A Comparison of the Relationship between Dynamic and Static Rock Mechanical Parameters

Abstract

:1. Introduction

2. Testing of Dynamic and Static Elastic Parameters

2.1. Static Elastic Parameter Acquisition Method

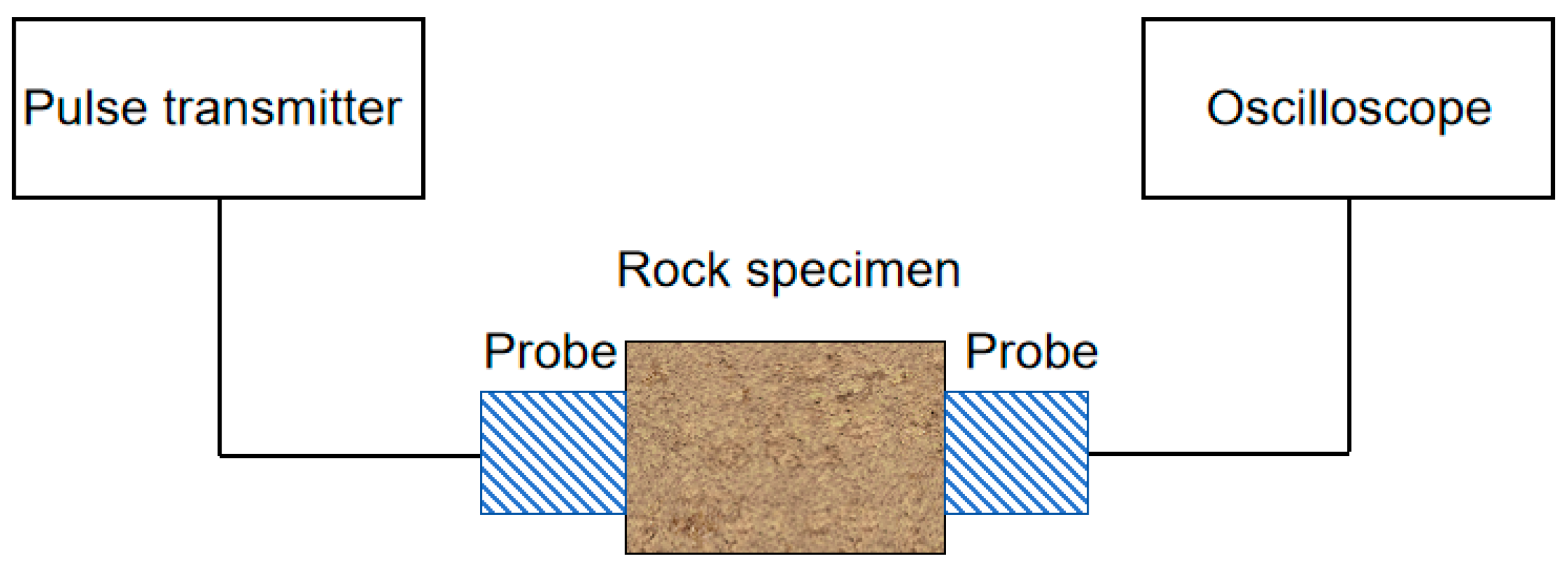

2.2. Dynamic Elastic Parameter Acquisition Method

2.3. Synchronized Testing Methods for Dynamic and Static Parameters

3. Dynamic–Static Conversion Relationship

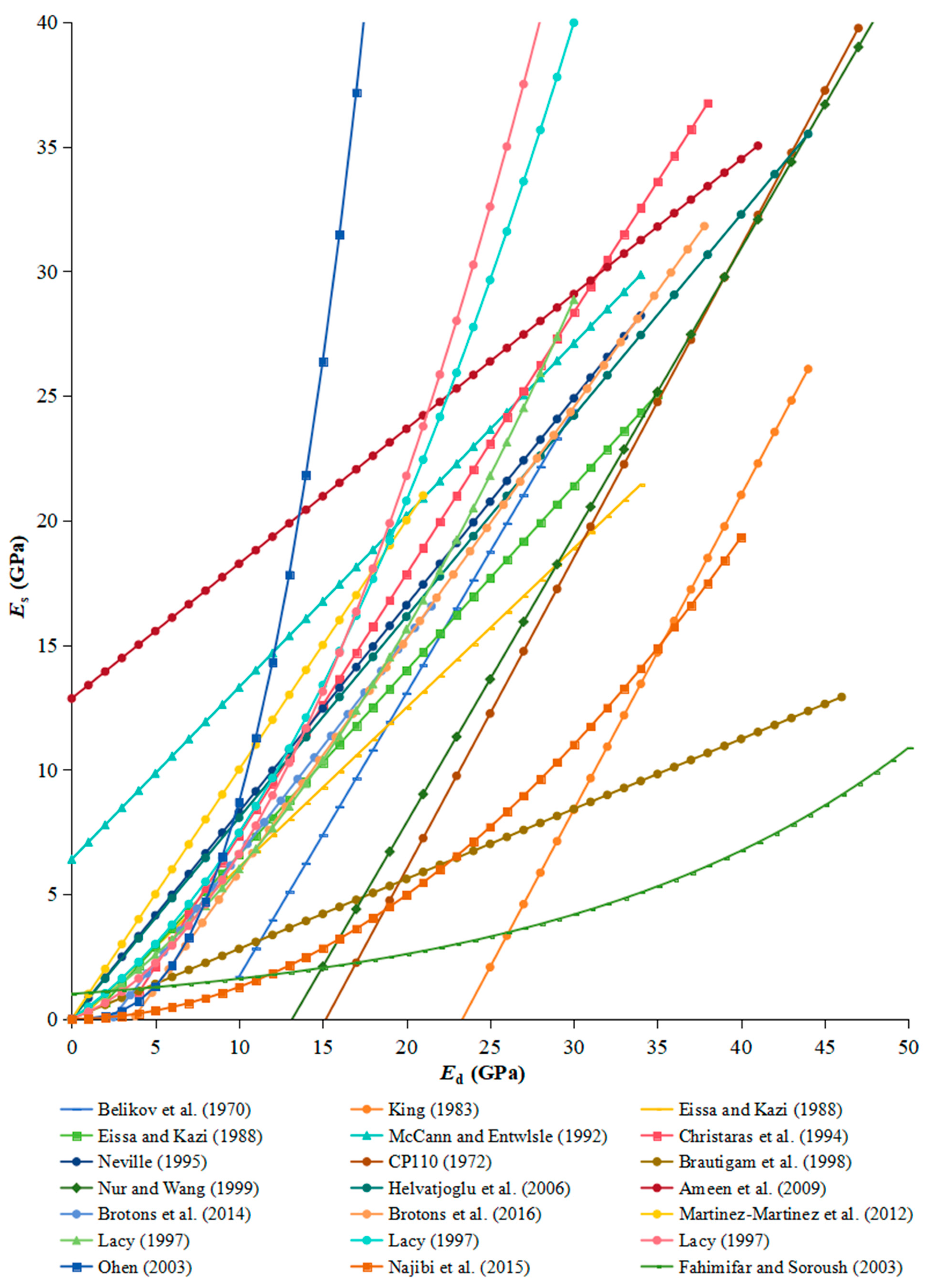

3.1. Methods

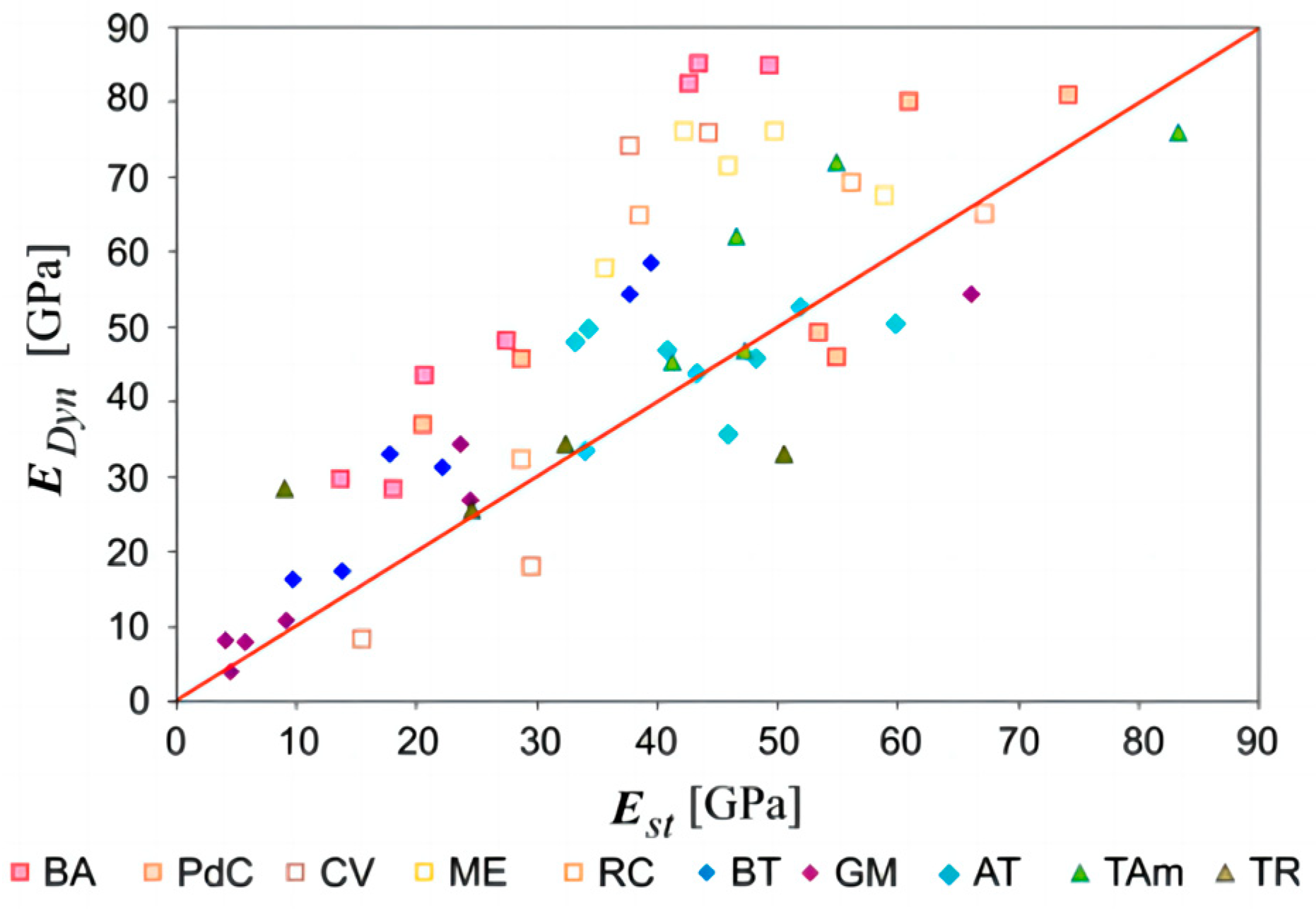

