Technological Properties of Tritordeum Starch

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Isolation of Starches

2.2.2. Analytical Determinations

Chemical Composition of Starches

Color Measurement

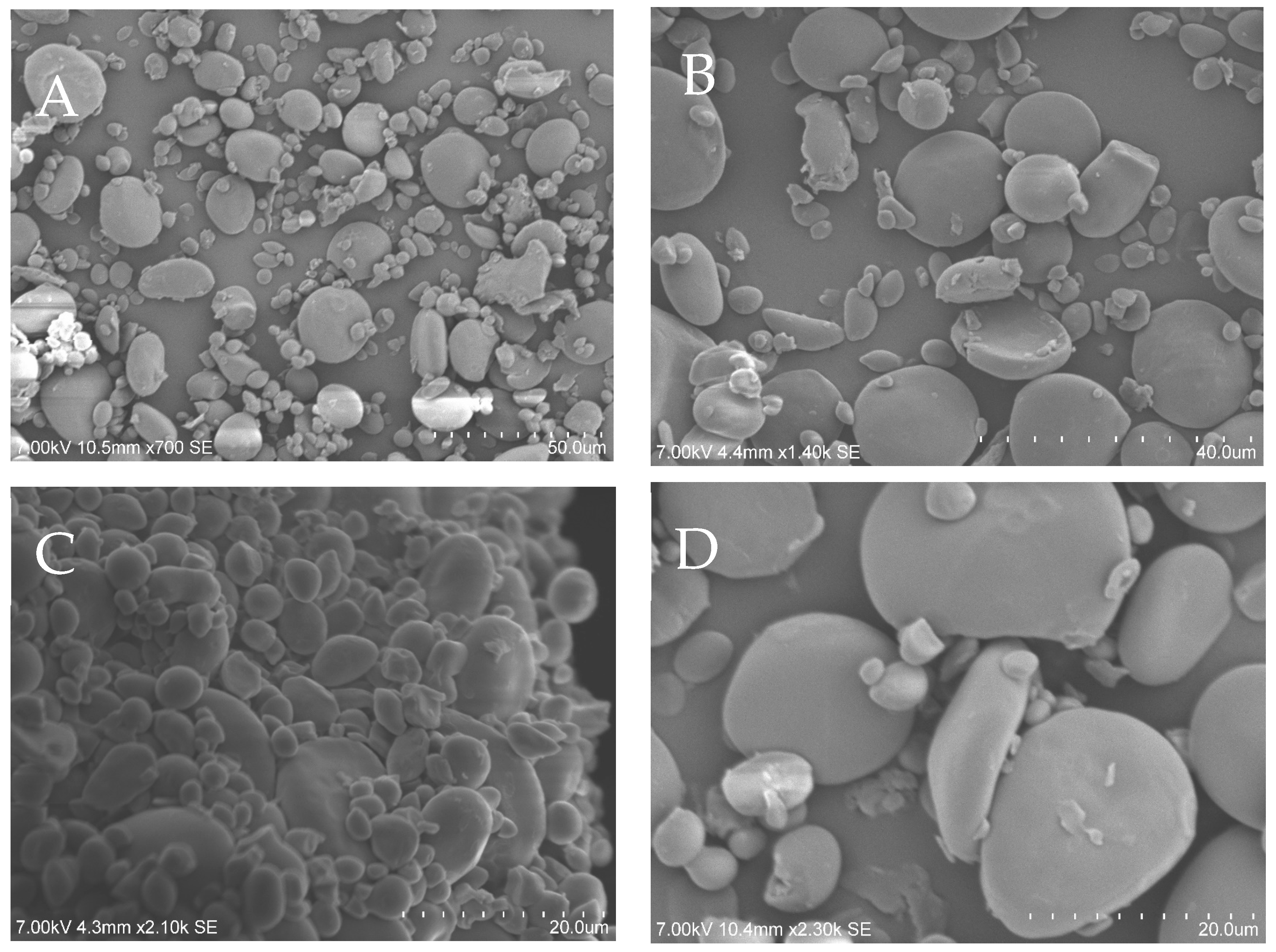

Granule Morphology

Particle Size Distribution

Thermal Properties

Pasting Properties

- V—viscosity during processing;

- Vpeak—peak viscosity;

- T—processing time parameter;

- R—the time that gives rise to 50% of peak viscosity;

- s—starch coefficient.

