The Efficiency of Calcium Oxide on Microbial Self-Healing Activity in Alkali-Activated Slag (AAS)

Abstract

1. Introduction

2. Experimental Program

2.1. Materials

2.2. AAS Mortar Manufacture

2.3. The Assessment Technique

2.3.1. Mechanical Property Testing

2.3.2. Durability Property Testing

2.3.3. Microstructural Analysis

3. Results and Analysis

3.1. Mechanical Properties

- Hydrolyzing urea to produce carbonate and ammonia in the presence of urease, followed by a series of biological reactions to produce bicarbonate and hydroxide ions.CO(NH2)2 + H2O → NH2COOH + NH3NH2COOH + H2O → NH3 + H2CO3H2CO3 ↔ HCO3− + H+2NH3 + 2H2O ↔ 2NH4+ + 2OH−

- Hydroxide ions elevate the pH value, promoting the formation of carbonate ions.

- An attraction force takes place between the positively charged calcium ions (Ca2+) and the negatively charged carbonate ions (), precipitating calcium carbonate (CaCO3) at the cell surface.Ca2+ + Cell → Cell-Ca2+Cell-Ca2+ → Cell-CaCO3↓

3.2. Durability Properties

3.2.1. Water Absorption and Porosity

3.2.2. Rapid Chloride Permeability Test (RCPT)

3.2.3. Surface Resistivity Test

3.3. XRD

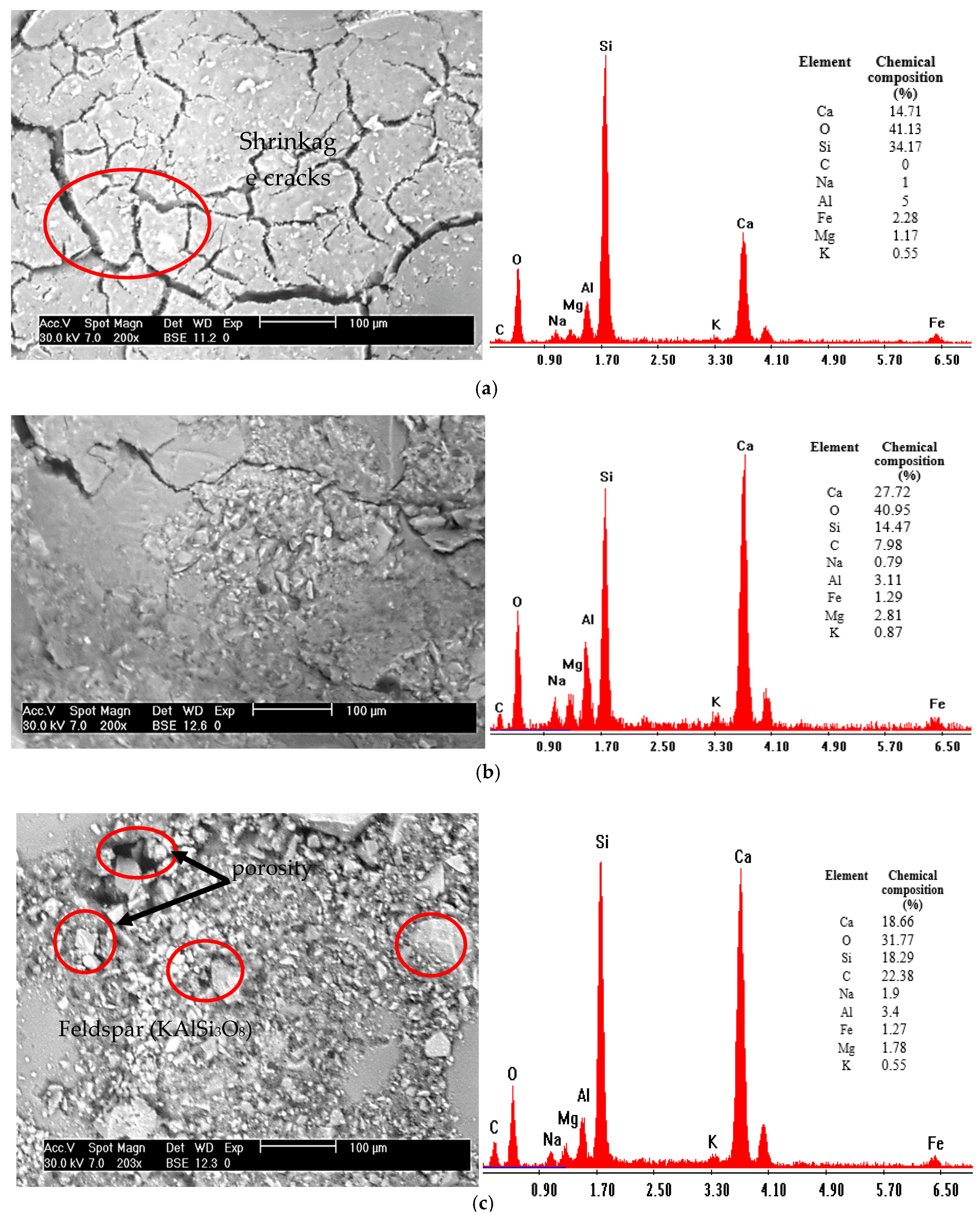

3.4. Microstructure Analysis

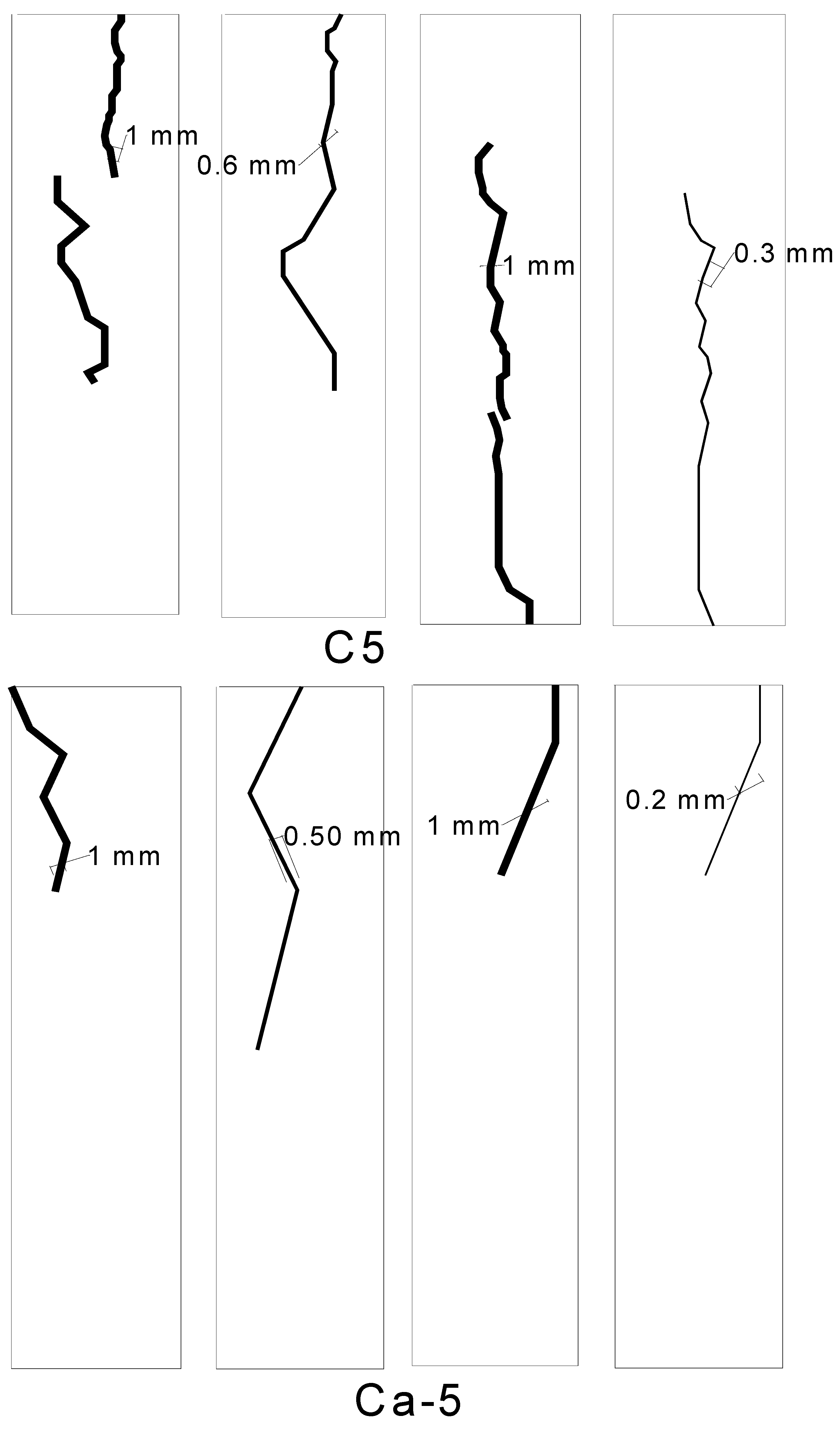

3.5. Visualization of Surface Crack Healing

4. Conclusions