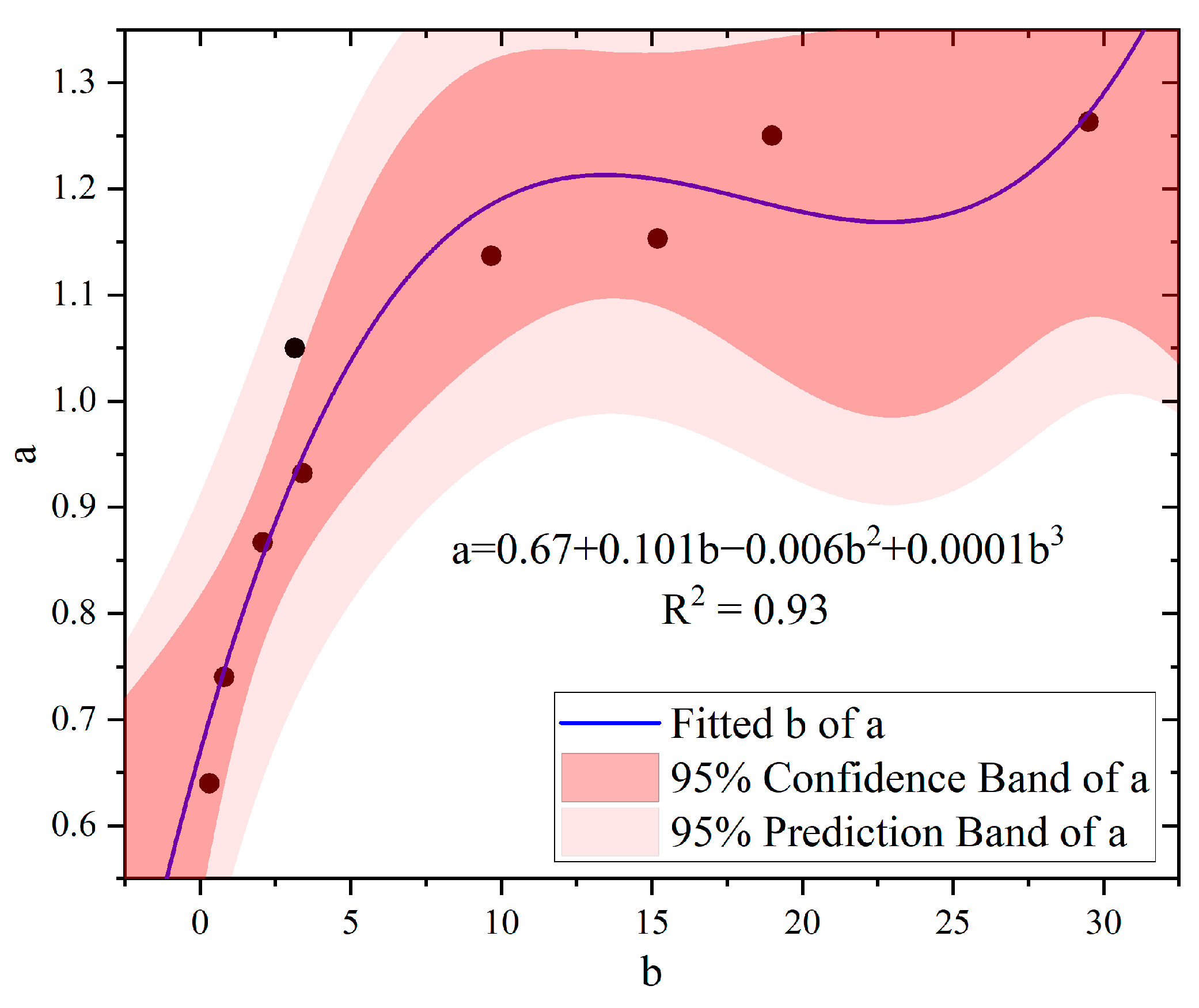

3.2. Relation Establishment

3.3. Model Optimization for Different Rock Types

4. Discussion

5. Conclusions and Prospects

- Based on comprehensive statistical analysis and theoretical framework research on the correlation between the static and dynamic elastic moduli of various rock types, a new method for estimating static elastic modulus based on a single parameter has been proposed while also considering the previous general form of the prediction equation.