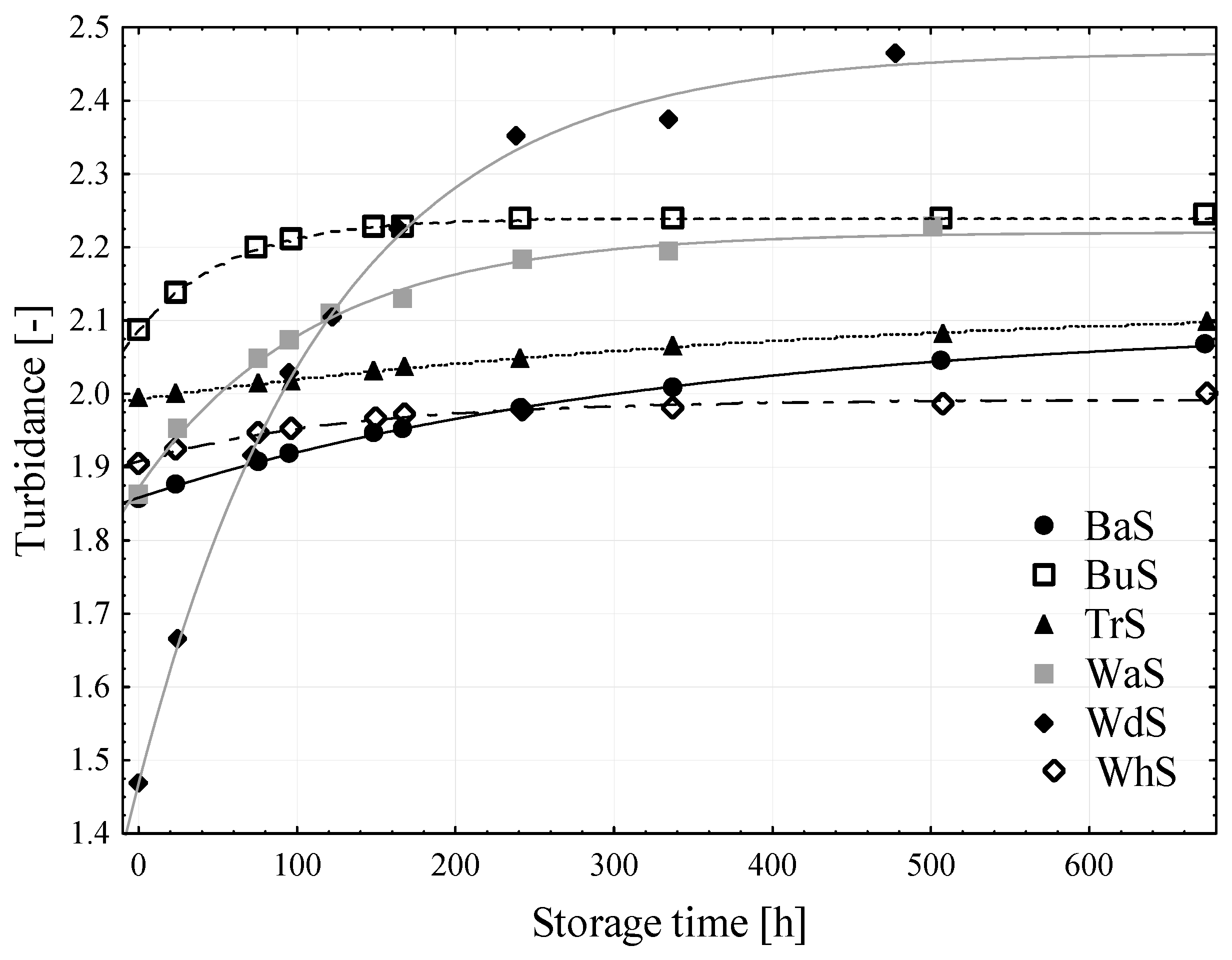

Retrogradation

- t—time;

- ΔA0—turbidance at zero time;

- ΔA∞—turbidance at ∞ time;

- K—rate constant;

- n—equation exponent (n = 1).

