An Experiment Study on Surface Topography of GH4169 Assisted by Ultrasonic Elliptical Vibration Ultra-Precision Turning

Abstract

:1. Introduction

2. Cutting Test

2.1. Test Equipment

2.2. Tool and Workpiece Materials

2.3. Experimental Methods and Plans

3. Analysis of Test Results

3.1. Ultrasonic Elliptical Vibratory Cutting and Conventional Cutting

3.1.1. Ultrasonic Elliptical Vibration Cutting Mechanism and GH4169 Material-Removal Mechanism

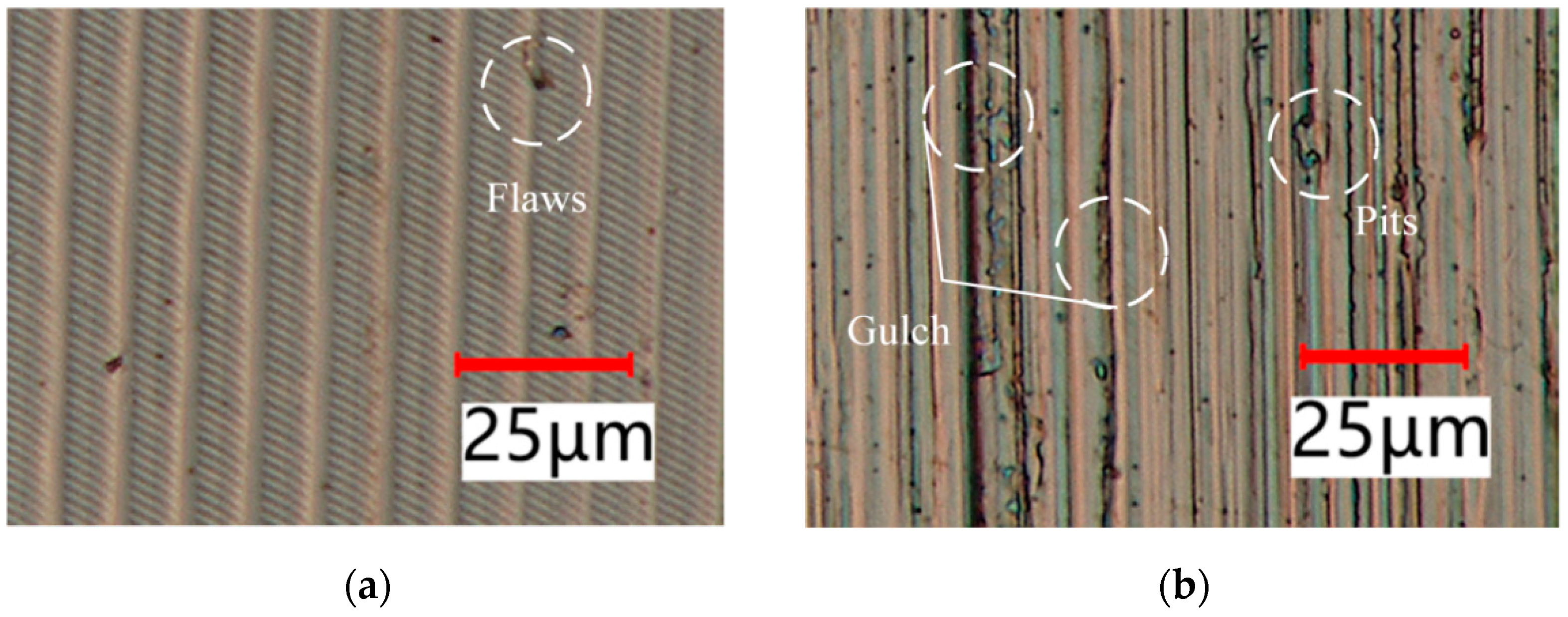

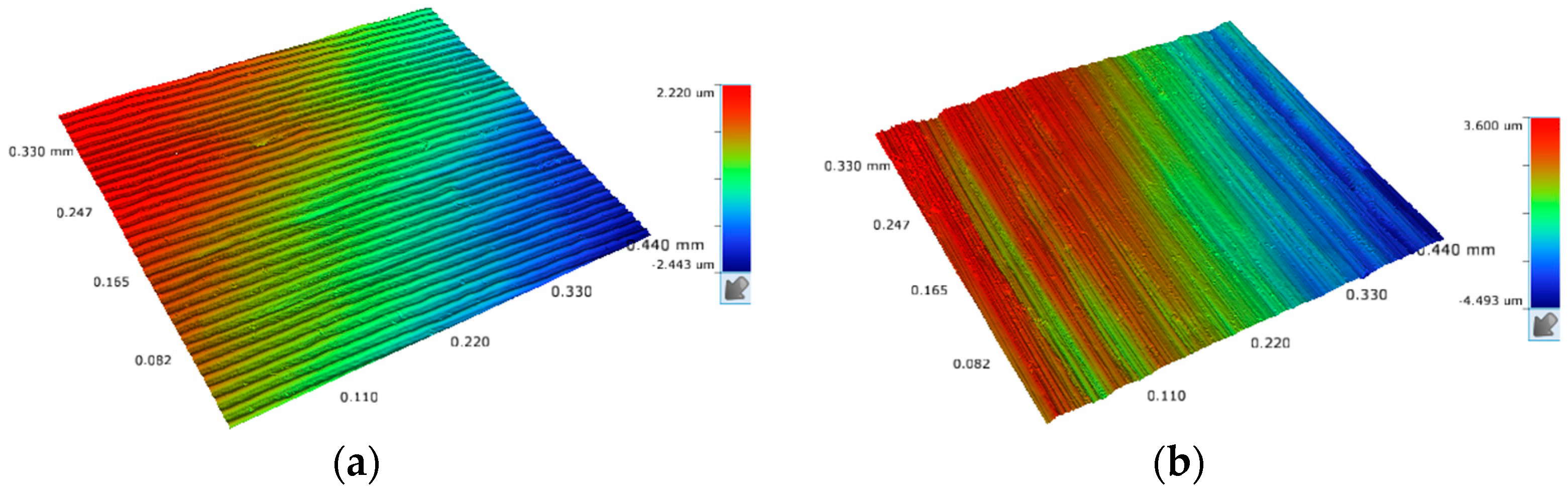

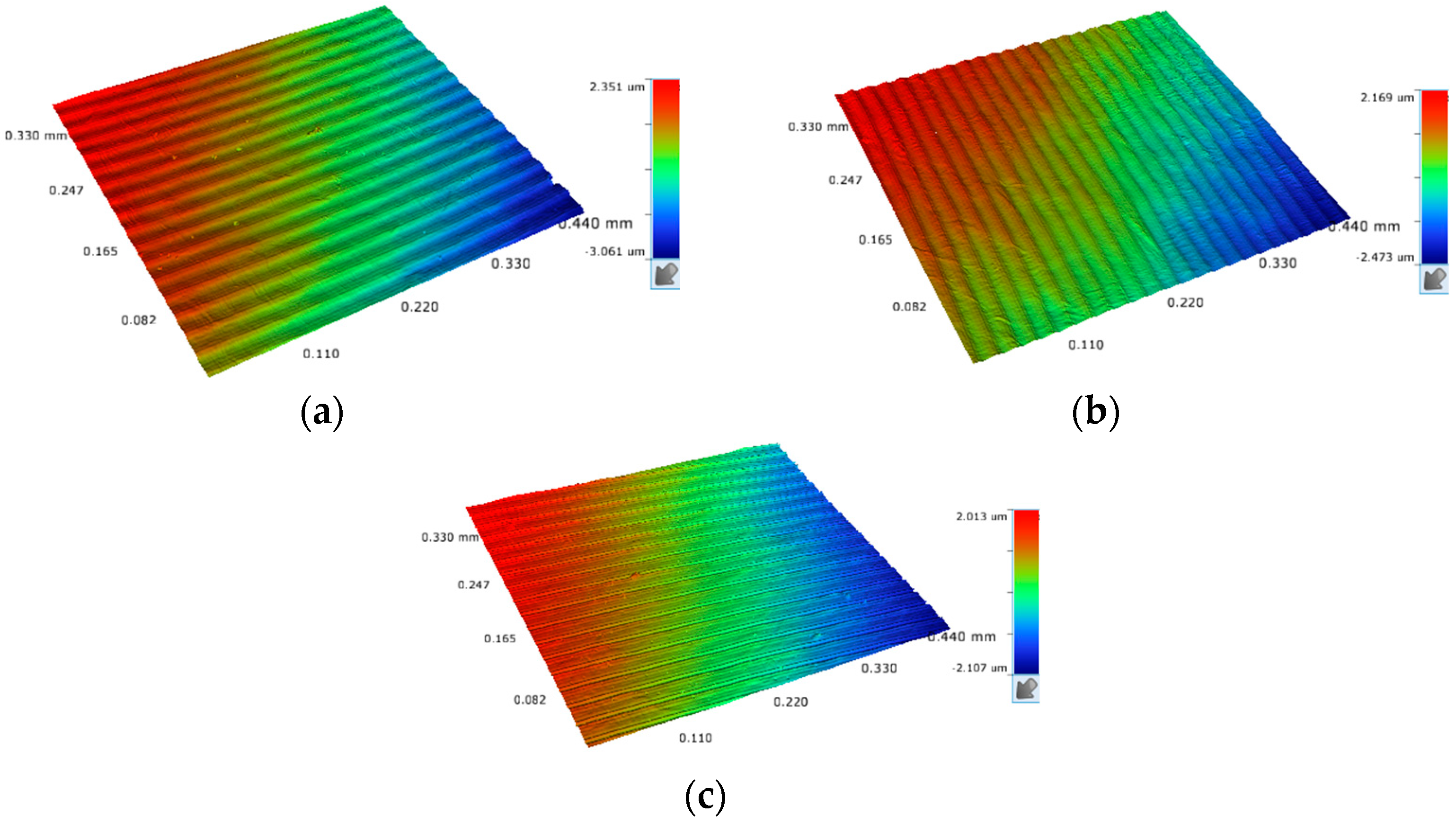