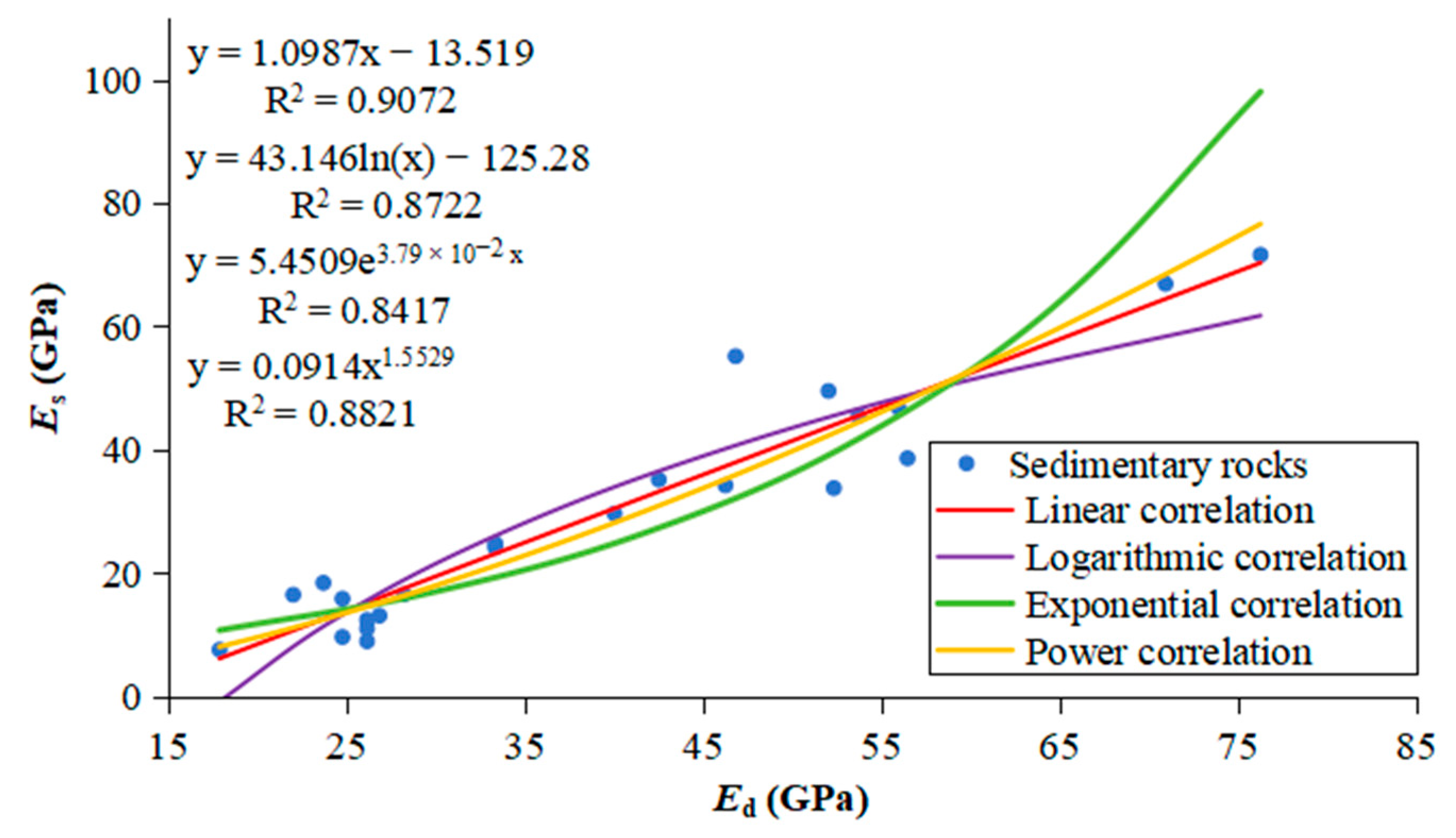

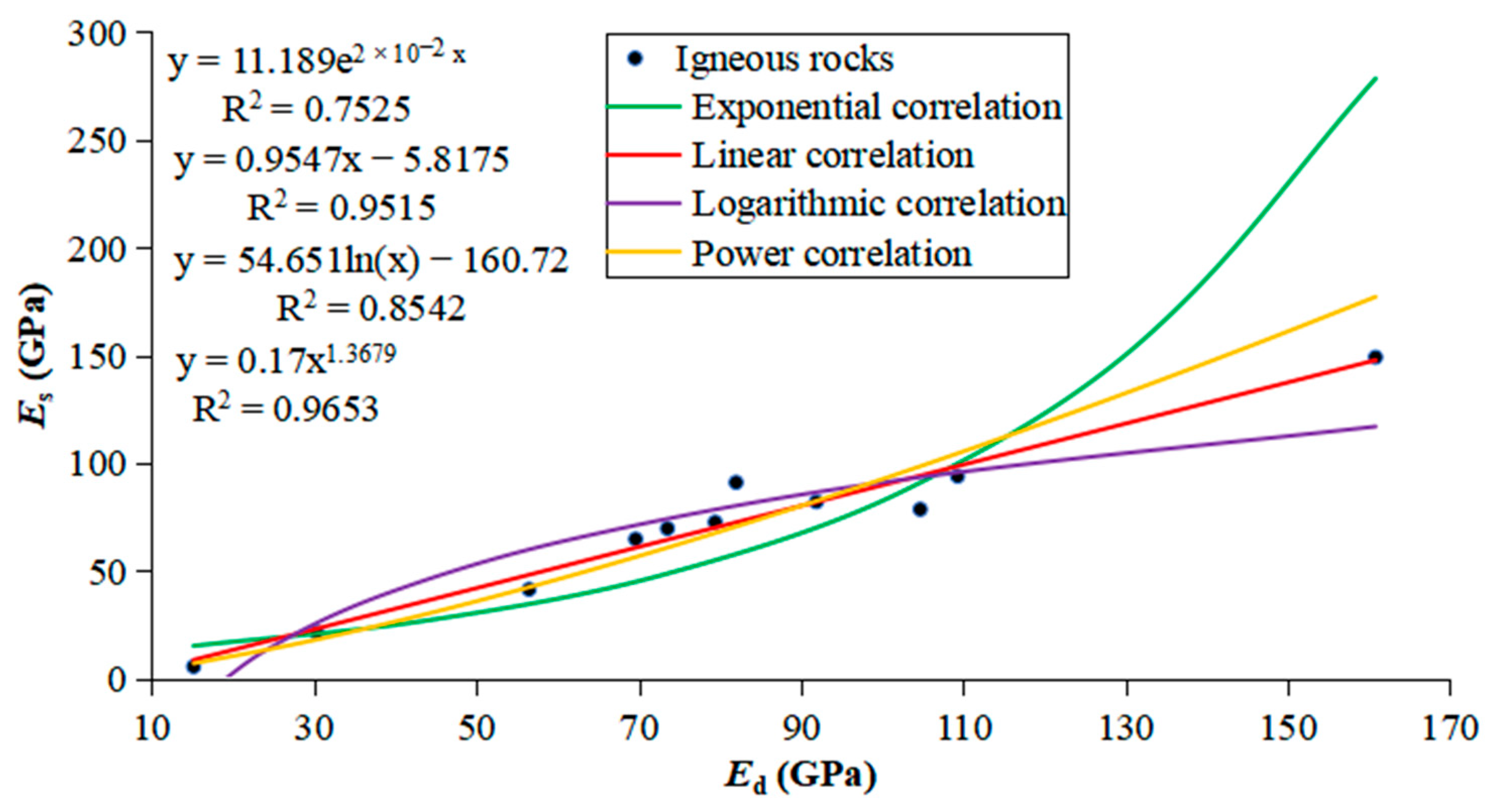

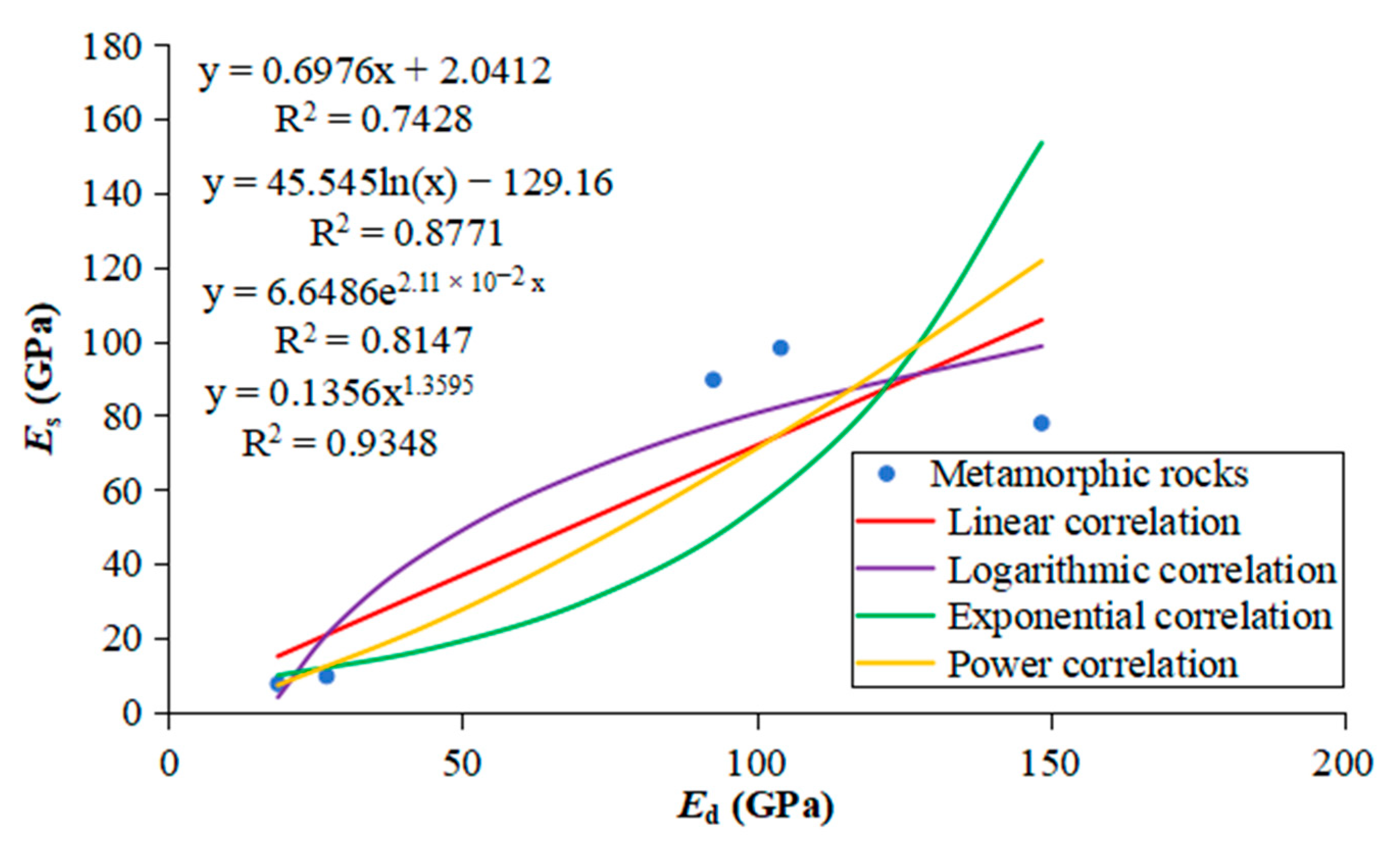

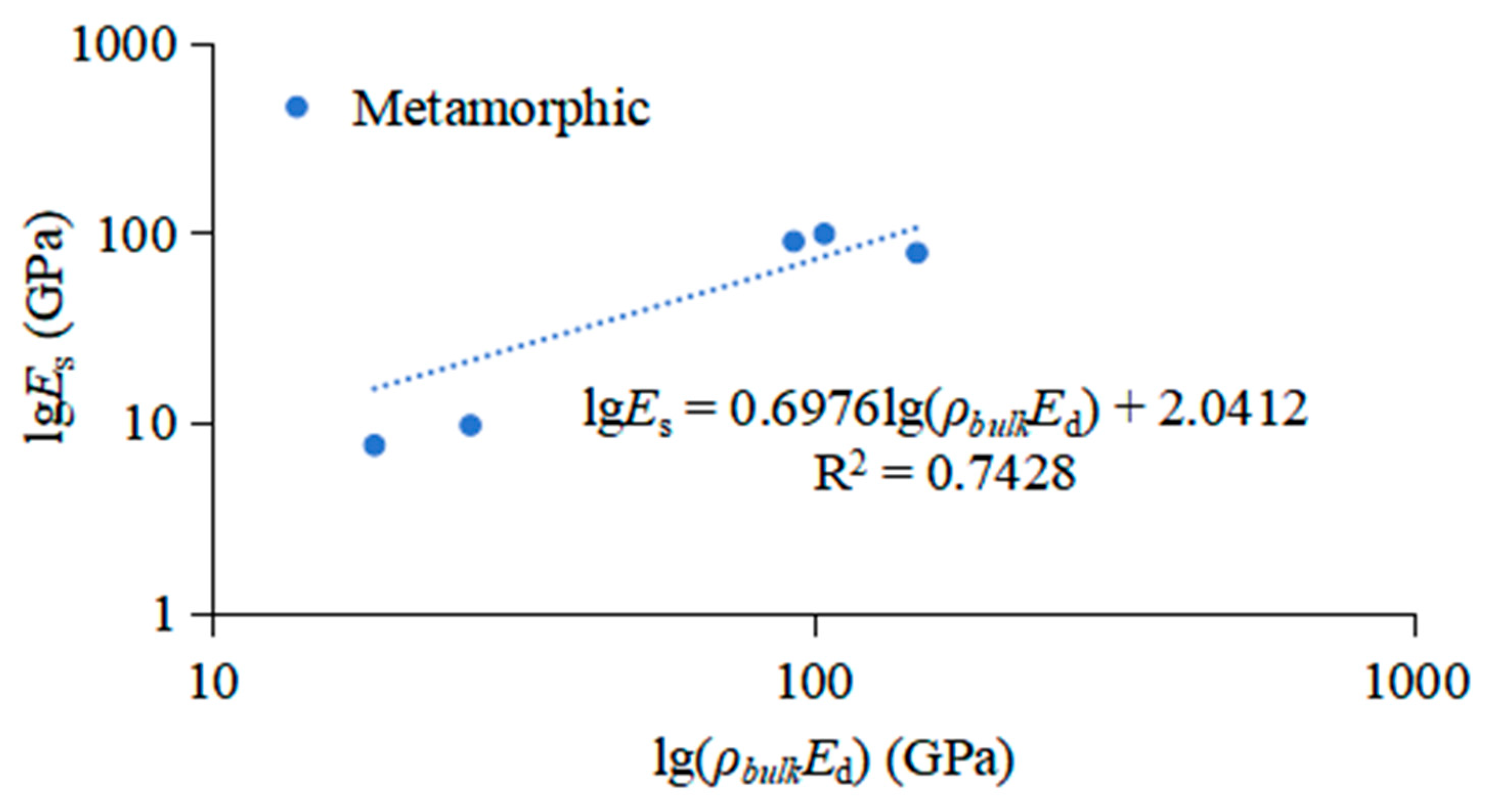

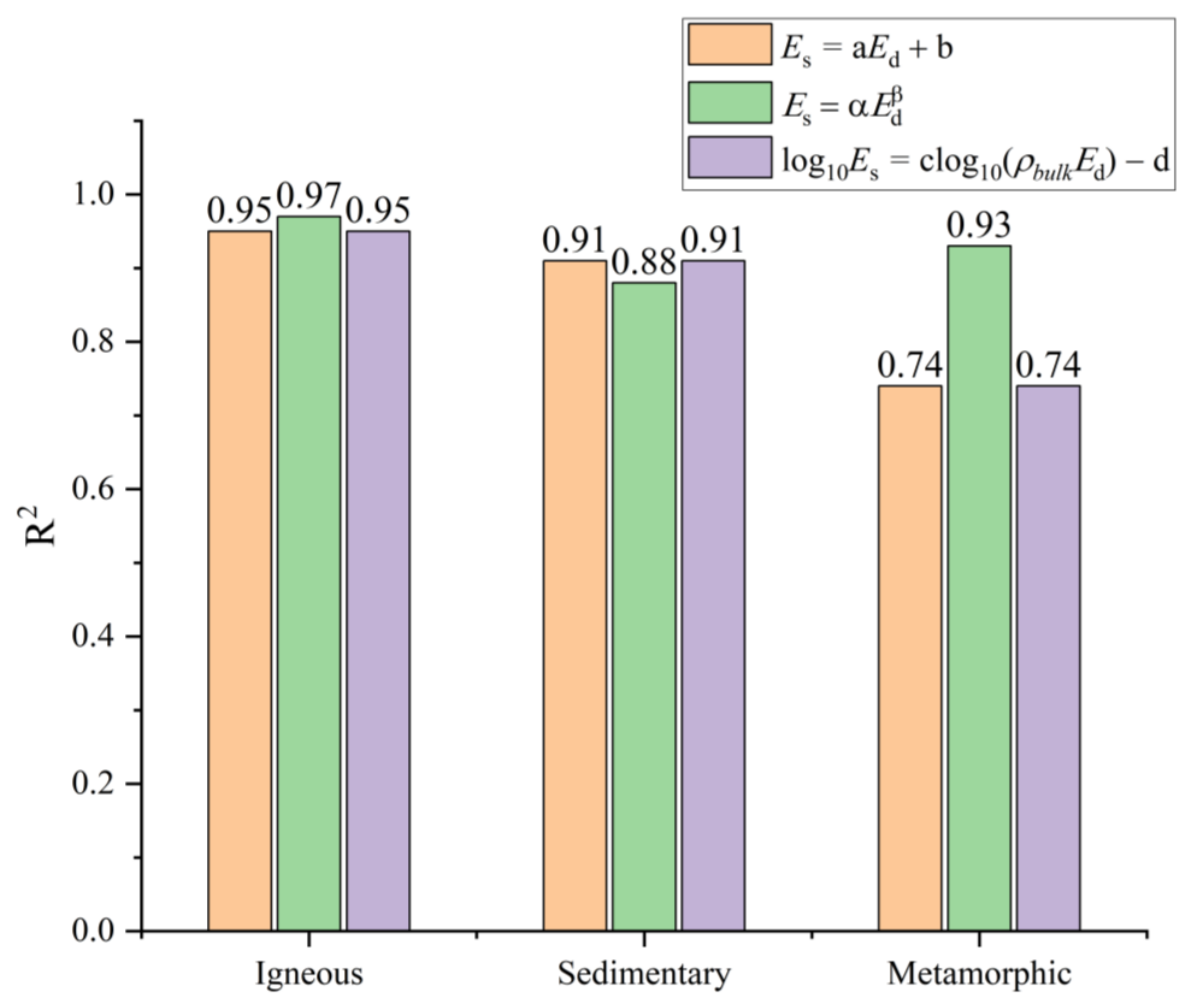

- Considering the correlation between static and dynamic moduli: In terms of different types of rocks, for igneous and metamorphic rocks, the optimal relationship between static and dynamic moduli of elasticity is a power-law correlation, with a value of (igneous R2 = 0.97, metamorphic R2 = 0.93), and for sedimentary rocks, a linear and nonlinear logarithmic correlation, with a value of (R2 = 0.91).

- Predictive equations obtained by previous researchers may have errors in practical applications, some of which may be appropriate for specific rock types. Therefore, it is necessary to calibrate the constant values, and any calibration may imply new correlations.

