Research on a Real-Time Control System for Discrete Factories Based on Digital Twin Technology

Abstract

1. Introduction

2. Methods

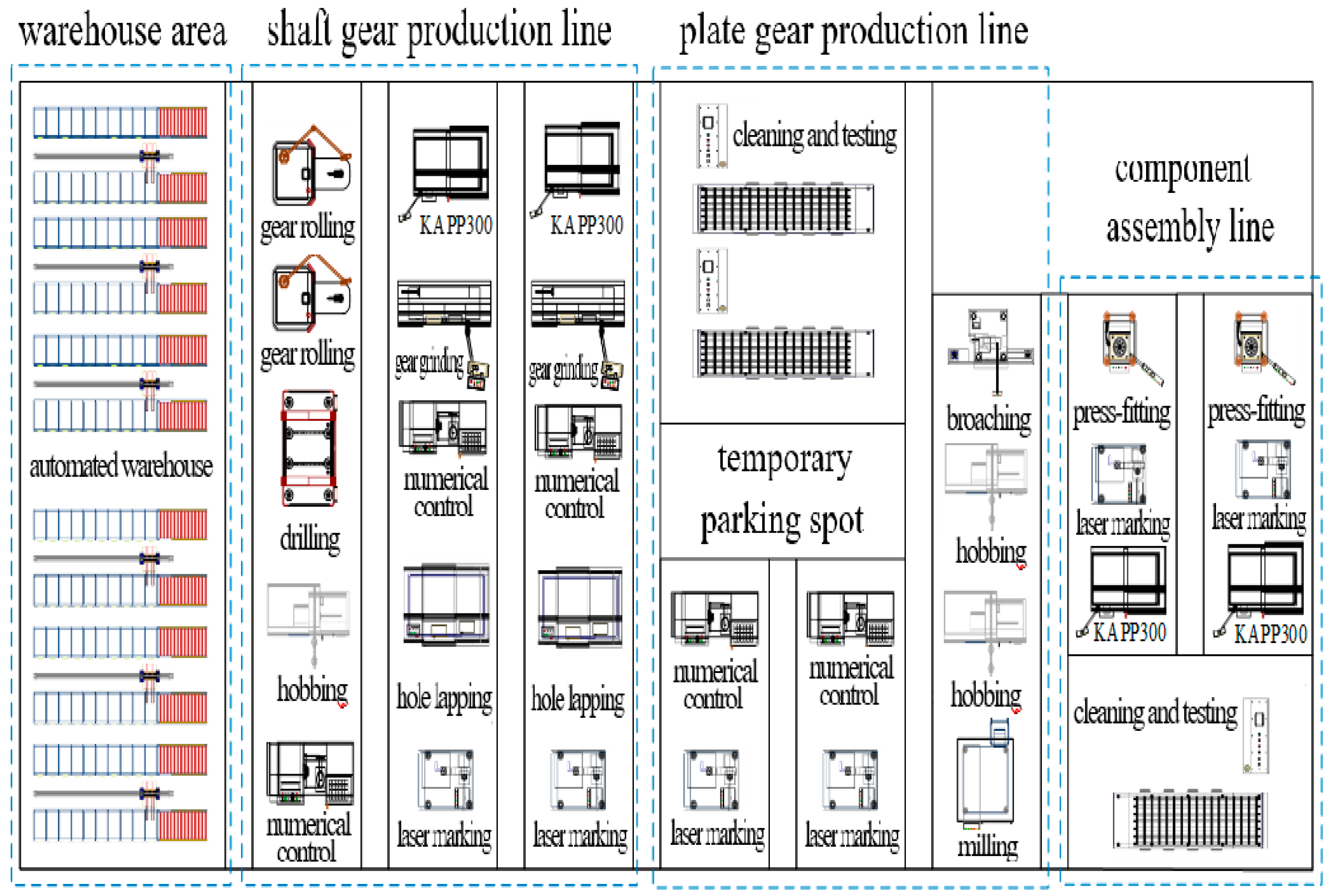

