1. Introduction

Road safety depends on many factors, including the condition of roads, the condition of vehicles and the experience and skills of road users. One of the most important factors is the vehicle itself, its design and reliability. Nowadays, designed and manufactured vehicles have a specific product lifespan. The time and expected mileage are estimated on the basis of a number of market research and analyses. It is crucial that during design, individual vehicle elements are designed optimally in accordance with their intended purpose. The most important elements are those that directly affect safety. One of the elements that has a direct impact on safety is the vehicle’s suspension, which includes damping elements such as shock absorbers. The shock absorber in the suspension is responsible for the comfort of passengers and the driver [

1] as well as for safety and ensuring wheel contact with the ground. Moreover, as shown by Miraglia [

2], the shock absorber can, through its appropriate design, contribute to reducing energy consumption while driving, e.g., in a class B SUV passenger car. A thorough review of regenerative shock absorber solutions was developed by Tiwarii et al. [

3]. Another solution for a shock absorber storing energy while driving in a large-sized vehicle such as a bus was presented by Ali A. et al. [

4]. For this purpose, the authors used a cam mechanism. In turn, Galuzzi R. et al. [

5] proposed a compact solution of a rotary generator shock absorber, enabling energy recovery from road unevenness. The completed prototype with automotive application potential was checked for damping capacity, overall conversion efficiency and acoustic behavior. Simulation considerations for the use of rotary shock absorbers in a passenger car were described by Tae Dong et al. [

6].

Each element undergoes gradual wear during operation, which causes their operating characteristics to change over time. Therefore, the degree of wear of key components of the vehicle should be as low as possible. Moreover, the user should know when individual components should be replaced. Ferrier et al. [

7] presented the characteristics of a sensor built into the shock absorber (SAES) used for the real-time monitoring of the condition of shock absorbers during daily operation. The SAES system has been shown to contribute to increased on-board comfort and vehicle safety by signaling the need to replace the shock absorber when it is worn out. In passenger cars, shock absorbers are most often tested during technical inspections. Additionally, the wear of some elements may have a significant impact on the operation of other elements in the entire system. Howard et al. [

8] assessed shock absorber wear through a simplified thermomechanical model, estimating the cumulative work performed by a shock absorber. According to the author, this approach makes it possible to assess the degree of wear and tear of the shock absorber over time.

In the case of commercial trailers, the wear and tear of shock absorbers is not monitored during technical inspections. Only a visual assessment is performed. A shock absorber that is incapable of further operation is considered to be vulnerable to leaks. Such a shock absorber should be replaced immediately. In ref. [

9], the authors checked the vertical shock absorber loads transferred to the road surface with respect to the condition of shock absorbers in the front suspension of a truck. New, used and damaged shock absorbers were analyzed. The analysis showed a significant impact of the shock absorber wear on the load on the surface upon which the vehicle moved across.

Shock absorber tests have been widely described in the literature. Zhang et al. [

10] presented the active car shock absorber with linear motor, developed for the purpose of suppressing vibration. The authors prepared a five-degrees-of-freedom space vibration model of the car and, subsequently, its state space equation was derived. Li et al. [

11] conducted research on magnetic dampers used in aviation depending on the material of the internal surface on the damping efficiency. In turn, Łukczo et al. [

12] described a numerical analysis of a quarter of a car with a modified twin tube hydraulic shock absorber compared to a classic one. This solution allows us to improve driving comfort at small amplitudes and to increase damping at large amplitudes, which undoubtedly increases safety. Polach et al. [

13] presented the tests of a semi-active air pressure-controlled hydraulic telescopic shock absorber. The new solution was tested with the use of the intercity bus, considered as the reference for research and the development of controlled shock absorbers. Wang et al. [

14] developed a test bench with a hydraulically driven vibrating table for testing shock absorbers. In turn, Guan et al. [

15] described experimental and simulation tests for a twin-tube hydraulic shock absorber. The most common damage to shock absorbers is a loss of efficiency due to leakage. Other damage types may include mechanical damage in the region of the attachment points [

16]. The efficiency of shock absorbers is largely dependent on temperature, which has also been widely described in the literature. In the work of Pavlov [

17] and Hryciów [

18], the influence of variable temperature conditions on the level of forces generated by the shock absorber is investigated. Harkishandas [

19] presented the results of a heat transfer test in the air gap and shock absorber body using different fluids. The operation of shock absorbers is also modeled by taking into account wear [

20]. The authors presented the fatigue model of a shock absorber equipped with shim-based clamped valves. Chang et al. [

21] developed a predictive model for the dynamic behavior of a road shock absorber. On this basis, the authors tried to determine the shock absorber’s service life and attributes for modeling vehicle dynamics. Ielluzi et al. [

22] described the operation of the suspension system, which can be shortened, and the response time of the system, which also reduces the amplitude of vibrations while driving. Polach [

23] validated the analytical model of the behavior of the air suspension based on a low-floor bus ride on an artificial test track. This paper is an introduction to solving the given problems and presents a comparison of the relative displacements between the axles and the chassis frame.

