Development and Assessment of a 4D Printing Technique for Space Applications

Abstract

:1. Introduction

- SMPs exhibit a significantly greater recoverable deformation compared with SMAs [10].

2. Materials and Methods

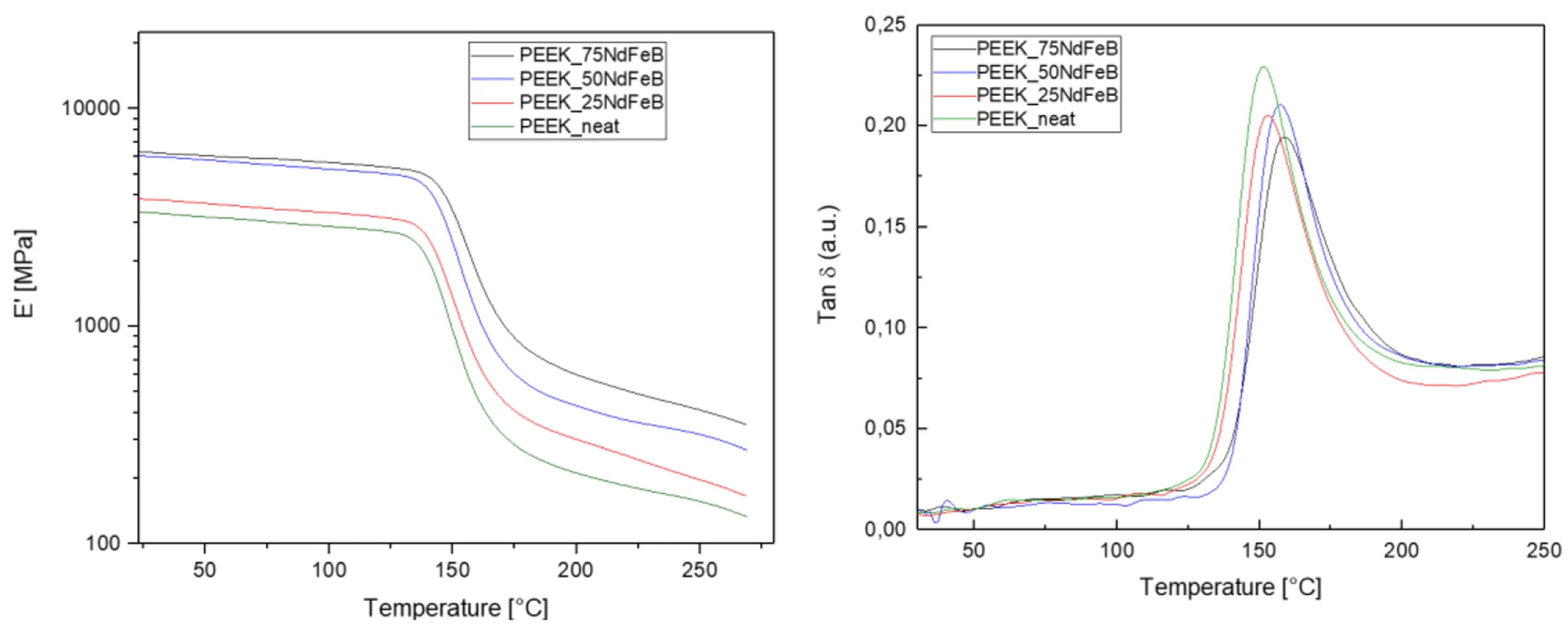

2.1. Materials: PEEK

2.2. 3D and 4D Printing

- CAD modelling:The hinge geometry was initially modelled using computer-aided design (CAD) software (https://www.solidworks.com, (accessed on 14 November 2023)). During this phase, careful consideration is given to the orientation in which the part will be printed to avoid challenges such as overhangs or difficult-to-print sections.

- Slicing:Once the CAD model was finalized, it was exported to a .stl file, creating a meshed version of the part. This file was then loaded into a slicing program, in this case, Cura. In the slicer, the printing process was planned, and various process parameters were fine-tuned based on the specific part geometry. Common parameters included print speed, print temperature, and line width, which significantly influenced the final printing outcome. The slicing software generated a G-code file containing the instructions for the 3D printer.

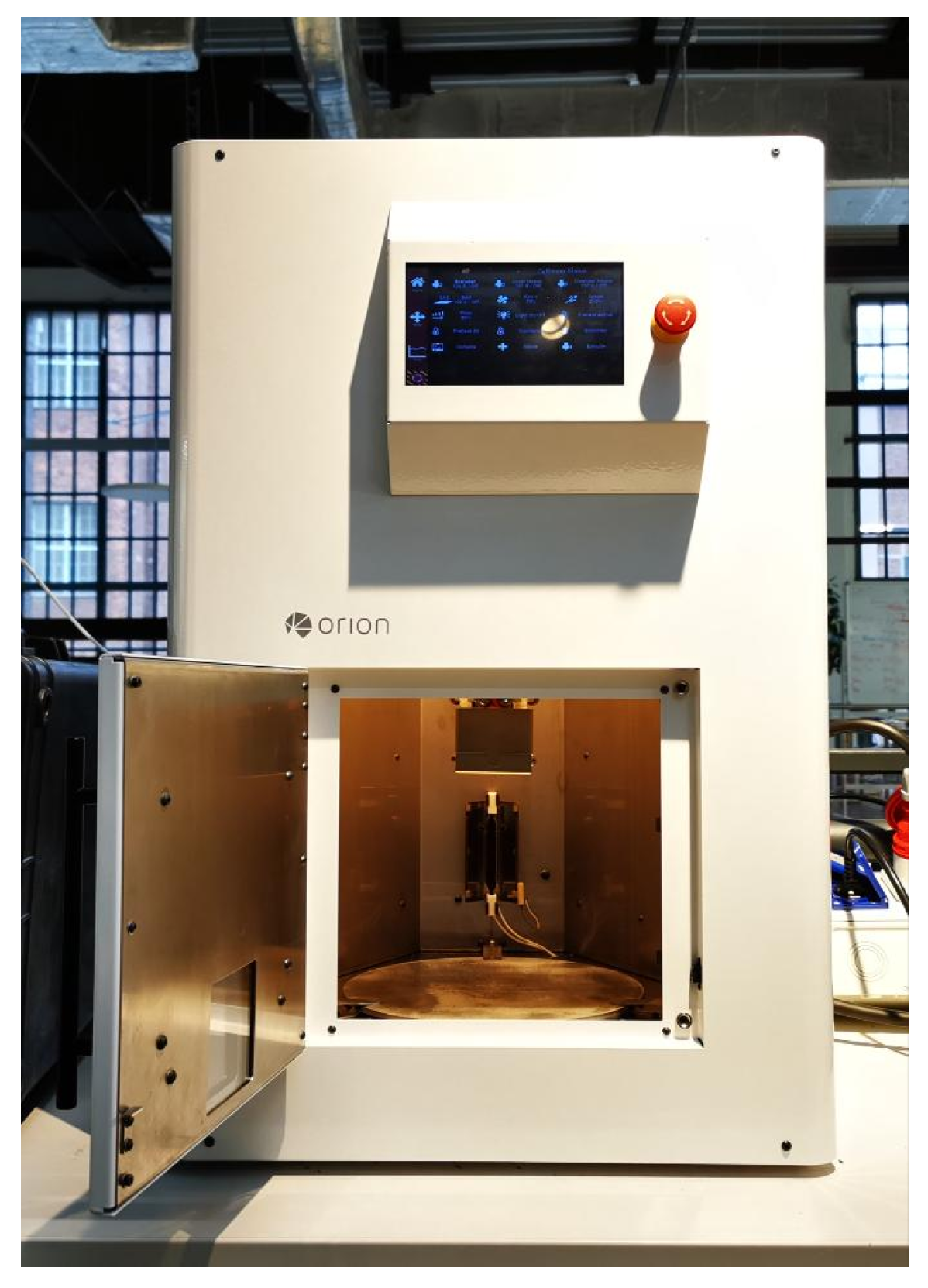

- 3D printing on Orion’s A150:The 3D printer employed in this study was developed by Orion Additive Manufacturing GmbH (Orion). Orion’s printer surpasses traditional FFF capabilities with its innovative system specifically designed for engineering polymers like PEEK. Notably, it achieves nearly density and isotropic strength values that are comparable or even better than those of injection-moulded parts [15]. The key to this success lies in Orion’s thermal radiation heating (TRH) system, maintaining a warm printing chamber. Active heating during printing ensures the effective fusion of layers, minimizing air pockets. Refer to Figure 2 for an illustration of one of Orion’s printers used in manufacturing and testing the hinges.The G-code that was maintained after slicing was then utilized by the 3D printer. The printer read the file, interpreting each line as instructions for movement or changes in process parameters, thus gradually printing the hinge.

