Enhanced Strain Field Reconstruction in Ship Stiffened Panels Using Optical Fiber Sensors and the Strain Function-Inverse Finite Element Method

Abstract

:1. Introduction

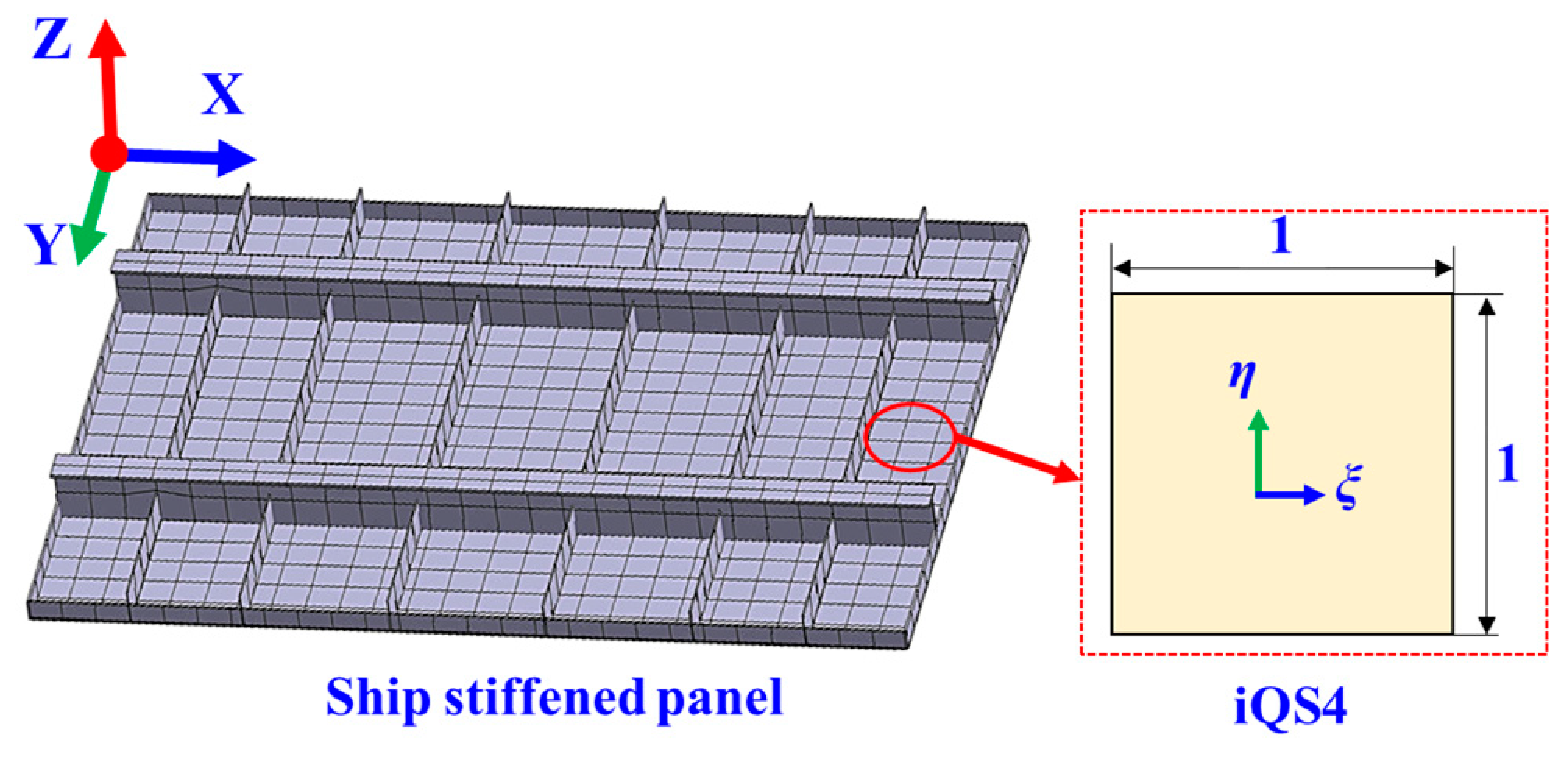

2. The SF-iFEM Methodology

2.1. Calculation of Element Theoretical Strain Based on the Element Strain Function

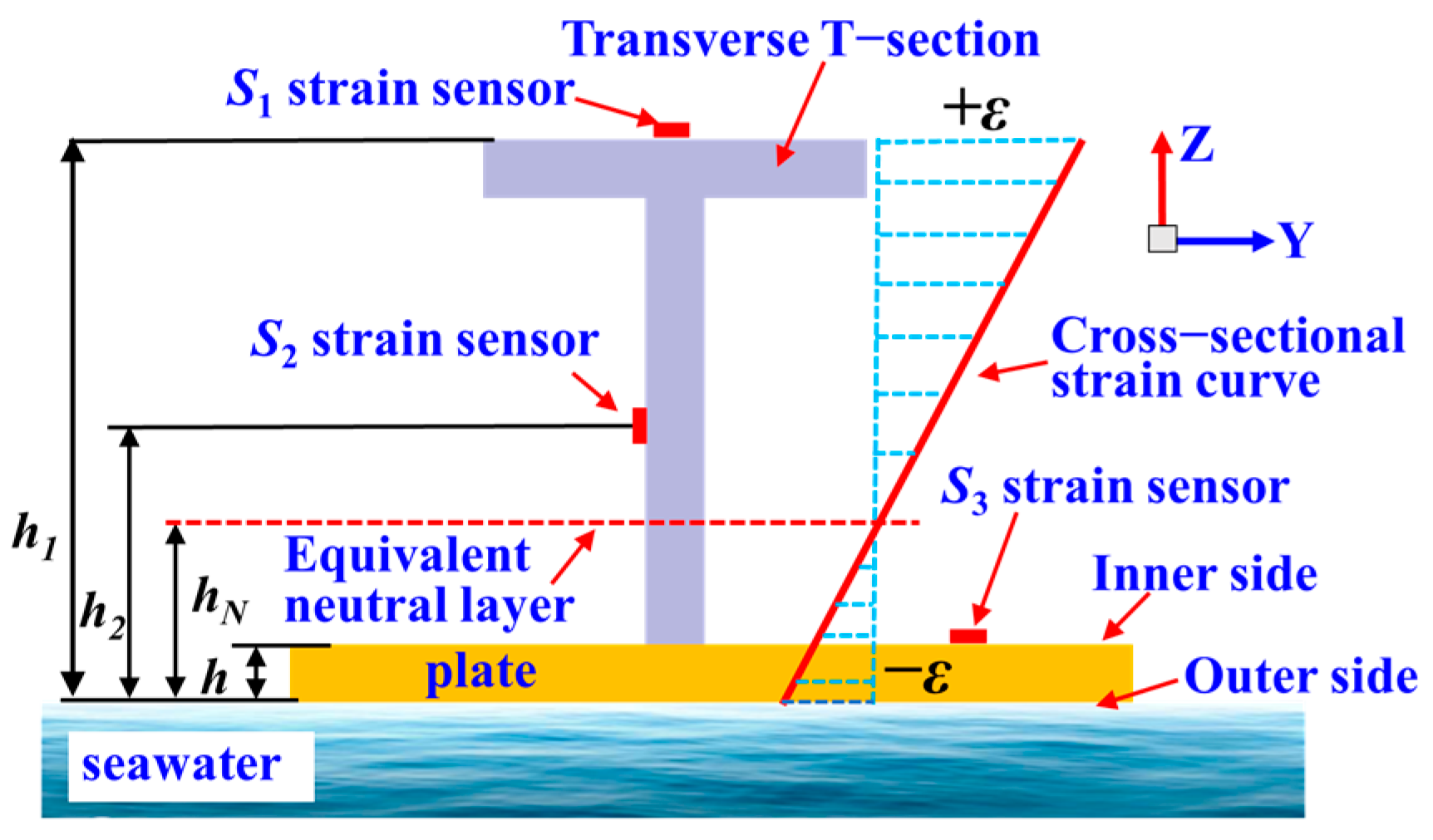