- The experimental evaluation indicated a deterioration in the mechanical properties of bio-AAS composites with calcium oxide incorporation, where a substantial drop (21.6%) in the mechanical properties was reported.

- Calcium oxide addition increased the free calcium ions that motivated the rapid formation of metal hydroxides. Metal hydroxide formation led to a reduction in the localized hydroxyl ions, disrupting the corresponding microbiological reactions of Bacillus subtilis.

- The presence of high silicate concentrations within these conditions resulted in instant silicate gelation with larger particle sizes. The overlapping between these larger particles created wider spaces, increasing the porosity of the composite.

- RCPT did not demonstrate the real chloride resistance of AAS mixtures because of the availability of mobile ions such as Na+, OH−, and HS− in addition to the Cl− mobility. Incorporating CaO increased calcium ions that reacted with some of these available ions, reducing the passing charges and improving the RCPT results.

- The surface electrical resistivity proved the good chloride resistance of the AAS mixtures based on the classification of AASHTO T358-15.

- The results of the microstructure analysis highly illustrated the results observed during the mechanical and durability properties tests. However, CaO addition requires more investigation in the presence of microbial bacteria to determine the required concentration of calcium ions for optimum microbial efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hossain, M.U.; Poon, C.S.; Lo, I.M.; Cheng, J.C. Comparative LCA on using waste materials in the cement industry: A Hong Kong case study. Resour. Conserv. Recycl. 2017, 120, 199–208. [Google Scholar] [CrossRef]

- Singh, G.B.; Subramaniam, K.V. Production and characterization of low-energy Portland composite cement from post-industrial waste. J. Clean. Prod. 2019, 239, 118024. [Google Scholar] [CrossRef]

- Rashad, A.M. A Concise on the Effect of Calcium Oxide on the Properties of Alkali-Activated Materials: A Manual for Civil Engineers. Int. J. Concr. Struct. Mater. 2023, 17, 72. [Google Scholar] [CrossRef]

- Zhang, L.V.; Suleiman, A.R.; Nehdi, M.L. Crack Self-Healing in NaOH-Activated Slag-Based Composites Incorporating Calcium Hydroxide. J. Mater. Civ. Eng. 2021, 33, 04021012. [Google Scholar] [CrossRef]

- Hammad, N.; Elnemr, A.; Shaaban, I.G. State-of-the-Art Report: The Self-Healing Capability of Alkali-Activated Slag (AAS) Concrete. Materials 2023, 16, 4394. [Google Scholar] [CrossRef]

- Hammad, N.; El-Nemr, A.; Hasan, H.E.-D. The performance of fiber GGBS based alkali-activated concrete. J. Build. Eng. 2021, 42, 102464. [Google Scholar] [CrossRef]