2.1. Modeling of Digital Twin Factory

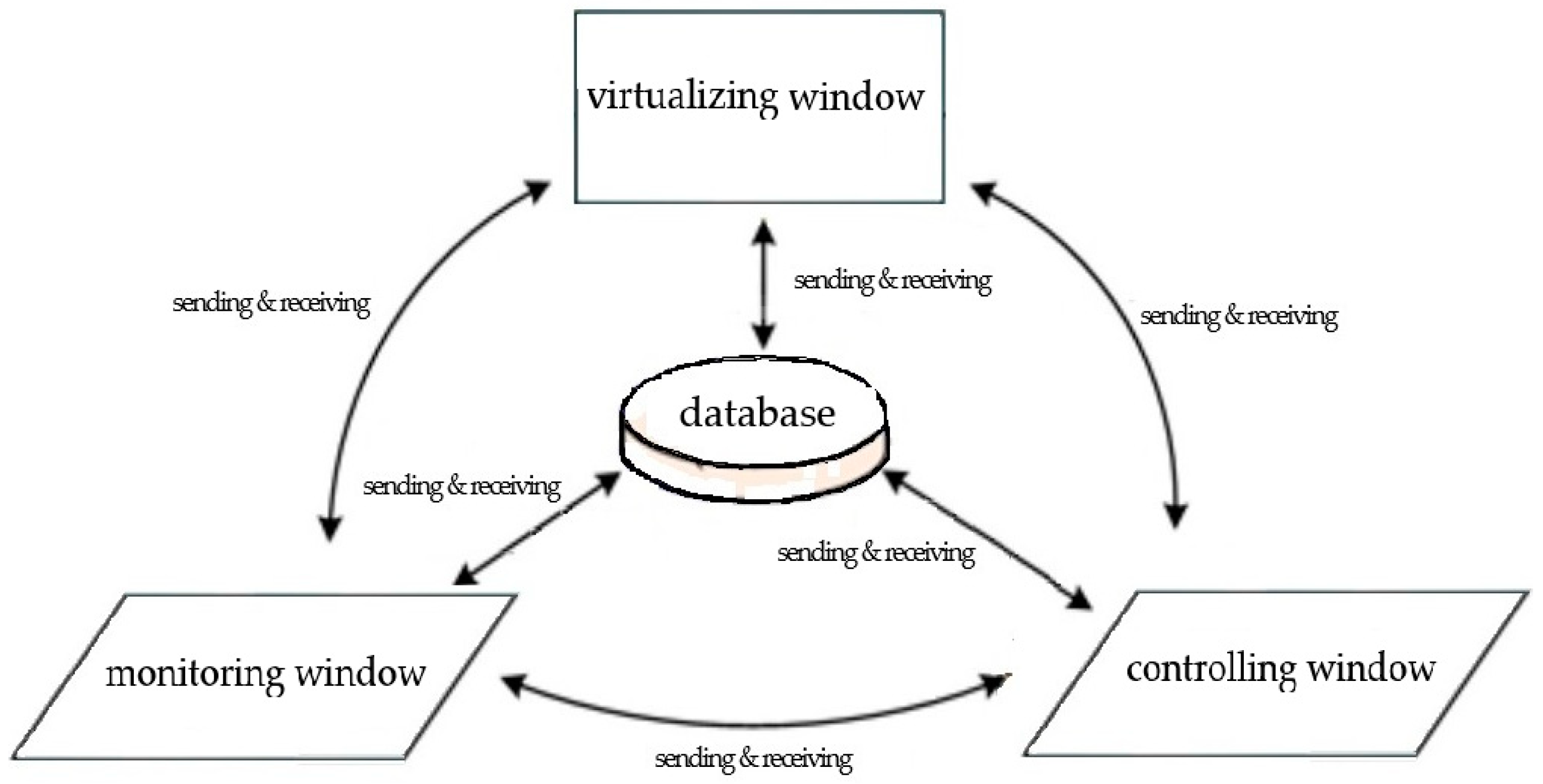

2.2. Design of the Interaction Architecture

2.3. Development of System Software