2.2.3. Statistical Evaluation of Results

3. Results and Discussion

3.1. Chemical Composition

3.2. Color of Starches

3.3. Morphology of Starch Granules

3.4. Particle Size Distribution of Starches

3.5. Thermal Properties of Starches

3.6. Pasting of Starches

3.7. Starch Retrogradation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| BaS | barley starch |

| BuS | buckwheat starch |

| TrS | tritordeum starch |

| WaS | wheat starch isolated from regular Artist variety |

| WdS | wheat starch isolated from durum Pentadur variety |

| WhS | wheat isolated from commercial wheat flour |

| WI | whiteness index |

| ΔE | difference between two colors |

| PSD | particle size distribution |

| DSC | differential scanning calorimeter |

| PT | pasting temperature; temperature at which an initial increase in viscosity was observed |

| PV | peak viscosity, maximum viscosity observed during the initial phase of the measurement |

| tPV | time to peak viscosity |

| TPV | temperature at PV |

| MV | minimum viscosity observed at the end of the high-temperature holding period |

| TV | trough viscosity; viscosity observed at the beginning of the second hold period, when the final temperature was reached |

| FV | final viscosity observed at the end of measurement |

| BD | breakdown, a decrease in viscosity during the first holding period (BD = PV − MV); BD% = (PV − MV)/PV |

| SB | setback, an increase in viscosity during cooling period (SB = TV − MV); SB% = (TV − MV)/TV |

| HPSI | hot paste stability index |

| V | viscosity during processing |

| Vpeak | peak viscosity |

| T | processing time parameter |

| R | the time that gives rise to 50% of peak viscosity |

| s | starch coefficient |

| t | time |

| ΔA0 | turbidance at zero time |

| ΔA∞ | turbidance at ∞ time |

| K | rate constant |

References

- Giordano, D.; Reyneri, A.; Locatelli, M.; Coïsson, J.D.; Blandino, M. Distribution of Bioactive Compounds in Pearled Fractions of Tritordeum. Food Chem. 2019, 301, 125228. [Google Scholar] [CrossRef] [PubMed]

- Villegas, D.; Casadesús, J.; Atienza, S.G.; Martos, V.; Maalouf, F.; Karam, F.; Aranjuelo, I.; Nogués, S. Tritordeum, Wheat and Triticale Yield Components under Multi-Local Mediterranean Drought Conditions. Field Crops Res. 2010, 116, 68–74. [Google Scholar] [CrossRef]

- Martinek, P.; Ohnoutkova, L.; Vyhnánek, T.; Bednář, J. Characteristics of Wheat-Barley Hybrids (x Tritordeum Ascherson et Graebner) under Central-European Climatic Conditions. Biul. IHAR 2003, 226/227, 87–95. [Google Scholar]

- Berski, W.; Krystyjan, M.; Buksa, K.; Zięć, G.; Gambuś, H. Chemical, Physical and Rheological Properties of Oat Flour Affected by the Isolation of Beta-Glucan Preparation. J. Cereal Sci. 2014, 60, 533–539. [Google Scholar] [CrossRef]

- Gao, J.; Kreft, I.; Chao, G.; Wang, Y.; Liu, X.; Wang, L.; Wang, P.; Gao, X.; Feng, B. Tartary Buckwheat (Fagopyrum tataricum Gaertn.) Starch, a Side Product in Functional Food Production, as a Potential Source of Retrograded Starch. Food Chem. 2016, 190, 552–558. [Google Scholar] [CrossRef] [PubMed]

