Integration of Building Services in Modular Construction: A PRISMA Approach

Abstract

1. Introduction

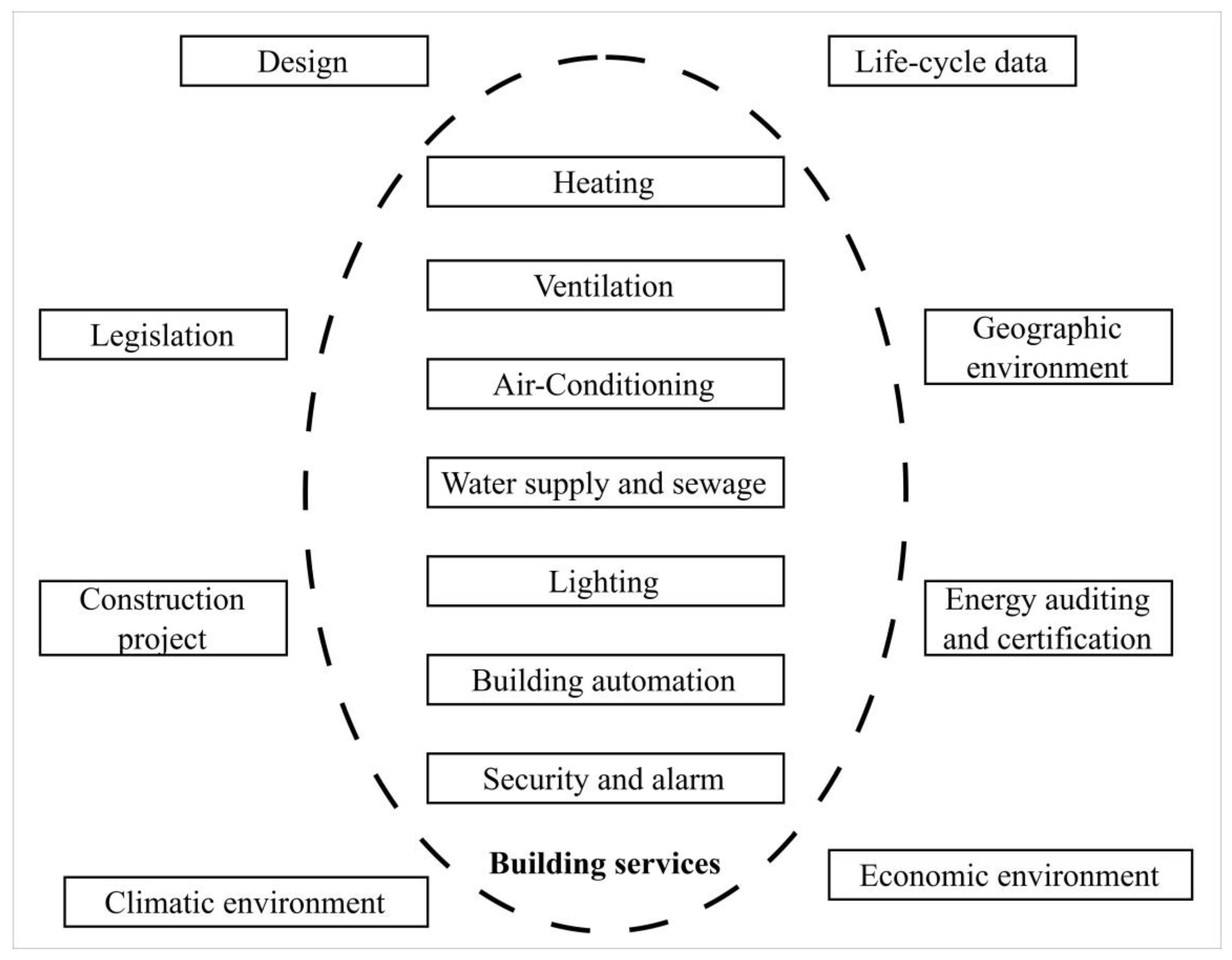

Overview of Building Services Integration

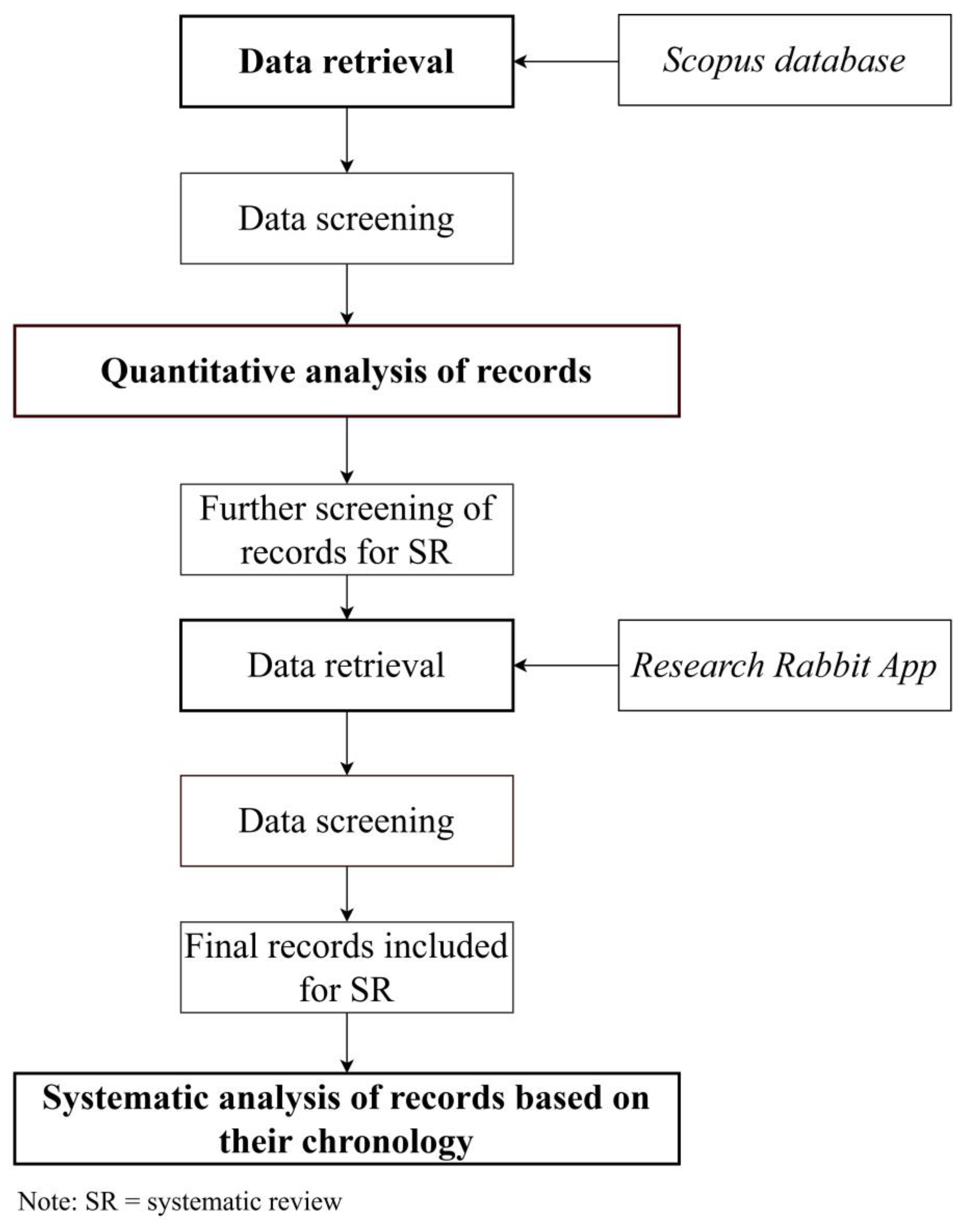

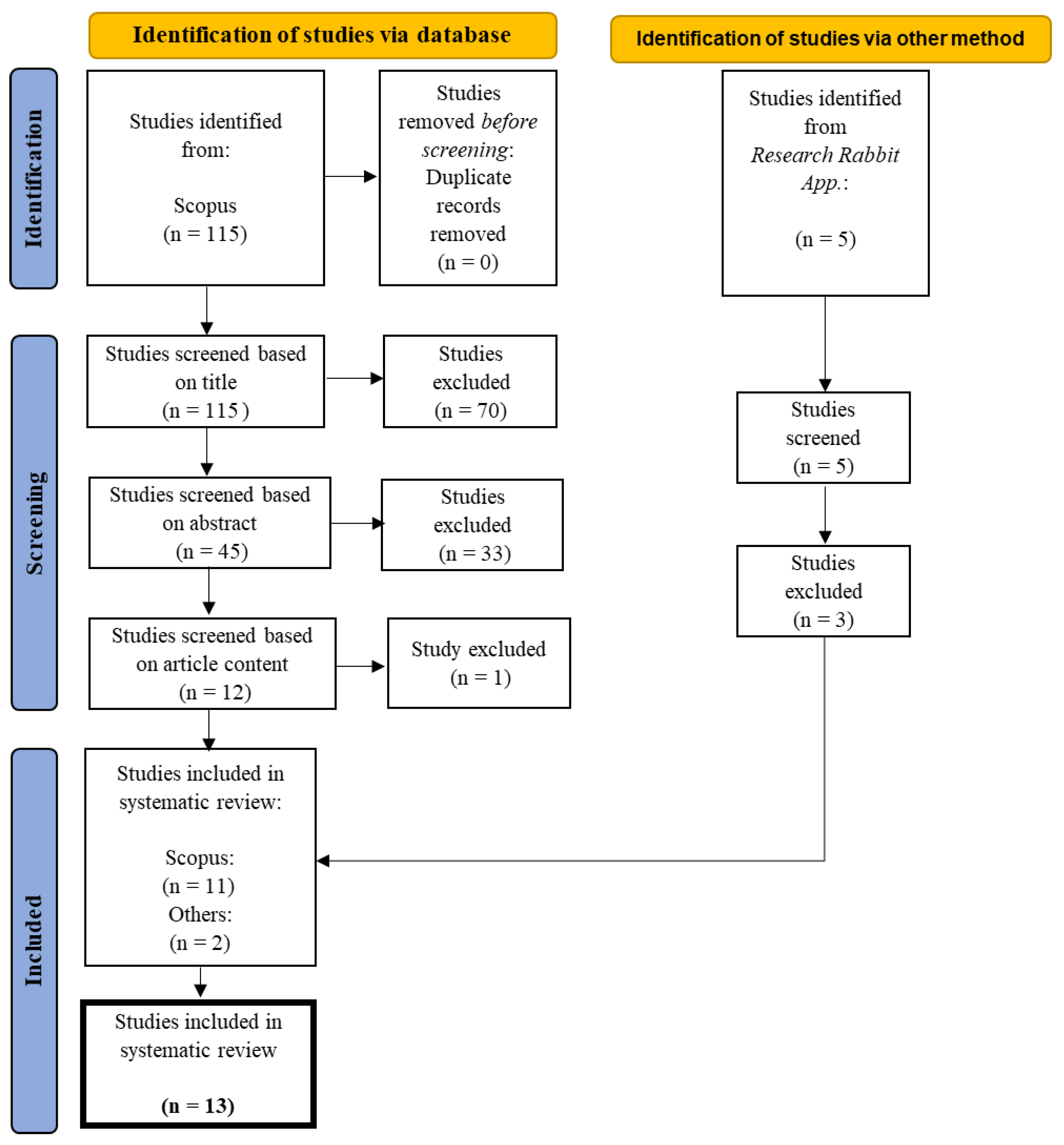

2. Materials and Methods

- SR analyses current research, evaluates scientific contributions, and synthesizes critical facts;

- Although a time-consuming and resource-intensive process, SR helps understand the best available evidence on a topic;

- It identifies, summarizes, and discusses current applications of the subject area.