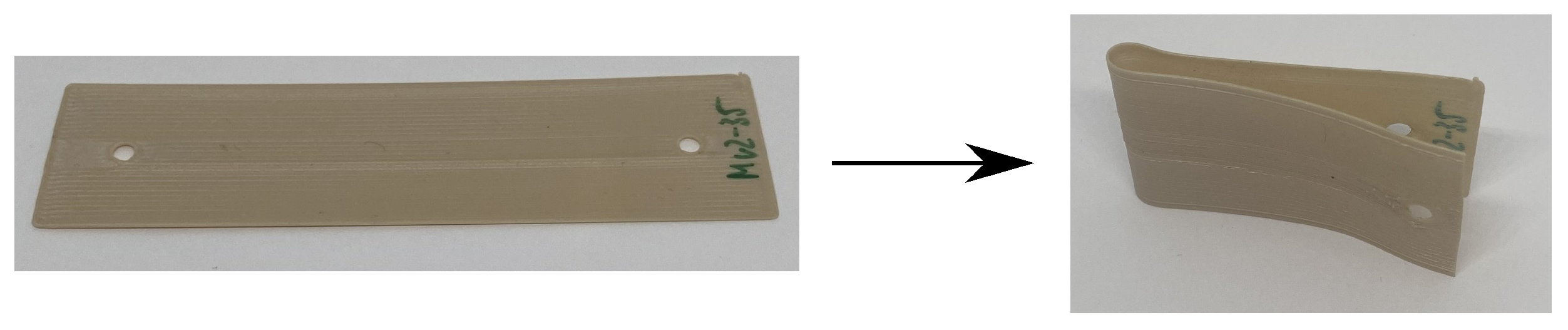

- 4D printing

- Shape Memory Effects in 4D Printing

- Programming: The polymer is initially in its undeformed state (shape A) and is subjected to thermal energy above a specific transition temperature (). This allows the polymer to undergo deformation under an applied force. Upon cooling below , the deformed state is fixed [24].

- Storage: The polymer, now in its deformed temporary state (shape B), stabilizes the deformation. This stage allows for convenient storage, with the polymer retaining its altered shape [24].

- Recovery: Reheating the polymer above reactivates its ability to recover the initial deformation, completing the shape memory cycle [24].

2.3. Design of Experiments

- Hinge Fabrication: Hinges made from PEEK will be 3D printed on Orion’s A150 3D printer to ensure high density and isotropy. Because of confidentiality agreements established with Orion, specific parameters employed for 3D printing the hinges on Orion’s printers cannot be disclosed at this point. This is integral to protect proprietary details, preserving Orion’s competitive edge, and protecting their techniques from unauthorized replication or exploitation.

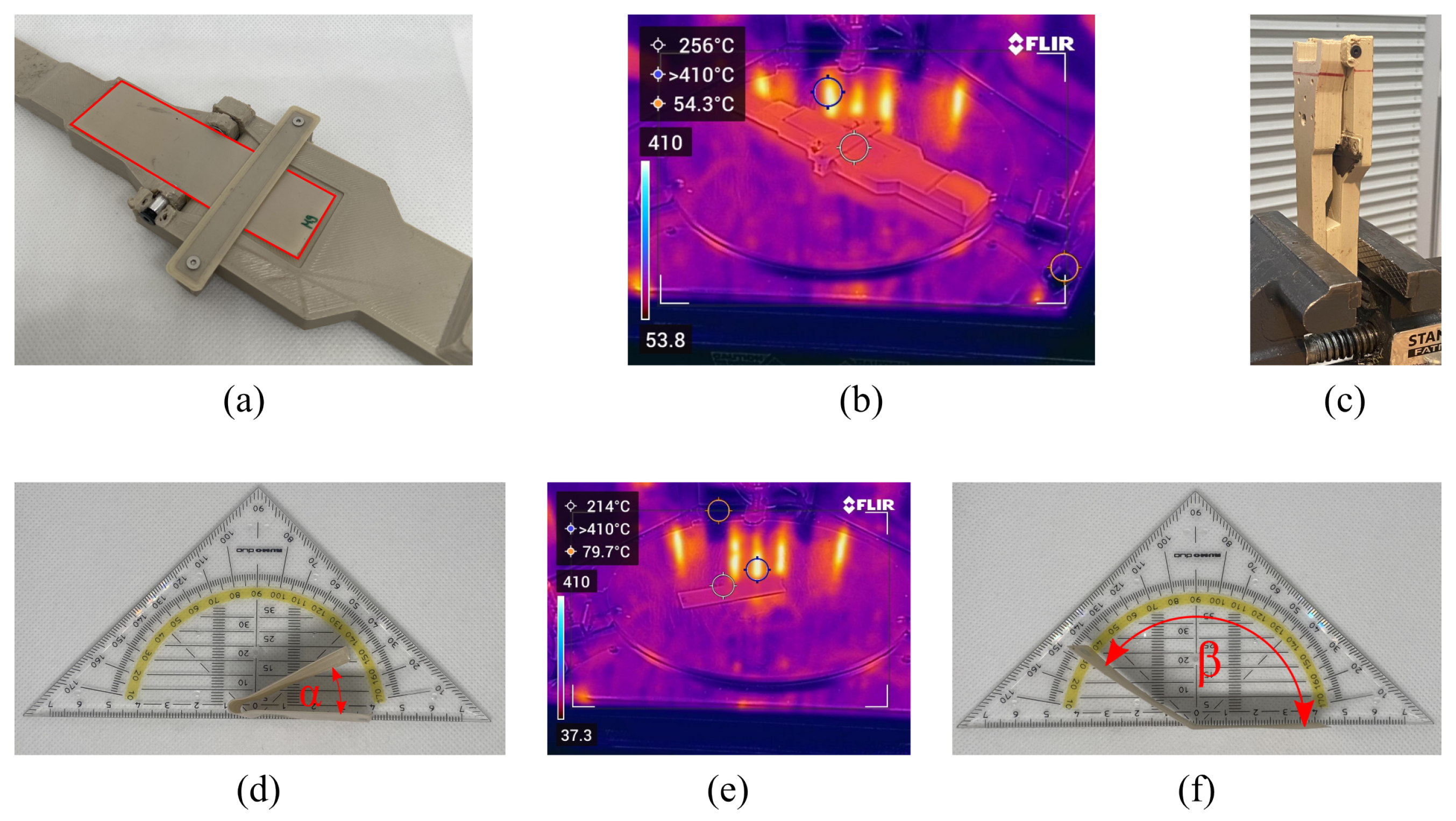

- Programming Process: After printing, the hinges will be programmed using the build chamber of Orion’s 3D printer. The programming process involves heating the hinges and utilizing a custom-made programming device. This device will be constructed and optimized to efficiently support the programming of hinges.