- Shevkani, K.; Singh, N.; Bajaj, R.; Kaur, A. Wheat Starch Production, Structure, Functionality and Applications—A Review. Int. J. Food Sci. Technol. 2017, 52, 38–58. [Google Scholar] [CrossRef]

- Tester, R.F.; Karkalas, J.; Qi, X. Starch—Composition, Fine Structure and Architecture. J. Cereal Sci. 2004, 39, 151–165. [Google Scholar] [CrossRef]

- Cornejo-Ramírez, Y.I.; Martínez-Cruz, O.; Del Toro-Sánchez, C.L.; Wong-Corral, F.J.; Borboa-Flores, J.; Cinco-Moroyoqui, F.J. The Structural Characteristics of Starches and Their Functional Properties. CyTA—J. Food 2018, 16, 1003–1017. [Google Scholar] [CrossRef]

- Palabiyik, İ.; Toker, O.S.; Karaman, S.; Yildiz, Ö. A Modeling Approach in the Interpretation of Starch Pasting Properties. J. Cereal Sci. 2017, 74, 272–278. [Google Scholar] [CrossRef]

- Liszka-Skoczylas, M.; Berski, W.; Witczak, M.; Skoczylas, Ł.; Kowalska, I.; Smoleń, S.; Szlachcic, P.; Kozieł, M. The Influence of Hydroponic Potato Plant Cultivation on Selected Properties of Starch Isolated from Its Tubers. Molecules 2022, 27, 856. [Google Scholar] [CrossRef]

- ISO EN ISO 3946:2000; Starches and Derived Products—Determination of Total Phosphorus Content—Spectrophotometric Method 2000. ISO: Geneva, Switzerland, 2000.

- Berski, W.; Ziobro, R.; Witczak, M.; Gambuś, H. The Retrogradation Kinetics of Starches of Different Botanical Origin in the Presence of Glucose Syrup. Int. J. Biol. Macromol. 2018, 114, 1288–1294. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Li, C.; Copeland, L.; Niu, Q.; Wang, S. Starch Retrogradation: A Comprehensive Review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 568–585. [Google Scholar] [CrossRef]

- Kurdziel, M.; Łabanowska, M.; Pietrzyk, S.; Sobolewska-Zielińska, J.; Michalec, M. Changes in the Physicochemical Properties of Barley and Oat Starches upon the Use of Environmentally Friendly Oxidation Methods. Carbohydr. Polym. 2019, 210, 339–349. [Google Scholar] [CrossRef] [PubMed]

- Punia, S. Barley Starch: Structure, Properties and in Vitro Digestibility—A Review. Int. J. Biol. Macromol. 2020, 155, 868–875. [Google Scholar] [CrossRef] [PubMed]

- Pycia, K.; Gałkowska, D.; Juszczak, L.; Fortuna, T.; Witczak, T. Physicochemical, Thermal and Rheological Properties of Starches Isolated from Malting Barley Varieties. J. Food Sci. Technol. 2015, 52, 4797–4807. [Google Scholar] [CrossRef] [PubMed]

- Zhu, F. Barley Starch: Composition, Structure, Properties, and Modifications. Compr. Rev. Food Sci. Food Saf. 2017, 16, 558–579. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Lin, R.; Corke, H. Physicochemical Properties of Common and Tartary Buckwheat Starch. Cereal Chem. 1997, 74, 79–82. [Google Scholar] [CrossRef]

- Qian, J.; Rayas-Duarte, P.; Grant, L. Partial Characterization of Buckwheat (Fagopyrum Esculentum) Starch. Cereal Chem. 1998, 75, 365–373. [Google Scholar] [CrossRef]

- Zhu, F. Buckwheat Starch: Structures, Properties, and Applications. Trends Food Sci. Technol. 2016, 49, 121–135. [Google Scholar] [CrossRef]

