Evaluation of the Possibilities of Using Oat Malt in Wheat Breadmaking

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Chemicals

2.1.2. Flours and Other Baking Materials

2.1.3. Preparation of Flour Mixtures for Baking

2.2. Methods

2.2.1. Characteristics of Quality Parameter of Basic Flours and Flour Mixtures

2.2.2. Laboratory Bread Baking Trial

2.2.3. Technological Properties and Color Parameters of Bread

2.2.4. Chemical Composition and Energy Value of Bread

2.2.5. Antioxidant Potential of Bread

Extract Preparation

Determination of Total Polyphenols Content with the Folin–Ciocalteu Reagent

Determination of Antioxidant Activity by DPPH Assay

2.2.6. Statistical Analysis

3. Results and Discussion

3.1. Chemical and Color Characteristics of Quality of Baking Flours

3.2. Characteristics of Quality Parameters of Tested Flour Mixtures

3.3. Characteristics of Technological Properties and Color Parameters of Bread

3.4. Characteristics of Nutritional Value and Antioxidant Potential of Bread

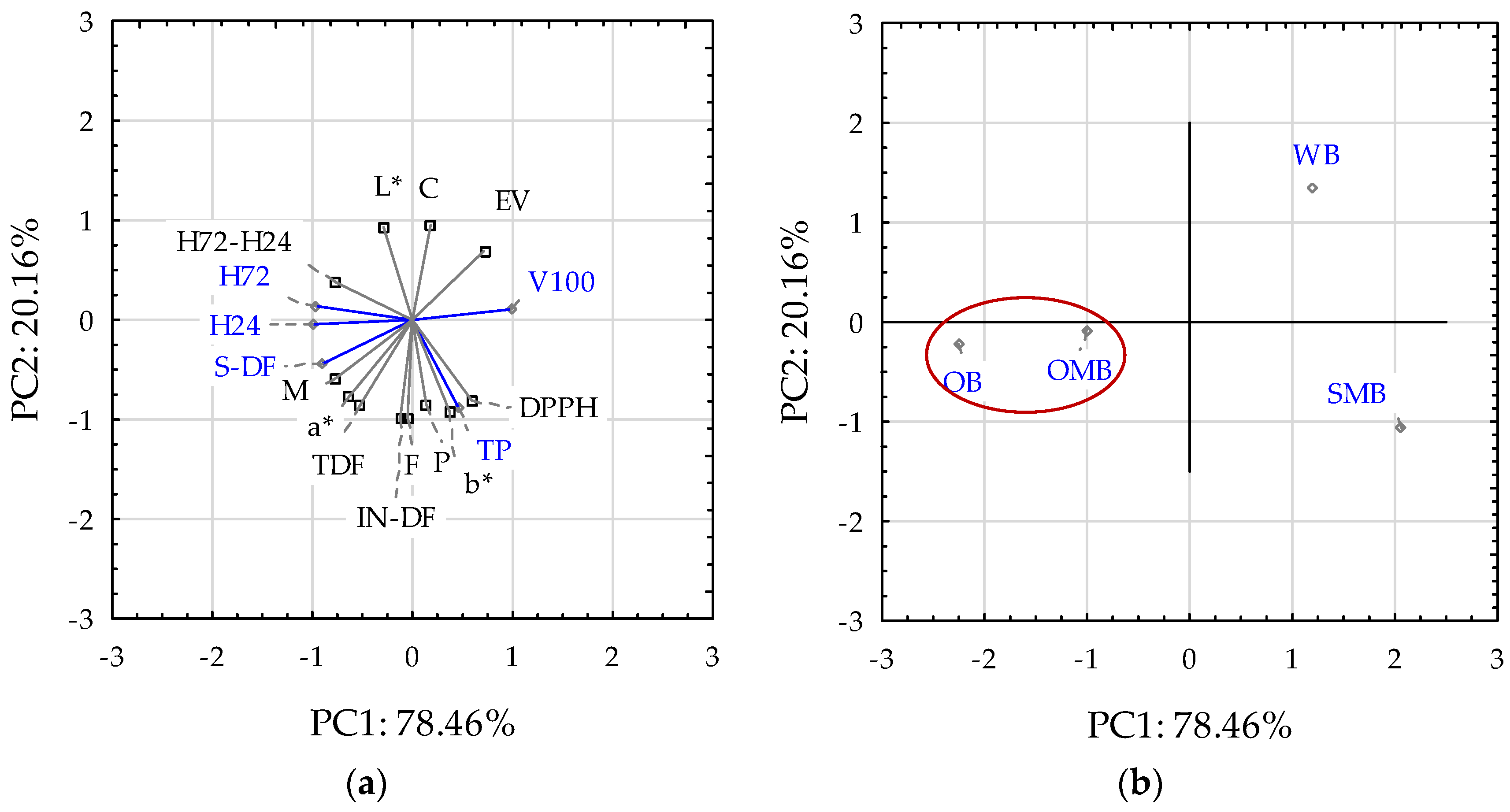

3.5. Comprehensive Assessment of the Quality Parameters, Nutritional Value, and Antioxidant Potential of Bread Samples Using Principal Component Analysis (PCA)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Benanti, A.; Ashkezary, M.R.; Gugino, I.M.; Canale, M.; Yeganehzad, S.; Todaro, A. Evaluation of biscuits obtained from novel composite flour containing Maiorca malt flour. Ital. J. Food Sci. 2023, 35, 49–56. [Google Scholar] [CrossRef]

- Codină, G.G.; Istrate, A.M.; Gontariu, I.; Mironeasa, S. Rheological Properties of Wheat-Flaxseed Composite Flours Assessed by Mixolab and Their Relation to Quality Features. Foods 2019, 8, 333. [Google Scholar] [CrossRef] [PubMed]

- Abdullah, M.; Tufail, T.; Hussain, M.; Nadeem, M.; Owais, M.; Zulkiffal, M.; Tanveer, M.H.; Al Jbawi, E. Effect of sprouted barley flour on the quality wheat of bread, biscuits and cakes. Cogent Food Agric. 2022, 8, 2122272. [Google Scholar] [CrossRef]

- Nakov, G.; Temkov, M.; Lazova-Borisova, I.; Lukinac, J. Properties of Flour Obtained from Malted Grains—Review. Int. J. Food Technol. Nutr. 2022, 5, 48–52. Available online: https://eprints.unite.edu.mk/1042/1/IJFTN/2022-48-52.pdf (accessed on 10 April 2024).

