Axial Load Transfer Mechanism in Fully Grouted Rock Bolting System: A Systematic Review

Abstract

:1. Introduction

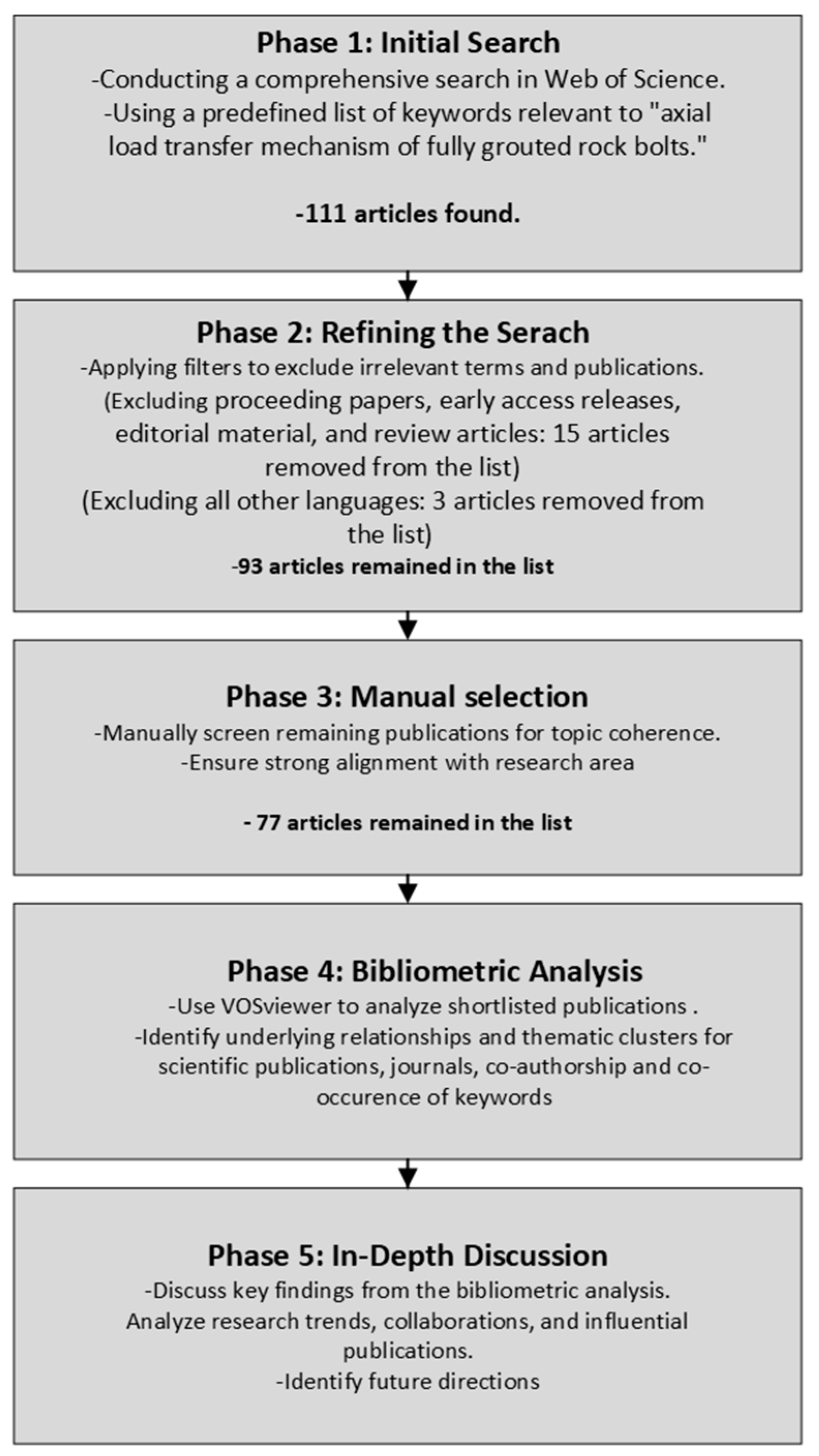

2. Materials and Methods

- Initial Search: This phase involves conducting a comprehensive search in the Web of Science using a predefined list of keywords relevant to the topic.

- Refining the Search: Irrelevant terms and publications are filtered out to ensure the search results are focused and aligned with the research topic.

- Manual Selection: To achieve the highest level of topic coherence, the remaining publications are further curated through a manual selection process, guaranteeing their strong alignment with the specific research area of the axial load transfer mechanism of FGRBS.

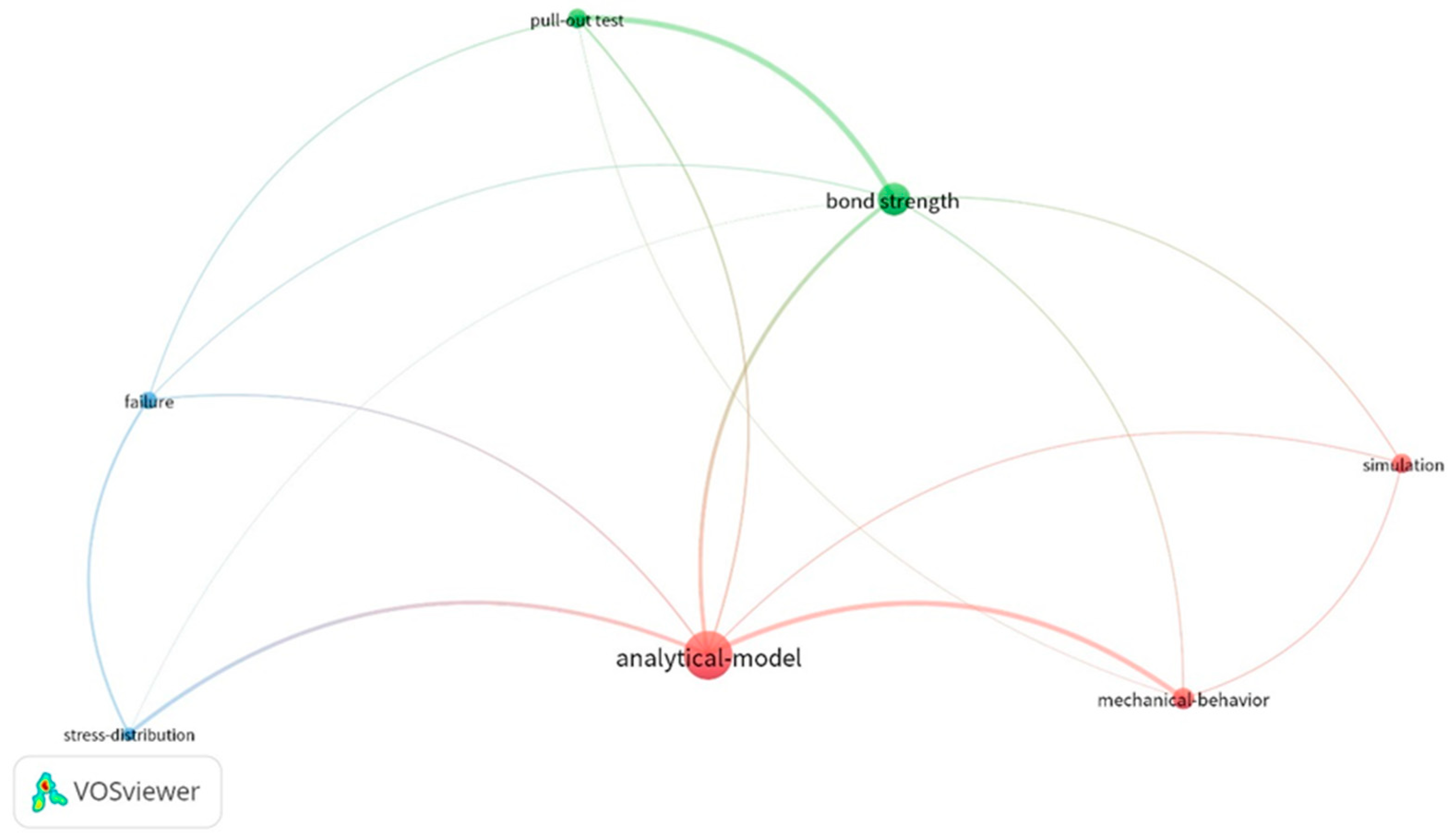

- Bibliometric Analysis: The shortlisted publications are subjected to analysis using the VOSviewer, a bibliometric software tool. This analysis will reveal underlying relationships and thematic clusters within the selected research.