3. Results

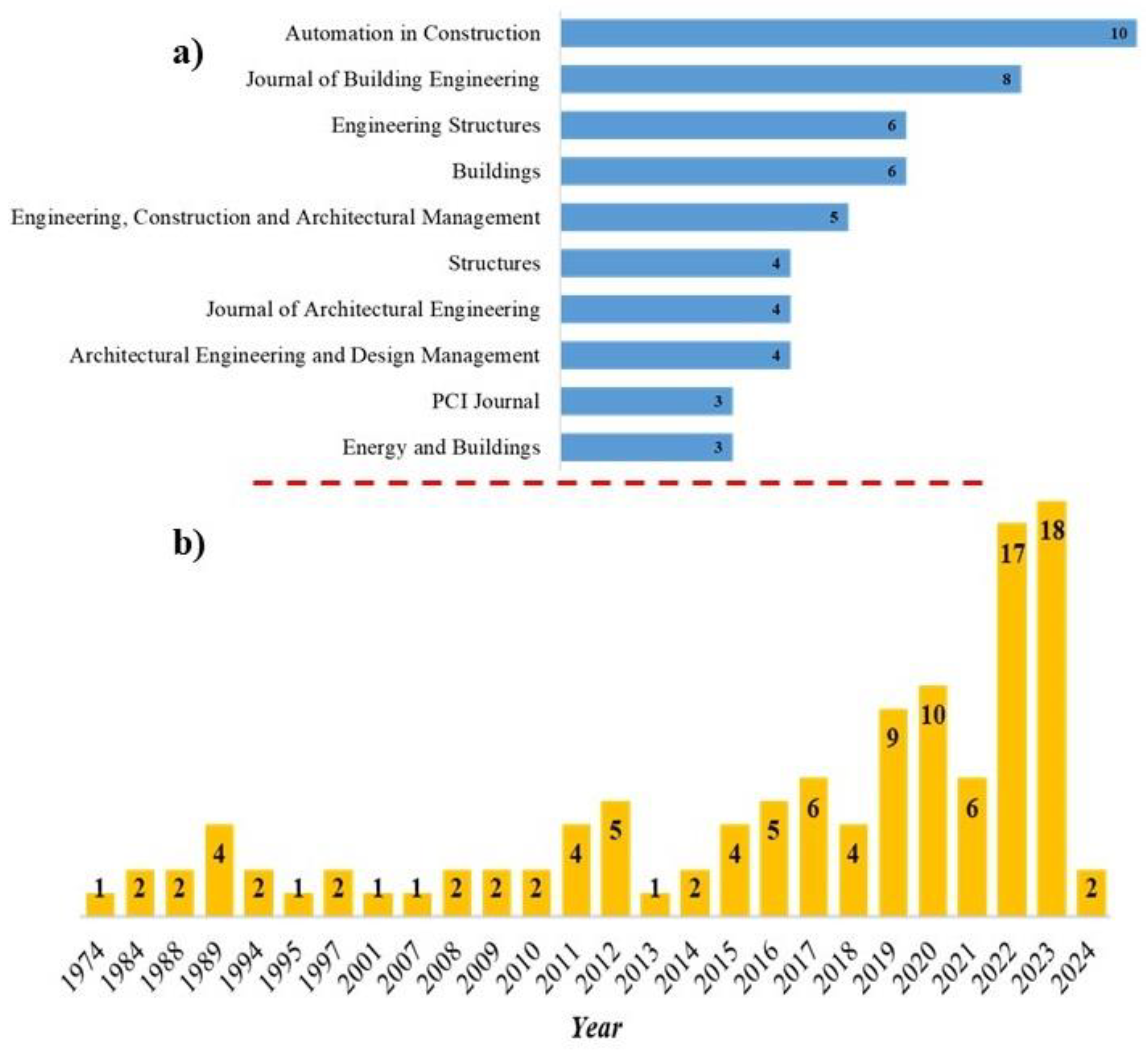

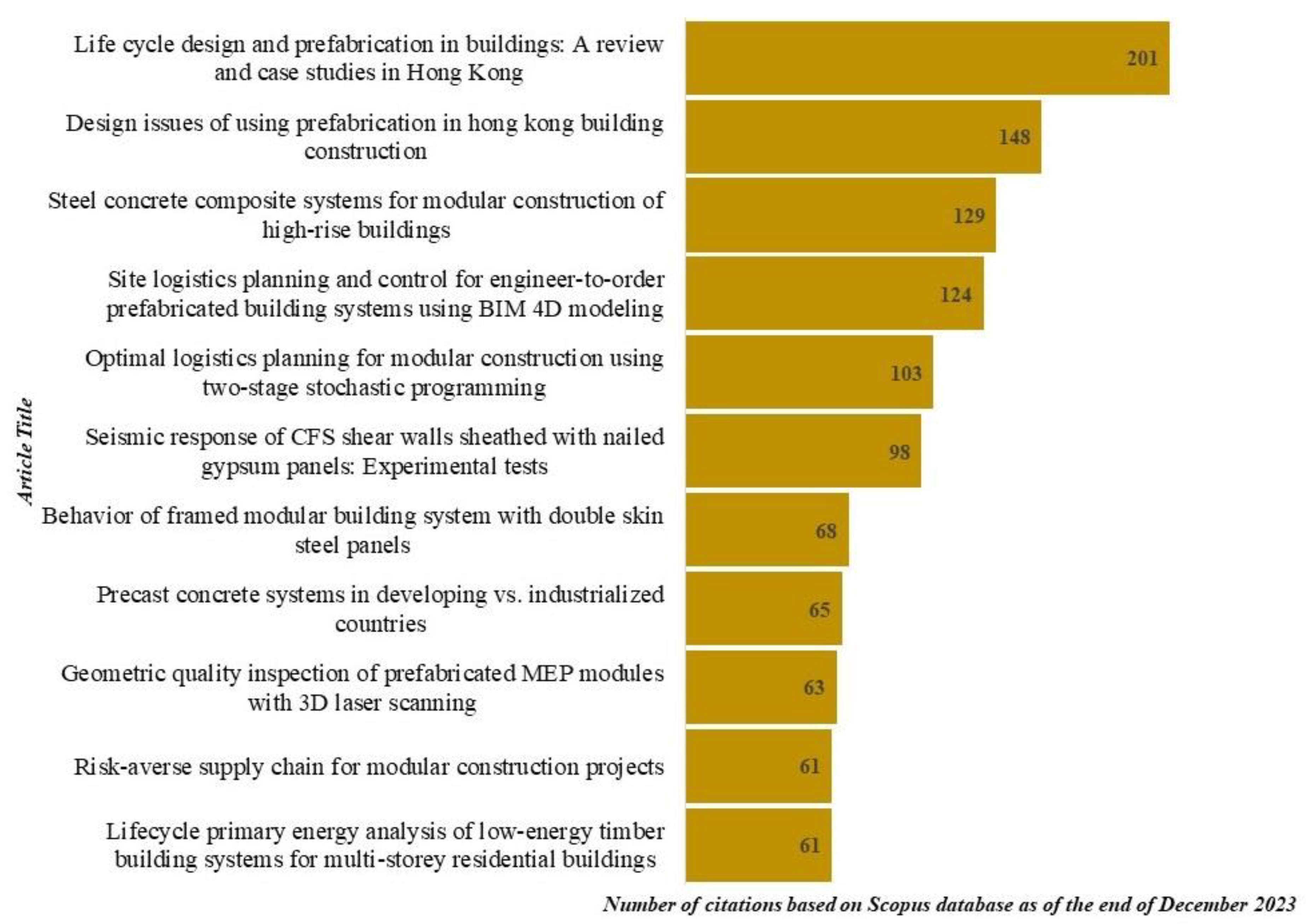

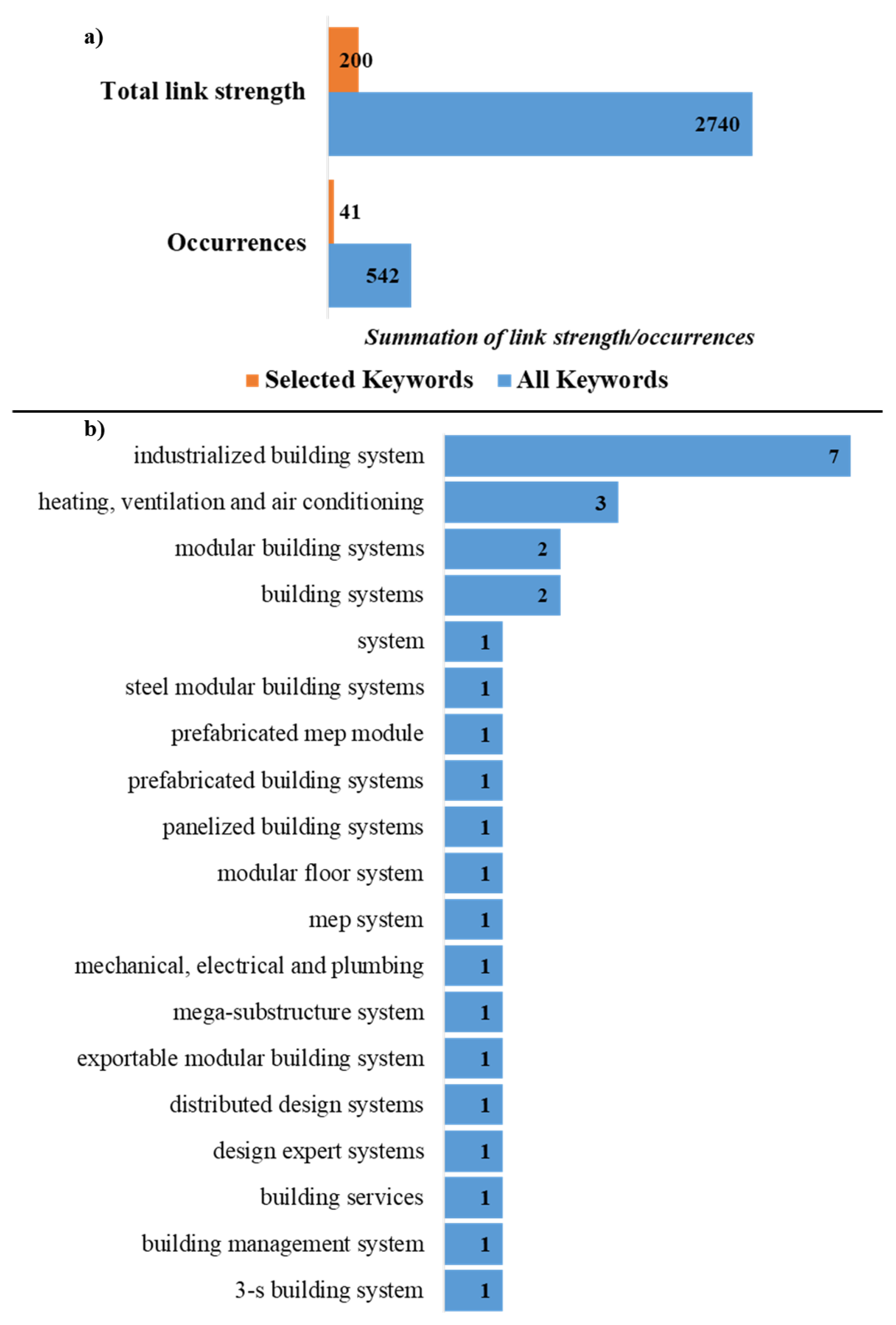

3.1. Quantitative Analysis of Publications in Modular Construction Building Services

3.2. Systematic Analysis of Integration of Building Services in Modular Construction

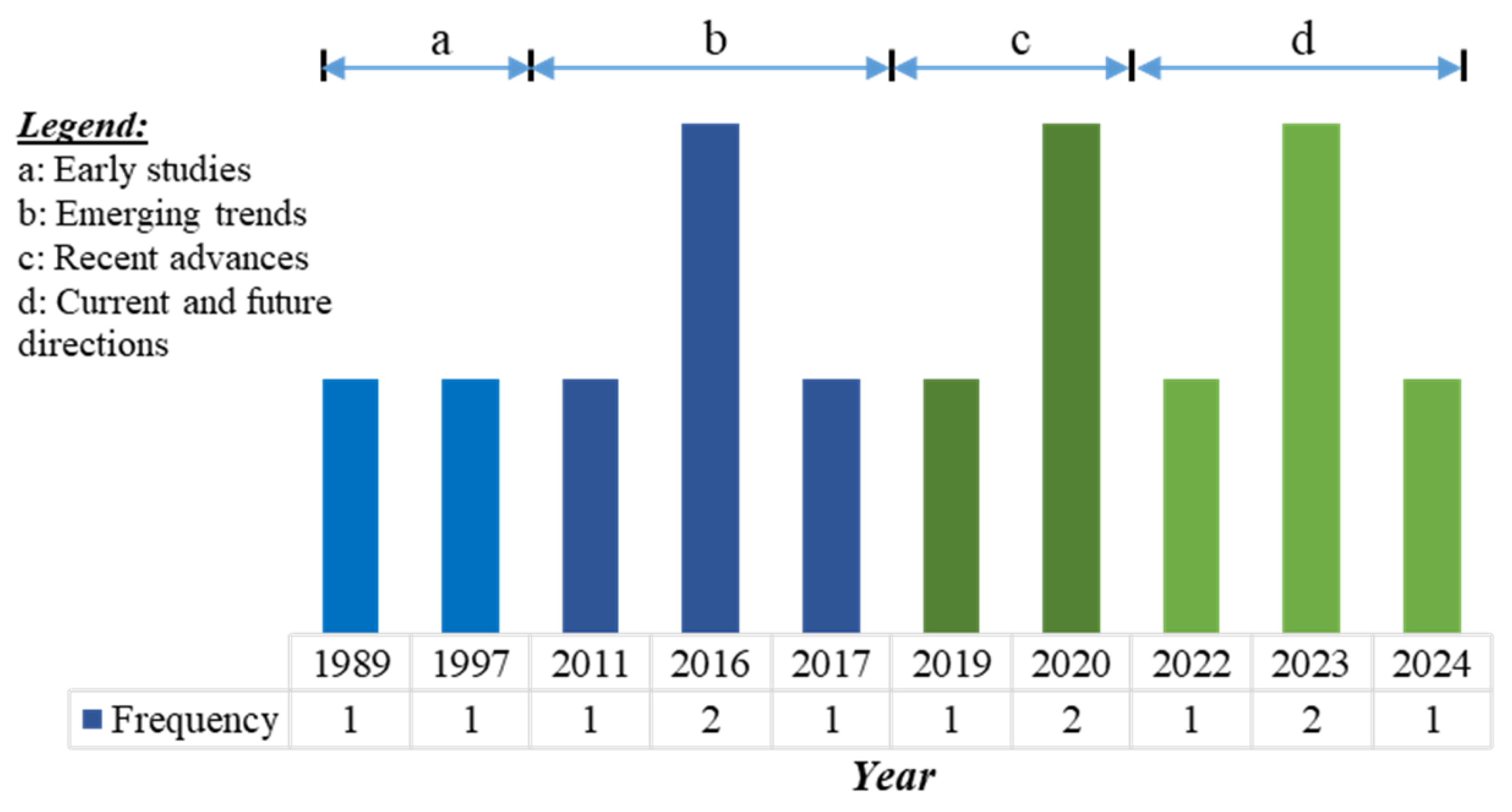

3.2.1. Overview of Included Studies

3.2.2. Building Services Integration within Modular Construction

- Early studies

- Emerging trends

- Recent advances

- Current and future directions

4. Discussion

4.1. Advancements and Integration of Technology in Modular Construction

4.2. Potential Influence of Recent Technologies on Building Services Integration in Modular Construction

5. Conclusions and Future Studies

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hua, Y.; Zhang, Y.; Zhang, S.; Hou, F.; Kang, M. Using Building Information Modeling to Enhance Supply Chain Resilience in Prefabricated Buildings: A Conceptual Framework. Appl. Sci. 2023, 13, 12694. [Google Scholar] [CrossRef]