- Man, S.M.; Stan, L.; Pӑucean, A.; Chiş, M.S.; Mureşan, V.; Socaci, S.A.; Pop, A.; Muste, S. Nutritional, Sensory, Texture Properties and Volatile Compounds Profile of Biscuits with Roasted Flaxseed Flour Partially Substituting for Wheat Flour. Appl. Sci. 2021, 11, 4791. [Google Scholar] [CrossRef]

- Czubaszek, A.; Wojciechowicz-Budzisz, A.; Spychaj, R.; Kawa-Rygielska, J. Effect and added brewer’s spent grain on the baking value of flour and the quality of wheat bread. Molecules 2022, 27, 1624. [Google Scholar] [CrossRef]

- Wójcik, M.; Dziki, D.; Różyło, R.; Biernacka, B.; Łysiak, G.; al Aridhee, J. Changes of dough and wheat bread physical properties as a result of black oat flour addition. Acta Agroph. 2017, 24, 163–172. (In Polish) [Google Scholar]

- Majzoobi, M.; Raiss Jalali, A.; Farahnaky, A. Impact of Whole Oat Flour on Dough Properties and Quality on Fresh and Stored Part-Baked Bread. J. Food Qual. 2016, 39, 620–626. [Google Scholar] [CrossRef]

- Amaral, O.; Guerreiro, C.S.; Gomes, A.; Cravo, M. Resistant starch production in wheat bread: Effect of ingredients, baking conditions and storage. Eur. Food Res. Technol. 2016, 242, 1747–1753. [Google Scholar] [CrossRef]

- Wyka, J.; Lipiec, K.; Mazurek, D.; Bułynko, J. The energy value of bread and its changes during storage. Bromatol. Toxicol. Chem. 2015, 48, 19–24. (In Polish) [Google Scholar]

- Gray, J.A.; Bemiller, J.N. Bread Staling: Molecular Basis and Control. Compr. Rev. Food Sci. Food Saf. 2003, 2, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Najafabadi, L.I.; Le-Bail, A.; Hamdami, N.; Monteau, J.-Y.; Keramat, J. Impact of baking conditions and storage temperature on staling of fully and part-baked Sangak bread. J. Cereal Sci. 2014, 60, 151–156. [Google Scholar] [CrossRef]

- Tarczyńska, A.S.; Malinowska, E.; Urbanowicz, A. Attitudes and Behaviours of Young Consumers towards Wasting Food: Case Study Based on Polish Students. Sustainability 2023, 15, 3328. [Google Scholar] [CrossRef]

- Demirtaş, B.; Kaya, A.; Dağıstan, E. Consumers’ Bread Consumption Habits and Waste Status: Hatay/Turkey Example. Tur. J. Agric. Food Sci. Technol. 2018, 6, 1653–1661. [Google Scholar] [CrossRef]