- Phase 1: Initial search

- Phase 2: Refining the Search

- Phase 3: Manual Selection

- Phase 4: Bibliometric Analysis

3. Analysis and Results

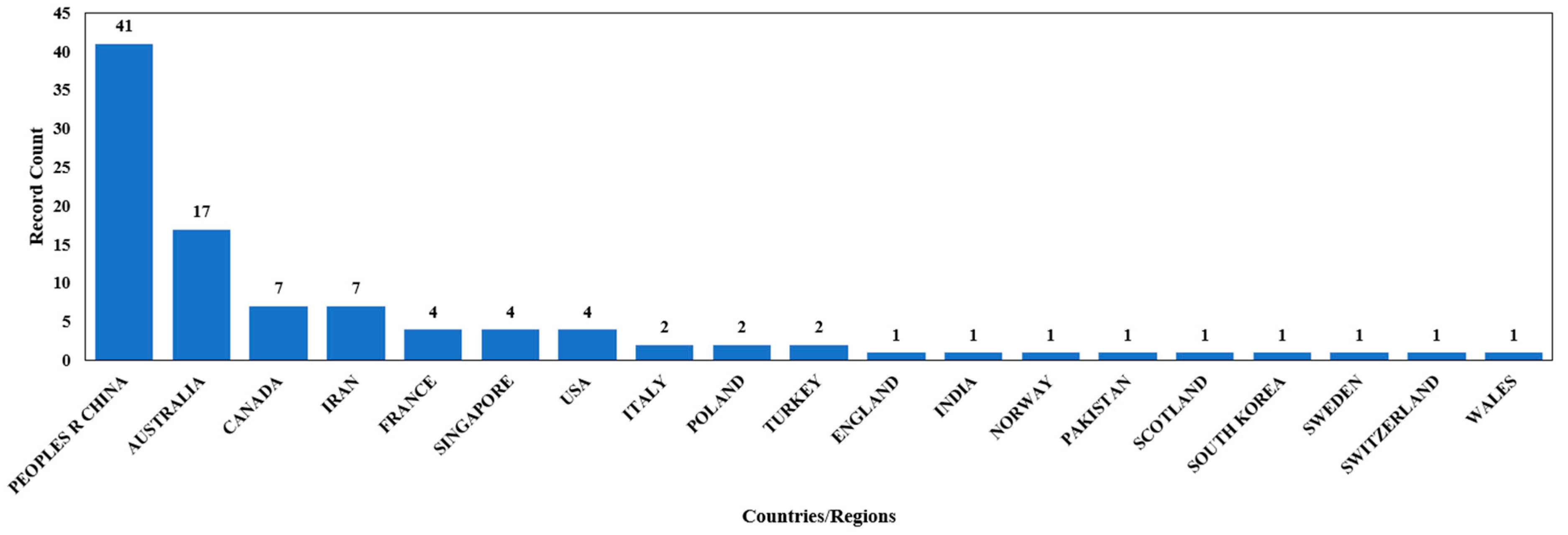

3.1. Descriptive Results

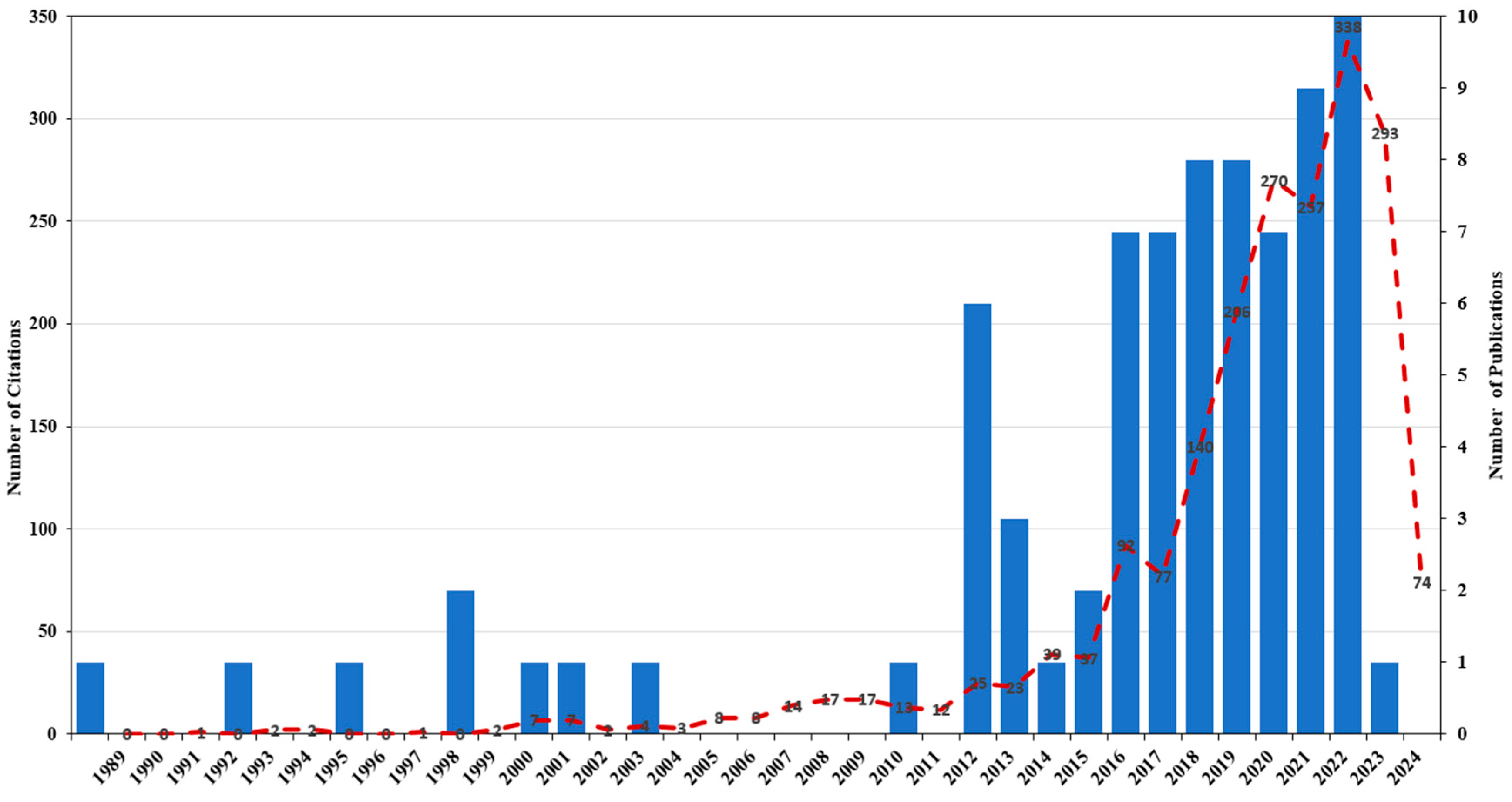

3.1.1. The Trend of Research on the Axial Load Transfer Mechanism of FGRBS

3.1.2. Journal Outlets Leading Research on Axial Load Transfer Mechanism of FGRBSs

3.1.3. Institutions Leading Research on Axial Load Transfer Mechanism of FGRBS

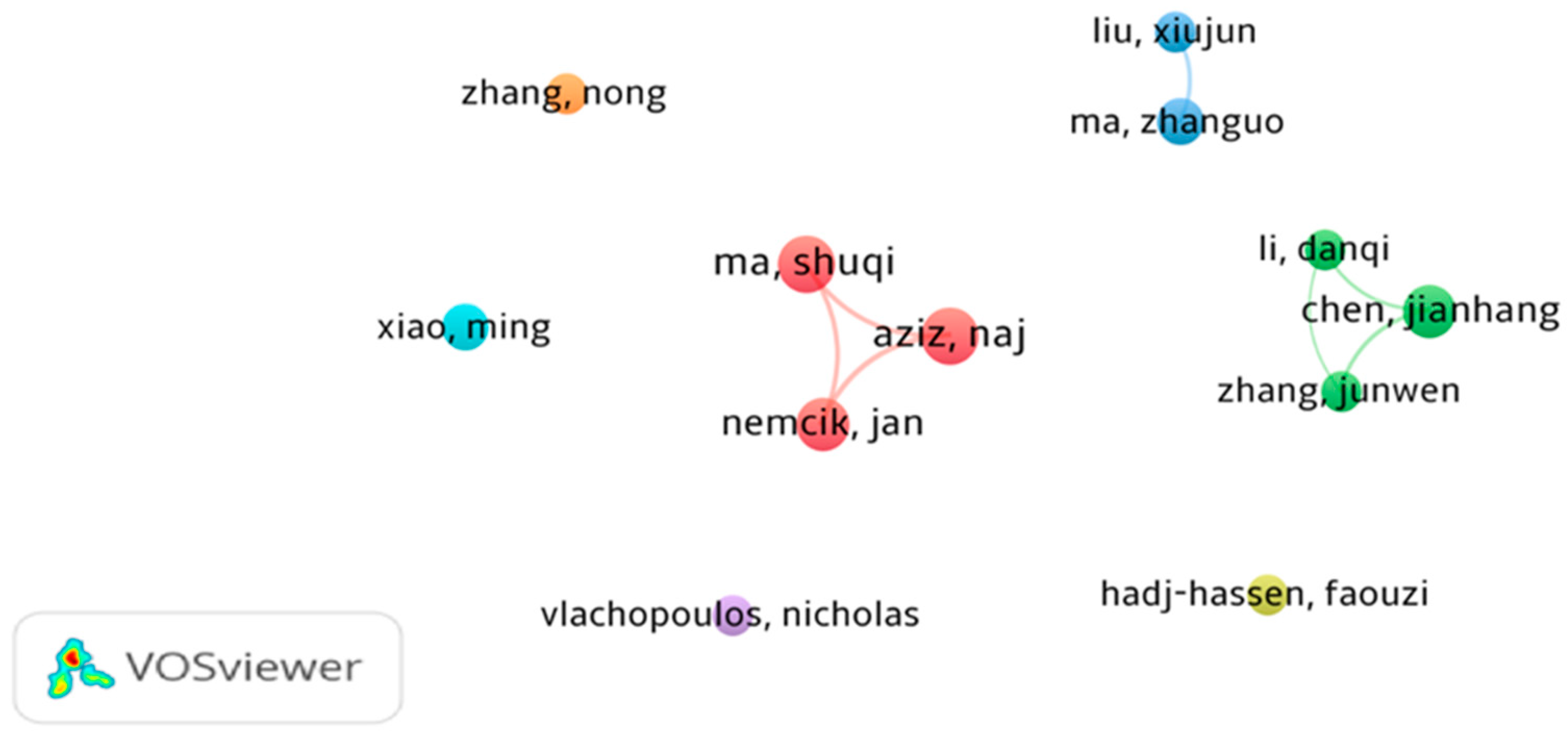

3.1.4. Researchers Leading Research on Axial Load Transfer Mechanism of FGRBSs

3.1.5. Articles Leading Research on Axial Load Transfer Mechanism of FGRBSs

| No. | Author(s) | Article | Journal Name | Citation Number | Method | Major Findings |

|---|---|---|---|---|---|---|

| 1 | Li and Stillborg [40] | Analytical models for rock bolts | International Journal of Rock Mechanics and Mining Sciences | 294 | Analytical models, laboratory pull-out tests | Proposing three different analytical models for three different rock bolting systems subjected to: (a) laboratory pull-out tests; (b) in-situ uniform rock deformation; and (c) in-situ opening of a rock joint. |

| 2 | Kilic, Yasar [38] | Effect of grout properties on the pull-out load capacity of fully grouted rock bolt | Tunnelling and Underground Space Technology | 170 | Laboratory pull-out tests, statistical relationships, mechanical grout characterisation | Investigating the effect of bolt profiles, including length, diameter, and bonding area, CT of the samples on the ultimate pull-out capacity; studying the influences of different grout materials and critical mechanical properties of grout, including UCS, (W/G) ratio, CT, and shear strength, on bolt bond strength (BS). |

| 3 | Ma, Nemcik [42] | An analytical model of fully grouted rock bolts subjected to tensile load | Construction and Building Materials | 135 | Analytical model, laboratory and in situ pull-out test | Proposing a new analytical model for investigating the mechanical behaviour of FGRBSs subjected to tensile load; Expressing formula of shear stress distribution along B–G interface, and axial load and load–displacement; Suggesting constitutive relationship of bolt–resin base on pull-out test. Verifying the results by comparing them with in-situ pull-out measurements. |

| 4 | Hyett, Moosavi [12] | Load distribution along fully grouted bolts, with emphasis on cable bolt reinforcement | International Journal for Numerical and Analytical Methods in Geomechanics | 106 | Analytical model, numerical simulation, pull-out tests | Proposing a new analytical model for load and displacement along an untensioned FGRBS; Suggesting a finite difference formulation with a combination of a non-linear model of a fully grouted cable bolt for investigating the debonding mechanism based on bolt and grout type; Parametric study of BS of fully grouted cable bolts, rock mass displacement, rock mass modulus, and excavation-induced stress change. |

