Analysis of the Effect of Vegetable Broth Addition to a Gelatin Pork Edible Film and Coating Method on Select Physical Properties of Freeze-Dried Coated Vegetable Bars

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Material

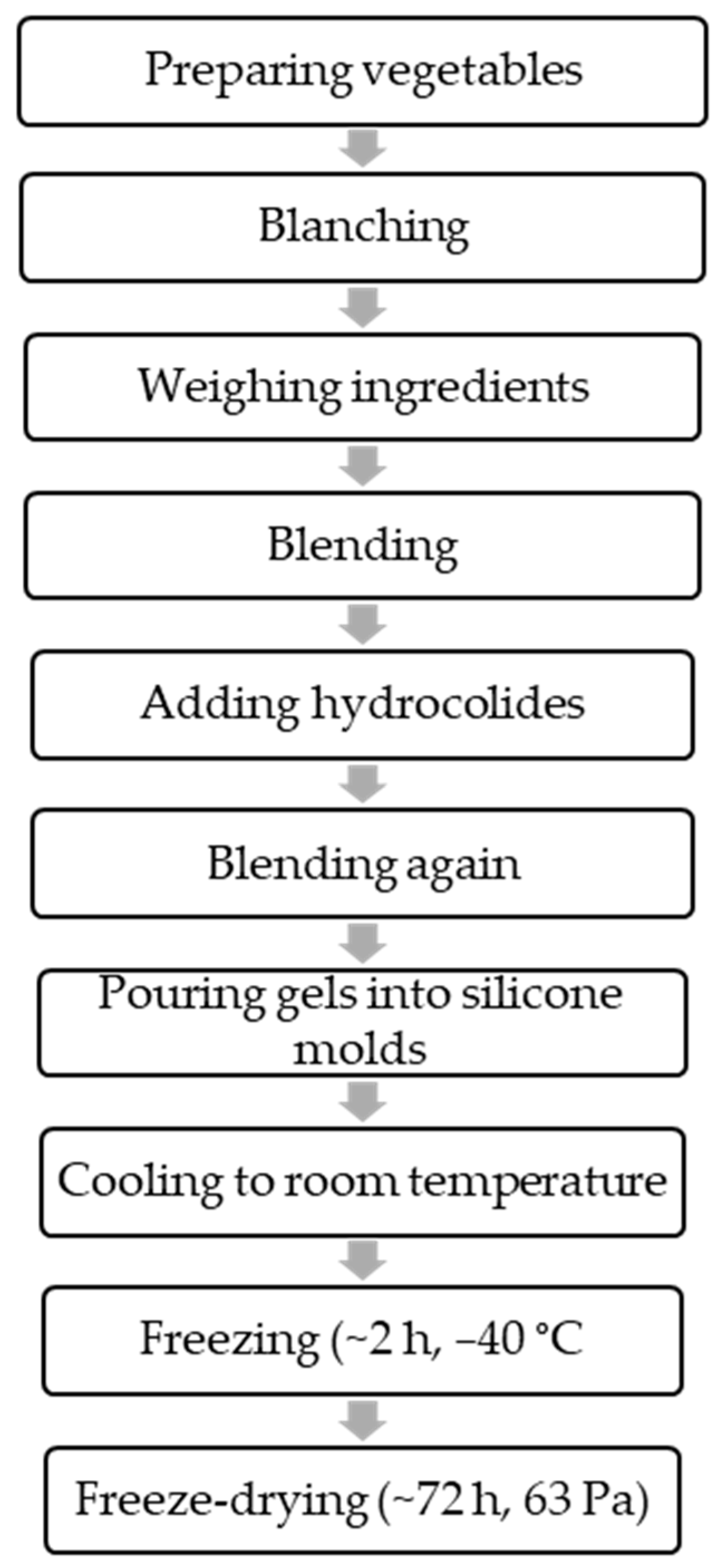

2.2. Preparation of Freeze-Dried Vegetable Bars

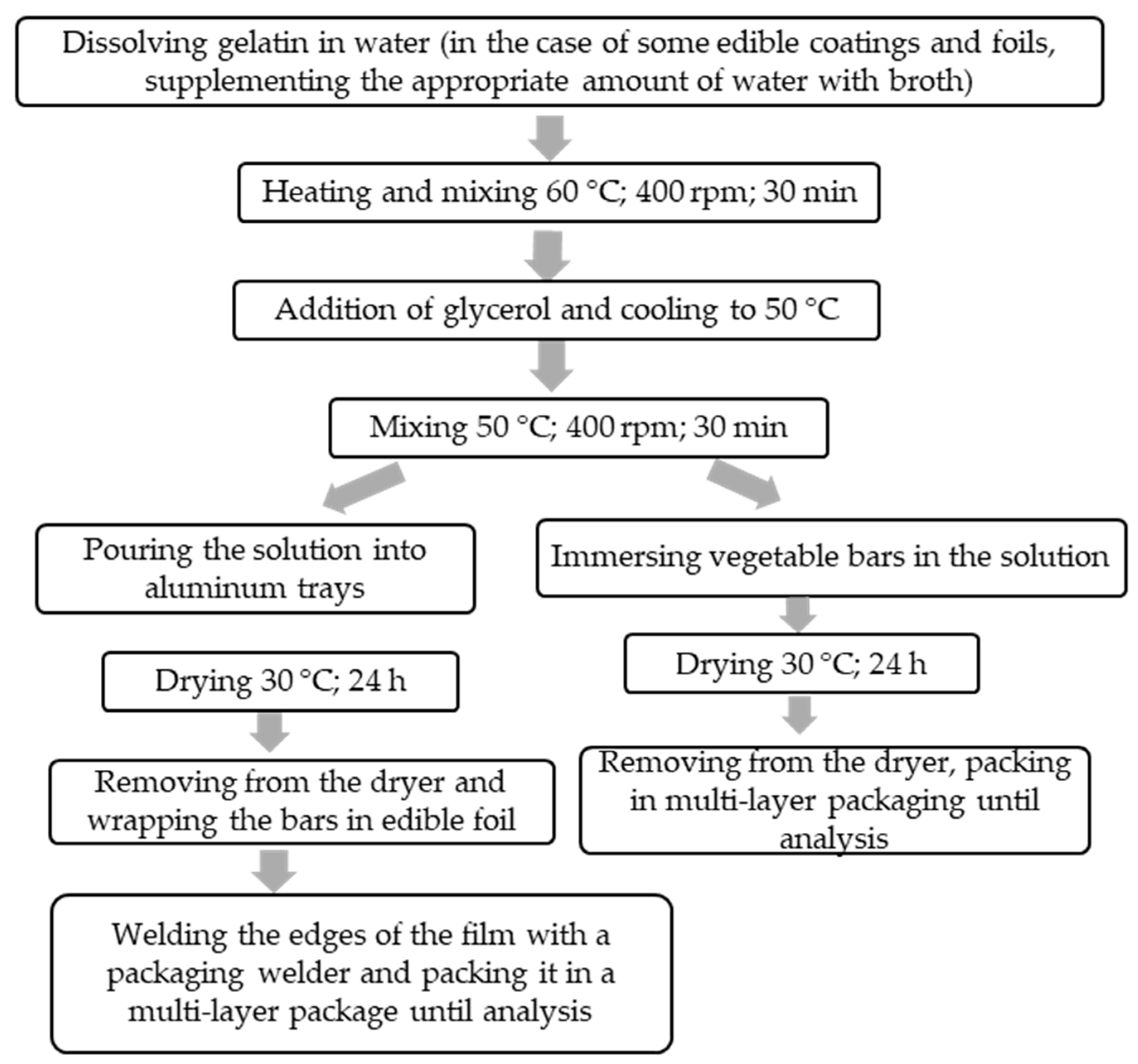

2.3. Preparation of Edible Coatings and Edible Films

2.4. Coating Methods

2.5. Analytical Methods

2.5.1. Water Activity

2.5.2. Dry Matter Content

2.5.3. Determination of Actual Density

2.5.4. Porosity

2.5.5. Microstructure

2.5.6. Statistical Methods

3. Results