- The discrepancy between the dynamic and static moduli of elasticity can be summarized as follows. The external factors include the amount of stress, strain amplitude, test confining pressure, test temperature, and the test frequency of the rock specimen. The internal factors are mainly the mineral composition, content, pore development degree, pore fluids, microfractures or microcracks, coupling between rock particles, cementation type and anisotropy of the rock, and so on. The existence of microfractures and pores in the rocks is the main reason for the differences.

- Many factors affect the mechanical properties of rocks, and the experimental results often show inevitable fluctuations. To obtain more representative results, research should be carried out based on the inclusion of a large number of empirical data for regression analysis.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, J.; Xie, L.; Xie, H.; Li, C. Triaxial mechanical characteristics and constitutive model of oil sand in Fengcheng. J. Sichuan Univ. Eng. Sci. Ed. 2015, 47, 1–9. [Google Scholar]

- Gao, Y.; Ren, Z.; Jiang, H.; Ding, S. A nonlinear elastic model for oil sands considering shear dilation and strain softening. Chin. J. Undergr. Space Eng. 2023, 19, 43–50. [Google Scholar]

- Howarth, D.F. Apparatus to determine static and dynamic elastic moduli. Rock Mech. Rock Eng. 1984, 17, 255–264. [Google Scholar] [CrossRef]

- Zisman, W.A. Comparison of the statically and seismologically determined elastic constants of rocks. Proc. Natl. Acad. Sci. USA 1933, 19, 680–686. [Google Scholar] [CrossRef]

- Ide, J.M. Comparison of statically and dynamically determined Young’s modulus of rocks. Proc. Natl. Acad. Sci. USA 1936, 22, 81–92. [Google Scholar] [CrossRef] [PubMed]

- Simmons, G.; Brace, W.F. Comparison of static and dynamic measurements of compressibility of rocks. J. Geophys. Res. 1965, 70, 5649–5656. [Google Scholar] [CrossRef]