The quality of the roads has a significant impact on the durability of the vehicle and its components. Road roughness is described, among others, by the IRI factor (International Roughness Index). The road profiles described by [

24] or IRI are for a single track and specific conditions [

25]. Bucinskas et al. [

26] analyzed and evaluated the vibration energy of the vehicle suspension generated by road excitations resulting from unevenness. The parameters of shock absorbers are matched by optimizing the best damping coefficients depending on the type of road and its quality.

During durability tests, it is important to adequately reproduce the conditions in which the vehicle will ultimately operate. Tests confirming the vehicle’s reliability may be performed in real conditions; however, it is important that the test itself should last as short as possible and, at the same time, confirm the long-term operation of the entire system. For this purpose, the accelerated durability tests are conducted and intended for entire vehicles or their components. Special test tracks or mechatronic stations are used as simulators. Czarnuch et al. [

27] presented the use of the MTS 320 road simulator station for accelerated durability tests of a truck semi-trailer. The authors pay special attention to reproduce the actual conditions and also to determine the duration of such tests, confirming the correlation between reality and simulation. In this regard, Kosobudzki and Stańko [

28] investigated the fatigue of the anti-roll bar as the selected suspension component and determined the overall fatigue factor for this component.

In the presented work, the authors analyzed the characteristics of shock absorbers after durability tests conducted with the use of an MTS 320 road simulator with those of known mileage dismantled from trailers and supplied by the customers. Based on the obtained research results, the methodology of the durability testing of large-sized vehicles described by the authors in previous papers was assessed. The shock absorber was chosen because it is a component used in most vehicles and its evaluation after testing can be used to compare it with new elements or theoretical characteristics provided by the manufacturer. Moreover, thanks to cooperation with a trailer manufacturer, the authors have easy access to a fleet of vehicles sold to various customers, and at the same time, it was possible to obtain shock absorbers removed from trailers with known mileage. Moreover, thanks to the information obtained as part of the after-sales (or warranty) service, the trailer manufacturer has information regarding the tonnage of loads transported by customers, and thus the type of load on the trailers. The damping characteristics of the shock absorber during tension and compression were determined. Temperature was also monitored to determine the degree of heating during repeated test cycles.

This type of research is very often carried out in the automotive industry. However, we would like to point out that currently, based on the authors’ knowledge, there are four stations in the world for carrying out the durability testing of large-sized vehicles. Two of them are located in Germany, one in China and one in Poland (which was described in the authors’ previous publications). None of the companies outside Poland shares their knowledge regarding the methodology of conducting durability tests and the results of these tests. What is new in this publication is the validation of the methodology for conducting durability tests previously proposed by the authors based on the selected component, which is the shock absorber. The authors have not yet encountered in the literature any attempt to validate the methodology for conducting durability tests for large-sized vehicles, which, in our opinion, is also new in the discussed issue.

2. Testing Methodology of Shock Absorber

The first stage of the research was to determine the dynamic characteristics of the shock absorbers for various stages of wear (equivalent to mileage). These characteristics were determined for new (unused) shock absorbers, shock absorbers dismantled from semi-trailers on which durability tests of large-sized vehicles were carried out, described, among others, by Czarnuch [

28] and used shock absorbers dismantled from semi-trailers from 6 users. While determining the dynamic characteristics of the shock absorbers, their temperature was monitored using a thermal imaging camera. Then, the maximum values of damping forces for tension and compression conditions were compared depending on their course.

Figure 1 shows a diagram of the procedure for conducting research.

2.1. Object of the Research

Shock absorbers designed for the air suspension of a 3-axle semi-trailer were used for the tests. The axle load capacity of the tested semi-trailers is 9 (Tons). Two shock absorbers are mounted on the semi-trailer axle. The upper part of the shock absorber is supported on the main half-spring bracket, while the lower part is attached to the axle behind the half-spring (

Figure 2).