2.2. Calculation of Element Measured Strain Based on the Equivalent Neutral Layer

2.3. Strain Field Reconstruction Based on Node Strain Vectors

3. Numerical Validations of Stiffened Ship Panel Strain Reconstruction

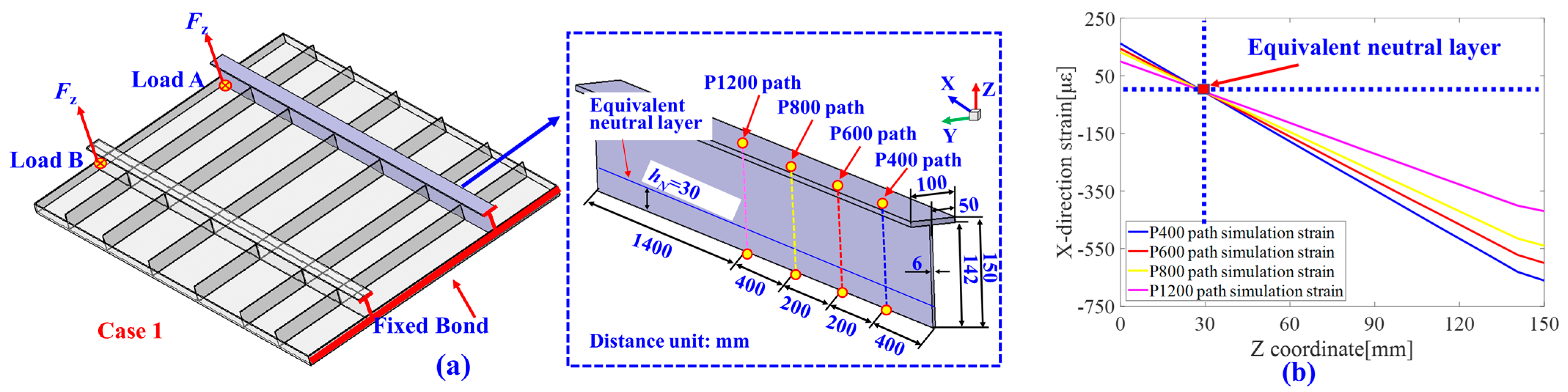

3.1. Ship Stiffened Panel Model

3.2. Element Division Based on Equivalent Neutral Layer

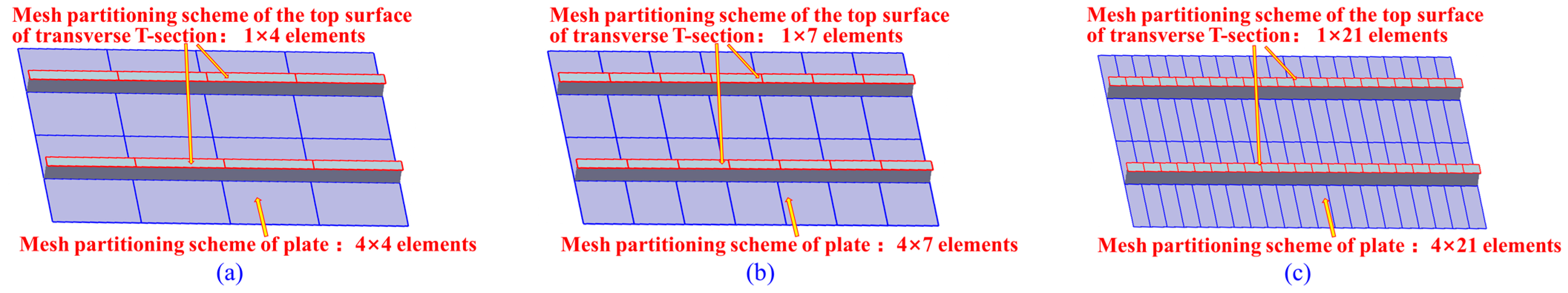