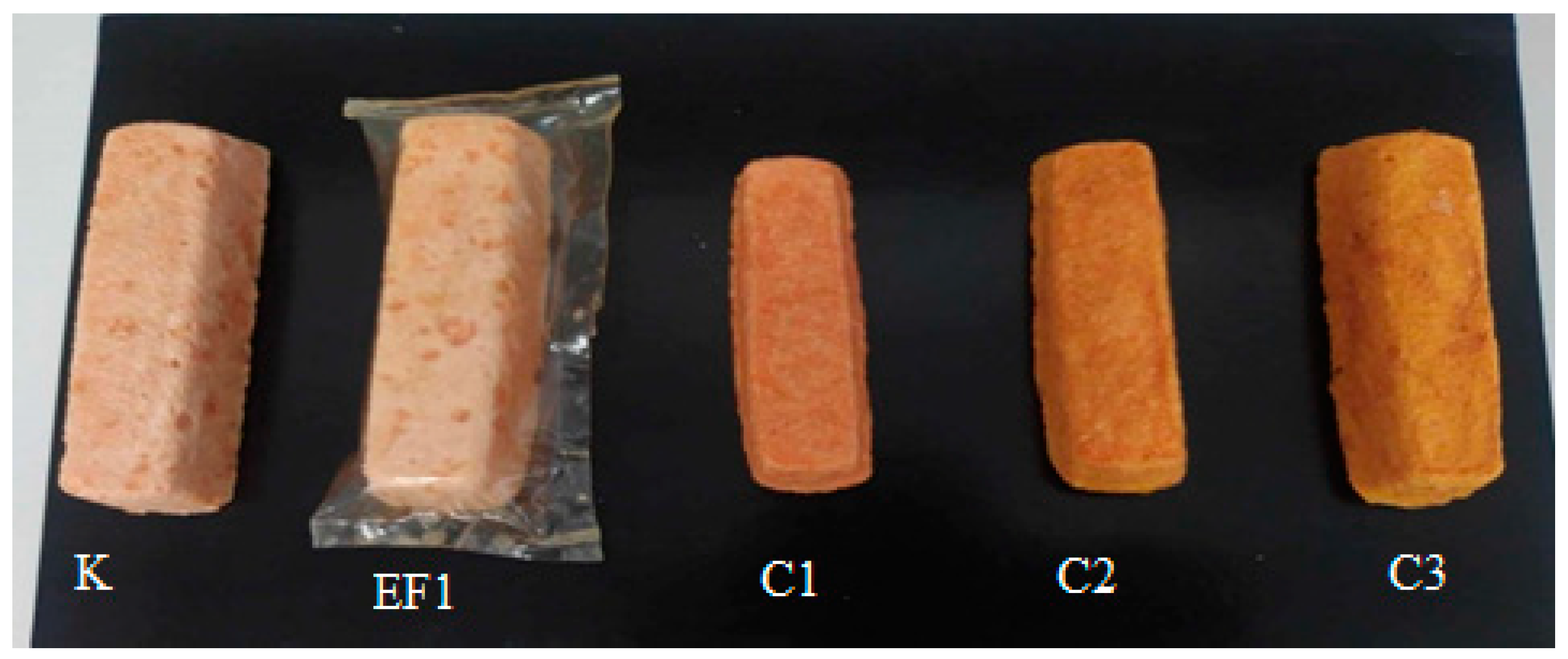

3.1. The Influence of the Coating Composition and Coating Method on Selected Properties of Freeze-Dried Vegetable Bars

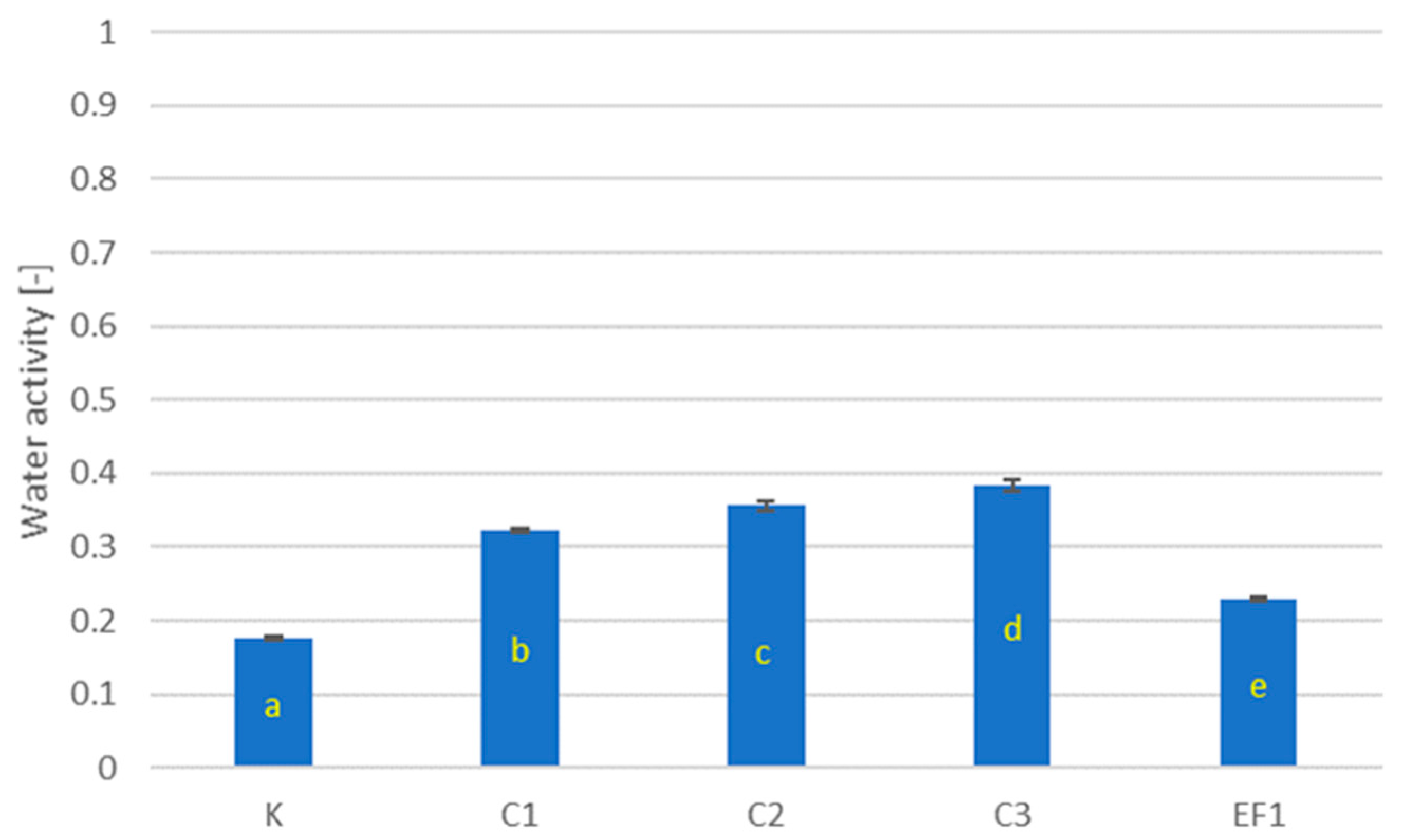

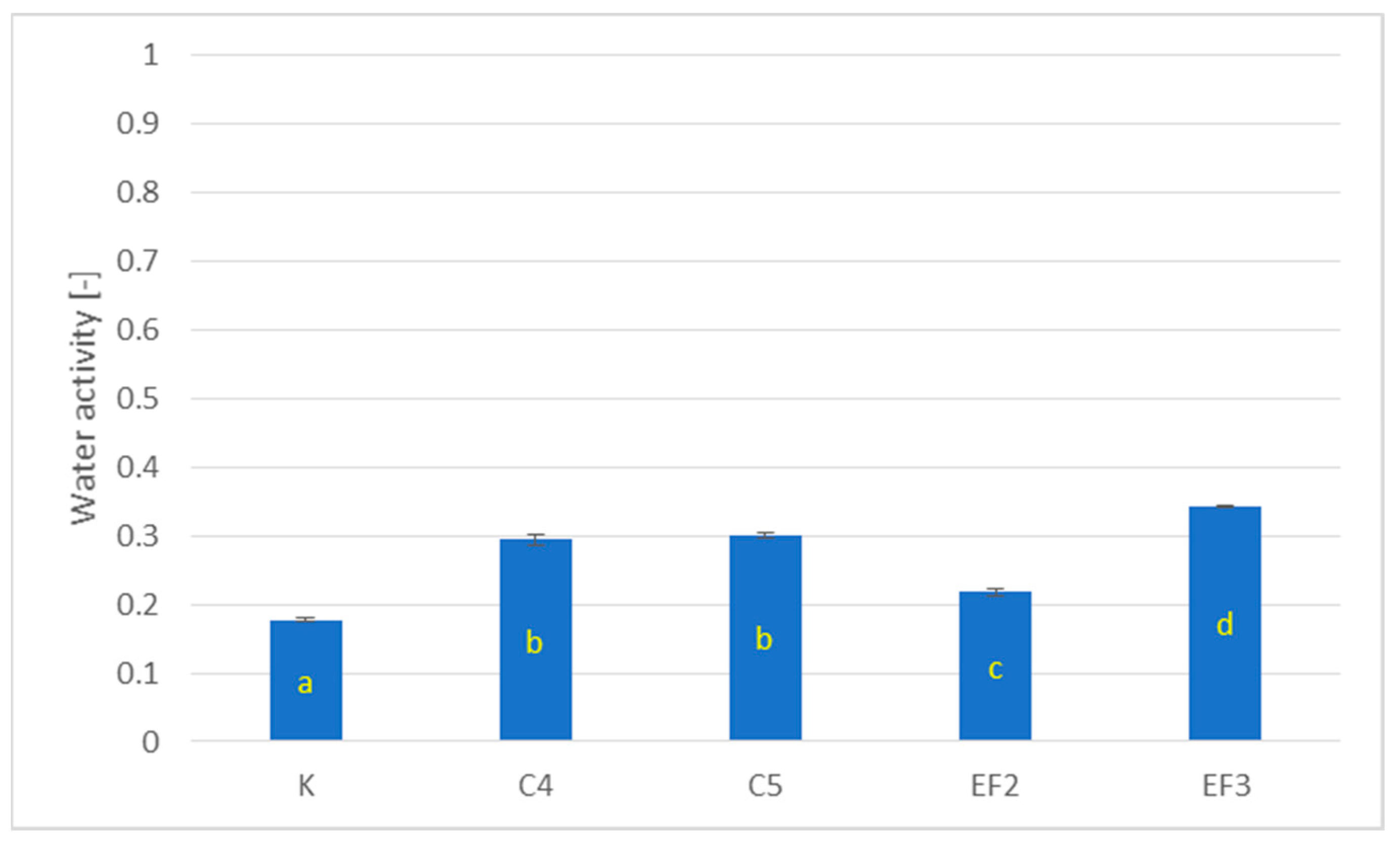

3.1.1. Water Activity

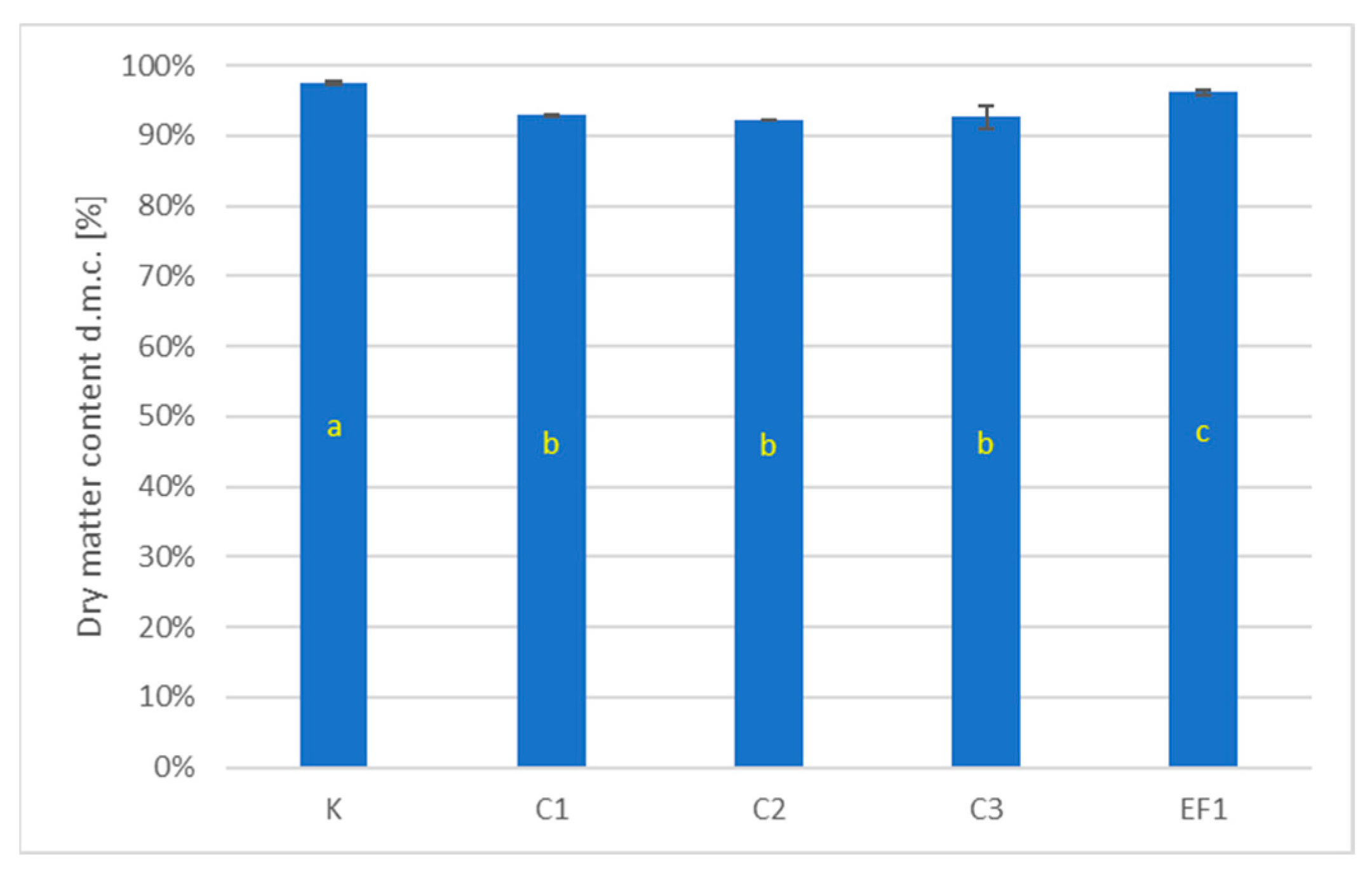

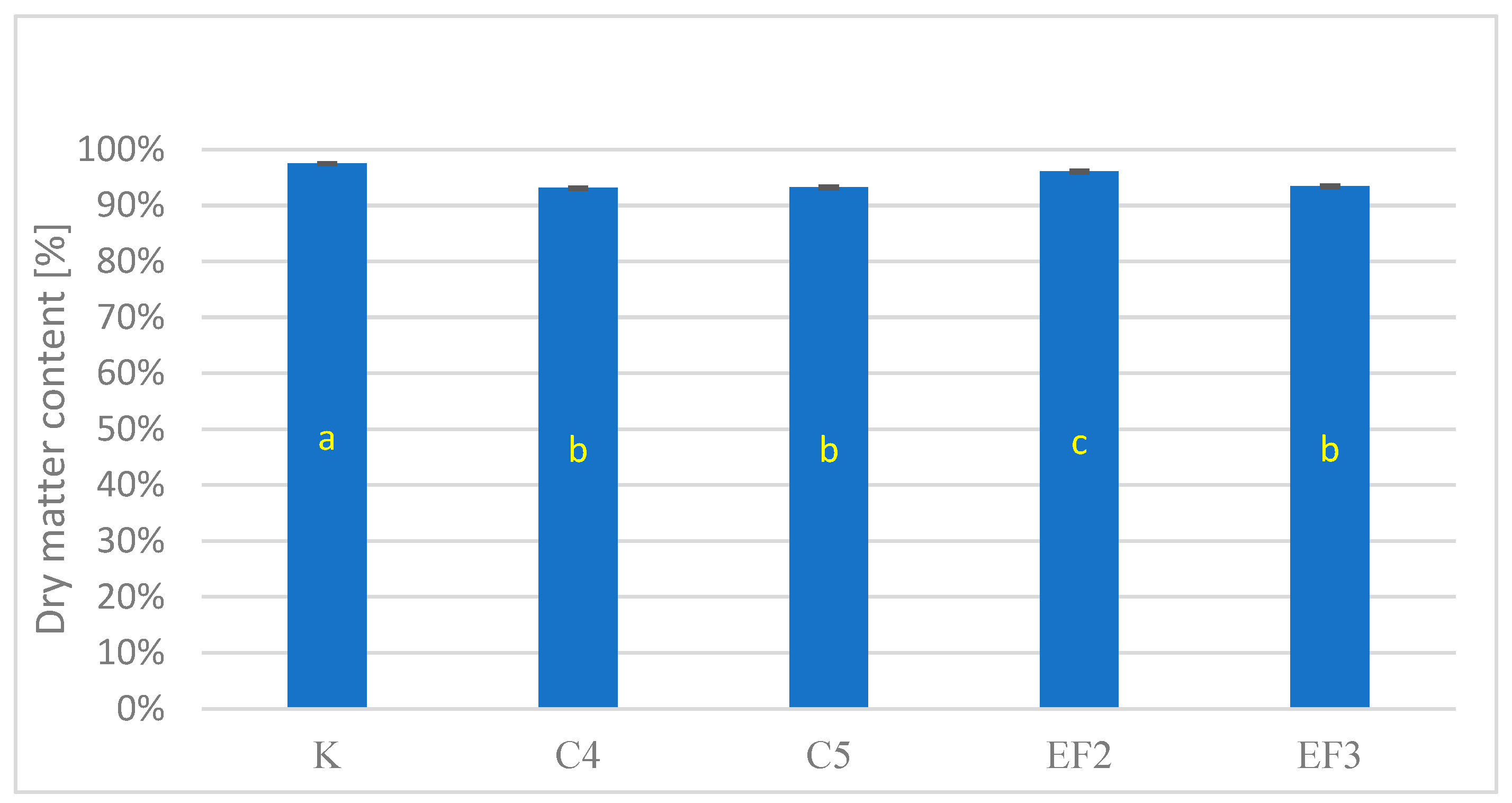

3.1.2. Dry Matter Content

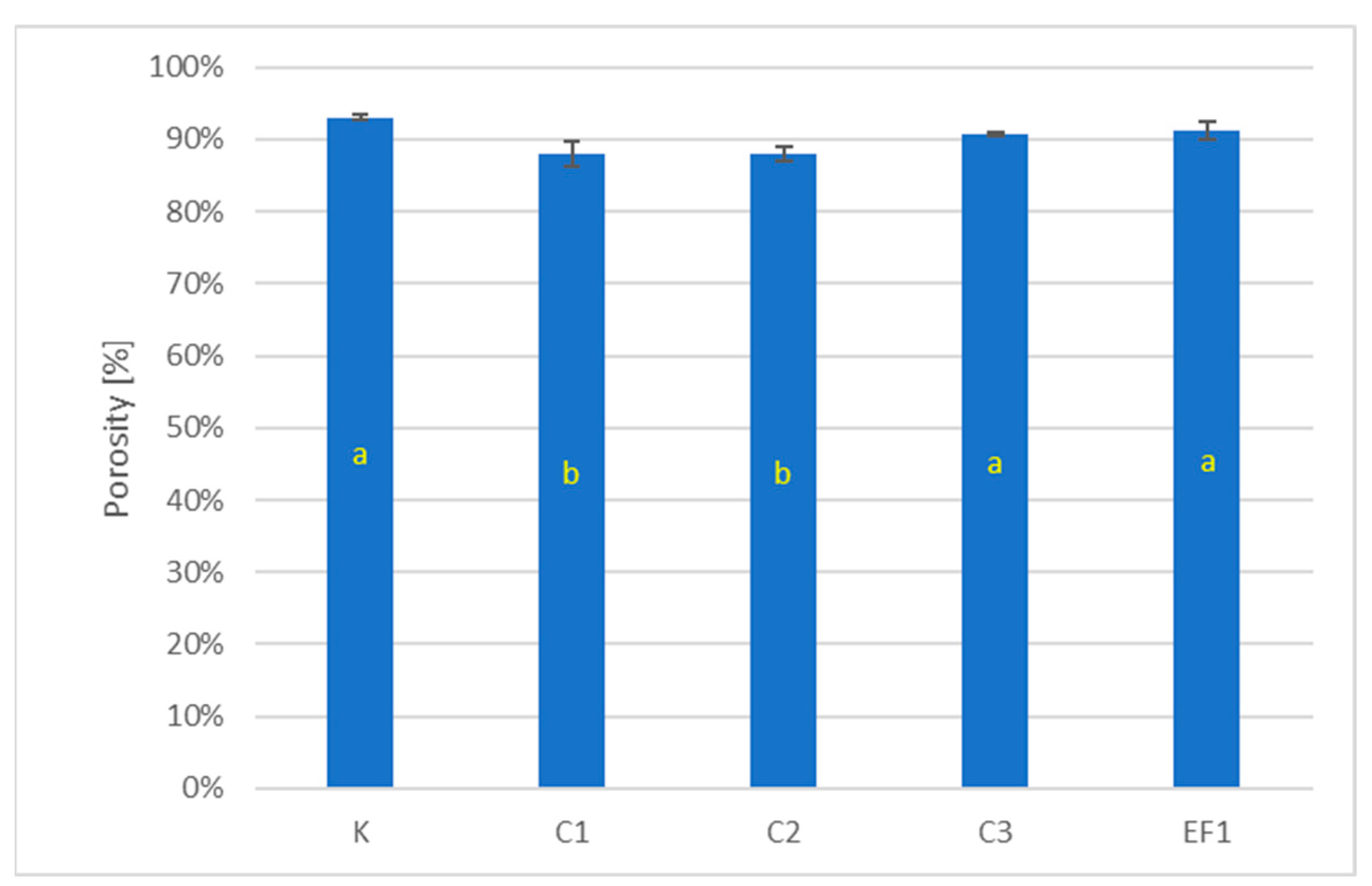

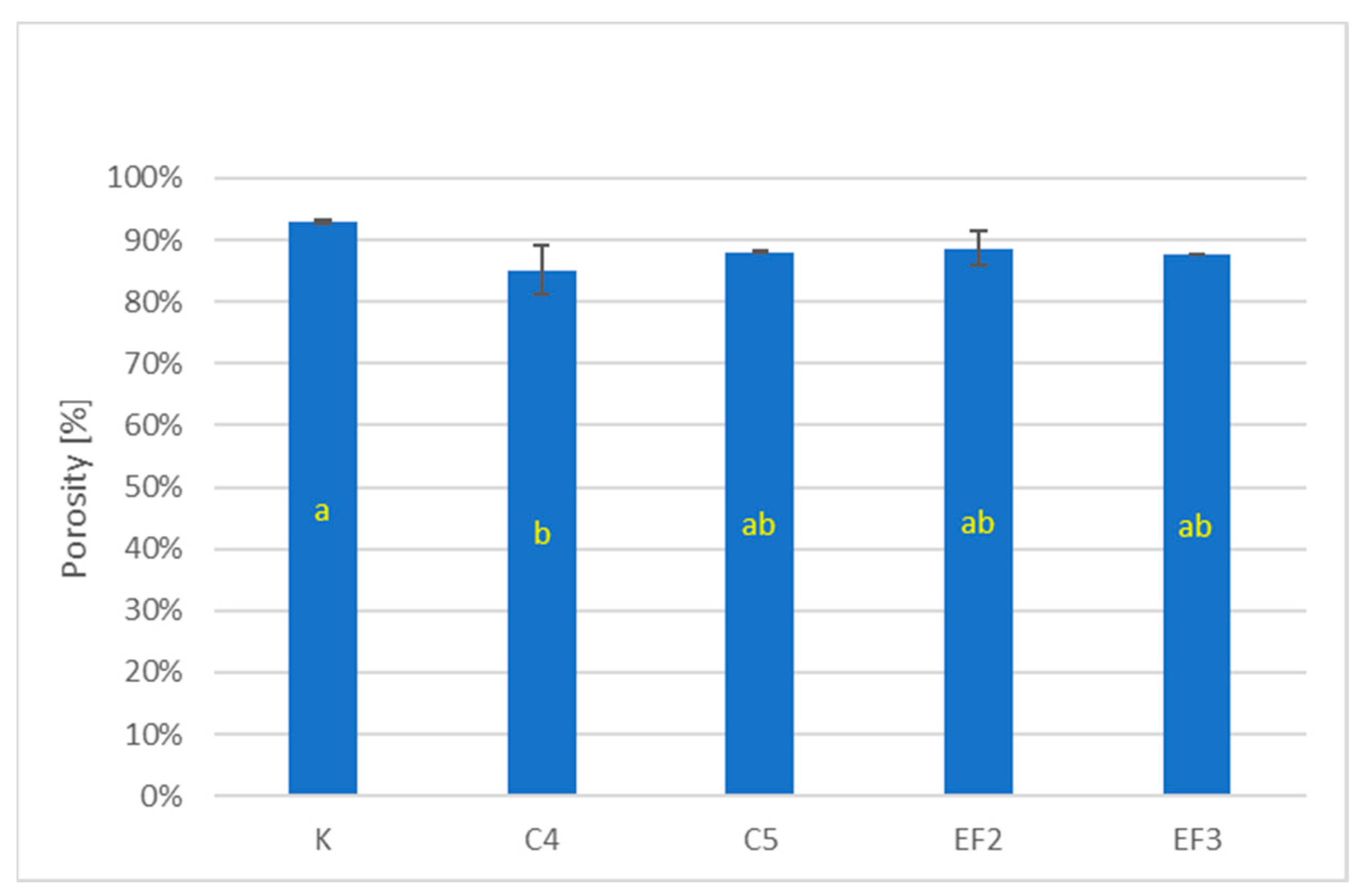

3.1.3. Porosity

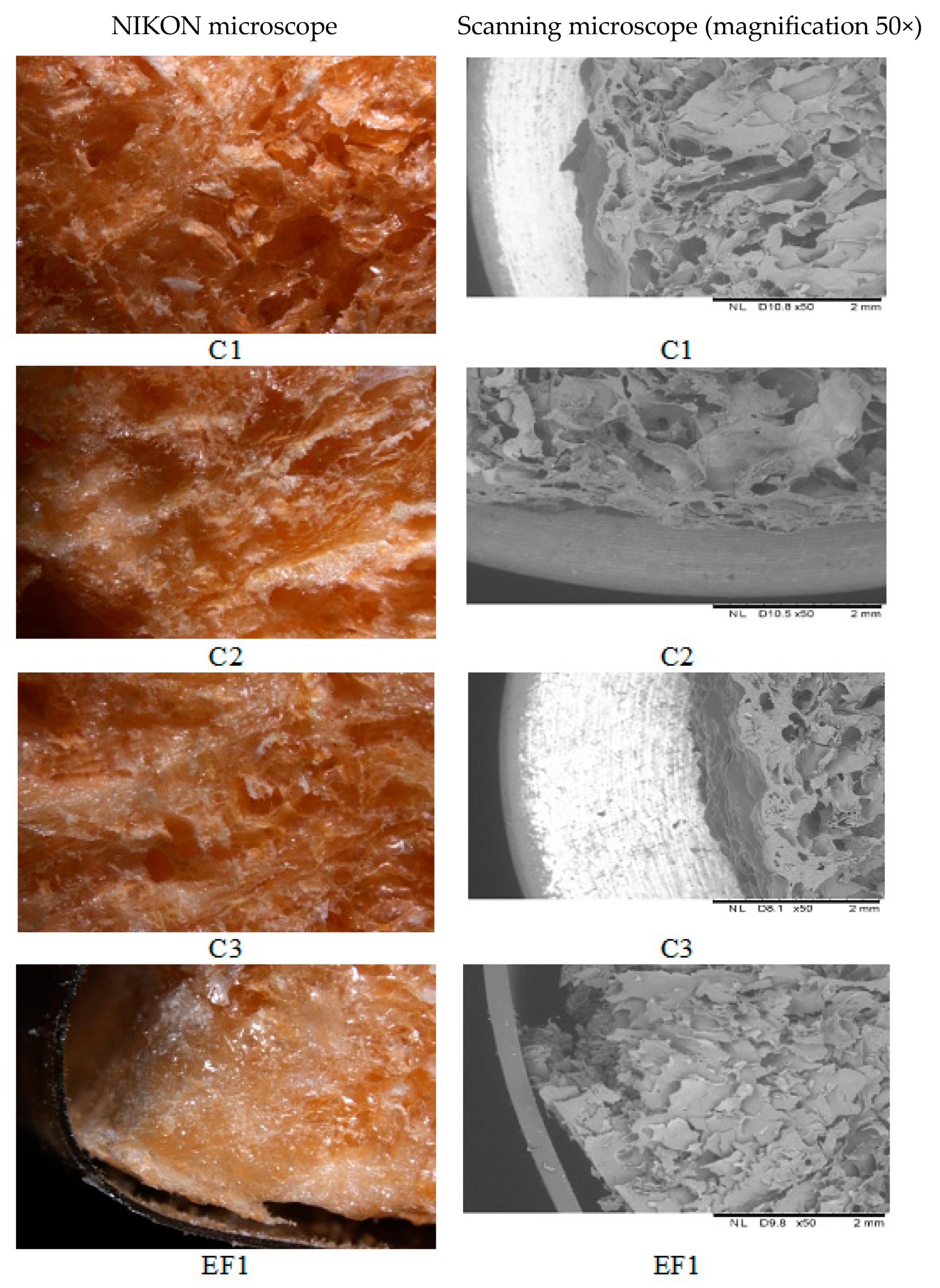

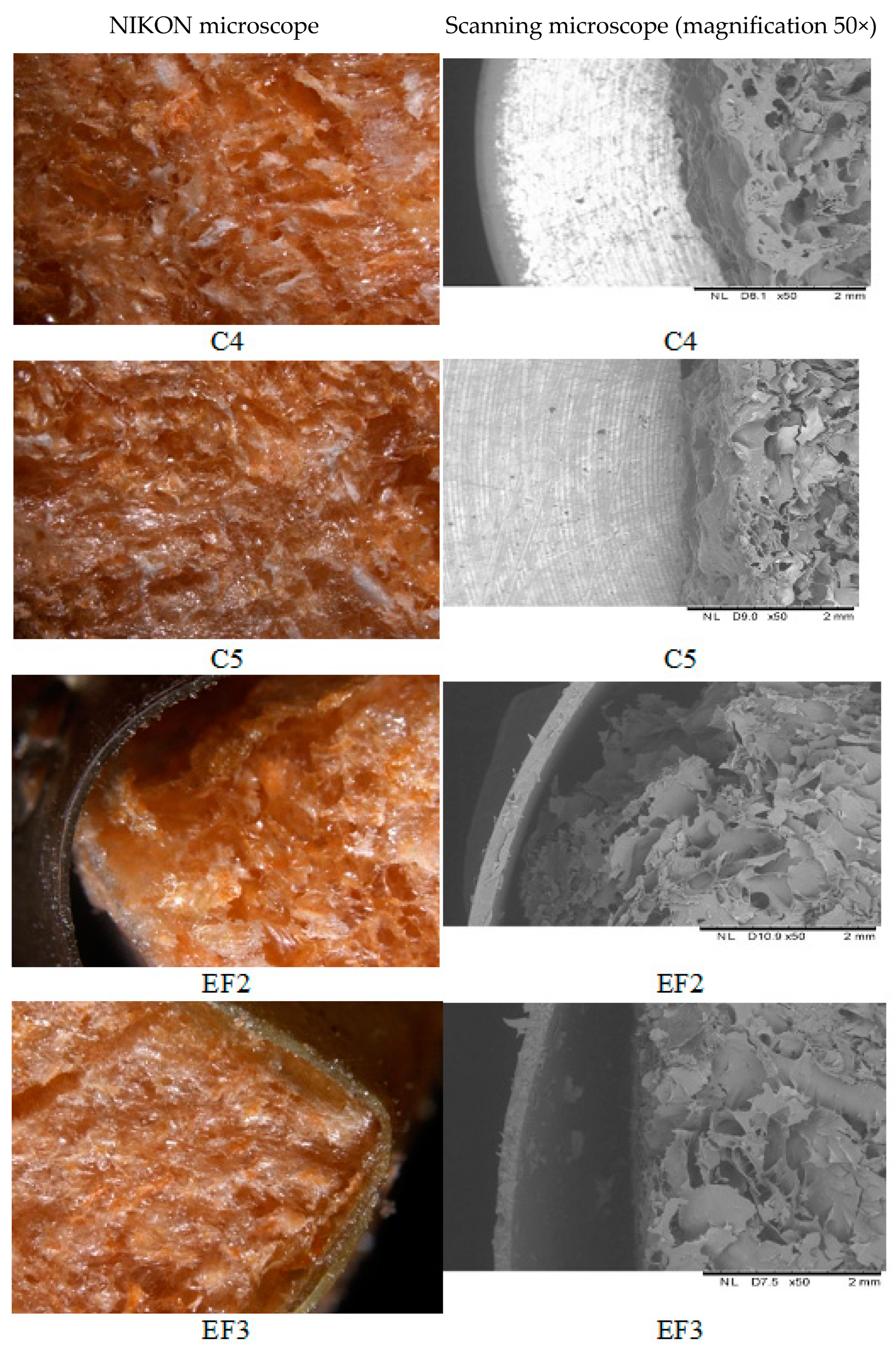

3.1.4. Structure

