Designing Sustainable Flexible Manufacturing Cells with Multi-Objective Optimization Models †

Abstract

:1. Introduction

2. Literature Review

3. Material and Methods

3.1. Problem Formulation

- In the system, the routing flexibility for each part is taken into account. Only one alternative route of each part can be chosen.

- The system has machine flexibility. Multiple part types can be processed on different machines.

- The capacities of the cells are limited, and there are upper and lower limits for the number of machines to be taken into account.

- The part demands are fixed and known values. The processing time of a part on its route is known.

- The amount of power that machines consume during production is considered. Indirect and energy-related carbon emissions arising from the operation of the machines are considered. Machine idle times are ignored.

- The movements of parts between cells are considered.

- The carbon emission conversion factor is a constant coefficient.

- The time required for the addition of machines to cells and the removal of machines from the cells is ignored.

- The system has worker flexibility, and different workers may have different skills.

- In addition, worker skills are assumed constant in each period.

3.2. Developed Goal Programming Model

| Indices: | |

| W | Set of part types (w W). |

| R | Set of alternative routes (r R). |

| Q | Set of cells (q Q). |

| S | Set of machine types (s S). |

| I | Set of worker types (I I). |

| L | Set of skills (l L). |

| E | Set of periods (e E). |

| Parameters: | |

| The demand of part w in period e. | |

| The time capacity of machine s in period e. | |

| The machining time of part w on machine s in cell q using alternative route r. | |

| The amount of power consumed while machining part w on machine s in cell q using alternative route r. | |

| The cost of moving part w between cells in a period e. | |

| The machine s carbon emission cost per period e. | |

| The machine s processing/operation cost per period e. | |

| The cost of adding machine s to cells per period e. | |

| The cost of removing machine s from cells per period e. | |

| The training cost of worker i in cell q in period e. | |

| The time that worker i spends on an operation of skill l. | |

| The limit value of skill l in cell q in period e. | |

| The limit time that workers with skill l in cell q in period e can spend. | |

| The maximum number of workers of cell q in period e. | |

| The lower bound for the number of machines in cell q in period e. | |

| The upper limit for the number of machines in cell q in period e. | |

| The carbon emission conversion factor. | |

| The carbon emission limit value of cell q in period e. | |

| The bonus wage to be received by l skilled worker. | |

| The training time received by worker i in the skill l in period e. | |

| Decision Variables | |

| The number of machine s assigned to cell q in period e. | |

| The number of machine s added to cell q in period e. | |

| The number of machine s removed from cell q in period e. | |

| The number of workers in cell q in period e. | |

| The total number of workers in the system in period e. | |

| The total training time that worker i will receive during all periods according to the worker’s abilities. |

Linearization of the Model

3.3. Developed ε-Constraint Model

3.4. Developed Augmented ε-Constraint Model (AUGMECON)

4. Results and Discussion

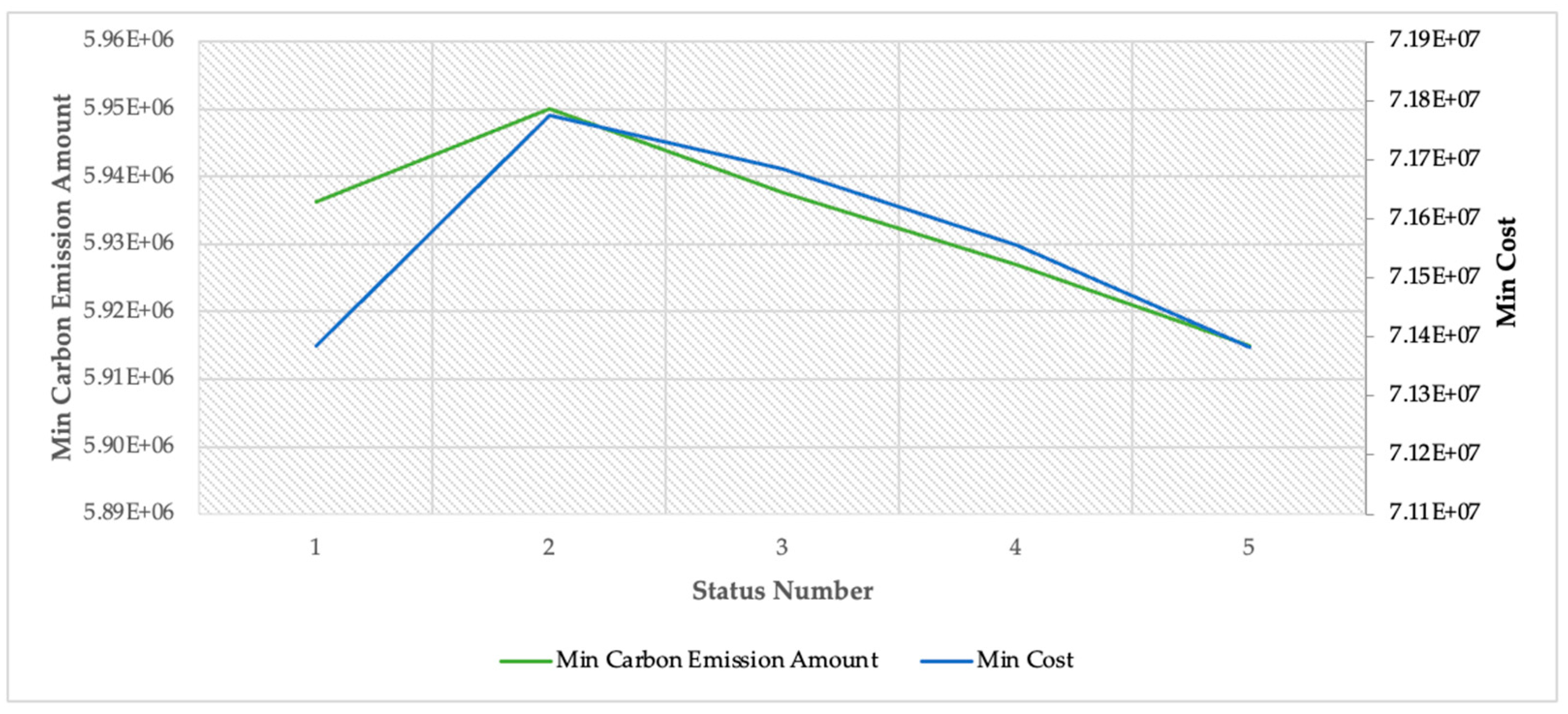

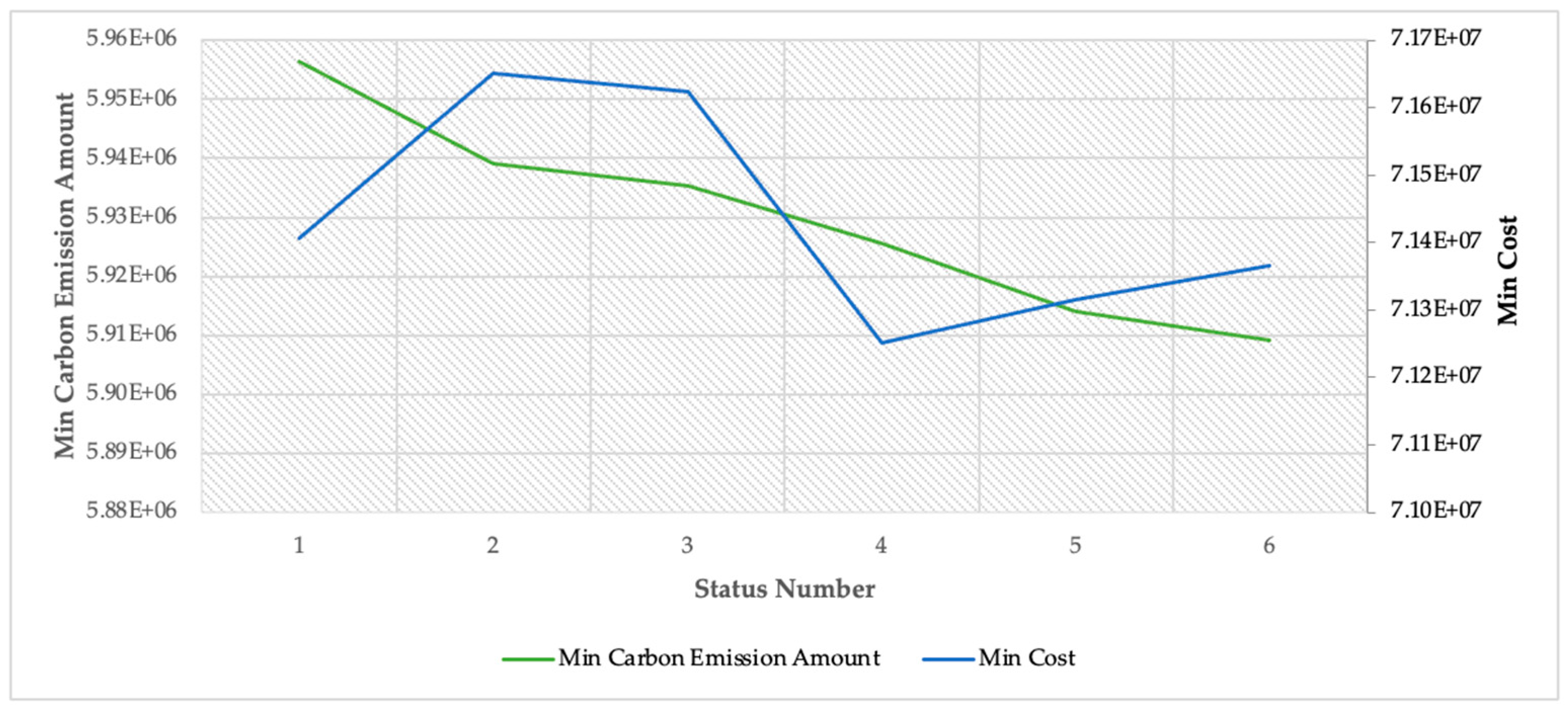

Sensitivity Analyses

5. Conclusions and Future Studies

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Part | Route | Cell–Machine (Operating Time)/(Machine Power Amount) |

|---|---|---|

| 1 | 1 | Q1-S1(9)/PW(14) Q2-S4(4)/PW(15) Q3-S7(6)/PW(13) Q4-S11(3)/PW(14)-S12(7)/PW(17) Q5-S14(7)/PW(18)-S15(5)/PW(14) Q6-S20(8)/PW(18) |

| 2 | Q1-S2(6)/PW(13)-S3(5)/PW(15) Q2-S5(7)/PW(17) Q4-S11(7)/PW(19)-S12(8)/PW(17)-S13(4)/PW(15) Q5-S14(9)/PW(18)-S15(4)/PW(14) Q6-S18(5)/PW(14) Q6-S20(7)/PW(18) | |

| 3 | Q1-S1(6)/PW(16)-S2(9)/PW(19)-S3(4)/PW(14) Q3-S8(2)/PW(22) Q4-S12(9)/PW(19)-S13(6)/PW(26) Q5-S14(8)/PW(18)-S15(4)/PW(24) Q6-S18(9)/PW(19)-S20(8)/PW(18) | |

| 4 | Q1-S1(11)/PW(19)-S2(6)/PW(18)-S3(5)PW(25) Q2-S5(5)/PW(25) Q4-S11(8)/PW(19)-S12(5)/PW(24)-S13(5)/PW(15) Q5-S14(5)/PW(23) Q5-S15(4)/PW(24) Q6-S20(8)/PW(18) | |

| 5 | Q1-S1(8)/PW(16)-S2(5)/PW(19)-S3(4)/PW(24) Q3-S8(8)/PW(16) Q4-S12(9)/PW(19)-S13(6)/PW(16) Q5-S14(7)/PW(18)-S15(4)/PW(24) Q6-S18(8)/PW(19)-S20(5)/PW(18) | |

| 2 | 1 | Q1-S3(8)/PW(18) Q2-S6(5)/PW(15) Q3-S7(4)/PW(14) Q4-S9(8)PW(14)-S10(6)/PW(15) Q5-S13(7)/PW(18)-S14(9)/PW(19) Q6-S19(4)/PW(24) |

| 2 | Q1-S1(6)/PW(20) Q2-S6(7)/PW(18) Q4-S11(8)/PW(18)-S13(5)/PW(23) Q5-S14(6)/PW(27) Q6-S18(8)/PW(18)-S19(3)/PW(22) | |

| 3 | Q1-S2(5)/PW(25)-S3(3)/PW(23) Q2-S6(6)/PW(16) Q3-S7(4)/PW(24)-S8(7)/PW(17) Q4-S8(8)/PW(8) Q5-S16(4)/PW(14) Q6-S20(7)/PW(17) | |

| 4 | Q1-S1(8)/PW(18)-S2(9)/PW(17)-S3(3)/PW(23) Q2-S6(8)/PW(8) Q4-S11(8)/PW(8)-S13(3)/PW(23) Q5-S14(7)/PW(17) Q6-S18(8)/PW(18)-S19(3)/PW(22) | |

| 5 | Q1-S2(5)/PW(15)-S3(3)/PW(23) Q3-S7(5)/PW(24)-S8(7)/PW(17) Q4-S8(7)/PW(18) Q5-S15(5)/PW(25)-S16(4)/PW(24) Q6-S20(9)/PW(17) | |

| 3 | 1 | Q1-S1(9)/PW(12)-S3(4)/PW(14) Q2-S6(6)/PW(17) Q4-S10(5)/PW(17)-S12(4)/PW(22) Q5-S15(5)/PW(18) Q6-S19(7)/PW(14)-S20(6)/PW(15) |

| 2 | Q1-S1(2)/PW(23) Q2-S4(5)/PW(15)-S5(7)/PW(18) Q3-S8(6)/PW(26) Q5-S16(4)/PW(24) Q6-S19(3)/PW(23)-S20(4)/PW(24) | |

| 3 | Q1-S1(7)/PW(17)-S2(5)/PW(21)-S3(3)/PW(13) Q2-S5(5)/PW(15) Q3-S7(6)/PW(16) Q4-S15(7)/PW(17) | |

| 4 | Q1-S1(5)/PW(23)-S2(7)/PW(17) Q2-S4(1)/PW(19)-S5(6)/PW(18) Q3-S8(5)/PW(16)-S9(6)/PW(16) Q6-S20(7)/PW(27) | |

| 5 | Q1-S1(8)/PW(11)-S2(1)/PW(17) Q2-S5(8)/PW(18) Q3-S8(2)/PW(14)-S9(6)/PW(16) Q6-S20(7)/PW(17) | |

| 4 | 1 | Q1-S1(5)/PW(21)-S2(7)/PW(22)-S3(3)/PW(14) Q2-S4(5)/PW(15)-S6(8)/PW(17) Q4-S10(7)/PW(17)-S12(4)/PW(12) Q5-S15(6)/PW(18) Q6-S19(4)/PW(14)-S20(5)/PW(15) |

| 2 | Q1-S1(3)/PW(23) Q2-S4(5)/PW(15)-S5(8)/PW(18) Q3-S8(6)/PW(16) Q5-S16(4)/PW(14) Q6-S19(3)/PW(23)-S20(4)/PW(24) | |

| 3 | Q1-S1(6)/PW(17)-S2(9)/PW(22)-S3(3)/PW(23) Q2-S5(5)/PW(15) Q3-S7(6)/PW(16) Q4-S15(7)/PW(17) | |

| 4 | Q1-S1(3)/PW(23)-S2(4)/PW(17) Q2-S4(6)/PW(21)-S5(1)7PW(18) Q3-S8(5)/PW(16)-S9(6)/PW(26) Q6-S20(7)/PW(17) | |

| 5 | Q1-S1(4)/PW(21)-S2(6)/PW(17) Q2-S5(7)/PW(18) Q3-S8(8)/PW(24)-S9(6)/PW(26) Q6-S20(3)/PW(27) | |

| 5 | 1 | Q1-S1(2)/PW(14)-S2(5)/PW(15)-S3(4)/PW(19) Q2-S6(8)/PW(18)-S7(10)/PW(19) Q4-S10(5)/PW(15)-S12(2)/PW(12) Q5-S15(6)/PW(16)-S16(5)/PW(15) Q6-S20(5)/PW(15) |

| 2 | Q1-S1(3)/PW(23)-S2(11)/PW(17) Q2-S4(9)/PW(19)-S5(8)/PW(18)-S6(6)/PW(16) Q3-S8(6)/PW(16)-S9(7)/PW(7) Q5-S16(4)/PW(24)-S17(5)/PW(25) Q6-S18(5)/PW(15)-S19(3)/PW(23)-S20(4)/PW(14) | |

| 3 | Q1-S1(8)/PW(18)-S3(3)/PW(23) Q2-S5(9)/PW(19) Q3-S7(7)/PW(17) Q4-S15(9)/PW(19)-S16(8)/PW(18) | |

| 4 | Q1-S1(6)/PW(16)-S2(8)/PW(18)-S3(5)/PW(25) Q2-S4(4)/PW(24)-S5(7)/PW(17)-S6(6)/PW(26) Q3-S8(6)/PW(16)-S9(5)/PW(25) Q6-S19(4)/PW(24)-S20(7)/PW(17) | |

| 5 | Q1-S1(5)/PW(15)-S2(6)/PW(16) Q2-S5(8)/PW(18) Q3-S8(8)/PW(18)-S9(6)/PW(16) Q6-S19(6)/PW(19) | |

| 6 | 1 | Q1-S1(9)/PW(17)-S2(6)/PW(15)-S3(8)/PW(18) Q2-S6(7)/PW(17)-S7(6)/PW(26) Q4-S10(7)/PW(17)-S12(2)/PW(22) Q5-S15(8)/PW(28) Q6-S19(4)/PW(24)-S20(5)/PW(15) |

| 2 | Q1-S1(3)/PW(23) Q2-S4(9)/PW(15)-S5(8)/PW(8) Q3-S8(6)/PW(16) Q5-S16(4)/PW(14) Q6-S19(3)/PW(23)-S20(4)/PW(24) | |

| 3 | Q1-S1(8)/PW(17)-S2(2)/PW(22)-S3(1)/PW(23) Q2-S5(5)/PW(15) Q3-S7(6)/PW(16) Q4-S15(7)/PW(17) | |

| 4 | Q1-S1(5)/PW(13)-S2(7)/PW(17) Q2-S4(2)/PW(19)-S5(4)/PW(18) Q3-S8(5)/PW(16)-S9(6)/PW(16) Q6-S20(3)/PW(17) | |

| 5 | Q1-S1(6)/PW(18)-S2(3)/PW(17) Q2-S5(8)/PW(8) Q3-S8(2)/PW(4)-S9(6)/PW(6) Q6-S20(6)/PW(7) | |

| 7 | 1 | Q1-S3(8)/PW(24) Q2-S5(5)/PW(8)-S6(7)/PW(17) Q4-S10(7)/PW(17)-S12(8)/PW(12) Q5-S15(8)/PW(8) Q6-S19(4)/PW(4)-S20(5)/PW(5) |

| 2 | Q1-S1(3)/PW(23) Q2-S4(7)/PW(5)-S5(8)/PW(8) Q3-S8(6)/PW(6) Q5-S16(5)/PW(14) Q6-S19(3)/PW(13)-S20(4)/PW(4) | |

| 3 | Q1-S1(7)/PW(7)-S2(1)/PW(18)-S3(3)/PW(13) Q2-S5(5)/PW(5) Q3-S7(6)/PW(6) Q4-S15(6)/PW(7) | |

| 4 | Q1-S1(4)/PW(3)-S2(7)/PW(7) Q2-S4(3)/PW(11)-S5(8)/PW(8) Q3-S8(9)/PW(6)-S9(6)/PW(6) Q6-S20(7)/PW(7) | |

| 5 | Q1-S1(5)/PW(12)-S2(6)/PW(17) Q2-S5(8)/PW(18) Q3-S8(4)/PW(14)-S9(5)/PW(16) Q6-S20(6)/PW(7) | |

| 8 | 1 | Q1-S1(9)/PW(9)-S3(8)/PW(8) Q2-S6(8)/PW(7) Q4-S10(5)/PW(7)-S12(3)/PW(12) Q5-S15(6)/PW(8) Q6-S19(5)/PW(14)-S20(5)/PW(15) |