- Pan, M.; Yang, Y.; Zheng, Z.; Pan, W. Artificial Intelligence and Robotics for Prefabricated and Modular Construction: A Systematic Literature Review. J. Constr. Eng. Manag. 2022, 148, 03122004. [Google Scholar] [CrossRef]

- Palani, H.; Karatas, A. Investigating the disparities between experimental and computational analyses of thermal performance in prefabricated wall panels. Appl. Therm. Eng. 2024, 236, 121568. [Google Scholar] [CrossRef]

- Alanne, K. An overview of game-based learning in building services engineering education. Eur. J. Eng. Educ. 2016, 41, 204–219. [Google Scholar] [CrossRef]

- Chen, Y.; Treado, S.J.; Messner, J.I. Building HVAC control knowledge data schema—Towards a unified representation of control system knowledge. Autom. Constr. 2016, 72, 174–186. [Google Scholar] [CrossRef]

- Tserng, H.P.; Yin, Y.L.; Jaselskis, E.J.; Hung, W.C.; Lin, Y.C. Modularization and assembly algorithm for efficient MEP construction. Autom. Constr. 2011, 20, 837–863. [Google Scholar] [CrossRef]

- Bertram, N.; Fuchs, S.; Mischke, J.; Palter, R.; Strube, G.; Woetzel, J. Modular construction: From projects to products. Cap. Proj. Infrastruct. 2019, 1, 1–34. [Google Scholar]

- Ayinla, K.O.; Cheung, F.; Tawil, A.R. Demystifying the concept of offsite manufacturing method. Constr. Innov. 2019, 20, 223–246. [Google Scholar] [CrossRef]

- Pan, W.; Gibb, A.G.F.; Dainty, A.R.J. Perspectives of UK housebuilders on the use of offsite modern methods of construction. Constr. Manag. Econ. 2007, 25, 183–194. [Google Scholar] [CrossRef]

- Švajlenka, J.; Kozlovská, M.; Spišáková, M. The benefits of modern method of construction based on wood in the context of sustainability. Int. J. Environ. Sci. Technol. 2017, 14, 1591–1602. [Google Scholar] [CrossRef]

- Rahman, M.M. Barriers of Implementing Modern Methods of Construction. J. Manag. Eng. 2014, 30, 69–77. [Google Scholar] [CrossRef]

