroic Ceramic Composites. J. Am. Ceram. Soc. 2015, 98, 1542–1547. [Google Scholar] [CrossRef]

- Vinnik, D.A.; Podgornov, F.V.; Zabeivorota, N.S.; Trofimov, E.A.; Zhivulin, V.E.; Chernukha, A.S.; Gavrilyak, M.V.; Gudkova, S.A.; Zherebtsov, D.A.; Ryabov, A.V.; et al. Effect of treatment conditions on structure and magnetodielectric properties of barium hexaferrites. J. Magn. Magn. Mater. 2020, 498, 166190. [Google Scholar] [CrossRef]

- Vinnik, D.A.; Zhivulin, V.E.; Starikov, A.Y.; Gudkova, S.A.; Trofimov, E.A.; Trukhanov, A.V.; Trukhanov, S.V.; Turchenko, V.A.; Matveev, V.V.; Lahderanta, E.; et al. Influence of titanium substitution on structure, magnetic and electric properties of barium hexaferrites BaFe12−xTixO19. J. Magn. Magn. Mater. 2020, 498, 166117. [Google Scholar] [CrossRef]

- Chun, S.H.; Chai, Y.S.; Oh, Y.S.; Jaiswal Nagar, D.; Haam, S.Y.; Kim, I.; Lee, B.; Nam, D.H.; Ko, K.T.; Park, J.H.; et al. Realization of Giant Magnetoelectricity in Helimagnets. Phys. Rev. Lett. 2010, 104, 037204. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Zou, T.; Yan, L.Q.; Liu, Y.; Sun, Y. Low magnetic field reversal of electric polarization in a Y-type hexaferrite. Appl. Phys. Lett. 2012, 100, 122901. [Google Scholar] [CrossRef]

- Samara, G.A. Pressure and temperature dependence of the dielectric properties and phase transition of the antiferroelectric perovskites: PbZrO3 and PbHfO3. Phys. Rev. B 1970, 1, 3777–3786. [Google Scholar] [CrossRef]

- Zhelnova, O.A.; Fesenko, O.E. Phase transitions and twinning in NaNbO3 crystals. Ferroelectrics 1987, 75, 469–475. [Google Scholar] [CrossRef]

- Hao, X.H.; Zhai, J.W.; Kong, L.B.; Xu, Z.K. A comprehensive review on the progress of lead zirconate-based antiferroelectric materials. Prog. Mater. Sci. 2014, 63, 1–57. [Google Scholar] [CrossRef]

- Pan, M.J.; Markowski, K.A.; Park, S.E.; Yoshikawa, S.; Cross, L.E. Antiferroelectric-to-ferroelectric phase switching PLSnZT ceramics. I. Structure, compositional modification and electrical properties. In Proceedings of the Tenth IEEE International Symposium on Applications of Ferroelectrics, East Brunswick, NJ, USA, 18–21 August 1996; Volume 1, pp. 267–270. [Google Scholar]

- Bharadwaja, S.S.N.; Laha, A.; Halder, S.; Krupanidhi, S.B. Reversible and irreversible switching processes in pure and lanthanum modified lead zirconate thin films. Mater. Sci. Eng. B 2002, 94, 218–222. [Google Scholar] [CrossRef]

- Bharadwaja, S.S.N.; Saha, S.; Bhattacharyya, S.; Krupanidhi, S.B. Dielectric properties of La-modified antiferroelectric PbZrO3 thin films. Mater. Sci. Eng. B 2002, 88, 22–25. [Google Scholar] [CrossRef]

- Bharadwaja, S.S.N.; Krupanidhi, S.B. Study of La-modified antiferroelectric PbZrO3 thin films. Thin Solid Film. 2003, 423, 88–96. [Google Scholar] [CrossRef]

- Yamashita, T.; Hayes, P. Analysis of XPS spectra of Fe2+ and Fe3+ ions in oxide materials. Appl. Surf. Sci. 2008, 254, 2441–2449. [Google Scholar] [CrossRef]

- Bagus, P.S.; Nelin, C.J.; Brundle, C.R.; Crist, B.V.; Lahiri, N.; Rosso, K.M. Combined multiplet theory and experiment for the Fe 2p and 3p XPS of FeO and Fe2O3. J. Chem. Phys. 2021, 154, 094709. [Google Scholar] [CrossRef]

- Van Doveren, H.; Verhoeven, J.A.T.H. XPS spectra of Ca, Sr, Ba and their oxides. J. Electron Spectrosc. Relat. Phenom. 1980, 21, 265–273. [Google Scholar] [CrossRef]

- Ivanova, O.P.; Naumkin, A.V.; Vasilyev, L.A. An XPS study of compositional changes induced by argon ion bombardment of the LaPO4 surface. Vacuum 1996, 47, 67–71. [Google Scholar] [CrossRef]

- Dai, X.; Viehland, D. Effects of lanthanum modification on the antiferroelectric-ferroelectric stability of high zirconium-content lead zirconate titanate. J. Appl. Phys. 1994, 76, 3701–3709. [Google Scholar] [CrossRef]

- Xu, Z.; Dai, X.; Viehland, D. Impurity-induced incommensuration in antiferroelectric La-modified lead zirconate titanate. Phys. Rev. B 1995, 51, 6261–6271. [Google Scholar] [CrossRef]

- Viehland, D.; Dai, X.H.; Li, J.F.; Xu, Z. Effects of quenched disorder on La-modified lead zirconate titanate: Long- and short-range ordered structurally incommensurate phases, and glassy polar clusters. J. Appl. Phys. 1998, 84, 458–471. [Google Scholar] [CrossRef]

- Hirohata, A.; Takanashi, K. Future perspectives for spintronic devices. J. Phys. D: Appl. Phys. 2014, 47, 193001. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Z.; Tan, G.-L. Full Antiferroelectric Performance and GMR Effect in Multiferroic La0.75Ba0.25Fe12O19 Ceramic. Appl. Sci. 2023, 13, 5718. https://doi.org/10.3390/app13095718

Xu Z, Tan G-L. Full Antiferroelectric Performance and GMR Effect in Multiferroic La0.75Ba0.25Fe12O19 Ceramic. Applied Sciences. 2023; 13(9):5718. https://doi.org/10.3390/app13095718

Chicago/Turabian StyleXu, Zhen, and Guo-Long Tan. 2023. "Full Antiferroelectric Performance and GMR Effect in Multiferroic La0.75Ba0.25Fe12O19 Ceramic" Applied Sciences 13, no. 9: 5718. https://doi.org/10.3390/app13095718