Simulation Analysis of Cyclone Separator for Separation of Cenospheres

Abstract

:1. Introduction

2. Methods

2.1. Basic Equation

- : Density of the fluid.

- : The vector of velocity, usually expressed as = (u,v,w), where u, v, and aw are the velocity components of the fluid in the x, y, and z directions, respectively.

- : Time.

- : Scatter of the product of the velocity vector and the density .

- : Fluid pressure.

- : Dynamic viscosity of a fluid, related to the viscosity of the fluid.

- : Vector of an external force acting on the fluid, e.g., gravity.

- : Density of the fluid.

- : Turbulent dissipation rate, which represents the rate of turbulent kinetic energy dissipation per unit mass of fluid.

- : Time.

- : The velocity vector of the fluid.

- : Turbulent kinetic energy generated by the mean velocity gradient.

- : Constants in the turbulent dissipation rate equation.

- : The molecular viscosity of a fluid.

- : Turbulent viscosity.

- : Turbulent Prandtl number for turbulent kinetic energy.

- : Turbulent Prandtl number for turbulent dissipation rate.

- and : Model constant.

- : User-defined source item.

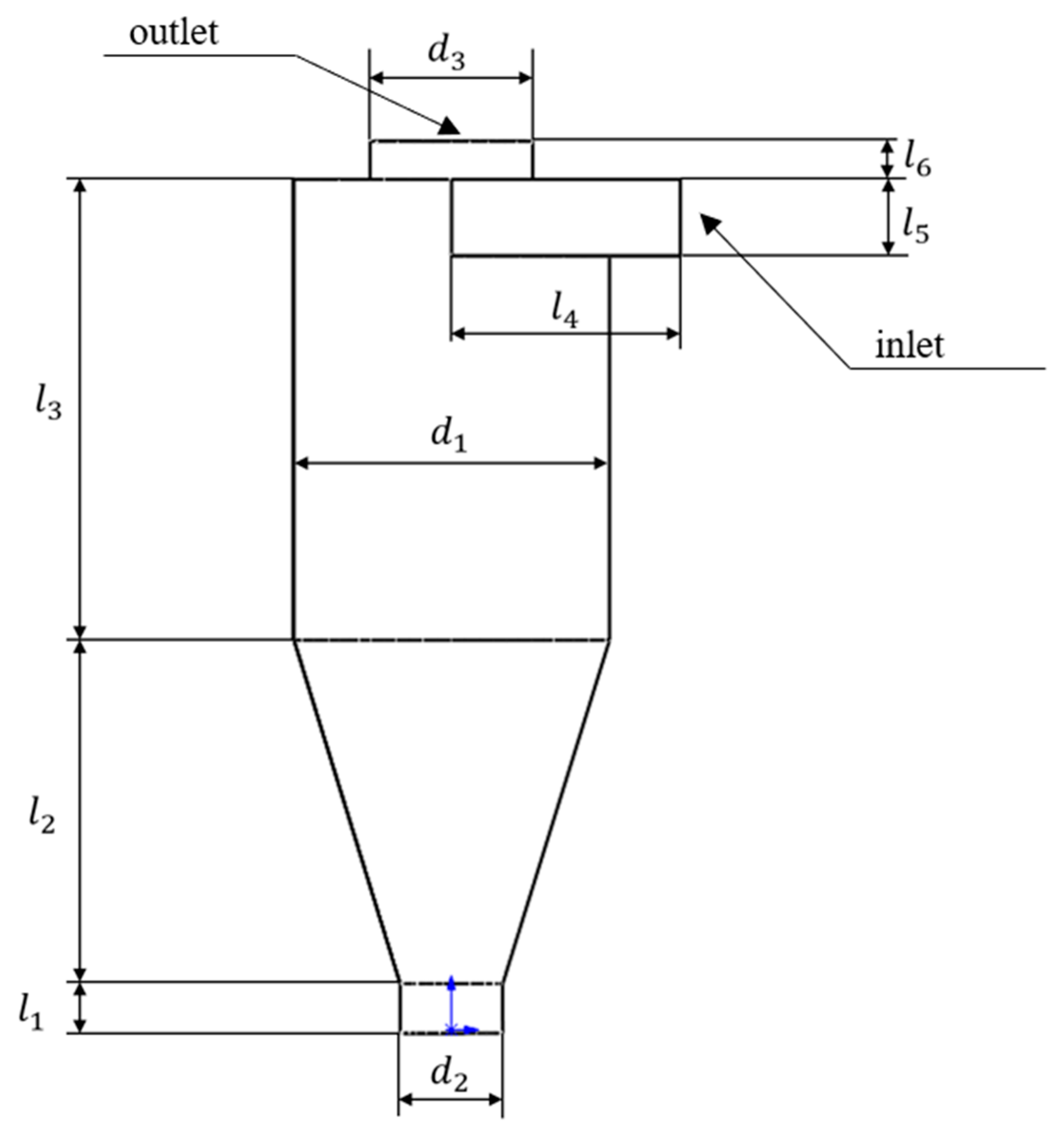

2.2. Physical Modeling and Meshing

2.3. Numerical Modeling and Boundary Conditions

3. Results and Discussion

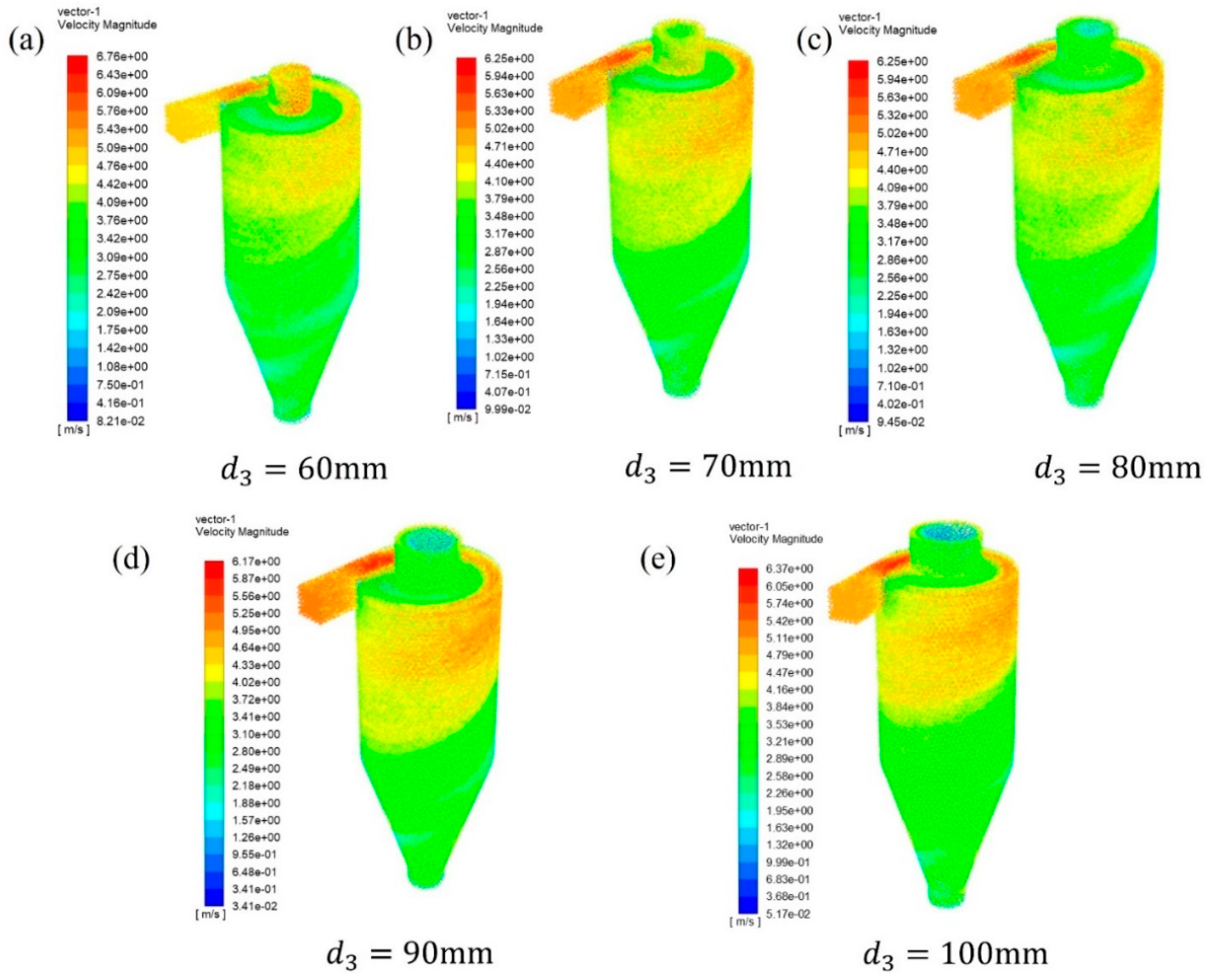

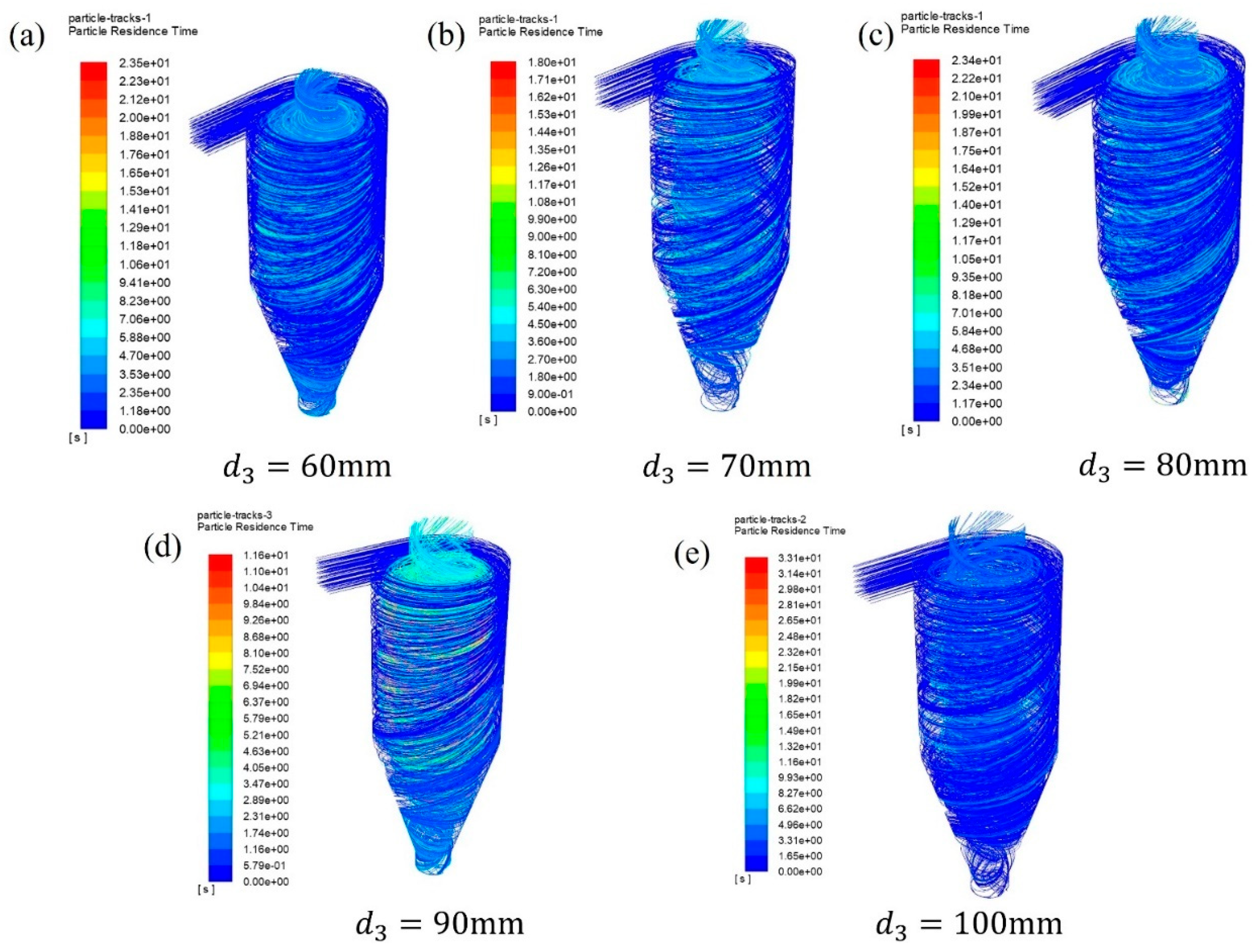