| 2 | Q1-S1(9)/PW(9) Q2-S4(6)/PW(16)-S5(8)/PW(8) Q3-S8(6)/PW(6) Q5-S16(4)/PW(14) Q6-S19(3)/PW(13)-S20(4)/PW(14) | |

| 3 | Q1-S1(7)/PW(17)-S2(5)/PW(15)-S3(3)/PW(13) Q2-S5(5)/PW(5) Q3-S7(6)/PW(16) Q4-S15(7)/PW(7) | |

| 4 | Q1-S1(7)PW(13)-S2(7)/PW(7) Q2-S4(9)/PW(11)-S5(8)/PW(8) Q3-S8(10)/PW(16)-S9(6)/PW(16) Q6-S20(7)/PW(7) | |

| 5 | Q1-S1(4)/PW(14)-S2(7)/PW(7) Q2-S5(8)/PW(8) Q3-S8(5)/PW(14)-S9(6)/PW(16) Q6-S20(2)/PW(7) | |

| 9 | 1 | Q1-S3(8)/PW(8) Q2-S5(8)/PW(18)-S6(3)/PW(17)-S7(12)/PW(19) Q4-S11(7)/PW(9)-S12(2)/PW(12) Q5-S15(8)/PW(18) Q6-S19(4)/PW(4)-S20(5)/PW(5) |

| 2 | Q1-S1(5)/PW(8)-S2(9/PW(9) Q2-S4(6)/PW(15)-S5(8)/PW(8) Q3-S7(7)/PW(7)-S8(6)/PW(6) Q5-S16(4)/PW(14)-S17(6)/PW(6) Q6-S20(4)/PW(4) | |

| 3 | Q1-S1(9)/PW(7)-S3(7)/PW(13) Q2-S5(6)/PW(5)-S6(8)/PW(8) Q3-S7(6)/PW(6)-S8(8)/PW(8) Q4-S15(7)/PW(17)-S16(9)/PW(9) | |

| 4 | Q1-S1(3)/PW(13)-S2(7)/PW(7)-S3(4)/PW(14) Q2-S4(6)/PW(11)-S5(8)/PW(18) Q3-S8(6)/PW(16)-S9(6)/PW(6) Q6-S20(2)/PW(7) | |

| 5 | Q1-S1(3)/PW(15)-S2(5)/PW(7)-S3(7)/PW(7) Q2-S5(8)/PW(8) Q3-S8(4)/PW(14)-S9(6)/PW(16) Q6-S19(3)/PW(18)-S20(6)/PW(17) | |

| 10 | 1 | Q2-S5(4)/PW(14)-S6(4)/PW(15) Q4-S10(7)/PW(17)-S11(8)/PW(18)-S12(5)/PW(22) Q5-S15(8)/PW(8)-S17(9)/PW(9) Q6-S19(1)/PW(14)-S20(5)/PW(15) |

| 2 | Q1-S1(3)/PW(23)-S2(5)/PW(25) Q2-S4(5)/PW(25)-S5(8)/PW(28)-S6(4)/PW(24) Q3-S8(6)/PW(6) Q5-S16(4)/PW(14)-S17(5)/PW(15) Q6-S19(3)/PW(13)-S20(4)/PW(14) | |

| 3 | Q1-S1(9)/PW(16)-S2(8)/PW(18)-S3(3)/PW(13) Q2-S5(5)/PW(15)-S6(6)/PW(17) Q3-S7(6)/PW(16)-S8(8)/PW(18) Q4-S15(7)/PW(17) | |

| 4 | Q1-S1(5)/PW(15)-S2(7)/PW(17) Q2-S4(4)/PW(14)-S5(8)/PW(8) Q3-S8(6)/PW(16)-S9(6)/PW(16) Q6-S18(8)/PW(18)-S20(7)/PW(17) | |

| 5 | Q1-S1(3)/PW(14)-S2(7)/PW(17)-S3(8)/PW(18) Q2-S5(8)/PW(18) Q3-S8(4)/PW(14)-S9(6)/PW(26) Q6-S19(4)/PW(17) | |

| 11 | 1 | Q1-S2(8)/PW(18) Q2-S5(4)/PW(14)-S6(7)7PW(17) Q4-S10(4)/PW(14)-S11(8)/PW(18)-S12(5)/PW(15) Q5-S15(8)/PW(8)-S16(7)/PW(7) Q6-S18(6)/PW(16)-S19(6)/PW(18)-S20(9)/PW(9) |

| 2 | Q1-S1(8)/PW(18)-S2(6)/PW(8) Q2-S4(5)/PW(15)-S5(4)/PW(8)-S6(9)/PW(9) Q3-S8(6)/PW(16) Q5-S16(4)/PW(14) Q6-S19(3)/PW(11)-S20(4)/PW(14) | |

| 3 | Q1-S2(5)/PW(15) Q2-S6(7)/PW(17)-S7(6)/PW(16) Q4-S15(7)/PW(17) | |

| 4 | Q1-S1(10)/PW(19)-S2(7)/PW(17)-S3(9)/PW(9) Q2-S4(3)/PW(8)-S5(8)/PW(8) Q3-S8(5)/PW(15)-S9(6)/PW(16) Q6-S18(4)/PW(14)-S19(8)/PW(18)-S20(7)/PW(17) | |

| 5 | Q1-S1(9)/PW(16)-S2(7)/PW(17) Q2-S4(7)/PW(17)-S5(8)/PW(8) Q3-S7(5)/PW(15)-S8(4)/PW(24)-S9(6)/PW(16) Q6-S19(4)/PW(18)-S20(6)/PW(16) | |

| 12 | 1 | Q1-S3(8)/PW(13) Q2-S6(6)/PW(16)-S7(5)/PW(15) Q4-S10(4)/PW(14)-S11(3)/PW(13)-S12(2)/PW(12) Q5-S15(8)/PW(18) Q6-S20(5)/PW(15) |

| 2 | Q1-S1(3)/PW(13)-S2(7)/PW(17) Q2-S4(7)/PW(26)-S5(7)/PW(17) Q3-S8(7)/PW(14) Q5-S16(5)/PW(15)-S17(4)/PW(14) Q6-S19(7)/PW(17)-S20(8)/PW(18) | |

| 3 | Q1-S1(2)/PW(22)-S2(8)/PW(18) Q2-S5(7)/PW(17)-S6(4)/PW(24) Q3-S7(6)/PW(6)-S8(5)/PW(5) Q4-S15(7)/PW(19)-S16(8)/PW(18) | |

| 4 | Q1-S1(6)/PW(7)-S2(6)/PW(16) Q2-S4(5)/PW(15)-S5(4)/PW(24) Q3-S8(4)/PW(24) Q6-S20(7)/PW(17) | |

| 5 | Q1-S2(1)/PW(8) Q2-S5(11)/PW(18) Q3-S8(2)/PW(24)-S9(6)/PW(16) Q6-S19(8)/PW(18) | |

| 13 | 1 | Q1-S2(7)/PW(18)-S3(5)/PW(12) Q2-S4(3)/PW(16)-S6(7)/PW(17) Q4-S10(6)/PW(17)-S11(3)/PW(18)-S12(2)/PW(22) Q5-S15(8)/PW(18)-S16(9)/PW(9) Q6-S18(7)/PW(17)-S19(6)/PW(16)-S20(5)/PW(25) |

| 2 | Q1-S1(5)/PW(15)-S2(7)/PW(26) Q2-S4(5)/PW(15)-S5(4)/PW(18)-S6(7)/PW(17) Q3-S8(6)/PW(6)-S9(7)/PW(7) Q5-S16(4)/PW(24)-S17(5)/PW(15) Q6-S19(6)/PW(16) | |

| 3 | Q1-S3(3)/PW(13) Q2-S5(3)/PW(15)-S6(7)/PW(17) Q3-S7(6)/PW(16)-S8(7)/PW(17) Q4-S15(7)/PW(17)-S16(6)/PW(16) | |

| 4 | Q1-S2(10)/PW(17) Q2-S5(8)/PW(18) Q3-S8(9)/PW(15)-S9(6)/PW(16)-S10(4)/PW(24) Q6-S19(8)/PW(18) | |

| 5 | Q1-S1(6)/PW(24)-S2(7)/PW(17) Q2-S5(1)/PW(21) Q3-S8(4)/PW(24)-S9(6)/PW(16) Q6-S18(9)/PW(9)-S19(8)/PW(18) | |

| 14 | 1 | Q2-S6(9)/PW(17) Q4-S10(5)/PW(21)-S12(2)/PW(22) Q5-S15(8)/PW(18) Q6-S19(4)/PW(14)-S20(5)/PW(15) |

| 2 | Q1-S1(3)/PW(23) Q2-S4(5)/PW(15)-S5(8)/PW(18) Q3-S8(6)/PW(16) Q5-S16(4)/PW(24) Q6-S19(3)/PW(23)-S20(4)/PW(24) | |

| 3 | Q1-S1(8)/PW(17)-S2(1)/PW(22)-S3(3)/PW(13) Q2-S5(5)/PW(15) Q3-S7(6)/PW(16) Q4-S15(7)/PW(17) | |

| 4 | Q1-S1(4)/PW(13)-S2(7)(PW(17) Q2-S4(1)/PW(21)-S5(5)/PW(28) Q3-S8(6)/PW(26)-S9(6)/PW(16) Q6-S20(7)/PW(17) | |

| 5 | Q1-S1(11)/PW(21)-S2(3)/PW(17) Q2-S5(8)/PW(18) Q3-S8(4)/PW(14)-S9(6)/PW(16) Q6-S20(4)/PW(17) | |

| 15 | 1 | Q1-S1(11)/PW(18) Q2-S6(7)/PW(17)-S7(5)/PW(15) Q3-S15(8)/PW(8) Q4-S10(3)/PW(17)-S11(5)/PW(15)-S12(2)/PW(23) Q5-S15(8)/PW(8) Q6-S18(9)/PW(19)-S19(4)/PW(24)-S20(5)/PW(15) |

| 2 | Q1-S1(3)/PW(23)-S2(7)/PW(17) Q3-S8(6)/PW(16) Q5-S16(4)/PW(14) Q6-S19(3)/PW(13)-S20(4)/PW(14) | |

| 3 | Q1-S1(10)/PW(19)-S3(3)/PW(23) Q2-S5(5)/PW(25) Q3-S7(6)/PW(16) Q4-S15(7)/PW(17) | |

| 4 | Q1-S1(3)/PW(23)-S2(7)/PW(17)-S3(8)/PW(18) Q2-S4(9)/PW(19)-S5(8)/PW(18) Q3-S8(6)/PW(16)-S9(3)/PW(16)-S10(7)/PW(17) Q6-S19(6)/PW(16) S20(9)/PW(19) | |

| 5 | Q1-S2(7)/PW(17) Q2-S5(8)/PW(8) Q3-S9(6)/PW(16) Q6-S19(3)/PW(18)-S20(7)/PW(17) | |

| 16 | 1 | Q4-S10(7)/PW(17)-S12(5)/PW(20) Q5-S15(8)/PW(18) |

| 2 | Q2-S4(12)/PW(15)-S5(8)/PW(18) Q3-S8(6)/PW(16) Q5-S16(2)/PW(24) Q6-S19(3)/PW(23)-S20(4)/PW(24) | |

| 3 | Q1-S1(4)/PW(17)-S2(8)/PW(22)-S3(3)/PW(23) Q2-S5(5)/PW(15) Q3-S7(6)/PW(16) Q4-S15(7)/PW(17) | |

| 4 | Q1-S1(3)/PW(13)-S2(7)/PW(17) Q2-S4(6)/PW(18)-S5(3)/PW(18) Q3-S8(7)/PW(16)-S9(6)/PW(16) Q6-S20(7)/PW(17) | |

| 5 | Q1-S1(7)/PW(17)-S2(3)/PW(19)-S3(5)/PW(15) Q2-S5(8)/PW(18) Q3-S6(4)/PW(14)-S8(4)/PW(14)-S9(6)/PW(16) Q6-S19(5)/PW(15)-S20(2)/PW(17) | |

| 17 | 1 | Q1-S2(6)/PW(17)-S3(5)/PW(15) Q2-S6(7)/PW(17) Q4-S10(1)/PW(17)-S12(2)/PW(22) Q5-S15(6)/PW(18)-S16(5)/PW(25) Q6-S18(6)/PW(26)-S20(5)/PW(25) |

| 2 | Q1-S1(3)/PW(23)-S2(8)/PW(18) Q2-S4(5)/PW(15) Q3-S7(4)/PW(14)-S8(6)/PW(16) Q5-S16(11)/PW(24)-S17(7)/PW(17) Q6-S20(9)/PW(19) | |

| 3 | Q1-S1(8)/PW(19)-S3(7)/PW(14) Q2-S5(5)/PW(15)-S6(7)/PW(17) Q3-S7(6)/PW(26)-S8(5)/PW(15) Q4-S15(7)/PW(17)-S16(8)/PW(18) Q5-S18(9)/PW(19) | |

| 4 | Q1-S1(6)/PW(23)-S2(7)/PW(27) Q2-S4(1)/PW(21)-S5(8)/PW(18) Q3-S8(4)/PW(16)-S9(6)/PW(16) Q6-S20(7)/PW(17) | |

| 5 | Q1-S2(4)/PW(17) Q2-S5(8)/PW(18) Q3-S8(4)/PW(14)-S9(6)/PW(16) | |

| 18 | 1 | Q1-S2(9)/PW(19)-S3(4)/PW(24) Q2-S6(7)/PW(17) Q4-S10(7)/PW(27)-S12(9)/PW(19) Q5-S15(8)/PW(18)-S19(4)/PW(24)-S20(5)/PW(25) Q6-S18(5)PW(15) |

| 2 | Q1-S1(9)/PW(19)-S2(5)/PW(25) Q2-S4(4)/PW(24) Q3-S8(6)/PW(16)-S9(6)/PW(16) Q5-S16(6)/PW(16)-S17(7)/PW(17) Q6-S19(8)/PW(18)-S20(4)/PW(24) | |

| 3 | Q1-S1(9)/PW(19)-S3(7)/PW(17) Q2-S5(5)PW(15) Q3-S7(6)/PW(16)-S8(5)/PW(15) Q4-S15(9)/PW(19)-S16(4)/PW(24) | |

| 4 | Q1-S2(9)/PW(9)-S3(4)/PW(14) Q2-S5(3)/PW(13)-S6(5)/PW(15) Q3-S8(6)/PW(16) Q6-S18(3)/PW(13)-S19(8)/PW(8)-S20(4)/PW(14) | |

| 5 | Q1-S1(6)/PW(16)-S2(7)/PW(17)-S3(5)/PW(25) Q2-S5(8)/PW(8)-S8(4)/PW(14) Q3-S8(4)/PW(14)-S9(6)/PW(16)-S10(5)/PW(15) Q6-S19(5)/PW(15)-S20(7)/PW(17) | |

| 19 | 1 | Q2-S6(4)/PW(14)-S7(8)/PW(18) Q4-S10(7)/PW(17)-S11(5)/PW(25)-S12(2)/PW(22) Q5-S15(8)/PW(18) Q6-S19(4)/PW(24)-S20(5)/PW(15) |

| 2 | Q1-S1(6)/PW(16) Q2-S4(5)/PW(15)-S5(8)/PW(18) Q3-S8(6)/PW(26) Q5-S16(6)/PW(26) Q6-S19(13)/PW(13)-S20(4)/PW(14) | |

| 3 | Q1-S2(9)/PW(9)-S3(8)/PW(18) Q2-S5(5)/PW(15) Q3-S7(11)/PW(16) Q4-S15(7)/PW(17) | |

| 4 | Q1-S2(9)/PW(19) Q2-S4(7)/PW(11)-S5(8)/PW(18) Q3-S8(7)/PW(7)-S9(6)/PW(16) Q6-S19(2)/PW(22)-S20(3)/PW(3) | |

| 5 | Q2-S5(8)/PW(8) Q3-S8(4)/PW(24)-S9(6)/PW(16) Q6-S19(9)/PW(15)-S20(6)/PW(16) | |

| 20 | 1 | Q2-S6(11)/PW(9)-S7(9)/PW(9) Q3-S9(5)PW(15) Q4-S10(6)/PW(16)-S11(8)/PW(18)-S12(2)/PW(22) Q5-S15(9)/PW(9) Q6-S18(6)/PW(16)-S19(4)/PW(24)-S20(5)/PW(25) |

| 2 | Q1-S1(3)/PW(13)-S2(8)/PW(18) Q2-S4(9)/PW(9)-S5(6)/PW(16) Q3-S7(7)/PW(17)-S8(6)/PW(16) Q6-S20(4)/PW(14) | |

| 3 | Q1-S2(12)/PW(12) Q2-S5(9)/PW(9) Q3-S7(6)/PW(16)-S8(7)/PW(17) Q4-S15(8)/PW(8)-S16(9)/PW(9) Q6-S19(8)/PW(8) | |

| 4 | Q1-S2(7)/PW(17)-S3(8)/PW(18) Q3-S8(3)/PW(16)-S9(6)/PW(16)-S10(5)/PW(25) Q5-S17(9)/PW(9) Q6-S19(5)/PW(25)-S20(8)/PW(18) | |

| 5 | Q2-S5(8)/PW(8) Q3-S8(7)/PW(9)-S9(10)/PW(6) | |

| 21 | 1 | Q1-S1(9)/PW(8)-S2(5)/PW(9)-S3(4)/PW(14) Q4-S10(8)/PW(15)-S11(6)/PW(16)-S12(2)/PW(22) Q6-S19(4)/PW(24)-S20(5)/PW(25) |

| 2 | Q2-S4(9)/PW(15)-S5(8)/PW(18) Q3-S8(8)/PW(16)-S9(7)/PW(17) Q6-S19(9)/PW(9) | |

| 3 | Q1-S3(9)/PW(9) Q2-S5(5)/PW(25)-S6(7)/PW(17) Q3-S7(6)/PW(26) Q4-S15(7)/PW(17) Q6-S18(8)/PW(18)-S19(9)/PW(19) | |

| 4 | Q1-S2(7)/PW(17) Q2-S4(13)/PW(11)-S5(4)/PW(18) Q3-S8(6)/PW(16)-S9(6)/PW(16) Q6-S20(7)/PW(17) | |

| 5 | Q1-S1(4)/PW(24)-S2(6)/PW(16) Q2-S5(5)/PW(17) Q3-S8(4)/PW(14)-S9(6)/PW(16) Q4-S11(7)/PW(17) | |

| 22 | 1 | Q1-S1(5)/PW(16)-S3(2)/PW(24) Q2-S5(5)/PW(18) Q4-S10(7)/PW(17)-S11(9)/PW(9)-S12(7)/PW(17) Q5-S15(8)/PW(8)-S16(5)/PW(15) Q6-S20(9)/PW(9) |

