Practical Test on the Operation of the Three-Phase Induction Motor under Single-Phasing Fault

Abstract

1. Introduction

- Analysis of the single-phasing fault and derivation of the electrical model of the three-phase induction motor.

- Verification of the results obtained under different load conditions.

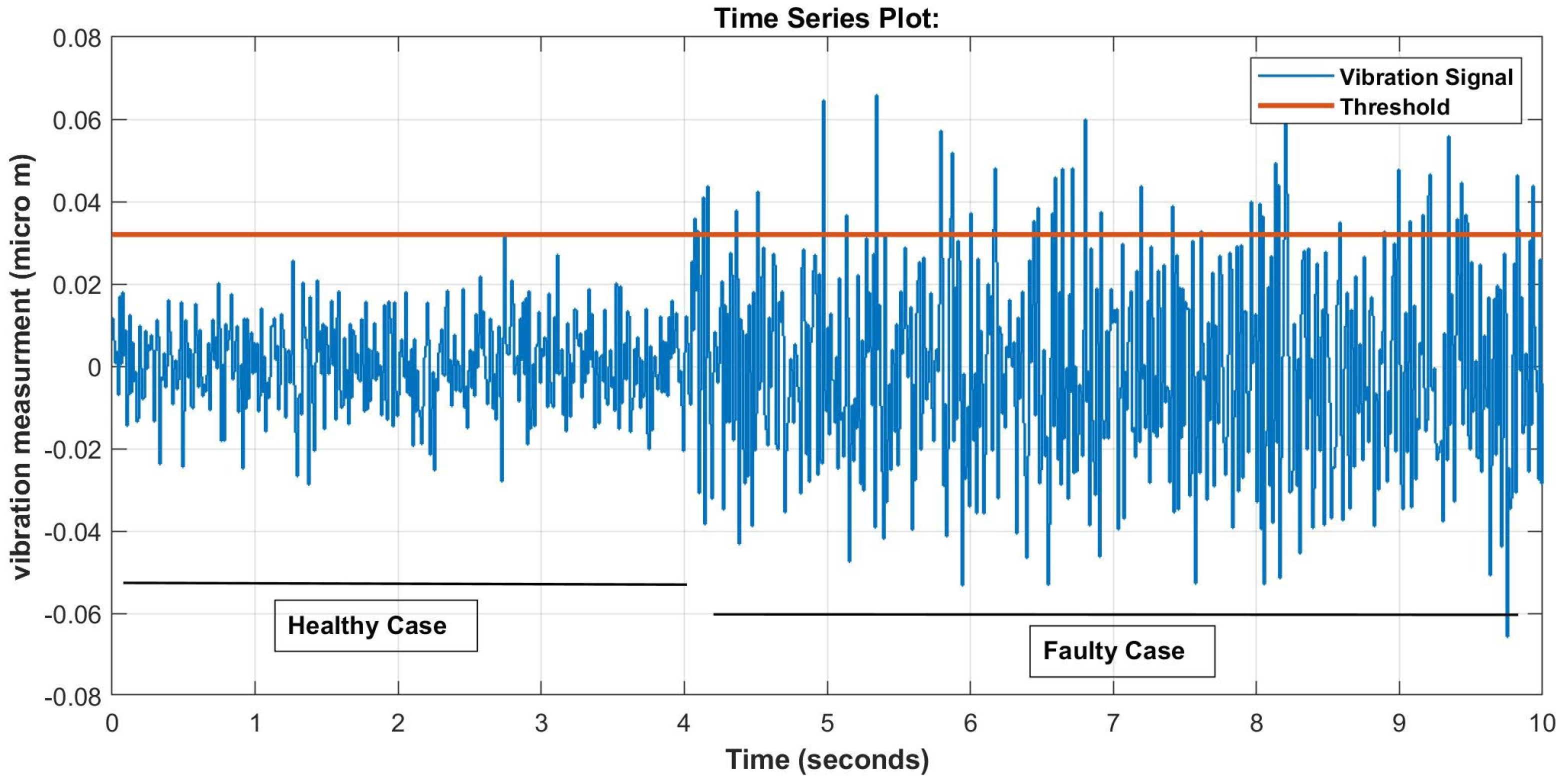

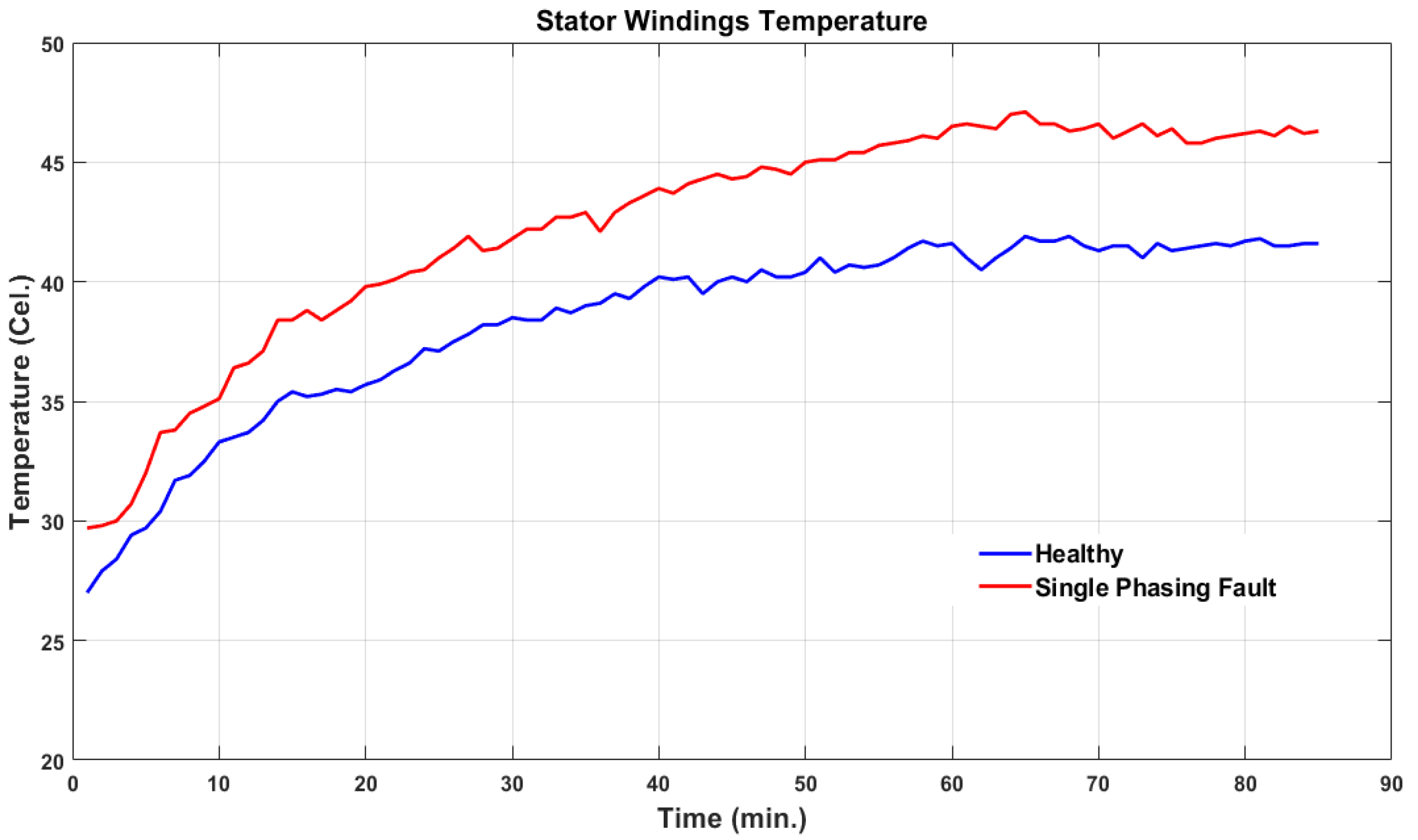

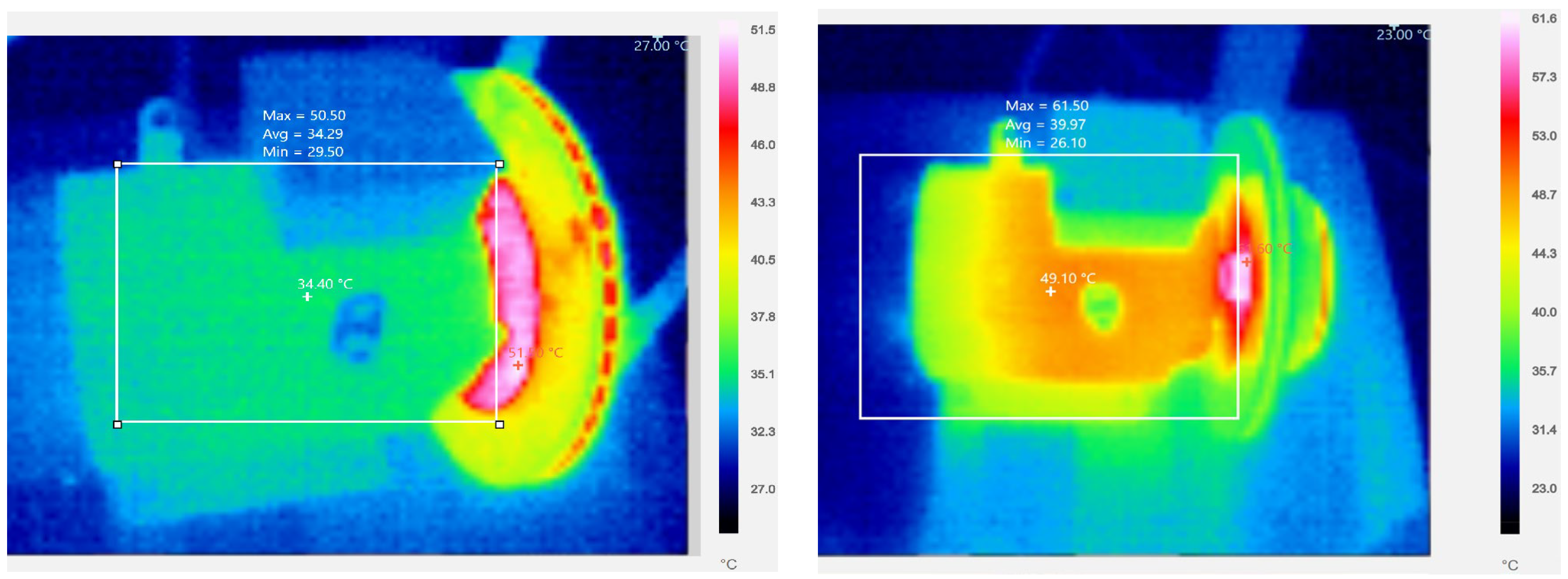

- Measure the stator winding temperatures and motor vibration.

- Conduct extensive experiments on a three-phase induction motor to determine the most effective protection settings.