| 5 | Blanco Martín, Tijani [43] | Assessment of the bolt-grout interface behaviour of fully grouted rock bolts from laboratory experiments under axial loads | International Journal of Rock Mechanics and Mining Sciences | 96 | Analytical analysis, laboratory pull-out tests | Proposing a new experimental bench to study the B–G interface debonding; investigating the effects of confining pressure, boundary conditions, bot type and profile on axial bearing capacity of full-grouted rock bolts; proposing semi-empirical formula for bot–grout interface under axial load. |

| 6 | Nemcik, Ma [45] | Numerical modelling of failure propagation in fully grouted rock bolts subjected to tensile load | International Journal of Rock Mechanics and Mining Sciences | 85 | Numerical simulation, laboratory pull-out test, analytical model | Developing a numerical simulation based on finite different methods (FDMs) using FLAC2D software; introducing the non-linear bond–slip relationship suggested by Ma, Nemcik [42] to FLAC software; verifying the results with experimental and analytical approaches. |

| 7 | Ma, Zhao [46] | A numerical model of fully grouted bolts considering the tri-linear shear bond–slip model | Tunnelling and Underground Space Technology | 72 | Numerical simulation, in- situ pull-out test | Implementing the model of tri-linear bond–slip of bolts suggested by Hyett, Moosavi [12] for the numerical framework; proposing a new numerical simulation for the debonding mechanism of B–G interface; parametric study; verifying the numeric results by pull-out tests. |

| 8 | Thenevin, Blanco-Martín [39] | Laboratory pull-out tests on fully grouted rock bolts and cable bolts: Results and lessons learned | Journal of Rock Mechanics and Geotechnical Engineering | 65 | Laboratory pull-out test | Investigating the influence of three different rock bolts, three different cable bolts, EL, confining pressure, resin, grouting materials, and different boundary conditions on the debonding mechanism at B–G interface with conducting pull-out test; providing an extensive dataset for studying the effects of confining pressure and EL on the performance of FGRBSs. |

| 9 | Jin-feng and Peng-hao [44] | Analytical model of fully grouted bolts in pull-out tests and in situ rock masses | International Journal of Rock Mechanics and Mining Sciences | 63 | Analytical model, pull-out test | Developing a new dynamic bond–slip model of fully grouted bolts under axial tension; proposing a new relationship for stress distribution, strain distribution, and load–slip relationship of the bolts; suggesting a new analytical model for in-situ rock bolt based on non-homogeneous deformation of the rock and the interaction between the bolt and surrounding rock mass; introducing a new analytical model to investigate of pretensioned and un-pretensioned rock bolts. |

| 10 | He, An [41] | Fully Grouted Rock Bolts: An Analytical Investigation | Rock Mechanics and Rock Engineering | 51 | Analytical investigation | Analytical investigations of the performance of FGRBSs in three different scenarios, including pull-out test, suspending loosened block, and join aperture; developing analytical models of Li and Stillborg (1999) by considering the constitutive model of the bolt, tensile failure of the bolt shank, debonding B–G interface, and loss of face plate. |