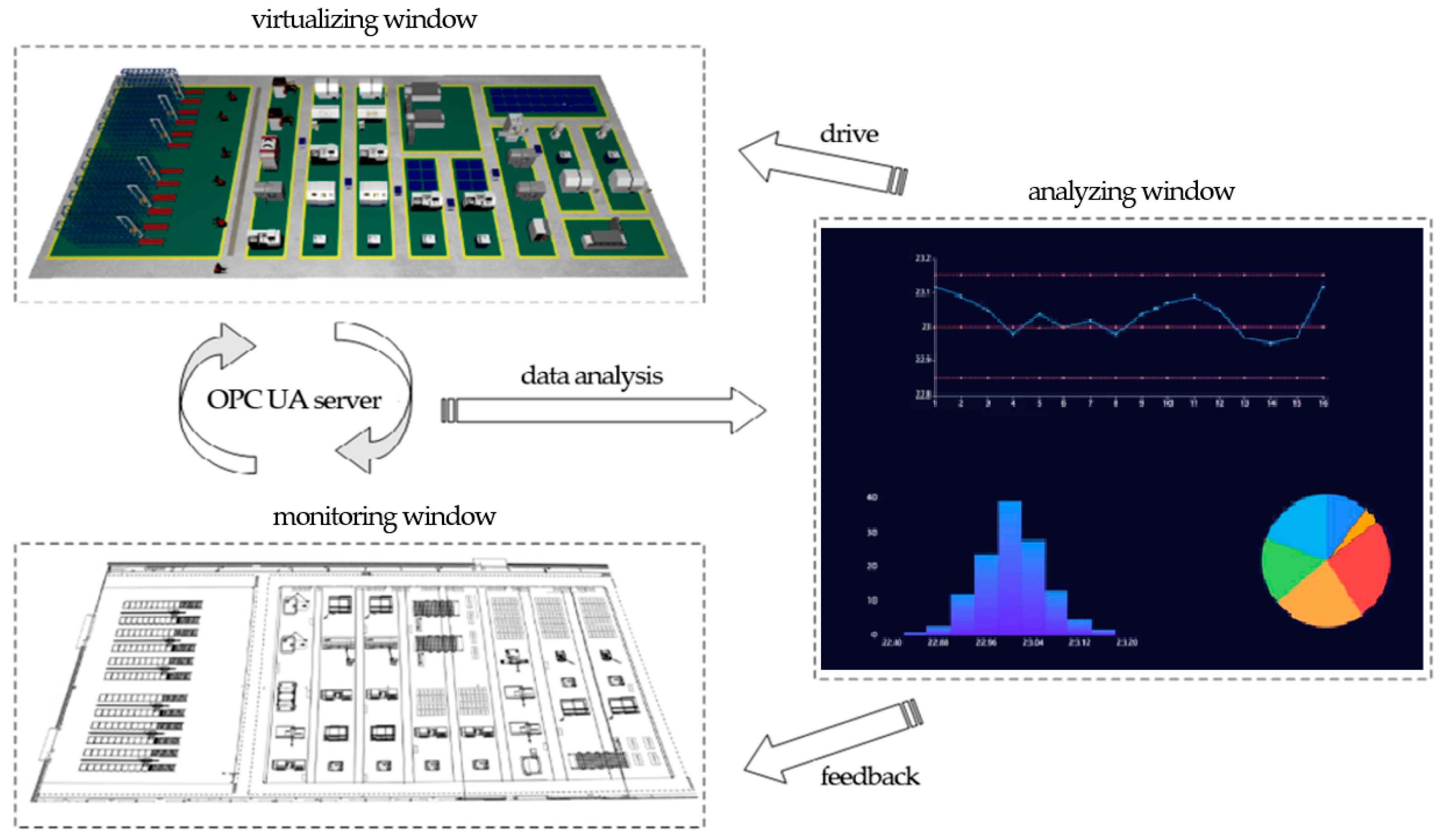

2.3.1. Scene Monitoring Design

2.3.2. Element/Process Virtualization

- Virtualization software tools

- 2.