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aguirre-Joya, J.A.; De Leon-Zapata, M.A.; Alvarez-Perez, O.B.; Torres-León, C.; Nieto-Oropeza, D.E.; Ventura-Sobrevilla, J.M.; Aguilar, C.N. Basic and applied concepts of edible packaging for foods. In Food Packaging and Preservation; Academic Press: Cambridge, MA, USA, 2018; pp. 1–61. [Google Scholar]

- Petkoska, A.T.; Daniloski, D.; D’Cunha, N.M.; Naumovski, N.; Broach, A.T. Edible packaging: Sustainable solutions and novel trends in food packaging. Food Res. Int. 2021, 140, 109981. [Google Scholar] [CrossRef] [PubMed]

- Galus, S.; Arik Kibar, E.A.; Gniewosz, M.; Kraśniewska, K. Novel Materials in the Preparation of Edible Films and Coatings—A Review. Coatings 2020, 10, 674. [Google Scholar] [CrossRef]

- López, O.; García, M.A.; Zaritzky, N.E. Novel sources of edible films and coatings. Stewart Postharvest Rev. 2010, 3, 1–8. [Google Scholar]

- Ganiari, S.; Choulitoudi, E.; Oreopoulou, V. Edible and active films and coatings as carriers of natural antioxidants for lipid food. Trends Food Sci. Technol. 2017, 68, 70–82. [Google Scholar] [CrossRef]

- Avramescu, S.M.; Butean, C.; Popa, C.V.; Ortan, A.; Moraru, I.; Temocico, G. Edible and functionalized films/coatings—performances and perspectives. Coatings 2020, 10, 687. [Google Scholar] [CrossRef]

