A Comparison of the Fuel Consumption and Truck Models in Different Production Scenarios

Abstract

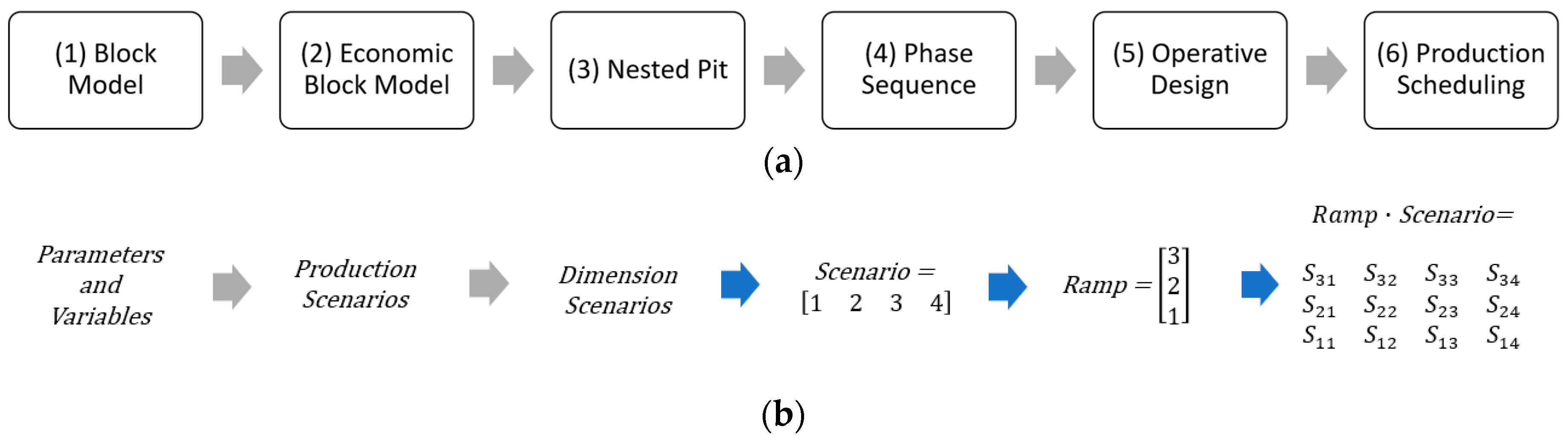

:1. Introduction

Case Study

2. Materials and Methods

2.1. Block Model

2.2. Economic Block Model

2.3. Nested Pits Definition

2.4. Phase Sequence

2.5. Operative Design

2.6. Production Scheduling

2.6.1. Equipment Selection

2.6.2. Haulage Profile

Cycles Times

Fuel Consumption

Performance

2.6.3. CO2 Emissions

3. Results and Discussion

3.1. Net Present Value

3.2. Ultimate Pit

3.3. Pit Design

3.4. Hauling

3.5. Production

3.6. Fuel Consumption

3.7. Environmental Impact Related to the Operation Process

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Newman, A.M.; Rubio, E.; Caro, R.; Weintraub, A.; Eurek, K. A Review of Operations Research in Mine Planning. Interfaces 2010, 40, 222–245. [Google Scholar] [CrossRef]

- Nicolet, J.P. Methods of Exploitation of Different Types of Uranium Deposits; Nuclear Fuel Cycle and Materials Section; International Atomic Energy Agency: Vienna, Austria, 2000. [Google Scholar]

- Askari-Nasab, H.; Frimpong, S.; Szymanski, J. Modelling Open Pit Dynamics Using Discrete Simulation. Int. J. Min. Reclam. Environ. 2007, 21, 35–49. [Google Scholar] [CrossRef]

- Hustrulid, W.; Kuchta, M.; Martin, R. Open Pit Mine Planning and Design; CRC Press/Balkema: London, UK, 2013; Volume 1, ISBN 978-1-4665-7512-7. [Google Scholar]

- Sanmiquel, L.; Bascompta, M.; Rossell, J.; Anticoi, H.; Guash, E. Analysis of Occupational Accidents in Underground and Surface Mining in Spain Using Data-Mining Techniques. Int. J. Environ. Res. Public Health 2018, 15, 462. [Google Scholar] [CrossRef] [PubMed]