3.1.2. Surface Topography and Surface Roughness

3.2. Analysis of the Effect of Cutting Parameters on Surface Roughness

3.2.1. Effect of Cutting Speed on Surface Roughness

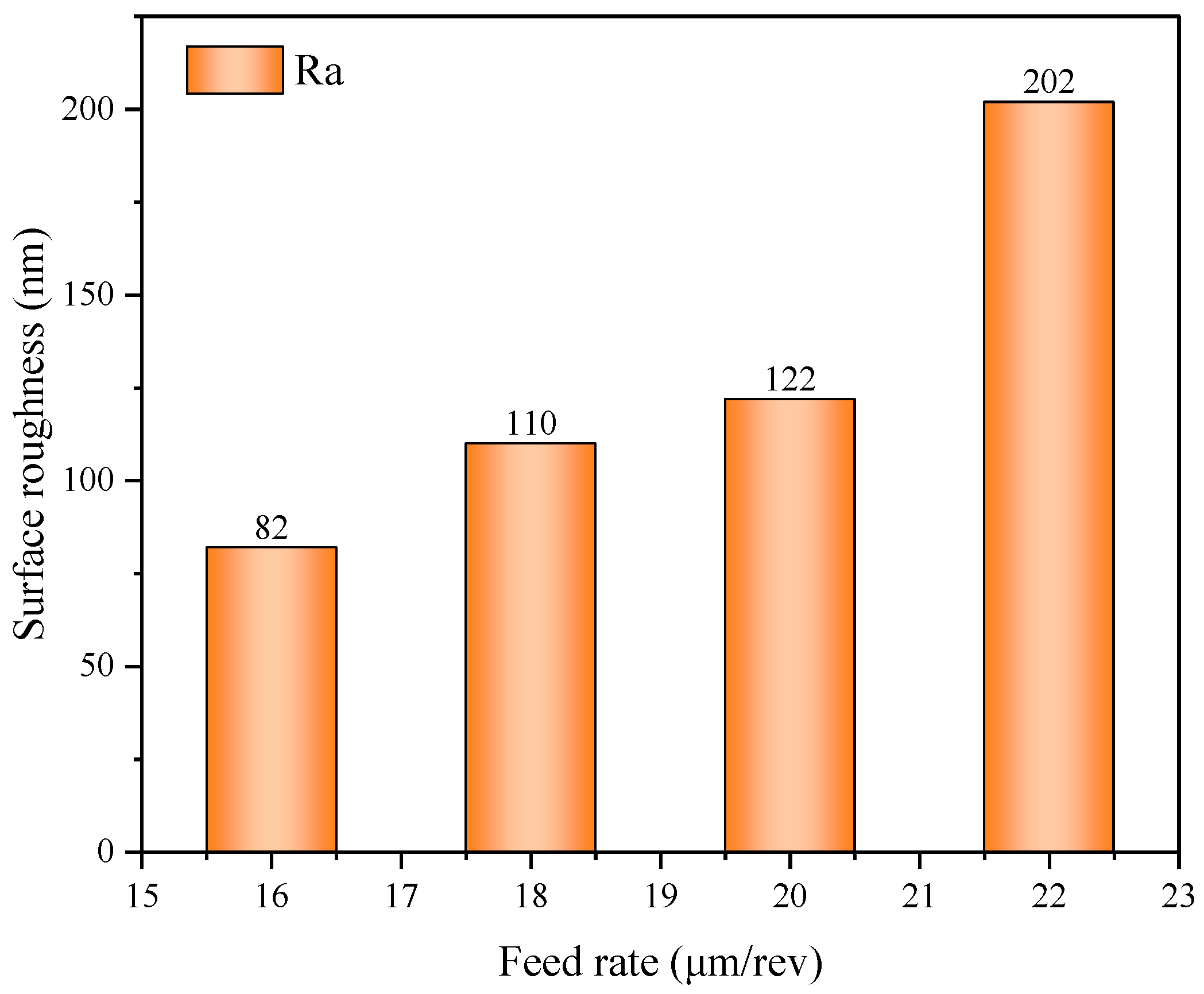

3.2.2. Effect of Feed Rate on Surface Roughness

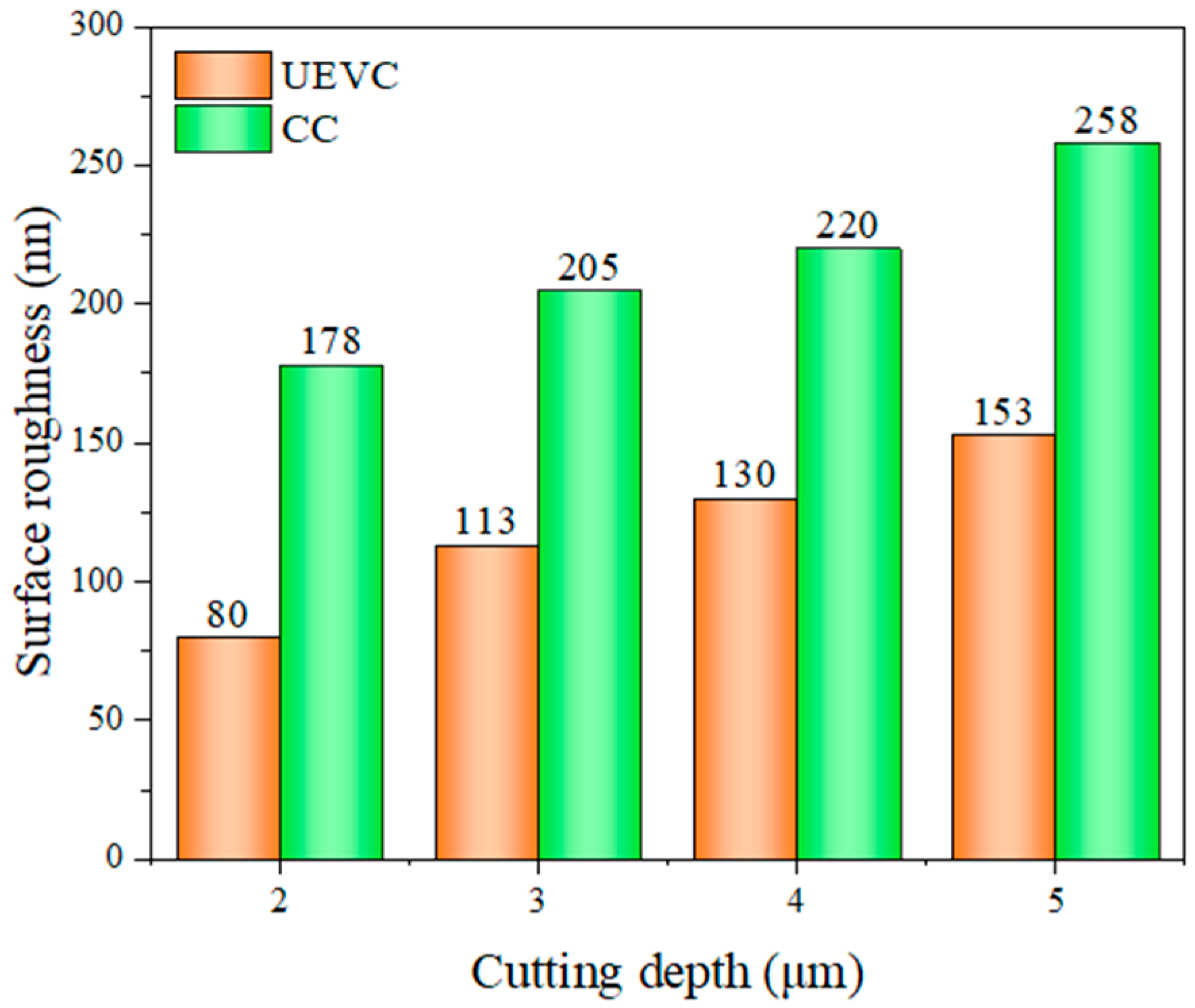

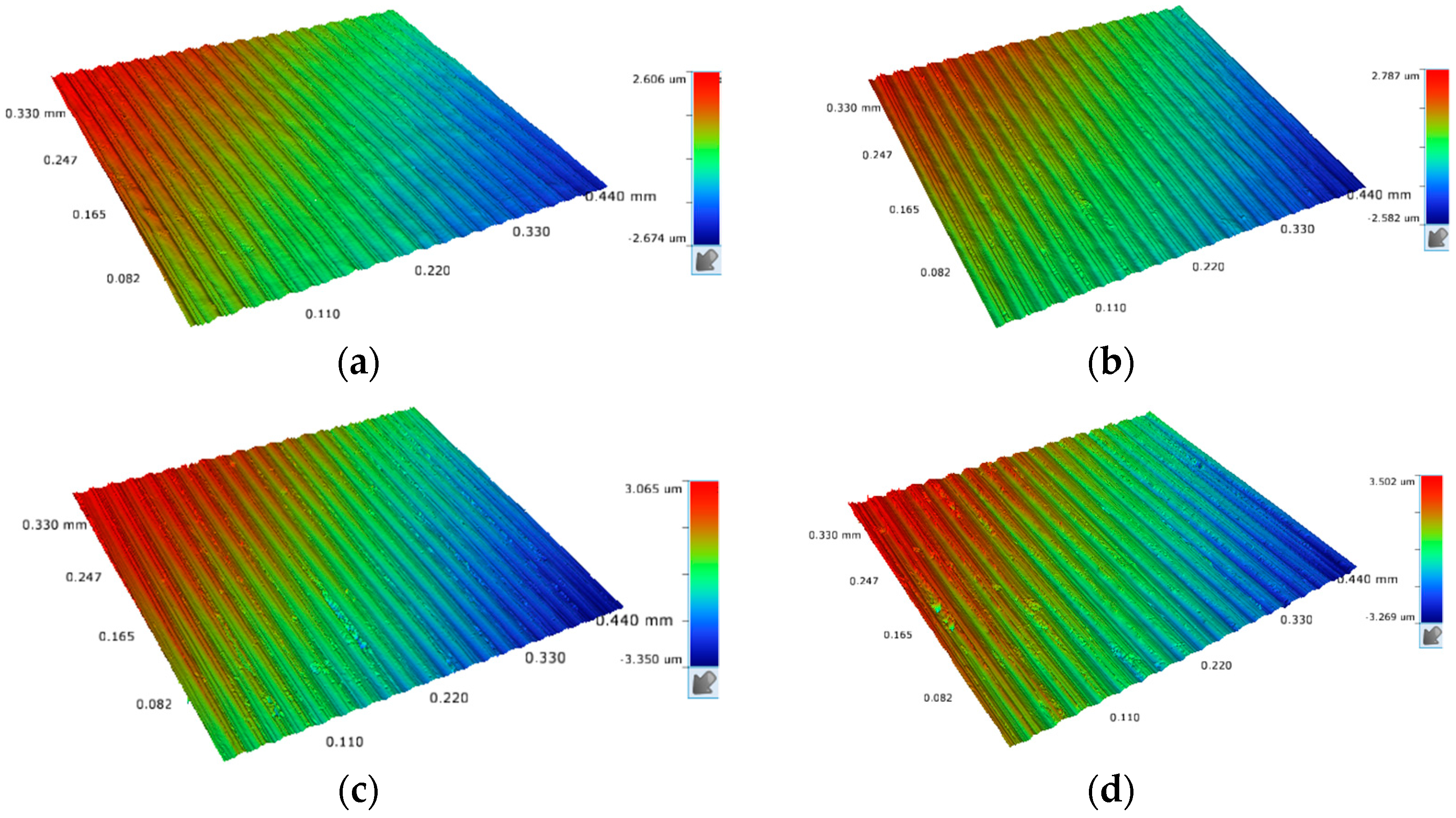

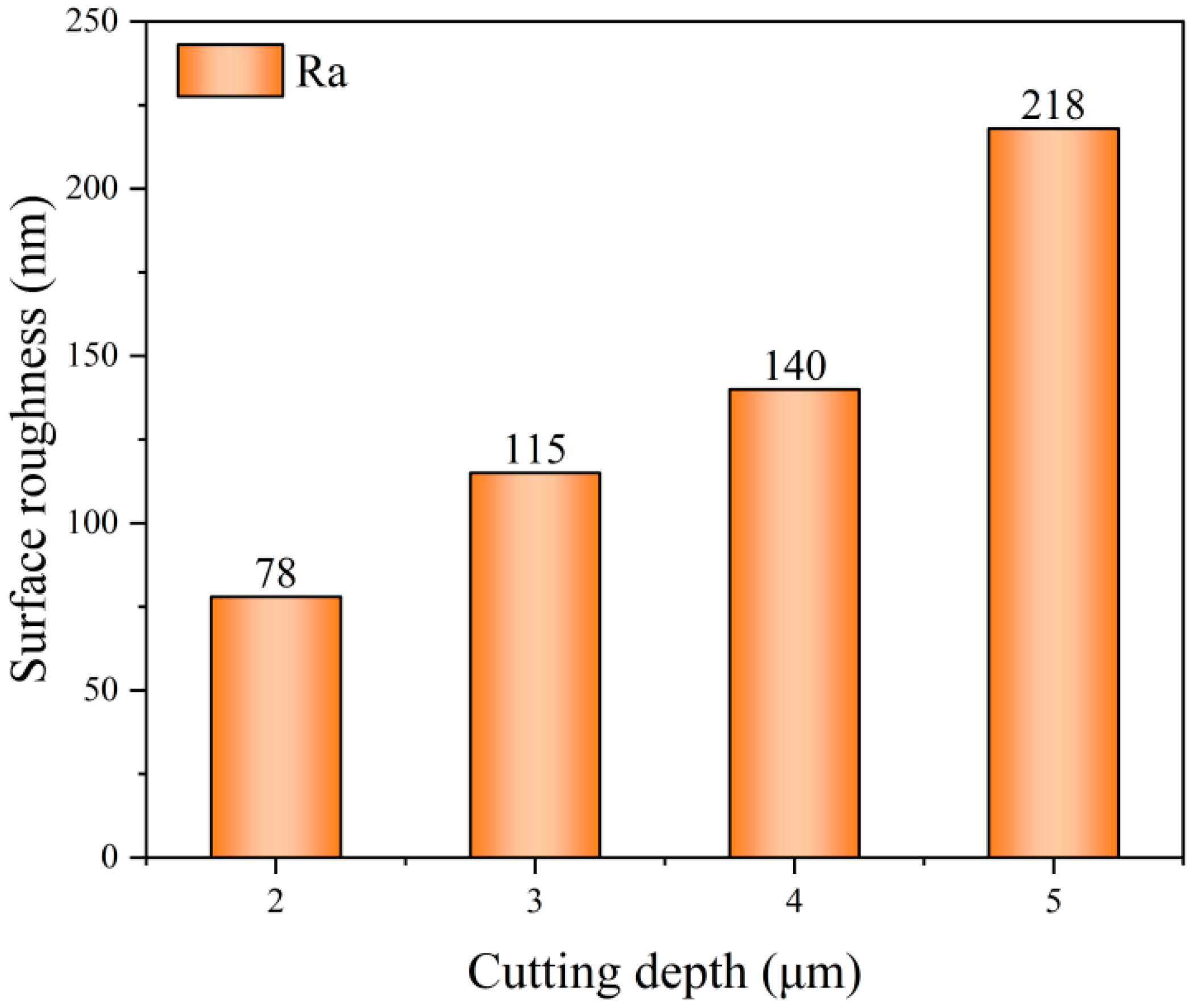

3.2.3. Effect of Cutting Depth on Surface Roughness

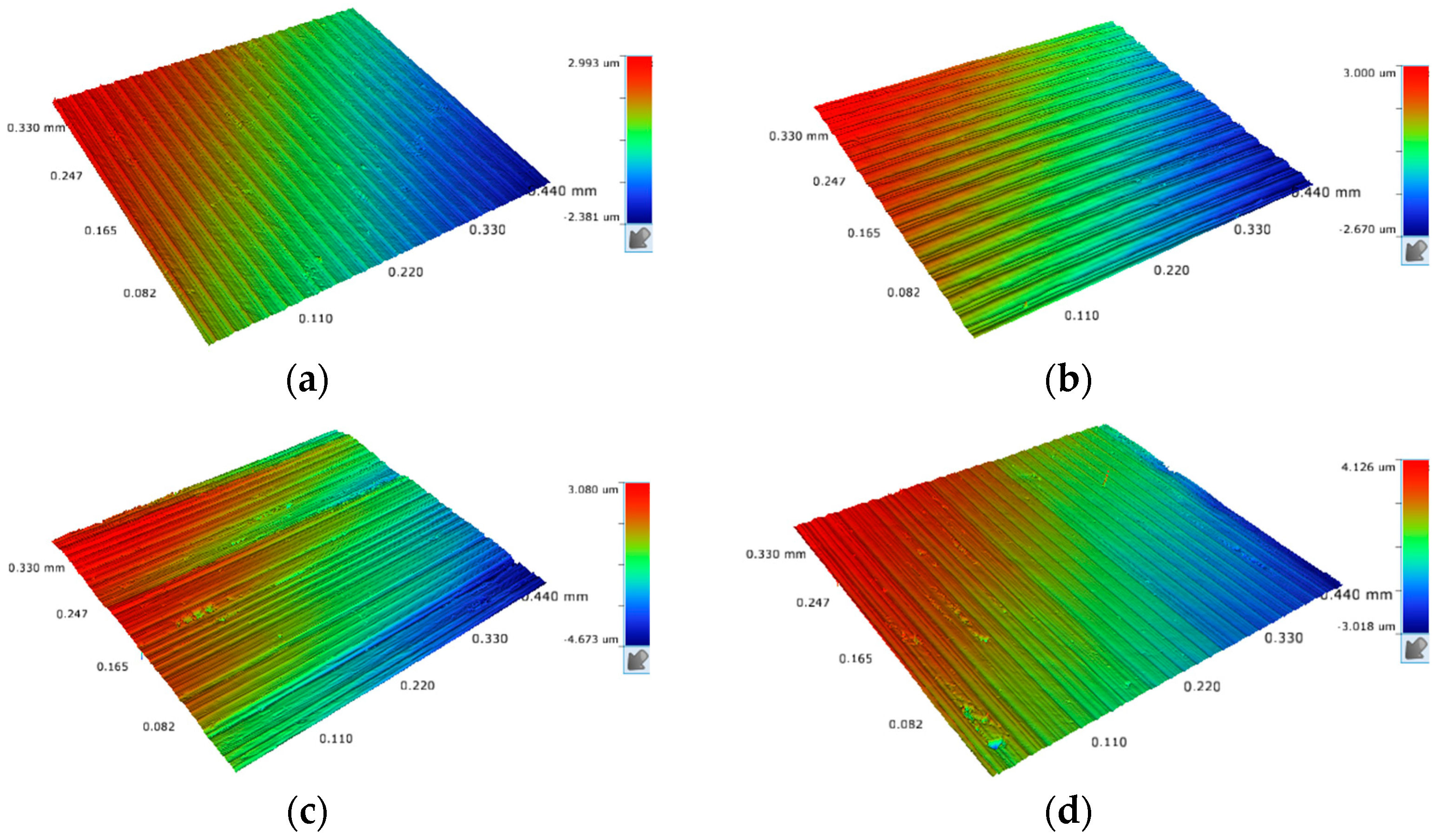

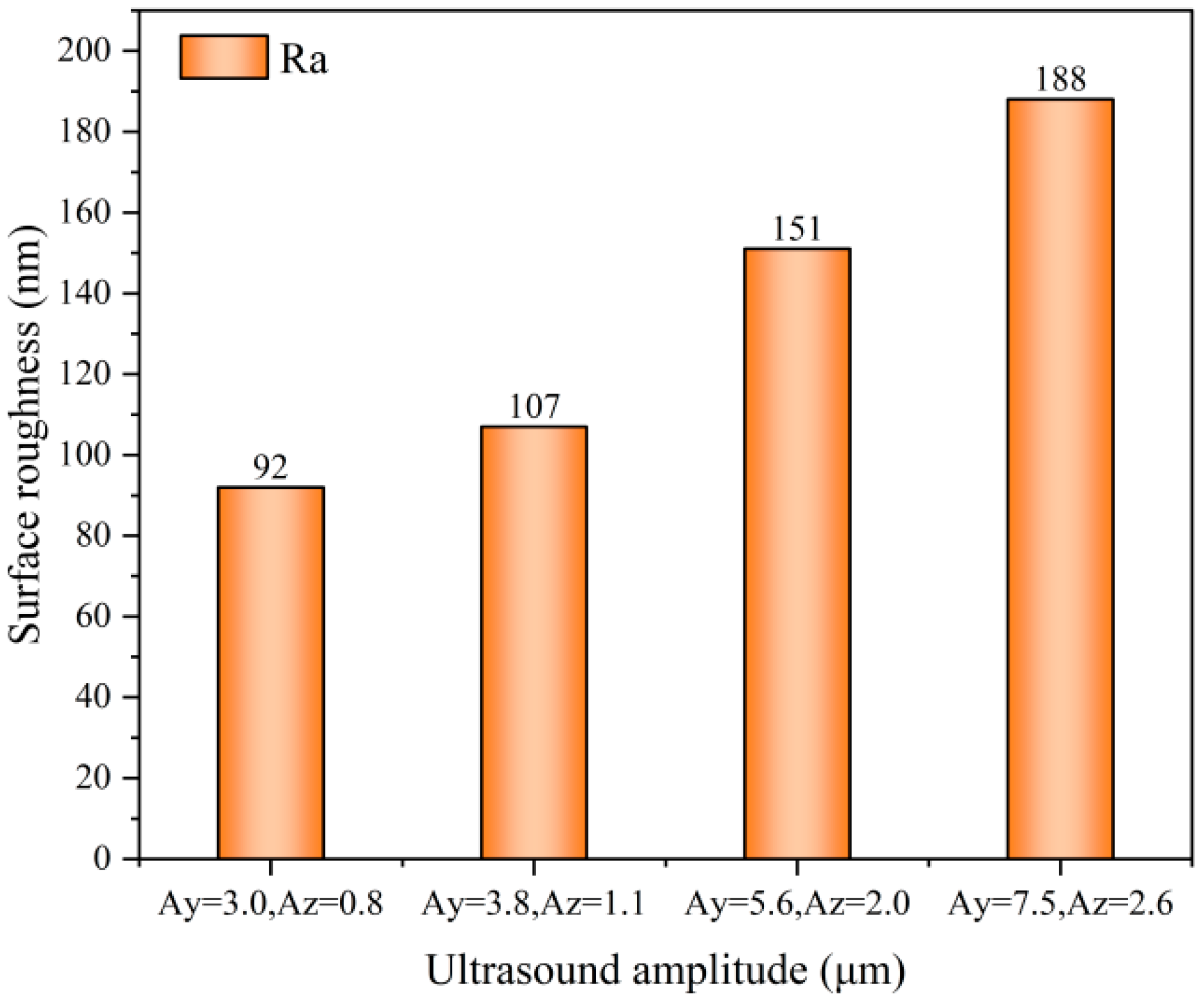

3.2.4. Effect of Ultrasound Amplitude on Surface Roughness