2. Preliminaries and Basic Idea

2.1. Circuit Analysis Single—Phasing Fault

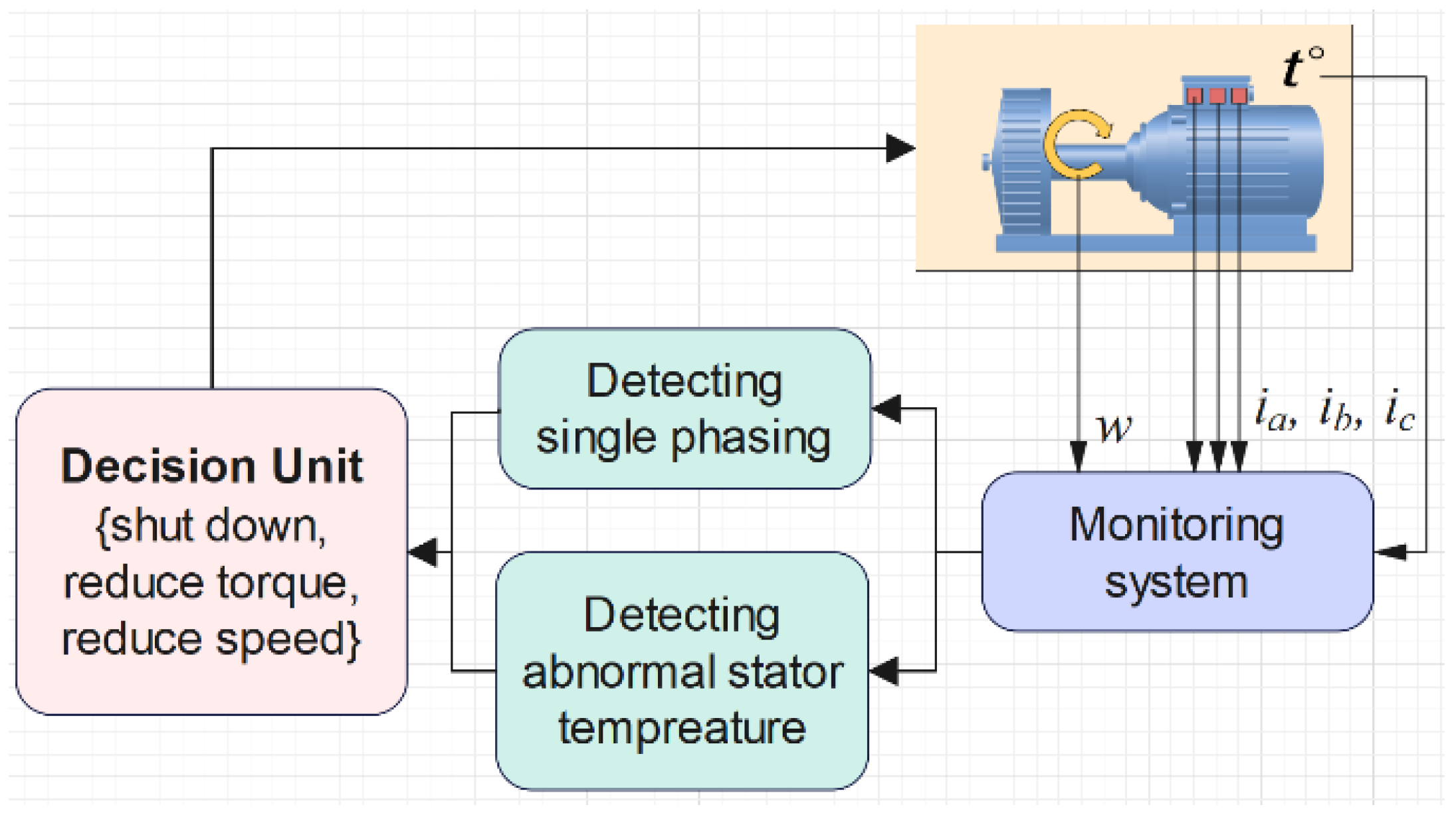

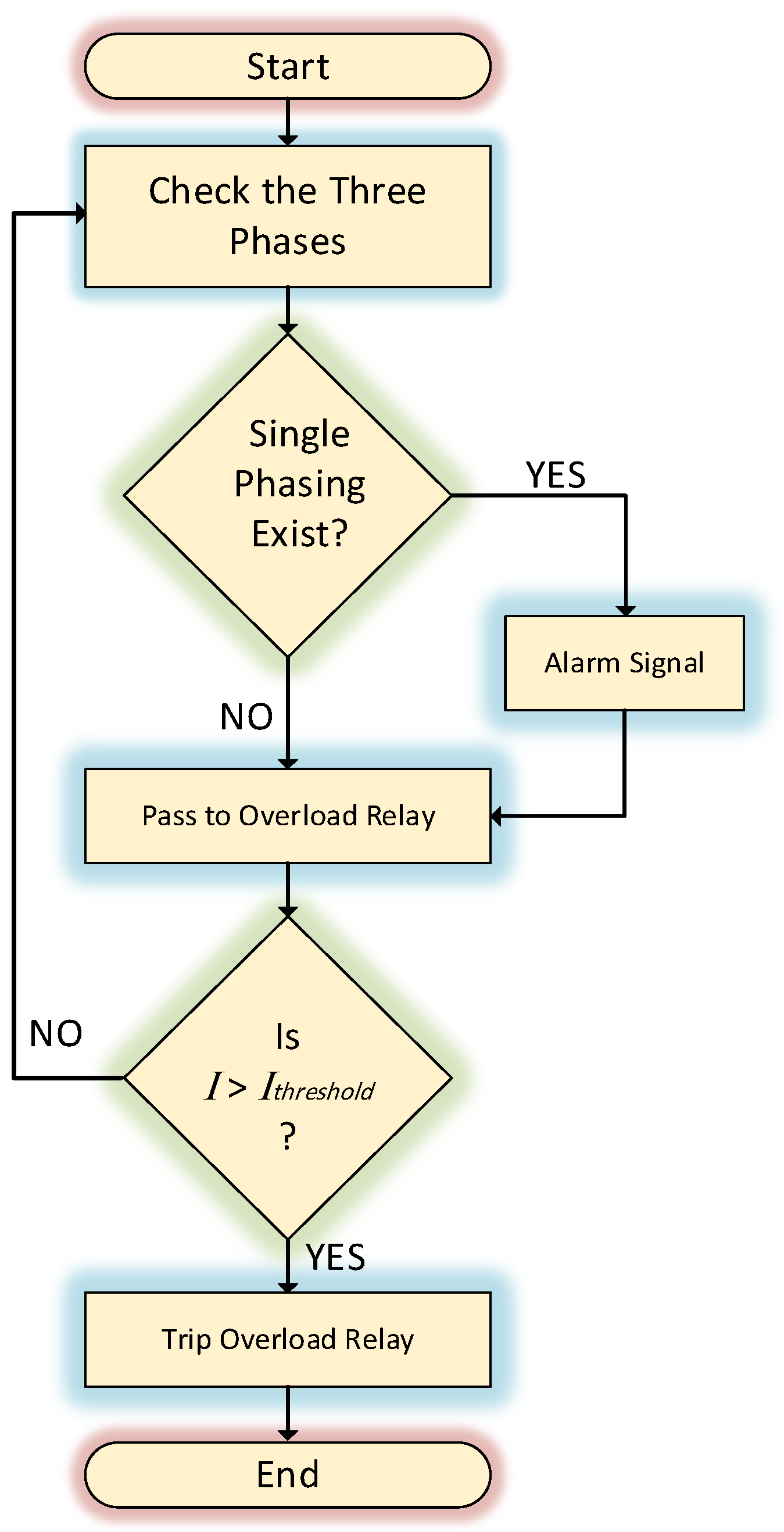

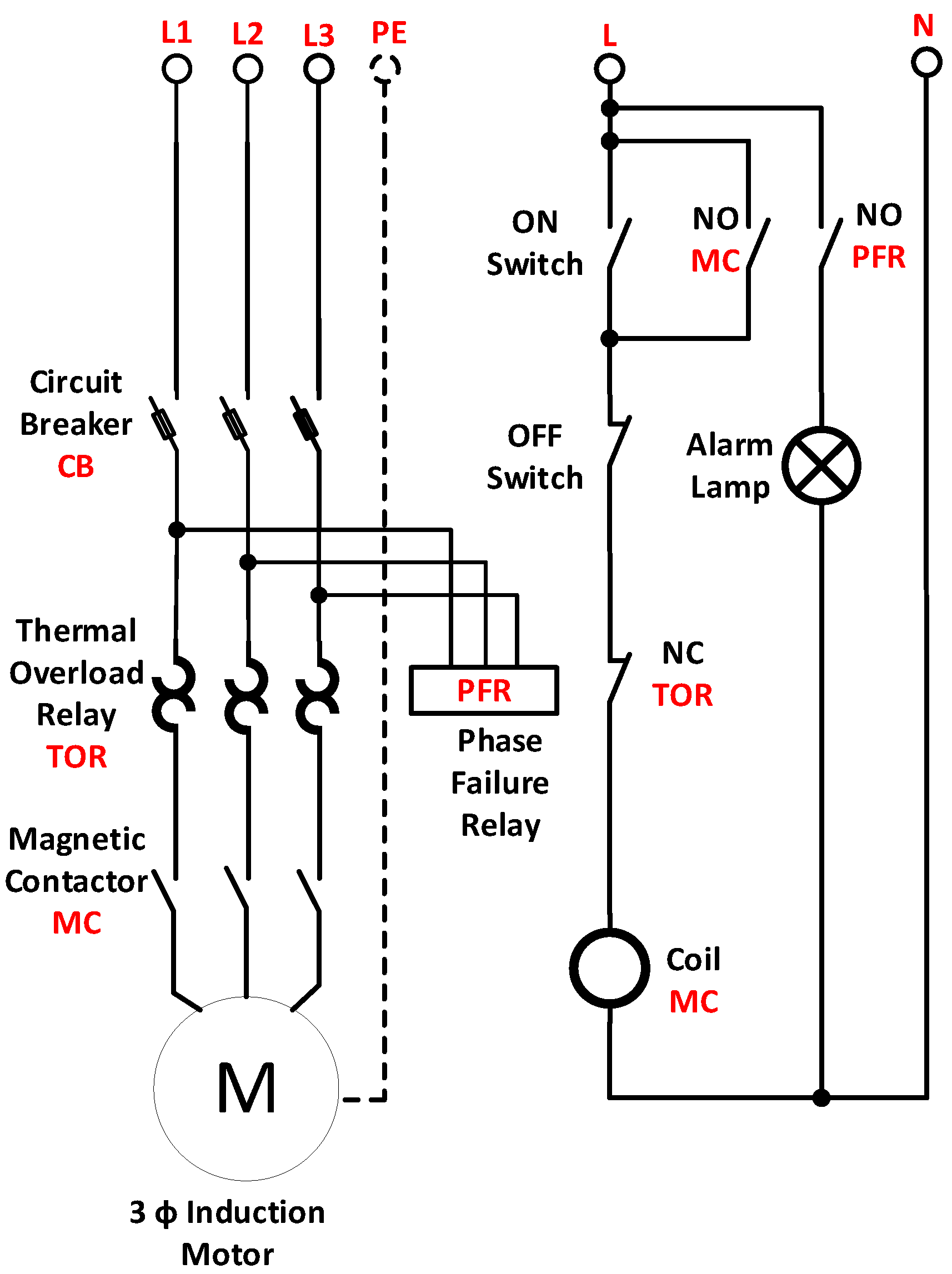

2.2. Proposed Scheme

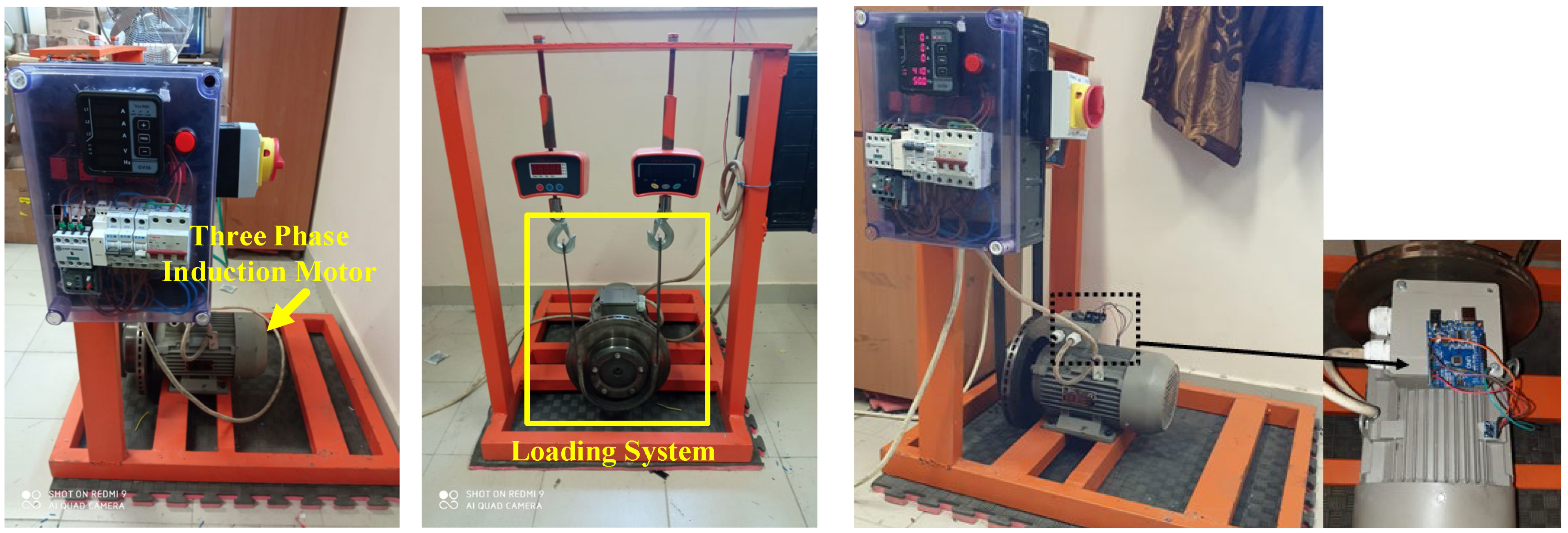

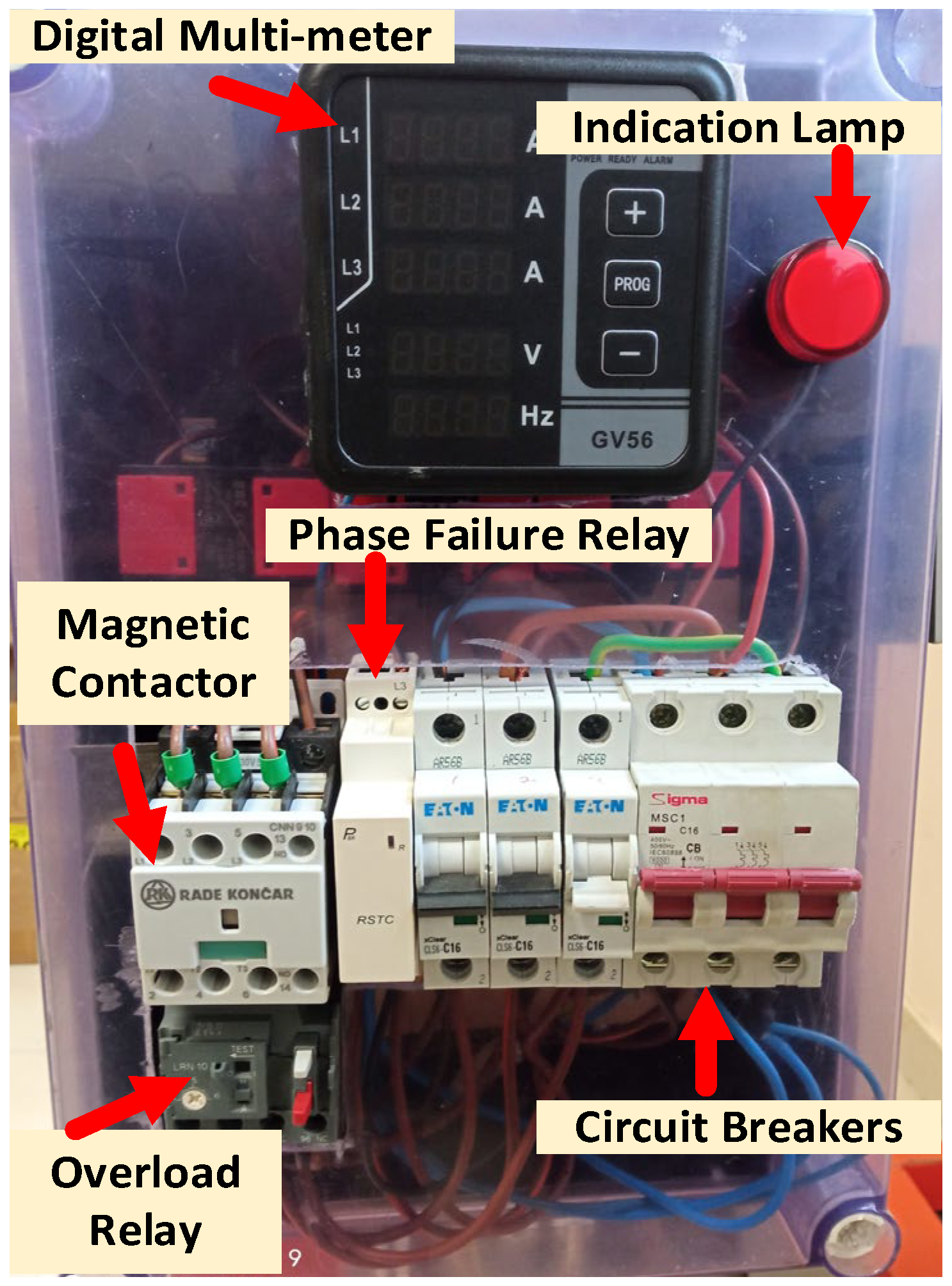

3. Practical Test

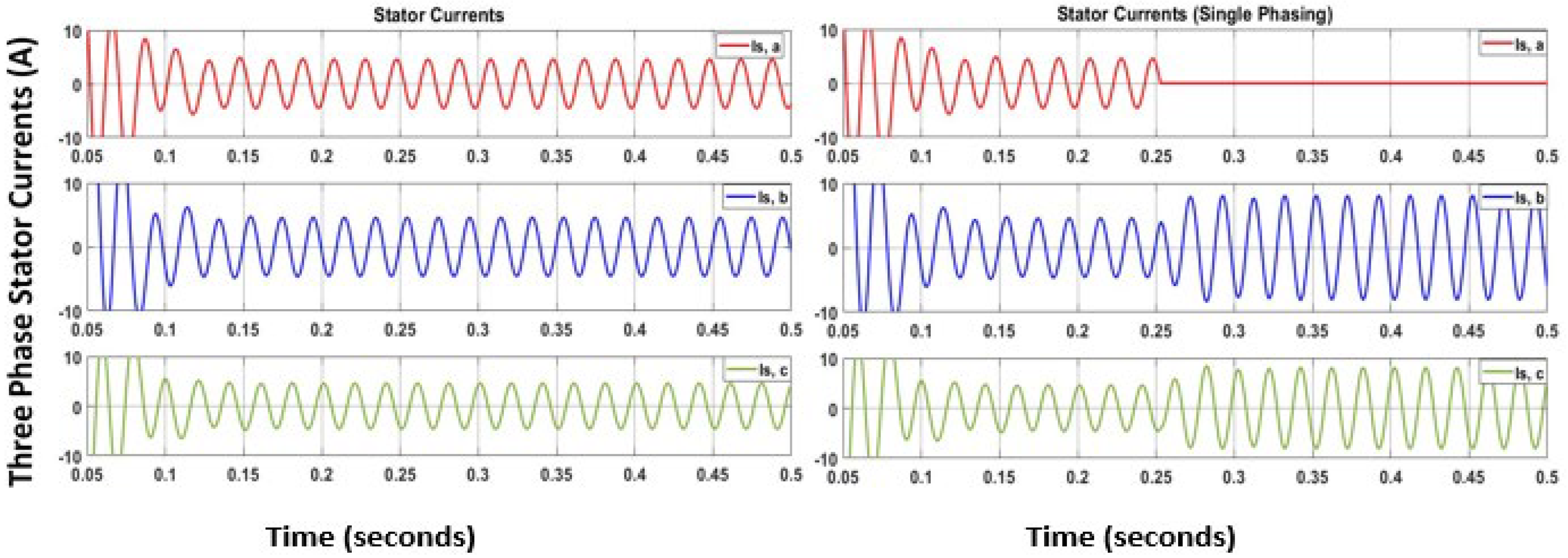

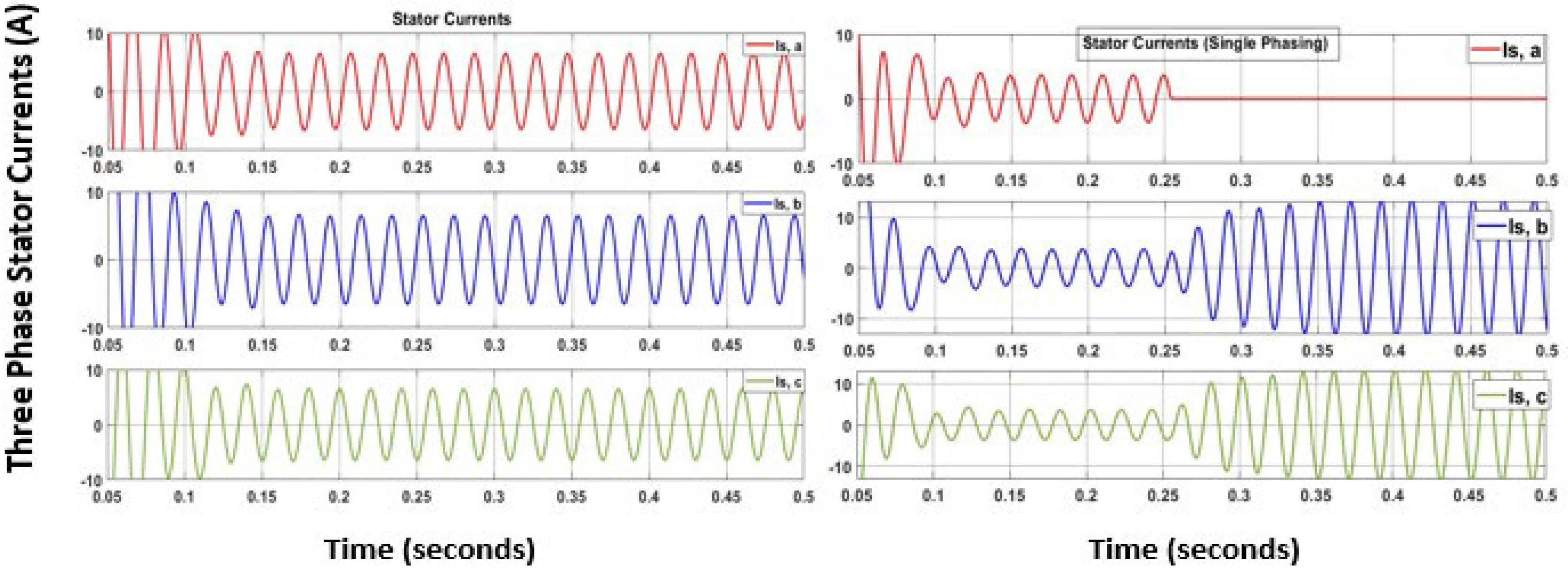

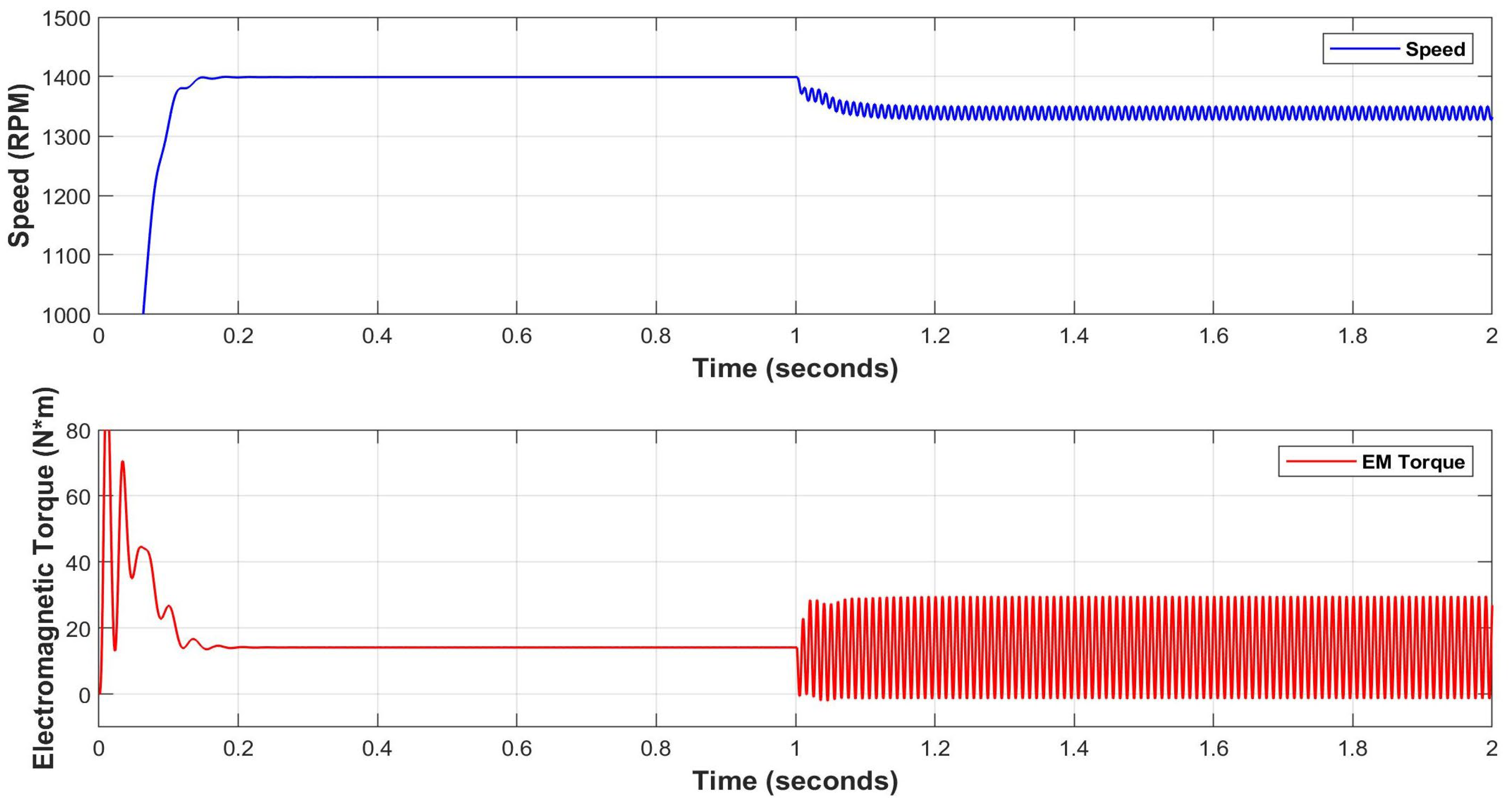

Theoretical Calculation and Simulation Results

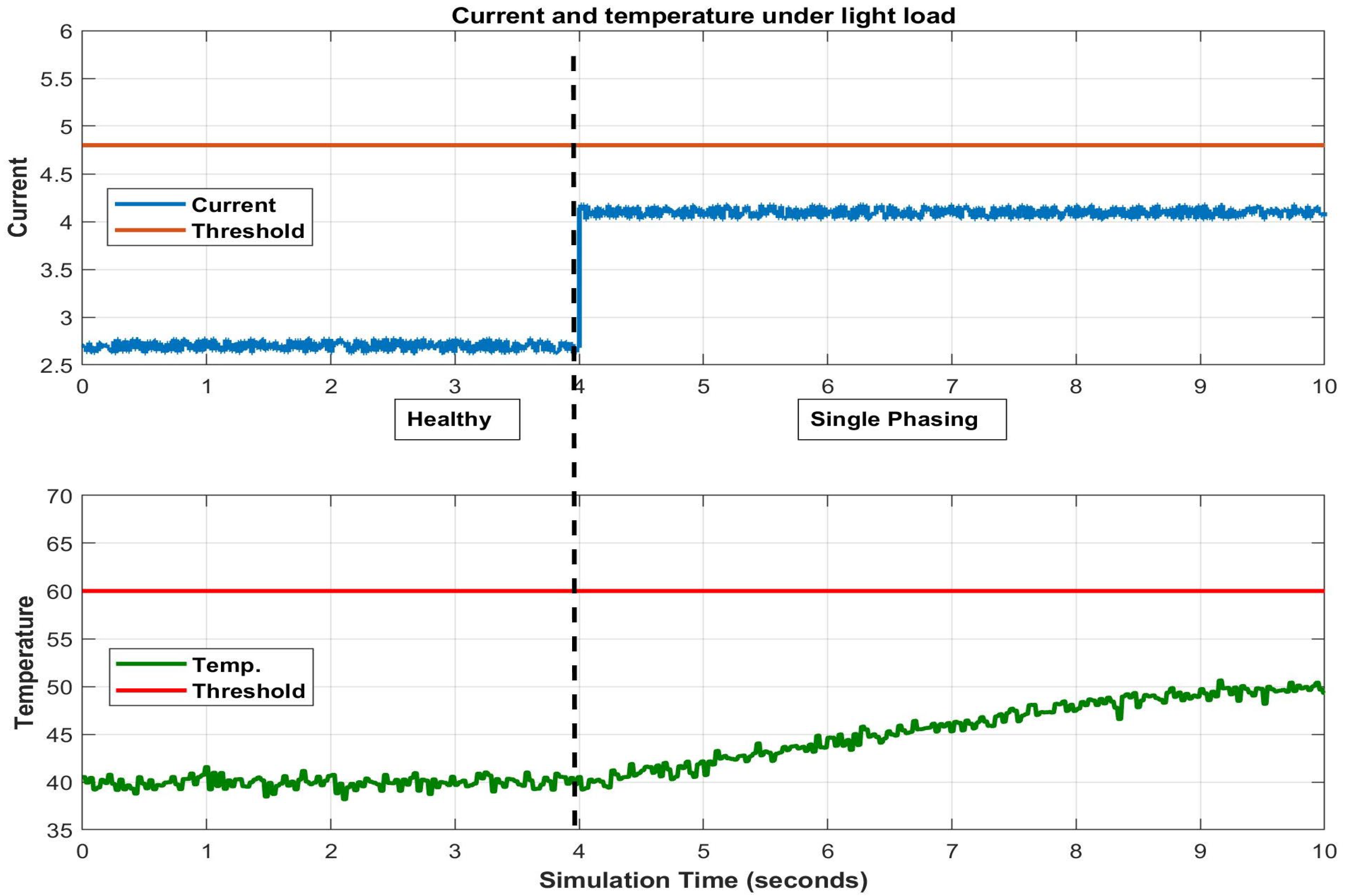

4. Operation Un44. Single Phasing—Protection Scheme

5. Discussion

Motor Operation with Fault Detection

6. Conclusions

- The proposed protection scheme is practical, and a fault-tolerant control scheme can be used to make the three-phase induction motor run more reliably and safely under the single-phasing fault.

- It has been discovered that the stator winding temperature should be considered in any advanced research on motor operation during single phasing.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Line to neutral voltages | Motor rotor current | ||