- Device Iteration: Following an initial set of experiments, the programming device will be altered and optimized, and all experiments will be repeated using this updated device. This device will also be 3D printed using PEEK to match the high-temperature environment required for programming. The device was printed using a rectangular infill pattern with an infill density of 30%.

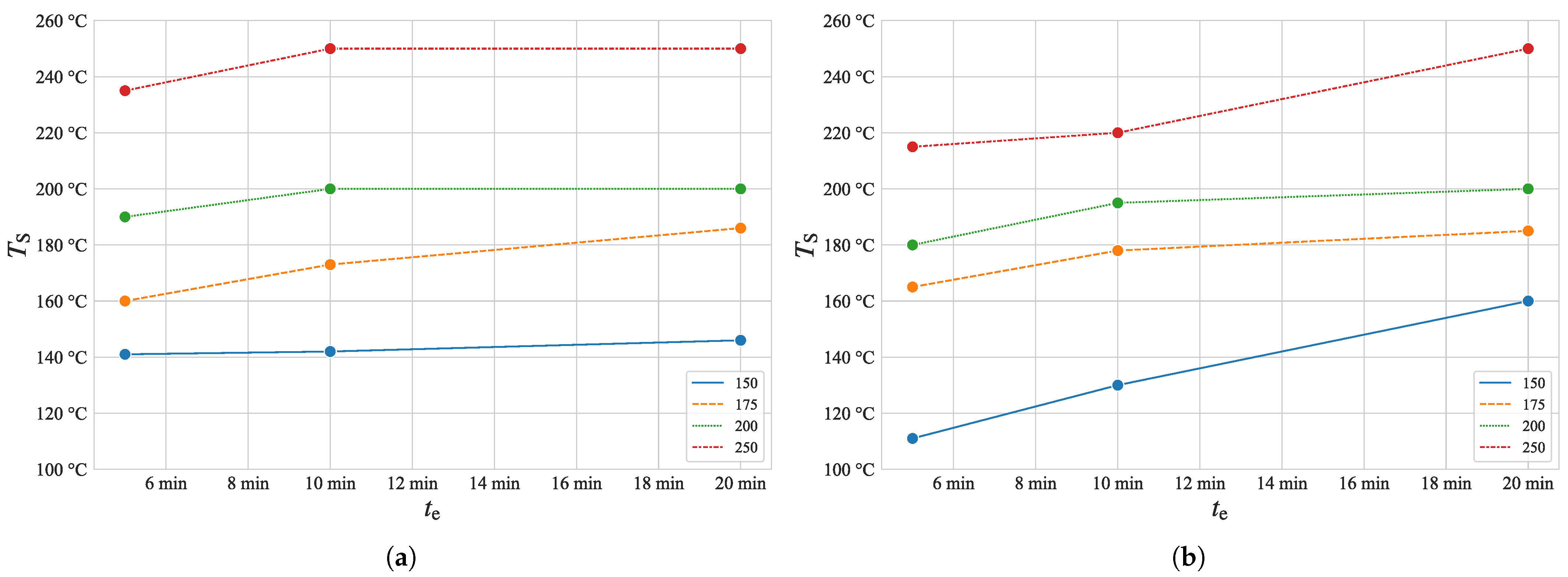

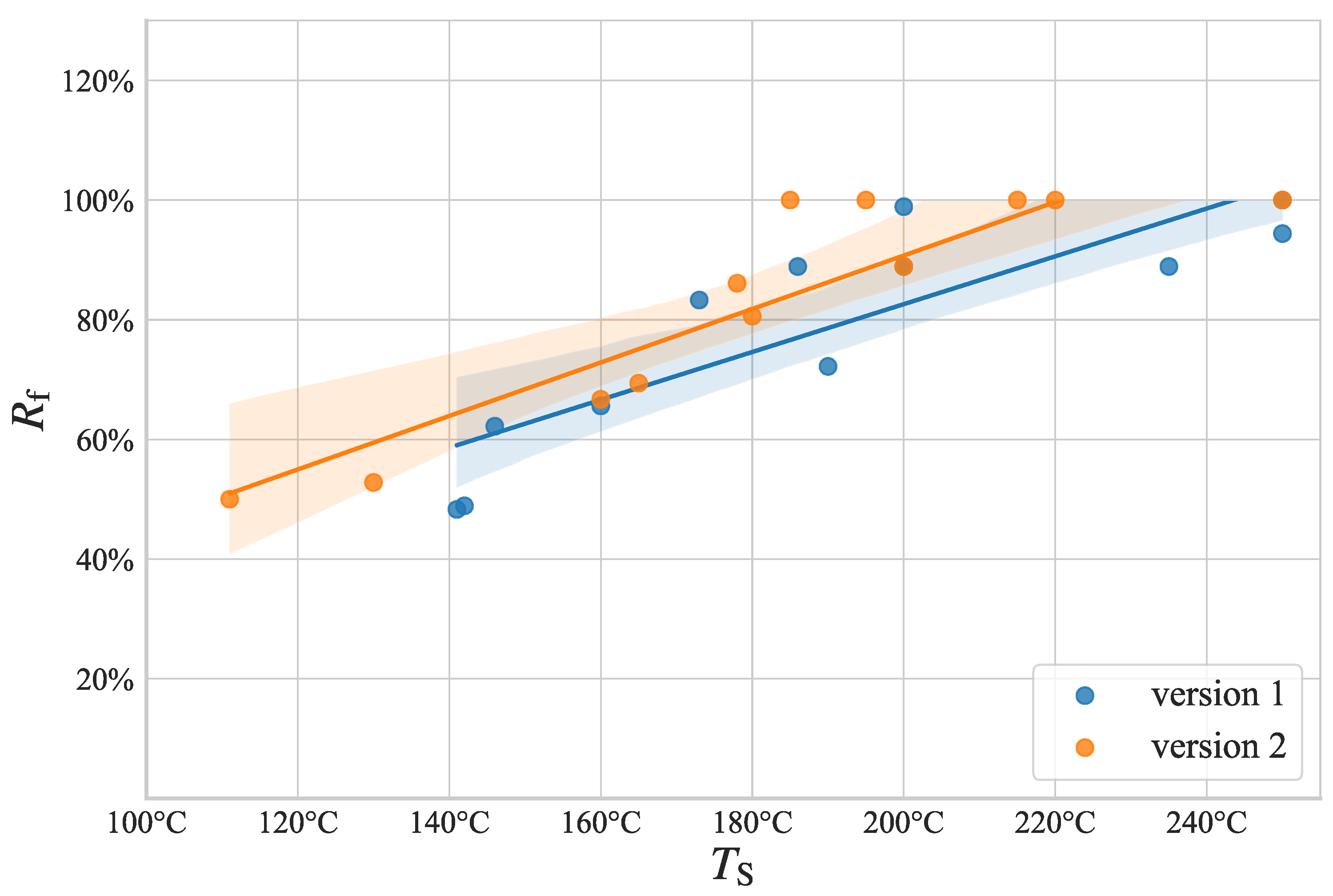

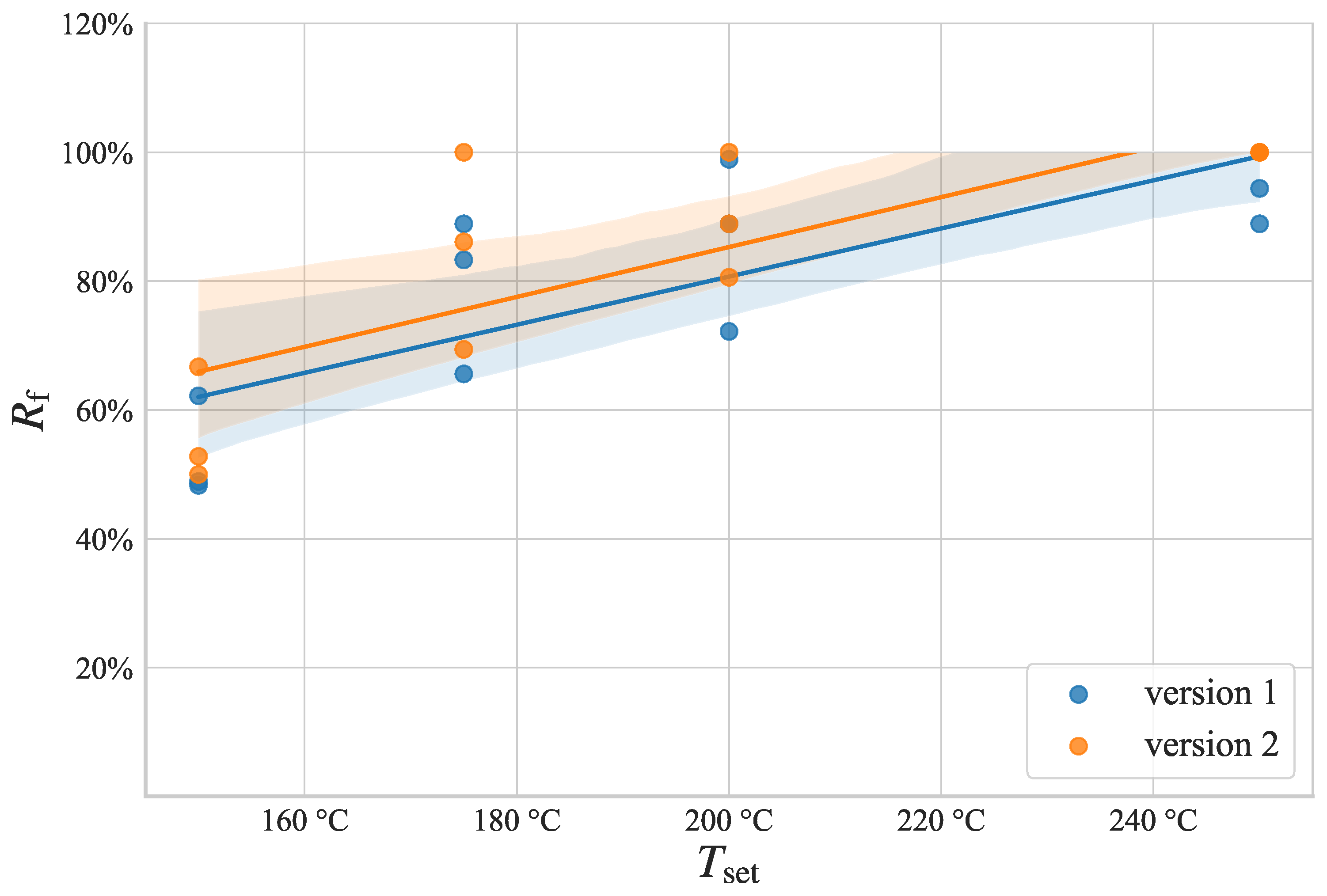

- Experiments: The experiments are designed to assess the shape memory characteristics of the hinges, with a focus on programming and recovery:

- (a)

- Programming Assessment: The hinges will be programmed at different temperatures inside the print chamber (150 °C, 175 °C, 200 °C, and 250 °C) and for varying time durations (5 min, 10 min, and 20 min). The success of the programming process will be measured using the achieved fixed angle, denoted as . This angle, as illustrated in Figure 5d), represents the angle between the inner two surfaces of the hinge after programming, with 0° being the smallest possible angle (perfect programming) and 180° being the largest possible angle (no programming at all). The fixity ratio () is calculated using the formula:Subsequently, the hinges will recover their deformation at the same temperature and time duration as the initial programming. The recovered angle will be measured to calculate the recovery ratio (). is the angle between the inner two surfaces of the hinge, with 180° being the largest possible angle (perfect recovery) and being the smallest possible angle (no recovery at all). The recovery ratio () is calculated using the formula:This experiment aims to determine the optimal temperature and minimum time required for effective programming.

- (b)