- Majzoobi, M.; Wang, Z.; Teimouri, S.; Pematilleke, N.; Brennan, C.S.; Farahnaky, A. Unlocking the Potential of Sprouted Cereals, Pseudocereals, and Pulses in Combating Malnutrition. Foods 2023, 12, 3901. [Google Scholar] [CrossRef]

- Salamon, A.; Kowalska, H.; Ignaczak, A.; Marzec, A.; Kowalska, J.; Szafrańska, A. Characteristic of Oat and Buckwheat Malt Grains for Use in the Fermented Foods. Foods 2023, 12, 3747. [Google Scholar] [CrossRef] [PubMed]

- Gasiński, A.; Kawa-Rygielska, J.; Błażewicz, J.; Leszczyńska, D. Malting procedure and its impact on the composition of volatiles and antioxidative potential of naked and covered oat varieties. J. Cereal Sci. 2022, 107, 103537. [Google Scholar] [CrossRef]

- Kordialik-Bogacka, E.; Bogdan, P.; Diowksz, A. Malted and unmalted oats in brewing. J. Inst. Brew. 2014, 120, 390–398. [Google Scholar] [CrossRef]

- Zdaniewicz, M.; Pater, A.; Hrabia, O.; Duliński, R.; Cioch-Skoneczny, M. Tritordeum malt: An innovative raw material for beer production. J. Cereal Sci. 2020, 96, 103095. [Google Scholar] [CrossRef]

- Trummer, J. Grains usable for malting and brewing: A practical overview. In Advances in Brewing and Malting Technology; Poreda, A., Zdaniewicz, M., Eds.; University of Agriculture: Cracow, Poland, 2018; pp. 67–87. [Google Scholar]

- Mäkinen, O.E.; Arendt, E.K. Oat malt as a baking ingredient—A comparative study of the impact of oat, barley and wheat malts on bread and dough properties. J. Cereal Sci. 2012, 56, 747–753. [Google Scholar] [CrossRef]

- Mäkinen, O.E.; Arendt, E.K. Nonbrewing applications of malted cereals, pseudocereals and legumes: A review. J. Am. Soc. Brew. Chem. 2015, 73, 223–227. [Google Scholar] [CrossRef]

- Kunze, W. Technology Brewing and Malting, 1st ed.; (8th ed. transl.); Piwochmiel Ltd.: Warsaw, Poland, 1999. [Google Scholar]

- Belcar, J.; Kaszuba, J.; Gorzelany, J. Effect of Wheat and Barley Malt Addition on the Quality of the Baking Blend and Wheat Bread. Pol. J. Food Nutr. Sci. 2022, 72, 129–139. [Google Scholar] [CrossRef]

- Honců, I.; Krejčířová, L.; Příhoda, J.; Sluková, M. The effect addition of malt flour on the dough, volume and sensory properties of bread. PARIPEX—Indian J. Res. 2015, 4, 152–155. [Google Scholar]

- Veluppillai, S.; Nithyanantharajah, K.; Vasantharuba, S.; Balakumar, S.; Arasaratnam, V. Optimization of Bread preparation from Wheat Flour and Malted Rice Flour. Rice Sci. 2010, 17, 51–59. [Google Scholar] [CrossRef]

- Karaoğlu, M.M.; Reis, G.S.; Gerçekaslan, K.E. The Effect of Different Malt Flours on Rheological Properties of Dough. GIDA 2022, 47, 220–230. [Google Scholar] [CrossRef]

- Tapsoba, F.W.-B.; Compaore-Sereme, D.; Compaore, C.S.; Ndig-Yenouba, T.J.; Yaogho, W.A.C.; Maina, N.H.; Sawadogo-Lingani, H. Effects of Cereals Malts Used as Improver on Physico-Chemical, Nutritional and Sensory Characteristic of Wheat and Millet Composited Breads. Food Nutr. Sci. 2022, 13, 669–689. [Google Scholar] [CrossRef]

- Hrušková, M.; Švec, I.; Kučerová, I. Effect of Malt Flour Addition on the Rheological Properties of Wheat Fermented Dough. Czech J. Food Sci. 2003, 21, 210–218. Available online: https://www.agriculturejournals.cz/publicFiles/50858.pdf (accessed on 10 April 2024). [CrossRef]

- Rögner, N.S.; Mall, V.; Steinhaus, M. Odour-active compounds in liquid malt extracts for the baking industry. Eur. Food Res. Technol. 2021, 247, 1263–1275. [Google Scholar] [CrossRef]

- Klupsaite, D.; Starkute, V.; Zokaityte, E.; Cernauskas, D.; Mockus, E.; Kentra, E.; Sliazaite, R.; Abramaviciute, G.; Sakaite, P.; Komarova, V.; et al. The Contribution of Scalded and Scalded-Fermented Rye Wholemeal Flour to Quality Parameters and Acrylamide Formation in Semi-Wheat-Rye Bread. Foods 2023, 12, 937. [Google Scholar] [CrossRef]