3.2.5. Effect of Tool Nose Radius on Surface Roughness

4. Conclusions

- Surface quality improvement: compared to conventional cutting (CC), the surface roughness of ultrasonic elliptical vibratory cutting was reduced by about 55%, 44%, 40%, and 40%, respectively, for the same parameters, significantly improving the quality of the machined surface;

- Effect of cutting parameters: The surface roughness of the ultrasonic elliptical vibratory cutting process decreased and then increased with the increase of cutting speed, indicating that there exists an optimal cutting speed that can achieve the lowest surface roughness. The surface roughness similarly increased with increasing feed and cutting depth, suggesting that higher feed and cut are not conducive to obtaining a smooth surface. Surface roughness increased with ultrasonic amplitude: The smaller the ultrasonic amplitude, the smoother its surface. An increase in the tool nose radius helped to reduce the surface roughness, and a larger radius of the tip circle reduced the residual height in the feed direction, thus improving the flatness of the machined surface;

- In this experiment, determined the optimal cutting parameters: a cutting speed of 3 m/min, a feed rate of 16 μm/rev, a cutting depth of 2 μm, an ultrasonic amplitude of Ay = 3.0 μm and Az = 0.8 μm, and a tool nose radius of 0.8 mm. However, vibration trajectory variation significantly affected the surface quality of the workpiece. The effects of different vibration trajectory settings on surface roughness and topography will be studied in future studies.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ezugwu, E.O. Key improvements in the machining of difficult-to-cut aerospace superalloys. Int. J. Mach. Tools Manuf. 2005, 45, 1353–1367. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Wang, Z.M.; Machado, A.R. The machinability of nickel-based alloys: A review. J. Mater. Process. Technol. 1999, 86, 1–16. [Google Scholar] [CrossRef]

- Arunachalam, R.; Mannan, M.A. Machinability of nickel-based high temperature alloys. Mach. Sci. Technol. 2000, 4, 127–168. [Google Scholar] [CrossRef]

- Li, S.; Xiao, G.; Chen, B.; Zhuo, X.; Xu, J.; Huang, Y. Surface formation modeling and surface integrity research of normal ultrasonic assisted flexible abrasive belt grinding. J. Manuf. Process. 2022, 80, 232–246. [Google Scholar] [CrossRef]