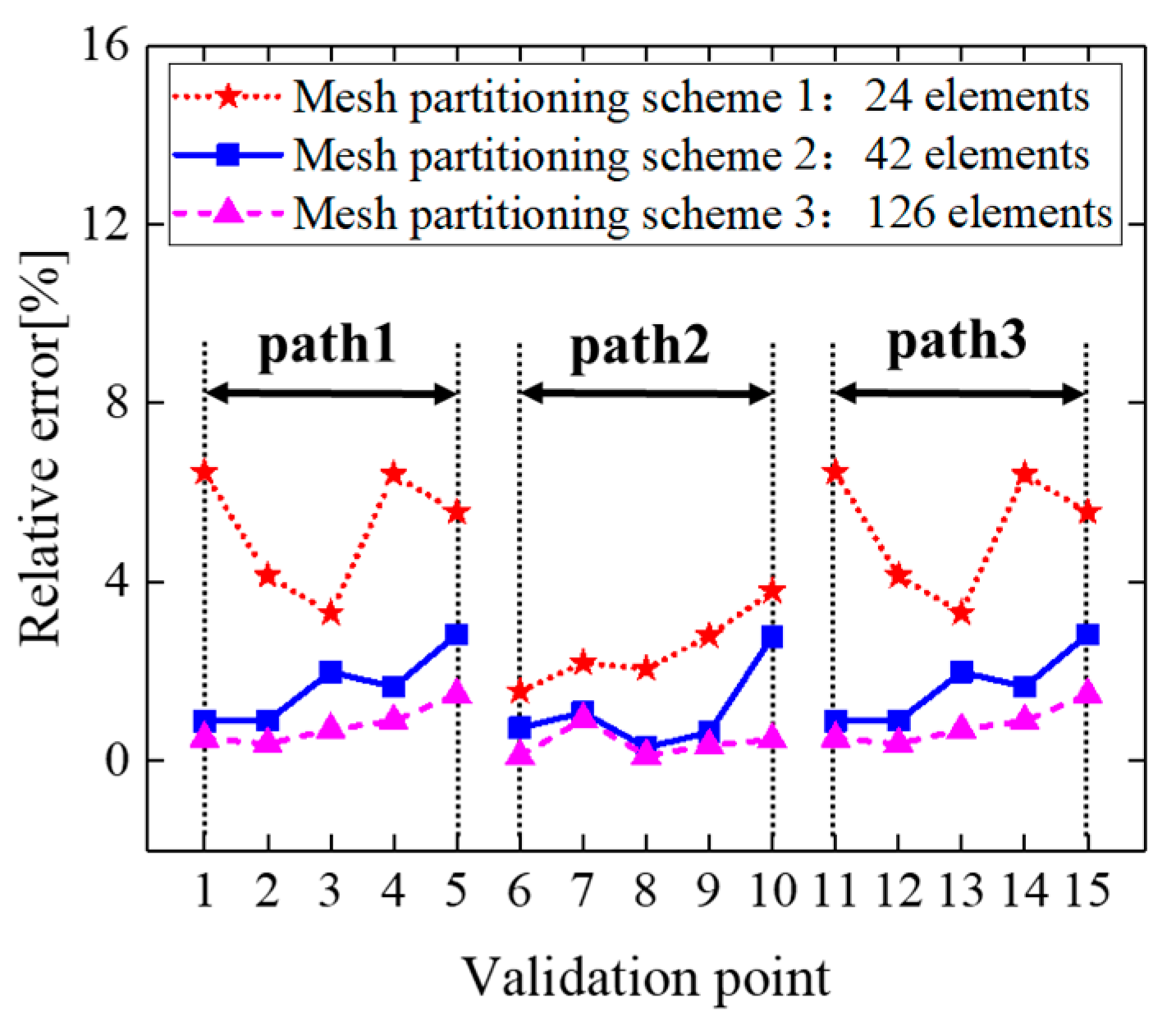

3.3. Influence of Different Mesh Partitioning Schemes on the Accuracy of Strain Field Inversion

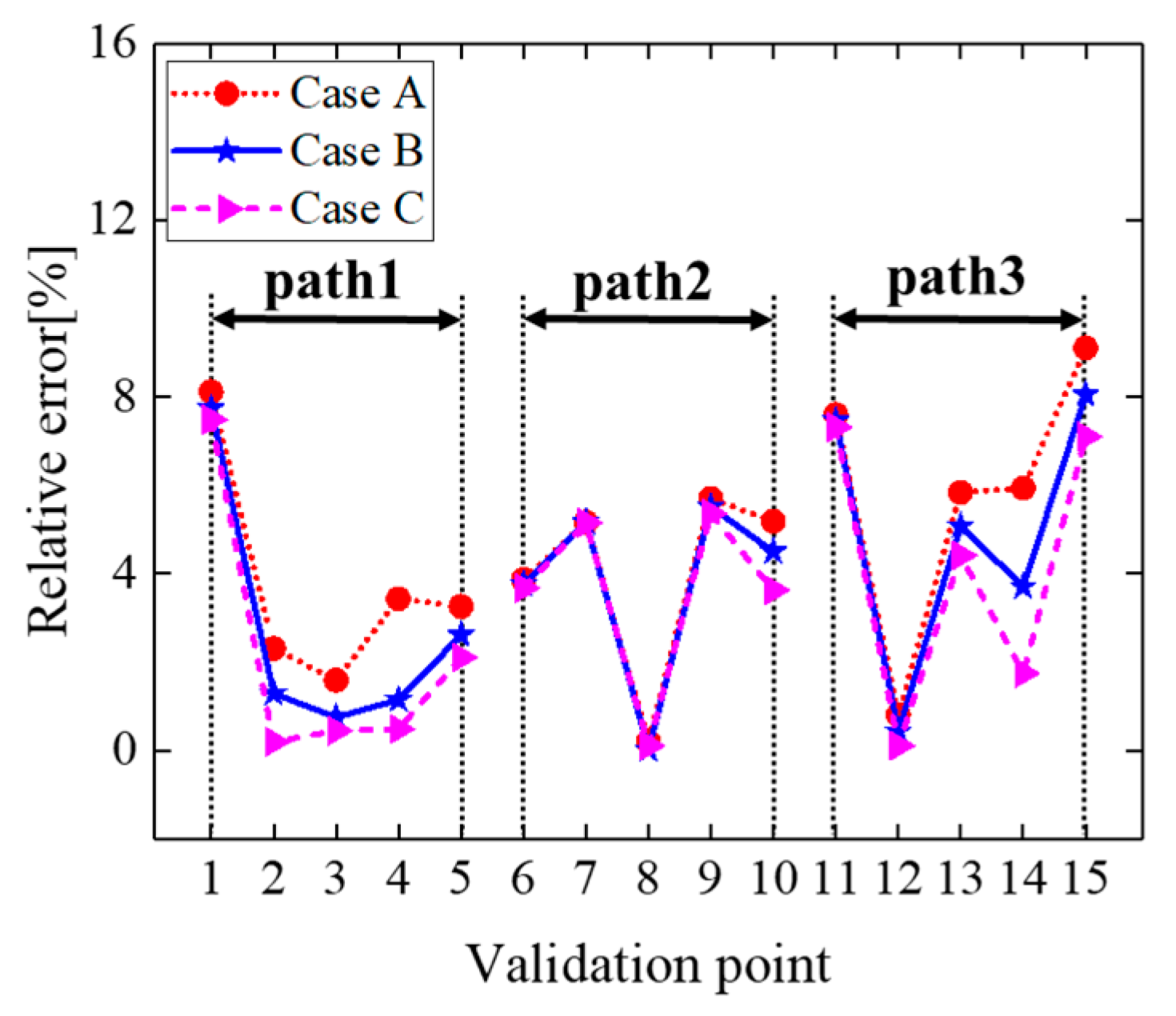

3.4. Impact of Different Load Magnitudes on Strain Field Inversion Accuracy

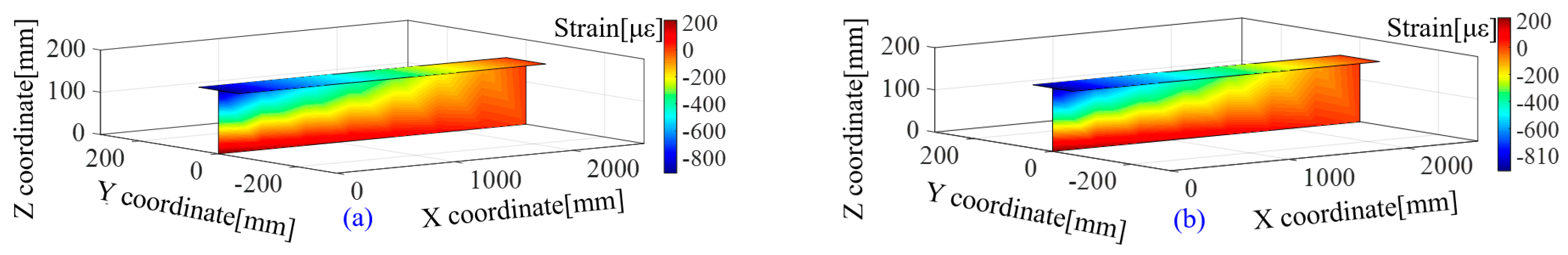

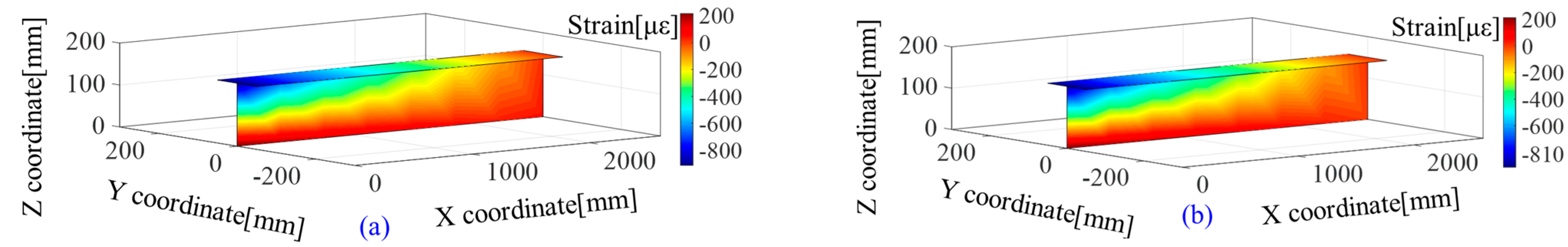