3.2. Research Hotspots in Axial Load Transfer Mechanism of FGRBSs

3.2.1. Failure Modes of the FGRBSs

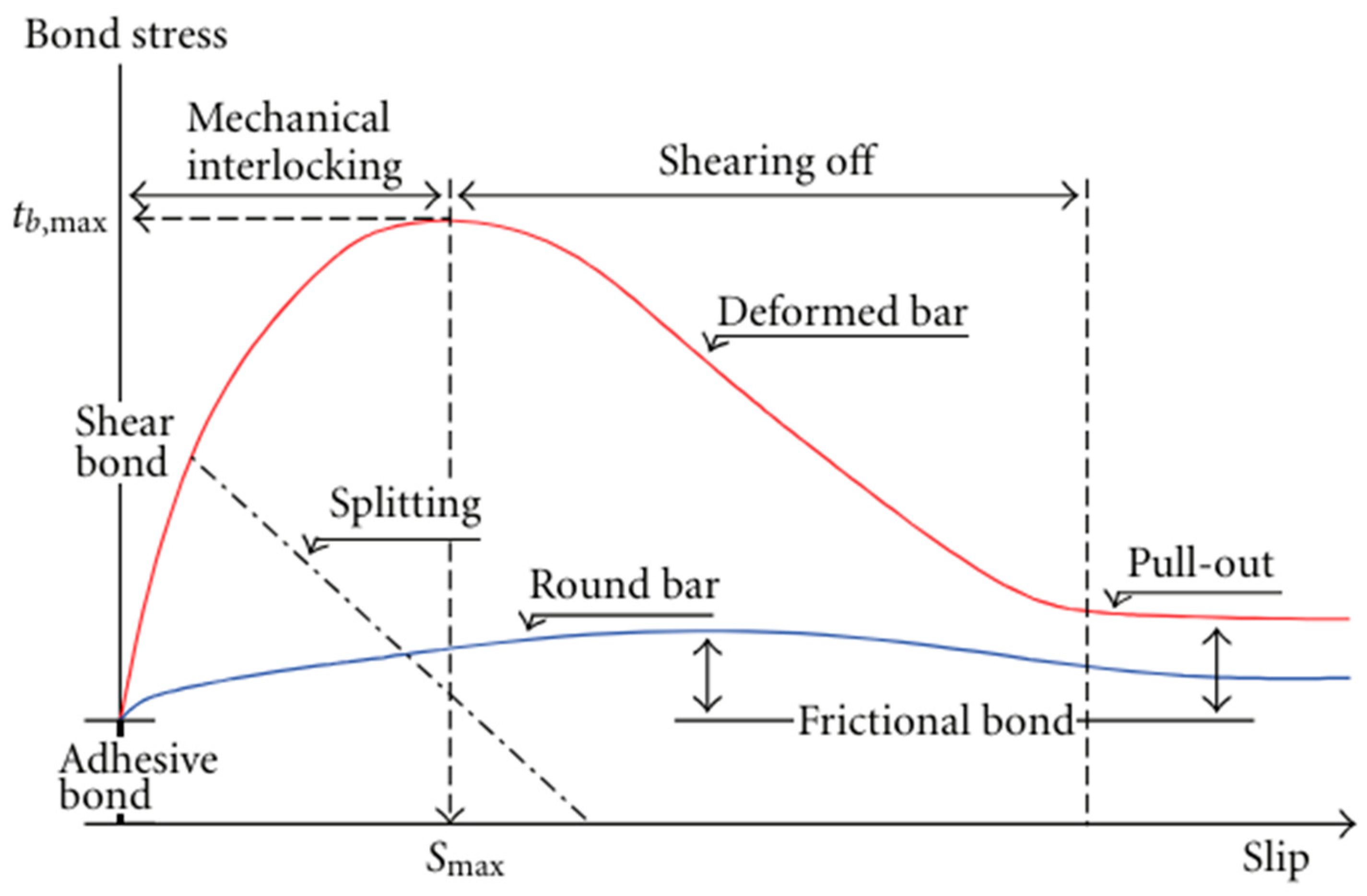

3.2.2. Failure Mechanism at the B–G Interface

3.3. Influential Parameters on the Axial Behaviour of FGRBSs

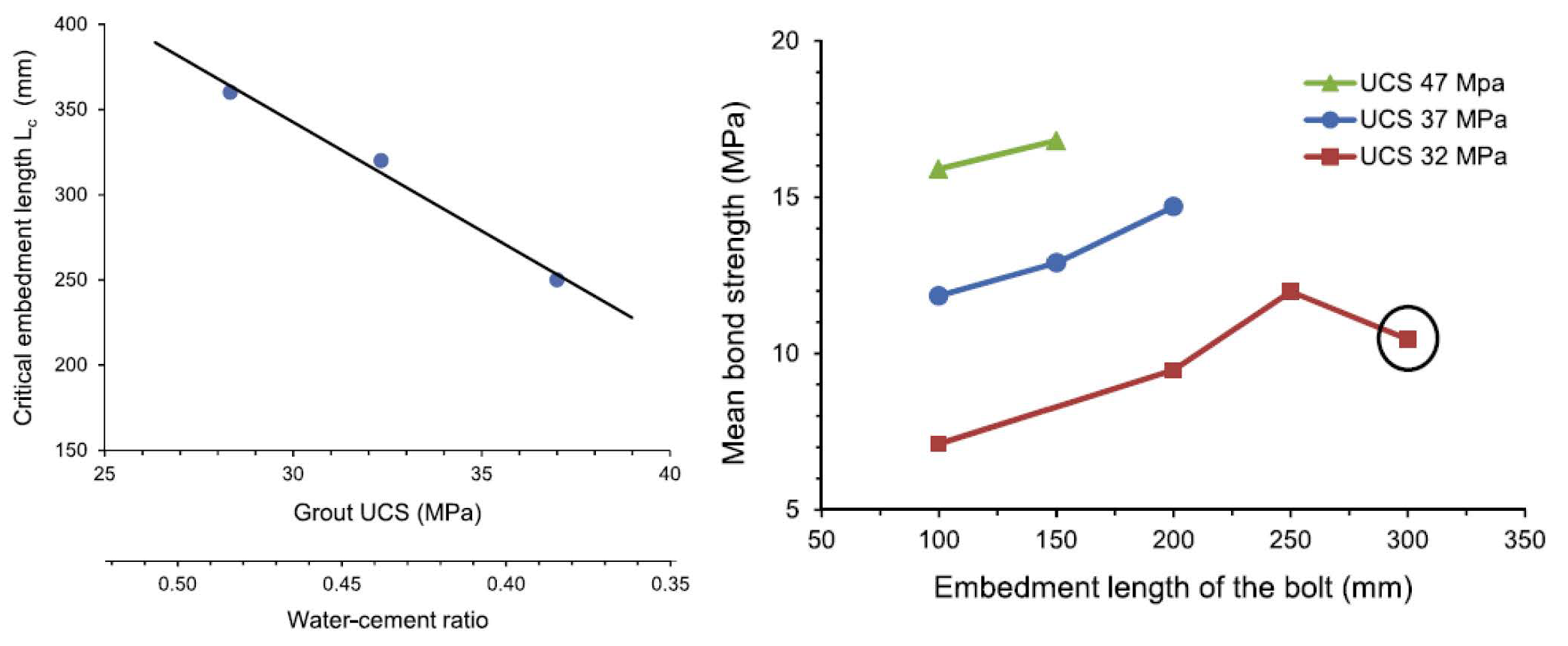

3.3.1. Effect of EL on the Axial Behaviour of FGRBSs

3.3.2. Effects of Boundary Conditions and Rock Mass on the Axial Performance of FGRBSs

3.3.3. Effects of Grout Mechanical Characteristics on the Axial Performance of FGRBSs

3.3.4. The Interaction between Grouting Process and Rock Mass Condition

3.3.5. Effects of Bolts Geometry and Surface Profile Configuration on FGRBS Performance

3.4. Summary of Review Findings

4. Conclusions and Further Directions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Symbols | Short definition | |

| AI | Artificial Intelligence | It can perform tasks typically requiring human-like abilities like learning, reasoning, and problem-solving. |

| B–G | Bolt–grout interface | Contact zone between rock bolt and surrounding grout where load transfer occurs [61]. |

| BS | Bond strength (MPa) | Shearing resistance between the bolt and grout [61]. |

| BU-100 | Bottom-Up 100 | An Australian grout type in which grouting is injected from the bottom of the borehole to the top. |

| CMC | Continuously mechanically coupled anchoring technique | This technique is a continuous mechanical connection between the bolt and the rock mass [1]. |

| CNL | Constant normal load | Under CNL conditions, the normal stress remains constant, and rock joints are free to dilate [106,107]. |

| CNS | Constant normal stiffness | CNS conditions involve varying normal stiffness, where joint dilation is partially or fully restricted by the surrounding rock mass [107]. |

| CFC | Continuously frictionally coupled anchoring technique | This technique relies on frictional coupling between the bolt and the rock surface [1]. |

| CT | Curing time (day, hour, min, sec) | Critical period for grout to harden and form a strong bond with rock mass [108]. |

| DMFC | Discretely mechanically/frictionally coupled anchoring technique | One of the rock bolts’ type have discrete mechanical or frictional connections [1]. |

| E | Elastic modulus (MPa) | Material’s stiffness, indicating its resistance to elastic deformation under stress. |

| EL | Embedment length (m) | Length of the bolt that is encased and bonded with grout within the rock mass [73]. |

| FA | Fly ash | An organic matter within the coal [109]. |

| FDM | Finite different method | |

| FGRBS | Fully grouted rock bolting system | A type of rock bolting system [8] |

| FOS | Fibre optic sensor | |

| LVDT | Linear variable differential transformer | An electromechanical transducer that converts linear motion into an electrical signal using a moveable ferromagnetic core and multiple coils [47]. |

| ML | Machine learning | The method empowers computers to learn from data, enabling them to make predictions or decisions without explicit programming. |

| R–G | Rock–grout (R–G) interface | Where the load transfers from bolt to the rock mass by grout [61]. |

| Q | rock mass quality (%) | Refers to how well rock will hold together under stress and excavation [110]. |

| UCS | Uniaxial compressive strength (MPa) | The maximum stress a rock or material can withstand when squeezed from one direction. |

| W/G | Water-to-grout ratio (%) | Refers to the proportion of water mixed with cementitious grout [38]. |

| Shear strength of grout (MPa) | The maximum resistance it offers against shear forces before failure occurs [47]. | |