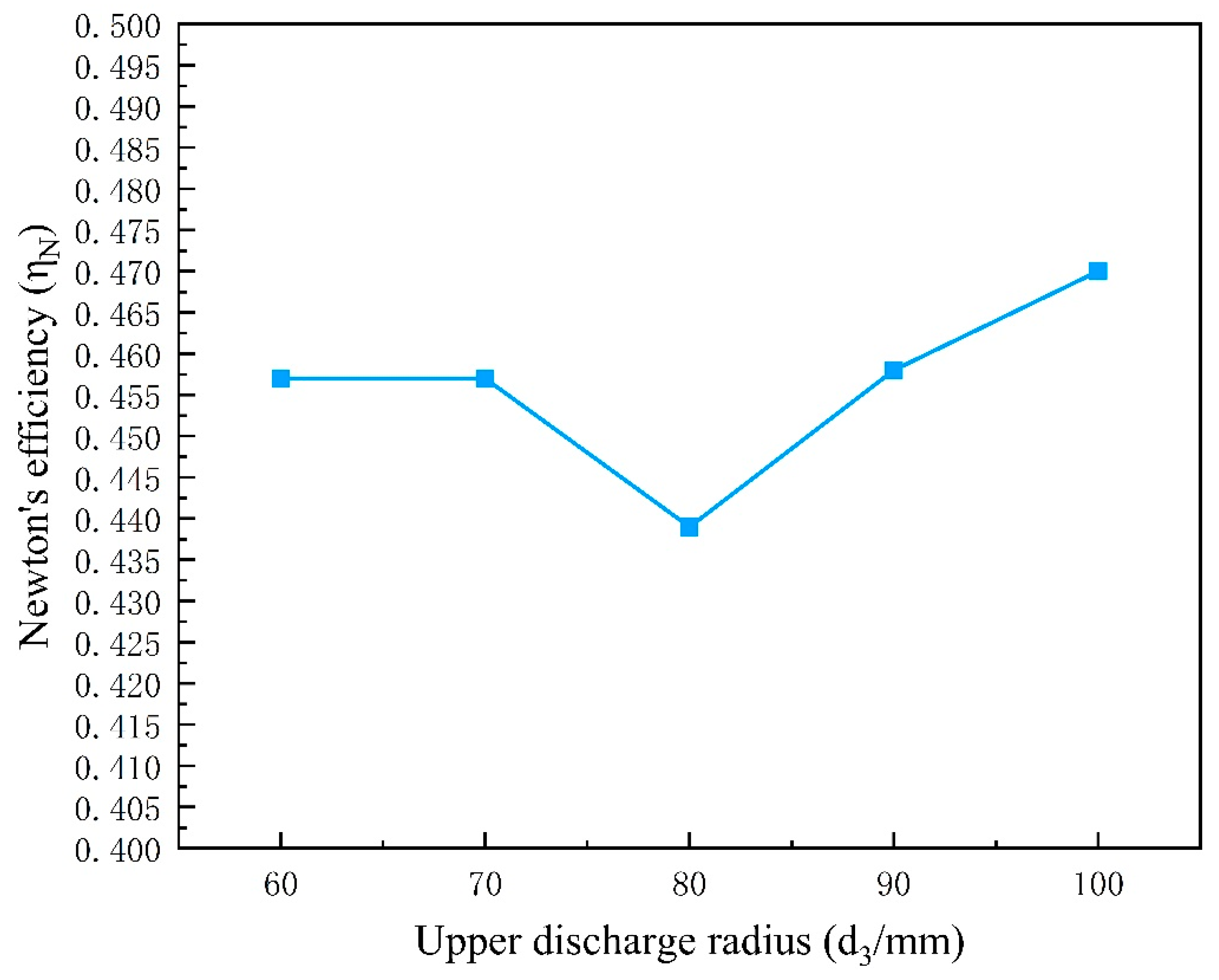

3.1. Influence of Upper Discharge Opening Radius Size on Separation Performance

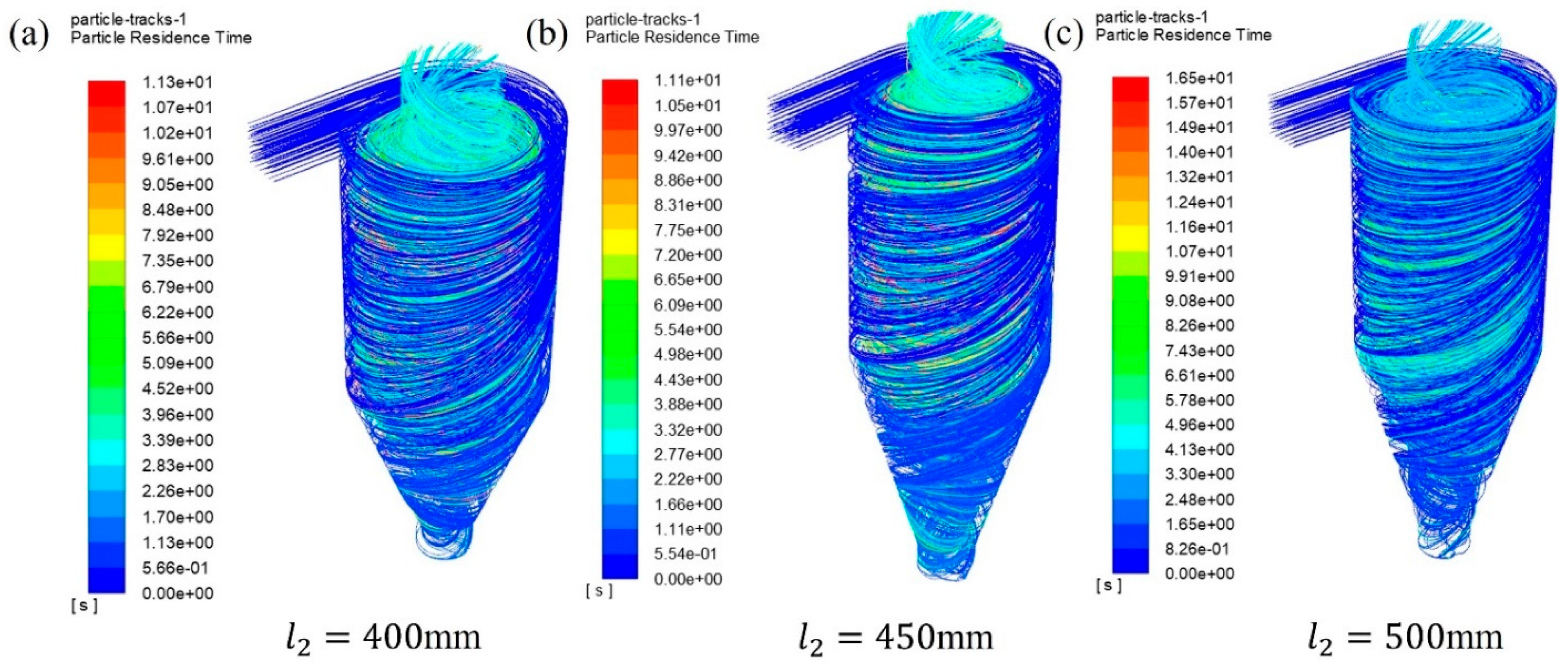

3.2. Effect of Different Sloping Wall Heights on Separation Performance

3.3. Effect of Different Incidence Velocities on Separation Performance

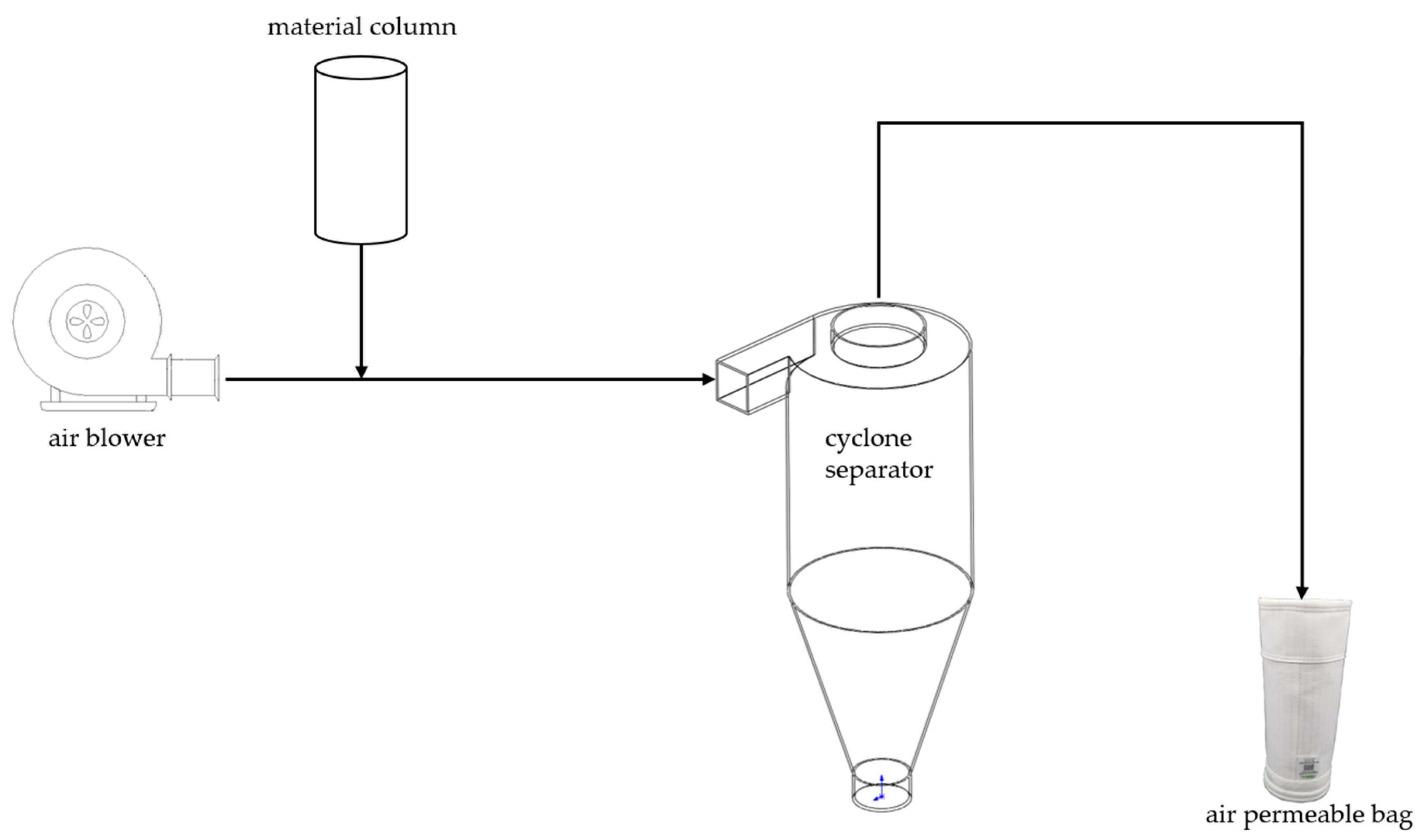

4. Experimental Part

4.1. Experimental Program

4.2. Experimental Procedure

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ranjbar, N.; Kuenzel, C. Cenospheres: A review. Fuel 2017, 207, 1–12. [Google Scholar] [CrossRef]

