Low-Carbon Operation Strategy of Park-Level Integrated Energy System with Firefly Algorithm

Abstract

1. Introduction

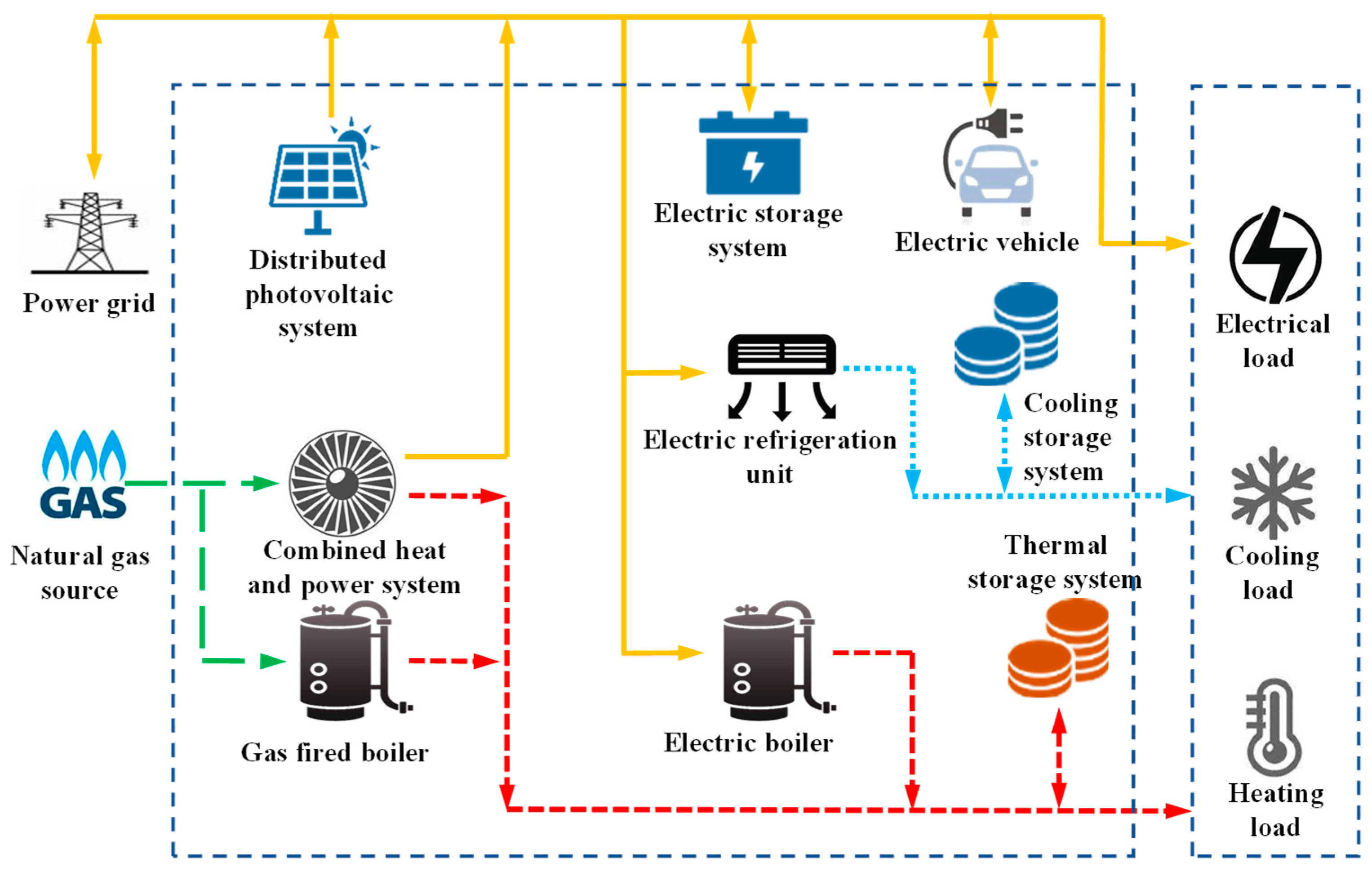

2. Low-Carbon Integrated Energy System Architecture

3. Mathematical Model of Low-Carbon Integrated Energy Systems

3.1. Mathematical Model of PV Power Generation

3.2. Mathematical Model of Micro Gas Turbines

3.3. Mathematical Model of Gas Boilers

3.4. Mathematical Model of Electric Refrigeration System

3.5. Mathematical Model of Energy Storage Devices

4. Operational Strategy Optimization Model

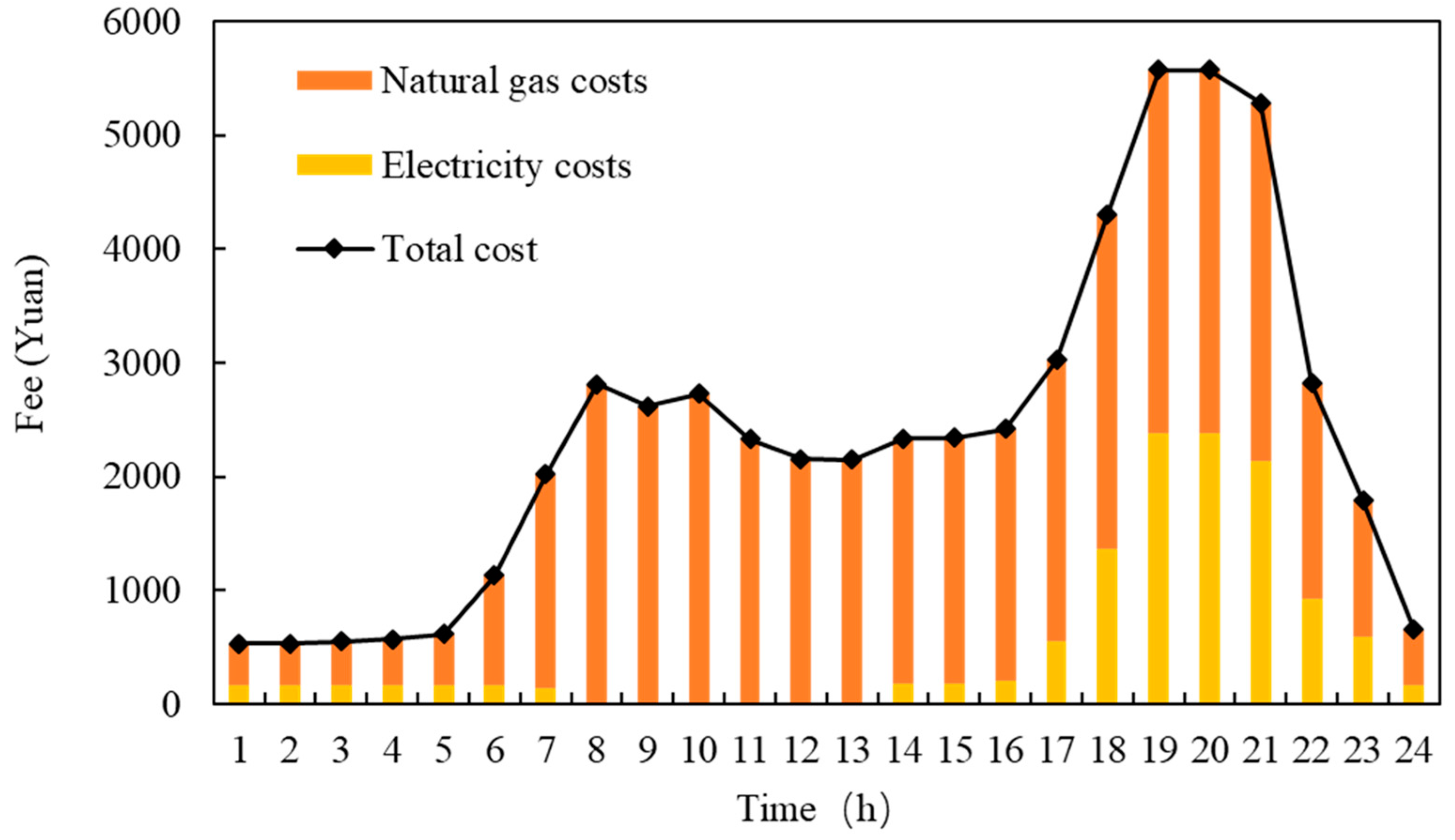

4.1. Operating Costs

4.2. Carbon Emissions

4.3. Energy Balance Constraints

4.4. Equipment Operational Constraints

4.5. Optimization Method