| Three phase current | Motor excitation current | ||

| Sequence currents (zero, positive, negative, respectively) | Synchronous motor speed (rpm) | ||

| Sequence voltages (zero, positive, negative, respectively) | Peak threshold value | ||

| Motor stator resistance | Motor speed (rpm) | ||

| Motor-reflected rotor resistance | Motor Phase Voltage | ||

| Motor stator reactance | Electrical frequency (50 Hz) | ||

| Motor-reflected rotor reactance | Motor number of poles | ||

| Motor excitation reactance | H | Healthy condition | |

| Motor stator current | F | Faulty condition (single phasing) | |

| Vibration measured signal |

References

- Chen, W.-K. Fortune Business Insight, Induction Motor Market Size, Share & Industry Analysis, by Type (Single Phase, Three Phase) by Application (Residential, Industrial, Commercial, Transportation, Others) and Regional Forecast; Report Id: Fbi101639, 2021; Linear Networks and Systems (Book Style); Wadsworth: Belmont, CA, USA, 1993; pp. 123–135. [Google Scholar]

- Kersting, W. Causes and Effects of Single-Phasing Induction Motors. IEEE Trans. Ind. Appl. 2005, 41, 1499–1505. [Google Scholar] [CrossRef]

- Guasch-Pesquer, L.; Youb, L.; González-Molina, F.; Zeppa-Durigutti, E.-R. Effects of Voltage Unbalance on Torque and Current of the Induction Motors. In Proceedings of the 2012 13th International Conference on Optimization of Electrical and Electronic Equipment (OP-TIM), Brasov, Romania, 24–26 May 2012; pp. 647–652. [Google Scholar] [CrossRef]

- Dash, R.N.; Sahu, S.; Panigrahi, C.K. Effect and Analysis of Unbalanced Voltage on Induction Motor Torque. In Proceedings of the 2018 International Conference on Recent Innovations in Electrical, Electronics & Communication Engineering (ICRIEECE), Bhubaneswar, India, 27–28 July 2018; pp. 2698–2703. [Google Scholar] [CrossRef]

- Siddique, J.A.; Yadava, G.S.; Singh, B. Effects of Voltage Unbalance on Induction Motors. In Proceedings of the Conference Record of the 2004 IEEE International Symposium on Electrical Insulation, Indianapolis, IN, USA, 19–22 September 2004; pp. 26–29. [Google Scholar] [CrossRef]