- Kolay, P.K.; Bhusal, S. Recovery of hollow spherical particles with two different densities from coal fly ash and their characterization. Fuel 2014, 117, 118–124. [Google Scholar] [CrossRef]

- Mathapati, M.; Amate, K.; Prasad, C.D.; Jayavardhana, M.L.; Raju, T.H. A review on fly ash utilization. Mater. Today Proc. 2022, 50, 1535–1540. [Google Scholar] [CrossRef]

- Acar, I.; Atalay, M.U. Characterization of sintered class F fly ashes. Fuel 2013, 106, 195–203. [Google Scholar] [CrossRef]

- Dewan, S. Ash Flood in Tennessee Is Found to Be Larger Than Initial Estimates. New York Times, 26 December 2008; p. 10. [Google Scholar]

- Blissett, R.S.; Rowson, N.A. A review of the multi-component utilisation of coal fly ash. Fuel 2012, 97, 1–23. [Google Scholar] [CrossRef]

- Ngu, L.-n.; Wu, H.; Zhang, D.-k. Characterization of Ash Cenospheres in Fly Ash from Australian Power Stations. Energy & Fuels 2008, 21, 3437–3445. [Google Scholar] [CrossRef]

- Arizmendi-Morquecho, A.; Chavez-Valdez, A.; Vargas, G. Ultra-low thermal conductivity thermal barrier coatings from recycled fly-ash cenospheres. Acta Mater. 2011, 59, 2556–2562. [Google Scholar] [CrossRef]

- Yao, Z.T.; Ji, X.S.; Sarker, P.K.; Tang, J.H.; Ge, L.Q.; Xia, M.S.; Xi, Y.Q. A comprehensive review on the applications of coal fly ash. Earth-Sci. Rev. 2015, 141, 105–121. [Google Scholar] [CrossRef]

- Quijorna, N.; Miguel, G.S.; Andrés, A. Incorporation of Waelz Slag into Commercial Ceramic Bricks: A Practical Example of Industrial Ecology. Ind. Eng. Chem. Res. 2011, 50, 5806–5814. [Google Scholar] [CrossRef]

- Iyer, R.S.; Scott, J.A. Power station fly ash—A review of value-added utilization outside of the construction industry. Resour. Conserv. Recycl. 2001, 31, 217–228. [Google Scholar] [CrossRef]

- Yih, S.M.; Tu, C.; Kuto, S.T.; Quo, L.W. Recovery of cenospheres and application to the manufacture of insulation materials. J Chin. Inst. Chem. Eng. 1988, 19, 23–29. [Google Scholar]

- Kolay, P.K.; Singh, D.N. Physical, chemical, mineralogical, and thermal properties of cenospheres from an ash lagoon. Cem. Concr. Res. 2001, 31, 539–542. [Google Scholar] [CrossRef]