References

- Windsor, C.R. Rock reinforcement systems. Int. J. Rock Mech. Min. Sci. 1997, 34, 919–951. [Google Scholar] [CrossRef]

- Schach, R.; Garshol, K.; Heltzen, A. Rock Bolting: A Practical Handbook; Pergamon: Oxford, UK, 1979; p. 92. [Google Scholar]

- Lang, T.A.; Bischoff, J.A.; Wagner, P.L. A program plan for determining optimum roof bolt tension. In Theory and Application of Rock Reinforcement Systems in Coal Mines; U.S. Department of Energy Office of Scientific and Technical Information: Oak Ridge, TN, USA, 1979. [Google Scholar]

- Bolstad, D.; Hill, J. Bureau of Mines rock bolting research. In Proceedings of the International Symposium on Rock Bolting, Abisko, Sweden, 28 August–2 September 1983; pp. 313–320. [Google Scholar]

- Rasekh, H. The Shear Performance of Cable Bolts in Experimental, Numerical and Mathematical Studies. In School of Civil, Mining and Environmental Engineering; University of Wollongong: Wollongong, Australia, 2017. [Google Scholar]

- Thompson, A.G.; Villaescusa, E.; Windsor, C.R. Ground Support Terminology and Classification: An Update. Geotech. Geol. Eng. 2012, 30, 553–580. [Google Scholar] [CrossRef]

- Cao, C.; Nemcik, J.; Aziz, N.; Ren, T. Failure modes of rockbolting. In Proceedings of the 12th Coal Operators’ Conference, Wollongong, Australia, 16 February 2012; pp. 135–173. [Google Scholar]

- Frenelus, W.; Peng, H.; Zhang, J. An Insight from Rock Bolts and Potential Factors Influencing Their Durability and the Long-Term Stability of Deep Rock Tunnels. Sustainability 2022, 14, 10943. [Google Scholar] [CrossRef]

- Li, C.C. A new energy-absorbing bolt for rock support in high stress rock masses. Int. J. Rock Mech. Min. Sci. 2010, 47, 396–404. [Google Scholar] [CrossRef]

- Nourizadeh, H.; Mirzaghorbanali, A.; McDougall, K.; Jeewantha, L.H.J.; Craig, P.; Motallebiyan, A.; Jodeiri Shokri, B.; Rastegarmanesh, A.; Aziz, N. Characterization of mechanical and bonding properties of anchoring resins under elevated temperature. Int. J. Rock Mech. Min. Sci. 2023, 170, 105506. [Google Scholar] [CrossRef]

- Zou, D. Ground Reinforcement and Support. In Theory and Technology of Rock Excavation for Civil Engineering; Springer: New York, NY, USA, 2017; pp. 579–637. [Google Scholar] [CrossRef]

- Hyett, A.J.; Moosavi, M.; Bawden, W.F. Load Distribution Along Fully Grouted Bolts, with Emphasis on Cable Bolt Reinforcement. Int. J. Numer. Anal. Methods Geomech. 1996, 20, 517–544. [Google Scholar] [CrossRef]

- Li, C.C. Principles of rockbolting design. J. Rock Mech. Geotech. Eng. 2017, 9, 396–414. [Google Scholar] [CrossRef]

- Luga, E.; Periku, E. A pioneer in-situ investigation on the bearing capacity and failure causes of real scale fully grouted rockbolts. Constr. Build. Mater. 2021, 310, 124826. [Google Scholar] [CrossRef]

- Vlachopoulos, N.; Cruz, D.; Tatone, B.S.A.; Lisjak, A.; Mahabadi, O.K.; Forbes, B.; Carrapatoso, C. The Performance of Axially Loaded, Fully Grouted Rock Bolts Based on Pull-Out Experiments Utilizing Fiber Optics Technology and Associated Numerical Modelling of Such Support Elements. Geotech. Geol. Eng. 2019, 38, 1389–1407. [Google Scholar] [CrossRef]

- Ma, S. Load transfer mechanism of fully encapsulated rockbolts. In School of Civil, Mining, and Environmental Engineering; University of Wollongong: Wollongong, Australia, 2014. [Google Scholar]

- Song, G.; Li, W.; Wang, B.; Ho, S.C. A Review of Rock Bolt Monitoring Using Smart Sensors. Sensors 2017, 17, 776. [Google Scholar] [CrossRef]

- Jalilfar, H. A new approach in determining the load transfer mechanism in fully grouted bolts. In School of Civil, Mining and Environmental Engineering—Faculty of Engineering; University of Wollongong: Wollongong, Australia, 2006. [Google Scholar]

- Skrzypkowski, K. The Influence of Room and Pillar Method Geometry on the Deposit Utilization Rate and Rock Bolt Load. Energies 2019, 12, 4770. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Korzeniowski, W.; Zagórski, K.; Zagórska, A. Adjustment of the Yielding System of Mechanical Rock Bolts for Room and Pillar Mining Method in Stratified Rock Mass. Energies 2020, 13, 2082. [Google Scholar] [CrossRef]

- Skrzypkowski, K. An Experimental Investigation into the Stress-Strain Characteristic under Static and Quasi-Static Loading for Partially Embedded Rock Bolts. Energies 2021, 14, 1483. [Google Scholar] [CrossRef]

- Ma, S.; Aziz, N.; Nemcik, J.; Mirzaghorbanali, A. The effects of installation procedure on bond characteristics of fully grouted rock bolts. Geotech. Test. J. 2017, 40, 20160239. [Google Scholar] [CrossRef]

- Windsor, C.; Thompson, A. Rock reinforcement-technology, testing, design and evaluation. Compr. Rock Eng. Princ. Pract. Proj. 1993, 4, 451–484. [Google Scholar]

- Littlejohn, G.; Bruce, D. Rock-anchors state of the art. Des. Ground Eng. Part1 1975, 8, 25–78. [Google Scholar]

- Harris, J.D.; Quatman, C.E.; Manring, M.M.; Siston, R.A.; Flanigan, D.C. How to Write a Systematic Review. Am. J. Sports Med. 2013, 42, 2761–2768. [Google Scholar] [CrossRef]

- Wright, R.W.; Brand, R.A.; Dunn, W.; Spindler, K.P. How to Write a Systematic Review. Clin. Orthop. Relat. Res. 2007, 455, 23–29. [Google Scholar] [CrossRef] [PubMed]

- Moher, D.; Shamseer, L.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A.; Group, P.-P. Preferred reporting items for systematic review and meta-analysis protocols (PRISMA-P) 2015 statement. Syst. Rev. 2015, 4, 1. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Grilo, A. Bibliometric analysis and review of Building Information Modelling literature published between 2005 and 2015. Autom. Constr. 2017, 80, 118–136. [Google Scholar] [CrossRef]

- Li, X.; Nemcik, J.; Mirzaghorbanali, A.; Aziz, N.; Rasekh, H. Analytical model of shear behaviour of a fully grouted cable bolt subjected to shearing. Int. J. Rock Mech. Min. Sci. 2015, 80, 31–39. [Google Scholar] [CrossRef]

- Eck, N.J.; Waltman, L. Manual for VOSviewer Version 1.6.20; Universiteit Leiden and CWTS Meaning Metrics: Leiden, The Netherlands, 2023; p. 55. [Google Scholar]

- Sharma, S.G.; Pande, G.N. Stability of rock masses reinforced by passive, fully-grouted rock bolts. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1988, 25, 273–285. [Google Scholar] [CrossRef]

- Vlachopoulos, N.; Cruz, D.; Forbes, B. Utilizing a novel fiber optic technology to capture the axial responses of fully grouted rock bolts. J. Rock Mech. Geotech. Eng. 2018, 10, 222–235. [Google Scholar] [CrossRef]