- Shi, Z.; Shi, C.; Wan, S.; Zhang, Z. Effects of alkali dosage and silicate modulus on alkali-silica reaction in alkali-activated slag mortars. Cem. Concr. Res. 2018, 111, 104–115. [Google Scholar] [CrossRef]

- Amer, I.; Kohail, M.; El-Feky, M.S.; Rashad, A.; Khalaf, M.A. A review on alkali-activated slag concrete. Ain Shams Eng. J. 2021, 12, 1475–1499. [Google Scholar] [CrossRef]

- Mastali, M.; Kinnunen, P.; Dalvand, A.; Firouz, R.M.; Illikainen, M. Drying shrinkage in alkali-activated binders—A critical review. Constr. Build. Mater. 2018, 190, 533–550. [Google Scholar] [CrossRef]

- Hammad, N.; ElNemr, A.M.; Hassan, H.E.-D. Flexural performance of reinforced Alkali-activated concrete beams incorporating steel and structural Macro synthetic polypropylene fiber. Constr. Build. Mater. 2022, 324, 126634. [Google Scholar] [CrossRef]

- Yang, L.Y.; Jia, Z.J.; Zhang, Y.M.; Dai, J.G. Effects of nano-TiO2 on strength, shrinkage and microstructure of alkali activated slag pastes. Cem. Concr. Compos. 2015, 57, 1–7. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Cheng, Y.; Huseien, G.F.; Shah, K.W. Shrinkage mechanisms and shrinkage-mitigating strategies of alkali-activated slag composites: A critical review. Constr. Build. Mater. 2022, 318, 125993. [Google Scholar] [CrossRef]

- Ye, H.; Radlińska, A. Shrinkage mitigation strategies in alkali-activated slag. Cem. Concr. Res. 2017, 101, 131–143. [Google Scholar] [CrossRef]

- Cartwright, C.; Rajabipour, F.; Radlińska, A. Shrinkage Characteristics of Alkali-Activated Slag Cements. J. Mater. Civ. Eng. 2015, 27, B4014007. [Google Scholar] [CrossRef]

- Li, Z.; Nedeljković, M.; Chen, B.; Ye, G. Mitigating the autogenous shrinkage of alkali-activated slag by metakaolin. Cem. Concr. Res. 2019, 122, 30–41. [Google Scholar] [CrossRef]

- Hassanin, A.; El-Nemr, A.; Shaaban, H.F.; Saidani, M.; Shaaban, I.G. Coupling Behavior of Autogenous and Autonomous Self-Healing Techniques for Durable Concrete. Int. J. Civ. Eng. 2024, 22, 925–948. [Google Scholar] [CrossRef]

- Jadhav, U.U.; Lahoti, M.; Chen, Z.; Qiu, J.; Cao, B.; Yang, E.-H. Viability of bacterial spores and crack healing in bacteria-containing geopolymer. Constr. Build. Mater. 2018, 169, 716–723. [Google Scholar] [CrossRef]

- Jogi, P.K.; Lakshmi, T.V. Self healing concrete based on different bacteria: A review. Mater. Today Proc. 2020, 43, 1246–1252. [Google Scholar] [CrossRef]

- Yildirim, G.; Sahmaran, M.; Ahmed, H.U. Influence of Hydrated Lime Addition on the Self-Healing Capability of High-Volume Fly Ash Incorporated Cementitious Composites. J. Mater. Civ. Eng. 2015, 27, 04014187. [Google Scholar] [CrossRef]

- Shaheen, N.; Khushnood, R.A.; Din, S.U.; Khalid, A. Influence of bio-immobilized lime stone powder on self-healing behaviour of cementitious composites. IOP Conf. Series Mater. Sci. Eng. 2018, 431, 062002. [Google Scholar] [CrossRef]

- Gharieb, M.; Rashad, A.M. Impact of sugar beet waste on strength and durability of alkali-activated slag cement. ACI Mater. J. 2022, 119, 79–90. [Google Scholar] [CrossRef]

- Seo, J.; Kim, S.; Park, S.; Bae, S.J.; Lee, H.K. Microstructural evolution and carbonation behavior of lime-slag binary binders. Cem. Concr. Compos. 2021, 119, 104000. [Google Scholar] [CrossRef]