- Molenda, M.; Stasiak, M.; Horabik, J.; Fornal, J.; Błaszczak, W.; Ornowski, A. Microstructure and Mechanical Parameters of Five Types of Starch. Pol. J. Food Nutr. Sci. 2006, 56, 161–168. [Google Scholar]

- Lin, P.-Y.; Czuchajowska, Z. Role of Phosphorus in Viscosity, Gelatinization, and Retrogradation of Starch. Cereal Chem. 1998, 75, 705–709. [Google Scholar] [CrossRef]

- Alcázar-Alay, S.C.; Meireles, M.A.A. Physicochemical Properties, Modifications and Applications of Starches from Different Botanical Sources. Food Sci. Technol. 2015, 35, 215–236. [Google Scholar] [CrossRef]

- Franco, C.M.L.; Wong, K.-S.; Yoo, S.; Jane, J. Structural and Functional Characteristics of Selected Soft Wheat Starches. Cereal Chem. 2002, 79, 243–248. [Google Scholar] [CrossRef]

- Li, W.; Cao, F.; Fan, J.; Ouyang, S.; Luo, Q.; Zheng, J.; Zhang, G. Physically Modified Common Buckwheat Starch and Their Physicochemical and Structural Properties. Food Hydrocoll. 2014, 40, 237–244. [Google Scholar] [CrossRef]

- Qian, J.; Kuhn, M. Physical Properties of Buckwheat Starches from Various Origins. Starch—Stärke 1999, 51, 81–85. [Google Scholar] [CrossRef]

- Ratnayake, W.S.; Jackson, D.S. Chapter 5 Starch Gelatinization. In Advances in Food and Nutrition Research; Academic Press: Cambridge, MA, USA, 2008; Volume 55, pp. 221–268. [Google Scholar]

- Chiotelli, E.; Le Meste, M. Effect of Small and Large Wheat Starch Granules on Thermomechanical Behavior of Starch. Cereal Chem. 2002, 79, 286–293. [Google Scholar] [CrossRef]

- Berski, W.; Krystyjan, M.; Zięć, G.; Litwinek, D.; Gambuś, H. The Influence of Starch Hydrolyzate on Physicochemical Properties of Pastes and Gels Prepared from Oat Flour and Starch. J. Cereal Sci. 2016, 70, 16–22. [Google Scholar] [CrossRef]

- Kumar, R.; Khatkar, B.S. Thermal, Pasting and Morphological Properties of Starch Granules of Wheat (Triticum aestivum L.) Varieties. J. Food Sci. Technol. 2017, 54, 2403–2410. [Google Scholar] [CrossRef] [PubMed]

- Berski, W.; Ziobro, R. Pasting and Gel Characteristics of Normal and Waxy Maize Starch in Glucose Syrup Solutions. J. Cereal Sci. 2018, 79, 253–258. [Google Scholar] [CrossRef]

- Karakelle, B.; Kian-Pour, N.; Toker, O.S.; Palabiyik, I. Effect of Process Conditions and Amylose/Amylopectin Ratio on the Pasting Behavior of Maize Starch: A Modeling Approach. J. Cereal Sci. 2020, 94, 102998. [Google Scholar] [CrossRef]

| Sample | Chemical Composition [%] | ||||

|---|---|---|---|---|---|

| Protein | Lipid | AAM | Ash | P | |

| BaS | 1.01 ± 0.01 d | 0.74 ± 0.01 d | 19.2 ± 0.03 b | 0.10 ± 0.00 a | 0.025 ± 0.001 a |

| BuS | 1.30 ± 0.01 e | 0.62 ± 0.04 c | 22.4 ± 0.01 e | 0.41 ± 0.00 e | 0.066 ± 0.001 d |

| TrS | 1.55 ± 0.01 f | 0.91 ± 0.03 e | 18.7 ± 0.02 a | 0.35 ± 0.00 d | 0.063 ± 0.001 d |