- Murniece, R.; Reidzane, S.; Galoburda, R.; Radenkovs, V.; Klava, D. The Impact of Fermented Scald on Rye and Hull-Less Barley Dough and Bread Structure Formation. Foods 2023, 12, 4475. [Google Scholar] [CrossRef]

- Li, H.; Dai, F.; Zhang, L.; Li, Z. Characterization of scalded dough and its impact on the growth of mixed yeasts originating from Jiaozi. Food Biosci. 2022, 49, 101920. [Google Scholar] [CrossRef]

- Wójcik, M.; Różyło, R.; Łysiak, G.; Kulig, R.; Cacak-Pietrzak, G. Textural and sensory properties of wheat bread fortified with nettle (Urtica dioica L.) produced by the scalded flour method. J. Food Process. Preserv. 2021, 45, e15851. [Google Scholar] [CrossRef]

- PN-R-74106; Cereal Grain—Oats. Polish Standardization Committee: Warsaw, Poland, 1996.

- MEBAK. Collection of Brewing Analysis Methods of the Mitteleuropäische Brautechnische Analysenkommission. Method 1.5.3—Micromalting; Published by Jacob, F.; MEBAK: Freising-Weihenstephan, Germany, 2011. [Google Scholar]

- ISO 3093; Wheat, Rye and Their Flours, Durum Wheat and Durum Wheat Semolina—Determination of the Falling Number according to Hagberg-Perten. International Organization for Standardization: Geneva, Switzerland, 2009.

- ISO 21415-2; Wheat and Wheat Flour—Gluten Content—Part 2: Determination of Wet Gluten and Gluten Index by Mechanical Means. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 712; Cereals and Cereal Products—Determination of Moisture Content—Reference Method. International Organization for Standardization: Geneva, Switzerland, 2009.

- ISO 20483; Cereals and Pulses—Determination of the Nitrogen Content and Calculation of the Crude Protein Content—Kjeldahl method. International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO 11085; Cereals, Cereals-Based Products and Animal Feeding Stuff—Determination of Crude Fat and Total Fat Content by the Randall Extraction Method. International Organization for Standardization: Geneva, Switzerland, 2008.

- ISO 2171; Cereals, Pulses and by-Products—Determination of Ash Yield by Incineration. International Organization for Standardization: Geneva, Switzerland, 2023.

- AACC 32-07; Soluble, Insoluble, and Total Dietary Fiber in Foods and Food Products. AACC Approved Methods of Analysis, 11th ed.; Cereals & Grains Association: St. Paul, MN, USA. Available online: https://methods.aaccnet.org/summaries/32-07-01.aspx (accessed on 10 April 2024).

- AOAC 991.43; Total, Soluble, and Insoluble Dietary Fibre in Foods (Official Method). AOAC International: Rockville, MD, USA. Available online: https://www.aoacofficialmethod.org/index.php?main_page=product_info&products_id=1183 (accessed on 10 April 2024).

- ISO 17718; Wholemeal and Flour From Wheat (Triticum aestivum L.)—Determination of Rheological Behavior as a Function of Mixing and Temperature Increase. International Organization for Standardization: Geneva, Switzerland, 2013.

- Suchowilska, E.; Szafrańska, A.; Słowik, E.; Wiwart, M. Flour from Triticum polonicum L. as a potential ingredient in bread production. Cereal Chem. 2019, 96, 554–563. [Google Scholar] [CrossRef]

- Stępniewska, S.; Cacak-Pietrzak, G.; Szafrańska, A.; Ostrowska-Ligęza, E.; Dziki, D. Assessment of the starch-amylolytic complex of rye flours by traditional methods and modern one. Materials 2021, 14, 7603. [Google Scholar] [CrossRef] [PubMed]

- Regulation (EU) No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the Provision of Food Information to Consumers, Amending Regulations (EC) No 1924/2006 and (EC) No 1925/2006 of the European Parliament and of the Council, and Repealing Commission Directive 87/250/EEC, Council Directive 90/496/EEC, Commission Directive 1999/10/EC, Directive 2000/13/EC of the European Parliament and of the Council, Commission Directives 2002/67/EC and 2008/5/EC and Commission Regulation (EC) No 608/2004. Official Journal of the European Union, L 304, 22 November 2011. Available online: https://data.europa.eu/eli/reg/2011/1169/oj (accessed on 10 April 2024).