During the tests, a total of 29 shock absorbers with a piston rod stroke of 160 mm were tested, as shown in

Figure 3 and listed in

Table 1.

As visible from the table, the dispersion in the number of kilometers traveled is quite significant, from 247,000 to almost a million kilometers. Moreover, the tested shock absorbers were used on semi-trailers for a period of 2 to 7 years. All shock absorbers were dismantled in 2023. As for the shock absorbers removed from semi-trailers after durability tests, these shock absorbers were only a few months old. In addition, information was obtained from customers about the conditions of the use of semi-trailers. Customers carried out domestic and international transport throughout Poland and Western and Southern Europe. The semi-trailers mainly moved on highways (70%), approximately 20% were national roads and only 10% were local roads due to the need to reach the destination and unload the transported goods.

Table 2 lists shock absorbers intended for testing, taking into account their actual or simulated course at the MTS stand. The mileage was divided into percentages depending on the load with which the vehicle was operated or tested.

Based on

Table 2, it should be stated that in the case of used semi-trailers, with the exception of customer No. 6, they were loaded to a very similar extent. Customer No. 6 transports courier parcels to large logistics centers between large cities; hence, the vehicle is mostly loaded less than 50% of the maximum load and travels on good-quality roads, such as highways. In the case of trailers after durability tests, the assumption was to simulate a mileage of 400,000 km with a fully loaded trailer and 100,000 km with an unloaded trailer. Accelerated durability tests of two trailers from the NS3-M4 and NS3-SL series were performed on the MTS 320 road simulator. The semi-trailer tests lasted 756 and 500 h, respectively. According to the assumed methodology of durability testing developed by Czarnuch et al. [

29], this simulation corresponds to the mileage for real conditions of 500,000 (km) and 350,000 (km).

As for the Wielton company, the conditions for carrying out durability tests result from the fact that surveys were conducted with customers (these were not the same customers whose shock absorbers were tested), which showed that in their case, only about 20% of the total mileage unloaded from the trailer drives, and the rest loaded to varying degrees (of course, from an economic point of view, it is best if the semi-trailer is fully loaded). Based on these surveys, the trailer manufacturer stated that durability tests should be carried out on an unloaded trailer, simulating approximately 20% of 500,000 km. When checking the unloaded semi-trailer, the main aim is to check the body assembly elements such as lamps, fenders, frame and other screwed elements due to the higher frequency of vibrations occurring during tests. However, the full load of the semi-trailer results from the fact that the product is checked for durability of key elements for the chassis structure, such as the frame or axles. It is inefficient to conduct tests with different load configurations. Research on one product costs approximately EUR 100,000. The durability test on a road simulator lasts from 4 to 6 weeks. Carrying out tests with a lower load and not with full load as is currently performed would result in an extension of this time and complications in collecting reference data for various types of load.

2.2. Measurement Technique

The dynamic characteristics of shock absorbers during tension and compression were determined. A view of the entire measurement test bench is shown in

Figure 4. For this purpose, a single-axis durability testing machine from Instron, model 8872 (1), was used, which has an operating range of up to ±25 (kN) with an effective stroke of 100 (mm). The machine is powered by a dedicated hydraulic pressure system (2), model 3520, and a force meter mounted in the upper grip. The tested shock absorber (3) was mounted in the jaws of the machine using designed adapters. The parameters (force and displacement over time) were recorded using a computer with appropriate software provided by Instron (4). The sampling frequency of the recorded signals was 50 (Hz). Moreover, during the test, the shock absorber temperature was controlled using a high-speed thermal imaging camera MVlab SC7000 from FLIR from TELEDYNE FLIR LLC, Tigarg, OR, USA (5). The camera made it possible to record temperature changes during the entire test cycle. The processing of the obtained measurement signals was carried out using dedicated ResearchIR software version 4.40.12. The recorded temperature allowed us to assess the rate of heating of the shock absorbers during the entire test cycle.