- Thakur, D.G.; Ramamoorthy, B.; Vijayaraghavan, L. A study on the parameters in high-speed turning of superalloy Inconel 718. Mater. Manuf. Process. 2009, 24, 497–503. [Google Scholar] [CrossRef]

- Chen, J.; Yin, H.; Kang, G.; Sun, Q. Fatigue crack growth in cold-rolled and annealed polycrystalline superelastic NiTi alloys. Acta Mech. Solida Sin. 2018, 31, 599–607. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, L.; Wang, Y.; Lin, B.; Dong, Y.; Shi, C. Mechanism study on ultrasonic vibration assisted face grinding of hard and brittle materials. J. Manuf. Process. 2020, 50, 520–527. [Google Scholar] [CrossRef]

- Hsu, C.Y.; Lin, Y.Y.; Lee, W.S.; Lo, S.P. Machining characteristics of Inconel 718 using ultrasonic and high temperature-aided cutting. J. Mater. Process. Technol. 2008, 198, 359–365. [Google Scholar] [CrossRef]

- Zhang, S.J.; To, S.; Wang, S.J.; Zhu, Z.W. A review of surface roughness generation in ultra-precision machining. Int. J. Mach. Tools Manuf. 2015, 91, 76–95. [Google Scholar] [CrossRef]

- Zou, P.; Xu, Y.; He, Y.; Chen, M.; Wu, H. Experimental investigation of ultrasonic vibration assisted turning of 304 austenitic stainless steel. Shock. Vib. 2015, 1, 817598. [Google Scholar] [CrossRef]

- Ulutan, D.; Ozel, T. Machining induced surface integrity in titanium and nickel alloys: A review. Int. J. Mach. Tools Manuf. 2011, 51, 250–280. [Google Scholar] [CrossRef]

- Klotz, T.; Delbergue, D.; Bocher, P.; Lévesque, M.; Brochu, M. Surface characteristics and fatigue behavior of shot peened Inconel 718. Int. J. Fatigue 2018, 110, 10–21. [Google Scholar] [CrossRef]

- Zhou, J.; Bushlya, V.; Avdovic, P.; Ståhl, J.E. Study of surface quality in high speed turning of Inconel 718 with uncoated and coated CBN tools. Int. J. Adv. Manuf. Technol. 2012, 58, 141–151. [Google Scholar] [CrossRef]

- Zhou, X.; Zuo, C.; Liu, Q.; Lin, J. Surface generation of freeform surfaces in diamond turning by applying double-frequency elliptical vibration cutting. Int. J. Mach. Tools Manuf. 2016, 104, 45–57. [Google Scholar] [CrossRef]

- Kurniawan, R.; Kumaran, S.T.; Ali, S.; Nurcahyaningsih, D.A.; Kiswanto, G.; Ko, T.J. Experimental and analytical study of ultrasonic elliptical vibration cutting on AISI 1045 for sustainable machining of round-shaped microgroove pattern. Int. J. Adv. Manuf. Technol. 2018, 98, 2031–2055. [Google Scholar] [CrossRef]

- Tong, J.; Wei, G.; Zhao, L.; Wang, X.; Ma, J. Surface microstructure of titanium alloy thin-walled parts at ultrasonic vibration-assisted milling. Int. J. Adv. Manuf. Technol. 2019, 101, 1007–1021. [Google Scholar] [CrossRef]

- Shamoto, E.; Moriwaki, T. Ultaprecision diamond cutting of hardened steel by applying elliptical vibration cutting. CIRP Ann. 1999, 48, 441–444. [Google Scholar] [CrossRef]

- Shamoto, E.; Moriwaki, T. Study on elliptical vibration cutting. CIRP Ann. 1994, 43, 35–38. [Google Scholar] [CrossRef]

- Moriwaki, T.; Shamoto, E.; Inoue, K. Ultraprecision ductile cutting of glass by applying ultrasonic vibration. CIRP Ann. 1992, 41, 141–144. [Google Scholar] [CrossRef]

- Kim, G.D.; Loh, B.G. Direct machining of micro patterns on nickel alloy and mold steel by vibration assisted cutting. Int. J. Precis. Eng. Manuf. 2011, 12, 583–588. [Google Scholar] [CrossRef]

- Babitsky, V.; Kalashnikov, A.; Meadows, A.; Wijesundara, A. Ultrasonically assisted turning of aviation materials. J. Mater. Process. Technol. 2003, 132, 157–167. [Google Scholar] [CrossRef]

- Lu, D.; Wang, Q.; Wu, Y.; Cao, J.; Guo, H. Fundamental turning characteristics of Inconel 718 by applying ultrasonic elliptical vibration on the base plane. Mater. Manuf. Process. 2015, 30, 1010–1017. [Google Scholar] [CrossRef]

- Zao, H. Theoretical and Experimental Investigations on Ultrasonic Elliptical Vibration Cutting of Nickel-based Superalloy. Ph.D. Thesis, Northeastern University, Boston, MA, USA, 2019. [Google Scholar]

- Tong, J.; Zhao, J.; Chen, P.; Zhao, B. Effect of ultrasonic elliptical vibration turning on the microscopic morphology of aluminum alloy surface. Int. J. Adv. Manuf. Technol. 2020, 106, 1397–1407. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Q.; Li, S.; Lu, D. Ultrasonic assisted machining of nickel-based superalloy Inconel 718. Superalloys Ind. Appl. 2018, 15, 708. [Google Scholar]

- Feng, L. Research on the Process Mechanism of Difficult-To-Machine Materials with Vibration Assisted Diamond Cutting. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2021. [Google Scholar]

- Pan, Y.; Kang, R.; Dong, Z.; Du, W.; Yin, S.; Bao, Y. On-line prediction of ultrasonic elliptical vibration cutting surface roughness of tungsten heavy alloy based on deep learning. J. Intell. Manuf. 2022, 33, 675–685. [Google Scholar] [CrossRef]

- Brehl, D.E.; Dow, T.A. Review of vibration-assisted machining. Precis. Eng. 2008, 32, 153–172. [Google Scholar] [CrossRef]