- Tsopa, V.; Cheberiachko, S.; Yavorska, O.; Deryugin, O.; Bas, I. Increasing the Safety of the Transport Process by Minimizing the Professional Risk of a Dump Truck Driver. Min. Miner. Depos. 2022, 16, 101–108. [Google Scholar] [CrossRef]

- Osanloo, M.; Gholamnejad, J.; Karimi, B. Long-Term Open Pit Mine Production Planning: A Review of Models and Algorithms. Int. J. Min. Reclam. Environ. 2008, 22, 3–35. [Google Scholar] [CrossRef]

- Jara, R.M.; Couble, A.; Emery, X.; Magri, E.J.; Ortiz, J.M. Block Size Selection and Its Impact on Open-Pit Design and Mine Planning. J. South Afr. Inst. Min. Metall. 2006, 106, 205–212. [Google Scholar]

- Meneses, D.; Sepúlveda, F.D. Modeling Productivity Reduction and Fuel Consumption in Open-Pit Mining Trucks by Considering the Temporary Deterioration of Mining Roads through Discrete-Event Simulation. Mining 2023, 3, 96–105. [Google Scholar] [CrossRef]

- Diddens, Z.M. Integration of Fleet Production and Cost Analysis in Mine Design and Planning. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2019. [Google Scholar]

- Bozorgebrahimi, E. The Evaluation of Haulage Truck Size Effects on Open Pit Mining; The University of British Columbia: Vancouver, BC, Canada, 2004. [Google Scholar]

- Bozorgebrahimi, E.; Hall, R.A.; Blackwell, G.H. Sizing Equipment for Open Pit Mining—A Review of Critical Parameters. Min. Technol. (Trans. Inst. Min. Metall. A) 2003, 112, 171–179. [Google Scholar] [CrossRef]

- Nakousi, C.; Pascual, R.; Anani, A.; Kristjanpoller, F.; Lillo, P. An Asset-Management Oriented Methodology for Mine Haul-Fleet Usage Scheduling. Reliab. Eng. Syst. Saf. 2018, 180, 336–344. [Google Scholar] [CrossRef]

- Golbasi, O.; Kina, E. Haul Truck Fuel Consumption Modeling under Random Operating Conditions: A Case Study. Transp. Res. Part D Transp. Environ. 2022, 102, 103135. [Google Scholar] [CrossRef]

- Soofastaei, A.; Aminossadati, S.M.; Arefi, M.M.; Kizil, M.S. Development of a Multi-Layer Perceptron Artificial Neural Network Model to Determine Haul Trucks Energy Consumption. Int. J. Min. Sci. Technol. 2016, 26, 285–293. [Google Scholar] [CrossRef]

- Ebrahimi, A. Ultimate Pit Size Selection, Where Is the Optimum Point? In Proceedings of the IMCET 2019— 26th International Mining Congress and Exhibition of Turkey, Antalya, Turkey, 16–19 April 2019; pp. 638–645. [Google Scholar]

- Baek, J.; Choi, Y. A New Method for Haul Road Design in Open-Pit Mines to Support Efficient Truck Haulage Operations. Appl. Sci. 2017, 7, 747. [Google Scholar] [CrossRef]

- Peralta, S.; Sasmito, A.P.; Kumral, M. Reliability Effect on Energy Consumption and Greenhouse Gas Emissions of Mining Hauling Fleet towards Sustainable Mining. J. Sustain. Min. 2016, 15, 85–94. [Google Scholar] [CrossRef]

- Kofanov, O.; Vasylkevych, O.; Kofanova, O.; Zozul’ov, O.; Kholkovsky, Y.; Khrutba, V.; Borysov, O.; Bobryshov, O. Mitigation of the Environmental Risks Resulting from Diesel Vehicle Operation at the Mining Industry Enterprises. Min. Miner. Depos. 2020, 14, 110–118. [Google Scholar] [CrossRef]