- Ranjith, P.G.; Zhao, J.; Ju, M.; De Silva, R.V.S.; Rathnaweera, T.D.; Bandara, A.K.M.S. Opportunities and Challenges in Deep Mining: A Brief Review. Engineering 2017, 3, 546–551. [Google Scholar] [CrossRef]

- Fairhurst, C. Some Challenges of Deep Mining. Engineering 2017, 3, 527–537. [Google Scholar] [CrossRef]

- Yokota, Y.; Zhao, Z.; Nie, W.; Date, K.; Iwano, K.; Koizumi, Y.; Okada, Y. Development of a new deformation-controlled rock bolt: Numerical modelling and laboratory verification. Tunn. Undergr. Space Technol. 2020, 98, 103305. [Google Scholar] [CrossRef]

- Hao, Y.; Wu, Y.; Ranjith, P.G.; Zhang, K.; Hao, G.; Teng, Y. A novel energy-absorbing rock bolt with high constant working resistance and long elongation: Principle and static pull-out test. Constr. Build. Mater. 2020, 243, 118231. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, S.; Zhu, Q.; Li, H.; Chen, G.; Zhang, P. Dynamic and static analysis of a kind of novel J energy-releasing bolts. Geomat. Nat. Hazards Risk 2020, 11, 2486–2508. [Google Scholar] [CrossRef]

- Kilic, A.; Yasar, E.; Celik, A.G. Effect of grout properties on the pull-out load capacity of fully grouted rock bolt. Tunn. Undergr. Space Technol. 2002, 17, 355–362. [Google Scholar] [CrossRef]

- Thenevin, I.; Blanco-Martín, L.; Hadj-Hassen, F.; Schleifer, J.; Lubosik, Z.; Wrana, A. Laboratory pull-out tests on fully grouted rock bolts and cable bolts: Results and lessons learned. J. Rock Mech. Geotech. Eng. 2017, 9, 843–855. [Google Scholar] [CrossRef]

- Li, C.; Stillborg, B. Analytical models for rock bolts. Int. J. Rock Mech. Min. Sci. 1999, 36, 1013–1029. [Google Scholar] [CrossRef]

- He, L.; An, X.M.; Zhao, Z.Y. Fully Grouted Rock Bolts: An Analytical Investigation. Rock Mech. Rock Eng. 2014, 48, 1181–1196. [Google Scholar] [CrossRef]

- Ma, S.; Nemcik, J.; Aziz, N. An analytical model of fully grouted rock bolts subjected to tensile load. Constr. Build. Mater. 2013, 49, 519–526. [Google Scholar] [CrossRef]

- Blanco Martín, L.; Tijani, M.; Hadj-Hassen, F.; Noiret, A. Assessment of the bolt-grout interface behaviour of fully grouted rockbolts from laboratory experiments under axial loads. Int. J. Rock Mech. Min. Sci. 2013, 63, 50–61. [Google Scholar] [CrossRef]

- Jin-feng, Z.; Peng-hao, Z. Analytical model of fully grouted bolts in pull-out tests and in situ rock masses. Int. J. Rock Mech. Min. Sci. 2019, 113, 278–294. [Google Scholar] [CrossRef]

- Nemcik, J.; Ma, S.; Aziz, N.; Ren, T.; Geng, X. Numerical modelling of failure propagation in fully grouted rock bolts subjected to tensile load. Int. J. Rock Mech. Min. Sci. 2014, 71, 293–300. [Google Scholar] [CrossRef]

- Ma, S.; Zhao, Z.; Nie, W.; Gui, Y. A numerical model of fully grouted bolts considering the tri-linear shear bond–slip model. Tunn. Undergr. Space Technol. 2016, 54, 73–80. [Google Scholar] [CrossRef]

- Nourizadeh, H. Axial Load Transfer Mechanism of Rock Bolts; University of Southern Queensland: Toowoomba, Australia, 2024. [Google Scholar]

- Lutz, L. Analysis of stresses in concrete near a reinforcing bar due to bond and transverse cracking. J. Proc. 1970, 67, 778–787. [Google Scholar]

- Aydan, Ö. The Stabilisation of Rock Engineering Structures by Rockbolts; Nagoya University: Nagoya, Japan, 1989. [Google Scholar]

- Chen, J.; Hagan, P.C.; Saydam, S. A New Laboratory Short Encapsulation Pull Test for Investigating Load Transfer Behavior of Fully Grouted Cable Bolts. Geotech. Test. J. 2018, 41, 20170139. [Google Scholar] [CrossRef]

- Chen, J.; He, F.; Zhang, S. A study of the load transfer behavior of fully grouted rock bolts with analytical modelling. Int. J. Min. Sci. Technol. 2020, 30, 105–109. [Google Scholar] [CrossRef]

- Cao, C.; Nemcik, J.; Aziz, N.; Ren, T. Analytical study of steel bolt profile and its influence on bolt load transfer. Int. J. Rock Mech. Min. Sci. 2013, 60, 188–195. [Google Scholar] [CrossRef]

- Cao, C.; Ren, T.; Cook, C.; Cao, Y. Analytical approach in optimising selection of rebar bolts in preventing rock bolting failure. Int. J. Rock Mech. Min. Sci. 2014, 72, 16–25. [Google Scholar] [CrossRef]

- Blanco Martín, L.; Tijani, M.; Hadj-Hassen, F. A new analytical solution to the mechanical behaviour of fully grouted rockbolts subjected to pull-out tests. Constr. Build. Mater. 2011, 25, 749–755. [Google Scholar] [CrossRef]

- Ma, S.; Nemcik, J.; Aziz, N. Simulation of fully grouted rockbolts in underground roadways using FLAC2D. Can. Geotech. J. 2014, 51, 911–920. [Google Scholar] [CrossRef]

- Moosavi, M.; Jafari, A.; Khosravi, A. Bond of cement grouted reinforcing bars under constant radial pressure. Cem. Concr. Compos. 2005, 27, 103–109. [Google Scholar] [CrossRef]

- Nie, W.; Zhao, Z.Y.; Guo, W.; Shang, J.; Wu, C. Bond-slip modeling of a CMC rockbolt element using 2D-DDA method. Tunn. Undergr. Space Technol. 2019, 85, 340–353. [Google Scholar] [CrossRef]

- Hyett, A.J.; Bawden, W.F.; Reichert, R.D. The effect of rock mass confinment on the bond strength of fully grouted cable bolts. Int. J. Rock Mech. Min. Sci. Geomech. 1992, 29, 503–524. [Google Scholar] [CrossRef]

- Cao, C.; Jan, N.; Ren, T.; Naj, A. A study of rock bolting failure modes. Int. J. Min. Sci. Technol. 2013, 23, 79–88. [Google Scholar] [CrossRef]

- Zhang, C.; Cui, G.; Chen, X.; Zhou, H.; Deng, L. Effects of bolt profile and grout mixture on shearing behaviors of bolt-grout interface. J. Rock Mech. Geotech. Eng. 2020, 12, 242–255. [Google Scholar] [CrossRef]

- Nourizadeh, H.; Mirzaghorbanali, A.; Serati, M.; Mutaz, E.; McDougall, K.; Aziz, N. Failure characterization of fully grouted rock bolts under triaxial testing. J. Rock Mech. Geotech. Eng. 2024, 16, 778–789. [Google Scholar] [CrossRef]

- Yazici, S.; Kaiser, P.K. Bond strength of grouted cable bolts. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1992, 29, 279–292. [Google Scholar] [CrossRef]

- Aziz, N.; Webb, B. Study of Load Transfer Capacity of Bolts Using Short Encapsulation Push Test. In Proceedings of the 2003 Coal Operators’ Conference, Mining Engineering, Wollongong, Australia, 12–14 February 2003; Kininmonth, N.A.A.B., Ed.; University of Wollongong: Wollongong, Australia, 2003; pp. 72–80. [Google Scholar]

- Cui, G.; Zhang, C.; Pan, Y.; Deng, L.; Zhou, H. Laboratory investigation into effect of bolt profiles on shear behaviors of bolt-grout interface under constant normal stiffness (CNS) conditions. J. Rock Mech. Geotech. Eng. 2020, 12, 1234–1248. [Google Scholar] [CrossRef]

- Hong, S.; Park, S.-K. Uniaxial Bond Stress-Slip Relationship of Reinforcing Bars in Concrete. Adv. Mater. Sci. Eng. 2012, 2012, 328570. [Google Scholar] [CrossRef]

- Benmokrane, B.; Chennouf, A.; Mitri, H. Laboratory evaluation of cement-based grouts and grouted rock anchors. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1995, 32, 633–642. [Google Scholar] [CrossRef]

- Kilic, A.; Yasar, E.; Atis, C.D. Effect of bar shape on the pull-out capacity of fully-grouted rockbolts. Tunn. Undergr. Space Technol. 2003, 18, 1–6. [Google Scholar] [CrossRef]