- Recovery Assessment: Once the optimal programming conditions are determined, the hinges will be tested to measure their recovery potential. After successful programming at the identified optimal conditions, the hinges will be subjected to recovery tests at various lower temperatures (−10 °C, −30 °C, −50 °C, and 150 °C), with the recovery time measured. The programming and recovery ratios will be calculated. This experiment aims to establish the lower limit for efficient recovery.

- (c)

- Forced Cool-Down Assessment: In this experiment, the hinges will be programmed at a temperature that did not yield ideal results for fixity and recovery. Subsequently, the hinges will be rapidly cooled by submersion in water. The results will be compared with a reference group programmed in the conventional manner. The goal of this experiment was two-fold; first, investigate what influence the rapid cool-down has on the performance of the hinges and, second, see if the cool-down time and ease of handling can be improved.

- Apparatus and Setup:

- Orion’s A150 3D printer for 4D printing.

- A simple triangular ruler to measure the achieved programmed and recovered angles.

- A thermal imaging camera from FLIR Systems Inc. (Flir C5) to measure and validate temperatures inside the printer.

- A custom-built programming device used for hinge programming.

- High-temperature gloves for taking the programming device out of the printer.

- The temperature set for the build chamber.

- The exposure time (the duration hinges were left inside the build chamber).

- The generation of the programming device used.

- Programmed angle , used to calculate the fixity ratio ().

- Recovered angle , used to calculate the recovery ratio ().

- Recovery time (specific to Experiment 2).

- Surface temperature measured before programming using the thermal imaging camera.