- Bascetin, A.; Adiguzel, D.; Tuylu, S. The Investigation of CO2 Emissions for Different Rock Units in the Production of Aggregate. Environ. Earth Sci. 2017, 76, 279. [Google Scholar] [CrossRef]

- Bascompta, M.; Sanmiquel, L.; Gangolells, M.; Sidki, N. LCA Analysis and Comparison in Quarrying: Drill and Blast vs Mechanical Extraction. J. Clean. Prod. 2022, 369, 133042. [Google Scholar] [CrossRef]

- Fortescue Metals Group Ltd.; Downer EDII Mining Pty Ltd. Analyses of Diesel Use for Mine Haul and Transport Operations; Department of Resources Energy and Tourism: Canberra, Australia, 2008; pp. 1–18. [Google Scholar]

- Muñoz, J.I.; Guzmán, R.R.; Botín, J.A. Development of a Methodology That Integrates Environmental and Social Attributes in the Ore Resource Evaluation and Mine Planning. IJMME 2014, 5, 38–58. [Google Scholar] [CrossRef]

- Soberón Bravo, E. Governance on Lithium Mining Shareholdings: Expanding Environment, Social and Governance (ESG) Indicators to Economic Regulation and Raw Material Politics. Miner. Econ. 2022, 36, 333–3475. [Google Scholar] [CrossRef]

- Lokuwaduge, C.S.D.S.; Heenetigala, K. Integrating Environmental, Social and Governance (ESG) Disclosure for a Sustainable Development: An Australian Study: ESG Disclosure in Australian De Silva Lokuwaduge and Heenetigala. Bus. Strat. Env. 2017, 26, 438–450. [Google Scholar] [CrossRef]

- Yellow Cake PLC Pure Exposure to the Uranium Commodity Investor Presentation November 2020. Available online: https://www.yellowcakeplc.com (accessed on 10 March 2023).

- Morales, N.; Seguel, S.; Cáceres, A.; Jélvez, E.; Alarcón, M. Incorporation of Geometallurgical Attributes and Geological Uncertainty into Long-Term Open-Pit Mine Planning. Minerals 2019, 9, 108. [Google Scholar] [CrossRef]

- Tolwinski, B.; Newton, M.; Lapworth, A.; Morrison, J. NPV Scheduler: Open Pit Planning: From Geological Model to Optimized Strategic Mine Plan; Datamine Group: Docklands, Australia, 2007. [Google Scholar]

- Heidari, S.M. Quantification of Geological Uncertainty and Mine Planning Risk Using Metric Spaces. Ph.D. Thesis, University of New South Wales, Sydney, Australia, 2015. [Google Scholar]

- Rossi, M.E.; Deutsch, C.V. Mineral Resource Estimation; Springer: Berlin/Heidelberg, Germany, 2014; ISBN 978-85-7811-079-6. [Google Scholar]

- Dagdelen, K. Open Pit Optimisation—Strategies for Improving Economics of Mining Projects through Mine Planning. In Proceedings of the IMCET2001—17* International 17th Mining Congress and Exhibition of Turkey, Istanbul, Turkey, 17–21 September 2001; pp. 145–148. [Google Scholar]

- Whittle, J. The Facts and Fallacies of Open Pit Optimization; Whittle Programming Pty Ltd.: North Balwyn, Australia, 1989. [Google Scholar]

- Ben-Awuah, E.; Richter, O.; Elkington, T.; Pourrahimian, Y. Strategic Mining Options Optimization: Open Pit Mining, Underground Mining or Both. Int. J. Min. Sci. Technol. 2016, 26, 1065–1071. [Google Scholar] [CrossRef]

- Jélvez, E.; Morales, N.; Askari-Nasab, H. A New Model for Automated Pushback Selection. Comput. Oper. Res. 2020, 115, 104456. [Google Scholar] [CrossRef]

- Lerchs, H.; Grossmann, I. Optimum Design of Open-Pit Mines. Trans CIM 1965, 68, 17–24. [Google Scholar]

- Taheri, M.; Irannajad, M.; Ataee-pour, M. Risk-Adjusted Discount Rate Estimation for Evaluating Mining Projects. J. Secur. Inst. Aust. 2009, 4, 36–42. [Google Scholar]