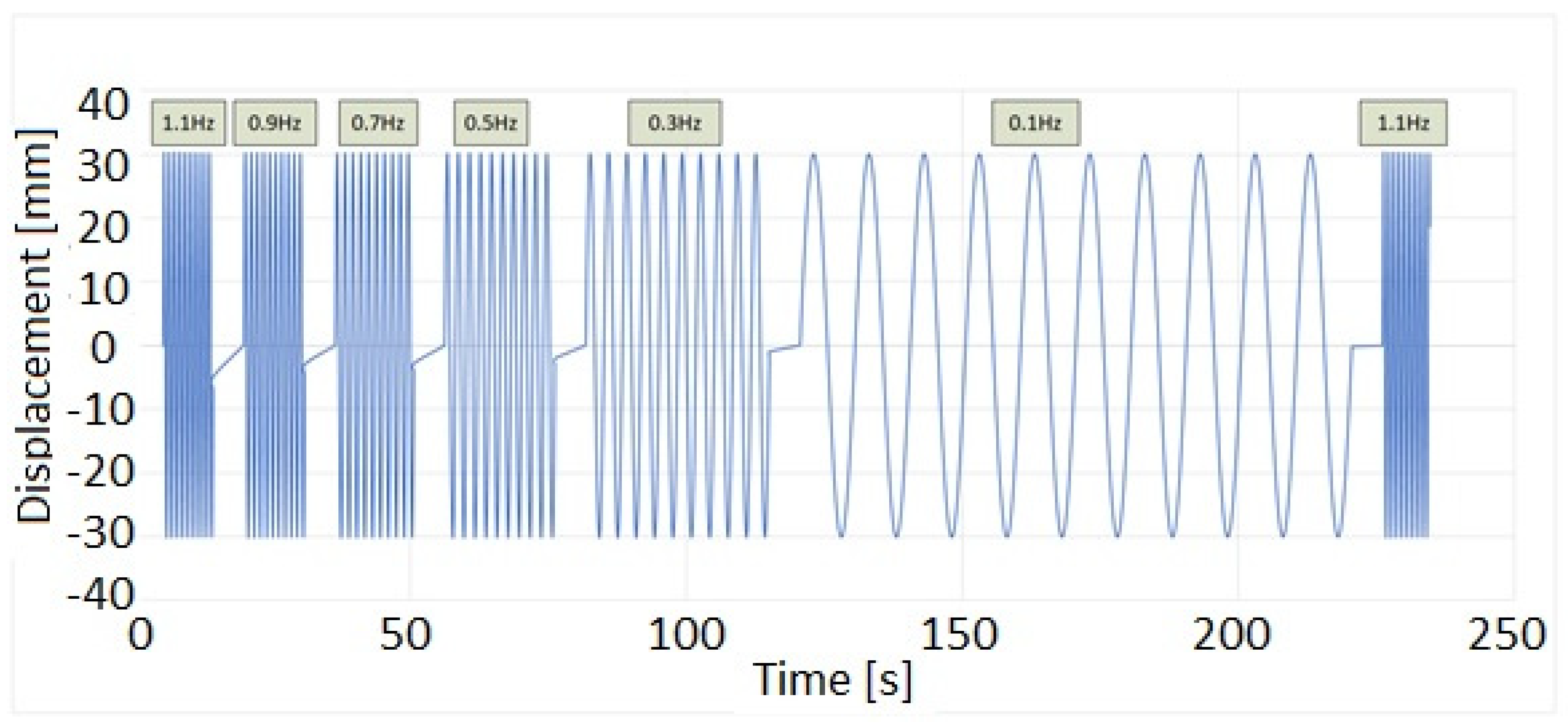

During the test, cyclic sinusoidal excitations were applied with variable frequencies, from 0.1 to 1.1 Hz, in steps of 0.2 (Hz). The cycle frequency was selected experimentally so as to not exceed the maximum values of forces possible to obtain on the durability machine. The shock absorber was stretched (compressed) within the range of ±30 mm. Knowing the given displacement in the cycle and the frequency, the peak value of the displacement velocity of the shock absorber piston rod was calculated. The speed value varied from 0.017 (m/s) for a frequency of 0.1 (Hz) to 0.205 (m/s) for a frequency of 1.1 (Hz). The manufacturer of the tested shock absorbers determines the dynamic characteristics for a maximum speed of 0.5 (m/s), but due to the limitations of the durability machine, a speed of 0.205 (m/s) was obtained during the described tests. For each frequency, a given cycle was repeated 10 times. At the beginning and end of the tests, the maximum frequency value of 1.1 (Hz) was set to check the rate of temperature changes from the very beginning. A time displacement signal operation of the shock absorber during the test is shown in

Figure 5. For each frequency, the speed and force for the compression and extension cycle of individual shock absorbers were determined.