- Chen, Z.; Ye, H. The role of CaO and MgO incorporation in chloride resistance of sodium carbonate-activated slag. Cem. Concr. Compos. 2022, 132, 104625. [Google Scholar] [CrossRef]

- Ju, C.; Liu, Y.; Jia, M.; Yu, K.; Yu, Z.; Yang, Y. Effect of calcium oxide on mechanical properties and microstructure of alkali-activated slag composites at sub-zero temperature. J. Build. Eng. 2020, 32, 101561. [Google Scholar] [CrossRef]

- Burciaga-Díaz, O.; Betancourt-Castillo, I.; Montes-Escobedo, M.; Escalante-García, J. One-part pastes and mortars of CaO-Na2CO3 activated blast furnace slag: Microstructural evolution, cost and CO2 emissions. Constr. Build. Mater. 2023, 368, 130431. [Google Scholar] [CrossRef]

- Rashad, A.M.; Gharieb, M. Solving the perpetual problem of imperative use heat curing for fly ash geopolymer cement by using sugar beet waste. Constr. Build. Mater. 2021, 307, 124902. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Phoo-Ngernkham, T.; Hanjitsuwan, S.; Horpibulsuk, S.; Poowancum, A.; Injorhor, B. Effect of calcium-rich compounds on setting time and strength development of alkali-activated fly ash cured at ambient temperature. Case Stud. Constr. Mater. 2018, 9, e00198. [Google Scholar] [CrossRef]

- Temuujin, J.; van Riessen, A.; Williams, R. Influence of calcium compounds on the mechanical properties of fly ash geopolymer pastes. J. Hazard. Mater. 2009, 167, 82–88. [Google Scholar] [CrossRef]

- Hassan, A.; ElNemr, A.; Goebel, L.; Koenke, C. Effect of hybrid polypropylene fibers on mechanical and shrinkage behavior of alkali-activated slag concrete. Constr. Build. Mater. 2024, 411, 134485. [Google Scholar] [CrossRef]

- ECP 203-2007; Egyptian Code for Design and Construction of Reinforced Concrete Structures, Design of Concrete Mixes. ECP: Islamabad, Pakistan, 2007.

- ASTM C109; Standard Test Method of Compressive Strength of Hydrualic Cement Mortars (Using 2-in. or [50 mm] Cube speciments), Annual Book of ASTM Standard. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C348-21; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars, Annual Book of ASTM Standard. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C642-21; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete, Annual Book of ASTM Standard. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C1202-19; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration, Annual Book of ASTM Standard. ASTM International: West Conshohocken, PA, USA, 2022.

- AASHTO-T277; Standard Method of Test for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. AASHTO: Washington, DC, USA, 2023.

- AASHTO-T358; Standard Method of Test for Surface Resistivity Indication of Concrete’s Ability to Resist Chloride Ion Penetration. AASHTO: Washington, DC, USA, 2019.

- Dombrowski, K.; Buchwald, A.; Weil, M. The influence of calcium content on the structure and thermal performance of fly ash based geopolymers. J. Mater. Sci. 2007, 42, 3033–3043. [Google Scholar] [CrossRef]

- Lee, W.; van Deventer, J. The effect of ionic contaminants on the early-age properties of alkali-activated fly ash-based cements. Cem. Concr. Res. 2002, 32, 577–584. [Google Scholar] [CrossRef]

- He, J.; Bai, W.; Zheng, W.; He, J.; Sang, G. Influence of hydrated lime on mechanical and shrinkage properties of alkali-activated slag cement. Constr. Build. Mater. 2021, 289, 123201. [Google Scholar] [CrossRef]

- Fang, G.; Bahrami, H.; Zhang, M. Mechanisms of autogenous shrinkage of alkali-activated fly ash-slag pastes cured at ambient temperature within 24 h. Constr. Build. Mater. 2018, 171, 377–387. [Google Scholar] [CrossRef]