3. Results

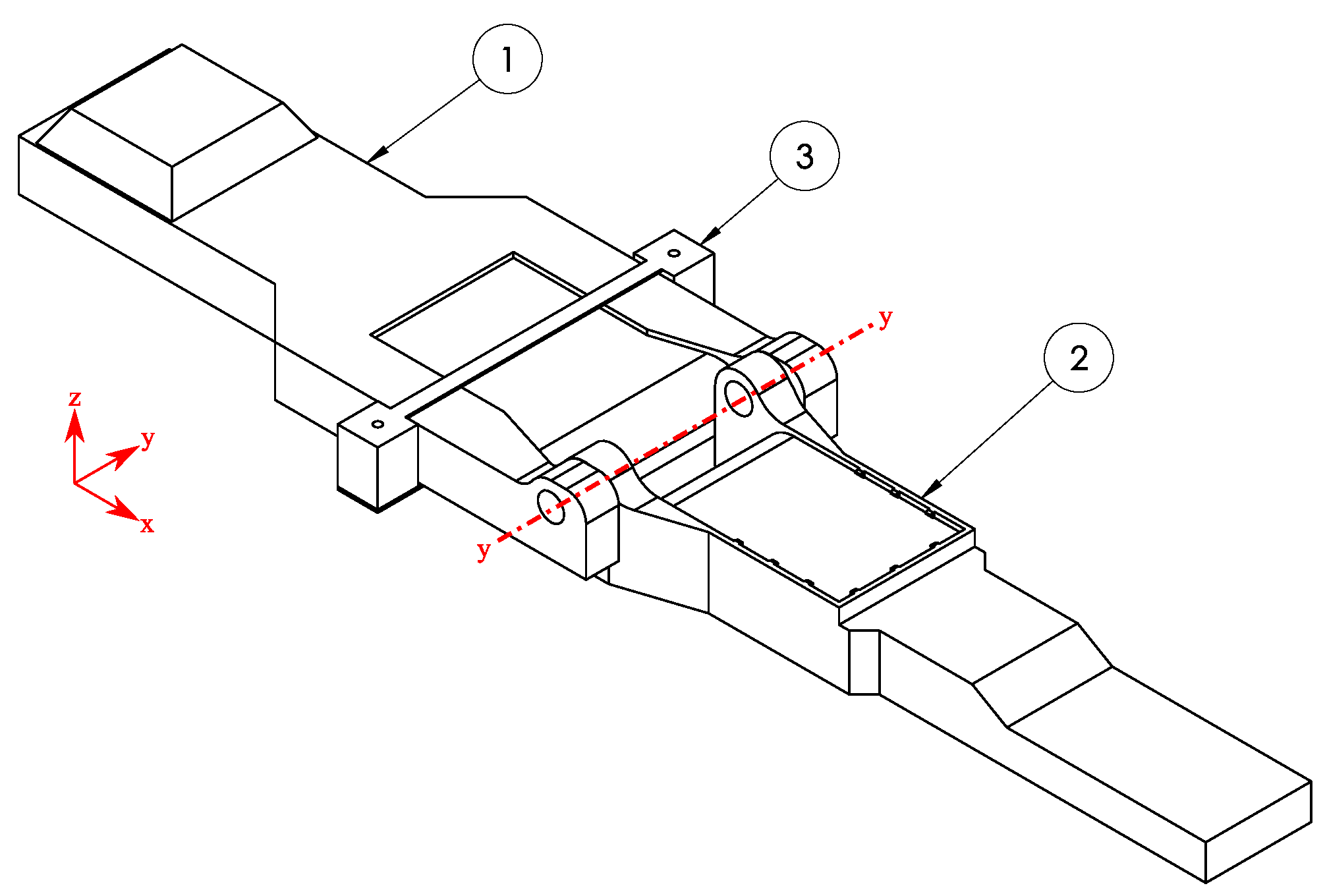

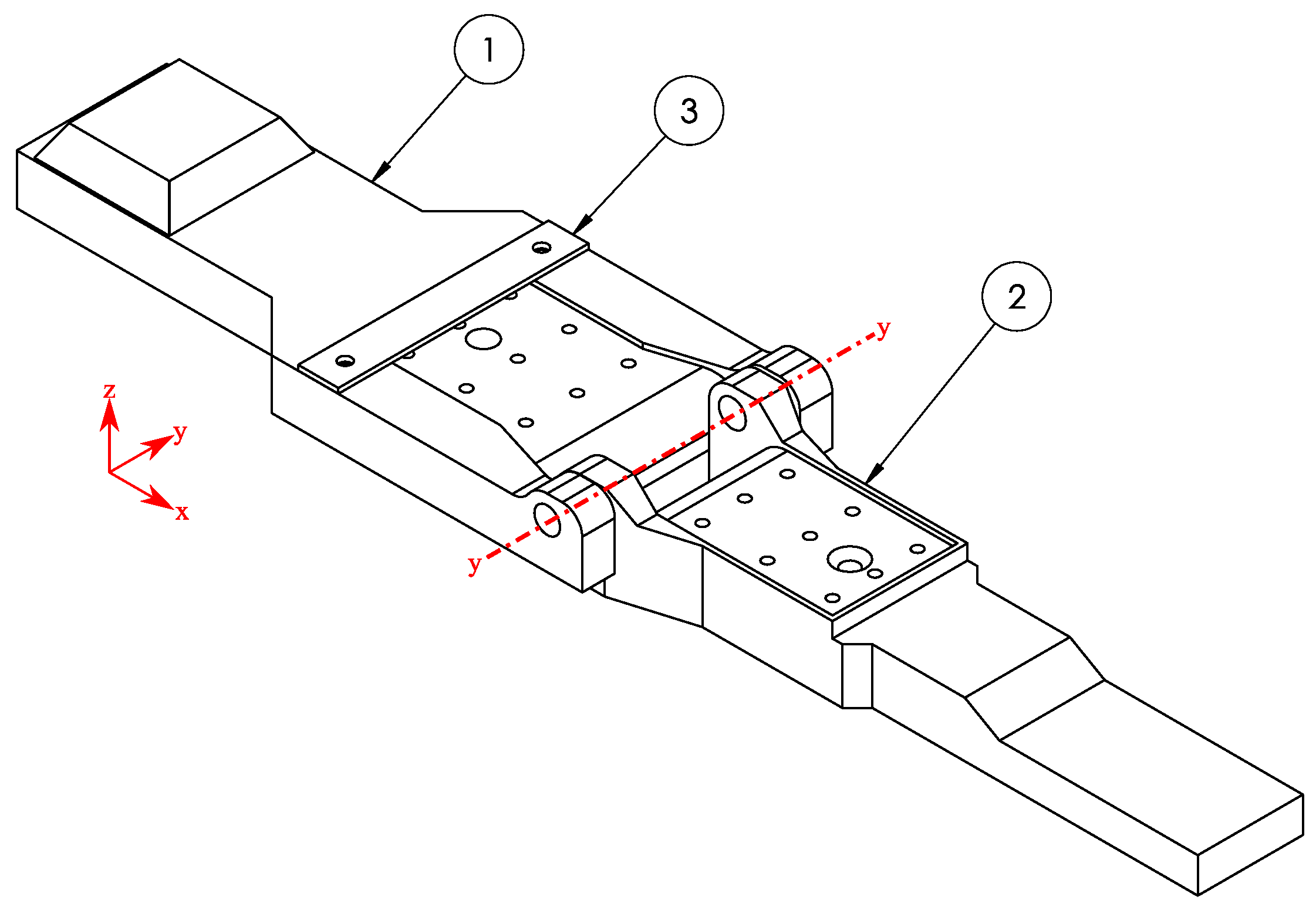

3.1. Programming Device

- Shared Features:

- Dual Handles: Each version incorporates two handles—a larger one referred to as the base handle and a smaller rotating handle. These handles are interconnected through a press fit along the y–y axis, achieved by embedding an M3 thread insert into connecting holes. For hinge programming, these two handles are pulled towards each other, allowing the hinge inside to be folded.

- Vertical Alignment Feature: Positioned at the end of the base handle, this feature prevents over-tightening when the device is secured in a vice for cooling. Conversely, the rotating handle features a negative counterpart of this alignment feature.

- First Version:

- Slide back the slidable hold-down mechanism on the base handle.

- Load the hinge into the programming device, ensuring the teeth grip the hinge.

- Slide the hold-down mechanism back above the hinge, securing it on the base handle side (shown in Figure 5a).

- Place the device with the loaded hinge in the build chamber of Orion’s A150 and heat (see Figure 5b).

- Quickly remove the device from the 3D printer.

- Pull both handles towards each other, effectively folding the hinge, while at the same time sliding back the hold-down mechanism on the base handle side.

- Clamp the device into a vice (for experiment 3 submerge in water) with the hinge still inside and allow both the device and hinge to cool down (Figure 5c).

- After cooling, extract the device from the vice, revealing the folded hinge (Figure 5d).

- Second Version:

- Carefully slide the hinge under the hold-down mechanism on the base handle.

- Align the holes in the hinge with those on the programming device.

- Use an M2 countersunk screw to fixate the hinge in the rotating handle.

- Place the device with the loaded hinge in the build chamber and heat.

- Quickly remove the device from the 3D printer.

- Pull both handles towards each other, effectively folding the hinge.

- Clamp the device into a vice (for experiment 3 submerge in water) with the hinge still inside, allowing both the device and hinge to cool down.

- After cooling, extract the screw using an allen key, enabling the device to open and revealing the folded hinge.