- Chlopicka, J.; Pasko, P.; Gorinstein, S.; Jedryas, A.; Zagrodzki, P. Total phenolic and total flavonoid content, antioxidant activity and sensory evaluation of pseudocereal breads. LWT—Food Sci. Technol. 2012, 46, 548–555. [Google Scholar] [CrossRef]

- Paśko, P.; Bartoń, H.; Zagrodzki, P.; Gorinstein, S.; Fołta, M.; Zachwieja, Z. Anthocyanins, total polyphenols and antioxidant activity in amaranth and quinoa seeds and sprouts during their growth. Food Chem. 2009, 115, 994–998. [Google Scholar] [CrossRef]

- Tsafrakidou, P.; Michaelidou, A.-M.; Biliaderis, C.G. Fermented Cereal-based Products: Nutritional Aspects, Possible Impact on Gut Microbiota and Health Implications. Foods 2020, 9, 734. [Google Scholar] [CrossRef]

- Hübner, F.; O’Neil, T.; Cashman, K.D.; Arendt, E.K. The Influence of Germination Conditions on Beta-Glucan, Dietary Fibre and Phytate during the Germination of Oats and Barley. Eur. Food Res. Technol. 2010, 231, 27–35. [Google Scholar] [CrossRef]

- Ćurić, D.; Karlović, D.; Tušak, D.; PetroviC, B.; Ðugum, J. Gluten as a Standard of Wheat Flour Quality. Food Technol. Biotechnol. 2001, 39, 353–361. Available online: https://www.ftb.com.hr/images/pdfarticles/2001/October-December/39-353.pdf (accessed on 10 April 2024).

- Aslam, J.; Hussain, A.; MueenUd-Din, G.; Kausar, T.; Siddique, T.; Kabir, K.; Gorsi, F.I.; Haroon, H.; Nisar, R.; Noreen, S.; et al. Utilization of malted barley flour as replacement of wheat flour to improve technological, rheological, physicochemical, and organoleptic parameters of fortified breads. Front. Sustain. Food Syst. 2023, 7, 1230374. [Google Scholar] [CrossRef]

- Nechita, V.; Niculita, I.; Afghire, C.; Izella, I.G. Strong flour improvement using malt flour. J. Agroaliment. Proc. Technol. 2009, 15, 242–244. Available online: https://journal-of-agroalimentary.ro/admin/articole/47352L11_Ionela_Niculita_242-244.pdf (accessed on 10 April 2024).

- Köksel, H.; Kahraman, K.; Şanal, T.; Ozay, D.S.; Dubat, A. Potential utilization of mixolab for quality evaluation of bread wheat genotypes. Cereal Chem. 2009, 86, 522–526. [Google Scholar] [CrossRef]

- Zadeike, D.; Jukonyte, R.; Juodeikiene, G.; Bartkiene, E.; Valatkeviciene, Z. Comparative study of ciabatta crust crispness through acoustic and mechanical methods: Effects of wheat malt and protease on dough rheology and crust crispness retention during storage. LWT—Food Sci. Technol. 2018, 89, 110–116. [Google Scholar] [CrossRef]

- El-Hadary, M.R.E.; El-Arby, G.M.; Abdel-Hady, M.M.; Abo-Elmaaty, S.M. Utilization of barley malt as a partial replacement of wheat flour in biscuits industries. Zagazig J. Agric. Res. 2018, 45, 239–249. [Google Scholar] [CrossRef]

- Dubat, A. A new AACC international approved method to measure rheological properties of a dough sample. Cereal Foods World 2010, 55, 150–153. [Google Scholar] [CrossRef]

- Szafrańska, A. Comparison of alpha-amylase activity of wheat flour estimated by traditional and modern techniques. Acta Agroph. 2014, 21, 493–505. (In Polish) [Google Scholar]

- Qiu, S.; Yadav, M.P.; Chen, H.; Liu, Y.; Tatsumi, E.; Yin, L. Effects of corn fiber gums (CFG) on the pasting and thermal behaviours of maize starch. Carbohydr. Polym. 2015, 115, 246–252. [Google Scholar] [CrossRef]

- PN-A-74108; Bread—Test Methods and Point Assessment. Polish Standardization Committee: Warsaw, Poland, 1989.

- Astiz, V.; Guardianelli, L.M.; Salinas, M.V.; Brites, C.; Puppo, M.C. High β-Glucans Oats for Healthy Wheat Breads: Physicochemical Properties of Dough and Bread. Foods 2023, 12, 170. [Google Scholar] [CrossRef]

- Krochmal-Marczak, B.; Tobiasz-Salach, R.; Kaszuba, J. The effect of adding oat flour on the nutritional and sensory quality of wheat bread. Br. Food J. 2020, 122, 2329–2339. [Google Scholar] [CrossRef]

- Litwinek, D.; Gambuś, H.; Zięć, G.; Sabat, R.; Wywrocka-Gurgul, A.; Berski, W. The comparison of quality and chemical composition of breads baked with residual and commercial oat flours and wheat flour. J. Microbiol. Biotechnol. Food Sci. 2013, 2, 1734–1743. Available online: https://www.academia.edu/download/86866988/72_jmbs_litwinek2_fbp_f.pdf (accessed on 10 April 2024).