| WaS | 0.68 ± 0.02 c | 0.36 ± 0.03 b | 20.5 ± 0.1 c | 0.26 ± 0.01 c | 0.047 ± 0.001 b |

| WdS | 0.51 ± 0.03 b | 0.41 ± 0.03 b | 27.3 ± 0.12 f | 0.29 ± 0.01 c | 0.054 ± 0.001 c |

| WhS | 0.25 ± 0.01 a | 0.21 ± 0.03 a | 20.9 ± 0.08 d | 0.22 ± 0.01 b | 0.046 ± 0.000 b |

| Sample | Color Parameters [-] | |||

|---|---|---|---|---|

| L* | a* | b* | WI | |

| BaS | 83.81 ± 0.17 a | 0.59 ± 0.02 d | 5.79 ± 0.08 e | 82.80 ± 0.19 a |

| BuS | 86.17 ± 0.03 c | 0.45 ± 0.01 c | 5.30 ± 0.04 d | 85.18 ± 0.04 b |

| TrS | 84.21 ± 0.05 b | 0.43 ± 0.01 c | 6.51 ± 0.03 f | 82.91 ± 0.06 a |

| WaS | 87.37 ± 0.00 d | 0.56 ± 0.01 d | 1.94 ± 0.02 b | 87.21 ± 0.01 c |

| WdS | 88.09 ± 0.95 e | 0.15 ± 0.13 b | 0.96 ± 0.58 a | 88.05 ± 0.86 d |

| WhS | 90.00 ± 0.02 f | −0.11 ± 0.01 a | 2.13 ± 0.01 c | 89.77 ± 0.02 e |

| Sample | Granularity [µm] | |||

|---|---|---|---|---|

| d(10) | d(50) | d(90) | Avd | |

| BaS | 0.6 | 8.3 | 21.5 | 8.3 |

| BuS | 2.8 | 7.0 | 9.8 | 6.8 |

| TrS | 1.4 | 5.6 | 14.1 | 7.1 |

| WaS | 2.6 | 12.9 | 26.1 | 14.8 |

| WdS | 2.3 | 14.3 | 25.4 | 14.6 |

| WhS | 2.4 | 14.5 | 28.3 | 15.0 |

| To [°C] | Tp [°C] | Tc [°C] | ΔT [°C] | ΔHgel [J/g] | |

|---|---|---|---|---|---|

| BaS | 58.26 ± 0.07 b | 63.13 ± 0.14 b | 69.51 ± 0.04 a | 11.25 ± 0.11 a | 7.25 a ± 0.04 a |

| BuS | 60.85 ± 0.24 c | 67.78 ± 0.00 c | 76.18 ± 0.3 b | 15.33 ± 0.06 b | 9.21 b ± 0.25 b |

| TrS | 55.33 ± 0.04 a | 60.75 ± 0.27 a | 67.65 ± 0.17 a | 12.33 ± 0.13 a | 7.18 a ± 0.01 a |

| WdS | 56.13 ± 0.68 a | 61.58 ± 0.30 a | 67.72 ± 0.43 a | 11.59 ± 0.25 a | 8.71 b ± 0.09 b |

| Sample | PT [°C] | tPV [sec.] | PV [BU] | PVT [°C] | MV [BU] | TV [BU] | FV [BU] | BD [BU] | SB [BU] | BD% [%] | SB% [%] | HPSI [%] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BaS | 82.1 ± 1.4 bc | 820.0 ± 7.1 d | 61.0 ± 0 c | 92.9 ± 0.8 bc | 44.5 ± 0.7 b | 101.0 ± 2.1 c | 82.0 ± 1.4 b | 16.5 ± 0.7 b | 57.0 ± 1.4 d | 27.0 ± 1.2 bc | 56.2 ± 0.2 c | 95.6 ± 1.6 c |

| BuS | 79.0 ± 0.1 b | 677.5 ± 10.6 b | 146. ± 2.1 d | 90.2 ± 2.3 b | 126. ± 1.4 c | 218.0 ± 1.4 d | 216.0 ± 4.2 c | 20.5 ± 0.7 b | 92.0 ± 0 e | 14.0 ± 0.3 ab | 42.2 ± 0.3 a | 91.5 ± 0.1 bc |