- Product virtualization methods

- 3.

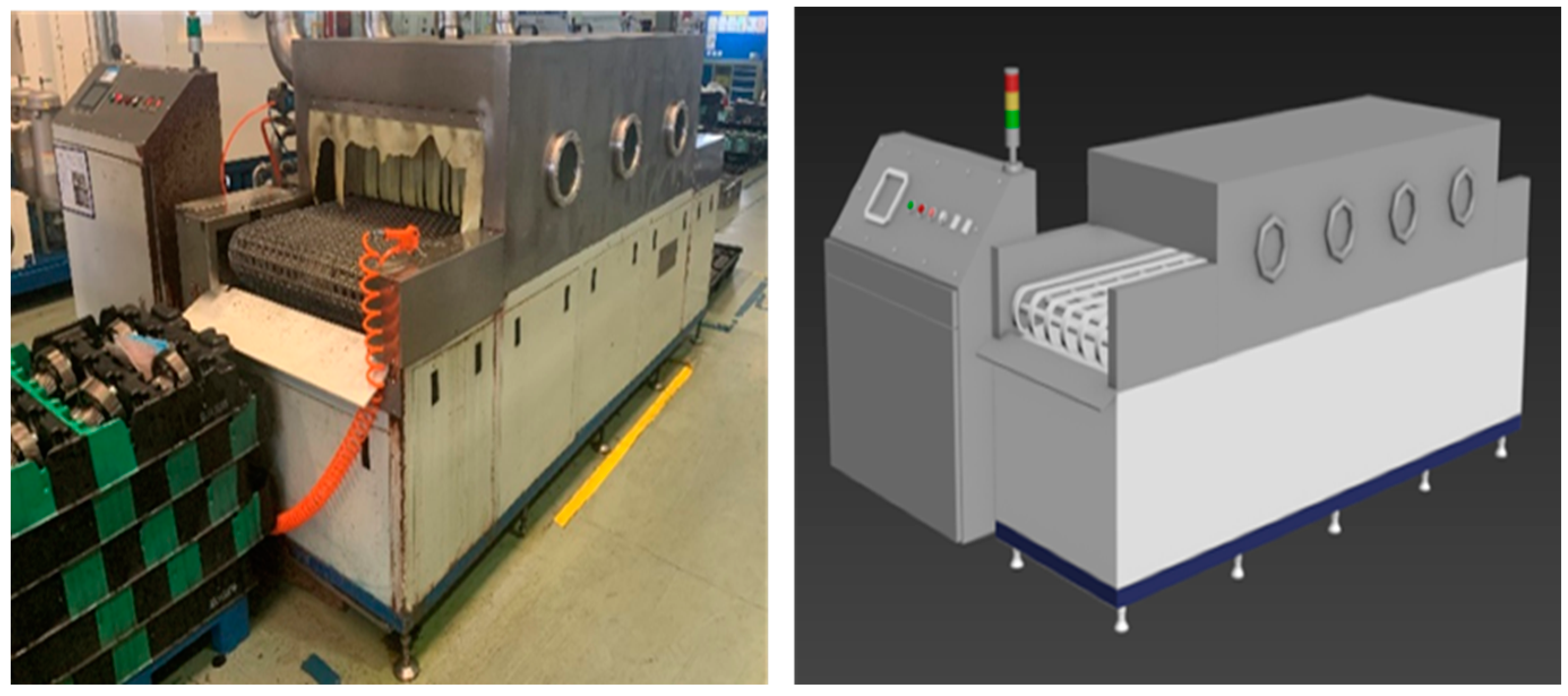

- Device virtualization methods

- 4.

- Scene virtualization methods

- 5.