| 2 | Q1-S1(5)/PW(3)-S2(9)/PW(9) Q3-S8(6)/PW(16)-S9(8)/PW(8) Q5-S16(4)/PW(14)-S17(5)/PW(15) Q6-S19(9)/PW(9) | |

| 3 | Q1-S1(8)/PW(18)-S2(2)/PW(12) Q2-S5(9)/PW(9) Q3-S7(7)/PW(16)-S8(7)/PW(17) Q4-S15(7)/PW(17)-S16(8)/PW(18) | |

| 4 | Q2-S5(8)/PW(8)-S6(7)/PW(7) Q3-S8(6)/PW(6)-S9(8)/PW(9) Q6-S18(3)/PW(3)-S20(9)/PW(9) | |

| 5 | Q1-S1(7)/PW(17)-S2(9)/PW(9) Q2-S4(2)/PW(20)-S5(8)/PW(18) Q3-S8(4)/PW(14)-S9(6)/PW(16)-S10(3)/PW(23) Q4-S16(4)/PW(14) Q5-S17(6)/PW(16)-S18(5)/PW(15) Q6-S20(7)/PW(17) | |

| 23 | 1 | Q1-S3(3)/PW(14) Q2-S6(7)/PW(14) Q5-S15(8)/PW(18)-S16(9)/PW(9) |

| 2 | Q1-S1(3)/PW(23)-S2(8)/PW(18) Q2-S4(5)/PW(15)-S5(6)/PW(18)-S6(7)/PW(17) Q3-S8(6)/PW(16) Q4-S15(6)/PW(16) Q6-S20(9)/PW(9) | |

| 3 | Q1-S1(9)/PW(9)-S2(8)/PW(8) Q2-S4(4)/PW(24)-S5(5)/PW(25) Q3-S7(6)/PW(26)-S8(7)/PW(17) | |

| 4 | Q2-S4(2)/PW(21)-S5(5)/PW(17)-S6(8)/PW(18) Q6-S19(3)/PW(23)-S20(9)/PW(9) | |

| 5 | Q2-S5(6)/PW(16) Q3-S9(6)/PW(6) Q6-S18(11)/PW(9)-S20(3)/PW(15) | |

| 24 | 1 | Q1-S1(9)/PW(8)-S2(2)/PW(13)-S3(1)/PW(14) Q2-S5(6)/PW(16)-S6(7)/PW(17) Q4-S10(6)/PW(14)-S11(8)/PW(18) Q5-S14(6)/PW(16)-S15(8)/PW(18) Q6-S19(6)/PW(16)-S20(3)/PW(13) |

| 2 | Q2-S5(7)/PW(16)-S6(7)/PW(17) Q3-S8(9)/PW(19)-S9(5)/PW(15) Q5-S16(3)/PW(23)-S17(2)/PW(22) Q6-S20(4)/PW(12) | |

| 3 | Q1-S1(6)/PW(16)-S3(8)/PW(9) Q4-S15(4)/PW(4)-S16(5)/PW(5) Q6-S19(8)/PW(8) | |

| 4 | Q1-S1(3)/PW(23)-S2(7)/PW(17)-S3(6)/PW(16) Q2-S5(8)/PW(8)-S6(5)/PW(15) Q6-S19(8)/PW(18)-S20(9)/PW(9) | |

| 5 | Q1-S2(7)/PW(17) Q2-S5(8)/PW(18)-S6(5)/PW(15) Q3-S8(4)/PW(14) | |

| 25 | 1 | Q1-S1(5)/PW(15)-S2(6)/PW(16)-S3(5)/PW(14) Q2-S5(8)PW(18)-S6(7)/PW(17)-S7(5)/PW(15) Q3-S8(5)/PW(23) Q4-S12(9)/PW(9) Q5-S15(8)/PW(18) |

| 2 | Q1-S1(3)/PW(3)-S2(1)/PW(5) Q2-S4(4)/PW(24)-S5(7)/PW(17) Q3-S8(5)/PW(15)-S9(4)PW(24) Q5-S16(3)/PW(8) Q6-S19(9)/PW(9)-S20(6)/PW(6) | |

| 3 | Q1-S2(8)/PW(18)-S3(9)/PW(9) Q2-S5(5)/PW(15) Q3-S6(4)/PW(10)-S7(6)/PW(16) | |

| 4 | Q1-S1(6)/PW(16)-S2(7)/PW(17)-S3(8)/PW(18) Q2-S4(2)/PW(12)-S5(8)/PW(18)-S6(3)/PW(11) Q3-S8(6)/PW(16)-S9(6)/PW(16) Q6-S19(8)/PW(18)-S20(7)/PW(17) | |

| 5 | Q1-S2(9)/PW(17) Q2-S4(4)/PW(14)-S5(8)/PW(8) Q3-S8(4)/PW(14)-S9(6)/PW(16) Q6-S19(9)/PW(16)-S20(7)/PW(17) | |

| 26 | 1 | Q1-S3(4)/PW(14) Q2-S6(10)/PW(17)-S7(8)/PW(18) Q4-S10(7)/PW(17) Q5-S15(8)/PW(8)-S16(8)/PW(8) Q6-S18(4)/PW(14)-S20(5)/PW(15) |

| 2 | Q1-S1(7)/PW(17)-S2(8)/PW(18) Q2-S4(2)/PW(21)-S5(3)/PW(13)-S6(4)/PW(24) Q3-S7(5)/PW(15)-S8(6)/PW(16)-S9(7)/PW(17) Q5-S16(4)/PW(14)-S17(5)/PW(15) Q6-S18(7)/PW(17)S20(4)/PW(24) | |

| 3 | Q1-S1(10)/PW(18)-S2(9)/PW(19) Q2-S5(5)/PW(15)-S6(6)/PW(16) Q3-S7(6)/PW(16)-S8(7)/PW(17) Q4-S14(7)/PW(17)-S15(8)/PW(18) | |

| 4 | Q2-S4(8)/PW(18)-S5(8)/PW(18) Q3-S8(9)/PW(19) | |

| 5 | Q1-S2(4)/PW(14) Q2-S5(6)/PW(16)-S6(7)/PW(17) Q3-S8(5)/PW(15)-S9(7)/PW(17) Q5-S16(6)/PW(16)-S17(3)/PW(23) Q6-S18(2)/PW(14)-S19(8)/PW(18) | |

| 27 | 1 | Q1-S1(7)/PW(9)-S2(1)/PW(21)-S3(4)/PW(14) Q2-S4(3)/PW(23)-S6(5)/PW(15) Q4-S10(5)/PW(15)-S11(6)/PW(16)-S12(2)/PW(12) Q6-S19(7)/PW(17) |

| 2 | Q1-S1(15)/PW(13)-S2(5)/PW(15)-S3(1)/PW(16) Q2-S5(5)/PW(15)-S6(2)/PW(2) Q3-S7(3)/PW(17)-S8(6)/PW(16) Q5-S6(4)/PW(4)-S17(5)PW(5) | |

| 3 | Q1-S1(6)/PW(16)-S3(3)/PW(23) Q2-S5(8)/PW(18)-S6(9)/PW(9) Q3-S7(7)/PW(17)-S8(5)/PW(15) Q4-S14(6)/PW(26)-S15(7)/PW(7) Q6-S19(8)/PW(18)-S20(4)/PW(14) | |

| 4 | Q1-S1(3)/PW(3)-S2(8)/PW(6)-S3(4)/PW(4) Q4-S5(7)/PW(8) Q6-S20(7)/PW(7) | |

| 5 | Q1-S1(4)/PW(24)-S2(7)/PW(17)-S3(8)/PW(18) Q2-S4(5)/PW(25)-S5(8)/PW(18) Q3-S8(4)/PW(24)-S9(6)/PW(16) Q5-S17(6)/PW(16) Q6-S19(5)/PW(17)-S20(7)/PW(17) | |

| 28 | 1 | Q1-S1(4)/PW(15)-S3(6)/PW(16) Q2-S6(9)/PW(9) Q4-S10(6)/PW(16)-S12(3)/PW(13) Q5-S15(8)/PW(18) Q6-S19(6)/PW(16)-S20(8)/PW(18) |

| 2 | Q1-S1(3)/PW(16) Q2-S4(12)/PW(22)-S5(8)/PW(18) Q3-S8(7)/PW(17) Q5-S16(6)/PW(6) Q6-S19(5)/PW(15)-S20(1)/PW(23) | |

| 3 | Q1-S1(9)/PW(19)-S3(6)/PW(26) Q2-S5(5)/PW(5) Q3-S7(7)/PW(7) Q4-S15(8)/PW(8) | |

| 4 | Q1-S1(4)/PW(14)-S2(8)/PW(18) Q2-S4(3)/PW(13)-S5(7)/PW(11) Q3-S8(9)PW(19)-S9(6)/PW(26) Q6-S19(4)/PW(14)-S20(8)/PW(18) | |

| 5 | Q1-S1(6)/PW(16)-S2(8)/PW(18) Q2-S5(8)(PW(18) Q3-S8(9)/PW(19)-S9(5)/PW(15) Q6-S19(3)/PW(23)-S20(6)/PW(16) | |

| 29 | 1 | Q1-S1(3)/PW(15)-S3(3)/PW(13) Q2-S6(8)/PW(8) Q4-S12(9)/PW(9) Q6-S20(6)/PW(16) |

| 2 | Q2-S4(5)/PW(9)-S5(6)/PW(16)-S6(5)/PW(15) Q3-S7(7)/PW(17)-S8(8)/PW(8) Q4-S9(9)/PW(9) Q5-S16(3)/PW(23)-S17(2)/PW(20) Q6-S20(4)/PW(14) | |

| 3 | Q1-S2(6)/PW(9)-S3(3)/PW(13) Q3-S7(7)/PW(17)-S8(8)/PW(18) Q6-S18(9)/PW(9) | |

| 4 | Q1-S2(7)/PW(17) Q2-S5(8)/PW(18)-S6(4)/PW(14) Q3-S7(5)/PW(15)-S8(4)/PW(16)-S9(6)/PW(16) Q6-S19(5)/PW(15)-S20(6)/PW(16) | |

| 5 | Q1-S2(7)/PW(17) Q2-S5(8)/PW(18) Q3-S8(4)/PW(14)-S9(6)/PW(16) Q5-S16(4)/PW(14)-S17(5)PW(15) Q6-S19(3)/PW(13)-S20(6)/PW(9) | |

| 30 | 1 | Q1-S1(9)/PW(9)-S2(1)/PW(13)-S3(5)/PW(15) Q2-S5(6)/PW(16)-S7(7)/PW(17) Q3-S8(5)/PW(15)-S9(4)/PW(24) Q5-S15(6)/PW(16) Q6-S20(9)/PW(19) |

| 2 | Q1-S1(9)/PW(13)-S2(5)/PW(15)-S3(8)/PW(18) Q2-S4(7)/PW(14)-S5(3)/PW(13) Q3-S7(9)/PW(13)-S8(9)/PW(9) Q5-S16(6)/PW(6)-S17(7)/PW(7) | |

| 3 | Q1-S2(7)/PW(17)-S3(3)PW(13) Q2-S5(6)/PW(16)-S6(7)/PW(17) Q3-S7(11)/PW(11) Q4-S15(3)/PW(23)-S16(4)/PW(14) Q6-S18(5)/PW(15)-S19(6)/PW(16) | |

| 4 | Q1-S1(9)/PW(9)-S2(7)/PW(17) Q2-S5(8)/PW(8) Q3-S8(5)/PW(15)-S9(4)/PW(14) Q6-S19(8)/PW(8)-S20(9)/PW(9) | |

| 5 | Q1-S2(9)/PW(9)-S3(7)/PW(17) Q2-S4(6)/PW(16)-S5(5)/PW(15) Q3-S8(4)/PW(14)-S9(6)/PW(16) Q4-S11(6)/PW(16)-S12(8)/PW(8) Q5-S16(9)/PW(9)-S17(8)/PW(8) | |

| 31 | 1 | Q1-S1(5)/PW(18)-S3(5)PW(15) Q2-S6(6)/PW(16) Q4-S10(6)/PW(16)-S12(3)/PW(23) Q5-S15(9)/PW(19) Q6-S19(7)-S20(3) |

| 2 | Q1-S1(6)/PW(16) Q2-S4(7)/PW(17)-S5(8)/PW(18) Q3-S8(9)/PW(19) Q5-S16(5)/PW(25) Q6-S19(4)/PW(24)-S20(5)/PW(15) | |

| 3 | Q1-S1(6)/PW(16)-S2(3)/PW(13)-S3(5)/PW(15) Q2-S5(9)/PW(19) Q3-S7(7)/PW(17) Q4-S15(9)/PW(19) | |

| 4 | Q1-S1(9)/PW(17)-S2(3)/PW(23) Q2-S4(2)/PW(20)-S5(4)/PW(14) Q3-S8(9)/PW(19)-S9(3)/PW(23) Q6-S20(8)/PW(18) | |

| 5 | Q1-S1(3)/PW(25)-S2(9)/PW(19) Q2-S5(4)/PW(24) Q3-S8(6)/PW(23)-S9(2)/PW(17) Q6-S20(8)/PW(18) | |

| 32 | 1 | Q3-S7(6)/PW(16) Q4-S10(8)/PW(18)-S11(7)/PW(17)-S12(1)/PW(23) Q5-S15(4)/PW(14) Q6-S20(5)/PW(15) |

| 2 | Q1-S1(13)/PW(13)-S2(8)/PW(18)-S3(4)/PW(24) Q2-S5(3)/PW(13) Q3-S7(5)/PW(13)-S8(7)/PW(18) Q5-S16(6)/PW(16)-S17(7)/PW(17) Q6-S19(8)/PW(18) | |

| 3 | Q1-S1(9)/PW(9) Q3-S7(6)/PW(16)-S8(9)/PW(9) Q4-S14(6)/PW(16)-S15(7)/PW(17) Q5-S16(9)/PW(9)-S17(3)/PW(13) Q6-S18(8)/PW(8)-S19(9)/PW(9) | |

| 4 | Q1-S1(6)/PW(16)-S2(10)/PW(17)-S3(5)/PW(10) Q2-S4(2)/PW(5) Q3-S8(3)/PW(13)-S9(7)/PW(7) Q5-S16(5)/PW(15) Q6-S18(5)/PW(15)-S19(9)/PW(9) | |

| 5 | Q1-S2(9)/PW(9) Q3-S8(6)/PW(13)-S9(2)/PW(21) Q6-S19(3)/PW(16)-S20(7)/PW(7) | |

| 33 | 1 | Q1-S1(3)/PW(9)-S2(3)/PW(12)-S3(9)/PW(23) Q2-S5(9)/PW(15)-S6(7)/PW(17) Q3-S7(6)/PW(16)-S8(5)/PW(20) Q4-S10(7)/PW(17)-S11(3)/PW(13)-S12(2)/PW(21) Q5-S15(8)/PW(18)-S16(4)/PW(18) Q6-S18(6)/PW(16)-S19(4)/PW(24)-S20(5)/PW(15) |

| 2 | Q1-S1(3)/PW(13)-S2(8)/PW(18) Q2-S4(5)/PW(13)-S5(8)/PW(18) Q3-S8(6)/PW(16)-S9(7)/PW(17) Q5-S16(4)/PW(14)-S17(5)/PW(23) Q6-S18(5)/PW(15)-S20(4)/PW(14) | |

| 3 | Q1-S1(7)/PW(16)-S3(10)/PW(23) Q2-S5(6)/PW(16) Q3-S7(3)/PW(19) Q4-S15(8)/PW(18)-S16(9)/PW(19) | |

| 4 | Q1-S2(9)/PW(19)-S3(5)/PW(15) Q2-S4(3)/PW(11)-S5(3)/PW(9) Q3-S7(4)/PW(14) Q4-S10(5)/PW(15)-S11(3)/PW(16) | |

| 5 | Q1-S2(8)/PW(18)-S3(9)/PW(19) Q2-S4(4)/PW(24)-S5(5)/PW(12) Q3-S8(3)PW(13)-S9(6)/PW(16)-S10(2)/PW(14) Q5-S16(2)/PW(20)-S17(3)/PW(13) Q6-S18(4)/PW(15)-S19(3)/PW(16)-S20(7)/PW(17) | |

| 34 | 1 | Q4-S10(6)/PW(16)-S11(5)/PW(18)-S12(2)PW(22) Q5-S15(6)/PW(18)-S16(8)/PW(18) Q6-S19(5)/PW(15) |

| 2 | Q1-S1(3)/PW(23)-S2(8)/PW(18) Q2-S5(6)/PW(18)-S6(7)/PW(21) Q3-S8(5)/PW(22)-S9(4)/PW(18)-S10(3)/PW(13) Q5-S16(4)/PW(14)-S17(5) Q6-S18(7)/PW(17)-S20(4)/PW(20) | |

| 3 | Q1-S1(8)/PW(9)-S3(5)/PW(15) Q2-S5(5)/PW(15)-S6(6)/PW(16) Q3-S7(6)/PW(16)-S8(8)/PW(18) Q4-S15(7)/PW(17)-S16(8)/PW(18) | |

| 4 | Q1-S1(3)/PW(23)-S2(7)/PW(17)-S3(4)/PW(24) Q2-S5(8)/PW(18) Q3-S8(6)/PW(16)-S9(5)/PW(15) Q6-S19(8)/PW(8) | |

| 5 | Q1-S1(6)/PW(16)-S2(3)/PW(23)-S3(5)/PW(15) Q2-S5(8)/PW(18)-S6(4)/PW(24) Q3-S8(9)/PW(14)-S9(6)/PW(15)-S10(3)/PW(23) Q6-S18(6)/PW(14)-S19(5)/PW(15)-S20(7)/PW(17) | |

| 35 | 1 | Q2-S6(8)/PW(18)-S7(9)/PW(19) Q4-S10(7)/PW(17)-S12(2)/PW(22) Q5-S15(8)/PW(18) |

| 2 | Q1-S1(3)/PW(23) Q2-S4(6)/PW(15)-S5(8)/PW(18) Q3-S8(6)/PW(16) Q5-S16(4)/PW(14) Q6-S19(3)/PW(23)-S20(4)/PW(14) | |

| 3 | Q1-S1(7)/PW(17)-S2(2)/PW(20)-S3(3)/PW(15) Q2-S5(5)/PW(5) Q3-S7(6)/PW(6) Q4-S15(7)/PW(7) | |

| 4 | Q1-S1(10)/PW(23)-S2(7)/PW(17) Q2-S4(3)/PW(21)-S5(9)/PW(18) Q3-S8(6)/PW(6)-S9(6)/PW(6) Q6-S20(7)/PW(17) | |

| 5 | Q1-S1(6)/PW(11)-S2(7)/PW(17) Q2-S5(8)/PW(8) Q3-S8(1)/PW(15)-S9(6)/PW(16) Q6-S20(2)/PW(17) | |

| 36 | 1 | Q1-S1(3)/PW(12) Q2-S4(5)/PW(17) Q3-S7(3)/PW(13) Q4-S11(3)/PW(14)-S12(7)/PW(17) Q5-S14(8)/PW(18)-S15(4)/PW(14) Q6-S20(8)/PW(18) |

| 2 | Q1-S2(3)/PW(23)-S3(5)/PW(18) Q2-S5(7)/PW(17) Q4-S11(9)/PW(19)-S12(6)/PW(17)-S13(5)/PW(15) Q5-S14(8)/PW(18)-S15(4)/PW(14) Q6-S18(4)/PW(14)-S20(8)/PW(18) | |

| 3 | Q1-S1(6)/PW(16)-S2(9)/PW(19)-S3(1)/PW(14) Q3-S8(2)/PW(22) Q4-S12(9)/PW(19)-S13(6)/PW(26) Q5-S14(8)/PW(18)-S15(4)/PW(24) Q6-S18(9)/PW(19)-S20(8)/PW(18) | |

| 4 | Q1-S1(9)/PW(21)-S2(7)/PW(18)-S3(5)/PW(25) Q2-S5(5)/PW(25) Q4-S11(9)/PW(19)-S12(4)/PW(24)-S13(5)/PW(15) Q5-S14(3)/PW(23)-S15(4)/PW(24) Q6-S20(8)/PW(18) | |