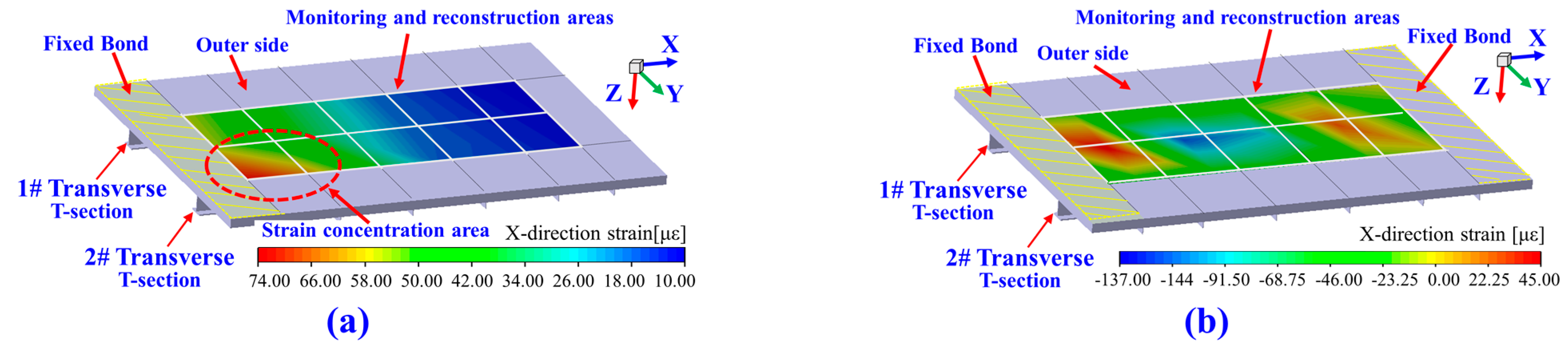

3.5. Results and Discussion

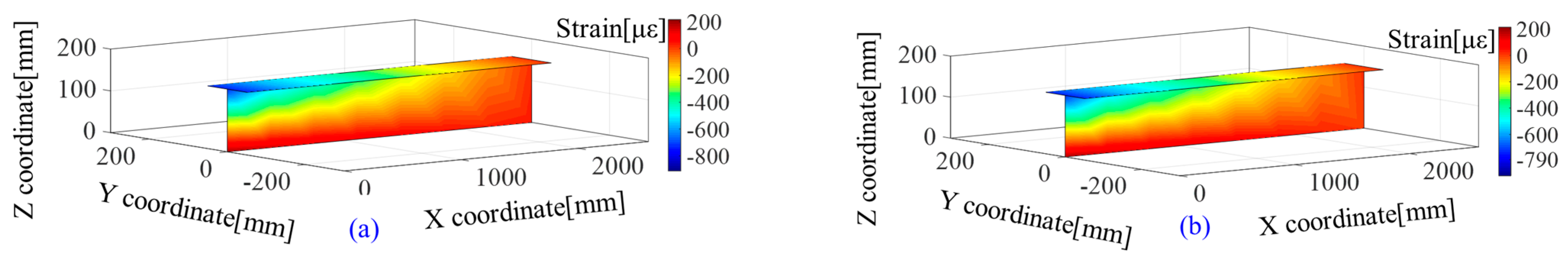

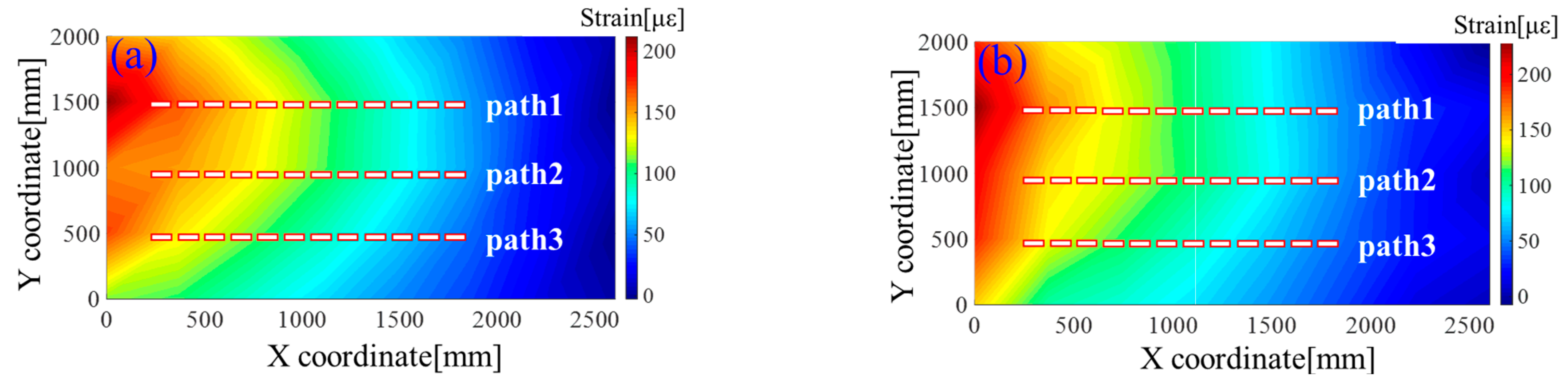

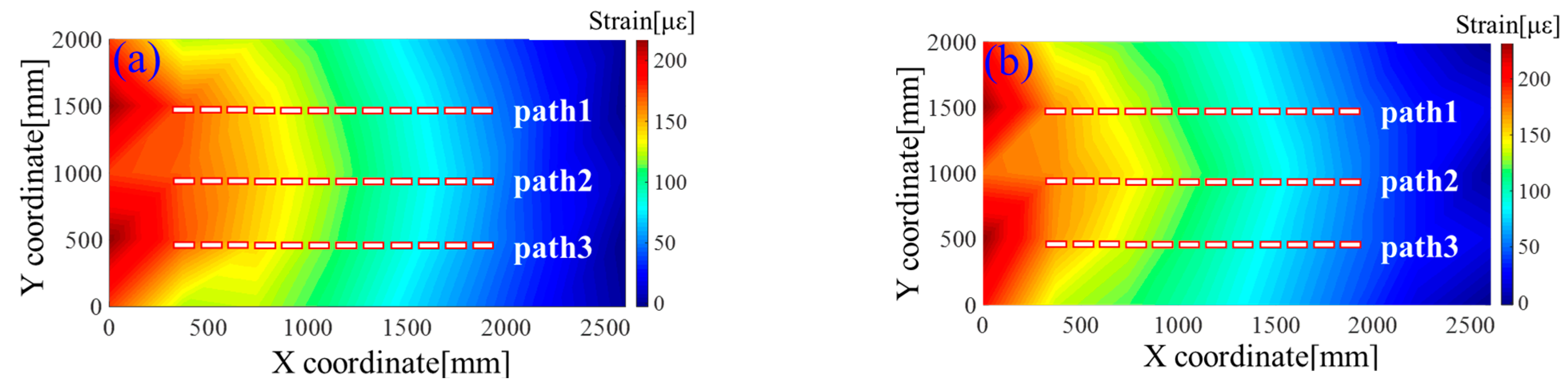

- (a)

- Comparison of Strain Contour Diagrams for Transverse T-Sections Obtained by FEM and SF-iFEM;

- (b)

- Comparison of Strain Cloud Diagrams on Plate Surfaces Obtained by FEM and SF-iFEM;