- Ma, C.; Shamoto, E.; Moriwaki, T.; Wang, L. Study of machining accuracy in ultrasonic elliptical vibration cutting. Int. J. Mach. Tools Manuf. 2004, 44, 1305–1310. [Google Scholar] [CrossRef]

- Jieqiong, L.; Jinguo, H.; Xiaoqin, Z.; Zhaopeng, H.; Mingming, L. Study on predictive model of cutting force and geometry parameters for oblique elliptical vibration cutting. Int. J. Mech. Sci. 2016, 117, 43–52. [Google Scholar] [CrossRef]

- Cheng, G. Study on Machining Mechanism and Related Technology of Nickel Base Superalloy GH4169. Ph.D. Thesis, Changchun University of Technology, Changchun, China, 2023. [Google Scholar]

- Jing, S. Mechanism and Experimental Study on Ultrasonic Elliptical Vibration Turning of Difficult Machining Materials. Master’s Thesis, Northeastern University, Boston, MA, USA, 2017. [Google Scholar]

| Workpiece | Density ρ (kg/m3) | Hardness (HB) | Yield Strength σ0.2 (MPa) | Tensile Strength σb (MPa) | Elongation δs (%) | Shrinking Percentage ψ (%) |

|---|---|---|---|---|---|---|

| GH4169 | 8280 | 240 | 1260 | 1430 | 24 | 40 |

| Element | Ni | Cr | Nb | Mo | Ti | Al | C | Si | Mn | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Wt (%) | 51.75 | 17 | 5.15 | 2.93 | 1.07 | 0.45 | 0.042 | 0.21 | 0.03 | 21.36 |

| No. | Cutting Speed v/(m/min) | Feed Rate f/(μm/rev) | Cutting Depth ap/(μm) | Ultrasonic Condition | Tool Nose Radius re/(mm) |

|---|---|---|---|---|---|

| 1 | 4 | 17 | 2 | ultrasonic and non-ultrasonic | 0.5 |

| 2 | 4 | 17 | 3 | 0.5 | |

| 3 | 4 | 17 | 4 | 0.5 | |

| 4 | 4 | 17 | 5 | 0.5 |

| No. | Cutting Speed v/(m/min) | Feed Rate f/(μm/rev) | Cutting Depth ap/(μm) | Ultrasonic Amplitude A/(μm) | Tool Nose Radius re/(mm) |

|---|---|---|---|---|---|

| 1 | 1 | 16 | 3 | Ay = 4.5, Az = 1.2 | 0.5 |

| 2 | 2 | 16 | 3 | Ay = 4.5, Az = 1.2 | 0.5 |

| 3 | 3 | 16 | 3 | Ay = 4.5, Az = 1.2 | 0.5 |

| 4 | 4 | 16 | 3 | Ay = 4.5, Az = 1.2 | 0.5 |

| 5 | 1 | 16 | 3.5 | Ay = 4.5, Az = 1.2 | 0.5 |

| 6 | 1 | 18 | 3.5 | Ay = 4.5, Az = 1.2 | 0.5 |

| 7 | 1 | 20 | 3.5 | Ay = 4.5, Az = 1.2 | 0.5 |

| 8 | 1 | 22 | 3.5 | Ay = 4.5, Az = 1.2 | 0.5 |

| 9 | 4 | 18 | 2 | Ay = 4.5, Az = 1.2 | 0.5 |

| 10 | 4 | 18 | 3 | Ay = 4.5, Az = 1.2 | 0.5 |

| 11 | 4 | 18 | 4 | Ay = 4.5, Az = 1.2 | 0.5 |

| 12 | 4 | 18 | 5 | Ay = 4.5, Az = 1.2 | 0.5 |

| 13 | 5 | 24 | 2 | Ay = 3.0, Az = 0.8 | 0.5 |

| 14 | 5 | 24 | 2 | Ay = 3.8, Az = 1.1 | 0.5 |

| 15 | 5 | 24 | 2 | Ay = 5.6, Az = 2.0 | 0.5 |

| 16 | 5 | 24 | 2 | Ay = 7.5, Az = 2.6 | 0.5 |

| 17 | 2 | 16 | 2.5 | Ay = 4.5, Az = 1.2 | 0.2 |

| 18 | 2 | 16 | 2.5 | Ay = 4.5, Az = 1.2 | 0.5 |

| 19 | 2 | 16 | 2.5 | Ay = 4.5, Az = 1.2 | 0.8 |

| No. | 1 | 2 | 3 | 4 |

| Cutting direction amplitude Ay (μm) | 3.0 | 3.8 | 5.6 | 7.5 |

| Feed direction amplitude Az (μm) | 0.8 | 1.1 | 2.0 | 2.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, G.; Zhang, M.; Xin, W.; Zhou, S.; Lu, Y.; Lu, J. An Experiment Study on Surface Topography of GH4169 Assisted by Ultrasonic Elliptical Vibration Ultra-Precision Turning. Appl. Sci. 2024, 14, 5515. https://doi.org/10.3390/app14135515

Hu G, Zhang M, Xin W, Zhou S, Lu Y, Lu J. An Experiment Study on Surface Topography of GH4169 Assisted by Ultrasonic Elliptical Vibration Ultra-Precision Turning. Applied Sciences. 2024; 14(13):5515. https://doi.org/10.3390/app14135515

Chicago/Turabian StyleHu, Gaofeng, Min Zhang, Wendong Xin, Shengming Zhou, Yanjie Lu, and Junti Lu. 2024. "An Experiment Study on Surface Topography of GH4169 Assisted by Ultrasonic Elliptical Vibration Ultra-Precision Turning" Applied Sciences 14, no. 13: 5515. https://doi.org/10.3390/app14135515

APA StyleHu, G., Zhang, M., Xin, W., Zhou, S., Lu, Y., & Lu, J. (2024). An Experiment Study on Surface Topography of GH4169 Assisted by Ultrasonic Elliptical Vibration Ultra-Precision Turning. Applied Sciences, 14(13), 5515. https://doi.org/10.3390/app14135515