- Dekhandji, F.Z.; Refoufi, L.; Bentarzi, H. Quantitative Assessment of Three Phase Supply Voltage Unbalance Effects on Induction Motors. Int. J. Syst. Assur. Eng. Manag. 2015, 8, 393–406. [Google Scholar] [CrossRef]

- Sudasinghe, P.; Perera, S.; Commins, P.; Moscrop, J.; Jayatunga, U.; Wadduwage, P. Rediscovering the Derating Mechanisms for Three-Phase Induction Motors Operating Under Supply Voltage Unbalance. In Proceedings of the 2020 19th International Conference on Harmonics and Quality of Power (ICHQP), Dubai, United Arab Emirates, 6–7 July 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Quispe, E.C.; López-Fernández, X.M.; Mendes, A.M.S.; Marques Cardoso, A.J.; Palacios, J.A. Experimental Study of the Effect of Positive Sequence Voltage on the Derating of Induction Motors Under Voltage Unbalance. In Proceedings of the 2011 IEEE Inter-national Electric Machines & Drives Conference (IEMDC), Niagara Falls, ON, Canada, 15–18 May 2011; pp. 908–912. [Google Scholar] [CrossRef]

- Ogbuka, C.U.; Bassey, O. Protection Method Against Induction Motor Single-Phasing Fault. Int. J. Innov. Technol. Explor. Eng. (IJITEE) 2014, 4, 61–65. [Google Scholar]