- King, M.S. Static and dynamic elastic properties of igneous and metamorphic rocks from the Canadian shield. Int. J. Rock Mech. Min. Sci. 1983, 20, 237–241. [Google Scholar] [CrossRef]

- Savich, A.I. Generalized relations between static and dynamic indices of rock deformability. Hydrotech. Constr. 1984, 18, 394–400. [Google Scholar] [CrossRef]

- Van Heerden, W.L. General relations between static and dynamic moduli of rocks. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. Pergamon 1987, 24, 381–385. [Google Scholar] [CrossRef]

- Eissa, E.A.; Kazi, A. Relation between static and dynamic Young’s moduli of rocks. Int. J. Rock Mech. Min. Geomech. Abstr. 1988, 25, 479–482. [Google Scholar] [CrossRef]

- Wang, Z.; Nur, A. Dynamic versus static elastic properties of reservoir rocks. Seism. Acoust. Veloc. Reserv. Rocks 2000, 3, 531–539. [Google Scholar]

- Al-Shayea, N.A. Effects of testing methods and conditions on the elastic properties of limestone rock. Eng. Geol. 2004, 74, 139–156. [Google Scholar] [CrossRef]

- Kolesnikov, Y.I. Dispersion effect of velocities on the evaluation of material elasticity. J. Min. Sci. 2009, 45, 347–354. [Google Scholar] [CrossRef]

- Aragón, G.; Pérez-Acebo, H.; Salas, M.Á.; Aragón-Torre, Á. Analysis f the static and dynamic elastic moduli of a one-coat rendering mortar with laboratory and in situ samples. Case Stud. Constr. Mater. 2024, 20, e02868. [Google Scholar] [CrossRef]

- Ahrens, B.; Duda, M.; Renner, J. Relations between hydraulic properties and ultrasonic velocities during brittle failure of a low-porosity sandstone in laboratory experiments. Geophys. J. Int. 2018, 212, 627–645. [Google Scholar] [CrossRef]

- Fjær, E. Relations between static and dynamic moduli of sedimentary rocks. Geophys. Prospect. 2019, 67, 128–139. [Google Scholar] [CrossRef]

- Fjær, E. Static and dynamic moduli of a weak sandstone. Geophysics 2009, 74, WA103–WA112. [Google Scholar] [CrossRef]

- Blake, O.O.; Faulkner, D.R.; Tatham, D.J. The role of fractures, effective pressure and loading on the difference between the static and dynamic Poisson’s ratio and Young’s modulus of Westerly granite. Int. J. Rock Mech. Min. Sci. 2019, 116, 87–98. [Google Scholar] [CrossRef]

- Li, J.; Li, S. Calculation of Rock Mechanics Parameters Using Compressional and Shear Wave Data and Its Application. Well Logging Technol. 2003, (Suppl. S1), 15–18+87. [Google Scholar] [CrossRef]

- Yale, D.P.; Jamieson, W.H. Static and Dynamic Rock Mechanical Properties in the Hugoton and Panoma Fields. In SPE Oklahoma City Oil and Gas Symposium/Production and Operations Symposium; SPE: Richardson, TX, USA, 1994; p. SPE-27939-MS. [Google Scholar]

- Wang, H.; Liu, Y.; Dong, D.; Zhao, Q.; Du, D. Scientific issues on effective development of marine shale gas in southern China. Pet. Explor. Dev. 2013, 40, 615–620. [Google Scholar] [CrossRef]

- Jia, C.; Chen, J.; Guo, Y.; Yang, C.; Xu, J.; Wang, L. Research on mechanical behaviors and failure modes of layer shale. Rock Soil Mech. 2013, 34 (Suppl. S2), 57–61. [Google Scholar]

- Makoond, N.; Cabané, A.; Pelà, L.; Molins, C. Relationship between the static and dynamic elastic modulus of brick masonry constituents. Constr. Build. Mater. 2020, 259, 120386. [Google Scholar] [CrossRef]

- Evans, W.M. A System for Combined Determination of Dynamic and Static Elastic Properties. In Permeability, Porosity and Resistivity of Rocks; The University of Texas: Austin, TX, USA, 1973. [Google Scholar]

- Lama, R.D.; Vutukuri, V.S. Handbook on Mechanical Properties of Rocks: Testing Technique and Results; Trans Tech Publications: Clausthal-Zellerfeld, Germany, 1978. [Google Scholar]

- Liao, J.J.; Hu, T.B.; Chang, C.W. Determination of dynamic elastic constants of transversely isotropic rocks using a single cylindrical specimen. Int. J. Rock Mech. Min. Sci. 1997, 34, 1045–1054. [Google Scholar] [CrossRef]

- Warpinski, N.R.; Peterson, R.E.; Branagan, P.T.; Engler, B.P.; Wolhart, S.L. In situ stress and moduli: Comparison of values derived from multiple techniques. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 27–30 September 1998; p. SPE-49190. [Google Scholar]

- Lin, Y.; Ge, H.; Wang, S. Testing Study on Dynamic and Static Elastic Parameters of Rcks. Chin. J. Rock Mech. Eng. 1998, 17, 216–222. [Google Scholar]

- Belikov, B.P.; Alexandrov, K.S.; Rysova, T.W. Upruie Svoistva Porodoobrasujscich Mineralov I Gornich Porod; Izdat Nauka: Moskva, Russia, 1970. [Google Scholar]

- McCann, D.M.; Entwisle, D.C. Determination of Young’s modulus of the rock mass from geophysical well logs. Geol. Soc. Spec. Pub. 1992, 65, 317–325. [Google Scholar] [CrossRef]

- Canady, W. A method for full-range Young’s modulus correction. In Proceedings of the SPE Unconventional Resources Conference/Gas Technology Symposium, The Woodlands, TX, USA, 14–16 June 2011; p. SPE-143604. [Google Scholar]

- Martínez-Martínez, J.; Benavente, D.; García-del-Cura, M.A. Comparison of the static and dynamic elastic modulus in carbonate rocks. Bull. Eng. Geol. Environ. 2012, 71, 263–268. [Google Scholar] [CrossRef]

- Brotons, V.; Tomás, R.; Ivorra, S.; Grediaga, A.; Martínez-Martínez, J.; Benavente, D.; Gómez-Heras, M. Improved correlation between the static and dynamic elastic modulus of different types of rocks. Mater. Struct. 2016, 49, 3021–3037. [Google Scholar] [CrossRef]

- Ciccotti, M.; Almagro, R.; Mulargia, F. Static and dynamic moduli of the seismogenic layer in Italy. Rock Mech. Rock Eng. 2004, 37, 229–238. [Google Scholar] [CrossRef]

- Zhou, Y.; Gao, J.; Sun, Z.; Qu, W. A fundamental study on compressive strength, static and dynamic elastic moduli of young concrete. Constr. Build. Mater. 2015, 98, 137–145. [Google Scholar] [CrossRef]

- Sun, Y.; Jing, W.; Ni, P.; Shen, W. Study on Dynamic and Static Elastic Modulus Transformation Relationship of Low Permeability Sandstone in CA Area. Oil Drill. Prod. Technol. 2022, 31, 15–18. [Google Scholar]

- Ulusay, R.; Hudson, J.A. The Complete ISRM Suggested Methods for Rock Characterization, Testing and Monitoring; ISRM Turkish National Group: Ankara, Türkiye, 2007. [Google Scholar]