| 5 | Q1-S1(9)/PW(20)-S2(9)/PW(23)-S3(4)/PW(24) Q3-S8(6)/PW(14) Q4-S12(9)/PW(15)-S13(6)/PW(16) Q5-S14(4)/PW(11)-S15(4)/PW(24) Q6-S18(3)/PW(17)-S20(8)/PW(16) | |

| 37 | 1 | Q1-S3(8)/PW(15) Q2-S6(5)/PW(24) Q3-S7(4)/PW(14) Q4-S9(4)PW(20)-S10(5)/PW(18) Q5-S13(8)/PW(18)-S14(9)/PW(19) Q6-S19(4)/PW(24) |

| 2 | Q1-S1(2)/PW(20) Q2-S6(8)/PW(28) Q4-S11(8)/PW(18)-S13(3)/PW(23) Q5-S14(7)/PW(27) Q6-S18(8)/PW(18)-S19(2)/PW(22) | |

| 3 | Q1-S2(9)/PW(25)-S3(3)/PW(23) Q2-S6(6)/PW(16) Q3-S7(4)/PW(24)-S8(7)/PW(17) Q4-S8(3)/PW(8) Q5-S16(4)/PW(14) Q6-S20(7)/PW(17) | |

| 4 | Q1-S1(5)/PW(18)-S2(7)/PW(17)-S3(3)/PW(23) Q2-S6(8)/PW(8) Q4-S11(8)/PW(8)-S13(3)/PW(23) Q5-S14(7)/PW(17) Q6-S18(8)/PW(18)-S19(2)/PW(22) | |

| 5 | Q1-S2(5)/PW(25)-S3(3)/PW(23) Q3-S7(4)/PW(24)-S8(7)/PW(17) Q4-S8(8)/PW(20) Q5-S15(5)/PW(22)-S16(4)/PW(24) Q6-S20(7)/PW(27) | |

| 38 | 1 | Q1-S1(2)/PW(19)-S3(14)/PW(17) Q2-S6(7)/PW(19) Q4-S10(7)/PW(20)-S12(2)/PW(22) Q5-S15(8)/PW(18) Q6-S19(4)/PW(14)-S20(5)/PW(15) |

| 2 | Q1-S1(3)/PW(23) Q2-S4(5)/PW(25)-S5(8)/PW(18) Q3-S8(6)/PW(16) Q5-S16(4)/PW(24) Q6-S19(3)/PW(13)-S20(4)/PW(24) | |

| 3 | Q1-S1(3)/PW(19)-S2(2)/PW(11)-S3(13)/PW(13) Q2-S5(5)/PW(15) Q3-S7(6)/PW(17) Q4-S15(7)/PW(19) | |

| 4 | Q1-S1(3)/PW(23)-S2(7)/PW(17) Q2-S4(1)/PW(19)-S5(8)/PW(18) Q3-S8(6)/PW(16)-S9(6)/PW(19) Q6-S20(7)/PW(24) | |

| 5 | Q1-S1(3)/PW(10)-S2(7)/PW(17) Q2-S5(8)/PW(18) Q3-S8(4)/PW(19)-S9(6)/PW(16) Q6-S20(10)/PW(21) | |

| 39 | 1 | Q1-S1(1)/PW(24)-S2(8)/PW(26)-S3(4)/PW(14) Q2-S4(5)/PW(18)-S6(7)/PW(17) Q4-S10(7)/PW(17)-S12(2)/PW(18) Q5-S15(8)/PW(18) Q6-S19(4)/PW(19)-S20(5)/PW(15) |

| 2 | Q1-S1(3)/PW(23) Q2-S4(5)/PW(22)-S5(8)/PW(18) Q3-S8(6)/PW(16) Q5-S16(4)/PW(14) Q6-S19(3)/PW(23)-S20(4)/PW(24) | |

| 3 | Q1-S1(3)/PW(17)-S2(2)/PW(22)-S3(3)/PW(23) Q2-S5(5)/PW(15) Q3-S7(6)/PW(16) Q4-S15(7)/PW(17) | |

| 4 | Q1-S1(3)/PW(23)-S2(7)/PW(17) Q2-S4(3)/PW(21)-S5(5)7PW(18) Q3-S8(6)/PW(16)-S9(6)/PW(26) Q6-S20(7)/PW(17) | |

| 5 | Q1-S1(4)/PW(21)-S2(9)/PW(27) Q2-S5(8)/PW(18) Q3-S8(4)/PW(24)-S9(6)/PW(26) Q6-S20(5)/PW(27) | |

| 40 | 1 | Q1-S1(2)/PW(14)-S2(5)/PW(15)-S3(4)/PW(19) Q2-S6(8)/PW(18)-S7(9)/PW(19) Q4-S10(5)/PW(15)-S12(2)/PW(12) Q5-S15(6)/PW(16)-S16(5)/PW(15) Q6-S20(5)/PW(15) |

| 2 | Q1-S1(13)/PW(23)-S2(7)/PW(27) Q2-S4(9)/PW(19)-S5(8)/PW(18)-S6(6)/PW(16) Q3-S8(6)/PW(26)-S9(7)/PW(7) Q5-S16(4)/PW(24)-S17(5)/PW(25) Q6-S18(5)/PW(15)-S19(3)/PW(23) S20(4)/PW(14) | |

| 3 | Q1-S1(8)/PW(18)-S3(3)/PW(28) Q2-S5(9)/PW(19) Q3-S7(7)/PW(17) Q4-S15(9)/PW(19)-S16(8)/PW(18) | |

| 4 | Q1-S1(3)/PW(19)-S2(8)/PW(18)-S3(5)/PW(25) Q2-S4(4)/PW(21)-S5(7)/PW(17)-S6(6)/PW(26) Q3-S8(4)/PW(16)-S9(5)/PW(25) Q6-S19(4)/PW(24)-S20(7)/PW(17) | |

| 5 | Q1-S1(5)/PW(15)-S2(6)/PW(16) Q2-S5(8)/PW(28) Q3-S8(8)/PW(18)-S9(6)/PW(16) Q6-S19(9)/PW(17) | |

| 41 | 1 | Q1-S1(8)/PW(16) Q2-S4(5)/PW(18) Q3-S7(3)/PW(13) Q4-S11(4)/PW(14)-S12(7)/PW(17) Q5-S14(8)/PW(18)-S15(4)/PW(14) Q6-S20(8)/PW(18) |

| 2 | Q1-S2(3)/PW(23)-S3(5)/PW(15) Q2-S5(7)/PW(17) Q4-S11(9)/PW(19)-S12(7)/PW(19)-S13(5)/PW(15) Q5-S14(8)/PW(18)-S15(4)/PW(14) Q6-S18(4)/PW(24) Q6-S20(8)/PW(18) | |

| 3 | Q1-S1(6)/PW(16)-S2(5)/PW(19)-S3(4)/PW(14) Q3-S8(2)/PW(22) Q4-S12(9)/PW(17)-S13(6)/PW(26) Q5-S14(8)/PW(18)-S15(4)/PW(21) Q6-S18(9)/PW(19)-S20(8)/PW(18) | |

| 4 | Q1-S1(9)/PW(19)-S2(8)/PW(18)-S3(5)PW(25) Q2-S5(5)/PW(25) Q4-S11(9)/PW(18)-S12(4)/PW(24)-S13(5)/PW(15) Q5-S14(13)/PW(23)-S15(4)/PW(24) Q6-S20(8)/PW(18) | |

| 5 | Q1-S1(6)/PW(19)-S2(9)/PW(19)-S3(4)/PW(24) Q3-S8(6)/PW(26) Q4-S12(11)/PW(19)-S13(6)/PW(16) Q5-S14(8)/PW(18)-S15(4)/PW(24) Q6-S18(3)/PW(14)-S20(8)/PW(18) | |

| 42 | 1 | Q1-S3(8)/PW(19) Q2-S6(5)/PW(25) Q3-S7(4)/PW(14) Q4-S9(4)PW(14)-S10(5)/PW(15) Q5-S13(8)/PW(18)-S14(7)/PW(19) Q6-S19(4)/PW(24) |

| 2 | Q1-S1(8)/PW(20) Q2-S6(8)/PW(18) Q4-S11(8)/PW(18)-S13(3)/PW(23) Q5-S14(7)/PW(27) Q6-S18(8)/PW(18)-S19(2)/PW(22 | |

| 3 | Q1-S2(7)/PW(25)-S3(3)/PW(23) Q2-S6(3)/PW(16) Q3-S7(4)/PW(24)-S8(7)/PW(17) Q4-S8(8)/PW(8) Q5-S16(4)/PW(14) Q6-S20(7)/PW(17) | |

| 4 | Q1-S1(6)/PW(18)-S2(7)/PW(17)-S3(3)/PW(23) Q2-S6(8)/PW(8) Q4-S11(8)/PW(8)-S13(3)/PW(23) Q5-S14(7)/PW(17) Q6-S18(8)/PW(18)-S19(2)/PW(22) | |

| 5 | Q1-S2(5)/PW(15)-S3(3)/PW(23) Q3-S7(4)/PW(24)-S8(7)/PW(17) Q4-S8(8)/PW(18) Q5-S15(5)/PW(25)-S16(4)/PW(24) Q6-S20(5)/PW(17) | |

| 43 | 1 | Q1-S1(8)/PW(19)-S3(4)/PW(14) Q2-S6(7)/PW(17) Q4-S10(7)/PW(17)-S12(1)/PW(22) Q5-S15(8)/PW(18) Q6-S19(4)/PW(14)-S20(5)/PW(15) |

| 2 | Q1-S1(3)/PW(13) Q2-S4(5)/PW(15)-S5(8)/PW(18) Q3-S8(6)/PW(26) Q5-S16(4)/PW(14) Q6-S19(3)/PW(23)-S20(4)/PW(24) | |

| 3 | Q1-S1(2)/PW(17)-S2(2)/PW(21)-S3(3)/PW(15) Q2-S5(5)/PW(15) Q3-S7(6)/PW(16) Q4-S15(7)/PW(17) | |

| 4 | Q1-S1(3)/PW(23)-S2(7)/PW(17) Q2-S4(5)/PW(19)-S5(3)/PW(18) Q3-S8(3)/PW(19)-S9(6)/PW(16) Q6-S20(7)/PW(27) | |

| 5 | Q1-S1(4)/PW(21)-S2(2)/PW(17) Q2-S5(8)/PW(18) Q3-S8(3)/PW(15)-S9(9)/PW(16) Q6-S20(2)/PW(27) | |

| 44 | 1 | Q1-S1(1)/PW(20)-S2(5)/PW(22)-S3(4)/PW(14) Q2-S4(5)/PW(15)-S6(7)/PW(27) Q4-S10(7)/PW(17)-S12(2)/PW(12) Q5-S15(8)/PW(18) Q6-S19(4)/PW(14)-S20(5)/PW(15) |

| 2 | Q1-S1(3)/PW(23) Q2-S4(5)/PW(15)-S5(8)/PW(18) Q3-S8(6)/PW(16) Q5-S16(4)/PW(14) Q6-S19(3)/PW(13)-S20(4)/PW(24) | |

| 3 | Q1-S1(4)/PW(17)-S2(2)/PW(12)-S3(3)/PW(23) Q2-S5(5)/PW(15) Q3-S7(6)/PW(16) Q4-S15(7)/PW(17) | |

| 4 | Q1-S1(3)/PW(25)-S2(5)/PW(17) Q2-S4(1)/PW(21)-S5(3)PW(18) Q3-S8(6)/PW(16)-S9(6)/PW(26) Q6-S20(7)/PW(17) | |

| 5 | Q1-S1(3)/PW(16)-S2(5)/PW(17) Q2-S5(8)/PW(18) Q3-S8(3)/PW(24)-S9(6)/PW(26) Q6-S20(3)/PW(17) | |

| 45 | 1 | Q1-S1(9)/PW(14)-S2(5)/PW(15)-S3(4)/PW(13) Q2-S6(8)/PW(18)-S7(6)/PW(12) Q4-S10(5)/PW(15)-S12(2)/PW(12) Q5-S15(6)/PW(16)-S16(5)/PW(15) Q6-S20(5)/PW(15) |

| 2 | Q1-S1(3)/PW(23)-S2(7)/PW(17) Q2-S4(6)/PW(19)-S5(8)/PW(18)-S6(6)/PW(16) Q3-S8(6)/PW(16)-S9(9)/PW(7) Q5-S16(4)/PW(24)-S17(5)/PW(25) Q6-S18(5)/PW(15)-S19(3)/PW(23)-S20(4)/PW(14) | |

| 3 | Q1-S1(8)/PW(18)-S3(3)/PW(23) Q2-S5(6)/PW(19) Q3-S7(7)/PW(17) Q4-S15(9)/PW(19)-S16(8)/PW(18) | |

| 4 | Q1-S1(6)/PW(16)-S2(8)/PW(18)-S3(5)/PW(25) Q2-S4(4)/PW(24)-S5(3)/PW(17)-S6(6)/PW(26) Q3-S8(6)/PW(16)-S9(5)/PW(25) Q6-S19(4)/PW(24)-S20(5)/PW(17) | |

| 5 | Q1-S1(5)/PW(15)-S2(6)/PW(16) Q2-S5(8)/PW(18) Q3-S8(8)/PW(21)-S9(6)/PW(16) Q6-S19(9)/PW(20) | |

| 46 | 1 | Q1-S1(4)/PW(17)-S2(2)/PW(15)-S3(8)/PW(18) Q2-S6(7)/PW(17)-S7(5)/PW(26) Q4-S10(7)/PW(17)-S12(2)/PW(22) Q5-S15(8)/PW(28) Q6-S19(4)/PW(24)-S20(5)/PW(15) |

| 2 | Q1-S1(3)/PW(23) Q2-S4(5)/PW(15)-S5(8)/PW(18) Q3-S8(6)/PW(16) Q5-S16(4)/PW(14) Q6-S19(3)/PW(23)-S20(4)/PW(24) | |

| 3 | Q1-S1(5)/PW(19)-S2(2)/PW(22)-S3(3)/PW(23) Q2-S5(5)/PW(15) Q3-S7(6)/PW(16) Q4-S15(7)/PW(14) | |

| 4 | Q1-S1(4)/PW(19)-S2(7)/PW(17) Q2-S4(2)/PW(19)-S5(8)/PW(18) Q3-S8(3)/PW(16)-S9(6)/PW(16) Q6-S20(7)/PW(17) | |

| 5 | Q1-S1(3)/PW(18)-S2(7)/PW(17) Q2-S5(8)/PW(8) Q3-S8(12)/PW(4)-S9(6)/PW(6) Q6-S20(3)/PW(16) | |

| 47 | 1 | Q1-S3(4)/PW(24) Q2-S5(8)/PW(8)-S6(7)/PW(17) Q4-S10(7)/PW(17)-S12(2)/PW(12) Q5-S15(8)/PW(18) Q6-S19(14)/PW(4)-S20(5)/PW(15) |

| 2 | Q1-S1(3)/PW(23) Q2-S4(5)/PW(5)-S5(8)/PW(8) Q3-S8(6)/PW(6) Q5-S16(4)/PW(14) Q6-S19(3)/PW(13)-S20(4)/PW(14) | |

| 3 | Q1-S1(7)/PW(17)-S2(9)/PW(18)-S3(3)/PW(13) Q2-S5(5)/PW(5) Q3-S7(6)/PW(6) Q4-S15(7)/PW(17) | |

| 4 | Q1-S1(6)/PW(13)-S2(7)/PW(17) Q2-S4(1)/PW(11)-S5(5)/PW(8) Q3-S8(3)/PW(16)-S9(6)/PW(21) Q6-S20(7)/PW(22) | |

| 5 | Q1-S1(3)/PW(12)-S2(7)/PW(17) Q2-S5(9)/PW(18) Q3-S8(4)/PW(14)-S9(6)/PW(16) Q6-S20(4)/PW(11) | |

| 48 | 1 | Q1-S1(6)/PW(19)-S3(8)/PW(18) Q2-S6(4)/PW(14) Q4-S10(7)/PW(17)-S12(2)/PW(12) Q5-S15(8)/PW(8) Q6-S19(4)/PW(14)-S20(5)/PW(15) |

| 2 | Q1-S1(6)/PW(21) Q2-S4(6)/PW(16)-S5(8)/PW(18) Q3-S8(6)/PW(19) Q5-S16(4)/PW(14) Q6-S19(3)/PW(13)-S20(4)/PW(14) | |

| 3 | Q1-S1(7)/PW(17)-S2(5)/PW(15)-S3(3)/PW(23) Q2-S5(5)/PW(15) Q3-S7(6)/PW(16) Q4-S15(7)/PW(17) | |

| 4 | Q1-S1(3)PW(13)-S2(7)/PW(17) Q2-S4(10)/PW(11)-S5(8)/PW(19) Q3-S8(4)/PW(16)-S9(6)/PW(16) Q6-S20(11)/PW(16) | |

| 5 | Q1-S1(4)/PW(14)-S2(7)/PW(17) Q2-S5(8)/PW(22) Q3-S8(6)/PW(14)-S9(3)/PW(16) Q6-S20(8)/PW(21) | |

| 49 | 1 | Q1-S3(6)/PW(11) Q2-S5(8)/PW(18)-S6(7)/PW(17)-S7(9)/PW(19) Q4-S11(6)/PW(9)-S12(4)/PW(12) Q5-S15(8)/PW(18) Q6-S19(5)/PW(13)-S20(5)/PW(11) |

| 2 | Q1-S1(6)/PW(8)-S2(9)/PW(9) Q2-S4(5)/PW(15)-S5(8)/PW(8) Q3-S7(7)/PW(7)-S8(6)/PW(6) Q5-S16(4)/PW(14)-S17(6)/PW(6) Q6-S20(4)/PW(14) | |

| 3 | Q1-S1(6)/PW(17)-S3(3)/PW(13) Q2-S5(5)/PW(15)-S6(8)/PW(18) Q3-S7(6)/PW(22)-S8(8)/PW(8) Q4-S15(7)/PW(17)-S16(9)/PW(9) | |

| 4 | Q1-S1(3)/PW(21)-S2(7)/PW(17)-S3(4)/PW(18) Q2-S4(3)/PW(11)-S5(6)/PW(18) Q3-S8(6)/PW(14)-S9(6)/PW(13) Q6-S20(7)/PW(17) | |

| 5 | Q1-S1(1)/PW(15)-S2(7)/PW(11)-S3(7)/PW(17) Q2-S5(8)/PW(8) Q3-S8(4)/PW(22)-S9(6)/PW(16) Q6-S19(8)/PW(18)-S20(7)/PW(21) | |

| 50 | 1 | Q2-S5(4)/PW(14)-S6(5)/PW(15) Q4-S10(7)/PW(17)-S11(8)/PW(18)-S12(2)/PW(22) Q5-S15(8)/PW(21)-S17(9)/PW(19) Q6-S19(4)/PW(14)-S20(5)/PW(15) |

| 2 | Q1-S1(7)/PW(23)-S2(5)/PW(25) Q2-S4(5)/PW(25)-S5(7)/PW(28)-S6(4)/PW(24) Q3-S8(4)/PW(14) Q5-S16(2)/PW(14)-S17(5)/PW(15) Q6-S19(3)/PW(13)-S20(4)/PW(14) | |

| 3 | Q1-S1(6)/PW(16)-S2(8)/PW(18)-S3(3)/PW(13) Q2-S5(5)/PW(15)-S6(7)/PW(17) Q3-S7(6)/PW(16)-S8(8)/PW(18) Q4-S15(7)/PW(17) | |

| 4 | Q1-S1(4)/PW(15)-S2(7)/PW(17) Q2-S4(4)/PW(14)-S5(8)/PW(21) Q3-S8(5)/PW(16)-S9(6)/PW(16) Q6-S18(5)/PW(18)-S20(7)/PW(17) | |

