Stand-Up Time Dependence on Protective Roof–Pillar Bearing Structure of Bauxite

Abstract

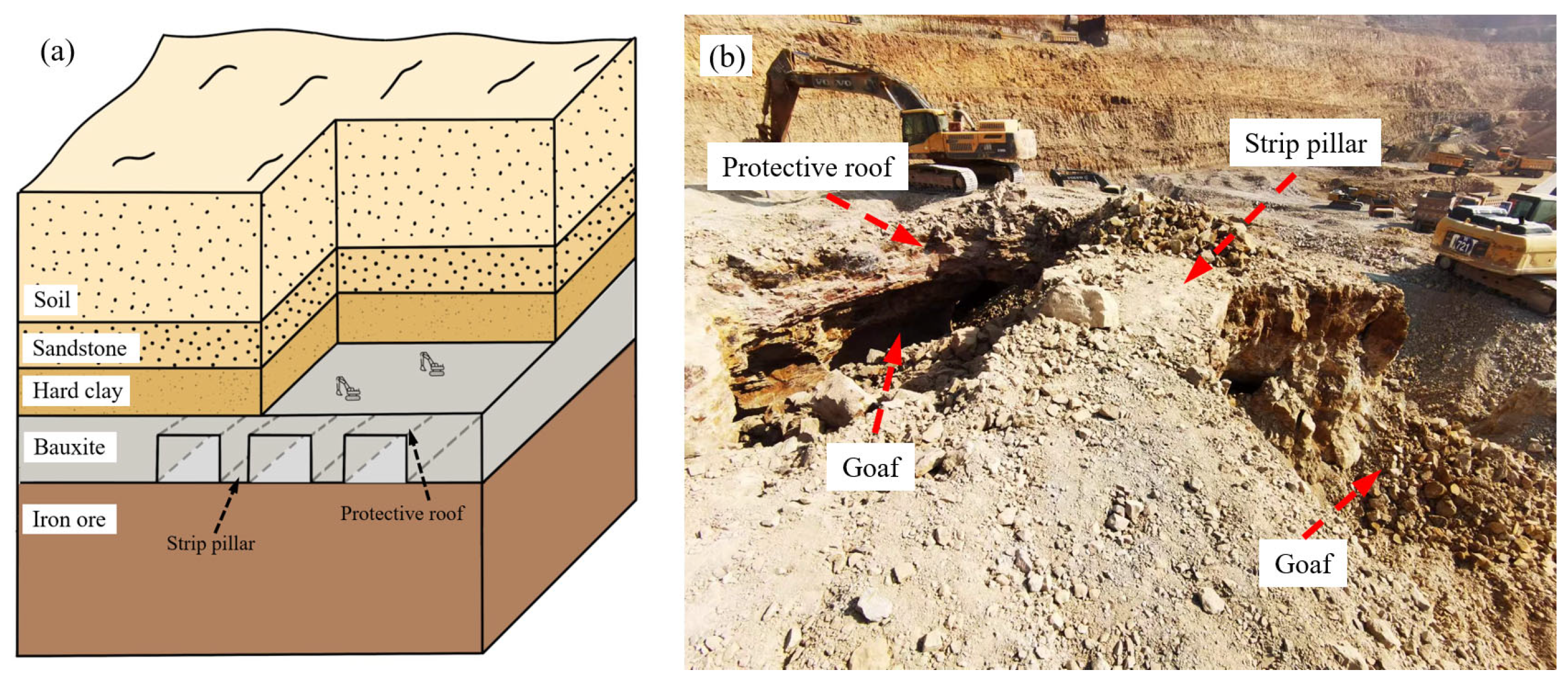

:1. Introduction

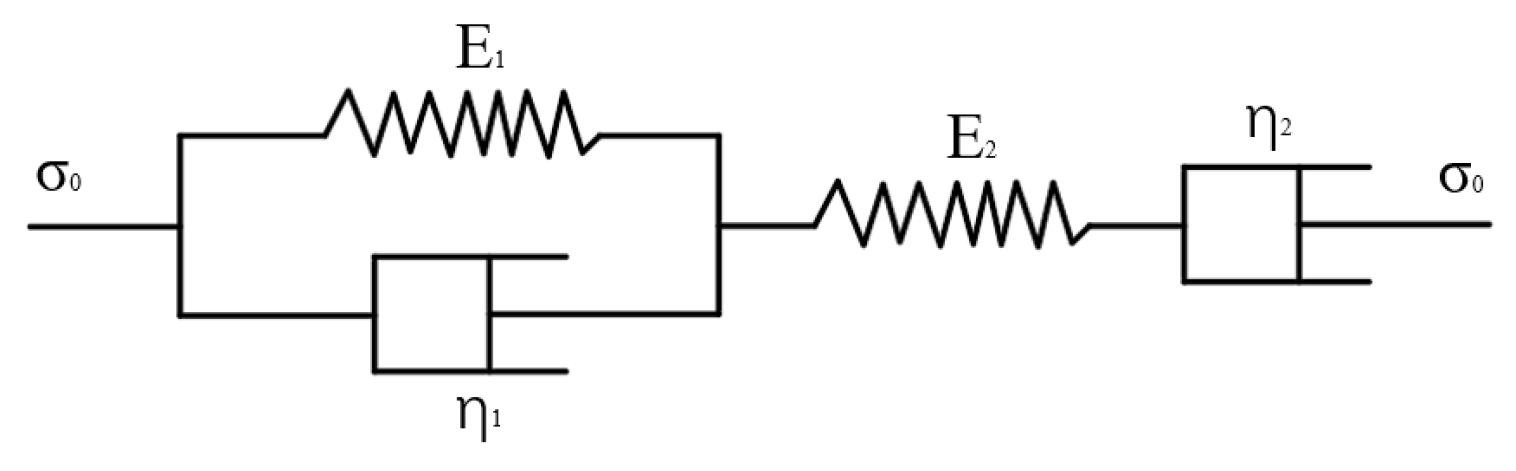

2. Rheological Model of Bearing Structure

2.1. Selection of Ore-Rock Failure Constitutive Relation

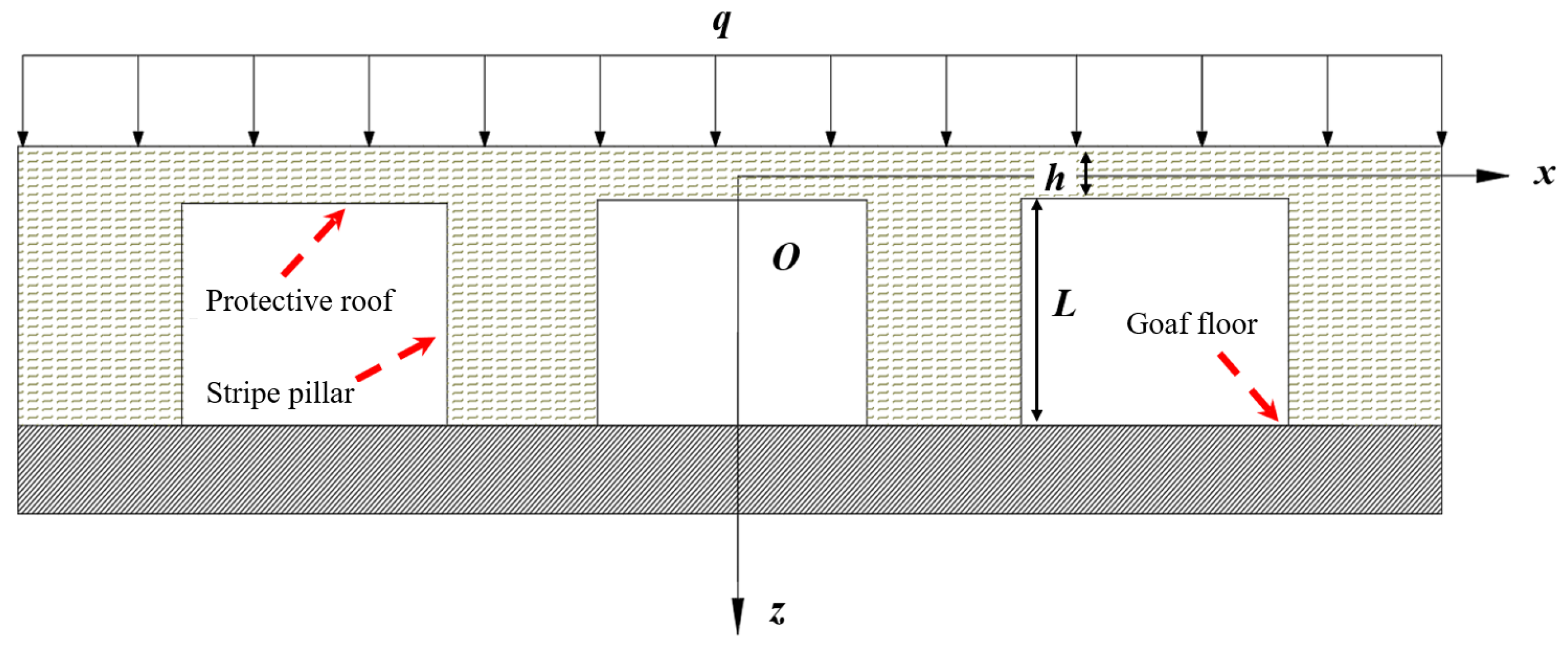

2.2. Mechanical Model and Solution of Protective Roof—Pillar Bearing Structure

- (1)

- The difference of occurrence of rock mass in bearing structures is not considered;

- (2)

- The pillar is regarded as a regular rectangular body and the top layer is regarded as a thin plate structure of equal thickness, without considering the occurrence of special shape pillar and the protective roof;

- (3)

- The gravity load of the overlying rock layer on the bearing structure is regarded as a uniform load and the influence of mechanical load and blasting load on the bearing structure is not considered.