- Han, S.H.; Kim, J.K. Effect of temperature and age on the relationship between dynamic and static elastic modulus of concrete. Cem. Concr. Res. 2004, 34, 1219–1227. [Google Scholar] [CrossRef]

- Davarpanah, S.M.; Ván, P.; Vásárhelyi, B. Investigation of the relationship between dynamic and static deformation moduli of rocks. Geomech. Geophy. Geo-Energy Geo-Resour. 2020, 6, 29. [Google Scholar] [CrossRef]

- Sun, F.; Yang, C.; Ma, S. An S-Wave Velocity Predicted Method. Prog. Geophys. 2008, 23, 470–474. [Google Scholar]

- Shan, Y.; Liu, W. Experimental Study on Dynamic and Static Mechanics Parameters of Rocks under Formation Conditions. J. Chengdu Univ. Technol. Sci. Technol. Ed. 2000, 27, 249–254. [Google Scholar]

- Gao, Y.; Chen, M.; Pang, H. Experimental investigations on elastoplastic deformation and permeability evolution of terrestrial Karamay oil sands at high temperatures and pressures. J. Pet. Sci. Eng. 2020, 190, 107124. [Google Scholar] [CrossRef]

- Christaras, B.; Auger, F.; Mosse, E. Determination of the moduli of elasticity of rocks. Comparison of the ultrasonic velocity and mechanical resonance frequency methods with direct static methods. Mater. Struct. 1994, 27, 222–228. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Longman: London, UK, 1995; Volume 4. [Google Scholar]

- CP110, Code of Practice for the Structural Use of Concrete; British Standards Institution: London, UK, 1972.

- Lacy, L.L. Dynamic rock mechanics testing for optimized fracture designs. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 5–8 October 1997. [Google Scholar]

- Brautigam, T.; Knochel, A.; Lehne, M. Prognosis of uniaxial compressive strength and stiffness of rocks based on point load and ultrasonic tests. Otto-Graf-J 1998, 9, 61–79. [Google Scholar]

- Nur, A.; Wang, Z. Seismic and Acoustic Velocities in Reservoir Rocks: Recent Developments; Society of Exploration Geophysicists: Tulsa, OK, USA, 1999. [Google Scholar]

- Helvatjoglu-Antoniades, M.; Papadogiannis, Y.; Lakes, R.S.; Dionysopoulos, P.; Papadogiannis, D. Dynamic and static elastic moduli of packable and flowable composite resins and their development after initial photo curing. Dent. Mater. 2006, 22, 450–459. [Google Scholar] [CrossRef]

- Mockovčiaková, A.; Pandula, B. Study of the relation between the static and dynamic moduli of rocks. Metalurgija 2003, 42, 37–39. [Google Scholar]

- Fahimifar, A.; Soroush, H. Evaluation of Some Physical and Mechanical Properties of Rocks Using Ultrasonic Pulse Technique and Presenting Equations between Dynamic and Static Elastic Constants. In ISRM Congress; South African Institute of Mining and Etallurgy–Technology Roadmap for Rock Mechanics, ISRM: Lisbon, Portugal, 2003. [Google Scholar]

- Al-Tahini, A.M. The Effect of Cementation on the Mechanical Properties for Jauf Reservoir at Saudi Arabia. Ph.D. Thesis, University of Oklahoma, Norman, OK, USA, 2003. [Google Scholar]

- Ohen, H.A. Calibrated Wireline Mechanical Rock Properties Method for Predicting and Preventing Wellbore Collapse and Sanding. In Proceedings of the SPE European Formation Damage Conference and Exhibition, The Hague, The Netherlands, 13–14 May 2003; p. SPE-82236. [Google Scholar]

- Ameen, M.S.; Smart, B.G.; Somerville, J.M.; Hammilton, S.; Naji, N.A. Predicting rock mechanical properties of carbonates from wireline logs (A ase study: Arab-D reservoir, Ghawar field, Saudi Arabia). Mar. Pet. Geol. 2009, 26, 430–444. [Google Scholar] [CrossRef]

- Brotons, V.; Tomás, R.; Ivorra, S.; Grediaga, A. Relationship between static and dynamic elastic modulus of calcarenite heated at different temperatures: The San Julián’s stone. Bull. Eng. Geol. Environ. 2014, 73, 791–799. [Google Scholar] [CrossRef]

- Najibi, A.R.; Ghafoori, M.; Lashkaripour, G.R.; Asef, M.R. Empirical relations between strength and static and dynamic elastic properties of Asmari and Sarvak limestones, two main oil reservoirs in Iran. J. Pet. Sci. Eng. 2015, 126, 78–82. [Google Scholar] [CrossRef]

- Horsrud, P. Estimating mechanical properties of shale from empirical correlations. SPE Drill. Complet. 2001, 16, 68–73. [Google Scholar] [CrossRef]

- Asef, M.R.; Farrokhrouz, M. A semi-empirical relation between static and dynamic elastic modulus. J. Pet. Sci. Eng. 2017, 157, 359–363. [Google Scholar] [CrossRef]

- Tutuncu, A.N.; Podio, A.L.; Gregory, A.R.; Sharma, M.M. Nonlinear viscoelastic behavior of sedimentary rocks, Part I: Effect of frequency and strain amplitude. Geophysics 1998, 63, 184–194. [Google Scholar] [CrossRef]

- Gong, F.; Di, B.; Wei, J.; Ding, P.; Tian, H.; Han, J. A study of the anisotropic static and dynamic elastic properties of transversely isotropic rocks. Geophysics 2019, 84, C281–C293. [Google Scholar] [CrossRef]

- Zhang, L.; Ba, J.; Fu, L.; Carcione, J.M.; Cao, C. Estimation of pore microstructure by using the static and dynamic moduli. Int. J. Rock Mech. Min. Sci. 2019, 113, 24–30. [Google Scholar] [CrossRef]

- Fei, W.; Huiyuan, B.; Jun, Y.; Yonghao, Z. Correlation of dynamic and static elastic parameters of rock. Electron. J. Geotech. Eng. 2016, 21, 1551–1560. [Google Scholar]

- Bakhorji, A.; Schmitt, D.R. Laboratory measurements of static and dynamic bulk moduli in carbonate. In ARMA US Rock Mechanics/Geomechanics Symposium; ARMA: Alexandria, VA, USA, 2010; p. ARMA-10. [Google Scholar]

- Blake, O.O.; Faulkner, D.R. The effect of fracture density and stress state on the static and dynamic bulk moduli of Westerly granite. J. Geophys. Res. Solid Earth 2016, 121, 2382–2399. [Google Scholar] [CrossRef]