The tests were performed for two initial positions of the shock absorber piston. The first (I) (

Figure 6A) position corresponds to the position of the shock absorber in an unloaded semi-trailer and the second (II) (

Figure 6B) position corresponds to the position of the piston in the event of a lack of air in the bellows of the semi-trailer suspension cushion. The distance difference between positions I and II is 40 mm. Two operating ranges were selected to determine the influence of the position of the shock absorber piston on the obtained efficiencies.

In order to ensure the repeatability of the temperature measurement method, the area where the temperature was measured was determined in the lower part of the shock absorber piston rod, near its mounting.

3. Durability Tests

Durability tests were carried out on the MTS road simulator. Due to the fact that the methodology for conducting this type of research by companies related to the automotive and trucking industries is not publicly available, the authors have developed their own method of conducting this type of research [

29].

Table 3 presents the method of carrying out durability tests on the MTS road simulator.

In order to prepare the vehicle for testing, it was equipped with a number of various types of sensors, including accelerometers, strain gauges, displacement sensors and pressure sensors. All sensors were placed on the vehicle frame. Displacement sensors (six pieces) were placed on the axles and the change in the distance between the semi-trailer axle and its frame was measured. Accelerometers (10 pieces) were placed on the axles, if technically possible, near the wheel (6 pieces), while the remaining 4 were located in the front part of the frame, near the seat plate and the front posts of the semi-trailer. As for the pressure sensors, they were connected to the pneumatic suspension system and located at a distance of no more than 50 cm from the suspension cushion. The strain gauges were glued to the so-called “neck” (place of changing the thickness of the main beam and web in the trailer) of roads with the worst surface quality (local roads). After installing the vehicle on the MTS durability test stand, these data were used to develop so-called control profiles, i.e., appropriately prepared runs that generate inputs from eight hydraulic actuators in such a way as to reproduce the amplitudes measured using sensors during reference runs. MTS RPC Pro (Remote Parameter Control) software release 5.1.1.49 was used to process measurement data and appropriate station configuration. Generating control profiles involves selecting data of time courses characterized by the highest fatigue accumulation coefficient.

Figure 7 shows example signals for which the time range with the highest accumulation of fatigue was selected. The white areas represent the portion of the signal selected for further simulation. The signals were cut off at the same time for all analyzed physical quantities. The cut sections were combined into one signal. Signal connections were made with a transition time of 0.3 (s). This is the time allotted for combining the two cut signals. The signals edited in this way had lengths ranging from 28 to 250 (s), and these signals were used in subsequent steps to recreate road data in the simulation.

The next stage is to build a system model. The purpose of building a system model is to define the relationship between input and output signals:

- -

The input signals are signals controlling the station actuators, referred to as DRV (Drive);

- -

The output signals are signals from sensors installed in the vehicle, called RSP (Response);

- -

The system model is the frequency response function FRF (Frequency Response Function). This is the relationship of outputs to inputs over the entire frequency band.

MTS RPC Pro software enables the creation of a system model in the form of transmittance. The sensors installed on the vehicle are used in the same configuration as on the road to determine the FRF for each frequency. FRF binds the output of the vibration system to the input, as described and confirmed by Zhang [

32]. To generate matrix (H) Equation (1), the inputs are the displacement of the platform actuators and the outputs are the responses of the transducers, as shown in

Figure 8.

where:

CSD—Cross Spectral Density, which is the power spectral density at each frequency proportional to the power between the input and output signals.

ASD—Auto Spectral Density, which is the spectral density at each frequency, proportional to the input signal.

After creating the system model, it is possible to generate a signal controlling the station actuators (DRV). The displacement of hydraulic actuators and the force generated on them are analyzed as signals controlling the operation of the station. As for the signals coming from the sensors, this was indicated in the article in the earlier fragment regarding the description of the sensors used. The DRV signal, as the displacement of the actuators, was determined by multiplying the signals collected from the road using the inverse of the matrix

H Equation (2):

where:

After creating the model, the MTS test bench generates the inputs under the wheels to match the signals registered by the actuators installed on the frame of the vehicle. This is performed in several iterative steps. At each iteration step, the level of signal reproduction, the level of frequency reproduction and the error measurement are checked, taking into account the root mean square (RMS) of the expected signal to the reproduced signal. An example of mapping the acceleration signal of one of the axes to the signal set in the time domain is shown in

Figure 9A; the graph shows the waveform required as road data (black line) and the response waveform as mapped data (blue line).