- Process virtualization methods

2.3.3. System Controlling Design

2.3.4. Data Communication Design

3. Results

4. Discussion

- The relationship between the final research result and title of this article: The intermediate shaft dual gear of a new energy vehicle gearbox is a type of mechanical gear, and mechanical gears are widely used as mechanical components. Gear manufacturing enterprises are most typical discrete manufacturing enterprises. The factory is the main department for each manufacturing enterprise. A gear factory is an abbreviation for a gear manufacturing factory, and a discrete factory is an abbreviation for a discrete manufacturing factory. The gear factory is a most typical discrete factory, and the research methods and achievements of a real-time control system based on digital twin technology are also suitable for other discrete factories.

- The relationship between the digital factory and a real-time control system: A digital twin factory consists of a physical factory and a digital factory. The physical factory includes the hardware of a digital twin factory and the software that is not related to the digital factory. The digital factory includes the software, except for some specialized software which is unrelated to the digital factory, of the digital twin factory. Then, a real-time control system consists of the hardware of the real-time control system and the software of the real-time control system. The hardware includes some objects of a real-time control system, such as sensors, controllers, computers, camera lenses, cable connections, etc. The software includes other components of a real-time control system, such as computer applications, surveillance videos, images and data, databases, etc. Therefore, the digital factory is just the software of the real-time control system of the digital twin factory. Due to the extremely simple hardware of the real-time control system and its standardization, the research on the real-time control system mainly focuses on the software of a real-time control system or the digital factory. The software development of a real-time control system can be transformed into the development of a digital factory, laying an important technical path for researchers studying real-time control systems.

- The impact of the model for a digital twin gear factory on the prototype software of the real-time control system for the dual gear factory: the model for a digital twin gear factory is the centralized display of software and hardware resources, as well as the operating methods for the digital twin gear factory. And it determines the functionality and applicability of the prototype software of the real-time control system, and also affects the requirement analysis and functional implementation of software development.

- The impact of the human–computer interaction architecture for the real-time control system on the prototype software of the real-time control system for the dual gear factory: The human–computer interaction architecture mainly affects the performance and operation of software, and also has a certain impact on the requirement analysis and functional implementation of software development.

- The impact of the virtual tools, such as 3D MAX and WebGL, and communication standards, such as OPC UA and REST, on the prototype software of the real-time control system for the dual gear factory: The selection and use of virtual tools affect the quality of THE virtualized images and development efficiency, while the selection and use of communication standards affect system data transmission and interactions. The reasonable combination of 3D MAX and WebGL can basically meet the requirements of virtualization development, and the reasonable combination of OPC UA and REST can also basically achieve the requirements of data communication.

- Reasons for imperfect and immature software system development: A prototype software of the real-time control system for the factory, which is specialized in manufacturing the intermediate shaft dual gear for a new energy vehicle gearbox, is developed. But only a small number of functions for monitoring, virtualizing, and controlling can be achieved and need to be further improved. The failure to make the software of the real-time control system more powerful and mature is not due to technical reasons, but rather the authors’ insufficient understanding of the prototype factory and excessive software development workload.

- However, only the physical geometric properties and basic processing actions of the virtual factory are researched in this article, and the factory operation logic and processing trajectory have not yet been considered. More realistic methods need to be further studied and improved. The practice of digital twin factories is still in the exploratory stage, and there are still many key issues that need to be further studied and improved in the implementation process. In virtual factory modeling, the virtual factory needs to reflect the real production scene, which places high demands on modeling techniques. The integration control of the factory prototype system only provides critical control for the digital twin factory, and the provided control is not comprehensive enough to integrate other management systems. In the future, more artificial intelligence and big data technologies will be combined to achieve more levels of data analysis work.

5. Conclusions

- A gear factory is a typical discrete manufacturing factory, and the research methods and achievements of a real-time control system for the dual gear factory based on digital twin technology are also suitable for other discrete factories.

- The digital factory is just the software of the real-time control system of the digital twin factory. The research on a real-time control system mainly focuses on the software of a real-time control system or focuses on the digital factory.