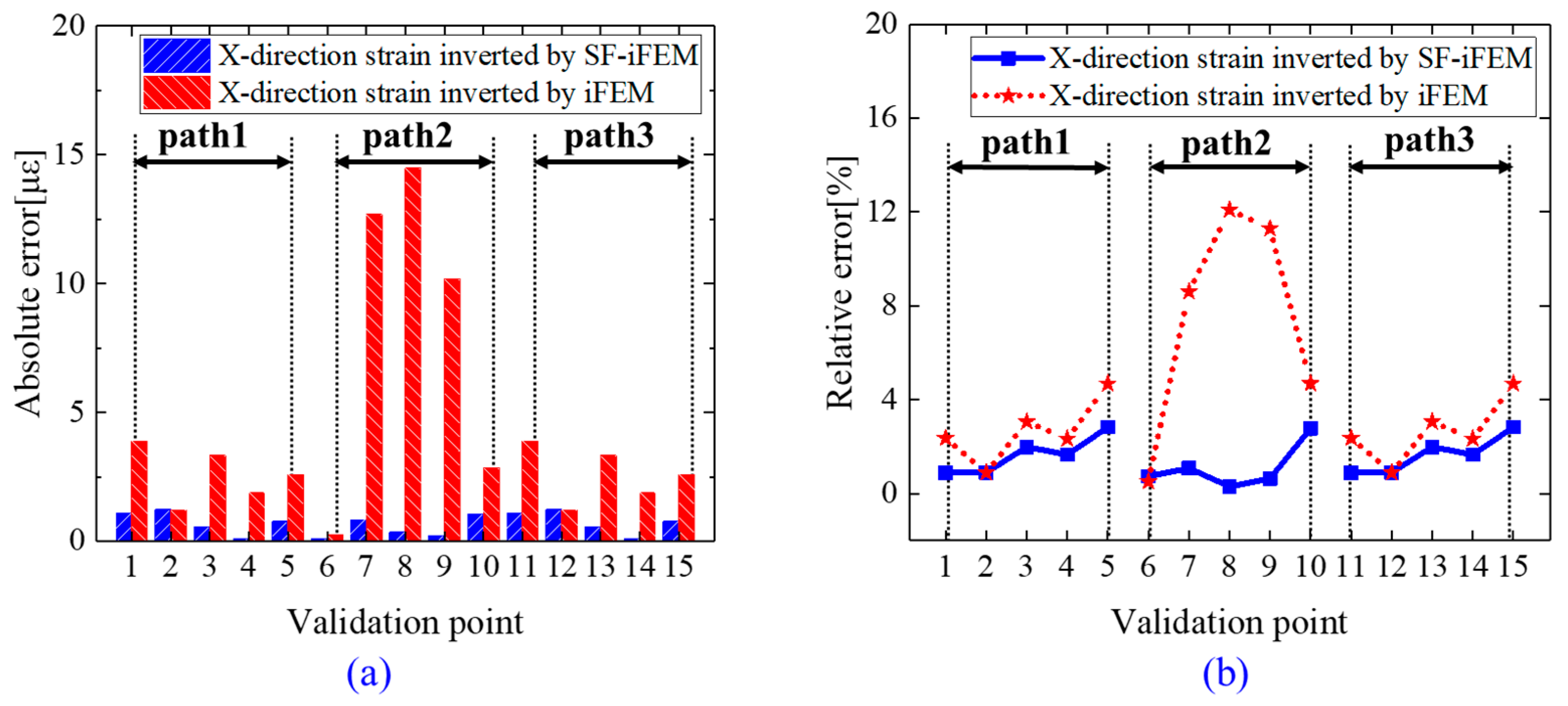

- (c)

- Comparison of Strain Reconstruction Errors between iFEM and SF-iFEM;

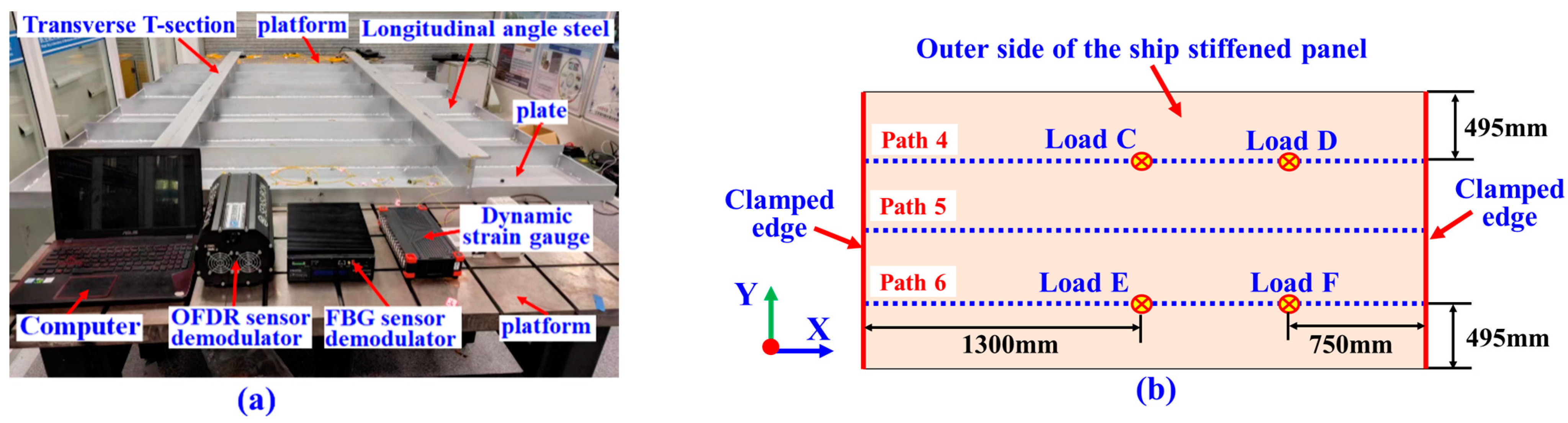

4. Experimental Validations for Ship Stiffened Panel Strain Reconstruction

4.1. Test Setup

- (a)

- Construction of Strain Monitoring System;

- (b)

- Test Cases;