| 5 | Q1-S1(4)/PW(14)-S2(6)/PW(17)-S3(8)/PW(18) Q2-S5(8)/PW(18) Q3-S8(5)/PW(14)-S9(6)/PW(26) Q6-S19(7)/PW(17) | |

| 51 | 1 | Q1-S2(9)/PW(18) Q2-S5(4)/PW(14)-S6(7)7PW(17) Q4-S10(4)/PW(14)-S11(8)/PW(18)-S12(5)/PW(15) Q5-S15(8)/PW(8)-S16(7)/PW(7) Q6-S18(6)/PW(16)-S19(8)/PW(18)-S20(9)/PW(21) |

| 2 | Q1-S1(8)/PW(10)-S2(8)/PW(12) Q2-S4(5)/PW(17)-S5(8)/PW(20)-S6(9)/PW(19) Q3-S8(6)/PW(16) Q5-S16(3)/PW(14) Q6-S19(3)/PW(11)-S20(4)/PW(14) | |

| 3 | Q1-S2(5)/PW(15) Q2-S6(6)/PW(15)-S7(7)/PW(17) Q4-S15(7)/PW(16) | |

| 4 | Q1-S1(8)/PW(17)-S2(4)/PW(19)-S3(9)/PW(9) Q2-S4(8)/PW(21)-S5(5)/PW(10) Q3-S8(5)/PW(15)-S9(6)/PW(16) Q5-S18(4)/PW(14) Q6-S19(8)/PW(18)-S20(7)/PW(17) | |

| 5 | Q1-S1(5)/PW(16)-S2(7)/PW(17) Q2-S4(7)/PW(17)-S5(8)/PW(12) Q3-S7(5)/PW(15)-S8(4)/PW(24)-S9(6)/PW(16) Q6-S19(8)/PW(20)-S20(6)/PW(16) | |

| 52 | 1 | Q1-S3(8)/PW(23) Q2-S6(6)/PW(16)-S7(5)/PW(15) Q4-S10(3)/PW(14)-S11(3)/PW(13)-S12(2)/PW(12) Q5-S15(8)/PW(18) Q6-S20(5)/PW(15) |

| 2 | Q1-S1(5)/PW(21)-S2(6)/PW(18) Q2-S4(6)/PW(24)-S5(7)/PW(17) Q3-S8(7)/PW(14) Q5-S16(5)/PW(15)-S17(4)/PW(14) Q6-S19(7)/PW(17)-S20(8)/PW(18) | |

| 3 | Q1-S1(4)/PW(22)-S2(6)/PW(18) Q2-S5(7)/PW(17)-S6(5)/PW(24) Q3-S7(6)/PW(11)-S8(5)/PW(15) Q4-S15(7)/PW(19)-S16(8)/PW(18) | |

| 4 | Q1-S1(4)/PW(18)-S2(6)/PW(16) Q2-S4(5)/PW(15)-S5(4)/PW(24) Q3-S8(7)/PW(24) Q6-S20(7)/PW(21) | |

| 5 | Q1-S2(8)/PW(8) Q2-S5(7)/PW(18) Q3-S8(4)/PW(24)-S9(6)/PW(16) Q6-S19(9)/PW(19) | |

| 53 | 1 | Q1-S2(9)/PW(18)-S3(3)/PW(12) Q2-S4(6)/PW(16)-S6(7)/PW(17) Q4-S10(6)/PW(20)-S11(8)/PW(18)-S12(2)/PW(12) Q5-S15(7)/PW(18)-S16(9)/PW(9) Q6-S18(7)/PW(17)-S19(6)/PW(16)-S20(5)/PW(20) |

| 2 | Q1-S1(8)/PW(15)-S2(6)/PW(26) Q2-S4(5)/PW(15)-S5(8)/PW(18)-S6(7)/PW(17) Q3-S8(6)/PW(24)-S9(7)/PW(17) Q5-S16(4)/PW(24)-S17(5)/PW(15) Q6-S19(6)/PW(16) | |

| 3 | Q1-S3(3)/PW(13) Q2-S5(5)/PW(15)-S6(7)/PW(17) Q3-S7(6)/PW(16)-S8(7)/PW(17) Q4-S15(7)/PW(17)-S16(6)/PW(16) | |

| 4 | Q1-S2(7)/PW(17) Q2-S5(8)/PW(18) Q3-S8(5)/PW(15)-S9(6)/PW(16)-S10(4)/PW(24) Q6-S19(8)/PW(18) | |

| 5 | Q1-S1(1)/PW(24)-S2(7)/PW(17) Q2-S5(3)/PW(21) Q3-S8(4)/PW(24)-S9(6)/PW(16) Q6-S18(4)/PW(22)-S19(8)/PW(19) | |

| 54 | 1 | Q2-S6(9)/PW(17) Q4-S10(7)/PW(21)-S12(1)/PW(22) Q5-S15(10)/PW(18) Q6-S19(11)/PW(14)-S20(5)/PW(15) |

| 2 | Q1-S1(3)/PW(23) Q2-S4(5)/PW(15)-S5(8)/PW(18) Q3-S8(6)/PW(16) Q5-S16(4)/PW(24) Q6-S19(3)/PW(23)-S20(4)/PW(24) | |

| 3 | Q1-S1(4)/PW(17)-S2(2)/PW(22)-S3(3)/PW(13) Q2-S5(5)/PW(15) Q3-S7(6)/PW(16) Q4-S15(7)/PW(17) | |

| 4 | Q1-S1(3)/PW(12)-S2(6)(PW(14) Q2-S4(2)/PW(11)-S5(8)/PW(18) Q3-S8(6)/PW(23)-S9(6)/PW(16) Q6-S20(7)/PW(17) | |

| 5 | Q1-S1(1)/PW(21)-S2(5)/PW(17) Q2-S5(3)/PW(18) Q3-S8(4)/PW(14)-S9(6)/PW(16) Q6-S20(7)/PW(22) | |

| 55 | 1 | Q1-S1(5)/PW(18) Q2-S6(7)/PW(17)-S7(5)/PW(15) Q3-S15(8)/PW(8) Q4-S10(4)/PW(17)-S11(5)/PW(15)-S12(2)/PW(23) Q5-S15(8)/PW(8) Q6-S18(9)/PW(19)-S19(4)/PW(14)-S20(5)/PW(15) |

| 2 | Q1-S1(3)/PW(23)-S2(7)/PW(17) Q3-S8(6)/PW(16) Q5-S16(4)/PW(14) Q6-S19(3)/PW(13)-S20(4)/PW(14) | |

| 3 | Q1-S1(11)/PW(19)-S3(3)/PW(23) Q2-S5(5)/PW(25) Q3-S7(6)/PW(16) Q4-S15(7)/PW(17) | |

| 4 | Q1-S1(6)/PW(26)-S2(7)/PW(11)-S3(8)/PW(18) Q2-S4(9)/PW(15)-S5(8)/PW(18) Q3-S8(8)/PW(16)-S9(6)/PW(19)-S10(7)/PW(17) Q6-S19(6)/PW(16)-S20(9)/PW(16) | |

| 5 | Q1-S2(7)/PW(17) Q2-S5(8)/PW(8) Q3-S9(6)/PW(16) Q6-S19(9)/PW(24)-S20(7)/PW(17) | |

| 56 | 1 | Q4-S10(7)/PW(15)-S12(9)/PW(20) Q5-S15(8)/PW(18) |

| 2 | Q2-S4(5)/PW(15)-S5(8)/PW(18) Q3-S8(6)/PW(16) Q5-S16(5)/PW(24) Q6-S19(3)/PW(13)-S20(4)/PW(24) | |

| 3 | Q1-S1(9)/PW(18)-S2(2)/PW(24)-S3(3)/PW(23) Q2-S5(5)/PW(15) Q3-S7(6)/PW(16) Q4-S15(7)/PW(17) | |

| 4 | Q1-S1(3)/PW(18)-S2(7)/PW(17) Q2-S4(3)/PW(19)-S5(8)/PW(21) Q3-S8(10)/PW(21)-S9(6)/PW(15) Q6-S20(7)/PW(18) | |

| 5 | Q1-S1(4)/PW(13)-S2(9)/PW(20)-S3(9)/PW(15) Q2-S5(8)/PW(19) Q3-S6(4)/PW(16)-S8(7)/PW(18)-S9(6)/PW(16) Q6-S19(5)/PW(17)-S20(4)/PW(21) | |

| 57 | 1 | Q1-S2(9)/PW(21)-S3(5)/PW(15) Q2-S6(4)/PW(17) Q4-S10(7)/PW(17)-S12(5)/PW(22) Q5-S15(8)/PW(18)-S16(5)/PW(25) Q6-S18(6)/PW(26)-S20(5)/PW(25) |

| 2 | Q1-S1(3)/PW(23)-S2(8)/PW(18) Q2-S4(5)/PW(15) Q3-S7(4)/PW(14)-S8(6)/PW(16) Q5-S16(4)/PW(24)-S17(3)/PW(17) Q6-S20(9)/PW(19) | |

| 3 | Q1-S1(8)/PW(19)-S3(4)/PW(14) Q2-S5(5)/PW(15)-S6(7)/PW(17) Q3-S7(6)/PW(26)-S8(5)/PW(15) Q4-S15(7)/PW(17)-S16(8)/PW(18) Q5-S18(9)/PW(19) | |

| 4 | Q1-S1(3)/PW(23)-S2(7)/PW(17) Q2-S4(1)/PW(21)-S5(4)/PW(8) Q3-S8(6)/PW(13)-S9(6)/PW(19) Q6-S20(7)/PW(22) | |

| 5 | Q1-S2(9)/PW(21) Q2-S5(8)/PW(18) Q3-S8(4)/PW(14)-S9(6)/PW(16) | |

| 58 | 1 | Q1-S2(9)/PW(18)-S3(4)/PW(14) Q2-S6(7)/PW(17) Q4-S10(7)/PW(27)-S12(9)/PW(19) Q5-S15(8)/PW(18) Q6-S18(5)PW(15)-S19(4)/PW(24)-S20(5)/PW(25) |

| 2 | Q1-S1(8)/PW(19)-S2(5)/PW(25) Q2-S4(9)/PW(24) Q3-S8(6)/PW(26)-S9(6)/PW(16) Q5-S16(6)/PW(16)-S17(7)/PW(17) Q6-S19(8)/PW(18)-S20(4)/PW(24) | |

| 3 | Q1-S1(9)/PW(19)-S3(7)/PW(17) Q2-S5(5)PW(15) Q3-S7(6)/PW(16)-S8(5)/PW(15) Q4-S15(9)/PW(19)-S16(4)/PW(24) | |

| 4 | Q1-S2(9)/PW(9)-S3(4)/PW(14) Q2-S5(3)/PW(13)-S6(5)/PW(15) Q3-S8(6)/PW(16) Q6-S18(3)/PW(13)-S19(8)/PW(18)-S20(4)/PW(14) | |

| 5 | Q1-S1(6)/PW(19)-S2(7)/PW(16)-S3(5)/PW(15) Q2-S5(8)/PW(8)-S8(4)/PW(14) Q3-S8(4)/PW(14)-S9(6)/PW(26)-S10(5)/PW(15) Q6-S19(9)/PW(18)-S20(7)/PW(13) | |

| 59 | 1 | Q2-S6(3)/PW(14)-S7(8)/PW(18) Q4-S10(7)/PW(17)-S11(5)/PW(25)-S12(2)/PW(22) Q5-S15(8)/PW(18) Q6-S19(4)/PW(24)-S20(5)/PW(15) |

| 2 | Q1-S1(6)/PW(16) Q2-S4(5)/PW(15)-S5(8)/PW(18) Q3-S8(6)/PW(26) Q5-S16(5)/PW(26) Q6-S19(13)/PW(13)-S20(4)/PW(14) | |

| 3 | Q1-S2(9)/PW(9)-S3(7)/PW(18) Q2-S5(5)/PW(15) Q3-S7(6)/PW(16) Q4-S15(7)/PW(17) | |

| 4 | Q1-S2(9)/PW(19) Q2-S4(11)/PW(11)-S5(8)/PW(18) Q3-S8(4)/PW(7)-S9(6)/PW(16) Q6-S19(2)/PW(22)-S20(3)/PW(14) | |

| 5 | Q2-S5(8)/PW(8) Q3-S8(4)/PW(24)-S9(6)/PW(16) Q6-S19(5)/PW(15)-S20(6)/PW(19) | |

| 60 | 1 | Q2-S6(7)/PW(11)-S7(9)/PW(9) Q3-S9(8)PW(15) Q4-S10(3)/PW(19)-S11(8)/PW(18)-S12(2)/PW(22) Q5-S15(9)/PW(9) Q6-S18(6)/PW(16)-S19(4)/PW(14)-S20(5)/PW(25) |

| 2 | Q1-S1(3)/PW(23)-S2(8)/PW(18) Q2-S4(9)/PW(9)-S5(6)/PW(16) Q3-S7(7)/PW(17)-S8(6)/PW(16) Q6-S20(4)/PW(14) | |

| 3 | Q1-S2(12)/PW(12) Q2-S5(8)/PW(9) Q3-S7(6)/PW(16)-S8(7)/PW(17) Q4-S15(8)/PW(19)-S16(9)/PW(9) Q6-S19(8)/PW(18) | |

| 4 | Q1-S2(7)/PW(17)-S3(8)/PW(18) Q3-S8(6)/PW(16)-S9(6)/PW(16)-S10(5)/PW(25) Q5-S17(9)/PW(19) Q6-S19(5)/PW(25)-S20(8)/PW(18) | |

| 5 | Q2-S5(3)/PW(18) Q3-S8(5)/PW(21)-S9(6)/PW(16) | |

| 61 | 1 | Q1-S1(6)/PW(21)-S2(5)/PW(19)-S3(4)/PW(14) Q4-S10(5)/PW(15)-S11(7)/PW(16)-S12(8)/PW(22) Q6-S19(4)/PW(24)-S20(5)/PW(15) |

| 2 | Q2-S4(5)/PW(25)-S5(8)/PW(18) Q3-S8(6)/PW(26)-S9(7)/PW(17) Q6-S19(9)/PW(9) | |

| 3 | Q1-S3(5)/PW(9) Q2-S5(5)/PW(25)-S6(7)/PW(17) Q3-S7(6)/PW(26) Q4-S15(7)/PW(17) Q6-S18(8)/PW(18)-S19(9)/PW(19) | |

| 4 | Q1-S2(7)/PW(17) Q2-S4(11)/PW(11)-S5(8)/PW(18) Q3-S8(6)/PW(19)-S9(6)/PW(18) Q6-S20(7)/PW(20) | |

| 5 | Q1-S1(4)/PW(24)-S2(5)/PW(16) Q2-S5(8)/PW(27) Q3-S8(4)/PW(22)-S9(6)/PW(16) Q4-S11(4)/PW(17) | |

| 62 | 1 | Q1-S1(8)/PW(18)-S3(7)/PW(24) Q2-S5(6)/PW(18) Q4-S10(7)/PW(17)-S11(8)/PW(9)-S12(5)/PW(17) Q5-S15(9)/PW(8)-S16(3)/PW(15) Q6-S20(7)/PW(9) |

| 2 | Q1-S1(6)/PW(3)-S2(8)/PW(9) Q3-S8(4)/PW(16)-S9(5)/PW(8) Q5-S16(8)/PW(14)-S17(5)/PW(15) Q6-S19(7)/PW(9) | |

| 3 | Q1-S1(6)/PW(18)-S2(7)/PW(12) Q2-S5(7)/PW(9) Q3-S7(8)/PW(16)-S8(4)/PW(19) Q4-S15(7)/PW(27)-S16(6)/PW(18) | |

| 4 | Q2-S5(9)/PW(8)-S6(3)/PW(7) Q3-S8(9)/PW(6)-S9(5)/PW(9) Q6-S18(3)/PW(3)-S20(9)/PW(9) | |

| 5 | Q1-S2(5)/PW(17)-S3(9)/PW(9) Q2-S4(2)/PW(20)-S5(8)/PW(18) Q3-S8(5)/PW(21)-S9(6)/PW(16)-S10(3)/PW(13) Q4-S16(4)/PW(14) Q5-S17(3)/PW(18)-S18(5)/PW(15) Q6-S20(9)/PW(21) | |

| 63 | 1 | Q1-S3(9)/PW(24) Q2-S6(7)/PW(17) Q5-S15(8)/PW(18)-S16(9)/PW(9) |

| 2 | Q1-S1(7)/PW(23)-S2(3)/PW(18) Q2-S4(5)/PW(15)-S5(8)/PW(18)-S6(7)/PW(17) Q3-S8(6)/PW(16) Q4-S15(6)/PW(16) Q6-S20(9)/PW(19) | |

| 3 | Q1-S1(7)/PW(9)-S2(8)/PW(8) Q2-S4(4)/PW(24)-S5(5)/PW(25) Q3-S7(6)/PW(26)-S8(9)/PW(17) | |

| 4 | Q2-S4(3)/PW(23)-S5(7)/PW(17)-S6(3)/PW(18) Q6-S19(9)/PW(23)-S20(7)/PW(11) | |

| 5 | Q2-S5(7)/PW(19) Q3-S9(6)/PW(6) Q6-S18(8)/PW(9)-S20(5)/PW(15) | |

| 64 | 1 | Q1-S1(9)/PW(14)-S2(3)/PW(20)-S3(2)/PW(14) Q2-S5(9)/PW(16)-S6(7)/PW(17) Q4-S10(2)/PW(19)-S11(8)/PW(18) Q5-S14(6)/PW(16)-S15(8)/PW(18) Q6-S19(6)/PW(16)-S20(3)/PW(13) |

| 2 | Q2-S5(6)/PW(16)-S6(7)/PW(17) Q3-S8(9)/PW(19)-S9(5)/PW(15) Q5-S16(7)/PW(23)-S17(2)/PW(22) Q6-S20(4)/PW(12) | |

| 3 | Q1-S1(6)/PW(16)-S3(9)/PW(9) Q4-S15(7)/PW(21)-S16(5)/PW(15) Q6-S19(8)/PW(18) | |

| 4 | Q1-S1(3)/PW(13)-S2(7)/PW(17)-S3(6)/PW(16) Q2-S5(8)/PW(8)-S6(5)/PW(15) Q6-S19(8)/PW(18)-S20(9)/PW(9) | |

| 5 | Q1-S2(3)/PW(17) Q2-S5(9)/PW(14)-S6(5)/PW(15) Q3-S8(7)/PW(21) | |

| 65 | 1 | Q1-S1(7)/PW(15)-S2(4)/PW(16)-S3(5)/PW(14) Q2-S5(8)PW(18)-S6(7)/PW(17)-S7(5)/PW(15) Q3-S8(3)/PW(23) Q4-S12(9)/PW(9) Q5-S15(8)/PW(18) |

| 2 | Q1-S1(9)/PW(9)-S2(5)/PW(15) Q2-S4(4)/PW(24)-S5(7)/PW(17) Q3-S8(5)/PW(15)-S9(4)PW(24) Q5-S16(8)/PW(8) Q6-S19(9)/PW(9)-S20(6)/PW(6) | |

| 3 | Q1-S2(7)/PW(18)-S3(9)/PW(9) Q2-S5(5)/PW(15) Q3-S6(4)/PW(10)-S7(6)/PW(16) | |

| 4 | Q1-S1(5)/PW(16)-S2(7)/PW(17)-S3(8)/PW(18) Q2-S4(9)/PW(12)-S5(8)/PW(18)-S6(3)/PW(11) Q3-S8(6)/PW(16)-S9(6)/PW(16) Q6-S19(8)/PW(18)-S20(7)/PW(17) | |