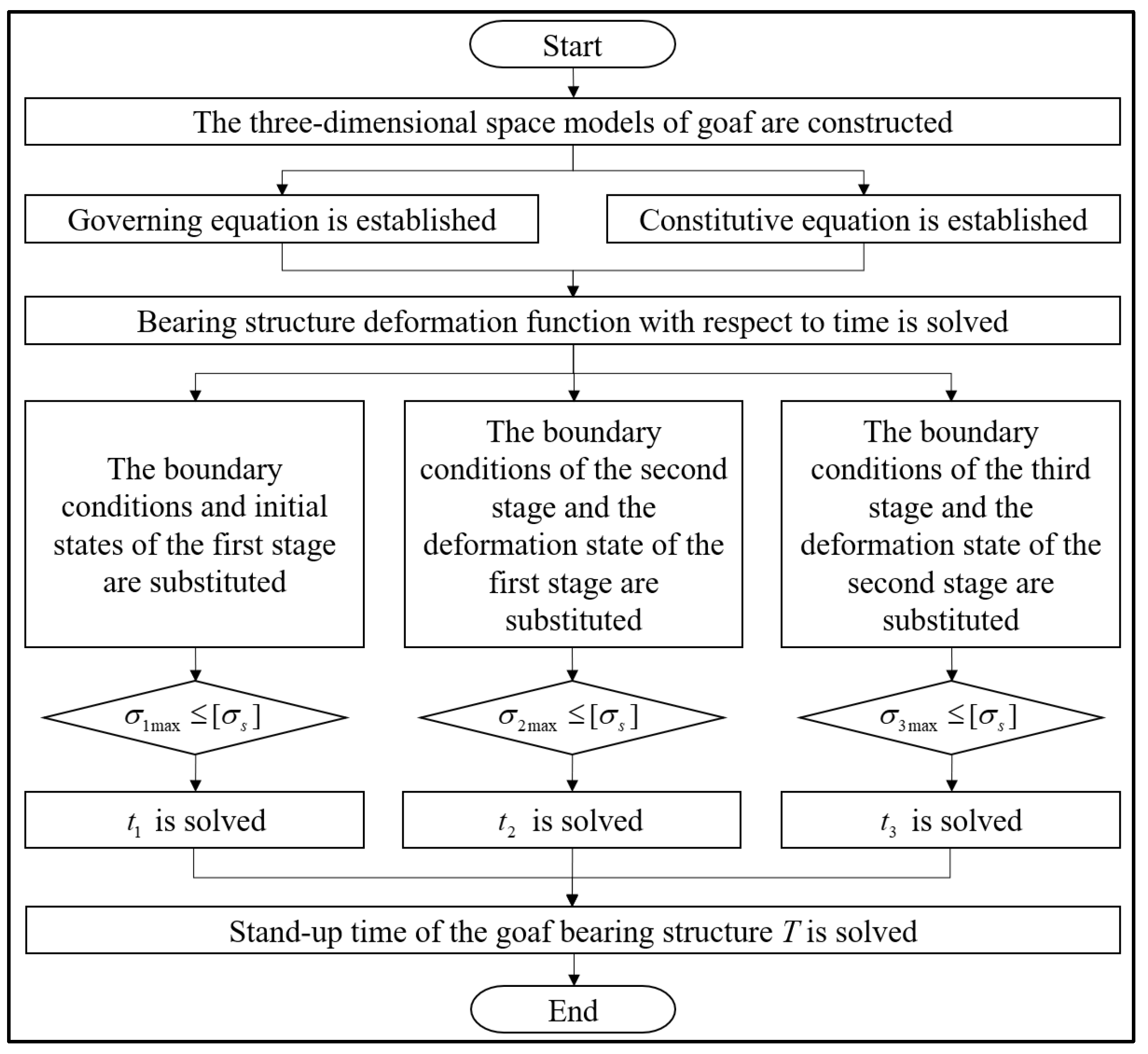

3. Computation of Stand-Up Time of Bearing Structure

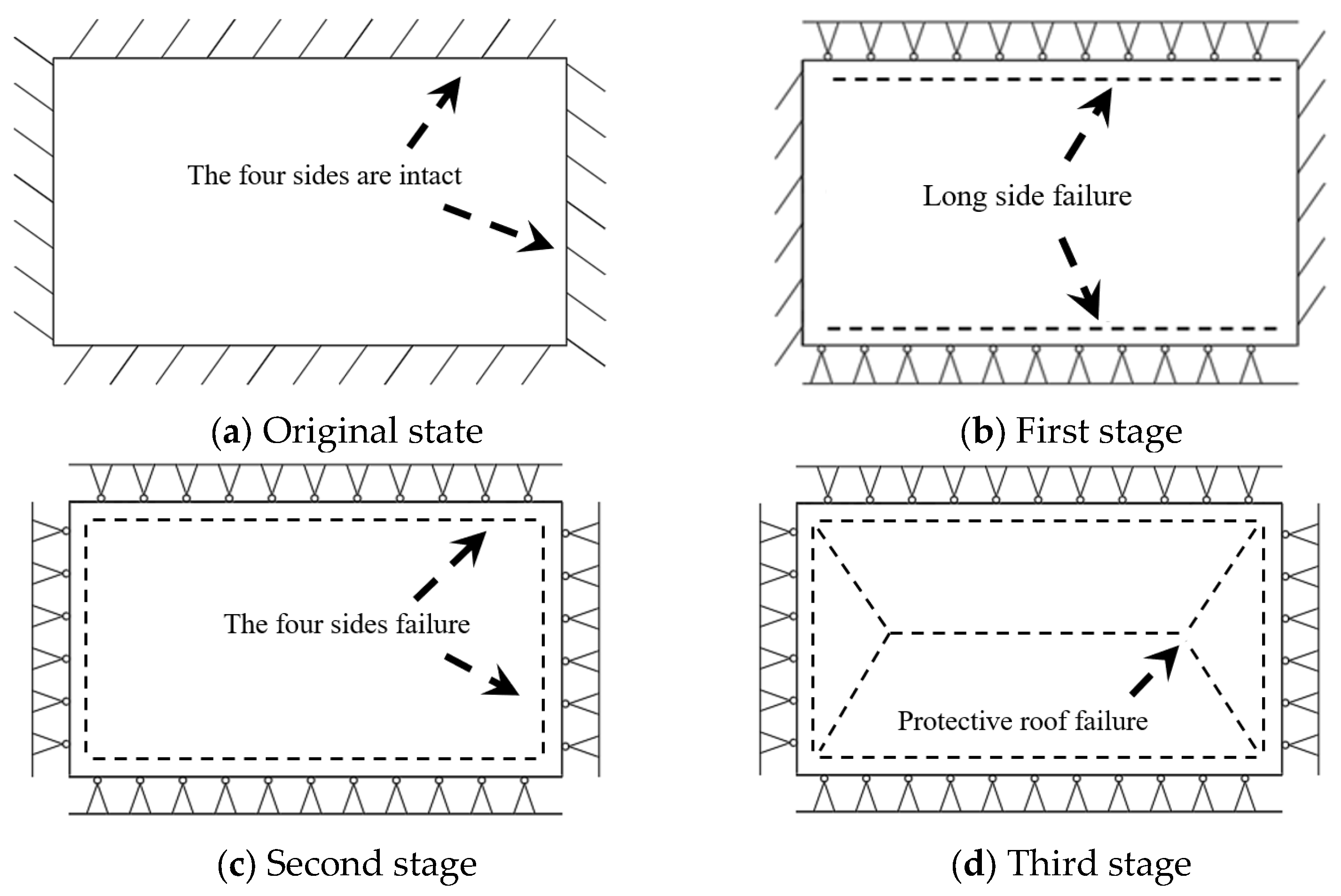

3.1. Pillar Failure Process

3.2. Protective Roof Failure Process

3.2.1. Original State

3.2.2. First Stage

3.2.3. Second Stage

3.2.4. Third Stage

4. Influencing Factors of Bearing Structure Stand-Up Time

4.1. Engineering Characteristics

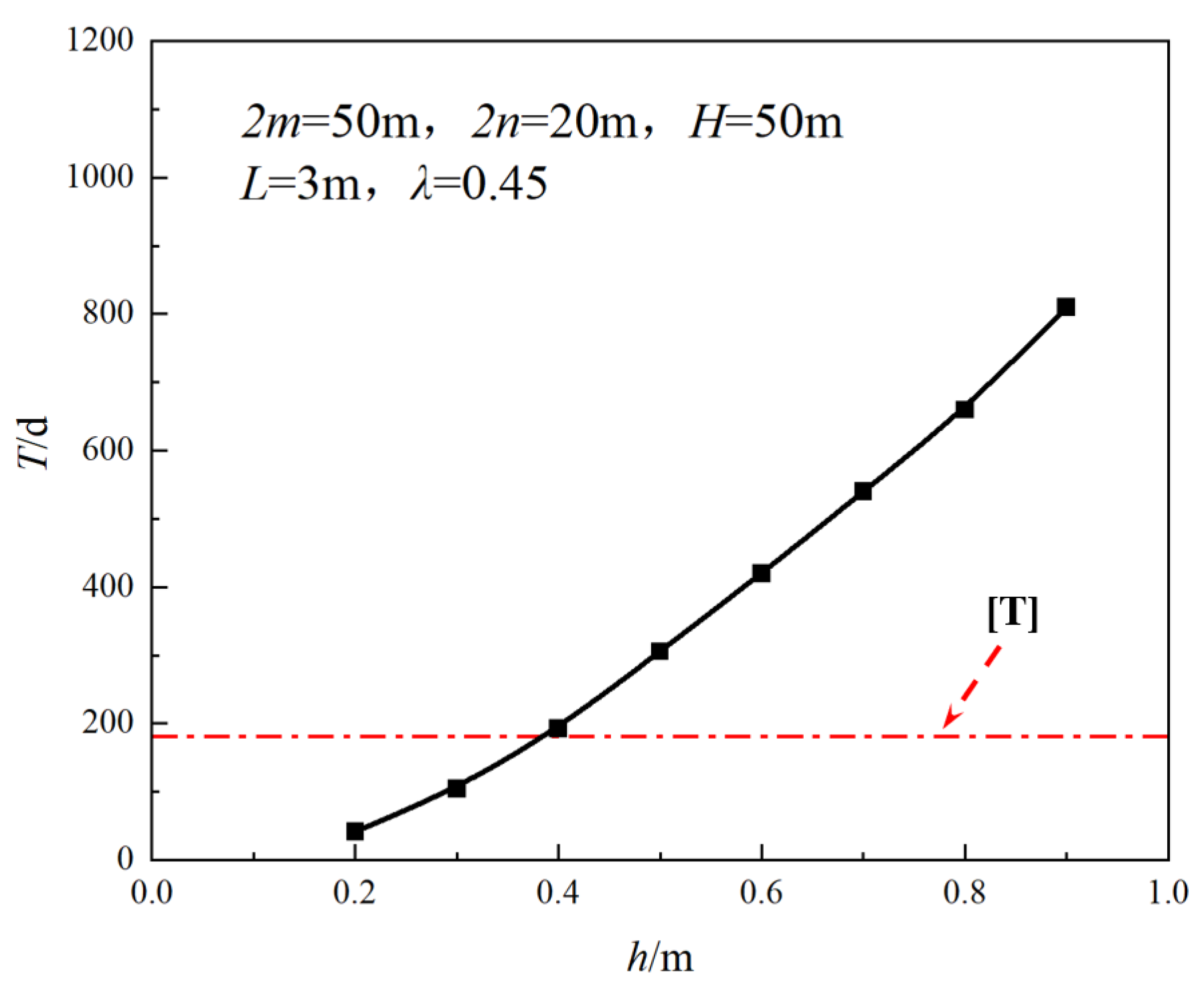

4.2. Thickness of Protective Roof

4.3. Equivalent Uniform Surface Force Coefficient of Pillar

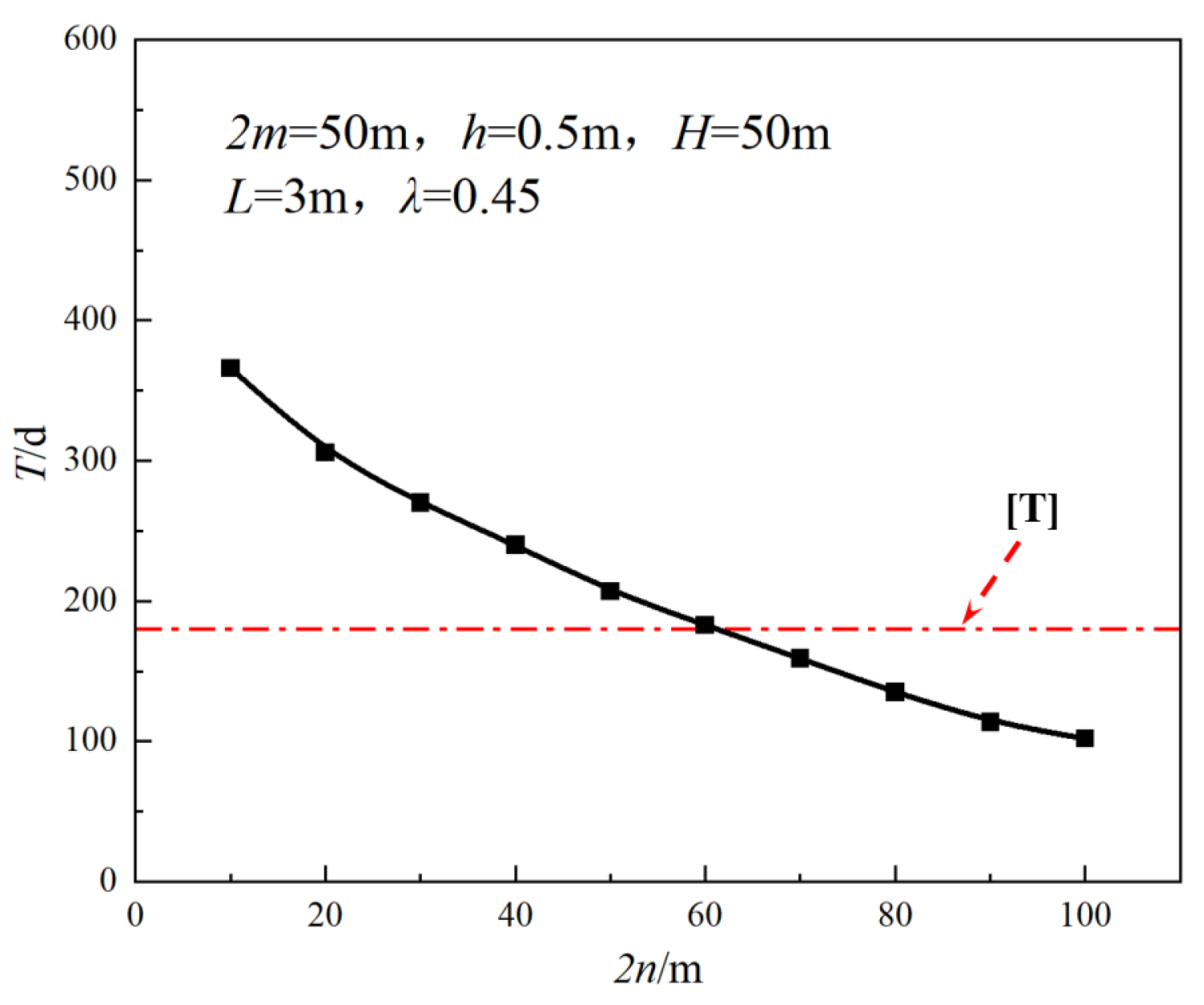

4.4. Goaf Span

4.5. Thickness of the Overlying Soil Layer

5. Engineering Verification

5.1. Case 1 (Region 1)

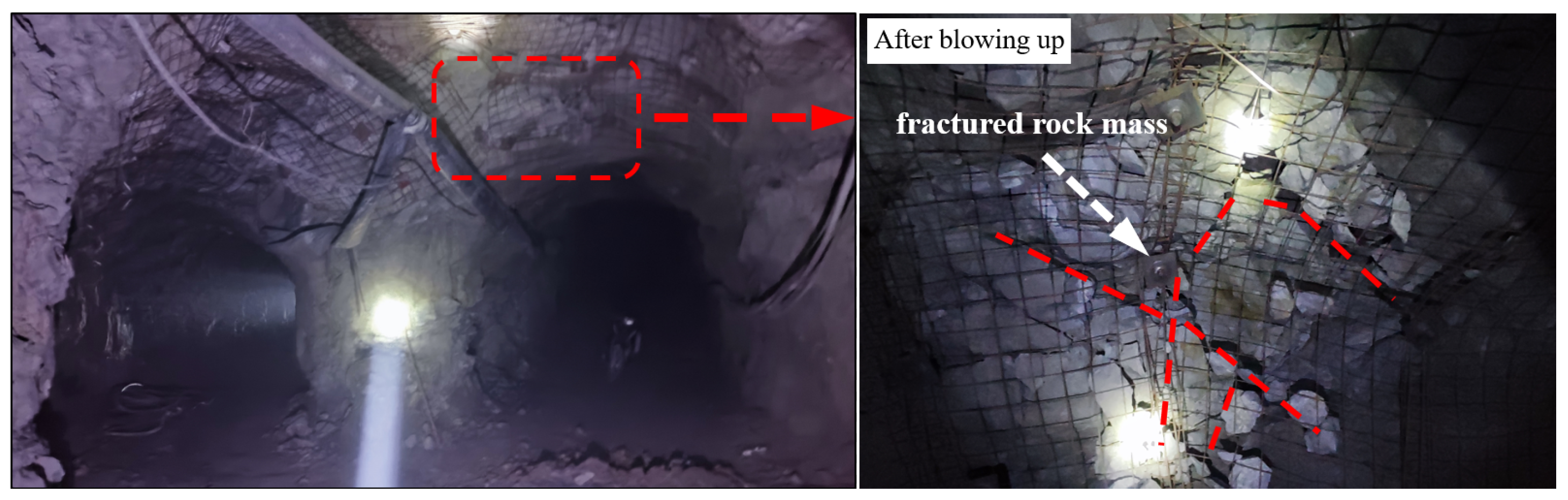

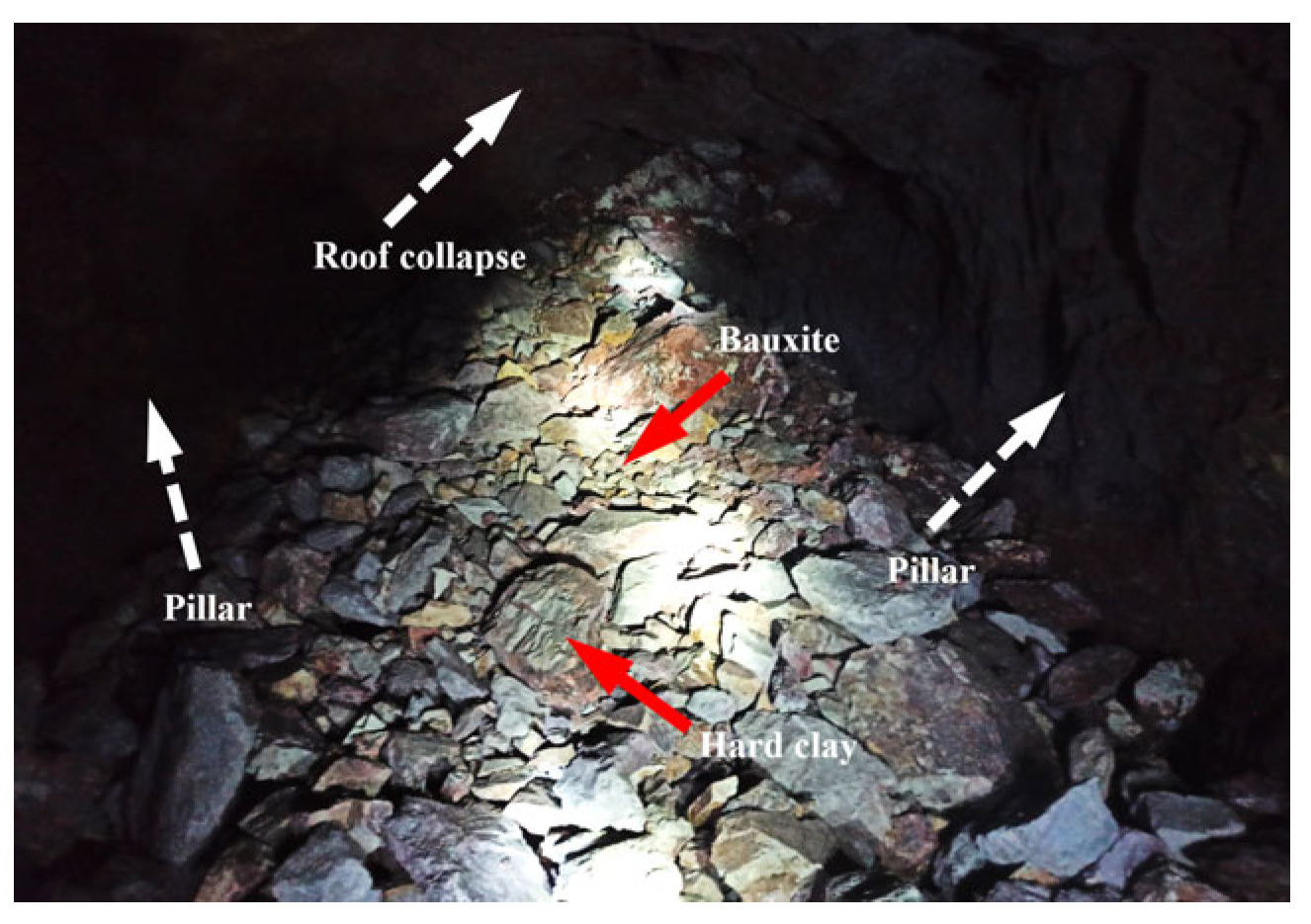

5.2. Case 2 (Region 2)

6. Discussion

- (1)

- There may be other factors in the paper that have an impact on the stand-up time, for example, (a) when analyzing the influence of one factor on the stand-up time of bauxite bearing structure, it is assumed that other factors are established and the effect of only one factor is considered instead of multi-factor coupling effect which may be different from the actual project. (b) The research object of this paper is the underground bauxite mine in the Loess Plateau landform. The rock layer is dry, surface water and cracks are not developed and