- Jha, N.; Badkul, A.; Mondal, D.P.; Das, S.; Singh, M. Sliding wear behaviour of aluminum syntactic foam: A comparison with Al–10 wt% SiC composites. Tribol. Int. 2011, 44, 220–231. [Google Scholar] [CrossRef]

- Chalivendra, V.B.; Shukla, A.; Bose, A.; Parameswaran, V. Processing and mechanical characterization of lightweight polyurethane composites. J. Mater. Sci. 2003, 38, 1631–1643. [Google Scholar] [CrossRef]

- Cardoso, R.J.; Shukla, A.; Bose, A. Effect of particle size and surface treatment on constitutive properties of polyester-cenosphere composites. J. Mater. Sci. 2002, 37, 603–613. [Google Scholar] [CrossRef]

- Parameswaran, V.; Shukla, A. Processing and characterization of a model functionally gradient material. J. Mater. Sci. 2000, 35, 21–29. [Google Scholar] [CrossRef]

- Wasekar, P.A.; Kadam, P.G.; Mhaske, S.T. Effect of Cenosphere Concentration on the Mechanical, Thermal, Rheological and Morphological Properties of Nylon 6. J. Miner. Mater. Charact. Eng. 2012, 11, 807–812. [Google Scholar] [CrossRef]

- Rohatgi, P.; Gupta, N.; Schultz, B.; Luong, D. The synthesis, compressive properties, and applications of metal matrix syntactic foams. JOM 2011, 63, 36–42. [Google Scholar] [CrossRef]

- Shunmugasamy, V.C.; Gupta, N.; Nguyen, N.Q.; Coelho, P.G. Strain rate dependence of damage evolution in syntactic foams. Mater. Sci. Eng. A 2010, 527, 6166–6177. [Google Scholar] [CrossRef]

- Ozcivici, E.S.; Raman, P. Fabrication and Characterization of Ceramic Foams Based on Silicon Carbide Matrix and Hollow Alumino-Silicate Spheres. J. Am. Ceram. Soc. 2005, 88, 3338–3345. [Google Scholar] [CrossRef]

- Lilkov, V.; Djabarov, N.; Bechev, G.; Petrov, O. Properties and hydration products of lightweight and expansive cements Part II. Cem. Concr. Res. 1999, 29, 1641–1646. [Google Scholar] [CrossRef]

- Barbare, N.; Shukla, A.; Bose, A. Uptake and loss of water in a cenosphere-concrete composite material. Cem. Concr. Res. 2003, 33, 1681–1686. [Google Scholar] [CrossRef]

- Acar, I.; Atalay, M.U. Recovery potentials of cenospheres from bituminous coal fly ashes. Fuel 2016, 180, 97–105. [Google Scholar] [CrossRef]

- Fomenko, E.V.; Anshits, N.N.; Solovyov, L.A.; Mikhaylova, O.A.; Anshits, A.G. Composition and Morphology of Fly Ash Cenospheres Produced from the Combustion of Kuznetsk Coal. Energy Fuels 2013, 27, 5440–5448. [Google Scholar] [CrossRef]

- McCarthy, G.J. Mineralogy of western (US) fly ash. Cem. Concr. Res. 1984, 14, 471–478. [Google Scholar] [CrossRef]

- Law, H.-S.; Masliyah, J.H.; MacTaggart, R.S.; Nandakumar, K. Gravity separation of bidisperse suspensions: Light and heavy particle species. Chem. Eng. Sci. 1987, 42, 1527–1538. [Google Scholar] [CrossRef]

- Yoriya, S.; Intana, T.; Tepsri, P. Separation of Cenospheres from Lignite Fly Ash Using Acetone–Water Mixture. Appl. Sci. 2019, 9, 3792. [Google Scholar] [CrossRef]

- Borm, P.J.A. Toxicity and occupational health hazards of coal fly ash (CFA). A review of data and comparison to coal mine dust. Ann. Work. Expo. Health 1997, 41, 659–676. [Google Scholar] [CrossRef]

- Shapiro, M.; Galperin, V. Air classification of solid particles: A review. Chem. Eng. Process. Process. Intensif. 2005, 44, 279–285. [Google Scholar] [CrossRef]

- Hirajima, T.; Petrus, H.T.B.M.; Oosako, Y.; Nonaka, M.; Sasaki, K.; Ando, T. Recovery of cenospheres from coal fly ash using a dry separation process: Separation estimation and potential application. Int. J. Miner. Process. 2010, 95, 18–24. [Google Scholar] [CrossRef]