| 5 | Q1-S2(8)/PW(17) Q2-S4(5)/PW(14)-S5(3)/PW(8) Q3-S8(7)/PW(14)-S9(6)/PW(16) Q6-S19(6)/PW(16)-S20(7)/PW(17) | |

| 66 | 1 | Q1-S3(4)/PW(14) Q2-S6(7)/PW(17)-S7(8)/PW(18) Q4-S10(7)/PW(17) Q5-S15(8)/PW(8)-S16(8)/PW(8) Q6-S18(4)/PW(14)-S20(5)/PW(15) |

| 2 | Q1-S1(7)/PW(17)-S2(8)/PW(18) Q2-S4(2)/PW(21)-S5(3)/PW(13)-S6(4)/PW(24) Q3-S7(5)/PW(15)-S8(6)/PW(16)-S9(7)/PW(17) Q5-S16(4)/PW(14)-S17(5)/PW(15) Q6-S18(7)/PW(17)-S20(4)/PW(24) | |

| 3 | Q1-S1(8)/PW(18)-S2(9)/PW(19) Q2-S5(5)/PW(15)-S6(6)/PW(16) Q3-S7(6)/PW(16)-S8(7)/PW(17) Q4-S14(7)/PW(17)-S15(8)/PW(18) | |

| 4 | Q2-S4(7)/PW(18)-S5(8)/PW(18) Q3-S8(9)/PW(19) | |

| 5 | Q1-S2(5)/PW(14) Q2-S5(8)/PW(16)-S6(7)/PW(17) Q3-S8(5)/PW(15)-S9(7)/PW(17) Q5-S16(6)/PW(16)-S17(3)/PW(23) Q6-S18(4)/PW(14)-S19(8)/PW(18) | |

| 67 | 1 | Q1-S1(7)/PW(19)-S2(1)/PW(21)-S3(4)/PW(14) Q2-S4(3)/PW(23)-S6(5)/PW(15) Q4-S10(7)/PW(15)-S11(6)/PW(16)-S12(2)/PW(12) Q6-S19(7)/PW(17) |

| 2 | Q1-S1(11)/PW(13)-S2(5)/PW(15)-S3(5)/PW(16) Q2-S5(9)/PW(15)-S6(7)/PW(8) Q3-S7(4)/PW(17)-S8(5)/PW(16) Q5-S6(6)/PW(4)-S17(8)PW(5) | |

| 3 | Q1-S1(6)/PW(16)-S3(8)/PW(23) Q2-S5(8)/PW(18)-S6(9)/PW(9) Q3-S7(7)/PW(17)-S8(8)/PW(19) Q4-S14(6)/PW(26)-S15(7)/PW(7) Q6-S19(8)/PW(18)-S20(6)/PW(14) | |

| 4 | Q1-S1(3)/PW(3)-S2(6)/PW(6)-S3(4)/PW(4) Q4-S5(8)/PW(8) Q6-S20(7)/PW(7) | |

| 5 | Q1-S1(6)/PW(24)-S2(7)/PW(17)-S3(8)/PW(18) Q2-S4(5)/PW(25)-S5(8)/PW(18) Q3-S8(3)/PW(24)-S9(6)/PW(16) Q5-S17(6)/PW(16) Q6-S19(4)/PW(21)-S20(7)/PW(17) | |

| 68 | 1 | Q1-S1(7)/PW(22)-S3(6)/PW(14) Q2-S6(9)/PW(9) Q4-S10(6)/PW(16)-S12(3)/PW(13) Q5-S15(8)/PW(18) Q6-S19(6)/PW(16)-S20(8)/PW(18) |

| 2 | Q1-S1(6)/PW(16) Q2-S4(6)/PW(22)-S5(8)/PW(18) Q3-S8(9)/PW(17) Q5-S16(6)/PW(6) Q6-S19(7)/PW(15)-S20(3)/PW(23) | |

| 3 | Q1-S1(9)/PW(19)-S3(6)/PW(26) Q2-S5(5)/PW(5) Q3-S7(7)/PW(7) Q4-S15(8)/PW(8) | |

| 4 | Q1-S1(4)/PW(14)-S2(8)/PW(18) Q2-S4(3)/PW(16)-S5(11)/PW(11) Q3-S8(9)PW(19)-S9(6)/PW(26) Q6-S19(4)/PW(14)-S20(8)/PW(18) | |

| 5 | Q1-S1(6)/PW(16)-S2(8)/PW(18) Q2-S5(8)(PW(18) Q3-S8(9)/PW(11)-S9(5)/PW(15) Q6-S19(3)/PW(23)-S20(6)/PW(16) | |

| 69 | 1 | Q1-S1(7)/PW(17)-S3(5)/PW(13) Q2-S6(9)/PW(8) Q4-S12(9)/PW(9) Q6-S20(6)/PW(16) |

| 2 | Q2-S4(9)/PW(11)-S5(6)/PW(16)-S6(5)/PW(15) Q3-S7(7)/PW(17)-S8(8)/PW(8) Q4-S9(9)/PW(9) Q5-S16(3)/PW(23)-S17(2)/PW(20) Q6-S20(4)/PW(9) | |

| 3 | Q1-S2(6)/PW(9)-S3(3)/PW(13) Q3-S7(7)/PW(17)-S8(8)/PW(18) Q6-S18(9)/PW(9) | |

| 4 | Q1-S2(9)/PW(17) Q2-S5(7)/PW(18)-S6(4)/PW(14) Q3-S7(6)/PW(15)-S8(6)/PW(16)-S9(6)/PW(16) Q6-S19(5)/PW(15)-S20(6)/PW(16) | |

| 5 | Q1-S2(7)/PW(17) Q2-S5(8)/PW(18) Q3-S8(4)/PW(14)-S9(6)/PW(16) Q5-S16(4)/PW(14)-S17(5)PW(15) Q6-S19(3)/PW(13)-S20(8)/PW(19) | |

| 70 | 1 | Q1-S1(10)/PW(17)-S2(2)/PW(11)-S3(4)/PW(15) Q2-S5(6)/PW(16)-S7(7)/PW(17) Q3-S8(5)/PW(15)-S9(4)/PW(24) Q5-S15(6)/PW(16) Q6-S20(9)/PW(19) |

| 2 | Q1-S1(3)/PW(14)-S2(5)/PW(15)-S3(8)/PW(18) Q2-S4(4)/PW(19)-S5(3)/PW(13) Q3-S7(3)/PW(23)-S8(9)/PW(9) Q5-S16(6)/PW(16)-S17(7)/PW(17) | |

| 3 | Q1-S2(13)/PW(17)-S3(3)PW(13) Q2-S5(6)/PW(16)-S6(7)/PW(17) Q3-S7(11)/PW(11) Q4-S15(3)/PW(23)-S16(4)/PW(14) Q6-S18(5)/PW(15)-S19(6)/PW(16) | |

| 4 | Q1-S1(9)/PW(9)-S2(7)/PW(17) Q2-S5(8)/PW(8) Q3-S8(5)/PW(15)-S9(4)/PW(14) Q6-S19(8)/PW(8)-S20(9)/PW(9) | |

| 5 | Q1-S2(8)/PW(9)-S3(7)/PW(17) Q2-S4(6)/PW(16)-S5(5)/PW(15) Q3-S8(4)/PW(24)-S9(3)/PW(16) Q4-S11(7)/PW(16)-S12(8)/PW(8) Q5-S16(10)/PW(19)-S17(8)/PW(18) | |

| 71 | 1 | Q1-S1(7)/PW(18)-S3(5)PW(25) Q2-S6(6)/PW(16) Q4-S10(6)/PW(16)-S12(3)/PW(23) Q5-S15(9)/PW(19) Q6-S19/PW(17)-S20(3)/PW(13) |

| 2 | Q1-S1(6)/PW(16) Q2-S4(9)/PW(17)-S5(8)/PW(18) Q3-S8(5)/PW(19) Q5-S16(5)/PW(25) Q6-S19(4)/PW(24)-S20(5)/PW(15) | |

| 3 | Q1-S1(6)/PW(16)-S2(3)/PW(13)-S3(5)/PW(15) Q2-S5(8)/PW(19) Q3-S7(3)/PW(17) Q4-S15(9)/PW(19) | |

| 4 | Q1-S1(7)/PW(17)-S2(3)/PW(23) Q2-S4(2)/PW(20)-S5(4)/PW(14) Q3-S8(7)/PW(22)-S9(3)/PW(23) Q6-S20(10)/PW(18) | |

| 5 | Q1-S1(3)/PW(25)-S2(3)/PW(19) Q2-S5(5)/PW(24) Q3-S8(6)/PW(23)-S9(8)/PW(17) Q6-S20(8)/PW(26) | |

| 72 | 1 | Q3-S7(9)/PW(16) Q4-S10(8)/PW(18)-S11(6)/PW(17)-S12(3)/PW(23) Q5-S15(5)/PW(14) Q6-S20(5)/PW(15) |

| 2 | Q1-S1(8)/PW(19)-S2(8)/PW(18)-S3(4)/PW(24) Q2-S5(3)/PW(13) Q3-S7(5)/PW(23)-S8(7)/PW(18) Q5-S16(6)/PW(16)-S17(7)/PW(17) Q6-S19(8)/PW(18) | |

| 3 | Q1-S1(7)/PW(9) Q3-S7(6)/PW(16)-S8(9)/PW(19) Q4-S14(6)/PW(26)-S15(7)/PW(17) Q5-S16(9)/PW(9)-S17(3)/PW(13) Q6-S18(8)/PW(8)-S19(9)/PW(9) | |

| 4 | Q1-S1(10)/PW(16)-S2(3)/PW(17)-S3(5)/PW(10) Q2-S4(2)/PW(5) Q3-S8(3)/PW(13)-S9(7)/PW(7) Q5-S16(5)/PW(15) Q6-S18(5)/PW(15)-S19(9)/PW(9) | |

| 5 | Q1-S2(9)/PW(9) Q3-S8(3)/PW(13)-S9(2)/PW(21) Q6-S19(5)/PW(16)-S20(3)/PW(27) | |

| 73 | 1 | Q1-S1(6)/PW(23)-S2(2)/PW(19)-S3(4)/PW(13) Q2-S5(5)/PW(15)-S6(7)/PW(17) Q3-S7(3)/PW(16)-S8(5)/PW(20) Q4-S10(4)/PW(17)-S11(3)/PW(13)-S12(2)/PW(21) Q5-S15(8)/PW(18)-S16(4)/PW(24) Q6-S18(6)/PW(16)-S19(4)/PW(24)-S20(5)/PW(15) |

| 2 | Q1-S1(5)/PW(13)-S2(8)/PW(18) Q2-S4(5)/PW(15)-S5(8)/PW(18) Q3-S8(6)/PW(16)-S9(7)/PW(17) Q5-S16(4)/PW(14)-S17(5)/PW(23) Q6-S18(5)/PW(15)-S20(4)/PW(24) | |

| 3 | Q1-S1(7)/PW(16)-S3(13)/PW(23) Q2-S5(6)/PW(16) Q3-S7(9)/PW(19) Q4-S15(8)/PW(18)-S16(9)/PW(19) | |

| 4 | Q1-S2(9)/PW(19)-S3(5)/PW(15) Q2-S4(3)/PW(11)-S5(9)/PW(9) Q3-S7(4)/PW(14) Q4-S10(5)/PW(15)-S11(6)/PW(16) | |

| 5 | Q1-S2(8)/PW(19)-S3(8)/PW(19) Q2-S4(4)/PW(22)-S5(8)/PW(12) Q3-S8(3)PW(13)-S9(9)/PW(16)-S10(2)/PW(14) Q5-S16(8)/PW(20)-S17(3)/PW(13) Q6-S18(7)/PW(15)-S19(6)/PW(11)-S20(3)/PW(27) | |

| 74 | 1 | Q4-S10(8)/PW(16)-S11(8)/PW(18)-S12(2)PW(22) Q5-S15(9)/PW(18)-S16(3)/PW(18) Q6-S19(5)/PW(15) |

| 2 | Q1-S1(3)/PW(23)-S2(8)/PW(18) Q2-S5(8)/PW(18)-S6(7)/PW(21) Q3-S8(5)/PW(22)-S9(4)/PW(18)-S10(3)/PW(13) Q5-S16(4)/PW(14)-S17(5) Q6-S18(5)/PW(17)-S20(4)/PW(20) | |

| 3 | Q1-S1(9)/PW(9)-S3(5)/PW(15) Q2-S5(5)/PW(15)-S6(6)/PW(16) Q3-S7(6)/PW(16)-S8(8)/PW(18) Q4-S15(7)/PW(17)-S16(8)/PW(18) | |

| 4 | Q1-S1(8)/PW(23)-S2(7)/PW(17)-S3(4)/PW(24) Q2-S5(8)/PW(18) Q3-S8(6)/PW(16)-S9(5)/PW(15) Q6-S19(9)/PW(8 | |

| 5 | Q1-S1(6)/PW(16)-S2(7)/PW(23)-S3(6)/PW(15) Q2-S5(7)/PW(18)-S6(8)/PW(24) Q3-S8(4)/PW(14)-S9(6)/PW(25)-S10(8)/PW(23) Q6-S18(4)/PW(14)-S19(6)/PW(15)-S20(8)/PW(17) | |

| 75 | 1 | Q2-S6(4)/PW(18)-S7(9)/PW(19) Q4-S10(6)/PW(17)-S12(5)/PW(22) Q5-S15(8)/PW(18) |

| 2 | Q1-S1(7)/PW(23) Q2-S4(5)/PW(15)-S5(8)/PW(18) Q3-S8(6)/PW(16) Q5-S16(5)/PW(14) Q6-S19(6)/PW(23)-S20(4)/PW(14) | |

| 3 | Q1-S1(6)/PW(17)-S2(2)/PW(22)-S3(5)/PW(15) Q2-S5(4)/PW(5) Q3-S7(3)/PW(6) Q4-S15(5)/PW(7) | |

| 4 | Q1-S1(4)/PW(23)-S2(7)/PW(17) Q2-S4(5)/PW(21)-S5(6)/PW(18) Q3-S8(8)/PW(6)-S9(6)/PW(6) Q6-S20(6)/PW(17) | |

| 5 | Q1-S1(1)/PW(11)-S2(4)/PW(17) Q2-S5(3)/PW(18) Q3-S8(5)/PW(15)-S9(6)/PW(16) Q6-S20(9)/PW(25) | |

| 76 | 1 | Q1-S1(7)/PW(24) Q2-S4(7)/PW(15) Q3-S7(4)/PW(13) Q4-S11(6)/PW(14)-S12(7)/PW(17) Q5-S14(5)/PW(18)-S15(4)/PW(14) Q6-S20(8)/PW(18) |

| 2 | Q1-S2(3)/PW(13)-S3(5)/PW(15) Q2-S5(7)/PW(17) Q4-S11(5)/PW(19)-S12(4)/PW(17)-S13(3)/PW(15) Q5-S14(8)/PW(18)-S15(4)/PW(14) Q6-S18(4)/PW(14)-S20(8)/PW(18) | |

| 3 | Q1-S1(5)/PW(16)-S2(7)/PW(19)-S3(4)/PW(14) Q3-S8(8)/PW(22) Q4-S12(9)/PW(19)-S13(8)/PW(26) Q5-S14(8)/PW(18)-S15(4)/PW(24). Q6-S18(9)/PW(19)-S20(8)/PW(18) | |

| 4 | Q1-S1(9)/PW(19)-S2(8)/PW(18)-S3(5)/PW(25) Q2-S5(5)/PW(25) Q4-S11(9)/PW(19)-S12(4)/PW(24)-S13(5)/PW(15) Q5-S14(3)/PW(23)-S15(4)/PW(24) Q6-S20(8)/PW(28) | |

| 5 | Q1-S1(7)/PW(16)-S2(8)/PW(19)-S3(4)/PW(24) Q3-S8(6)/PW(16) Q4-S12(7)/PW(19)-S13(6)/PW(16) Q5-S14(8)/PW(18)-S15(4)/PW(24) Q6-S18(10)/PW(19)-S20(6)/PW(28) | |

| 77 | 1 | Q1-S3(7)/PW(18) Q2-S6(5)/PW(15) Q3-S7(4)/PW(14) Q4-S9(6)PW(24)-S10(5)/PW(15) Q5-S13(7)/PW(18)-S14(9)/PW(19) Q6-S19(6)/PW(24) |

| 2 | Q1-S1(5)/PW(20) Q2-S6(8)/PW(18) Q4-S11(8)/PW(18)-S13(3)/PW(23) Q5-S14(7)/PW(27) Q6-S18(8)/PW(18)-S19(5)/PW(22) | |

| 3 | Q1-S2(3)/PW(25)-S3(6)/PW(23) Q2-S6(4)/PW(19) Q3-S7(7)/PW(24)-S8(8)/PW(17) Q4-S8(5)/PW(8) Q5-S16(5)/PW(14) Q6-S20(7)/PW(17) | |

| 4 | Q1-S1(8)/PW(21)-S2(7)/PW(17)-S3(3)/PW(23) Q2-S6(8)/PW(8) Q4-S11(9)/PW(8)-S13(2)/PW(23) Q5-S14(7)/PW(17) Q6-S18(8)/PW(28)-S19(2)/PW(22) | |

| 5 | Q1-S2(5)/PW(15)-S3(3)/PW(23) Q3-S7(7)/PW(24)-S8(7)/PW(17) Q4-S8(8)/PW(18) Q5-S15(3)/PW(25)-S16(6)/PW(24) Q6-S20(7)/PW(24) | |

| 78 | 1 | Q1-S1(8)/PW(22)-S3(4)/PW(14) Q2-S6(6)/PW(17) Q4-S10(8)/PW(17)-S12(2)/PW(22) Q5-S15(8)/PW(18) Q6-S19(4)/PW(14)-S20(5)/PW(15) |

| 2 | Q1-S1(3)/PW(23) Q2-S4(5)/PW(15)-S5(8)/PW(18) Q3-S8(6)/PW(26) Q5-S16(4)/PW(18) Q6-S19(3)/PW(23)-S20(4)/PW(24) | |

| 3 | Q1-S1(6)/PW(17)-S2(2)/PW(21)-S3(3)/PW(13) Q2-S5(5)/PW(15) Q3-S7(6)/PW(16) Q4-S15(7)/PW(17) | |

| 4 | Q1-S1(8)/PW(23)-S2(7)/PW(17) Q2-S4(6)/PW(19)-S5(6)/PW(18) Q3-S8(5)/PW(16)-S9(6)/PW(16) Q6-S20(3)/PW(17) | |

| 5 | Q1-S1(3)/PW(11)-S2(7)/PW(17) Q2-S5(8)/PW(18) Q3-S8(8)/PW(24)-S9(6)/PW(16) Q6-S20(5)/PW(26) | |

| 79 | 1 | Q1-S1(5)/PW(11)-S2(2)/PW(22)-S3(4)/PW(14) Q2-S4(1)/PW(25)-S6(7)/PW(17) Q4-S10(7)/PW(17)-S12(2)/PW(12) Q5-S15(8)/PW(18) Q6-S19(4)/PW(14)-S20(5)/PW(15) |