Figure 9B shows the signal mapping in the frequency domain. Determining the error with which signals are reproduced for individual iterations was performed by comparing the RMS (effective value) of the reproduced signal to the RMS of the target signal.

Figure 10 shows the normalized RMS comparison of the target signal to the reproduced signal for selected signals from acceleration, displacement and pressure sensors installed on the second axle of the semi-trailer. The quality of the ride was between 90 and 99%. The level of signal mapping in terms of time course and frequency is controlled at each iteration step.

4. Results from the Test

4.1. Dynamic Characteristics

In the first step of the research, the influence of selected measurement initial positions of the shock absorber piston on the obtained results was checked.

Figure 11 shows a comparison of dynamic characteristics for shock absorbers removed from an SL (super light) semi-trailer after durability tests, depending on the measurement range carried out in accordance with

Figure 6.

Upon analyzing the results obtained from the drawing above, it should be stated that the measurements carried out in the initial positions of the actuator pistons I and II are very similar. In the case of tensile conditions, the discrepancies between the ranges reached 3%. Only for the lowest speed of 0.017 (m/s) was the discrepancy greater and amounted to 13%. When it comes to shock absorber compression, the most noticeable difference also occurred at the lowest speed and amounted to 8%. For this reason, the results presented later in the article will concern the measurement range for position I of the actuator piston.

In the next stage, the dynamic characteristics for all tested shock absorbers were determined. For this purpose, the relationship between displacement and force when stretching (compressing) the shock absorber was determined.

Figure 12 shows exemplary dynamic characteristics of the tested shock absorber with a frequency of 1.1 (Hz).

The dynamic characteristics of all tested shock absorbers have a similar shape, but the value of the maximum forces during stretching is different, whereas for compression, the maximum values are similar.

As a result of the observed differences in the maximum values of forces when stretching the shock absorber, in the next stage of the analysis, the maximum values of forces during compression and extension of the shock absorber were determined for individual speeds. The determined characteristics for individual shock absorbers were related to the theoretical values declared by the shock absorber manufacturer.

Figure 13 graphically presents the values of the maximum force during tension and compression depending on the velocity for shock absorbers after durability tests from M4 and SL semi-trailers.

Figure 14 presents a similar list but for new shock absorbers and shock absorbers dismantled from used semi-trailers with various mileage.

Analyzing the above test results, it should be concluded that the maximum force values in the case of shock absorbers dismantled from the M4 semi-trailer after durability tests on the MTS stand (simulation of 500,000 km) are below the range of values permitted by the manufacturer in the case of new shock absorbers. The lowest values of forces during stretching were measured on shock absorbers installed during durability tests on the third axis. A 5% difference was also observed between the left side and the right side. Shock absorbers mounted on the left side of the trailer presented better damping properties.

In the case of the SL semi-trailer (after durability tests at the MTS stand), it should be stated that the range of average values when stretching the tested shock absorbers is within the range recommended by the manufacturer. The force values were only below tolerance in the case of low speeds of 0.05 (m/s). Moreover, when analyzing the damping on individual axes, practically no difference was observed (max difference reached 1%). When it comes to comparing shock absorbers depending on the side of the semi-trailer, the test results are consistent with those observed for the M4 semi-trailer. The shock absorbers on the left side showed 5% better damping properties than the shock absorbers installed on the right side.

Analyzing

Figure 13A, it should be concluded that the average value of the maximum force when stretching or compressing the new shock absorbers above the speed of 0.05 is within the tolerance limits recommended by the manufacturer. These forces are out of range for very low speeds below 0.05 (m/s).

As for shock absorbers dismantled from trailers used by various customers, it should be stated that for speeds above 0.05 (m/s), the maximum values of forces when stretching the shock absorbers are within tolerance limits. However, for speeds below 0.05 (m/s), these forces are much higher than those accepted by the shock absorber manufacturer. In addition, shock absorbers mounted on the left side were characterized by 1% to 13% greater force during extension compared to shock absorbers mounted on the right side of the trailer.