- Ren, F.F.; Yang, Z.J.; Chen, J.F.; Chen, W.W. An analytical analysis of the full-range behaviour of grouted rockbolts based on a tri-linear bond-slip model. Constr. Build. Mater. 2010, 24, 361–370. [Google Scholar] [CrossRef]

- Zou, X.; Sneed, L.H.; D’Antino, T. Full-range behavior of fiber reinforced cementitious matrix (FRCM)-concrete joints using a trilinear bond-slip relationship. Compos. Struct. 2020, 239, 112024. [Google Scholar] [CrossRef]

- Lee, S.W.; Kang, S.-B.; Tan, K.H.; Yang, E.-H. Experimental and analytical investigation on bond-slip behaviour of deformed bars embedded in engineered cementitious composites. Constr. Build. Mater. 2016, 127, 494–503. [Google Scholar] [CrossRef]

- Li, C.C.; Kristjansson, G.; Høien, A.H. Critical embedment length and bond strength of fully encapsulated rebar rockbolts. Tunn. Undergr. Space Technol. 2016, 59, 16–23. [Google Scholar] [CrossRef]

- Yu, S.; Zhu, W.; Niu, L.; Zhou, S.; Kang, P. Experimental and numerical analysis of fully grouted long rockbolt load-transfer behavior. Tunn. Undergr. Space Technol. 2019, 85, 56–66. [Google Scholar] [CrossRef]

- Høien, A.H.; Li, C.C.; Zhang, N. Pull-out and Critical Embedment Length of Grouted Rebar Rock Bolts-Mechanisms When Approaching and Reaching the Ultimate Load. Rock Mech. Rock Eng. 2021, 54, 1431–1447. [Google Scholar] [CrossRef]

- Tepfers, R. Cracking of concrete cover along anchored deformed reinforcing bars. Mag. Concr. Res. 1979, 31, 3–52. [Google Scholar] [CrossRef]

- Yi, W.; Wang, M.; Zhao, S.; Tong, J.; Liu, C. The effect of rock hardness and integrity on the failure mechanism of mortar bolt composite structure in a jointed rock mass. Eng. Fail. Anal. 2023, 143, 106831. [Google Scholar] [CrossRef]

- Li, D.; Li, Y.; Chen, J.; Masoumi, H. An analytical model for axial performance of rock bolts under constant confining pressure based on continuously yielding criterion. Tunn. Undergr. Space Technol. 2021, 113, 103955. [Google Scholar] [CrossRef]

- Yu, S.; Niu, L.; Chen, J. Experimental and Numerical Studies on Bond Quality of Fully Grouted Rockbolt under Confining Pressure and Pull-Out Load. Shock. Vib. 2022, 2022, 7012510. [Google Scholar] [CrossRef]

- Aziz, N.; Hawker, R.; Mirza, A.; Nemcik, J.; Li, X.; Rasekh, H. Strength characteristics of secura hollow groutable cable bolts. In Proceedings of the 15th Coal Operators’ Conference, Wollongong, Australia, 3–10 August 2015; pp. 160–167. [Google Scholar]

- Aziz, N.; Craig, P.; Mirzaghorbanali, A.; Nemcik, J. Factors Influencing the Quality of Encapsulation in Rock Bolting. Rock Mech. Rock Eng. 2016, 49, 3189–3203. [Google Scholar] [CrossRef]

- Aziz, N.; Majoor, D.; Mirzaghorbanali, A. Strength Properties of Grout for Strata Reinforcement. Procedia Eng. 2017, 191, 1178–1184. [Google Scholar] [CrossRef]

- Mirza, A.; Aziz, N.; Ye, W.; Nemcik, J. Mechanical properties of grouts at various curing times. In Proceedings of the 16th Coal Operators’ Conference, Wollongong, Australia, 10–12 February 2016; Bob, N.A., Kininmonth, A., Eds.; University of Wollongong: Wollongong, Australia, 2016; pp. 84–90. [Google Scholar]

- Mirzaghorbanali, A.; Gregor, P.; Ebrahim, Z.; Alfahed, A.; Aziz, N.; McDougall, K. Strength properties of grout for strata reinforcement. In Proceedings of the 2019 Coal Operators Conference, Wollongong, Australia, 16–21 June 2019; Kininmonth, N.A.A.B., Ed.; University of Wollongong: Wollongong, Australia, 2019; pp. 196–202. [Google Scholar]

- Mirzaghornanali, A.; Gregor, P.; Alkandari, H.; Aziz, N.; McDougall, K. Mechanical behaviours of grout for strata reinforcement. In Proceedings of the 2018 Coal Operators’ Conference, Wollongong, Australia, 7–9 February 2018; University of Wollongong: Wollongong, Australia, 2018; pp. 373–375. [Google Scholar]

- Entezam, S.; Jodeiri Shokri, B.; Nourizadeh, H.; Motallebiyan, A.; Mirzaghorbanali, A.; McDougall, K.; Aziz, N.; Karunasena, W. Investigation of the effect of using fly ash in the Grout mixture on performing the fully grouted rock bolt systems. In Proceedings of the 2023 Resource Operators Conference, Wollongong, Australia, 9–10 February 2023; pp. 296–301. [Google Scholar]

- Jodeiri Shokri, B.; Entezam, S.; Nourizadeh, H.; Motallebiyan, A.; Mirzaghorbanali, A.; McDougall, K.; Aziz, N.; Karunasena, K. The effect of changing confinement diameter on axial load transfer mechanisms of fully grouted rock bolts. In Proceedings of the 2023 Resource Operators Conference, Wollongong, Australia, 9–10 February 2023; pp. 290–295. [Google Scholar]

- Teymen, A. Effect of mineral admixture types on the grout strength of fully-grouted rockbolts. Constr. Build. Mater. 2017, 145, 376–382. [Google Scholar] [CrossRef]

- Toutanji, H.; El-Korchi, T. Tensile and Compressive Strength of Silica Fume-Cement Pastes and Mortars. Cem. Concr. Aggreg. 1996, 18, 78–84. [Google Scholar] [CrossRef]

- Türkmen, I.; Gavgali, M.; Gül, R. Influence of mineral admixtures on the mechanical properties and corrosion of steel embedded in high strength concrete. Mater. Lett. 2003, 57, 2037–2043. [Google Scholar] [CrossRef]

- Badogiannis, E.; Kakali, G.; Dimopoulou, G.; Chaniotakis, E.; Tsivilis, S. Metakaolin as a main cement constituent. Exploitation of poor Greek kaolins. Cem. Concr. Compos. 2005, 27, 197–203. [Google Scholar] [CrossRef]

- Nassif, H.H.; Najm, H.; Suksawang, N. Effect of pozzolanic materials and curing methods on the elastic modulus of HPC. Cem. Concr. Compos. 2005, 27, 661–670. [Google Scholar] [CrossRef]

- Chang, X.; Wang, G.; Liang, Z.; Yang, J.; Tang, C. Study on grout cracking and interface debonding of rockbolt grouted system. Constr. Build. Mater. 2017, 135, 665–673. [Google Scholar] [CrossRef]

- Kim, H.; Rehman, H.; Ali, W.; Naji, A.M.; Kim, J.-J.; Kim, J.; Yoo, H. Classification of Factors Affecting the Performance of Fully Grouted Rock Bolts with Empirical Classification Systems. Appl. Sci. 2019, 9, 4781. [Google Scholar] [CrossRef]

- Nourizadeh, H.; Williams, S.; Mirzaghorbanali, A.; McDougall, K.; Aziz, N.; Serati, M. Axial behaviour of rock bolts—Part (A) Experimental study. In Proceedings of the 2021 Resources Operators Conference, Wollongong, Australia, 15–17 March 2021; pp. 294–302. [Google Scholar]

- Kovacevic, M.S.; Vrkljan, I.; Szavits-Nossan, A.A. Nondestructive procedure for testing grouting quality of rock bolt anchor. In Proceedings of the 9th International Congress on Rock Mechanics, Paris, France, 25–28 August 2020; pp. 1475–1478. [Google Scholar]

- Bacic, M.; Kovacevic, M.S.; Kacunic, D.J. Non-Destructive Evaluation of Rock Bolt Grouting Quality by Analysis of Its Natural Frequencies. Materials 2020, 13, 282. [Google Scholar] [CrossRef] [PubMed]

- Peter, K.; Moshood, O.; Akinseye, P.O.; Martha, A.; Khadija, S.O.; Abdulsalam, J.; Ismail, L.A.; Emman, A.A. An Overview of the Use of Rockbolts as Support Tools in Mining Operations. Geotech. Geol. Eng. 2021, 40, 1637–1661. [Google Scholar] [CrossRef]