- Hoffmann, A.; Stein, L.; Bradshaw, P. Gas Cyclones and Swirl Tubes: Principles, Design and Operation. Appl. Mech. Rev. 2003, 56, B28–B29. [Google Scholar] [CrossRef]

- Zhou, F.; Sun, G.; Zhang, Y.; Ci, H.; Wei, Q. Experimental and CFD study on the effects of surface roughness on cyclone performance. Sep. Purif. Technol. 2018, 193, 175–183. [Google Scholar] [CrossRef]

- Yao, Y.; Huang, Z.; Zhang, M.; Yang, H.; Lyu, J.; Wang, J. Effects of the Y-shape stud and outer insulating layer on heat dissipation and wall temperature of the hot cyclone in a circulating fluidized bed boiler. Appl. Therm. Eng. 2022, 204, 117989. [Google Scholar] [CrossRef]

- Pukkella, A.K.; Cilliers, J.J.; Hadler, K. A comprehensive review and recent advances in dry mineral classification. Miner. Eng. 2023, 201, 108208. [Google Scholar] [CrossRef]

| Model Parameters | ||

|---|---|---|

| Lower discharge tube height/mm | 60 | |

| Sloping wall height/mm | 450 | |

| Separation chamber height/mm | 600 | |

| Length of feed tube/mm | 200 | |

| Inlet height/mm | 90 | |

| Height of upper discharge opening/mm | 30 | |

| Separation chamber radius/mm | 200 | |

| Lower discharge opening radius/mm | 60 | |

| Upper discharge radius/mm | 90 | |

| Number of Grids | Separation Efficiency of Cenospheres (%) | Fly Ash Separation Efficiency (%) | Newton’s Efficiency |

|---|---|---|---|

| 24,786 | 92.86 | 47.02 | 0.457 |

| 29,120 | 93.33 | 46.11 | 0.472 |

| 42,456 | 95.76 | 47.64 | 0.4812 |

| 52,089 | 95.71 | 47.37 | 0.4834 |

| Upper Discharge Radius (mm) | Separation Efficiency of Cenospheres (%) | Fly Ash Separation Efficiency (%) | Newton’s Efficiency |

|---|---|---|---|

| 60 | 92.68 | 46.95 | 0.457 |

| 70 | 92.68 | 46.95 | 0.457 |

| 80 | 89.02 | 45.12 | 0.439 |

| 90 | 92.86 | 47.02 | 0.458 |

| 100 | 91.67 | 44.64 | 0.470 |

| Sloping Wall Height (mm) | Separation Efficiency of Cenospheres (%) | Fly Ash Separation Efficiency (%) | Newton’s Efficiency |

|---|---|---|---|

| 400 | 93.75 | 45 | 0.488 |

| 450 | 92.86 | 47.02 | 0.458 |

| 500 | 77.5 | 36.25 | 0.412 |

| Incidence Velocity (m/s) | Separation Efficiency of Cenospheres (%) | Fly Ash Separation Efficiency (%) | Newton’s Efficiency |

|---|---|---|---|

| 2.5 | 92.5 | 37.5 | 0.55 |

| 5.0 | 93.75 | 45 | 0.488 |

| 7.5 | 91.25 | 47.5 | 0.438 |

| 10.0 | 80 | 36.9 | 0.431 |

| 12.5 | 6.3 | 46.9 | −0.406 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, R.; He, P.; Yoriya, S.; Chen, N.; Wu, J.; Hu, T.; He, K.; Cai, Q. Simulation Analysis of Cyclone Separator for Separation of Cenospheres. Appl. Sci. 2024, 14, 5132. https://doi.org/10.3390/app14125132

Shen R, He P, Yoriya S, Chen N, Wu J, Hu T, He K, Cai Q. Simulation Analysis of Cyclone Separator for Separation of Cenospheres. Applied Sciences. 2024; 14(12):5132. https://doi.org/10.3390/app14125132

Chicago/Turabian StyleShen, Rui, Ping He, Sorachon Yoriya, Naichao Chen, Jiang Wu, Tianyang Hu, Kangsai He, and Qian Cai. 2024. "Simulation Analysis of Cyclone Separator for Separation of Cenospheres" Applied Sciences 14, no. 12: 5132. https://doi.org/10.3390/app14125132

APA StyleShen, R., He, P., Yoriya, S., Chen, N., Wu, J., Hu, T., He, K., & Cai, Q. (2024). Simulation Analysis of Cyclone Separator for Separation of Cenospheres. Applied Sciences, 14(12), 5132. https://doi.org/10.3390/app14125132