- Falguera, V.; Quintero, J.P.; Jiménez, A.; Muñoz, J.A.; Ibarz, A. Edible films and coatings: Structures, active functions and trends in their use. Trends Food Sci. Technol. 2011, 22, 292–303. [Google Scholar] [CrossRef]

- Suhag, R.; Kumar, N.; Petkoska, A.T.; Upadhyay, A. Film formation and deposition methods of edible coating on food products: A review. Food Res. Int. 2020, 136, 109582. [Google Scholar] [CrossRef]

- Senturk-Parreidt, T.; Schmid, M.; Müller, K. Effect of dipping and vacuum impregnation coating techniques with alginate based coating on physical quality parameters of cantaloupe melon. J. Food Sci. 2018, 83, 929–936. [Google Scholar] [CrossRef] [PubMed]

- de Moraes, J.O.; Scheibe, A.S.; Sereno, A.; Laurindo, J.B. Scale-up of the production of cassava starch based films using tape-casting. J. Food Eng. 2013, 119, 800–808. [Google Scholar] [CrossRef]

- Ogonek, A.; Lenart, A. Wpływ selektywnych powłok jadalnych na odwadnianie osmotyczne truskawek. Żywn. Nauka. Technol. Jakość. 2021, 8, 62–74. [Google Scholar]

- Hassan, M.; Hussain, D.; Kanwal, T.; Xiao, H.M.; Musharraf, S.G. Methods for detection and quantification of gelatin from different sources. Food Chem. 2023, 438, 137970. [Google Scholar] [CrossRef] [PubMed]

- Noor, N.Q.I.M.; Razali, R.S.; Ismail, N.K.; Ramli, R.A.; Razali, U.H.M.; Bahauddin, A.R.; Shaarani, S.M. Application of green technology in gelatin extraction: A review. Proceedings 2021, 9, 2227. [Google Scholar] [CrossRef]

- Gómez-Guillén, M.C.; Giménez, B.; López-Caballero, M.A.; Montero, M.P. Functional and bioactive properties of collagen and gelatin from alternative sources: A review. Food Hydrocoll. 2011, 25, 1813–1827. [Google Scholar] [CrossRef]

- Schrieber, R.; Gareis, H. Gelatine Handbook: Theory and Industrial Practice; John Wiley & Sons: Hoboken, NJ, USA, 2007; Volume 68, pp. 81–88. [Google Scholar]