- Shang, J.; Hencher, S.R.; West, L.J.; Handley, K. Forensic Excavation of Rock Masses: A Technique to Investigate Discontinuity Persistence. Rock Mech. Rock Eng. 2017, 50, 2911–2928. [Google Scholar] [CrossRef]

- Kang, H.; Li, W.; Gao, F.; Yang, J. Grouting theories and technologies for the reinforcement of fractured rocks surrounding deep roadways. Deep. Undergr. Sci. Eng. 2022, 2, 2–19. [Google Scholar] [CrossRef]

- Aziz, N.; Jalalifar, H.; Remennikov, A.; Sinclair, S.; Green, A. Optimisation of the bolt profile configuration for load transfer enhancement. In Proceedings of the 2008 Coal Operators’ Conference, Mining Engineering, Wollongong, Australia, 14–15 February 2008; Aziz, N., Kininmonth, B., Eds.; University of Wollongong: Wollongong, Australia, 2008. [Google Scholar]

- Aziz, N.; Jalalifar, H.; Concalves, J. Bolt surface configurations and load transfer mechanism. In Proceedings of the 2006 Coal Operators’ Conference, Wollongong, Australia, 6–7 July 2006; University of Wollongong: Wollongong, Australia, 2006; pp. 236–245. [Google Scholar]

- Ito, F.; Nakahara, F.; Kawano, R.; Kang, S.S.; Obara, Y. Visualization of failure in a pull-out test of cable bolts using X-ray CT. Constr. Build. Mater. 2001, 15, 263–270. [Google Scholar] [CrossRef]

- Tao, W.; Chen, C.; Jun, H.; Ting, R. Effect of bolt rib spacing on load transfer mechanism. Int. J. Min. Sci. Technol. 2017, 27, 431–434. [Google Scholar] [CrossRef]

- Yokota, Y.; Zhao, Z.; Nie, W.; Date, K.; Iwano, K.; Okada, Y. Experimental and Numerical Study on the Interface Behaviour Between the Rock Bolt and Bond Material. Rock Mech. Rock Eng. 2018, 52, 869–879. [Google Scholar] [CrossRef]

- Yokota, Y.; Zhao, Z.; Shang, J.; Nie, W.; Date, K.; Iwano, K.; Okada, Y. Effect of bolt configuration on the interface behaviour between a rock bolt and bond material: A comprehensive DDA investigation. Comput. Geotech. 2019, 105, 116–128. [Google Scholar] [CrossRef]

- Motallebiyan, A.; Nourizadeh, H.; Jodeiri shokri, B.; Entezam, S.; Mirzaghorbanali, A.; Aziz, N.; McDougall, K. Effects of rib distances on axial load transfer mechanisms of fully grouted rock bolts. In Proceedings of the Resources Operators Conference, Wollongong, Australia, 9–10 February 2023; University of Wollongong: Wollongong, Australia, 2023; pp. 231–235. [Google Scholar]

- Thirukumaran, S.; Indraratna, B.; Brown, E.T.; Kaiser, P.K. Stability of a Rock Block in a Tunnel Roof Under Constant Normal Stiffness Conditions. Rock Mech. Rock Eng. 2016, 49, 1587–1593. [Google Scholar] [CrossRef]

- Niktabar, S.M.M.; Rao, K.S.; Shrivastava, A.K.; Ščučka, J. Effect of Varying Normal Stiffness on Soft Rock Joints under Cyclic Shear Loads. Materials 2023, 16, 4272. [Google Scholar] [CrossRef] [PubMed]

- Madenga, V.; Zou, D.H.; Zhang, C. Effects of curing time and frequency on ultrasonic wave velocity in grouted rock bolts. J. Appl. Geophys. 2006, 59, 79–87. [Google Scholar] [CrossRef]

- Chou, M.-I.M. Fly Ashfly ash. In Encyclopedia of Sustainability Science and Technology; Meyers, R.A., Ed.; Springer: New York, NY, USA, 2012; pp. 3820–3843. [Google Scholar] [CrossRef]

- Barton, N.; Lien, R.; Lunde, J. Engineering classification of rock masses for the design of tunnel support. Rock Mech. 1974, 6, 189–236. [Google Scholar] [CrossRef]

| No. | Journal | Number of Publications | Total Citation | Impact Factor | Publisher |

|---|---|---|---|---|---|

| 1 | Tunnelling and Underground Space | 10 | 445 | 6.9 | Elsevier |

| 2 | Rock Mechanics and Rock Engineering | 6 | 179 | 6.2 | Springer |

| 3 | International Journal of Rock Mechanics and Mining Sciences | 6 | 576 | 7.2 | Elsevier |

| 4 | Geotechnical and Geological Engineering | 4 | 16 | 1.7 | Springer |

| 5 | Canadian Geotechnical Engineering | 3 | 70 | 3.6 | Canadian Science Publishing |

| 6 | Journal of Geomechanics and Geotechnical Engineering | 3 | 102 | 7.3 | Elsevier |

| 7 | Construction and Building Materials | 3 | 139 | 7.4 | Elsevier |

| 8 | Computers and Geotechnics | 3 | 49 | 5.3 | Elsevier |

| 9 | Mathematical Problem in Engineering | 3 | 15 | -- | Hindawi |

| 10 | Applied Sciences | 3 | 27 | 2.7 | MDPI |

| No. | Institution | Number of Publications | Total Citation | Country |

|---|---|---|---|---|

| 1 | China University Mining and Technology | 12 | 138 | China |

| 2 | University of Wollongong | 7 | 321 | Australia |

| 3 | Curtin University | 5 | 66 | Australia |

| 4 | Nanyang Technological University | 4 | 187 | Singapore |

| 5 | Wuhan University | 4 | 15 | China |

| 6 | University of Adelaide | 3 | 74 | Australia |

| 7 | Southwest Jiaotong University | 3 | 45 | China |

| 8 | Queens University | 3 | 32 | Canada |

| 9 | Royal Military College Canada | 3 | 32 | Canada |

| 10 | Shandong University of Science Technology | 3 | 23 | China |

| No. | Author | Institution | Number of Publications | Total Citation |

|---|---|---|---|---|

| 1 | Shuqi Ma | Naniang Technological University | 6 | 362 |

| 2 | Naj Aziz | University of Wollongong | 6 | 320 |

| 3 | Jan Nemcik | University of Wollongong | 5 | 318 |

| 4 | Jianhang Chen | China University of Mining and Technology | 5 | 72 |

| 5 | Zhanguo Ma | China University of Mining and Technology | 4 | 15 |

| 6 | Xiujun Liu | Wuhan University | 4 | 15 |

| 7 | Ming Xiao | Wuhan University | 4 | 15 |

| 8 | Faouzi Hadj-Hassan | MINES ParisTech | 3 | 171 |

| 9 | Danqi Li | Curtin University | 3 | 75 |

| 10 | Junwen Zhang | China University of Mining and Technology | 3 | 37 |

| 11 | Nicholas Vlachopoulos | Royal Military College Canada | 3 | 32 |

| 12 | Nong Zhang | China University of Mining and Technology | 3 | 20 |

| Top Contributing Journals | Co-Authorship Analysis: Leading Authors | Co-Authorship Analysis: Leading Institutions | Research Hot Spot Areas | Frequency Keywords |

|---|---|---|---|---|

|

|

|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jodeiri Shokri, B.; Mirzaghorbanali, A.; Nourizadeh, H.; McDougall, K.; Karunasena, W.; Aziz, N.; Entezam, S.; Entezam, A. Axial Load Transfer Mechanism in Fully Grouted Rock Bolting System: A Systematic Review. Appl. Sci. 2024, 14, 5232. https://doi.org/10.3390/app14125232

Jodeiri Shokri B, Mirzaghorbanali A, Nourizadeh H, McDougall K, Karunasena W, Aziz N, Entezam S, Entezam A. Axial Load Transfer Mechanism in Fully Grouted Rock Bolting System: A Systematic Review. Applied Sciences. 2024; 14(12):5232. https://doi.org/10.3390/app14125232

Chicago/Turabian StyleJodeiri Shokri, Behshad, Ali Mirzaghorbanali, Hadi Nourizadeh, Kevin McDougall, Warna Karunasena, Naj Aziz, Shima Entezam, and Alireza Entezam. 2024. "Axial Load Transfer Mechanism in Fully Grouted Rock Bolting System: A Systematic Review" Applied Sciences 14, no. 12: 5232. https://doi.org/10.3390/app14125232