- A model for the digital twin gear factory is put forward based on the characteristics of gear factories. This model can transform the software development of a real-time control system into the development of a digital factory, laying an important technical path for researchers studying real-time control systems.

- A human–computer interaction architecture for the real-time control system is put forward. It consists of three parts as follows: a monitoring module, a virtualizing module, and a controlling module. At work, it appears as three interactive interfaces as follows: a monitoring window, a virtualizing window, and a controlling window. A template for the software development of a real-time control system is proposed.

- The virtual factory and some visualizing processes are created using 3D MAX and WebGL technology, and the device communication and interface management are implemented with OPC UA and REST standards. These technologies and standards can improve the software development efficiency of a real-time control system, thereby accelerating the development of virtual technology.

- A prototype software of the real-time control system for the factory, which is specialized in manufacturing the intermediate shaft dual gear of a new energy vehicle gearbox, is developed. But only a small number of functions for monitoring, virtualizing, and controlling can be achieved and need to be further improved. The failure to make the software of the real-time control system more powerful and mature is not due to technical reasons, but rather the authors’ insufficient understanding of the prototype factory and excessive software development workload.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xing, X.J. Research on the ecological environment of my country’s manufacturing industry. Contemp. Econ. 2018, 22, 20–23. [Google Scholar]

- Zhao, S.Q. Research on the strategy of improving product quality by using quality control Technology. China Plant Eng. 2019, 17, 29–31. [Google Scholar]

- Talkhestani, B.A.; Jung, T.; Lindemann, B.; Sahlab, N.; Jazdi, N.; Schloegl, W.; Weyrich, M. An architecture of an intelligent digital twin in a cyber-physical production system. AT-Autom. 2019, 67, 762–782. [Google Scholar] [CrossRef]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Caesar, B.; Hanel, A.; Wenkler, E.; Corinth, C.; Ihlenfeldt, S.; Fay, A. Information model of a digital process twin for machining processes. In Proceedings of the 25th IEEE International Conference on Emerging Technologies and Factory Automation, Vienna, Austria, 8–11 September 2020; IEEE: Piscataway, NJ, USA, 2020; Volume 1, pp. 1765–1772. [Google Scholar]

- Grieves, M. Virtually Perfect: Driving Innovative and Lean Products through Product Lifecycle Management. Master’s Thesis, Space Coast Press, Cocoa Beach, FL, USA, 2011. [Google Scholar]

- Uhlemann, T.H.-J.; Schock, C.; Lehmann, C.; Freiberger, S.; Steinhilper, R. The digital twin: Demonstrating the potential of real-time data acquisition in production systems. Procedia Manuf. 2017, 9, 113–120. [Google Scholar] [CrossRef]

- Schroeder, G.N.; Steinmetz, C.; Pereira, C.E.; Espindola, D.B. Digital twins data modeling with automation ML and a communication methodology for data exchange. IFAC Pap. Line 2016, 49, 12–17. [Google Scholar] [CrossRef]

- Morse, E.; Dantan, J.Y.; Anwer, N.; Söderberg, R.; Moroni, G.; Qureshi, A.; Jiang, X.; Mathieu, L. Tolerancing: Managing uncertainty form conceptual design to final product. CIRP Ann. Manuf. Technol. 2018, 67, 695–717. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M.; Cheng, J.F.; Qi, Q. Digital twin factory: A new paradigm for future factory. Comput. Integr. Manuf. Syst. 2017, 23, 1–9. [Google Scholar]

- Schluse, M.; Atorf, L.; Rossmann, J. Experimentable digital twins for model-based systems engineering and simulation-based development. In Proceedings of the 2017 Annual IEEE International Systems Conference (SysCon), Montreal, QC, Canada, 24–27 April 2017. [Google Scholar]

- Schluse, M.; Rossmann, J. From simulation to experimentable digital twins simulation-based development and operation of complex technical systems. In Proceedings of the 2016 IEEE International Symposium on Systems Engineering (ISSE), Edinburgh, UK, 3–5 October 2016. [Google Scholar]