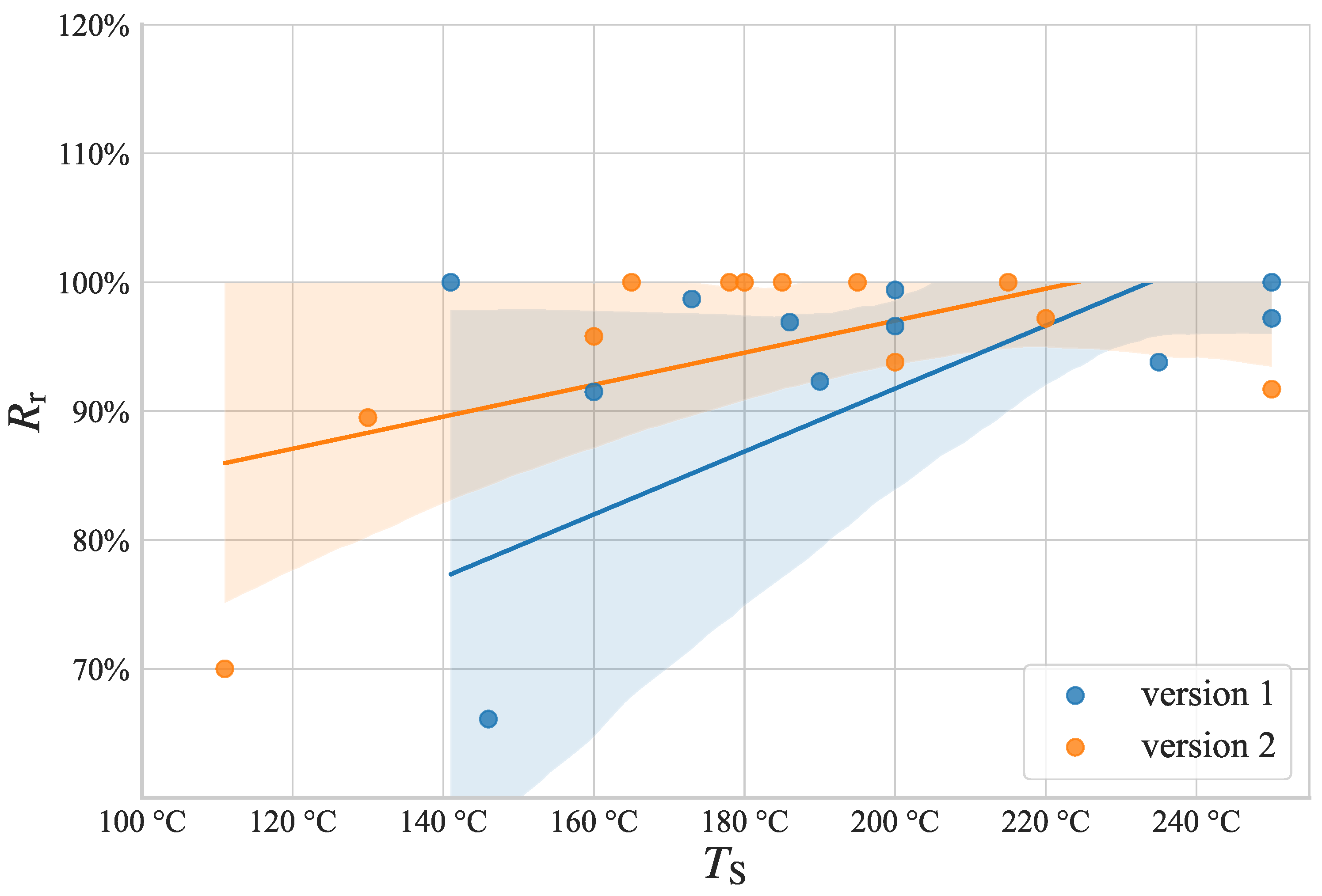

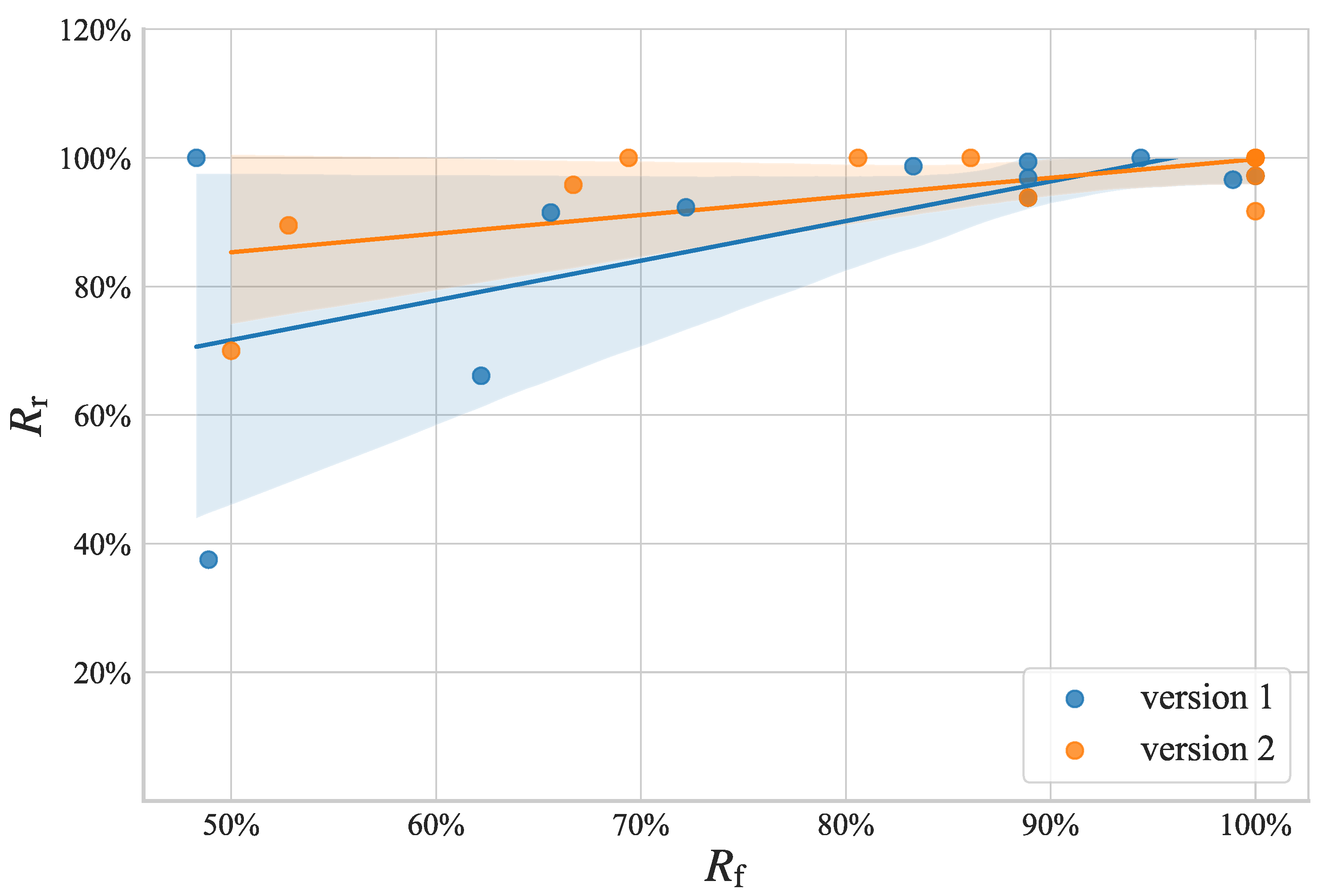

3.2. Programming Assessment

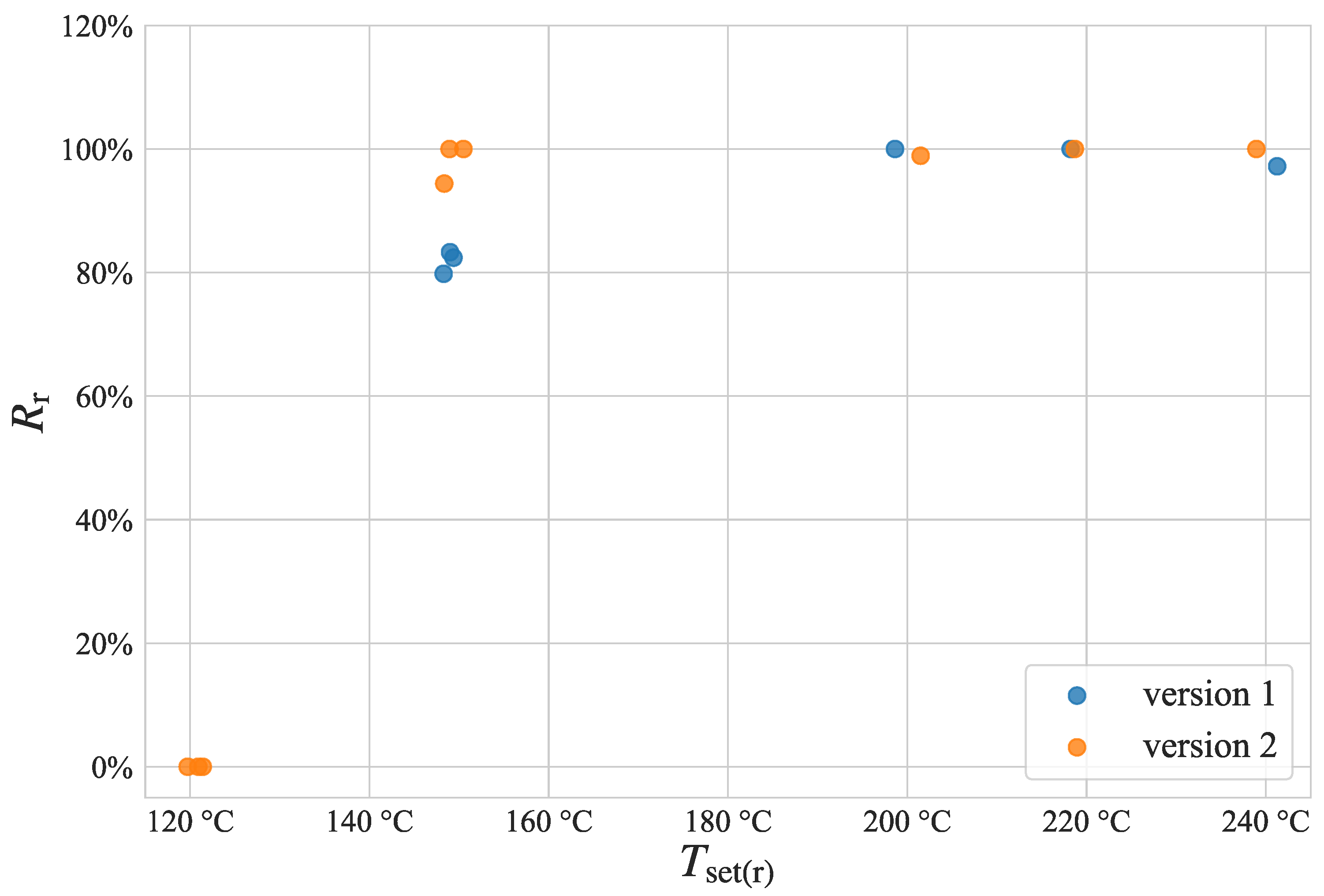

3.3. Recovery Assessment

3.4. Forced Cool-Down Assessment

4. Discussion

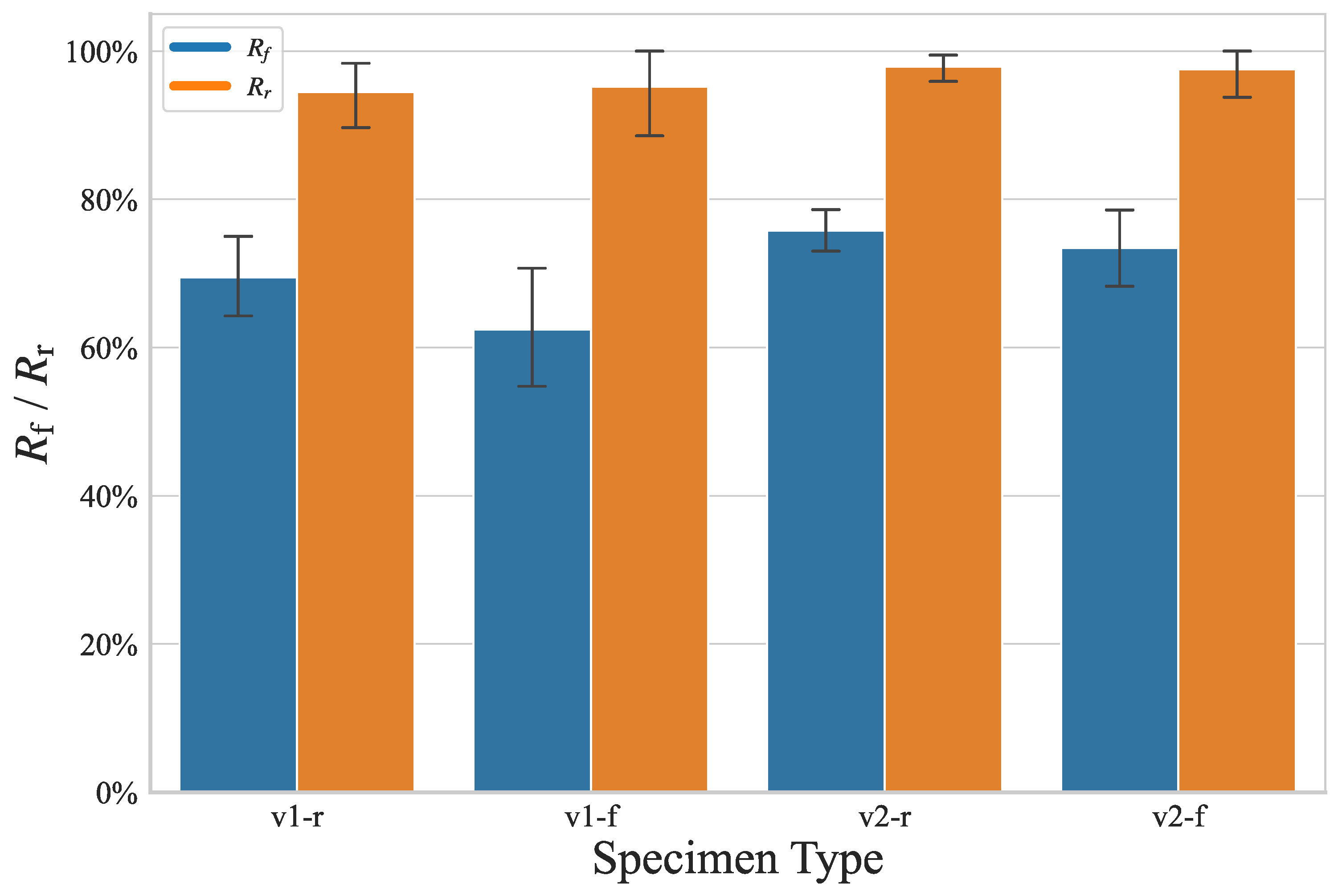

4.1. Influence of the Programming Device on the 4D Printing Performance

4.2. Programming

4.3. Recovery

4.4. Forced Cool-Down

4.5. Derived Use-Case Scenarios in Spacecrafts

5. Conclusions

- The two iterations of the programming device played a pivotal role in influencing the 4D printing performance, with the second version showcasing superior results across all experiments.

- The correlation between programming temperature and the quality of bending outcomes underscored the delicate balance in achieving optimal shape memory effects.

- Additionally, the unexpected independence of recovery from the recovery temperature up to introduced new considerations for deploying these hinges in diverse scenarios.

- The forced cool-down experiments, while revealing a nuanced interplay between cooling dynamics and 4D printing performance, indicated a potential need for methodological refinement.

- The derived use-case scenarios in spacecrafts highlighted the promising application of self-activating hinges, particularly in deploying structures such as solar arrays.