| TrS | 84.2 ± 1.1 cd | 1147.5 ± 24.7 cd | 31.5 ± 1.4 a | 95.0 ± 0.1 c | 32.0 ± 1.4 a | 71.0 ± 1.4 ab | 56.0 ± 1.4 a | 0.0 ± 0.0 a | 39.0 ± 0.0 c | 0.0 ± 0 a | 54.9 ± 1.1 c | 96.3 ± 4.7 c |

| WaS | 87.5 ± 0.6 d | 717.5 ± 3.5 bc | 63.0 ± 2.8 c | 95.0 ± 0.6 c | 49.0 ± 1.4 b | 105.0 ± 1.4 c | 87.0 ± 2.8 b | 13.5 ± 4.9 b | 54.5 ± 0.7 d | 21.3 ± 6.9 bc | 51.9 ± 1.4 bc | 80.0 ± 5.9 ab |

| WdS | 65.9 ± 0.8 a | 520.0 ± 7.1 a | 50.0 ± 0 b | 83.5 ± 0.5 a | 36.0 ± 2.8 a | 64.5 ± 3.5 a | 65.0 ± 2.8 a | 14.0 ± 2.8 b | 28.0 ± 0 a | 28.0 ± 5.7 bc | 43.5 ± 2.4 a | 68.6 ± 4.7 a |

| WhS | 82.7 ± 0.6 a | 825.0 ± 21.2 d | 53.0 ± 0 b | 93.7 ± 0.8 bc | 36.5 ± 0.7 a | 72.5 ± 0.7 b | 60.5 ± 0.7 a | 16.5 ± 0.7 b | 36.0 ± 0 c | 31.1 ± 1.3 a | 49.7 ± 0.5 b | 95.6 ± 1.3 c |

| Sample | The Initial Phase of Pasting | Avrami Equation Parameters | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Vpeak [BU] | R [sec.] | s [-] | R2 [-] | k [1/h] | ΔA∞ [-] | ΔA0 [-] | Rn [-] | R2 | |

| BaS | 60.573 | 646.078 | 15.521 | 0.999 | 0.0030 | 2.0967 | 1.8582 | 0.2385 | 0.9994 |

| BuS | 159.699 | 601.013 | 19.977 | 0.996 | 0.0171 | 2.2395 | 2.0864 | 0.1531 | 0.9986 |

| TrS | 29.189 | 606.907 | 16.836 | 0.998 | 0.0022 | 2.1278 | 1.9927 | 0.1351 | 0.9984 |

| WaS | 62.471 | 617.609 | 23.739 | 0.999 | 0.0548 | 2.2205 | 2.6696 | 0.0804 | 0.9917 |

| WdS | 86.457 | 496.846 | 3.607 | 0.984 | 0.0084 | 2.4667 | 1.9686 | 0.9981 | 0.9979 |

| WhS | 53.556 | 608.117 | 10.463 | 0.997 | 0.0075 | 1.9919 | 1.9078 | 0.0841 | 0.9833 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berski, W.; Zdaniewicz, M.; Sabat, R.; Wywrocka-Gurgul, A. Technological Properties of Tritordeum Starch. Appl. Sci. 2024, 14, 4999. https://doi.org/10.3390/app14124999

Berski W, Zdaniewicz M, Sabat R, Wywrocka-Gurgul A. Technological Properties of Tritordeum Starch. Applied Sciences. 2024; 14(12):4999. https://doi.org/10.3390/app14124999

Chicago/Turabian StyleBerski, Wiktor, Marek Zdaniewicz, Renata Sabat, and Anna Wywrocka-Gurgul. 2024. "Technological Properties of Tritordeum Starch" Applied Sciences 14, no. 12: 4999. https://doi.org/10.3390/app14124999