- Xiang, J.; Liu, L.; Cui, X.; He, Y.; Zheng, G.; Shi, C. Effect of limestone on rheological, shrinkage and mechanical properties of alkali—Activated slag/fly ash grouting materials. Constr. Build. Mater. 2018, 191, 1285–1292. [Google Scholar] [CrossRef]

- Adam, A.A.; Amiri, N.H.; Suarnita, I.W.; Rupang, N. The Effect of Lime Addition on the Setting Time and Strength of Ambient Cured Fly Ash Based Geopolymer Binder. MATEC Web Conf. 2016, 47, 01015. [Google Scholar] [CrossRef]

- Harutyunyan, V.S.; Kirchheim, A.P.; Monteiro, P.J.M.; Aivazyan, A.P.; Fischer, P. Investigation of early growth of calcium hydroxide crystals in cement solution by soft X-ray transmission microscopy. J. Mater. Sci. 2009, 44, 962–969. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, Y.; Hu, J.; Wang, H.; Zhang, Z. Review on chloride transport in alkali-activated materials: Role of precursors, activators and admixtures. Constr. Build. Mater. 2022, 328, 127081. [Google Scholar] [CrossRef]

- Mundra, S.; Bernal, S.A.; Criado, M.; Hlaváček, P.; Ebell, G.; Reinemann, S.; Gluth, G.J.; Provis, J. Steel corrosion in reinforced alkali-activated materials. RILEM Tech. Lett. 2017, 2, 33–39. [Google Scholar] [CrossRef]

- Lee, N.K.; Lee, H.K. Influence of the slag content on the chloride and sulfuric acid resistances of alkali-activated fly ash/slag paste. Cem. Concr. Compos. 2016, 72, 168–179. [Google Scholar] [CrossRef]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; Nicolas, R.S.; Brice, D.G.; Kilcullen, A.R.; Hamdan, S.; van Deventer, J.S. Influence of fly ash on the water and chloride permeability of alkali-activated slag mortars and concretes. Constr. Build. Mater. 2013, 48, 1187–1201. [Google Scholar] [CrossRef]

- García-Lodeiro, I.; Fernández-Jiménez, A.; Palomo, A. Cementos híbridos de bajo impacto ambiental: Reducción del factor clinker. Rev. Alconpat 2015, 5, 1–17. [Google Scholar] [CrossRef]

- Nguyễn, H.H.; Choi, J.-I.; Kim, H.-K.; Lee, B.Y. Effects of the type of activator on the self-healing ability of fiber-reinforced alkali-activated slag-based composites at an early age. Constr. Build. Mater. 2019, 224, 980–994. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Qureshi, Z.A.; Shaheen, N.; Ali, S. Bio-mineralized self-healing recycled aggregate concrete for sustainable infrastructure. Sci. Total. Environ. 2020, 703, 135007. [Google Scholar] [CrossRef]

| Precursor | % of CaO | Self-Healing Mechanism | Healing Agent | Influence | References |

|---|---|---|---|---|---|

| Blended cement-fly ash | 2.5 and 5 | Autogenous | Polyvinyl alcohol (PVA) | Enhanced the closure of crack openings | [19] |

| Slag | 7 | Autogenous | PVA | Improved crack self-healing ability | [4] |

| CaO | 100 | Autonomous | Bacillus subtilis | Preserved the survival of Bacillus subtilis | [20] |

| Precursor | % of CaO | Activator | Curing Condition | Mechanical Properties | Flowability | Setting Time | References |