While conducting an organoleptic assessment of the shock absorbers, the authors observed initial resistance to movement in tension or compression in the case of shock absorbers dismantled from trailers used by customers, i.e., shock absorbers that were a few years old. This phenomenon was not observed in the case of new shock absorbers or those after durability tests (2–3 months old). Moreover, the analysis of the results (

Figure 13 and

Figure 14) confirms the authors’ observations. The forces measured at low speeds below 0.05 (m/s) for shock absorbers from used semi-trailers are higher than for new shock absorbers or shock absorbers after durability tests. In further research plans, the authors intend to determine the static characteristics in order to determine the friction coefficient depending, for example, on the degree of wear determined by the operating time.

4.2. Temperature Characteristics

The recorded temperature allowed us to assess the rate of heating of the shock absorbers during the entire test cycle. The temperature measurement was carried out for new shock absorbers and after durability tests at the MTS stand. This measurement was not performed for shock absorbers removed from trailers used by customers. The first to be tested were new shock absorbers and those dismantled from semi-trailers on which durability tests were carried out. The temperature change recorded when determining the dynamic characteristics was relatively small; hence, the authors decided not to perform this type of measurement for shock absorbers from trailers used by customers.

Figure 15 shows the result of temperature measurement over time for the tested shock absorbers.

In all cases of the tested shock absorbers, an increase in temperature was observed as the frequency of their operation and the duration of continuous operation increased. For new shock absorbers and those after durability tests, the temperature varied in the range of 23–45 °C. At the beginning and end of the dynamic test, the shock absorber operating speed was set to 0.2 (m/s). The value of the temperature increase in the first and second case for this speed was similar and amounted to 1–2 °C. Even though the value of the temperature increase for the same shock absorber operating speed is the same, a reduction in the maximum force value was observed when stretching and compressing the shock absorber.

Table 4 shows the difference in the average value of the maximum force obtained during stretching (compression) at the beginning of the dynamic test and after the shock absorber temperature increased to approximately 35 °C.

Based on the obtained test results, it can be concluded that as the temperature increases, the efficiency of the shock absorber decreases by decreasing the maximum force generated during its operation. For the tested shock absorbers, the decrease in this force was between 2 and 9%, depending on the type of semi-trailer from which the shock absorber came. It should be noted that manufacturers of shock absorbers used in commercial trailers are aware of the increase in shock absorber temperature during their operation and allow shock absorber operation up to 110 °C as normal operating conditions. Above this temperature, it is recommended to introduce an additional cooling system. It should be noted that such high temperatures should not occur under operating conditions. Temperatures above 100 °C can be achieved during very high dynamics of shock absorber operation, i.e., during durability tests on stands intended for this purpose [

33] and tests carried out on test tracks [

34].

4.3. The Influence of the Semi-Trailer’s Mileage on the Damping Force of the Shock Absorber

When analyzing the decrease in the maximum damping force of the shock absorbers, the maximum force value obtained when stretching the shock absorbers on a test bench was taken into account. In the case of commercial trailers, these values were related to the number of kilometers traveled by customers. However, in the case of shock absorbers dismantled from semi-trailers after durability tests at the MTS station, the values were related to the number of simulated kilometers.

Figure 16 and

Figure 17 show the results of testing new shock absorbers, dismantled from trailers after tests on a road simulator, and from trailers used by customers.

Based on the collected data regarding the decrease in the maximum damping force of shock absorbers, it can be concluded that the mileage of the vehicle has a significant impact on the condition of the shock absorbers. When comparing the wear of shock absorbers for individual vehicles, a difference between 1 and 11% was found in the degree of wear of components removed from one vehicle. The largest difference occurred in the shock absorbers taken from customer 2, approximately 11%. The smallest difference was seen for customer 1, approximately 1%. The difference concerned the shock absorbers removed from the right and left sides of the vehicles.

The next stage of the analysis was to find a trend determining the percentage of reduction in the primary damping force for shock absorbers in correlation to the mileage. The force values were averaged for shock absorbers removed from individual vehicles.

Figure 18 shows the trend of damping force reductions. The dashed line shows the trend for shock absorbers removed from customer trailers. Customer No. 6 was not taken into account when determining the trend line, as their degree of load on the trailer during its operation differed from that of the others. The determined trend is a linear function with a slope coefficient of −0.0003. The dotted line shows the trend of shock absorbers removed from trailers after durability tests. The determined trend is a linear function with a slope coefficient of −0.0005.