- Sobczyk, M.; Haber, T.; Witkowska, K. The influence of an addition of oat flakes on the quality of dough and of wheat bread. Acta Agroph. 2010, 16, 423–433. (In Polish) [Google Scholar]

- Yang, B.; Guo, M.; Zhao, Z. Incorporation of wheat malt into a cookie recipe and its effect on the physicochemical properties of the corresponding dough and cookies. LWT—Food Sci. Technol. 2020, 117, 108651. [Google Scholar] [CrossRef]

- Goesaert, H.; Slade, L.; Levine, H.; Delcour, J.A. Amylases and bread firming—An integrated view. J. Cereal Sci. 2009, 50, 345–352. [Google Scholar] [CrossRef]

- Wojciechowska-Solis, J.; Smiglak-Krajewska, M. Consumer Education and Food Waste: An Example of the Bakery Market—The Case of Young Consumer. Eur. Res. Stud. J. 2020, 23, 89–96. [Google Scholar] [CrossRef]

- Salehifar, M.; Shahedi, M. Effects of Oat Flour on Dough Rheology, Texture and Organoleptic Properties of Taftoon Bread. J. Agric. Sci. Technol. 2007, 9, 227–234. Available online: http://dorl.net/dor/20.1001.1.16807073.2007.9.3.2.1 (accessed on 10 April 2024).

- Regulation (EC) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on Nutrition and Health Claims Made on Foods. Official Journal of the European Union, L 404, 30 December 2006. Available online: http://data.europa.eu/eli/reg/2006/1924/oj (accessed on 10 April 2024).

- Van den Abbeele, P.; Kamil, A.; Fleige, L.; Chung, Y.; De Chavez, P.; Marzorati, M. Different Oat Ingredients Stimulate Specific Microbial Metabolites in the Gut Microbiome of Three Human Individuals in Vitro. ACS Omega 2018, 3, 12446–12456. [Google Scholar] [CrossRef]

- Rasane, P.; Jha, A.; Sabikhi, L.; Kumar, A.; Unnikrishnan, V.S. Nutritional advantages of oats and opportunities for its processing as value added foods—A review. J. Food Sci. Technol. 2015, 52, 662–675. [Google Scholar] [CrossRef]

- Gani, A.; Wani, S.; Masoodi, F.; Hameed, G. Whole-grain cereal bioactive compounds and their health benefits: A review. J. Food Process. Technol. 2012, 3, 146. [Google Scholar] [CrossRef]

- Redaelli, R.; Del Frate, V.; Bellato, S.; Terracciano, G.; Ciccoritti, R.; Germeier, C.U.; De Stefanis, E.; Sgrulletta, D. Genetic and environmental variability in total and soluble beta-glucan in European oat genotypes. J. Cereal Sci. 2013, 57, 193–199. [Google Scholar] [CrossRef]

- Kawka, A.; Achremowicz, B. Oat—XXI century plant. Nutrition and industrial use. Sci. Nature Technol. 2014, 8, 41. (In Polish) [Google Scholar]

- Ninfali, P.; Mari, M.; Meli, M.A.; Roselli, C.; Antonini, E. In vitro bioaccessibility of avenanthramides in cookies made with malted oat flours. Int. J. Food Sci. Technol. 2019, 54, 1558–1565. [Google Scholar] [CrossRef]

- Leitao, C.; Marchioni, E.; Bergaentzlé, M.; Zhao, M.; Didierjean, L.; Miesch, L.; Holder, E.; Miesch, M.; Ennahar, S. Fate of polyphenols and antioxidant activity of barley throughout malting and brewing. J. Cereal Sci. 2012, 55, 318–322. [Google Scholar] [CrossRef]

- Šimić, G.; Horvat, D.; Dvojković, K.; Abičić, I.; Viljevac Vuletić, M.; Tucak, M.; Lalić, A. Evaluation of total phenolic content and antioxidant activity of malting and hulless barley grain and malt extracts. Czech J. Food Sci. 2017, 35, 73–78. [Google Scholar] [CrossRef]

- Alkaltham, M.S.; Salamatullah, A.M.; Özcan, M.M.; Uslu, N.; Hayat, K. The effects of germination and heating on bioactive properties, phenolic compounds and mineral contents of green gram seed. LWT—Food Sci. Technol. 2020, 134, 110106. [Google Scholar] [CrossRef]