- Bastante, F.G.; Taboada, J.; Ordónez, C. Design and Planning for Slate Mining Using Optimisation Algorithms. Eng. Geol. 2004, 73, 93–103. [Google Scholar] [CrossRef]

- Lane, K.F. The Economic Definition of Ore; COMET Strategy Pty Ltd.: Cleveland, Australia, 2015; ISBN 978-0-9941852-2-8. [Google Scholar]

- Adiansyah, J.S.; Rosano, M.; Biswas, W.; Haque, N. Life Cycle Cost Estimation and Environmental Valuation of Coal Mine Tailings Management. J. Sustain. Min. 2017, 16, 114–125. [Google Scholar] [CrossRef]

- Tannant, D.D.; Regensburg, B. Guidelines for Mine Haul Road Design; University of British Columbia: Kelowna, Canada, 2001. [Google Scholar]

- Ministry of Industry and Energy. Reglamento General de Normas Básicas de Seguridad Minera. In Boletin Oficial del Estado; Real Decreto 863/1985; Ministerio de Industria y Energía: Madrid, Spain, 1990; Volume 103, pp. 17869–17877. [Google Scholar]

- Xu, X.; Gu, X.; Wang, Q.; Gao, X.; Liu, J.; Wang, Z.; Wang, X. Production Scheduling Optimization Considering Ecological Costs for Open Pit Metal Mines. J. Clean. Prod. 2018, 180, 210–221. [Google Scholar] [CrossRef]

- O’Hara, T.A.; Suboleski, S.C. Costs and Cost Estimation. SME Min. Eng. Handb. 1992, 1, 405–424. [Google Scholar]

- Caterpillar. Surface Mining Primary Loading Tool: Selection Guide; Caterpillar: Irving, TX, USA, 2013. [Google Scholar]

- Caterpillar. 770G Off-Highway Truck Engine; Caterpillar: Irving, TX, USA, 2014. [Google Scholar]

- Caterpillar. Caterpillar Performance Handbook; Caterpillar: Irving, TX, USA, 2019; p. 2264. [Google Scholar]

- Runge, I.C. Mining Economics and Strategy; Society for Mining, Metallurgy and Exploration, Inc.: Englewood, CO, USA, 2009. [Google Scholar]

- Dzakpata, I.; Knights, P.; Kizil, M.S.; Nehring, M.; Aminossadati, S.M. Truck and shovel versus in-pit conveyor systems: A comparison of the valuable operating time. In Proceedings of the 16th Coal Operators’ Conference, Wollongong, Australia, 10–12 February 2016; University of Wollongong: Wollongong, Australia, 2016; pp. 463–476. [Google Scholar]

- Norgate, T.; Haque, N. Energy and Greenhouse Gas Impacts of Mining and Mineral Processing Operations. J. Clean. Prod. 2010, 18, 266–274. [Google Scholar] [CrossRef]

- Anas, A.V.; Amalia, R.; Qaidahiyani, N.F.; Djamaluddin; Herin, S.R.D. Sensitivity Analysis of Net Present Value Due to Optimal Pit Limit in PT Ceria Nugraha Indotama, Kolaka Regency, Southeast Sulawesi Province. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Chennai, India, 16–17 September 2020; Volume 875, pp. 1–11. [Google Scholar]

| Economic Parameters | Value |

|---|---|

| Product price (USD/pounds) | 95 |

| Mining costs (USD/t) | 9 |

| Milling costs (USD/t) | 12 |

| Recovery | 0.85 |

| Cut-off (ppm) | 118 |

| Annual Production (t/yr) | Daily Production (t/day) | Hourly Production (t/h) | Comment | |

|---|---|---|---|---|

| Scenario 1 | 600,000 | 1644 | 103 | Production decrease |

| Scenario 2 | 1,200,000 | 3288 | 205 | Base Case |

| Scenario 3 | 3,000,000 | 8219 | 514 | Production increase |

| Scenario 4 | 6,000,000 | 16,438 | 1027 | Production increase |

| Maximum Annual Production Capacity (t/yr) | 600,000 | 1,200,000 | 3,000,000 | 6,000,000 |