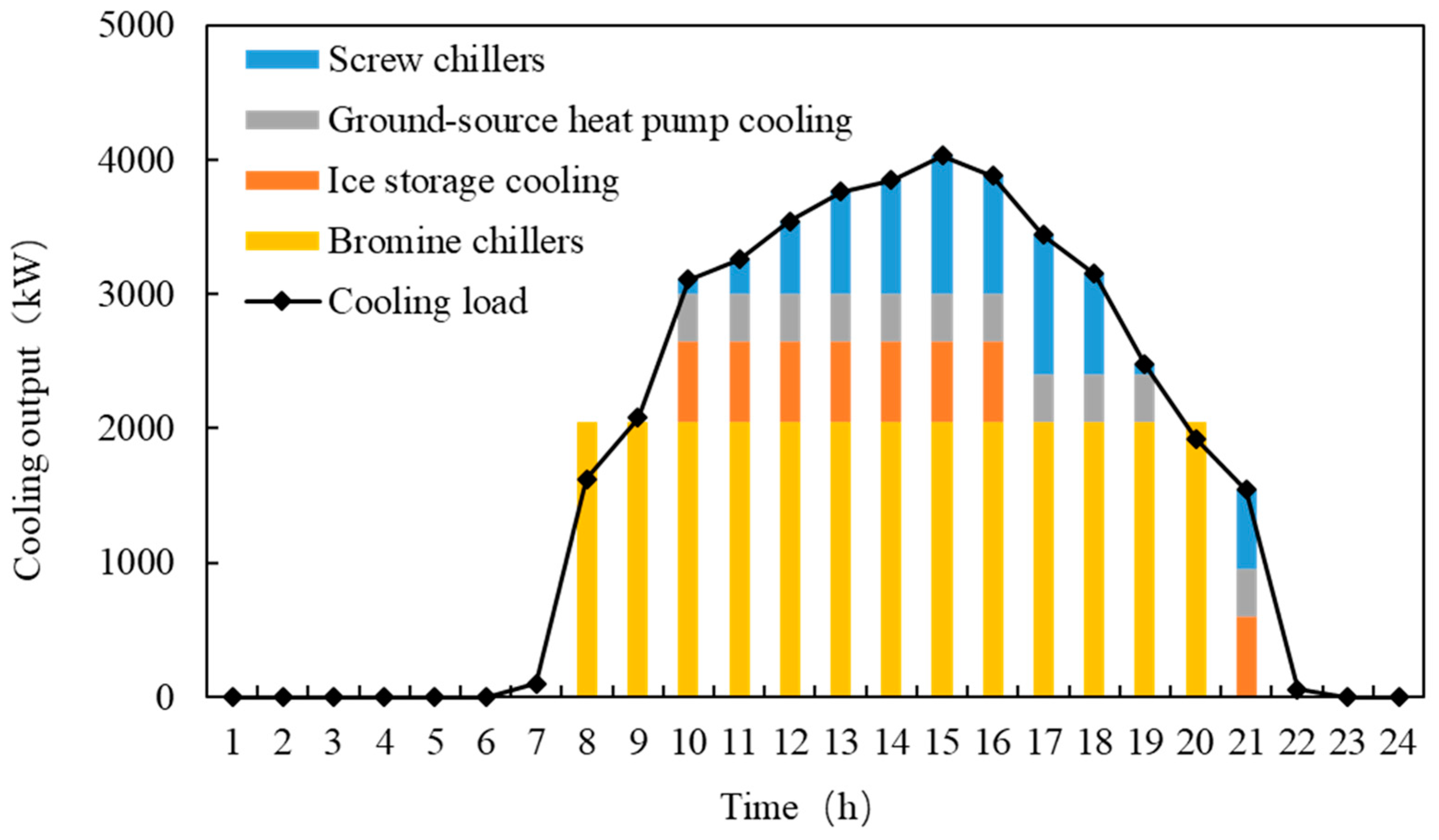

5. Case Study

6. Conclusions

- (1)

- To cater to the diverse energy demands of the park, including cold, heat, electricity, and gas, a multi-energy complementary system is formulated, incorporating distributed clean energy and energy storage. This system is designed based on the principle of energy–economy–environment integration, and its unique features are thoroughly analyzed.

- (2)

- Leveraging the firefly optimization algorithm, an operational optimization model is formulated for multi-energy coupling systems. This approach offers precision in determining the operational state parameters of these systems.

- (3)

- An autonomous, economical, energy-efficient, low-carbon, and optimized operational mode has been successfully established.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yan, J.Y.; Yang, Y.; Campana, P.E.; He, J.J. City-level analysis of subsidy-free solar photovoltaic electricity price, profits and grid parity in China. Nat. Energy 2019, 4, 709–717. [Google Scholar] [CrossRef]

- Wen, Q.; Hong, J.K.; Liu, G.W.; Xu, P.P.; Tang, M.H.; Li, Z.F. Regional efficiency disparities in China’s construction sector: A combination of multiregional input-output and data envelopment analyses. Appl. Energy 2020, 257, 113964. [Google Scholar] [CrossRef]

- Zhang, T.; Yan, X.; Zhang, R.; Ye, Q.; Ma, J. Optimized Dispatching for Integrated Energy System With Wind Power. Front. Energy Res. 2022, 10, 917805. [Google Scholar] [CrossRef]