- Tao, F.; Liu, W.R.; Zhang, M.; Hu, T. Five dimension digital twin model and its ten applications. Comput. Integr. Manuf. Syst. 2019, 25, 1–18. [Google Scholar]

- Ma, Y.; Wang, C.X.; Yin, Z.Y.; Li, M.; Wang, Z.; Chai, A. Design and construction of digital twin laboratory model based on SAMP of Chinese academy of sciences. J. Chin. Comput. Syst. 2019, 40, 2343–2347. [Google Scholar]

- Chen, M.R.; Deng, C.Y.; Zhang, J.; Guo, R.-F. Research on 3D detection and interaction algorithm of production line based on digital twin. J. Chin. Comput. Syst. 2020, 41, 979–984. [Google Scholar]

- Nguyen, N.T.; Leu, M.C.; Liu, X.F. Real-time communication for manufacturing cyber-physical systems. In Proceedings of the 2017 IEEE 16th International Symposium on Network Computing and Applications, Cambridge, MA, USA, 30 October–1 November 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–4. [Google Scholar]

- Åkerman, M.; Stahre, J.; Engström, U.; Angelsmark, O.; McGillivray, D.; Holmberg, T.; Bärring, M.; Lundgren, C.; Friis, M.; Fast-Berglund, Å. Technical interoperability for machine connectivity on the shop floor. Technologies 2018, 6, 57. [Google Scholar] [CrossRef]

- Latif, H.; Shao, G.; Starly, B. Integrating a dynamic simulator and advanced process control using the OPC UA standard. Procedia Manuf. 2019, 34, 813–819. [Google Scholar] [CrossRef]

- Mathias, S.G.; Schmied, S.; Grossmann, D. An investigation on database connections in OPC UA applications. Procedia Comput. Sci. 2020, 170, 602–609. [Google Scholar] [CrossRef]

- Otrebski, R.; Pospisil, D.; Engelhardt-Nowitzki, C.; Kryvinska, N.; Aburaia, M. Flexibility enhancements in digital manufacturing by means of ontological data modeling. Procedia Comput. Sci. 2019, 155, 296–302. [Google Scholar] [CrossRef]

- Jin, S.S.; Liu, X.Q.; Wu, R.; Xin, R.; Wang, Y. Product quality management model based on digital twins. High Technol. Lett. 2022, 32, 101–110. [Google Scholar]

- Liu, X.Q. Design of Automobile Gear Manufacturing Workshop Based on Digital Twin. Master’s Thesis, Zhejiang University of Technology, Hangzhou, China, 30 June 2021. [Google Scholar]

- Zhang, M. Research on Digital Twin Workshop of New Energy Vehicle Intermediate Shaft. Master’s Thesis, Zhejiang University of Technology, Hangzhou, China, 30 June 2022. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, S.; Yu, F.; Wang, B.; Zhang, M.; Wang, Y. Research on a Real-Time Control System for Discrete Factories Based on Digital Twin Technology. Appl. Sci. 2024, 14, 4076. https://doi.org/10.3390/app14104076

Jin S, Yu F, Wang B, Zhang M, Wang Y. Research on a Real-Time Control System for Discrete Factories Based on Digital Twin Technology. Applied Sciences. 2024; 14(10):4076. https://doi.org/10.3390/app14104076

Chicago/Turabian StyleJin, Shousong, Fengyi Yu, Boyu Wang, Min Zhang, and Yaliang Wang. 2024. "Research on a Real-Time Control System for Discrete Factories Based on Digital Twin Technology" Applied Sciences 14, no. 10: 4076. https://doi.org/10.3390/app14104076

APA StyleJin, S., Yu, F., Wang, B., Zhang, M., & Wang, Y. (2024). Research on a Real-Time Control System for Discrete Factories Based on Digital Twin Technology. Applied Sciences, 14(10), 4076. https://doi.org/10.3390/app14104076