|---|---|---|---|---|---|---|---|

| Slag | 2.5, 5, and 10 | NaOH and Na2SiO3 | Room | ↑ | ↓ | ↓ | [21] |

| Slag | 15 | NaOH and Na2SiO3 | Room | ↓ | - | - | [21] |

| Slag | 7 | Ca(OH)2 | Room | ↑ | ↑ | [11] | |

| Slag | 10 | Ca(OH)2 | Room | ↓ | ↓ | ↓ | [11] |

| Slag | 5, 10, and 15 | NaOH and Na2SiO3 | Room | ↓ | - | - | [22] |

| Slag | 2.5 and 5 | Na2CO3 | - | ↑ | ↓ | ↓ | [23] |

| Slag | 1–3 | KOH and K2SiO3 | 20 °C | ↑ | - | ↓ | [24] |

| Slag | 6 | CaO as sole activator | 20 °C | ↓ | - | - | [25] |

| Slag | 6 | CaO as sole activator | 60 °C | ↓ | - | - | [25] |

| Flyash | 2.5, 5, and 7 | NaOH and Na2SiO3 | Room | ↑ | ↓ | ↓ | [26] |

| Flyash | 5, 10, and 15 | NaOH and Na2SiO3 | Room | ↓ | - | - | [27] |

| Flyash | 1, 3, and 5 | NaOH and Na2SiO3 | 20 °C | ↑ | - | ↓ | [28] |

| Flyash | 1, 3, and 5 | NaOH and Na2SiO3 | 70 °C for 24 h | ↓ | - | ↓ | [28] |

| Oxides | % |

|---|---|

| SiO2 | 35.40 |

| CaO | 36.87 |

| Al2O3 | 17.40 |

| MgO | 6.83 |

| MnO | 0.26 |

| Fe2O3 | 1.4 |

| MnO | 0.35 |

| TiO2 | 0.11 |

| S | 0.24 |

| L.O.I | 0.50 |

| Characteristics of Bacillus subtilis | Value |

|---|---|

| Growth medium | 3 |

| Incubation time | 24 h |

| Subculture | 30 days |

| Gram stain | Positive |

| shape | Rod |

| Oxygen demand | Facultative |

| Mix ID | Slag kg/m3 | NaOH kg/m3 | Na2SiO3 kg/m3 | H2O kg/m3 | Na2O% | Ms Ratio | L/B Ratio | Bacteria Concentration Cells/mL | CaO kg/m3 |

|---|---|---|---|---|---|---|---|---|---|

| C | 387.40 | 60.45 | 82.81 | 81.61 | 8% | 0.8 | 0.38 | - | - |

| C5 | 387.40 | 60.45 | 82.81 | 81.61 | 8% | 0.8 | 0.38 | 105 | - |

| Ca-5 | 359.60 | 60.45 | 82.81 | 81.61 | 8% | 0.8 | 0.38 | 105 | 27.80 (7%) |

| t (min) | 0 | 30 | 60 | 90 | 120 | 150 | 180 | 210 | 240 | 270 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Q (C) | 260 | 919 | 1908 | 3253 | - | |||||

| I (A) | 260 | 386 | 601 | 621 | |||||||

| C-5 | Q (C) | 124 | 443 | 777 | 1080 | - | |||||

| I (A) | 138 | 177 | 185 | 168 | |||||||

| Ca-5 | Q (C) | 112 | 408 | 743 | 1122 | 1529 | 1970 | 2452 | 2970 | 3531 | - |

| I (A) | 125 | 164 | 186 | 210 | 226 | 245 | 267 | 288 | 311 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hammad, N.; El-Nemr, A.; Shaaban, I.G. The Efficiency of Calcium Oxide on Microbial Self-Healing Activity in Alkali-Activated Slag (AAS). Appl. Sci. 2024, 14, 5299. https://doi.org/10.3390/app14125299

Hammad N, El-Nemr A, Shaaban IG. The Efficiency of Calcium Oxide on Microbial Self-Healing Activity in Alkali-Activated Slag (AAS). Applied Sciences. 2024; 14(12):5299. https://doi.org/10.3390/app14125299

Chicago/Turabian StyleHammad, Nancy, Amr El-Nemr, and Ibrahim G. Shaaban. 2024. "The Efficiency of Calcium Oxide on Microbial Self-Healing Activity in Alkali-Activated Slag (AAS)" Applied Sciences 14, no. 12: 5299. https://doi.org/10.3390/app14125299

APA StyleHammad, N., El-Nemr, A., & Shaaban, I. G. (2024). The Efficiency of Calcium Oxide on Microbial Self-Healing Activity in Alkali-Activated Slag (AAS). Applied Sciences, 14(12), 5299. https://doi.org/10.3390/app14125299