- Ivanišová, E.; Čech, M.; Hozlár, P.; Zaguła, G.; Gumul, D.; Grygorieva, O.; Makowska, A.; Kowalczewski, P.Ł. Nutritional, Antioxidant and Sensory Characteristics of Bread Enriched with Wholemeal Flour from Slovakian Black Oat Varieties. Appl. Sci. 2023, 13, 4485. [Google Scholar] [CrossRef]

| Sample Code | Sample Description |

|---|---|

| WF | wheat flour (control flour) |

| OF | oat flour |

| MF | oat malt flour |

| W-OF | mixture of wheat flour 90%, and oat flour 10% |

| W-OMF | mixture of wheat flour 90%, oat flour 10%, and oat malt flour 0.6% * |

| W-MF | mixture of wheat flour 90%, and oat malt flour 10% (without scalding) |

| WB | wheat bread (control bread) |

| OB | bread with 10% oat flour |

| OMB | bread with 10% oat flour and oat malt flour 0.6% * |

| SMB | bread with 10% scalded oat malt flour |

| Indicators/Sample Codes | WF | OF | MF |

|---|---|---|---|

| Chemical Composition | |||

| MF (%) | 14.08 ± 0.04 c | 10.42 ± 0.02 b | 6.91 ± 0.03 a |

| PF (% d.m.) | 12.60 ± 0.06 a | 13.61 ± 0.00 b | 14.30 ± 0.07 b |

| FF (% d.m.) | 1.06 ± 0.17 a | 7.42 ± 0.06 b | 8.69 ± 0.17 c |

| AF (% d.m.) | 0.50 ± 0.03 a | 2.30 ± 0.04 b | 2.42 ± 0.05 b |

| CF (% d.m.) | 82.74 ± 0.06 c | 63.62 ± 0.06 a | 64.35 ± 0.03 b |

| TDFF (% d.m.) | 3.15 ± 0.02 a | 13.05 ± 0.04 c | 10.24 ± 0.02 b |

| including: IN-DFF (% d.m.) | 1.47 ± 0.03 a | 10.11 ± 0.03 c | 8.44 ± 0.04 b |

| S-DFF (% d.m.) | 1.68 ± 0.00 a | 2.94 ± 0.01 c | 1.80 ± 0.01 b |

| Color parameters | |||

| L* | 90.48 ± 0.06 c | 81.64 ± 0.02 b | 75.98 ± 0.02 a |

| a* | −1.94 ± 0.01 a | 0.32 ± 0.05 c | 0.14 ± 0.01 b |

| b* | 9.95 ± 0.06 a | 10.44 ± 0.03 b | 15.60 ± 0.08 c |

| Indicators/Sample Codes | WF | W-OF | W-OMF | W-MF |

|---|---|---|---|---|

| Protein Complex Parameters | ||||

| G (%) | 28.1 | n.a. | n.a. | n.a. |

| GI | 91 | n.a. | n.a. | n.a. |

| WA (%) | 57.8 ± 0.4 b | 57.7 ± 0.1 b | 57.2 ± 0.1 b | 55.6 ± 0.1 a |

| T1 (min) | 1.7 ± 0.0 a | 6.6 ± 0.5 b | 5.7 ± 0.8 b | 2.0 ± 0.2 a |

| S (min) | 10.1 ± 0.0 c | 8.4 ± 0.0 b | 7.4 ± 0.5 b | 2.2 ± 0.0 a |

| C2 (N·m) | 0.50 ± 0.01 d | 0.47 ± 0.00 c | 0.36 ± 0.01 b | 0.12 ± 0.00 a |

| Starch complex parameters | ||||

| FN (s) | 349 ± 6 c | 354 ± 2 c | 238 ± 3 b | 60 ± 1 a |

| C3 (N·m) | 2.06 ± 0.02 c | 1.98 ± 0.01 b,c | 1.86 ± 0.05 b | 1.03 ± 0.00 a |

| C4 (N·m) | 1.78 ± 0.05 c | 1.88 ± 0.02 c | 1.38 ± 0.09 b | 0.22 ± 0.01 a |

| C5 (N·m) | 2.73 ± 0.08 c | 3.12 ± 0.00 d | 1.94 ± 0.12 b | 0.14 ± 0.01 a |

| C3-C2 (N·m) | 1.56 ± 0.01 b | 1.51 ± 0.01 b | 1.51 ± 0.04 b | 0.91 ± 0.00 a |

| C3-C4 (N·m) | 0.28 ± 0.03 b | 0.09 ± 0.01 a | 0.48 ± 0.04 c | 0.82 ± 0.01 d |

| C5-C4 (N·m) | 0.95 ± 0.03 c | 1.23 ± 0.01 d | 0.56 ± 0.04 b | −0.08 ± 0.00 a |