|---|---|---|---|---|

| Product price (USD/pounds) | 95 | |||

| Selling Costs (USD/pounds) | 0 | |||

| Mining Costs (USD/t) | 9 | |||

| Milling Costs (USD/t) | 12 | |||

| Final Slope Angle (º) | 50 | |||

| Decrements in block value (%) | 2 | |||

| Discount rate (%) | 8 | |||

| Ramp Width (m) | 15 | 25 | 35 |

|---|---|---|---|

| Final Slope Angle (°) | 50 | 47 | 44 |

| Ramp Slope (%) | 10 | ||

| Grade Resistance (%) | 2 | ||

| Bench Height (m) | 10 | ||

| Bench Slope (°) | 70 | ||

| Berm Width (m) | 4 | ||

| Ramp Width (m) | Truck Model | Wheel Loader Model | Width Truck (m) | Empty Truck Weight (kg) | Gross Vehicle Weight (kg) | Payload (m3) | Payload (tons) |

|---|---|---|---|---|---|---|---|

| 15 | 770G | 992 | 4.78 | 33,224 | 71,214 | 17.20 | 38 |

| 25 | 777G | 994 | 6.10 | 70,753 | 163,360 | 42.00 | 93 |

| 35 | 789D | 998 | 7.65 | 141,214 | 324,319 | 108.00 | 183 |

| Schedule Parameters | Value |

|---|---|

| Shift (u) | 2 |

| Shift (hours) | 8 |

| Working days (days) | 365 |

| Calendar time (hours) | 5840 |

| Available Time (%) | 80 |

| Utilized Time (%) | 75 |

| Annual Production (t/yr) | Ultimate Pit | Ore—Best (Mt) | Waste—Best (Mt) | SR (Waste/Ore) | NPV (MUSD) | LOM (yrs) | |

|---|---|---|---|---|---|---|---|

| Scenario 1 | 600,000 | 4 | 3.12 | 11.39 | 3.65 | (16.08) | 24.18 |

| Scenario 2 | 1,200,000 | 8 | 3.91 | 16.36 | 4.18 | 24.30 | 16.89 |

| Scenario 3 | 3,000,000 | 14 | 8.58 | 31.13 | 3.63 | 105.15 | 13.24 |

| Scenario 4 | 6,000,000 | 23 | 10.49 | 40.55 | 3.86 | 158.17 | 8.51 |

| Ramp Width (m) | Final Slope Angle | Ultimate Pit | Ore—Best (Mt) | Waste—Best (Mt) | SR (Waste/ Ore) | NPV (M USD) | LOM (yrs) | |

|---|---|---|---|---|---|---|---|---|

| Scenario 4 | 15 | 50 | 23 | 10.50 | 40.55 | 3.86 | 158.17 | 8.51 |

| 25 | 47 | 20 | 8.88 | 33.42 | 3.76 | 142.68 | 7.05 | |

| 35 | 44 | 15 | 8.74 | 35.06 | 4.01 | 113.71 | 7.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vera-Burau, A.; Álvarez-Ramírez, D.; Sanmiquel, L.; Bascompta, M. A Comparison of the Fuel Consumption and Truck Models in Different Production Scenarios. Appl. Sci. 2023, 13, 5769. https://doi.org/10.3390/app13095769

Vera-Burau A, Álvarez-Ramírez D, Sanmiquel L, Bascompta M. A Comparison of the Fuel Consumption and Truck Models in Different Production Scenarios. Applied Sciences. 2023; 13(9):5769. https://doi.org/10.3390/app13095769

Chicago/Turabian StyleVera-Burau, Alejandra, Daniel Álvarez-Ramírez, Lluís Sanmiquel, and Marc Bascompta. 2023. "A Comparison of the Fuel Consumption and Truck Models in Different Production Scenarios" Applied Sciences 13, no. 9: 5769. https://doi.org/10.3390/app13095769

APA StyleVera-Burau, A., Álvarez-Ramírez, D., Sanmiquel, L., & Bascompta, M. (2023). A Comparison of the Fuel Consumption and Truck Models in Different Production Scenarios. Applied Sciences, 13(9), 5769. https://doi.org/10.3390/app13095769