- Lu, N. The Current Use of Offsite Construction Techniques in the United States Construction Industry. In Construction Research Congress 2009; American Society of Civil Engineers: Reston, VA, USA, 2009; pp. 946–955. [Google Scholar]

- Wuni, I.Y.; Shen, G.Q.P. Holistic Review and Conceptual Framework for the Drivers of Offsite Construction: A Total Interpretive Structural Modelling Approach. Buildings 2019, 9, 117. [Google Scholar] [CrossRef]

- Wusu, G.E.; Alaka, H.; Yusuf, W.; Mporas, I.; Toriola-Coker, L.; Oseghale, R. A machine learning approach for predicting critical factors determining adoption of offsite construction in Nigeria. Smart Sustain. Built Environ. 2022; ahead of print. [Google Scholar] [CrossRef]

- Bello, A.O.; Eje, D.O.; Idris, A.; Semiu, M.A.; Khan, A.A. Drivers for the implementation of modular construction systems in the AEC industry of developing countries. J. Eng. Des. Technol. 2023, 2018. [Google Scholar] [CrossRef]

- Nanyam, V.P.S.N.; Sawhney, A.; Gupta, P.A. Evaluating Offsite Technologies for Affordable Housing. Procedia Eng. 2017, 196, 135–143. [Google Scholar] [CrossRef]

- Razkenari, M.; Fenner, A.; Shojaei, A.; Hakim, H.; Kibert, C. Perceptions of offsite construction in the United States: An investigation of current practices. J. Build. Eng. 2020, 29, 101138. [Google Scholar] [CrossRef]

- Lehmann, B.; Dorer, V.; Gwerder, M.; Renggli, F.; Tödtli, J. Thermally activated building systems (TABS): Energy efficiency as a function of control strategy, hydronic circuit topology and (cold) generation system. Appl. Energy 2011, 88, 180–191. [Google Scholar] [CrossRef]

- Yang, X.; Ji, Y.; Gu, J.; Niu, M. An Electricity Consumption Disaggregation Method for HVAC Terminal Units in Sub-Metered Buildings Based on CART Algorithm. Buildings 2023, 13, 967. [Google Scholar] [CrossRef]

- Sun, K.; Yan, D.; Hong, T.; Guo, S. Stochastic modeling of overtime occupancy and its application in building energy simulation and calibration. Build. Environ. 2014, 79, 1–12. [Google Scholar] [CrossRef]

- Lück, K. Energy efficient building services for tempering performance-oriented interior spaces—A literature review. J. Clean. Prod. 2012, 22, 1–10. [Google Scholar] [CrossRef]

- Sihn, W.; Sobottka, T.; Heinzl, B.; Kamhuber, F. Interdisciplinary multi-criteria optimization using hybrid simulation to pursue energy efficiency through production planning. CIRP Ann. 2018, 67, 447–450. [Google Scholar] [CrossRef]

- De Silva, D.T.; Setunge, S.; Tran, H. Effect of Runtime on the Deterioration of HVAC Components in Building Services. J. Infrastruct. Syst. 2022, 28, 1–10. [Google Scholar] [CrossRef]

- Abdelhameed, W.; Saputra, W. Integration of building service systems in architectural design. J. Inf. Technol. Constr. 2020, 25, 109–122. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. Int. J. Surg. 2021, 88, 105906. [Google Scholar] [CrossRef] [PubMed]

- Olawumi, T.O.; Chan, D.W.M.; Ojo, S.; Yam, M.C.H. Automating the modular construction process: A review of digital technologies and future directions with blockchain technology. J. Build. Eng. 2022, 46, 103720. [Google Scholar] [CrossRef]

- Stern, C.; Lizarondo, L.; Carrier, J.; Godfrey, C.; Rieger, K.; Salmond, S.; Apóstolo, J.; Kirkpatrick, P.; Loveday, H. Methodological guidance for the conduct of mixed methods systematic reviews. JBI Evid. Synth. 2020, 18, 2108–2118. [Google Scholar] [CrossRef]

- Zhou, S.; Gheisari, M. Unmanned aerial system applications in construction: A systematic review. Constr. Innov. 2018, 18, 453–468. [Google Scholar] [CrossRef]

- Kachouie, R.; Sedighadeli, S.; Khosla, R.; Chu, M.T. Socially Assistive Robots in Elderly Care: A Mixed-Method Systematic Literature Review. Int. J. Hum. Comput. Interact. 2014, 30, 369–393. [Google Scholar] [CrossRef]

- Tsafnat, G.; Glasziou, P.; Choong, M.K.; Dunn, A.; Galgani, F.; Coiera, E. Systematic review automation technologies. Syst. Rev. 2014, 3, 74. [Google Scholar] [CrossRef]

- Lam, E.W.; Chan, A.P.C.; Olawumi, T.O.; Wong, I.; Kazeem, K.O. Sustainability concepts in global high-rise residential buildings: A scientometric and systematic review. Smart Sustain. Built Environ. 2023; ahead of print. [Google Scholar] [CrossRef]

- Osei-Kyei, R.; Chan, A.P.C. Review of studies on the Critical Success Factors for Public–Private Partnership (PPP) projects from 1990 to 2013. Int. J. Proj. Manag. 2015, 33, 1335–1346. [Google Scholar] [CrossRef]

- Tober, M. PubMed, ScienceDirect, Scopus or Google Scholar—Which is the best search engine for an effective literature research in laser medicine? Med. Laser Appl. 2011, 26, 139–144. [Google Scholar] [CrossRef]

- Opoku, D.G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M. Digital twin application in the construction industry: A literature review. J. Build. Eng. 2021, 40, 102726. [Google Scholar] [CrossRef]

- Harzing, A.W.; Alakangas, S. Google Scholar, Scopus and the Web of Science: A longitudinal and cross-disciplinary comparison. Scientometrics 2016, 106, 787–804. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Barriers to the adoption of modular integrated construction: Systematic review and meta-analysis, integrated conceptual framework, and strategies. J. Clean. Prod. 2020, 249, 119347. [Google Scholar] [CrossRef]