| NO | Equation | Unit | R2 | Rock Type | Reference |

|---|---|---|---|---|---|

| 5 | GPa | 0.92 | Granite | Belikov et al. (1970) [29] | |

| 6 | GPa | 0.82 | Igneous–metamorphic | King (1983) [7] | |

| 7 | GPa | 0.96–0.99 | Sandstone–granite | Van Heerden (1987) [9] | |

| 8 | GPa | 0.84 | All types | Eissa and Kazi (1988) [10] | |

| 9 | GPa | 0.84 | All types | Eissa and Kazi (1988) [10] | |

| 10 | GPa | 0.96 | Sedimentary | Eissa and Kazi (1988) [10] | |

| 11 | GPa | 0.75 | All types | McCann and Entwisle (1992) [30] | |

| 12 | GPa | 0.99 | Sedimentary | Christaras et al. (1994) [43] | |

| 13 | GPa | - | Goncrele | Neville (1995) [44] | |

| 14 | GPa | - | Structural design | CP110 (1972) [45] | |

| 15 | MPsi | 0.75 | Sedimentary | Lacy (1997) [46] | |

| 16 | MPsi | 0.74 | Sandstones | Lacy (1997) [46] | |

| 17 | MPsi | 0.93 | Shales | Lacy (1997) [46] | |

| 18 | GPa | 0.60 | Sedimentary | Brautigam et al. (1998) [47] | |

| 19 | GPa | - | Hard rocks (Es > 15 GPa) | Nur and Wang (1999) [48] | |

| 20 | GPa | 0.92 | Composite resin | Helvatjoglu et al. (2006) [49] | |

| 21 | GPa | 0.96 | All types | Mokovciakova and Pandula (2003) [50] | |

| 22 | GPa | 0.72 | All types | Fahimifar and Soroush (2003) [51] | |

| 23 | Psi | 0.60 | Sandstone | Al-Tahini (2003) [52] | |

| 24 | GPa | - | Shale | Ohen (2003) [53] | |

| 25 | GPa | 0.60 | Limestone | Ameen et al. (2009) [54] | |

| 26 | GPa | 0.96 | Sedimentary | Brotons et al. (2014) [55] | |

| 27 | GPa | 0.97 | Sedimentary | Brotons et al. (2014) [55] | |

| 28 | GPa | 0.97 | All types | Brotons et al. (2016) [33] | |

| 29 | GPa | 0.99 | All types | Brotons et al. (2016) [33] | |

| 30 | GPa | 0.87 | Limestone | Najibi et al. (2015) [56] | |

| 31 | GPa | - | Carbonate rocks | Martinez-Martinez et al. (2012) [32] | |

| 32 | GPa | - | Shale | Horsrud (2001) [57] | |

| 33 | GPa | 0.90 | Limestone | Najibi et al. (2015) [56] | |

| 34 | - | - | Limestone–marble | Martinez-Martinez et al. (2012) [32] |

| Equation Type | Relationship | Equations | Vars. |

|---|---|---|---|

| Ⅰ | (5), (6), (8), (9), (11), (12), (14), (19), (21), (23), (25), (26), and (28) | ||

| Ⅱ | (10), (27), and (29) | ; | |

| Ⅲ | (7), (13), (18), (20), (24), (30) and (31) | ||

| Ⅳ | (15)–(17) | ||

| Ⅴ | (32) and (33) | ||

| Ⅵ | (22) | ||

| Ⅶ | (34) | , |

| a | b | Rock Type | Reference |

|---|---|---|---|

| 1.137 | 9.68 | Granite | Belikov et al. (1970) [29] |

| 1.263 | 29.5 | Igneous–metamorphic | King (1983) [7] |

| 0.64 | 0.32 | All types | Eissa and Kazi (1988) [10] |

| 0.74 | 0.82 | All types | Eissa and Kazi (1988) [10] |

| 0.69 | −6.40 | All types | McCann and Entwisle (1992) [30] |

| 1.05 | 3.16 | Sedimentary | Christaras et al. (1994) [43] |

| 1.25 | 19 | Structural design | CP110 (1972) [45] |

| 1.153 | 15.2 | Hard rocks (Es >15 GPa) | Nur and Wang (1999) [48] |

| 0.541 | −12.852 | Limestone | Ameen et al. (2009) [54] |

| 0.867 | 2.085 | Sedimentary | Brotons et al. (2014) [55] |

| 0.932 | 3.421 | All types | Brotons et al. (2016) [33] |

| Rock Name | ||||

|---|---|---|---|---|

| Chalcedonic limestone | 0.18 | 0.25 | 55.16 | 46.85 |

| Limestone | 0.25 | 0.28 | 66.99 | 70.96 |

| Oolitic | 0.18 | 0.21 | 45.51 | 53.74 |

| Quartzose shale | 0.08 | - | 16.5 | 22.04 |

| Stylolitic limestone | 0.11 | 0.27 | 38.61 | 56.49 |

| Limestone | 0.18 | 0.2 | 16.55 | 28.24 |

| Limestone | 0.17 | 0.31 | 33.78 | 52.36 |

| Siltstone | 0.05 | 0.08 | 13.1 | 26.87 |

| Subgraywacke | 0.03 | 0.19 | 12.41 | 26.18 |

| Sericite schist | 0.02 | 0.44 | 7.58 | 17.91 |

| Subgraywacke | 0.02 | 0.06 | 11.03 | 26.18 |

| Calcareous shale | 0.02 | - | 15.86 | 24.80 |

| Subgraywacke | 0.02 | 0.29 | 9.65 | 24.80 |

| Subgraywacke | 0.05 | 0.08 | 8.96 | 26.18 |

| Leuders limestone | 0.21 | 0.22 | 24.13 | 33.37 |

| Leuders limestone | 0.21 | 0.22 | 24.82 | 33.37 |

| Green River shale | 0.18 | 0.22 | 29.65 | 40.06 |

| Green River shale | 0.17 | 0.27 | 35.16 | 42.54 |

| Sandstone with chalcedonic | - | - | 71.58 | 76.29 |

| Equigranular dolomite | - | - | 49.52 | 52.06 |

| Limestone | - | - | 18.43 | 23.73 |

| Calcareous dolomite | - | - | 34.22 | 46.28 |

| Fine-grained detrital limestone | - | - | 46.77 | 55.99 |

| Rock Name | ||||

|---|---|---|---|---|

| Granite | - | - | 64.71 | 69.62 |

| Gabbro | - | - | 69.62 | 73.54 |

| Dunite | - | - | 149.1 | 160.81 |

| Granite (slightly altered) | 0.04 | 0.1 | 5.52 | 15.15 |

| Monzonite porphyry | 0.18 | 0.21 | 41.37 | 56.49 |

| Quartz diorite | 0.05 | 0.19 | 21.37 | 30.31 |

| Uralite basalt | 0.15 | 0.28 | 78.5 | 104.7 |

| Dolerite | 0.13 | 0.29 | 82 | 91.9 |

| Uralite diabase | 0.25 | 0.32 | 91 | 82 |

| Dolerite | 0.2 | 0.25 | 93.9 | 109.3 |

| Syenite | - | - | 72.56 | 79.42 |

| Rock Name | ||||

|---|---|---|---|---|

| Quartzose phyllite | - | - | 7.58 | 18.60 |

| Graphitic phyllite | - | - | 9.65 | 26.87 |

| Tremolite schist | 0.11 | 0.29 | 89.6 | 92.7 |

| Hornblende schist | 0.28 | 0.29 | 98.2 | 104.2 |

| Actinolite schist | 0.29 | 0.26 | 77.9 | 148.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, S.; Gao, Y.; Jia, L. A Comparison of the Relationship between Dynamic and Static Rock Mechanical Parameters. Appl. Sci. 2024, 14, 4487. https://doi.org/10.3390/app14114487

Shen S, Gao Y, Jia L. A Comparison of the Relationship between Dynamic and Static Rock Mechanical Parameters. Applied Sciences. 2024; 14(11):4487. https://doi.org/10.3390/app14114487

Chicago/Turabian StyleShen, Shijie, Yanfang Gao, and Lichun Jia. 2024. "A Comparison of the Relationship between Dynamic and Static Rock Mechanical Parameters" Applied Sciences 14, no. 11: 4487. https://doi.org/10.3390/app14114487