In both cases of the shock absorbers from customers and after tests at the MTS stand, the trend lines are similar to each other, so the trend is maintained. In addition, the shock absorbers from customer semi-trailer no. 6 have a significant maximum damping force. The reduction in strength is only 14% despite a mileage of up to 1 million km. This proves that the type of load on the trailer during its operation has a very significant impact on the wear of shock absorbers. The less load the trailer has, the longer the shock absorber will last. Additionally, it should be emphasized that the time of use will have a slight impact on the life of the shock absorber. The trailer of customer no. 6 has been in use for 6 years (the oldest tested trailer); however, the shock absorbers are characterized by significant damping force compared to the others tested due to the low load on the trailer during this period. Below the designated line, there are samples taken from vehicles after tests on a road simulator, which may indicate that the conditions adopted for the simulation are characterized by a higher fatigue accumulation coefficient in relation to the road conditions on which the vehicles were driving.

5. Discussion and Conclusions

The authors conducted comparative tests of shock absorbers dismantled from semi-trailers after durability tests for large-sized vehicles at the MTS stand and shock absorbers dismantled from semi-trailers with various mileage, which were obtained from six customers. As a reference point, five new shock absorbers were also tested. The research carried out included the determination of dynamic characteristics for two selected positions of the shock absorber piston. Additionally, for new shock absorbers and those after durability tests, the influence of temperature on the change in damping force was checked. The authors carried out the described tests in order to verify the method of carrying out durability tests of large-sized vehicles proposed and described in [

23,

26]. Verification of the research methodology is crucial for manufacturers of large-sized vehicles as it is extremely important to conduct the tests on a road simulator reflecting real operating conditions. As a result, structural imperfections such as cracks or fatigue can be quickly observed. This represents a significant saving in time, energy and financial outlays compared to operational road tests, which would involve covering a distance of 500,000 km. The summary of the research conducted by the authors was the determination of the damping force for all shock absorbers depending on the mileage of a given vehicle or kilometers simulated at the MTS station. Correct durability testing methodology allows for a more precise estimation of the product life cycle. The effect of temperature increase on the damping force in the shock absorber was described by Hryciow [

18]. The temperature varied in the range of –30 °C to 130 °C at a speed of up to 0.5 m/s and an amplitude of 80 mm. With such a significant temperature change, the maximum value of force at a temperature of –30 °C was 2.5 times greater than for 20 °C.

The authors, due to the technical limitations of the fatigue machine used in the tests, were not able to achieve a speed higher than 0.2 (m/s) with an amplitude of the shock absorber piston rod displacement of 30 mm. With such selected parameters and a test lasting up to 4 min, the range of temperature changes was 23–45 °C. However, the drop in force at maximum speed was 2–5% in the case of shock absorber extension and 7–9% in compression. The research results described in the paper should be treated as preliminary research. In the future, the authors plan to extend the dynamic testing time to increase the range of temperature changes. Moreover, the maximum temperature of shock absorbers should be precisely determined during durability tests on the MTS stand with and without cooling.

The correlation between the number of kilometers traveled by the semi-trailer or kilometers simulated during durability tests and the maximum damping force of the shock absorber was determined. When comparing the wear of shock absorbers for individually used vehicles, a difference of 1 to 11% in damping force of components removed from one vehicle was found. The largest difference occurred in the shock absorbers taken from customer 2, approximately 11%. The smallest difference occurred for customer 1, approximately 1%. For the M4-type semi-trailer after durability tests, the maximum damping force decreased by 25%, and in the case of the SL-type semi-trailer, a decrease by 15% was observed. It should also be stated that in all tested cases, shock absorbers removed from the left side were characterized by a greater efficiency than shock absorbers removed from the right side of the trailer. This property was also confirmed in the case of semi-trailers validated on the MTS road simulator. The tested semi-trailers were used in Europe, where right-hand traffic applies, which is the most probable cause of this phenomenon.

The obtained correlation between the change in the damping force of the shock absorber and the mileage of the semi-trailer does not apply to semi-trailers operated in different load conditions. In the future, the authors plan to conduct similar tests on a much larger number of samples and take into account other operating parameters of trailers, which, according to the authors, may have a significant impact on the life of the shock absorber, e.g., trailer load, number of sudden braking or operational period. However, based on the results presented in the article, it should be concluded that one of the most important aspects affecting the life of the shock absorber is the degree of load on the semi-trailer. The less load the trailer has during its life, the longer the shock absorber will last. Moreover, the operating period has a much smaller impact on the life cycle of the shock absorber. However, taking into account the trend lines obtained in the results, it can be assumed that the durability research methodology proposed by the authors is correct.