the effect of groundwater is not considered. In the karst water development area in the south, the influence of groundwater should be considered. The influence of groundwater on the stability of the gob should be considered in the gob developed by underground water. The theoretical results in this paper may not be applicable.

- (2)

- The theoretical model and basic assumptions in this paper are simplified. For example, (a) the difference in occurrence of rock mass in bearing structure is not considered. (b) In the theoretical calculation in this paper, the protective roof-pillar bearing structure is regarded as a regular rectangular body, but the shape of pillar, protective roof and goaf in actual engineering is irregular. (c) The gravity load of the overlying rock layer on the bearing structure is regarded as a uniform load, and the influence of mechanical load and blasting load on the bearing structure is not considered. These assumptions may differ from the actual engineering situation, and our future research will be more suitable for the actual engineering situation.

- (3)

- In this paper, Galerkin algorithm and nonhomogeneous linear equations are used for theoretical calculations. Galerkin method is a common method for approximate calculation of elastic plate structures, especially when there is no analytical solution as it is difficult to modify and solve. The use of Galerkin’s method can usually transform the problem into a function weighted integral involving the calculation of the physical domain of the problem from the equilibrium equation or the equation of motion, but there may be a large error between the theoretical results and the actual results, and the accuracy of the theoretical results may need to be further improved.

7. Conclusions

- (1)

- Taking the protective roof-pillar bearing structure in the goaf of bauxite mine as the research object, based on the elastic sheet theory and rheological theory and considering the interaction of roof or pillar, a physical model of the protective roof-pillar bearing structure is constructed to solve the problem. The stand-up time T is used as the index to consider the bearing capacity of the goaf bearing structure and the calculation method of the stand-up time of the bearing structure is given.

- (2)

- The stand-up time (T) of the bearing structure in the goaf of bauxite is mainly affected by the thickness of the protective roof (h), the uniform surface force coefficient (λ) of pillar, the span of the goaf (2n) and the thickness of the overlying rock layer (H).

- (a)

- When other factors remain unchanged, T is positively correlated with h, which increases with the increase of h. When h is within the range of 0.3–0.4 m, the bearing capacity of the bearing structure reaches the limit state.

- (b)

- When other factors remain unchanged, T is positively correlated with λ which increases with the increase of λ and the increasing speed is gradually accelerated. When λ is in the range of 0.3–0.4, the bearing capacity of the bearing structure reaches the limit state.

- (c)

- When other factors remain unchanged, T is negatively correlated with 2n which decreases with the increase of 2n and the decreasing speed slows down gradually. When 2n is greater than 60.0 m, the bearing capacity of the bearing structure reaches the limit state.

- (d)

- When other factors remain unchanged, T is negatively correlated with H and decreases with H increasing and the decreasing speed slows down gradually. When H comes 90.0 m, the bearing capacity of the structure reaches the limit state.

- (3)

- The engineering application shows that the goaf bearing structure in case 1 is within stand-up time range and the goaf is basically stable. In case 2, the goaf bearing structure loses its bearing capacity and the goaf has become unstable and collapsed. The results of theoretical calculation are basically consistent with those of engineering examples, which verifies the scientific nature of the calculation results of load-bearing mechanics model.