- Ma, C.J.; Menke, J.H.; Dasenbrock, J.; Braun, M.; Haslbeck, M.; Schmid, K.H. Evaluation of energy losses in low voltage distribution grids with high penetration of distributed generation. Appl. Energy 2019, 256, 113907. [Google Scholar] [CrossRef]

- Zhang, T.; Hu, Z. Optimal Scheduling Strategy of Virtual Power Plant With Power-to-Gas in Dual Energy Markets. IEEE Trans. Ind. Appl. 2022, 58, 2921–2929. [Google Scholar] [CrossRef]

- Ghasemi, H.; Aghaei, J.; Gharehpetian, G.B.; Safdarian, A. MILP model for integrated expansion planning of multi-carrier active energy systems. IET Gener. Transm. Distrib. 2019, 13, 1177–1189. [Google Scholar] [CrossRef]

- de la Nieta, A.A.S.; Paterakis, N.G.; Gibescu, M. Participation of photovoltaic power producers in short-term electricity markets based on rescheduling and risk-hedging mapping. Appl. Energy 2020, 266, 114741. [Google Scholar] [CrossRef]

- Bloess, A. Modeling of combined heat and power generation in the context of increasing renewable energy penetration. Appl. Energy 2020, 267, 114727. [Google Scholar] [CrossRef]

- Amuzu-Sefordzi, B.; Martinus, K.; Tschakert, P.; Wills, R. Disruptive innovations and decentralized renewable energy systems in Africa: A socio-technical review. Energy Res. Soc. Sci. 2018, 46, 140–154. [Google Scholar] [CrossRef]

- Mancarella, P. MES (multi-energy systems): An overview of concepts and evaluation models. Energy 2014, 65, 1–17. [Google Scholar] [CrossRef]

- Wang, R. Multi-objective configuration optimization method for a diesel-based hybrid energy system. Energy Rep. 2020, 6, 2146–2152. [Google Scholar] [CrossRef]

- Wang, Y.L.; Wang, Y.D.; Huang, Y.J.; Yang, J.L.; Ma, Y.Z.; Yu, H.Y.; Zeng, M.; Zhang, F.; Zhang, Y. Operation optimization of regional integrated energy system based on the modeling of electricity-thermal-natural gas network. Appl. Energy 2019, 251, 113410. [Google Scholar] [CrossRef]

- Ju, L.W.; Li, H.H.; Zhao, J.W.; Chen, K.T.; Tan, Q.K.; Tan, Z.F. Multi-objective stochastic scheduling optimization model for connecting a virtual power plant to wind-photovoltaic-electric vehicles considering uncertainties and demand response. Energy Convers. Manag. 2016, 128, 160–177. [Google Scholar] [CrossRef]

- Tan, J.; Wu, Q.W.; Hu, Q.R.; Wei, W.; Liu, F. Adaptive robust energy and reserve co-optimization of integrated electricity and heating system considering wind uncertainty. Appl. Energy 2020, 260, 114230. [Google Scholar] [CrossRef]

- Lyu, J.; Zhang, S.; Cheng, H.; Yuan, K.; Song, Y.; Fang, S. Optimal Sizing of Energy Station in the Multi-energy System Integrated with Data Center. IEEE Trans. Ind. Appl. 2021, 57, 1222–1234. [Google Scholar] [CrossRef]

| Parameters | ηE | ηH | ηGB |

|---|---|---|---|

| Value | 40% | 90% | 98% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Wang, S.; Yu, Y.; Guo, Y.; Jin, L.; Jia, X.; Liu, K.; Zhang, X. Low-Carbon Operation Strategy of Park-Level Integrated Energy System with Firefly Algorithm. Appl. Sci. 2024, 14, 5433. https://doi.org/10.3390/app14135433

Chen H, Wang S, Yu Y, Guo Y, Jin L, Jia X, Liu K, Zhang X. Low-Carbon Operation Strategy of Park-Level Integrated Energy System with Firefly Algorithm. Applied Sciences. 2024; 14(13):5433. https://doi.org/10.3390/app14135433

Chicago/Turabian StyleChen, Hongyin, Songcen Wang, Yaoxian Yu, Yi Guo, Lu Jin, Xiaoqiang Jia, Kaicheng Liu, and Xinhe Zhang. 2024. "Low-Carbon Operation Strategy of Park-Level Integrated Energy System with Firefly Algorithm" Applied Sciences 14, no. 13: 5433. https://doi.org/10.3390/app14135433

APA StyleChen, H., Wang, S., Yu, Y., Guo, Y., Jin, L., Jia, X., Liu, K., & Zhang, X. (2024). Low-Carbon Operation Strategy of Park-Level Integrated Energy System with Firefly Algorithm. Applied Sciences, 14(13), 5433. https://doi.org/10.3390/app14135433