- Giceva, I.Z.; Sarac, V.J.; Gelev, S.A.; Cingoski, V.T. Single Phasing of Three Phase Induction Motors Under Various Load Conditions. In Proceedings of the 2018 23rd International Scientific-Professional Conference on Information Technology (It), Zabljak, Montenegro, 19–24 February 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Duarte, S.X.; Kagan, N. A Power-Quality Index to Assess the Impact of Voltage Harmonic Distortions and Unbalanced to Three-Phase Induction Motors. IEEE Trans. Power Deliv. 2010, 25, 1846–1854. [Google Scholar] [CrossRef]

- Gonzalez-Cordoba, J.L.; Osornio-Rios, R.A.; Granados-Lieberman, D.; Romero-Troncoso, R.D.J.; Valtierra-Rodriguez, M. Thermal-Impact-Based Protection of Induction Motors Under Voltage Unbalance Conditions. IEEE Trans. Energy Convers. 2018, 33, 1748–1756. [Google Scholar] [CrossRef]

- Sudha, M.; Anbalagan, P. A Novel Protecting Method for Induction Motor Against Faults Due to Voltage Unbalance and Single Phasing. In Proceedings of the IECON 2007—33rd Annual Conference of the IEEE Industrial Electronics Society, Taipei, Taiwan, 5–8 November 2007; pp. 1144–1148. [Google Scholar] [CrossRef]