- (4)

- Taking the bauxite mine in Shanxi Province studied in this paper as an example, a proposed range of goaf structural parameters is given in consideration of economic benefits and production safety. Under the condition that the thickness of the overlaying rock and soil layer is 50 m, the thickness of the protective roof is 0.5 m, the uniform surface force coefficient of pillars is 0.5 and the goaf span is 30 m. Such a scheme is relatively safe and reliable.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiang, L.C.; Jiao, H.; Xie, B.; Yang, H. Study on Safety Coefficient of Sedimentary Bauxite Strip Pillar under Valley Terrain. Int. J. Environ. Res. Public Health 2022, 19, 10991. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, V.M.; Nguyen, Q.P. Analytical solution for estimating the stand-up time of the rock mass surrounding tunnel. Tunn. Undergr. Space Technol. 2015, 47, 10–15. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Z. Analytical solution to the roof bending deflection with mixed boundary conditions under uniform load. Appl. Math. Inf. Sci. 2013, 7, 579–585. [Google Scholar] [CrossRef]

- Jiang, L.C.; Jiao, H.; Xie, B. Analysis of Sliding and sudden instability of pillar and roof support System in goaf of sedimentary Bauxite Mine. J. Northeast. Univ. (Nat. Sci. Ed.) 2020, 41, 1767–1773+1787. [Google Scholar]

- Skrzypkowski, K. Comparative Analysis of the Mining Cribs Models Filled with Gangue. Energies 2020, 13, 5290. [Google Scholar] [CrossRef]

- Liu, R. The mechanical model on surface subsidence caused by backfilling mined-out area on thick loose loess layer: Taking a sedimentary bauxite mine as an example. Geotech. Geol. Eng. 2023, 41, 1083–1099. [Google Scholar] [CrossRef]

- Gao, B.; Cao, S.; Yilmaz, E. Effect of content and length of polypropylene fibers on strength and microstructure of cementitious tailings-waste rock fill. Minerals 2023, 13, 142. [Google Scholar] [CrossRef]

- Jing, W.; Zhou, J.; Yuan, L.; Jin, R.; Jing, L. Deformation and Failure Mechanism of Surrounding Rock in Deep Soft Rock Tunnels Considering Rock Rheology and Different Strength Criteria. Rock Mech. Rock Eng. 2023, 56, 1–36. [Google Scholar] [CrossRef]

- He, Z.; Xie, Z.; Zhang, N.; Han, C.; Xiang, Z.; Yan, G.; Qiao, H.; Shao, C. Research on Spatiotemporal Evolution Law of Surrounding Rock Fractures and Hierarchical Collaborative Control Technology in High-stress Soft Rock Roadway: A Case Study. Eng. Fail. Anal. 2023, 150, 107366. [Google Scholar] [CrossRef]

- Qin, S.Q.; Wang, S.J. Brittle instability and nonlinear evolution mechanism of coal pillar-roof synergistic interaction. Chin. J. Eng. Geol. 2005, 4, 437–446. Available online: http://www.cqvip.com/qk/98122x/20054/20793048.html (accessed on 22 December 2023).

- Xu, X.D.; Zhou, Y.J.; Pang, S. Sudden instability analysis of plastic support system in old goaf of gypsum mine. Chin. J. Rock Mech. Eng. 2018, 37, 2548–2555. [Google Scholar]

- Chen, D.D.; Xie, S.R.; He, F.L.; Pan, H.; Song, H.Z.; Zeng, J.C. Fracture law of basic roof thin plate at the boundary of elastic foundation of long side goaf (coal pillar). J. Min. Saf. Eng. 2018, 35, 1191–1199. [Google Scholar]

- Zhao, Y.; Wang, S.; Zou, Z.; Ge, L.; Cui, F. Instability characteristics of the cracked roof rock beam under shallow mining conditions. Int. J. Min. Sci. Technol. 2018, 28, 437–444. [Google Scholar] [CrossRef]

- Wang, X.; Guan, K.; Liu, J.; Liu, X. Instability and pillar burst mechanism in roof-pillar system with rock beam embedded in elastic foundation. Bull. Eng. Geol. Environ. 2021, 80, 2447–2459. [Google Scholar] [CrossRef]

- Li, B.; Tian, Y.; Tian, J.; Zuo, S.; Chen, S. Bending-damaged fracture criterion and numerical implementation of limestone beam under three-point bending test. Front. Earth Sci. 2023, 11, 1147129. [Google Scholar] [CrossRef]

- Qin, T.; Duan, B.; Duan, Y.; Ni, Y.; Hou, X.; Ma, P.; Yang, Y. “Migrate-Transfer-Control” Support System of Surrounding Rock in the Deep Roadway and Its Application. Appl. Sci. 2023, 13, 6325. [Google Scholar] [CrossRef]

- Huang, M.L.; Shi, Y.D.; Wang, M. A comparative study on nanoparticle network-dependent electrical conductivity, electromagnetic wave shielding effectiveness and rheological properties in multiwall carbon nanotubes filled polymer nanocomposites. Polym. Compos. 2023, 44, 1188–1200. [Google Scholar] [CrossRef]

- Lv, M.; An, X.; Bai, H.; Zhang, J.; Li, P.; Shao, K. Improved mechanical models for self-compacting concrete in the paste rheological thresholds theory considering the pressure between particles. J. Build. Eng. 2023, 64, 105656. [Google Scholar] [CrossRef]

- Wang, L.; Tian, H.; Zhang, W.; Li, C.; Xiang, D. Insights into interaction mechanism between xanthan gum and galactomannan based on density functional theory and rheological properties. Food Chem. 2023, 418, 135990. [Google Scholar] [CrossRef]

- Niu, Y.; Cheng, H.; Wu, S.; Sun, J.; Wang, J. Rheological properties of cemented paste backfill and the construction of a prediction model. Case Stud. Constr. Mater. 2022, 16, e01140. [Google Scholar] [CrossRef]

- Ren, Z.; Liu, H.; Li, L.; Wang, Y.; Sun, Q. On the effects of rheological behavior on landslide motion and tsunami hazard for the Baiyun Slide in the South China Sea. Landslides 2023, 20, 1599–1616. [Google Scholar] [CrossRef]

- Li, C.; Li, X.; Ruan, Z.E. Rheological properties of a multiscale granular system during mixing of cemented paste backfill: A review. Int. J. Miner. Metall. Mater. 2023, 30, 1444–1454. [Google Scholar] [CrossRef]

- Cui, P.; Cao, W.; Xu, Z.; Li, H.; Hu, M. One-dimensional nonlinear rheological consolidation analysis of soft ground under continuous drainage boundary conditions. Comput. Geotech. 2023, 156, 105283. [Google Scholar] [CrossRef]

- Xiao, C.; Zheng, H.; Hou, X.; Zhang, X. A stability study of goaf based on mechanical properties degradation of rock caused by rheological and disturbing loads. Int. J. Min. Sci. Technol. 2015, 25, 741–747. [Google Scholar] [CrossRef]