- Usman, M.; Ishaq, A.; Regenstein, J.M.; Sahar, A.; Aadil, R.M.; Sameen, A.; Alam, A. Valorization of animal by-products for gelatin extraction using conventional and green technologies: A comprehensive review. Biomass Convers. Bioref. 2023, 13, 1–13. [Google Scholar] [CrossRef]

- Liu, D.; Nikoo, M.; Boran, G.; Zhou, P.; Regenstein, J.M. Collagen and gelatin. Annu. Rev. Food Sci. Technol. 2015, 6, 527–557. [Google Scholar] [CrossRef] [PubMed]

- Ciurzyńska, A.; Janowicz, M.; Karwacka, M.; Nowacka, M.; Galus, S. Development and characteristics of protein edible film derived from pork gelatin and beef broth. Polymers 2024, 16, 1009. [Google Scholar] [CrossRef] [PubMed]

- Ciurzyńska, A.; Marczak, W.; Lenart, A.; Janowicz, M. Production of innovative freeze-dried vegetable snack with hydrocolloids in terms of technological process and carbon footprint calculation. Food Hydrocoll. 2020, 108, 105993. [Google Scholar] [CrossRef]

- Ciurzyńska, A.; Lenart, A. Effect of the aerated structure on selected properties of freeze-dried hydrocolloid gels. Int. Agroph. 2016, 30, 9–17. [Google Scholar] [CrossRef]

- Isengard, H.-D. Water content, one of the most important properties of food. Food Contr. 2001, 12, 395–400. [Google Scholar] [CrossRef]

- Pałacha, Z.; Makarewicz, M. Aktywność wody wybranych grup produktów spożywczych. Postępy Technol. Przet. Spoż. 2011, 2, 24–29. [Google Scholar]

- Invichian, N. Development of Composite Film Coating for Freeze-Dried Fruit Slices. Master’s Thesis, Chulalongkorn University, Bangkok, Thailand, 2019. [Google Scholar]

- Karwacka, M.; Ciurzyńska, A.; Galus, S.; Janowicz, M. Freeze-dried snacks obtained from frozen vegetable by-products and apple pomace—Selected properties, energy consumption and carbon footprint. Innov. Food Sci. Emerg. Technol. 2022, 77, 102949. [Google Scholar] [CrossRef]

- Gronowska-Senger, A.; Drywień, M.; Hamułka, J.; Wawrzyniak, A. Oznaczenie Zawartości Wody i Suchej Masy w Wybranych Produktach Spożywczych. W: Analiza Żywności Zbiór Ćwiczeń (Red. Gronowska-Segner); Wydawnictwo SGGW: Warszawa, Poland, 2018; pp. 13–20. [Google Scholar]

- Kanarek, A. Badanie Wpływu Metody Powlekania na Właściwości Suszonych Sublimacyjnie Batonów. Praca Magisterska; Szkoła Główna Gospodarstwa Wiejskiego: Warszawa, Poland, 2023. [Google Scholar]

- Hussain, M.A.; Rahman, M.S.; Ng, C.W. Prediction of pores formation (porosity) in foods during drying: Generic models by the use of hybrid neural network. J. Food Eng. 2002, 51, 239–248. [Google Scholar] [CrossRef]

- Sundaram, J.; Durance, T.D. Water sorption and physical properties of locust bean gum–pectin–starch composite gel dried using different drying methods. Food Hydrocoll. 2008, 2, 1352–1361. [Google Scholar] [CrossRef]

- Wu, X.; Liu, Y.; Li, X.; Wen, P.; Zhang, Y.; Long, Y.; Gao, J. Preparation of aligned porous gelatin scaffolds by unidirectional freeze-drying method. Acta Biomat. 2010, 6, 1167–1177. [Google Scholar] [CrossRef] [PubMed]

| Composition of Vegetable Bars | Percentage [%] |

|---|---|

| Water | 58.4 |

| Carrot | 39.6 |

| Sodium Alginate | 1.5 |

| Salt | 0.4 |

| Calcium Lactate | 0.1 |

| Rodzaj Produktu | Broth Percentage Solution by Volume (%) | Gelatin Percentage by Mass of the Solution (%) | Glycerol Mass Percentage of the Solution (%) |

|---|---|---|---|

| Coating 1 | - | 8 | 4 |

| Coating 2 | 25 | 8 | 4 |

| Coating 3 | 50 | 8 | 4 |

| Coating 4 | - | 12 | 6 |

| Coating 5 | 25 | 12 | 6 |

| Edible film 1 | - | 8 | 4 |

| Edible film 2 | - | 12 | 6 |

| Edible film 3 | 25 | 12 | 6 |

| Sample Symbol | Sample Type |

|---|---|

| K | Control sample |

| C1 | Coating with 8% of gelatin |

| C2 | Coating with 8% of gelatin and 25% of both |

| C3 | Coating with 8% of gelatin and 50% of both |

| C4 | Coating with 12% of gelatin |

| C5 | Coating with 12% of gelatin and 25% of both |

| EF1 | Edible film with 8% of gelatin |

| EF2 | Edible film with 12% of gelatin |

| EF3 | Edible film with 12% of gelatin and 25% of broth |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciurzyńska, A.; Janowicz, M.; Karwacka, M.; Galus, S. Analysis of the Effect of Vegetable Broth Addition to a Gelatin Pork Edible Film and Coating Method on Select Physical Properties of Freeze-Dried Coated Vegetable Bars. Appl. Sci. 2024, 14, 5215. https://doi.org/10.3390/app14125215

Ciurzyńska A, Janowicz M, Karwacka M, Galus S. Analysis of the Effect of Vegetable Broth Addition to a Gelatin Pork Edible Film and Coating Method on Select Physical Properties of Freeze-Dried Coated Vegetable Bars. Applied Sciences. 2024; 14(12):5215. https://doi.org/10.3390/app14125215

Chicago/Turabian StyleCiurzyńska, Agnieszka, Monika Janowicz, Magdalena Karwacka, and Sabina Galus. 2024. "Analysis of the Effect of Vegetable Broth Addition to a Gelatin Pork Edible Film and Coating Method on Select Physical Properties of Freeze-Dried Coated Vegetable Bars" Applied Sciences 14, no. 12: 5215. https://doi.org/10.3390/app14125215

APA StyleCiurzyńska, A., Janowicz, M., Karwacka, M., & Galus, S. (2024). Analysis of the Effect of Vegetable Broth Addition to a Gelatin Pork Edible Film and Coating Method on Select Physical Properties of Freeze-Dried Coated Vegetable Bars. Applied Sciences, 14(12), 5215. https://doi.org/10.3390/app14125215