- In addition to the aforementioned insights, it is noteworthy to acknowledge the instrumental role of the A150 3D printer from Orion Additive Manufacturing in this study. A150 is an innovative tool in the realm of 4D printing, paving the way for more streamlined and efficient experimentation in the field of 4D printing.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CAD | Computer-aided design |

| CNC | Computerized numerical control |

| DMA | Dynamic mechanical analysis |

| DMTA | Dynamic mechanical thermal analysis |

| FDM | Fused deposition modelling |

| FFF | Fused filament fabrication |

| GEO | Geostationary orbit |

| ISS | International Space Station |

| LEO | Lower Earth orbit |

| PEEK | Polyetheretherketon |

| PLA | Polylactic acid |

| PTM | Partial-transition mechanism |

| SMA | Shape memory alloy |

| SME | Shape memory effect |

| SMP | Shape memory polymer |

| TMA | Thermal mechanical analysis |

| TRH | Thermal radiation heating |

References

- Ahmed, A.; Arya, S.; Gupta, V.; Furukawa, H.; Khosla, A. 4D printing: Fundamentals, materials, applications and challenges. Polymer 2021, 228, 123926. [Google Scholar] [CrossRef]

- Tibbits, S. 4D Printing: Multi–Material Shape Change. Wiley 2014, 84, 116–121. [Google Scholar] [CrossRef]

- Razzaq, M.Y.; Gonzalez-Gutierrez, J.; Mertz, G.; Ruch, D.; Schmidt, D.F.; Westermann, S. 4D Printing of Multicomponent Shape-Memory Polymer Formulations. Appl. Sci. 2022, 12, 7880. [Google Scholar] [CrossRef]

- Yakacki, C.M.; Shandas, R.; Lanning, C.; Rech, B.; Eckstein, A.; Gall, K. Unconstrained recovery characterization of shape-memory polymer networks for cardiovascular applications. Biomaterials 2007, 28, 2255–2263. [Google Scholar] [CrossRef] [PubMed]

- Jeong, J.W.; Yoo, Y.I.; Lee, J.J.; Lim, J.H.; Kim, K.W. Development of a Tape Spring Hinge with a SMA Latch for a Satellite Solar Array Deployment Using the Independence Axiom. IERI Procedia 2012, 1, 225–231. [Google Scholar] [CrossRef]

- Concilio, A. Shape Memory Alloy Engineering, 2nd ed.; Elsevier Science & Technology: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Lendlein, A. (Ed.) Shape-Memory Polymers; Advances in Polymer Science; Springer: Berlin/Heidelberg, Germany, 2010; Volume 226. [Google Scholar]

- Ishizawa, J.; Imagawa, K.; Minami, S.; Hayashi, S.; Miwa, N. Research on Application of Shape Memory Polymers to Space Inflatable Systems. In Proceedings of the 7th International Symposium on Artificial Intelligence, Robotics and Automation in Space: I-SAIRAS 2003, Nara, Japan, 19–23 May 2003. [Google Scholar]

- Margoy, D.; Gouzman, I.; Grossman, E.; Bolker, A.; Eliaz, N.; Verker, R. Epoxy-based shape memory composite for space applications. Acta Astronaut. 2021, 178, 908–919. [Google Scholar] [CrossRef]

- Liu, C.; Qin, H.; Mather, P.T. Review of progress in shape-memory polymers. J. Mater. Chem. 2007, 17, 1543. [Google Scholar] [CrossRef]

- Fu, S.; Ren, H.; Ge, Z.; Zhuo, H.; Chen, S. Shape Memory Polyurethanes Based on Zwitterionic Hard Segments. Polymers 2017, 9, 465. [Google Scholar] [CrossRef] [PubMed]

- Pigliaru, L.; Rinaldi, M.; Ciccacci, L.; Norman, A.; Rohr, T.; Ghidini, T.; Nanni, F. 3D printing of high performance polymer-bonded PEEK-NdFeB magnetic composite materials. Funct. Compos. Mater. 2020, 1, 1–17. [Google Scholar] [CrossRef]

- Overview of Materials for Polyetheretherketone, Unreinforced. 2023. Available online: https://www.matweb.com/search/datasheet_print.aspx?matguid=2164cacabcde4391a596640d553b2ebe (accessed on 23 June 2023).

- INFINAM® PEEK|Filament for Industrial 3D Printing–Evonik Industries. 2023. Available online: https://www.infinam.com/en/peek-filaments-for-industrial-3d-printing (accessed on 20 September 2023).

- Home|Orion Additive Manufacturing GmbH. 2023. Available online: https://orion-am.com/ (accessed on 26 September 2023).

- Thiruchitrambalam, M.; Bubesh Kumar, D.; Shanmugam, D.; Jawaid, M. A review on PEEK composites—Manufacturing methods, properties and applications. Mater. Today Proc. 2020, 33, 1085–1092. [Google Scholar] [CrossRef]

- Shi, Y.; Yoonessi, M.; Weiss, R.A. High Temperature Shape Memory Polymers. Macromolecules 2013, 46, 4160–4167. [Google Scholar] [CrossRef]

- Caldwell, S. 6.0 Structures, Materials, and Mechanisms. 2021. Available online: https://www.nasa.gov/smallsat-institute/sst-soa/structures-materials-and-mechanisms (accessed on 5 April 2023).

- Huang, W.M.; Zhao, Y.; Wang, C.C.; Ding, Z.; Purnawali, H.; Tang, C.; Zhang, J.L. Thermo/chemo-responsive shape memory effect in polymers: A sketch of working mechanisms, fundamentals and optimization. J. Polym. Res. 2012, 19, 9952. [Google Scholar] [CrossRef]

- Madhavan Nampoothiri, K.; Nair, N.R.; John, R.P. An overview of the recent developments in polylactide (PLA) research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef] [PubMed]

- Yadav, N.; Richter, T.; Löschke, O.; Abali, B.E.; Auhl, D.; Völlmecke, C. Towards Self-Reinforced PLA Composites for Fused Filament Fabrication. Appl. Sci. 2023, 13, 2637. [Google Scholar] [CrossRef]

- Thompson, M.S. Current status and future roles of additives in 3D printing—A perspective. J. Vinyl Addit. Technol. 2022, 28, 3–16. [Google Scholar] [CrossRef]

- Yakacki, C.M. Characterization of Active Shape—Memory Polymers. TA Instruments, YouTube. Available online: https://www.youtube.com/watch?v=7hwPVTFo2ww (accessed on 5 April 2023).

- Behl, M.; Lendlein, A. Shape-memory polymers. Science 2007, 10, 20–28. [Google Scholar] [CrossRef]

- Jeannette Plante, B.L. Environmental Conditions for Space Flight Hardware—A Survey; NASA: Washington, DC, USA, 2004. [Google Scholar]

| Description | Value |

|---|---|

| Tensile Modulus | |

| Yield stress | |

| Yield strain | |

| Melting temperature | |

| Glass transition temperature | |

| Density | |

| Filament Diameter |

| Specimen Type | SD() | SD() | ||

|---|---|---|---|---|

| M-i 3r | ||||

| M-i 3f | ||||

| M-i 3v2r | ||||

| M-i 3v2f |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Richter, T.; Völlmecke, C. Development and Assessment of a 4D Printing Technique for Space Applications. Appl. Sci. 2024, 14, 339. https://doi.org/10.3390/app14010339

Richter T, Völlmecke C. Development and Assessment of a 4D Printing Technique for Space Applications. Applied Sciences. 2024; 14(1):339. https://doi.org/10.3390/app14010339

Chicago/Turabian StyleRichter, Tim, and Christina Völlmecke. 2024. "Development and Assessment of a 4D Printing Technique for Space Applications" Applied Sciences 14, no. 1: 339. https://doi.org/10.3390/app14010339

APA StyleRichter, T., & Völlmecke, C. (2024). Development and Assessment of a 4D Printing Technique for Space Applications. Applied Sciences, 14(1), 339. https://doi.org/10.3390/app14010339