- Yuan, K.; Lu, Y.; Li, W.; Yu, H.; Gao, S. Rheological Characterization and Accumulation Tests for Strong Thixotropic Engineering Slurry. Materials 2022, 15, 6891. [Google Scholar] [CrossRef] [PubMed]

- Hu, B.; Zhang, Q.; Li, S.; Yu, H.; Wang, X.; Wang, H. Application of numerical simulation methods in solving complex mining engineering problems in dingxi mine, China. Minerals 2022, 12, 123. [Google Scholar] [CrossRef]

- Ma, H.; Ji, H.; Zhang, M. Study on the roof-pillar rheological collapse of goaf based on HK model. In Proceedings of the 2016 4th International Conference on Sensors, Mechatronics and Automation, Zhuhai, China, 12–13 November 2016; pp. 162–171. [Google Scholar]

- Liu, S.J.; Zhai, S.R. Roof failure analysis of pillar rheology based on H-K Body. China Work Saf. Sci. Technol. 2015, 11, 25–30. [Google Scholar]

- Xie, X.B.; Deng, R.N.; Dong, X.J.; Yan, Z.Z. Stability of goaf group system based on mutation and rheology theory. Rock Soil Mech. 2018, 39, 1963–1972. [Google Scholar]

- Zhu, Z.H.; Zhao, Y.L.; Xu, Y.F.; Sun, X.K. Teaching research of eight typical rock mechanics rheological combination models. Contemp. Educ. Theory Pract. 2011, 3, 85–89. [Google Scholar]

- Jiang, L.C.; Shen, B.B.; Xue, L.L. Determining the critical blasting load of cracked strip bauxite pillars. Bull. Eng. Geol. Environ. 2021, 80, 4639–4650. [Google Scholar] [CrossRef]

- Jiang, L.C.; Shen, B.B.; Chen, M. Instability mechanism of layered bauxite goaf group induced by cyclic blasting cumulative damage. J. Cent. South Univ. (Sci. Technol.) 2022, 53, 1429–1438. [Google Scholar]

- Cockburn, B. Hybridizable discontinuous Galerkin methods for second-order elliptic problems: Overview, a new result and open problems. Jpn. J. Ind. Appl. Math. 2023, 40, 1637–1676. [Google Scholar] [CrossRef]

- Wang, J.A.; Shang, X.C.; Ma, H.T. Investigation of catastrophic ground collapse in Xingtai gypsum mines in China. Int. J. Rock Mech. Min. Sci. 2008, 45, 1480–1499. [Google Scholar] [CrossRef]

- Li, D.H. Stability analysis of roadway surrounding rock in high stress soft rock. Energy Energy Conserv. 2021, 191, 16–17+31. [Google Scholar]

- Gong, X.H.; Hou, K.P.; Yang, Z.Q. Study on the span of mining room by open stoping method in gently inclined Bauxite mine. Light Met. 2014, 9, 15–17. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, W.Y.; Wang, W.; Shao, J.F.; Gu, J.J. Rheological mechanics test and parameter identification of soft rock in fracture zone. Chin. J. Rock Mech. Eng. 2014, 33, 3412–3420. [Google Scholar]

- Ma, S.-W.; Hu, J.-H.; Qin, Y.-G.; Ren, Q.-F.; Yang, D.-J. Bearing mechanism and thickness optimization of ore roof in bauxite stope. Trans. Nonferrous Met. Soc. China 2022, 32, 285–295. [Google Scholar] [CrossRef]

| Lithology | Test Weight γ/KN·m−3 | Young’s Modulus E/GPa | Poisson’s Ratio μ | Cohesion c/kPa | Internal Friction Angle φ/(°) | Tensile Strength [σt]/MPa | Thickness H/m |

|---|---|---|---|---|---|---|---|

| Surface soil | 24.6 | 3.25 | 0.25 | 0.56 | 35.6 | 0.002 | 20–60 |

| Metasandstone | 25.1 | 8.02 | 0.27 | 4.23 | 38.9 | 1.51 | 5–20 |

| Clay rock | 22.5 | 3.50 | 0.24 | 1.29 | 31.7 | 1.42 | 5–20 |

| Sedimentary bauxite | 25.7 | 4.50 | 0.27 | 12.72 | 44.2 | 2.27 | 2–10 |

| Iron ore deposit | 30.2 | 10.91 | 0.29 | 13.19 | 41.8 | 3.84 | 5–20 |

| Case | Thickness of Protective Roof h/m | Equivalent Uniform Surface Force Coefficient of Pillar λ | Goaf Span 2n/m | Length of Protective Roof 2m/m | Thickness of Overlying Soil Layer H/m | Pillar Height L/m |

|---|---|---|---|---|---|---|

| Case 1 (Region 1) | 0.5 | 0.45 | 20.0 | 50.0 | 50.0 | 3.0 |

| Case 2 (Region 2) | 0.5 | 0.45 | 35.0 | 75.0 | 50.0 | 3.0 |

| E1/MPa | E2/MPa | η1/(MPa·h) | η2/(MPa·h) | |

|---|---|---|---|---|

| Pillar | 3.69 × 103 | 2.25 × 103 | 1.499 × 104 | 4.686 × 105 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, L.; Liu, W. Stand-Up Time Dependence on Protective Roof–Pillar Bearing Structure of Bauxite. Appl. Sci. 2024, 14, 325. https://doi.org/10.3390/app14010325

Jiang L, Liu W. Stand-Up Time Dependence on Protective Roof–Pillar Bearing Structure of Bauxite. Applied Sciences. 2024; 14(1):325. https://doi.org/10.3390/app14010325

Chicago/Turabian StyleJiang, Lichun, and Wei Liu. 2024. "Stand-Up Time Dependence on Protective Roof–Pillar Bearing Structure of Bauxite" Applied Sciences 14, no. 1: 325. https://doi.org/10.3390/app14010325

APA StyleJiang, L., & Liu, W. (2024). Stand-Up Time Dependence on Protective Roof–Pillar Bearing Structure of Bauxite. Applied Sciences, 14(1), 325. https://doi.org/10.3390/app14010325