| 2 | Q1-S1(3)/PW(23) Q2-S4(5)/PW(19)-S5(8)/PW(18) Q3-S8(6)/PW(26) Q5-S16(5)/PW(14) Q6-S19(3)/PW(23)-S20(4)/PW(24) | |

| 3 | Q1-S1(7)/PW(17)-S2(6)/PW(22)-S3(3)/PW(23) Q2-S5(4)/PW(19) Q3-S7(6)/PW(16) Q4-S15(7)/PW(17) | |

| 4 | Q1-S1(3)/PW(23)-S2(7)/PW(17) Q2-S4(3)/PW(21)-S5(8)7PW(18) Q3-S8(2)/PW(16)-S9(6)/PW(26) Q6-S20(11)/PW(17) | |

| 5 | Q1-S1(4)/PW(21)-S2(6)/PW(17) Q2-S5(8)/PW(18) Q3-S8(5)/PW(24)-S9(6)/PW(26) Q6-S20(8)/PW(27) | |

| 80 | 1 | Q1-S1(8)/PW(19)-S2(5)/PW(25)-S3(4)/PW(19) Q2-S6(8)/PW(18)-S7(9)/PW(19) Q4-S10(5)/PW(15)-S12(2)/PW(12) Q5-S15(6)/PW(16)-S16(5)/PW(15) Q6-S20(5)/PW(15) |

| 2 | Q1-S1(7)/PW(23)-S2(4)/PW(17) Q2-S4(5)/PW(19)-S5(7)/PW(18)-S6(6)/PW(16) Q3-S8(5)/PW(16)-S9(7)/PW(7) Q5-S16(4)/PW(24)-S17(3)/PW(25) Q6-S18(5)/PW(25)-S19(6)/PW(23)-S20(4)/PW(14) | |

| 3 | Q1-S1(6)/PW(18)-S3(7)/PW(23) Q2-S5(7)/PW(19) Q3-S7(5)/PW(17) Q4-S15(6)/PW(25)-S16(8)/PW(18) | |

| 4 | Q1-S1(6)/PW(16)-S2(8)/PW(18)-S3(5)/PW(25) Q2-S4(4)/PW(24)-S5(7)/PW(17)-S6(6)/PW(26) Q3-S8(6)/PW(16)-S9(5)/PW(25) Q6-S19(5)/PW(24)-S20(7)/PW(19) | |

| 5 | Q1-S1(7)/PW(15)-S2(6)/PW(20) Q2-S5(7)/PW(21) Q3-S8(4)/PW(18)-S9(6)/PW(16) Q6-S19(8)/PW(19) |

| Part | Part Demands | Movement Costs between Cells | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1. Period | 2. Period | 3. Period | 4. Period | 5. Period | 1. Period | 2. Period | 3. Period | 4. Period | 5. Period | |

| 1 | 150 | 90 | 80 | 70 | 65 | 45 | 40 | 35 | 30 | 40 |

| 2 | 80 | 75 | 70 | 75 | 70 | 35 | 50 | 45 | 40 | 45 |

| 3 | 40 | 35 | 30 | 50 | 45 | 30 | 47 | 40 | 37 | 47 |

| 4 | 75 | 70 | 65 | 85 | 80 | 34 | 48 | 40 | 38 | 48 |

| 5 | 80 | 75 | 70 | 100 | 95 | 52 | 40 | 55 | 40 | 45 |

| 6 | 120 | 100 | 90 | 85 | 80 | 55 | 50 | 55 | 50 | 55 |

| 7 | 60 | 55 | 50 | 65 | 60 | 37 | 45 | 40 | 35 | 45 |

| 8 | 50 | 45 | 40 | 55 | 50 | 36 | 45 | 35 | 35 | 40 |

| 9 | 85 | 75 | 70 | 85 | 75 | 33 | 50 | 44 | 40 | 45 |

| 10 | 90 | 70 | 65 | 90 | 85 | 40 | 35 | 30 | 30 | 35 |

| 11 | 90 | 75 | 70 | 45 | 40 | 55 | 43 | 40 | 33 | 38 |

| 12 | 60 | 55 | 50 | 50 | 45 | 32 | 52 | 50 | 36 | 42 |

| 13 | 50 | 45 | 40 | 40 | 35 | 35 | 45 | 45 | 40 | 45 |

| 14 | 55 | 50 | 45 | 55 | 50 | 38 | 40 | 50 | 48 | 55 |

| 15 | 70 | 60 | 55 | 65 | 60 | 45 | 45 | 40 | 39 | 49 |

| 16 | 110 | 90 | 85 | 70 | 65 | 47 | 42 | 40 | 32 | 45 |

| 17 | 100 | 80 | 75 | 55 | 50 | 45 | 55 | 50 | 45 | 48 |

| 18 | 50 | 45 | 40 | 40 | 38 | 40 | 38 | 35 | 32 | 38 |

| 19 | 65 | 50 | 45 | 55 | 50 | 33 | 45 | 40 | 39 | 42 |

| 20 | 80 | 75 | 70 | 80 | 75 | 52 | 45 | 40 | 35 | 45 |

| 21 | 70 | 65 | 60 | 60 | 55 | 40 | 50 | 55 | 50 | 55 |

| 22 | 100 | 95 | 85 | 90 | 75 | 45 | 55 | 50 | 50 | 55 |

| 23 | 60 | 55 | 50 | 50 | 45 | 40 | 37 | 35 | 33 | 38 |

| 24 | 55 | 50 | 45 | 55 | 50 | 43 | 38 | 35 | 30 | 35 |

| 25 | 70 | 60 | 55 | 65 | 60 | 40 | 30 | 35 | 32 | 38 |

| 26 | 50 | 45 | 40 | 40 | 35 | 45 | 45 | 40 | 36 | 40 |

| 27 | 90 | 85 | 80 | 90 | 80 | 55 | 55 | 50 | 48 | 55 |

| 28 | 45 | 40 | 35 | 70 | 65 | 40 | 45 | 45 | 43 | 53 |

| 29 | 55 | 50 | 45 | 80 | 75 | 33 | 40 | 40 | 38 | 45 |

| 30 | 90 | 80 | 75 | 90 | 85 | 40 | 45 | 45 | 40 | 45 |

| 31 | 120 | 85 | 80 | 60 | 55 | 45 | 38 | 30 | 29 | 45 |

| 32 | 90 | 85 | 80 | 100 | 95 | 46 | 55 | 50 | 48 | 52 |

| 33 | 100 | 75 | 70 | 85 | 80 | 32 | 52 | 50 | 45 | 55 |

| 34 | 85 | 70 | 65 | 80 | 70 | 35 | 48 | 45 | 40 | 45 |

| 35 | 80 | 70 | 65 | 80 | 70 | 52 | 45 | 35 | 30 | 40 |

| 36 | 150 | 125 | 115 | 105 | 100 | 41 | 38 | 50 | 45 | 55 |

| 37 | 90 | 85 | 80 | 80 | 75 | 37 | 52 | 40 | 35 | 45 |

| 38 | 40 | 35 | 30 | 65 | 60 | 33 | 45 | 45 | 40 | 45 |

| 39 | 45 | 40 | 35 | 40 | 35 | 43 | 40 | 40 | 35 | 48 |

| 40 | 90 | 80 | 75 | 60 | 55 | 40 | 43 | 40 | 39 | 42 |

| 41 | 90 | 65 | 60 | 60 | 50 | 47 | 38 | 35 | 30 | 35 |

| 42 | 70 | 65 | 60 | 65 | 60 | 45 | 43 | 40 | 35 | 38 |

| 43 | 60 | 55 | 50 | 75 | 70 | 40 | 45 | 40 | 35 | 40 |

| 44 | 95 | 60 | 55 | 65 | 60 | 42 | 48 | 45 | 40 | 45 |

| 45 | 70 | 60 | 50 | 65 | 60 | 51 | 50 | 55 | 50 | 55 |

| 46 | 150 | 115 | 105 | 75 | 70 | 43 | 35 | 35 | 30 | 39 |

| 47 | 70 | 65 | 55 | 80 | 70 | 37 | 40 | 40 | 35 | 42 |

| 48 | 60 | 55 | 45 | 75 | 65 | 33 | 42 | 45 | 42 | 45 |

| 49 | 75 | 70 | 60 | 80 | 70 | 35 | 46 | 50 | 46 | 50 |

| 50 | 80 | 70 | 50 | 90 | 80 | 48 | 43 | 45 | 43 | 53 |

| 51 | 120 | 115 | 95 | 75 | 70 | 43 | 35 | 30 | 30 | 45 |

| 52 | 70 | 65 | 60 | 60 | 55 | 37 | 53 | 55 | 53 | 55 |

| 53 | 50 | 45 | 40 | 40 | 35 | 30 | 45 | 45 | 40 | 45 |

| 54 | 65 | 60 | 55 | 55 | 50 | 34 | 40 | 40 | 35 | 45 |

| 55 | 70 | 60 | 55 | 55 | 55 | 52 | 45 | 55 | 45 | 50 |

| 56 | 50 | 45 | 40 | 40 | 37 | 45 | 48 | 40 | 38 | 40 |

| 57 | 90 | 70 | 60 | 80 | 75 | 34 | 48 | 45 | 44 | 45 |

| 58 | 70 | 65 | 60 | 75 | 73 | 40 | 45 | 55 | 45 | 48 |

| 59 | 65 | 60 | 55 | 65 | 64 | 38 | 40 | 35 | 30 | 35 |

| 60 | 70 | 65 | 60 | 60 | 58 | 52 | 45 | 40 | 38 | 42 |

| 61 | 130 | 105 | 100 | 95 | 90 | 47 | 36 | 40 | 36 | 40 |

| 62 | 80 | 65 | 60 | 60 | 55 | 30 | 47 | 45 | 43 | 45 |

| 63 | 80 | 70 | 60 | 75 | 70 | 35 | 39 | 35 | 33 | 35 |

| 64 | 70 | 60 | 55 | 70 | 65 | 30 | 41 | 40 | 31 | 35 |

| 65 | 85 | 70 | 65 | 75 | 70 | 50 | 45 | 45 | 40 | 45 |

| 66 | 130 | 85 | 80 | 80 | 75 | 40 | 52 | 50 | 42 | 48 |

| 67 | 80 | 75 | 65 | 70 | 65 | 38 | 55 | 55 | 50 | 55 |

| 68 | 70 | 65 | 60 | 85 | 80 | 37 | 45 | 40 | 38 | 42 |

| 69 | 85 | 80 | 70 | 90 | 85 | 40 | 40 | 45 | 40 | 45 |

| 70 | 90 | 80 | 70 | 75 | 70 | 45 | 50 | 55 | 50 | 55 |

| 71 | 110 | 95 | 90 | 70 | 65 | 40 | 45 | 50 | 45 | 48 |

| 72 | 90 | 85 | 80 | 65 | 60 | 35 | 52 | 55 | 52 | 55 |

| 73 | 70 | 65 | 60 | 60 | 55 | 30 | 45 | 40 | 38 | 42 |

| 74 | 85 | 50 | 45 | 40 | 35 | 38 | 44 | 45 | 40 | 45 |

| 75 | 80 | 70 | 60 | 60 | 55 | 55 | 43 | 40 | 38 | 42 |

| 76 | 60 | 55 | 50 | 65 | 60 | 40 | 50 | 50 | 45 | 55 |

| 77 | 70 | 65 | 60 | 95 | 90 | 30 | 55 | 55 | 50 | 55 |

| 78 | 80 | 75 | 70 | 105 | 100 | 40 | 39 | 35 | 36 | 40 |

| 79 | 65 | 60 | 55 | 70 | 65 | 35 | 49 | 45 | 42 | 45 |

| 80 | 70 | 55 | 50 | 55 | 45 | 40 | 50 | 50 | 45 | 55 |

Appendix B

| Parts | Optimal Route for Goal Programming | Optimal Route for ε-Constraint | Optimal Route for AUGMECON |

|---|---|---|---|

| 1 | x111, x211, x311, x411, x511 | x111, x211, x311, x411, x511 | x111, x211, x311, x411, x511 |

| 2 | x123, x222, x323, x422, x523 | x122, x222, x323, x422, x523 | x122, x222, x323, x423, x523 |

| 3 | x135, x235, x335, x435, x535 | x135, x235, x335, x435, x535 | x135, x235, x335, x435, x535 |

| 4 | x142, x242, x342, x443, x542 | x142, x242, x342, x443, x542 | x142, x242, x342, x443, x542 |

| 5 | x155, x255, x355, x455, x555 | x155, x255, x355, x455, x555 | x155, x255, x355, x455, x555 |

| 6 | x165, x265, x365, x465, x565 | x165, x265, x365, x465, x565 | x165, x265, x365, x465, x565 |

| 7 | x173, x273, x373, x473, x573 | x173, x273, x373, x473, x573 | x173, x273, x373, x473, x573 |

| 8 | x185, x285, x385, x483, x585 | x185, x285, x385, x483, x585 | x185, x285, x385, x483, x585 |

| 9 | x192, x295, x395, x492, x592 | x195, x295, x395, x494, x592 | x195, x295, x395, x494, x592 |

| 10 | x1,10,4, x2,10,1, x3,10,1, x4,10,1, x5,10,5 | x1,10,5, x2,10,5, x3,10,1, x4,10,1, x5,10,5 | x1,10,5, x2,10,5, x3,10,1, x4,10,1, x5,10,5 |

| 11 | x1,11,3, x2,11,3, x3,11,3, x4,11,3, x5,11,3 | x1,11,3, x2,11,3, x3,11,3, x4,11,3, x5,11,3 | x1,11,3, x2,11,3, x3,11,3, x4,11,3, x5,11,3 |

| 12 | x1,12,5, x2,12,5, x3,12,5, x4,12,5, x5,12,5 | x1,12,5, x2,12,5, x3,12,5, x4,12,5, x5,12,5 | x1,12,5, x2,12,5, x3,12,5, x4,12,5, x5,12,5 |

| 13 | x1,13,5, x2,13,5, x3,13,5, x4,13,5, x5,13,5 | x1,13,5, x2,13,5, x3,13,5, x4,13,5, x5,13,5 | x1,13,5, x2,13,5, x3,13,5, x4,13,5, x5,13,5 |

| 14 | x1,14,3, x2,14,3, x3,14,3, x4,14,3, x5,14,3 | x1,14,3, x2,14,3, x3,14,3, x4,14,3, x5,14,3 | x1,14,3, x2,14,3, x3,14,3, x4,14,3, x5,14,3 |

| 15 | x1,15,5, x2,15,5, x3,15,2, x4,15,2, x5,15,2 | x1,15,5, x2,15,5, x3,15,2, x4,15,2, x5,15,2 | x1,15,5, x2,15,5, x3,15,2, x4,15,2, x5,15,2 |

| 16 | x1,16,2, x2,16,1, x3,16,1, x4,16,1, x5,16,3 | x1,16,2, x2,16,1, x3,16,1, x4,16,1, x5,16,3 | x1,16,2, x2,16,1, x3,16,1, x4,16,1, x5,16,3 |

| 17 | x1,17,5, x2,17,5, x3,17,5, x4,17,5, x5,17,5 | x1,17,5, x2,17,5, x3,17,5, x4,17,5, x5,17,5 | x1,17,5, x2,17,5, x3,17,5, x4,17,5, x5,17,5 |

| 18 | x1,18,4, x2,18,4, x3,18,4, x4,18,4, x5,18,4 | x1,18,4, x2,18,4, x3,18,4, x4,18,4, x5,18,4 | x1,18,4, x2,18,4, x3,18,4, x4,18,4, x5,18,4 |

| 19 | x1,19,5, x2,19,5, x3,19,5, x4,19,5, x5,19,5 | x1,19,5, x2,19,5, x3,19,5, x4,19,5, x5,19,5 | x1,19,5, x2,19,5, x3,19,5, x4,19,5, x5,19,5 |

| 20 | x1,20,5, x2,20,5, x3,20,5, x4,20,5, x5,20,5 | x1,20,5, x2,20,5, x3,20,5, x4,20,5, x5,20,5 | x1,20,5, x2,20,5, x3,20,5, x4,20,5, x5,20,5 |

| 21 | x1,21,5, x2,21,5, x3,21,5, x4,21,5, x5,21,5 | x1,21,5, x2,21,5, x3,21,5, x4,21,5, x5,21,5 | x1,21,5, x2,21,5, x3,21,5, x4,21,5, x5,21,5 |

| 22 | x1,22,4, x2,22,4, x3,22,4, x4,22,4, x5,22,4 | x1,22,4, x2,22,4, x3,22,4, x4,22,4, x5,22,4 | x1,22,4, x2,22,4, x3,22,4, x4,22,4, x5,22,4 |

| 23 | x1,23,5, x2,23,5, x3,23,5, x4,23,5, x5,23,5 | x1,23,5, x2,23,5, x3,23,5, x4,23,5, x5,23,5 | x1,23,5, x2,23,5, x3,23,5, x4,23,5, x5,23,5 |

| 24 | x1,24,5, x2,24,5, x3,24,5, x4,24,5, x5,24,5 | x1,24,5, x2,24,5, x3,24,5, x4,24,5, x5,24,5 | x1,24,5, x2,24,5, x3,24,5, x4,24,5, x5,24,5 |

| 25 | x1,25,3, x2,25,3, x3,25,3, x4,25,3, x5,25,3 | x1,25,3, x2,25,3, x3,25,3, x4,25,3, x5,25,3 | x1,25,3, x2,25,3, x3,25,3, x4,25,3, x5,25,3 |

| 26 | x1,26,4, x2,26,4, x3,26,4, x4,26,4, x5,26,4 | x1,26,4, x2,26,4, x3,26,4, x4,26,4, x5,26,4 | x1,26,4, x2,26,4, x3,26,4, x4,26,4, x5,26,4 |

| 27 | x1,27,4, x2,27,4, x3,27,4, x4,27,4, x5,27,4 | x1,27,4, x2,27,4, x3,27,4, x4,27,4, x5,27,4 | x1,27,4, x2,27,4, x3,27,4, x4,27,4, x5,27,4 |

| 28 | x1,28,3, x2,28,3, x3,28,3, x4,28,3, x5,28,3 | x1,28,3, x2,28,3, x3,28,3, x4,28,3, x5,28,3 | x1,28,3, x2,28,3, x3,28,3, x4,28,3, x5,28,3 |

| 29 | x1,29,1, x2,29,1, x3,29,1, x4,29,1, x5,29,1 | x1,29,1, x2,29,1, x3,29,1, x4,29,1, x5,29,1 | x1,29,1, x2,29,1, x3,29,1, x4,29,1, x5,29,1 |

| 30 | x1,30,4, x2,30,4, x3,30,4, x4,30,4, x5,30,4 | x1,30,4, x2,30,4, x3,30,4, x4,30,4, x5,30,4 | x1,30,4, x2,30,4, x3,30,4, x4,30,4, x5,30,4 |

| 31 | x1,31,5, x2,31,3, x3,31,3, x4,31,3, x5,31,5 | x1,31,5, x2,31,3, x3,31,3, x4,31,3, x5,31,5 | x1,31,5, x2,31,3, x3,31,3, x4,31,3, x5,31,5 |

| 32 | x1,32,5, x2,32,5, x3,32,5, x4,32,5, x5,32,5 | x1,32,5, x2,32,5, x3,32,5, x4,32,5, x5,32,5 | x1,32,5, x2,32,5, x3,32,5, x4,32,5, x5,32,5 |

| 33 | x1,33,2, x2,33,4, x3,33,4, x4,33,4, x5,33,2 | x1,33,2, x2,33,4, x3,33,4, x4,33,4, x5,33,2 | x1,33,2, x2,33,4, x3,33,4, x4,33,4, x5,33,2 |

| 34 | x1,34,4, x2,34,1, x3,34,1, x4,34,1, x5,34,4 | x1,34,4, x2,34,1, x3,34,1, x4,34,1, x5,34,4 | x1,34,4, x2,34,1, x3,34,1, x4,34,1, x5,34,4 |

| 35 | x1,35,3, x2,35,3, x3,35,3, x4,35,3, x5,35,3 | x1,35,3, x2,35,3, x3,35,3, x4,35,3, x5,35,3 | x1,35,3, x2,35,3, x3,35,3, x4,35,3, x5,35,3 |