- Singh, V.K.; Singh, P.; Karmakar, M.; Leta, J.; Mayr, P. The journal coverage of Web of Science, Scopus and Dimensions: A comparative analysis. Scientometrics 2021, 126, 5113–5142. [Google Scholar] [CrossRef]

- Mongeon, P.; Paul-Hus, A. The journal coverage of Web of Science and Scopus: A comparative analysis. Scientometrics 2016, 106, 213–228. [Google Scholar] [CrossRef]

- Pranckutė, R. Web of Science (WoS) and Scopus: The Titans of Bibliographic Information in Today’s Academic World. Publications 2021, 9, 12. [Google Scholar] [CrossRef]

- Benzies, K.M.; Premji, S.; Hayden, K.A.; Serrett, K. State-of-the-Evidence Reviews: Advantages and Challenges of Including Grey Literature. Worldviews Evid. Based Nurs. 2006, 3, 55–61. [Google Scholar] [CrossRef]

- Adams, R.J.; Smart, P.; Huff, A.S. Shades of Grey: Guidelines for Working with the Grey Literature in Systematic Reviews for Management and Organizational Studies. Int. J. Manag. Rev. 2017, 19, 432–454. [Google Scholar] [CrossRef]

- Mahood, Q.; Van Eerd, D.; Irvin, E. Searching for grey literature for systematic reviews: Challenges and benefits. Res. Synth. Methods 2014, 5, 221–234. [Google Scholar] [CrossRef]

- Lopez, R.; Chong, H.Y.; Pereira, C. Obstacles Preventing the Off-Site Prefabrication of Timber and MEP Services: Qualitative Analyses from Builders and Suppliers in Australia. Buildings 2022, 12, 1044. [Google Scholar] [CrossRef]

- Li, X.; Li, Z.; Wu, G. Modular and Offsite Construction of Piping: Current Barriers and Route. Appl. Sci. 2017, 7, 547. [Google Scholar] [CrossRef]

- Lenart, M. Construction problems as tiling puzzles. Des. Stud. 1989, 10, 40–52. [Google Scholar] [CrossRef]

- Kazeem, K.O.; Olawumi, T.O.; Osunsanmi, T. Roles of Artificial Intelligence and Machine Learning in Enhancing Construction Processes and Sustainable Communities. Buildings 2023, 13, 2061. [Google Scholar] [CrossRef]

- Baek, S.; Won, J.; Jang, S. Economic Integrated Structural Framing for BIM-Based Prefabricated Mechanical, Electrical, and Plumbing Racks. Appl. Sci. 2023, 13, 3677. [Google Scholar] [CrossRef]

- Liew, J.Y.R.; Chua, Y.S.; Dai, Z. Steel concrete composite systems for modular construction of high-rise buildings. Structures 2019, 21, 135–149. [Google Scholar] [CrossRef]

- Guo, J.; Wang, Q.; Park, J.H. Geometric quality inspection of prefabricated MEP modules with 3D laser scanning. Autom. Constr. 2020, 111, 103053. [Google Scholar] [CrossRef]

- Martinez, P.; Livojevic, M.; Jajal, P.; Aldrich, D.R.; Al-Hussein, M.; Ahmad, R. Simulation-Driven Design of Wood Framing Support Systems for Off-Site Construction Machinery. J. Constr. Eng. Manag. 2020, 146, 1–12. [Google Scholar] [CrossRef]

- Kiu, M.S.; Chia, F.C.; Wong, P.F. Exploring the potentials of blockchain application in construction industry: A systematic review. Int. J. Constr. Manag. 2022, 22, 2931–2940. [Google Scholar] [CrossRef]

- Suárez, J.L.; Gosselin, L.; Lehoux, N. Optimizing Modularity of Prefabricated Residential Plumbing Systems for Construction in Remote Communities. J. Constr. Eng. Manag. 2023, 149, 1–16. [Google Scholar] [CrossRef]

- Slaughter, E.S.; Sause, R.S.; Pessiki, S. Precast Concrete Floor Framing Systems to Accommodate Nonstructural Requirements. J. Archit. Eng. 1997, 3, 109–117. [Google Scholar] [CrossRef]

- Martín-Gómez, C.; Ibáñez-Puy, M.; Bermejo-Busto, J.; Sacristán Fernández, J.A.; Ramos, J.C.; Rivas, A. Thermoelectric cooling heating unit prototype. Build. Serv. Eng. Res. Technol. 2016, 37, 431–449. [Google Scholar] [CrossRef]

- Ferdous, W.; Bai, Y.; Ngo, T.D.; Manalo, A.; Mendis, P. New advancements, challenges and opportunities of multi-storey modular buildings—A state-of-the-art review. Eng. Struct. 2019, 183, 883–893. [Google Scholar] [CrossRef]

- Khan, A.; Yu, R.; Liu, T.; Guan, H.; Oh, E. Drivers towards Adopting Modular Integrated Construction for Affordable Sustainable Housing: A Total Interpretive Structural Modelling (TISM) Method. Buildings 2022, 12, 637. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K.; Milani, A.S. Life cycle sustainability performance assessment framework for residential modular buildings: Aggregated sustainability indices. Build. Environ. 2018, 138, 21–41. [Google Scholar] [CrossRef]

- Lawson, R.M.; Ogden, R.G.; Bergin, R. Application of Modular Construction in High-Rise Buildings. J. Archit. Eng. 2012, 18, 148–154. [Google Scholar] [CrossRef]

- Li, C.Z.; Li, S.; Li, X.; Wu, H.; Xiao, B.; Tam, V.W.Y.; Asiedu-Kwakyewa, C. A Scientometric Review of Management of Prefabricated Construction from 2011–2021. Buildings 2022, 12, 1515. [Google Scholar] [CrossRef]

- Li, X.; Shen, G.Q.; Wu, P.; Fan, H.; Wu, H.; Teng, Y. RBL-PHP: Simulation of Lean Construction and Information Technologies for Prefabrication Housing Production. J. Manag. Eng. 2018, 34, 1–18. [Google Scholar] [CrossRef]

- Zhou, J.X.; Shen, G.Q.; Yoon, S.H.; Jin, X. Customization of on-site assembly services by integrating the internet of things and BIM technologies in modular integrated construction. Autom. Constr. 2021, 126, 103663. [Google Scholar] [CrossRef]