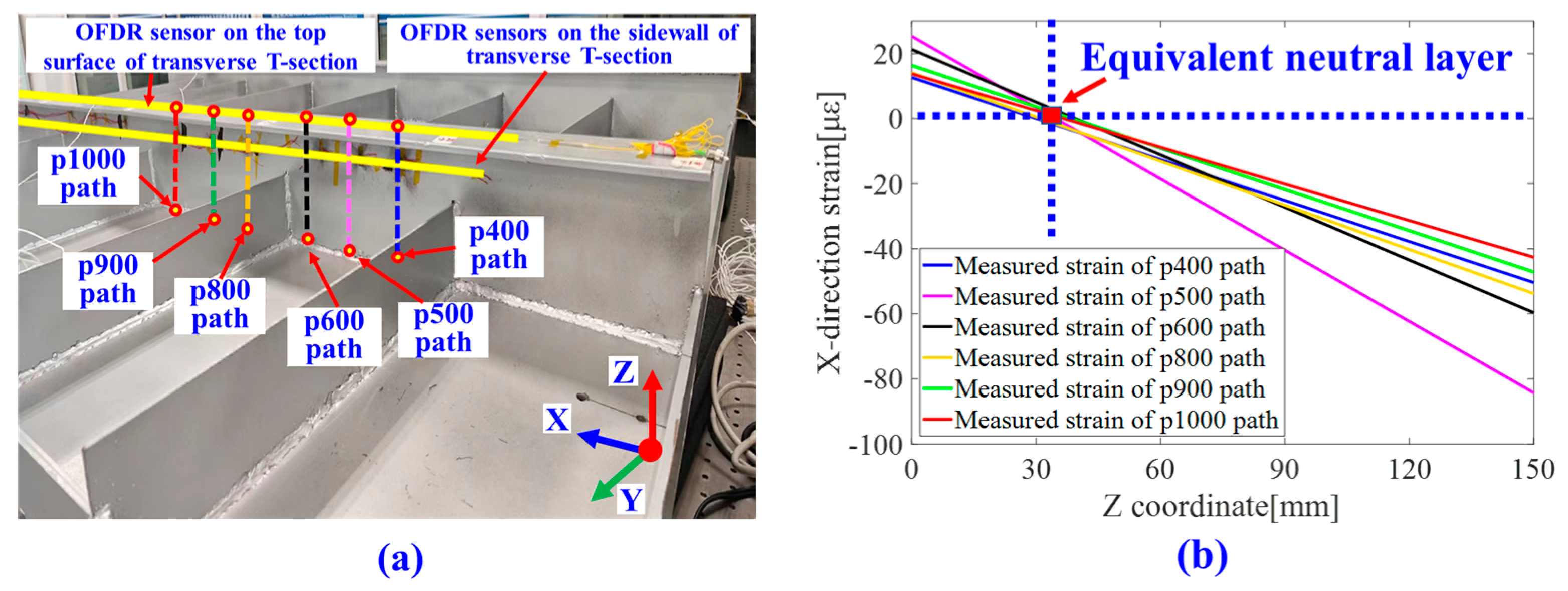

4.2. Fiber Optic Sensor Layout Based on Equivalent Neutral Layer

- (a)

- Equivalent Neutral Layer Calculation Based on Measured Data;

- (b)

- Optical Fiber Sensor Layout and Element Division;