| 36 | x1,36,1, x2,36,1, x3,36,1, x4,36,1, x5,36,1 | x1,36,1, x2,36,1, x3,36,1, x4,36,1, x5,36,1 | x1,36,1, x2,36,1, x3,36,1, x4,36,1, x5,36,1 |

| 37 | x1,37,2, x2,37,4, x3,37,3, x4,37,4, x5,37,3 | x1,37,2, x2,37,2, x3,37,3, x4,37,2, x5,37,3 | x1,37,2, x2,37,2, x3,37,3, x4,37,3, x5,37,3 |

| 38 | x1,38,3, x2,38,3, x3,38,3, x4,38,3, x5,38,3 | x1,38,3, x2,38,3, x3,38,3, x4,38,3, x5,38,3 | x1,38,3, x2,38,3, x3,38,3, x4,38,3, x5,38,3 |

| 39 | x1,39,3, x2,39,3, x3,39,3, x4,39,3, x5,39,3 | x1,39,3, x2,39,3, x3,39,3, x4,39,3, x5,39,3 | x1,39,3, x2,39,3, x3,39,3, x4,39,3, x5,39,3 |

| 40 | x1,40,5, x2,40,5, x3,40,5, x4,40,1, x5,40,5 | x1,40,5, x2,40,5, x3,40,5, x4,40,5, x5,40,5 | x1,40,5, x2,40,5, x3,40,5, x4,40,5, x5,40,5 |

| 41 | x1,41,1, x2,41,1, x3,41,1, x4,41,1, x5,41,1 | x1,41,1, x2,41,1, x3,41,1, x4,41,1, x5,41,1 | x1,41,1, x2,41,1, x3,41,1, x4,41,1, x5,41,1 |

| 42 | x1,42,3, x2,42,4, x3,42,3, x4,42,4, x5,42,3 | x1,42,4, x2,42,4, x3,42,3, x4,42,4, x5,42,3 | x1,42,4, x2,42,4, x3,42,3, x4,42,3, x5,42,3 |

| 43 | x1,43,3, x2,43,3, x3,43,3, x4,43,3, x5,43,3 | x1,43,3, x2,43,3, x3,43,3, x4,43,3, x5,43,3 | x1,43,3, x2,43,3, x3,43,3, x4,43,3, x5,43,3 |

| 44 | x1,44,3, x2,44,3, x3,44,3, x4,44,3, x5,44,3 | x1,44,3, x2,44,3, x3,44,3, x4,44,3, x5,44,3 | x1,44,3, x2,44,3, x3,44,3, x4,44,3, x5,44,3 |

| 45 | x1,45,5, x2,45,5, x3,45,5, x4,45,1, x5,45,5 | x1,45,5, x2,45,5, x3,45,5, x4,45,5, x5,45,5 | x1,45,5, x2,45,5, x3,45,5, x4,45,5, x5,45,5 |

| 46 | x1,46,5, x2,46,5, x3,46,5, x4,46,5, x5,46,5 | x1,46,5, x2,46,3, x3,46,5, x4,46,5, x5,46,5 | x1,46,5, x2,46,3, x3,46,5, x4,46,5, x5,46,5 |

| 47 | x1,47,2, x2,47,2, x3,47,2, x4,47,2, x5,47,2 | x1,47,2, x2,47,2, x3,47,2, x4,47,2, x5,47,2 | x1,47,2, x2,47,2, x3,47,2, x4,47,2, x5,47,2 |

| 48 | x1,48,3, x2,48,3, x3,48,3, x4,48,3, x5,48,3 | x1,48,3, x2,48,3, x3,48,3, x4,48,3, x5,48,3 | x1,48,3, x2,48,3, x3,48,3, x4,48,3, x5,48,3 |

| 49 | x1,49,2, x2,49,2, x3,49,2, x4,49,2, x5,49,2 | x1,49,2, x2,49,2, x3,49,2, x4,49,2, x5,49,2 | x1,49,2, x2,49,2, x3,49,2, x4,49,2, x5,49,2 |

| 50 | x1,50,4, x2,50,4, x3,50,4, x4,50,3, x5,50,4 | x1,50,4, x2,50,5, x3,50,4, x4,50,3, x5,50,4 | x1,50,4, x2,50,5, x3,50,4, x4,50,3, x5,50,4 |

| 51 | x1,51,3, x2,51,3, x3,51,3, x4,51,3, x5,51,3 | x1,51,3, x2,51,3, x3,51,3, x4,51,3, x5,51,3 | x1,51,3, x2,51,3, x3,51,3, x4,51,3, x5,51,3 |

| 52 | x1,52,5, x2,52,5, x3,52,5, x4,52,5, x5,52,5 | x1,52,5, x2,52,5, x3,52,5, x4,52,5, x5,52,5 | x1,52,5, x2,52,5, x3,52,5, x4,52,5, x5,52,5 |

| 53 | x1,53,5, x2,53,5, x3,53,5, x4,53,5, x5,53,5 | x1,53,5, x2,53,5, x3,53,5, x4,53,5, x5,53,5 | x1,53,5, x2,53,5, x3,53,5, x4,53,5, x5,53,5 |

| 54 | x1,54,5, x2,54,3, x3,54,3, x4,54,3, x5,54,3 | x1,54,5, x2,54,3, x3,54,3, x4,54,3, x5,54,3 | x1,54,5, x2,54,3, x3,54,3, x4,54,3, x5,54,3 |

| 55 | x1,55,2, x2,55,2, x3,55,2, x4,55,2, x5,55,2 | x1,55,2, x2,55,2, x3,55,2, x4,55,2, x5,55,2 | x1,55,2, x2,55,2, x3,55,2, x4,55,2, x5,55,2 |

| 56 | x1,56,2, x2,56,1, x3,56,1, x4,56,1, x5,56,2 | x1,56,2, x2,56,1, x3,56,1, x4,56,1, x5,56,3 | x1,56,2, x2,56,1, x3,56,1, x4,56,1, x5,56,3 |

| 57 | x1,57,5, x2,57,5, x3,57,5, x4,57,5, x5,57,5 | x1,57,5, x2,57,5, x3,57,5, x4,57,5, x5,57,5 | x1,57,5, x2,57,5, x3,57,5, x4,57,5, x5,57,5 |

| 58 | x1,58,4, x2,58,4, x3,58,4, x4,58,4, x5,58,4 | x1,58,4, x2,58,4, x3,58,4, x4,58,4, x5,58,4 | x1,58,4, x2,58,4, x3,58,4, x4,58,4, x5,58,4 |

| 59 | x1,59,5, x2,59,5, x3,59,5, x4,59,5, x5,59,5 | x1,59,5, x2,59,5, x3,59,5, x4,59,5, x5,59,5 | x1,59,5, x2,59,5, x3,59,5, x4,59,5, x5,59,5 |

| 60 | x1,60,5, x2,60,5, x3,60,5, x4,60,5, x5,60,5 | x1,60,5, x2,60,5, x3,60,5, x4,60,5, x5,60,5 | x1,60,5, x2,60,5, x3,60,5, x4,60,5, x5,60,5 |

| 61 | x1,61,2, x2,61,2, x3,61,5, x4,61,5, x5,61,5 | x1,61,5, x2,61,2, x3,61,5, x4,61,5, x5,61,5 | x1,61,5, x2,61,2, x3,61,5, x4,61,5, x5,61,5 |

| 62 | x1,62,4, x2,62,4, x3,62,4, x4,62,4, x5,62,4 | x1,62,4, x2,62,4, x3,62,4, x4,62,4, x5,62,4 | x1,62,4, x2,62,4, x3,62,4, x4,62,4, x5,62,4 |

| 63 | x1,63,5, x2,63,5, x3,63,5, x4,63,5, x5,63,5 | x1,63,5, x2,63,5, x3,63,5, x4,63,5, x5,63,5 | x1,63,5, x2,63,5, x3,63,5, x4,63,5, x5,63,5 |

| 64 | x1,64,5, x2,64,5, x3,64,5, x4,64,5, x5,64,5 | x1,64,5, x2,64,5, x3,64,5, x4,64,5, x5,64,5 | x1,64,5, x2,64,5, x3,64,5, x4,64,5, x5,64,5 |

| 65 | x1,65,3, x2,65,3, x3,65,3, x4,65,3, x5,65,3 | x1,65,3, x2,65,3, x3,65,3, x4,65,3, x5,65,3 | x1,65,3, x2,65,3, x3,65,3, x4,65,3, x5,65,3 |

| 66 | x1,66,4, x2,66,4, x3,66,4, x4,66,4, x5,66,4 | x1,66,4, x2,66,4, x3,66,4, x4,66,4, x5,66,4 | x1,66,4, x2,66,4, x3,66,4, x4,66,4, x5,66,4 |

| 67 | x1,67,4, x2,67,4, x3,67,4, x4,67,4, x5,67,4 | x1,67,4, x2,67,4, x3,67,4, x4,67,4, x5,67,4 | x1,67,4, x2,67,4, x3,67,4, x4,67,4, x5,67,4 |

| 68 | x1,68,3, x2,68,3, x3,68,3, x4,68,3, x5,68,3 | x1,68,3, x2,68,3, x3,68,3, x4,68,3, x5,68,3 | x1,68,3, x2,68,3, x3,68,3, x4,68,3, x5,68,3 |

| 69 | x1,69,3, x2,69,1, x3,69,3, x4,69,1, x5,69,3 | x1,69,3, x2,69,1, x3,69,3, x4,69,1, x5,69,3 | x1,69,3, x2,69,1, x3,69,3, x4,69,1, x5,69,3 |

| 70 | x1,70,4, x2,70,4, x3,70,4, x4,70,4, x5,70,4 | x1,70,4, x2,70,4, x3,70,4, x4,70,4, x5,70,4 | x1,70,4, x2,70,4, x3,70,4, x4,70,4, x5,70,4 |

| 71 | x1,71,3, x2,71,3, x3,71,3, x4,71,3, x5,71,3 | x1,71,3, x2,71,3, x3,71,3, x4,71,3, x5,71,3 | x1,71,3, x2,71,3, x3,71,3, x4,71,3, x5,71,3 |

| 72 | x1,72,5, x2,72,5, x3,72,5, x4,72,5, x5,72,5 | x1,72,5, x2,72,5, x3,72,5, x4,72,5, x5,72,5 | x1,72,5, x2,72,5, x3,72,5, x4,72,5, x5,72,5 |

| 73 | x1,73,2, x2,73,4, x3,73,4, x4,73,4, x5,73,2 | x1,73,2, x2,73,4, x3,73,4, x4,73,4, x5,73,2 | x1,73,2, x2,73,4, x3,73,4, x4,73,4, x5,73,2 |

| 74 | x1,74,4, x2,74,1, x3,74,1, x4,74,1, x5,74,4 | x1,74,4, x2,74,1, x3,74,1, x4,74,1, x5,74,4 | x1,74,4, x2,74,1, x3,74,1, x4,74,1, x5,74,4 |

| 75 | x1,75,3, x2,75,3, x3,75,3, x4,75,3, x5,75,3 | x1,75,3, x2,75,3, x3,75,3, x4,75,3, x5,75,3 | x1,75,3, x2,75,3, x3,75,3, x4,75,3, x5,75,3 |

| 76 | x1,76,1, x2,76,1, x3,76,1, x4,76,1, x5,76,1 | x1,76,2, x2,76,1, x3,76,1, x4,76,1, x5,76,1 | x1,76,2, x2,76,1, x3,76,1, x4,76,1, x5,76,1 |

| 77 | x1,77,3, x2,77,2, x3,77,3, x4,77,2, x5,77,3 | x1,77,2, x2,77,2, x3,77,3, x4,77,2, x5,77,3 | x1,77,2, x2,77,2, x3,77,3, x4,77,3, x5,77,3 |

| 78 | x1,78,3, x2,78,3, x3,78,3, x4,78,3, x5,78,3 | x1,78,3, x2,78,3, x3,78,3, x4,78,3, x5,78,3 | x1,78,3, x2,78,3, x3,78,3, x4,78,3, x5,78,3 |

| 79 | x1,79,3, x2,79,3, x3,79,3, x4,79,3, x5,79,3 | x1,79,3, x2,79,3, x3,79,3, x4,79,3, x5,79,3 | x1,79,3, x2,79,3, x3,79,3, x4,79,3, x5,79,3 |

| 80 | x1,80,5, x2,80,5, x3,80,5, x4,80,5, x5,80,5 | x1,80,5, x2,80,5, x3,80,5, x4,80,5, x5,80,5 | x1,80,5, x2,80,5, x3,80,5, x4,80,5, x5,80,5 |

References

- Coca, G.; Castrillón, O.D.; Ruiz, S.; Mateo-Sanz, J.M.; Jiménez, L. Sustainable evaluation of environmental and occupational risks scheduling flexible job shop manufacturing systems. J. Clean. Prod. 2019, 209, 146–168. [Google Scholar] [CrossRef]

- Singh, S.; Olugu, E.U.; Musa, S.N. Development of sustainable manufacturing performance evaluation expert system for small and medium enterprises. Procedia CIRP 2016, 40, 608–613. [Google Scholar] [CrossRef]

- Ahmad, S.; Wong, K.Y.; Rajoo, S. Sustainability indicators for manufacturing sectors A literature survey and maturity analysis from the triple-bottom line perspective. J. Manuf. Technol. Manag. 2019, 30, 312–334. [Google Scholar] [CrossRef]

- Sutherland, J.W.; Richter, J.S.; Hutchins, M.J.; Dornfeld, D.; Dzombak, R.; Mangold, J.; Robinson, S.; Hauschild, M.Z.; Bonou, A.; Schönsleben, P.; et al. The role of manufacturing in affecting the social dimension of sustainability. CIRP Ann. Manuf. Technol. 2016, 65, 689–712. [Google Scholar] [CrossRef]

- Galal, N.M.; Moneim, A.F.A. A mathematical programming approach to the optimal sustainable product mix for the process industry. Sustainability 2015, 7, 13085–13103. [Google Scholar] [CrossRef]

- Rajak, S.; Vinodh, S. Application of fuzzy logic for social sustainability performance evaluation: A case study of an Indian automotive component manufacturing organization. J. Clean. Prod. 2015, 108, 1184–1192. [Google Scholar] [CrossRef]

- Vimal, K.E.K.; Vinodh, S.; Raja, A. Modelling, assessment and deployment of strategies for ensuring sustainable shielded metal arc welding process-a case study. J. Clean. Prod. 2015, 93, 364–377. [Google Scholar] [CrossRef]

- Lin, C.J.; Belis, T.T.; Kuo, T.C. Ergonomics-based factors or criteria for the evaluation of sustainable product manufacturing. Sustainability 2019, 11, 4955. [Google Scholar] [CrossRef]

- Mengistu, A.T.; Panizzolo, R. Tailoring sustainability indicators to small and medium enterprises for measuring industrial sustainability performance. Meas. Bus. Excell. 2023, 27, 54–70. [Google Scholar] [CrossRef]

- Giret, A.; Trentesaux, D.; Prabhu, V. Sustainability in manufacturing operations scheduling: A state of the art review. J. Manuf. Syst. 2015, 37, 126–140. [Google Scholar] [CrossRef]

- Niakan, F.; Baboli, A.; Moyaux, T.; Botta-Genoulaz, V. A bi-objective model in sustainable dynamic cell formation problem with skill-based worker assignment. J. Manuf. Syst. 2016, 38, 46–62. [Google Scholar] [CrossRef]

- Jain, A.K.; Kasilingam, R.G.; Bhole, S.D. Joint consideration of cell formation and tool provisioning problems in flexible manufacturing systems. Comput. Ind. Eng. 1991, 20, 271–277. [Google Scholar] [CrossRef]

- Alhourani, F. Cellular manufacturing system design considering machines reliability and parts alternative process routings. Int. J. Prod. Res. 2016, 54, 846–863. [Google Scholar] [CrossRef]

- Ghodsi, R.; Mostafayi, S.; Mansouri, Z.; Bakhtiari, M. Designing a bi-objective integrating mathematical model for dynamic sustainable cellular manufacturing systems considering production planning. J. Appl. Mech. Eng. 2015, 4, 184. [Google Scholar]

- Aljuneidi, T.; Bulgak, A.A. A mathematical model for designing reconfigurable cellular hybrid manufacturing-remanufacturing systems. Int. J. Adv. Manuf. Technol. 2016, 87, 1585–1596. [Google Scholar] [CrossRef]

- Mehdizadeh, E.; Niaki, S.V.D.; Rahimi, V. A vibration damping optimization algorithm for solving a new multi-objective dynamic cell formation problem with workers training. Comput. Ind. Eng. 2016, 101, 35–52. [Google Scholar] [CrossRef]

- Niakan, F.; Baboli, A.; Moyaux, T.; Botta-Genoulaz, V. A new multi-objective mathematical model for dynamic cell formation under demand and cost uncertainty considering social criteria. Appl. Math. Model. 2016, 40, 2674–2691. [Google Scholar] [CrossRef]

- Imran, M.; Kang, C.; Lee, Y.H.; Jahanzaib, M.; Aziz, H. Cell formation in a cellular manufacturing system using simulation integrated hybrid genetic algorithm. Comput. Ind. Eng. 2017, 105, 123–135. [Google Scholar] [CrossRef]

- Arghish, O.; Tavakkoli-Moghaddam, R.; Shahandeh-Nookabadi, A.; Rezaeian, J. Comparison among four calibrated meta-heuristic algorithms for solving a type-2 fuzzy cell formation problem considering economic and environmental criteria. Adv. Prod. Eng. Manag. 2018, 13, 5–17. [Google Scholar] [CrossRef]

- Iqbal, A.; Al-Ghamdi, K.A. Energy-efficient cellular manufacturing system: Eco-friendly revamping of machine shop configuration. Energy 2018, 163, 863–872. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, S.P. Simulated annealing-based embedded meta-heuristic approach to solve bi-objective robust stochastic sustainable cellular layout. Glob. J. Flex. Syst. Manag. 2018, 19, 69–93. [Google Scholar] [CrossRef]

- Raoofpanah, H.; Ghezavati, V.; Tavakkoli-Moghaddam, R. Solving a new robust green cellular manufacturing problem with environmental issues under uncertainty using Benders decomposition. Eng. Optim. 2019, 51, 1229–1250. [Google Scholar] [CrossRef]

- Telegraphi, A.H.; Bulgak, A.A. A mathematical model for designing sustainable cellular remanufacturing systems. J. Ind. Syst. Eng. 2021, 13, 98–123. [Google Scholar]

- Forghani, K.; Fatemi Ghomi, S.M.T.; Kia, R. Group layout design of manufacturing cells incorporating assembly and energy aspects. Eng. Optim. 2022, 54, 770–785. [Google Scholar] [CrossRef]

- Jafarzadeh, J.; Khalili, H.A.; Shoja, N. A multiobjective optimization model for a dynamic and sustainable cellular manufacturing system under uncertainty. Comput. Intell. Neurosci. 2022, 2022, 1334081. [Google Scholar] [CrossRef] [PubMed]

- Aryanezhad, M.B.; Deljoo, V.; Mirzapour Al-e-hashem, S.M.J. Dynamic cell formation and the worker assignment problem: A new model. Int. J. Adv. Manuf. Technol. 2009, 41, 329–342. [Google Scholar] [CrossRef]

- Fan, J.; Feng, D. Design of cellular manufacturing system with quasi-dynamic dual resource using multi-objective GA. Int. J. Prod. Res. 2013, 51, 4134–4154. [Google Scholar] [CrossRef]

- Bagheri, M.; Bashiri, M. A new mathematical model towards the integration of cell formation with operator assignment and inter-cell layout problems in a dynamic environment. Appl. Math. Model. 2014, 38, 1237–1254. [Google Scholar] [CrossRef]