- Sobanski, P.; Orlowska-Kowalska, T. Faults Diagnosis and Control in a Low-Cost Fault-Tolerant Induction Motor Drive System. Math. Comput. Simul. 2017, 131, 217–233. [Google Scholar] [CrossRef]

- Abbasi, H.; Ghanbari, M.; Ebrahimi, R.; Jannati, M. Post-Fault Operation Strategy for Single Open-Phase Fault in Three-Phase Induction Motor Drives. IET Power Electron. 2022, 15, 1174–1188. [Google Scholar] [CrossRef]

- Abbasi, H.; Ghanbari, M.; Ebrahimi, R.; Jannati, M. IRFOC of Induction Motor Drives Under Open-Phase Fault Using Balanced and Unbalanced Transformation Matrices. IEEE Trans. Ind. Electron. 2020, 68, 9160–9173. [Google Scholar] [CrossRef]

- Jannati, M.; Idris, N.R.N.; Aziz, M.J.A. Performance Evaluation of the Field-Oriented Control of Star-Connected 3-Phase Induction Motor Drives Under Stator Winding Open-Circuit Faults. J. Power Electron. 2016, 16, 982–993. [Google Scholar] [CrossRef]

- Jannati, M.; Monadi, A.; Idris, N.R.N.; Abdul Aziz, M.J. Experimental Evaluation of FOC of 3-Phase IM Under Open-Phase Fault. Int. J. Electron. 2017, 104, 1675–1688. [Google Scholar] [CrossRef]

- Forstner, G.; Kugi, A.; Kemmetmüller, W. Fault-Tolerant Torque Control of a Three-Phase Permanent Magnet Synchronous Motor with Inter-Turn Winding Short Circuit. Control. Eng. Pr. 2021, 113, 104846. [Google Scholar] [CrossRef]

- Costa, B.L.G.; Graciola, C.L.; Angélico, B.A.; Goedtel, A.; Castoldi, M.F.; Andrade Pereira, W.C. A Practical Framework for Tuning Dtc-Svm Drive of Three-Phase Induction Motors. Control. Eng. Pr. 2019, 88, 119–127. [Google Scholar] [CrossRef]

- Saffar, E.; Ghanbari, M.; Ebrahimi, R.; Jannati, M. A Simple Fault-Tolerant Control Method for Open-Phase Three-Phase Induction Motor Drives. Control. Eng. Pract. 2023, 136, 105525. [Google Scholar] [CrossRef]

- Nikpayam, M.; Ghanbari, M.; Esmaeli, A.; Jannati, M. Fault-tolerant control of Y-connected three-phase induction motor drives without speed measurement. Measurement 2020, 149, 106993. [Google Scholar] [CrossRef]

- Saffar, E.; Ghanbari, M.; Ebrahimi, R. Single open-phase fault detection and tolerant control for wye-connected three-phase induction machine drives. Int. J. Circuit Theory Appl. 2024. [Google Scholar] [CrossRef]

- Klempner, G.; Kerszenbaum, I. Principles of Operation of Synchronous Machines. In Handbook of Large Turbo-Generator Operation and Maintenance; IEEE: Piscataway, NJ, USA, 2018; pp. 1–52. [Google Scholar] [CrossRef]

- Anderson, P.M.; Henville, C.; Rifaat, R.; Johnson, B.; Meliopoulos, S. Motor Protection. In Power System Protection; IEEE: Piscataway, NJ, USA, 2022; pp. 805–860. [Google Scholar] [CrossRef]

- Joe, H.C.; Juan, J. Sanchez-Gasca Load and Induction Motor Models. In Power System Modeling, Computation, and Control; IEEE: Piscataway, NJ, USA, 2020; pp. 295–325. [Google Scholar] [CrossRef]

- Rahmatullah, R.; OYMAN SERTELLER, N.F.; TOPUZ, V. Modeling and Simulation of Faulty Induction Motor in DQ Reference Frame Using MATLAB/SIMULINK with MATLAB/GUIDE for Educational Purpose. Int. J. Educ. Inf. Technol. 2023, 17, 7–20. [Google Scholar] [CrossRef]

- Chapman, S.J. Electric Machinery Fundamentals, 5th ed.; Mcgraw-Hill: New York, NY, USA, 2012. [Google Scholar]

| Motor | Three-Phase Squirrel Cage Induction Motor |

|---|---|

| Power Factor | 0.81 |

| Power | 2.2 kW |

| Frequency | 50 Hz |

| Rated Voltage Δ/Y | 230/400 V |

| Rated Current Δ/Y | 8.4/4.8 A |

| Weight | 19.8 kg |

| Rated Speed | 1420 rpm |

| Ambient Temp. | 40 °C |

| Class | B |

| Test | Parameters |

|---|---|

| DC test | |

| No-load test | |

| Blocked rotor test |

| Test | Light Load | Half Load | Full Load | |||

|---|---|---|---|---|---|---|

| H | F | H | F | H | F | |

| Speed [rpm] | 1497 | 1497 | 1440 | 1405 | 1410 | 1330 |

| Ia [A] | 2.7 | 0 | 3.7 | 0 | 4.4 | 0 |

| Ib [A] | 2.7 | 4.1 | 3.7 | 7 | 4.4 | 9.2 |

| Ic [A] | 2.7 | 4.1 | 3.7 | 7 | 4.4 | 9.2 |

| Test | motor current under healthy case [a] | motor current under single phasing [a] | |

|---|---|---|---|

| Light load torque | Practical | 2.7 | 4.1 |

| Theoretical | 2.68 | 4.25 | |

| Simulation | 2.6 | 4.27 | |

| Half load torque | Practical | 3.7 | 7.0 |

| Theoretical | 3.5 | 6.4 | |

| Simulation | 3.24 | 6.4 | |

| Full load torque | Practical | 4.4 | 9.2 |

| Theoretical | 4.3 | 9.07 | |

| Simulation | 4.6 | 9.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdo, A.; Siam, J.; Abdou, A.; Shehadeh, H.; Mustafa, R. Practical Test on the Operation of the Three-Phase Induction Motor under Single-Phasing Fault. Appl. Sci. 2024, 14, 4690. https://doi.org/10.3390/app14114690

Abdo A, Siam J, Abdou A, Shehadeh H, Mustafa R. Practical Test on the Operation of the Three-Phase Induction Motor under Single-Phasing Fault. Applied Sciences. 2024; 14(11):4690. https://doi.org/10.3390/app14114690

Chicago/Turabian StyleAbdo, Ali, Jamal Siam, Ahmed Abdou, Hakam Shehadeh, and Rashad Mustafa. 2024. "Practical Test on the Operation of the Three-Phase Induction Motor under Single-Phasing Fault" Applied Sciences 14, no. 11: 4690. https://doi.org/10.3390/app14114690

APA StyleAbdo, A., Siam, J., Abdou, A., Shehadeh, H., & Mustafa, R. (2024). Practical Test on the Operation of the Three-Phase Induction Motor under Single-Phasing Fault. Applied Sciences, 14(11), 4690. https://doi.org/10.3390/app14114690