| Indicators/Sample Codes | WB | OB | OMB | SMB | |

|---|---|---|---|---|---|

| Technological Value | |||||

| V100 (cm3/100 g) | 357 ± 1 b | 274 ± 2 a | 289 ± 4 a | 365 ± 3 b | |

| M (%) | 41.8 ± 0.1 a | 43.6 ± 0.1 c | 42.8 ± 0.0 b | 42.6 ± 0.1 b | |

| H24 (N) | 7.6 ± 0.3 a | 13.0 ± 0.3 c | 11.3 ± 0.3 b | 6.6 ± 0.3 a | |

| H72 (N) | 11.8 ± 0.7 b | 19.6 ± 1.4 c | 14.3 ± 0.6 b | 8.1 ± 0.3 a | |

| H72-H24 (N) | 4.2 ± 0.3 a,b | 6.6 ± 1.7 b | 3.0 ± 0.2 a,b | 1.5 ± 0.0 a | |

| Color parameters | |||||

| Crumb | L* | 74.87 ± 0.17 d | 72.33 ± 0.37 c | 70.56 ± 0.13 b | 67.37 ± 0.21 a |

| a* | −0.75 ± 0.03 a | 0.44 ± 0.04 d | 0.21 ± 0.01 c | 0.07 ± 0.03 b | |

| b* | 17.76 ± 0.29 a | 19.81 ± 0.03 b | 20.26 ± 0.09 b | 24.01 ± 0.11 c | |

| C* | 17.8 ± 0.3 a | 19.8 ± 1.6 b | 20.3 ± 0.0 b | 24.0 ± 0.3 c | |

| Indicators/Sample Codes | WB | OB | OMB | SMB |

|---|---|---|---|---|

| Nutritional Value | ||||

| P (% d.m.) | 12.82 ± 0.04 a | 12.92 ± 0.05 a,b | 13.08 ± 0.05 b | 13.11 ± 0.07 b |

| F (% d.m.) | 0.16 ± 0.00 a | 0.25 ± 0.03 b | 0.22 ± 0.01 a,b | 0.28 ± 0.01 b |

| C (% d.m.) | 82.18 ± 0.09 c | 81.44 ± 0.00 b | 81.30 ± 0.08 a,b | 81.18 ± 0.04 a |

| TDF (%) | 1.91 ± 0.01 a | 2.19 ± 0.01 b | 2.18 ± 0.01 b | 2.28 ± 0.03 c |

| TDF (% d.m.) | 3.29 ± 0.03 a | 3.88 ± 0.03 b | 3.80 ± 0.02 b | 3.78 ± 0.04 b |

| including: IN-DF (% d.m.) | 2.49 ± 0.01 a | 2.79 ± 0.00 b | 2.81 ± 0.01 b | 2.91 ± 0.01 c |

| S-DF (% d.m.) | 0.80 ± 0.05 a | 1.09 ± 0.03 c | 1.00 ± 0.04 b,c | 0.88 ± 0.05 a,b |

| EV (kcal/100 g) | 226 ± 1 c | 219 ± 1 a | 221 ± 0 b | 222 ± 0 b |

| Antioxidant potential | ||||

| TP (mg GAE/100 g d.m.) | 49.3 ± 2.2 a | 60.2 ± 3.8 a | 60.6 ± 5.0 a | 89.8 ± 1.8 b |

| DPPH (µM Trolox/g d.m.) | 0.54 ± 0.00 a | 0.67 ± 0.04 a,b | 0.76 ± 0.03 b | 1.63 ± 0.04 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salamon, A.; Kowalska, H.; Stępniewska, S.; Szafrańska, A. Evaluation of the Possibilities of Using Oat Malt in Wheat Breadmaking. Appl. Sci. 2024, 14, 4101. https://doi.org/10.3390/app14104101

Salamon A, Kowalska H, Stępniewska S, Szafrańska A. Evaluation of the Possibilities of Using Oat Malt in Wheat Breadmaking. Applied Sciences. 2024; 14(10):4101. https://doi.org/10.3390/app14104101

Chicago/Turabian StyleSalamon, Agnieszka, Hanna Kowalska, Sylwia Stępniewska, and Anna Szafrańska. 2024. "Evaluation of the Possibilities of Using Oat Malt in Wheat Breadmaking" Applied Sciences 14, no. 10: 4101. https://doi.org/10.3390/app14104101

APA StyleSalamon, A., Kowalska, H., Stępniewska, S., & Szafrańska, A. (2024). Evaluation of the Possibilities of Using Oat Malt in Wheat Breadmaking. Applied Sciences, 14(10), 4101. https://doi.org/10.3390/app14104101