- Zhai, Y.; Chen, K.; Zhou, J.X.; Cao, J.; Lyu, Z.; Jin, X.; Shen, G.Q.P.; Lu, W.; Huang, G.Q. An Internet of Things-enabled BIM platform for modular integrated construction: A case study in Hong Kong. Adv. Eng. Inform. 2019, 42, 100997. [Google Scholar] [CrossRef]

- Iacovidou, E.; Purnell, P.; Tsavdaridis, K.D.; Poologanathan, K. Digitally enabled modular construction for promoting modular components reuse: A UK view. J. Build. Eng. 2021, 42, 102820. [Google Scholar] [CrossRef]

- CICMiCProjects In Hong Kong: Dedicated Rehousing Estate at Hung Shui Kiu Phase IA [Internet] 2022. C.I.C. Available online: https://mic.cic.hk/en/ProjectsInHongKong/15 (accessed on 3 May 2024).

- Zhang, J.; Wei, W.; Chen, L.; Jiang, Z. Evaluation of Hidden Cost Risk of Prefabricated Construction Based on SEM-MEECM. Appl. Sci. 2023, 13, 7902. [Google Scholar] [CrossRef]

- Corfar, D.A.; Tsavdaridis, K.D. A hybrid inter-module connection for steel modular building systems with SMA and high-damping rubber components. Eng. Struct. 2023, 289, 116281. [Google Scholar] [CrossRef]

- Lu, N.; Korman, T. Implementation of Building Information Modeling (BIM) in Modular Construction: Benefits and Challenges. In Construction Research Congress 2010; American Society of Civil Engineers: Reston, VA, USA, 2010; pp. 1136–1145. Available online: http://ascelibrary.org/doi/10.1061/41109%28373%29114 (accessed on 3 May 2024).

- Li, X.; Shen, G.Q.; Wu, P.; Yue, T. Integrating Building Information Modeling and Prefabrication Housing Production. Autom. Constr. 2019, 100, 46–60. [Google Scholar] [CrossRef]

- Smith, R.E. Prefab Architecture: A Guide to Modular Design and Construction; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Nam, S.; Yoon, J.; Kim, K.; Choi, B. Optimization of prefabricated components in housing modular construction. Sustainability 2020, 12, 10269. [Google Scholar] [CrossRef]

| Study’s Title | Methodology | Application/Objective | Reference |

|---|---|---|---|

| Optimising Modularity of Prefabricated Residential Plumbing Systems for Construction in Remote Communities |

| The study examines multi-trade prefabrication, which combines mechanical, electrical, and plumbing services into a single module for off-site and on-site installation. | [52] |

| Precast Concrete Floor Framing Systems to Accommodate Nonstructural Requirements |

| The study examined modular off-site construction for piping systems, an essential part of building services. | [53] |

| Thermoelectric cooling heating unit prototype |

| The study analyses the prototype’s design, assembly, and energy behavior and its pros and cons compared to traditional HVAC systems. | [54] |

| Obstacles Preventing the Off-Site Prefabrication of Timber and MEP Services: Qualitative Analyses from Builders and Suppliers in Australia |

| The study recommends early involvement, collaborative procurement, digital tools, modular coordination, and system development for integrating off-site prefabricated timber and MEP services with in situ construction. | [43] |

| Economic Integrated Structural Framing for BIM-Based Prefabricated Mechanical, Electrical, and Plumbing Racks |

| The study examines multi-trade prefabrication, which combines mechanical, electrical, and plumbing services into a single module for off-site and on-site installation. | [47] |

| Modular and Offsite Construction of Piping: Current Barriers and Route |

| The study examined modular off-site construction for piping systems, an essential part of building services. | [44] |

| Simulation-Driven Design of Wood Framing Support Systems for Off-Site Construction Machinery |

| The study offers strategies for enhancing off-site production efficiency and performance. | [50] |

| Steel concrete composite systems for modular construction of high-rise buildings |

| This study integrates building services into the modules’ structural zone, utilizing a slim floor system to reduce the floor-to-floor depth and assure service compatibility with varying module sizes. | [48] |

| Investigating the disparities between experimental and computational analyses of thermal performance in prefabricated wall panels |

| The study investigated the thermal performance of prefabricated wall panels, commonly used in modular buildings. | [3] |

| Geometric quality inspection of prefabricated MEP modules with 3D laser scanning |

| The study used 3D laser scanning to inspect prefabricated MEP module geometry. | [49] |

| Building HVAC control knowledge data schema—Towards a unified representation of control system knowledge |

| Using the study’s data schema, a control self-configuration framework that interacts with a database of control modules to select and apply building system-specific control strategies can be developed. | [5] |

| Modularisation and assembly algorithm for efficient MEP construction |

| The paper discusses the benefits and challenges of modular construction and presents a case study of applying the algorithm to a fire suppression system project in Taiwan. | [6] |

| Construction problems such as tiling puzzles |

| Mathematical theory of tilings for modular construction. | [45] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kazeem, K.O.; Olawumi, T.O.; Adam, J.J.; Lam, E.W.-M. Integration of Building Services in Modular Construction: A PRISMA Approach. Appl. Sci. 2024, 14, 4151. https://doi.org/10.3390/app14104151

Kazeem KO, Olawumi TO, Adam JJ, Lam EW-M. Integration of Building Services in Modular Construction: A PRISMA Approach. Applied Sciences. 2024; 14(10):4151. https://doi.org/10.3390/app14104151

Chicago/Turabian StyleKazeem, Kayode O., Timothy O. Olawumi, Jibrin J. Adam, and Edmond Wai-Ming Lam. 2024. "Integration of Building Services in Modular Construction: A PRISMA Approach" Applied Sciences 14, no. 10: 4151. https://doi.org/10.3390/app14104151

APA StyleKazeem, K. O., Olawumi, T. O., Adam, J. J., & Lam, E. W.-M. (2024). Integration of Building Services in Modular Construction: A PRISMA Approach. Applied Sciences, 14(10), 4151. https://doi.org/10.3390/app14104151