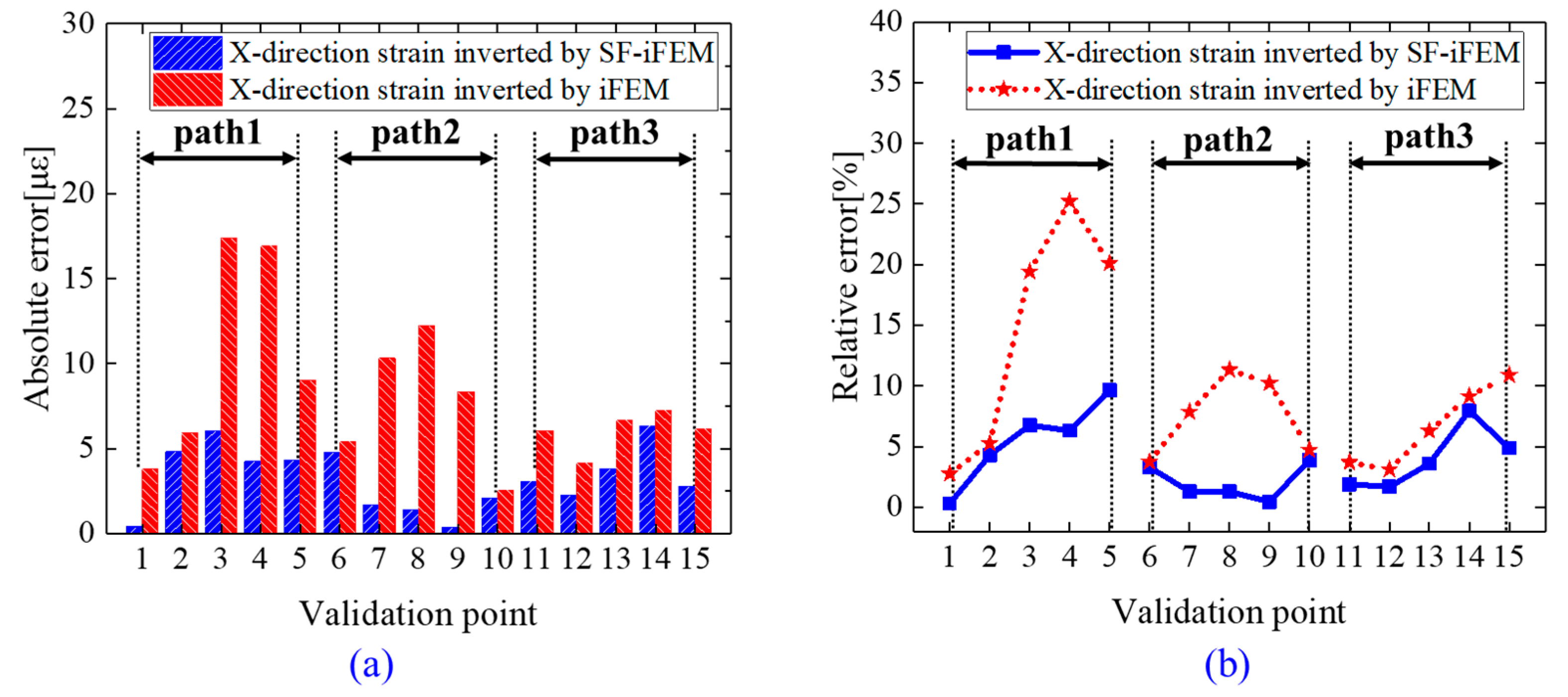

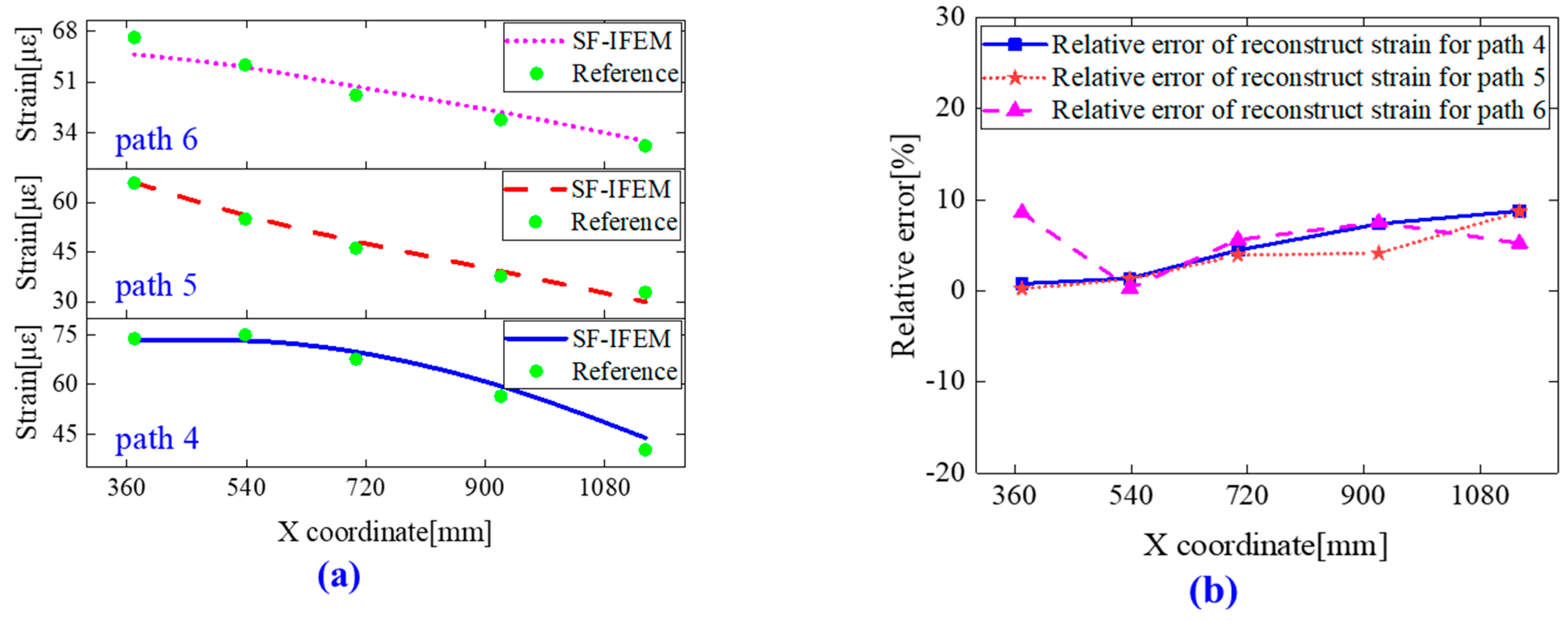

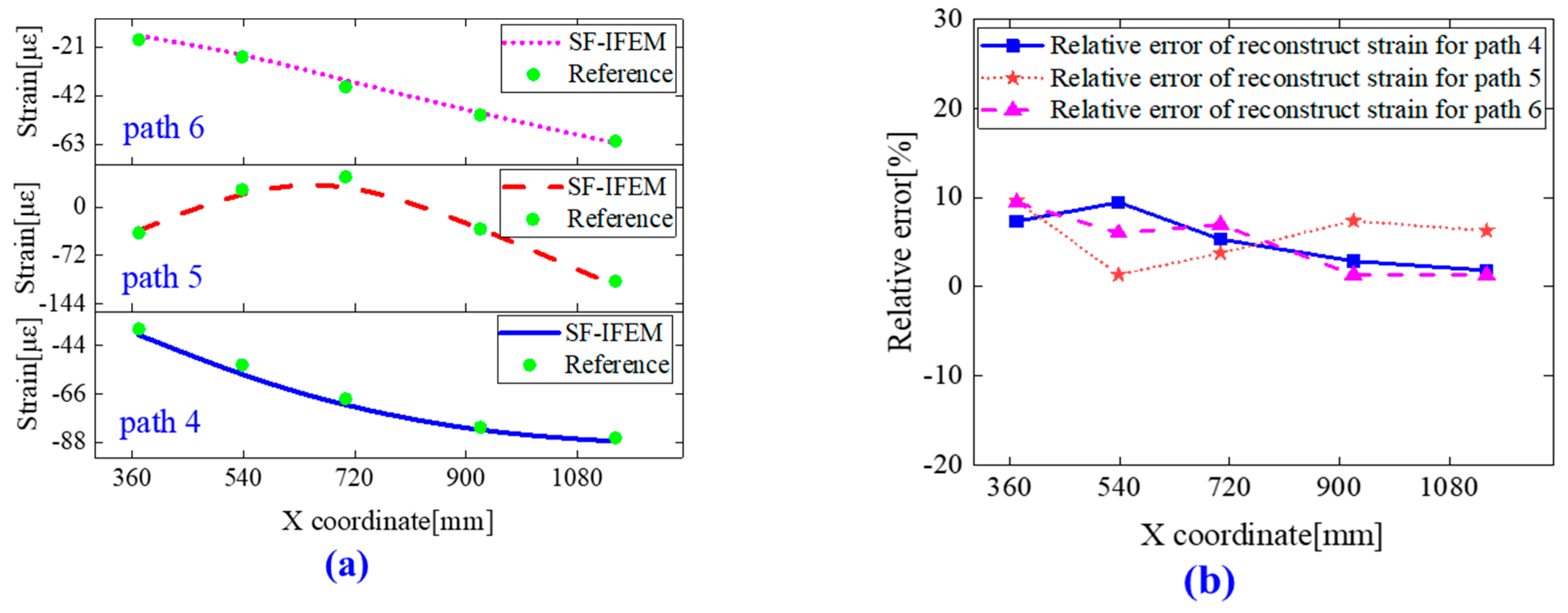

4.3. Results and Discussion

5. Conclusions

- (a)

- A novel strain field reconstruction method based on the nodal strain vector has been developed, resulting in improved accuracy compared to conventional iFEM. The simulation’s results demonstrate significant enhancements in strain reconstruction accuracy, particularly for bending and bending–torsion deformations.

- (b)

- This paper introduces a method for calculating the equivalent neutral layer of stiffened ship panels. This approach reduces the number of elements and establishes a strain mapping function between the inner and outer surfaces of the structure. This breakthrough addresses the limitations of conventional iFEM related to sensor arrangement. Experimental results indicate average relative errors of 4.45% and 4.87% for bending and torsion deformations under different support conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Katsoudas, A.S.; Silionis, N.E.; Anyfantis, K.N. Structural health monitoring for corrosion induced thickness loss in marine plates subjected to random loads. Ocean Eng. 2023, 273, 114037. [Google Scholar] [CrossRef]

- Silionis, N.E.; Anyfantis, K.N. Static strain-based identification of extensive damages in thin-walled structures. Struct. Health Monit. 2022, 21, 2026–2047. [Google Scholar] [CrossRef]

- Marzani, A.; Testoni, N.; De Marchi, L.; Messina, M.; Monaco, E.; Apicella, A. An open database for benchmarking guided waves structural health monitoring algorithms on a composite full-scale outer wing demonstrator. Struct. Health Monit. 2020, 19, 1524–1541. [Google Scholar] [CrossRef]

- Böhm, A.M.; Herrnring, H.; Ehlers, S. The measurement accuracy of instrumented ship structures under local ice loads using strain gauges. Mar. Struct. 2021, 76, 102919. [Google Scholar] [CrossRef]

- Corigliano, P.; Crupi, V.; Pei, X.; Dong, P. DIC-based structural strain approach for low-cycle fatigue assessment of AA 5083 welded joints. Theor. Appl. Fract. Mech. 2021, 116, 103090. [Google Scholar] [CrossRef]

- Mieloszyk, M.; Majewska, K.; Ostachowicz, W. Application of embedded fibre Bragg grating sensors for structural health monitoring of complex composite structures for marine applications. Mar. Struct. 2021, 76, 102903. [Google Scholar] [CrossRef]

- Min, R.; Liu, Z.; Pereira, L.; Yang, C.; Sui, Q.; Marques, C. Optical fiber sensing for marine environment and marine structural health monitoring: A review. Opt. Laser Technol. 2021, 140, 107082. [Google Scholar] [CrossRef]

- Li, Z.; Cheng, Y.; Zhang, L.; Wang, G.; Ju, Z.; Geng, X.; Jiang, M. Strain field reconstruction of high-speed train crossbeam based on FBG sensing network and load-strain linear superposition algorithm. IEEE Sens. J. 2021, 22, 3228–3235. [Google Scholar] [CrossRef]

- Kirkwood, H.J.; Zhang, S.Y.; Tremsin, A.S.; Korsunsky, A.M.; Baimpas, N.; Abbey, B. Neutron strain tomography using the radon transform. Mater. Today Proc. 2015, 2, S414–S423. [Google Scholar] [CrossRef]

- Li, J.; Yan, J.; Zhu, J.; Qing, X. K-BP neural network-based strain field inversion and load identification for CFRP. Measurement 2022, 187, 110227. [Google Scholar] [CrossRef]

- Tessler, A.; Roy, R.; Esposito, M.; Surace, C.; Gherlone, M. Shape sensing of plate and shell structures undergoing large displacements using the inverse finite element method. Shock Vib. 2018, 2018, 8076085. [Google Scholar] [CrossRef]

- Abdollahzadeh, M.A.; Kefal, A.; Yildiz, M. A comparative and review study on shape and stress sensing of flat/curved shell geometries using c0-continuous family of iFEM elements. Sensors 2020, 20, 3808. [Google Scholar] [CrossRef] [PubMed]

- Roy, R.; Gherlone, M.; Surace, C.; Tessler, A. Full-Field strain reconstruction using uniaxial strain measurements: Application to damage detection. Appl. Sci. 2021, 11, 1681. [Google Scholar] [CrossRef]

- Colombo, L.; Oboe, D.; Sbarufatti, C.; Cadini, F.; Russo, S.; Giglio, M. Shape sensing and damage identification with iFEM on a composite structure subjected to impact damage and non-trivial boundary conditions. Mech. Syst. Signal Process. 2021, 148, 107163. [Google Scholar] [CrossRef]

- Li, M.; Kefal, A.; Cerik, B.C.; Oterkus, E. Dent damage identification in stiffened cylindrical structures using inverse Finite Element Method. Ocean Eng. 2020, 198, 106944. [Google Scholar] [CrossRef]

- Kefal, A.; Oterkus, E. Displacement and stress monitoring of a chemical tanker based on inverse finite element method. Ocean Eng. 2016, 112, 33–46. [Google Scholar] [CrossRef]

- Phelps, C.; Tessler, A. IFEM for Marine Structure Digital Twins-Effective Modeling Strategies. In SNAME Maritime Convention; SNAME: Alexandria, VA, USA, 2020. [Google Scholar]

- Kefal, A.; Oterkus, E. Shape sensing of aerospace structures by coupling of isogeometric analysis and inverse finite element method. In Proceedings of the 58th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Grapevine, TX, USA, 9–13 January 2017. [Google Scholar] [CrossRef]

- Kefal, A.; Oterkus, E. Displacement and stress monitoring of a Panamax containership using inverse finite element method. Ocean Eng. 2016, 119, 16–29. [Google Scholar] [CrossRef]

- Kefal, A.; Oterkus, E. Isogeometric iFEM analysis of thin shell structures. Sensors 2020, 20, 2685. [Google Scholar] [CrossRef]

- Papa, U.; Russo, S.; Lamboglia, A.; Del Core, G.; Iannuzzo, G. Health structure monitoring for the design of an innovative UAS fixed wing through inverse finite element method (iFEM). Aerosp. Sci. Technol. 2017, 69, 439–448. [Google Scholar] [CrossRef]

- Oboe, D.; Colombo, L.; Sbarufatti, C.; Giglio, M. Comparison of strain pre-extrapolation techniques for shape and strain sensing by iFEM of a composite plate subjected to compression buckling. Compos. Struct. 2021, 262, 113587. [Google Scholar] [CrossRef]

- Esposito, M.; Mattone, M.; Gherlone, M. Experimental Shape Sensing and Load Identification on a Stiffened Panel: A Comparative Study. Sensors 2022, 22, 1064. [Google Scholar] [CrossRef] [PubMed]

- Ganjdoust, F.; Kefal, A.; Tessler, A. A Novel Delamination Damage Detection Strategy Based on Inverse Finite Element Method for Structural Health Monitoring of Composite Structures. Mech. Syst. Signal Process. 2023, 192, 110202. [Google Scholar] [CrossRef]

- Grigor’ev, V.; Kravtsov, V.; Mityurev, A.; Moroz, E.; Pogonyshev, A.; Savkin, K. Methods for Calibrating High-Resolution Optical Reflectometers Operating in the Frequency Domain. Meas. Tech. 2018, 61, 903–907. [Google Scholar] [CrossRef]

- Hegde, G.; Himakar, B.; Rao, S.; Hegde, G.; Asokan, S. Simultaneous measurement of pressure and temperature in a supersonic ejector using FBG sensors. Meas. Sci. Technol. 2022, 33, 125111. [Google Scholar] [CrossRef]

- Tanaka, N.; Okabe, Y.; Takeda, N. Temperature-compensated strain measurement using fiber Bragg grating sensors embedded in composite laminates. Smart Mater. Struct. 2003, 12, 940–946. [Google Scholar] [CrossRef]

- Mokhtar, M.; Owens, K.; Kwasny, J.; Taylor, S.; Basheer, P.; Cleland, D.; Bai, Y.; Sonebi, M.; Davis, G.; Gupta, A. Fiber-optic strain sensor system with temperature compensation for arch bridge condition monitoring. IEEE Sens. J. 2012, 12, 1470–1476. [Google Scholar] [CrossRef]

| Component Name | Length [mm] | Width [mm] | Thickness [mm] | |

|---|---|---|---|---|

| plate | 2600 | 1980 | 5 | |

| 1 #, 2 # transverse T-sections | Top surface | 2600 | 100 | 8 |

| Sidewalls | 2600 | 150 | 6 | |

| longitudinal angle steel | 1980 | 90 | 4 | |

| Mesh Partitioning Scheme | RMSE [με] | MRE [%] |

|---|---|---|

| Scheme 1: 24 elements | 9.03 | 4.27 |

| Scheme 2: 42 elements | 2.10 | 1.47 |

| Scheme 3: 126 elements | 1.20 | 0.66 |

| Case | Magnitude of Load on Point A [KN] | Magnitude of Load on Point B [KN] | RMSE [με] | MRE [%] |

|---|---|---|---|---|

| Case A | 10 | 5 | 4.96 | 4.53 |

| Case B | 10 | 7 | 4.54 | 3.81 |

| Case C | 10 | 9 | 4.24 | 3.29 |

| Case | Reconstruction Error | iFEM | SF-iFEM |

|---|---|---|---|

| Case 1 | MRE [%] | 4.25 | 1.47 |

| RMSE [με] | 17.12 | 2.10 | |

| Case 2 | MRE [%] | 9.57 | 3.83 |

| RMSE [με] | 31.58 | 12.39 |

| Path | p400 | p500 | p600 | p800 | p900 | p1000 |

| Position of zero strain point [mm] | 30.09 | 34.66 | 39.41 | 28.08 | 35.62 | 33.57 |

| Equivalent neutral layer position [mm] | 33.57 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Q.; Wu, G.; Zeng, J.; Jiang, Z.; Yue, Y.; Xiang, C.; Zhan, J.; Zhao, B. Enhanced Strain Field Reconstruction in Ship Stiffened Panels Using Optical Fiber Sensors and the Strain Function-Inverse Finite Element Method. Appl. Sci. 2024, 14, 370. https://doi.org/10.3390/app14010370

Zhu Q, Wu G, Zeng J, Jiang Z, Yue Y, Xiang C, Zhan J, Zhao B. Enhanced Strain Field Reconstruction in Ship Stiffened Panels Using Optical Fiber Sensors and the Strain Function-Inverse Finite Element Method. Applied Sciences. 2024; 14(1):370. https://doi.org/10.3390/app14010370

Chicago/Turabian StyleZhu, Qingfeng, Guoqing Wu, Jie Zeng, Zhentao Jiang, Yingping Yue, Chao Xiang, Jun Zhan, and Bohan Zhao. 2024. "Enhanced Strain Field Reconstruction in Ship Stiffened Panels Using Optical Fiber Sensors and the Strain Function-Inverse Finite Element Method" Applied Sciences 14, no. 1: 370. https://doi.org/10.3390/app14010370

APA StyleZhu, Q., Wu, G., Zeng, J., Jiang, Z., Yue, Y., Xiang, C., Zhan, J., & Zhao, B. (2024). Enhanced Strain Field Reconstruction in Ship Stiffened Panels Using Optical Fiber Sensors and the Strain Function-Inverse Finite Element Method. Applied Sciences, 14(1), 370. https://doi.org/10.3390/app14010370