Abstract

This paper introduces an evaluated initial model for how product lifecycles can be extended considering new and emerging existential design aspects concerning both general as well as digital/connected products. The initial model, which is cyclic, includes reverse logistics of components and raw materials, as well as information on how to manage data at the end of lifecycles. The aim is to improve long-term sustainability with a high degree of circularity while also achieving increased profitability and competitiveness. Further, we highlighted that product providers must start to evaluate and prepare for how to improve product durability, manage long and extendable lifespans, and achieve circularity with reverse logistics to close the loops. Additionally, updatability and upgradability are also required to stay current with time and create value while being cybersecure. Otherwise, customers’ expectations, various legal and regulatory aspects, as well as other existential design aspects can halt or even terminate a product’s lifecycle.

1. Introduction

This paper addresses an initial model for how product lifecycles can be extended and highlights new and emerging existential design aspects for both general products as well as digital/connected products. The term ‘design aspect’ is in line with the definition provided in [1]; however, caring for software, connectiveness, legal/regulatory, etc., matters as part of the recent design-for-Xs and increased digitalization of products. The initial model is aimed at the planning and improvement of circular product lifecycles at corporations providing general or digital/connected products primarily in business-to-business (B2B) contexts. Extending the product lifecycle reduces waste by minimizing the frequency of disposal and the need for new manufacturing processes, thus conserving natural resources and reducing environmental impact [2]. Additionally, it promotes a circular economy where products are reused, repaired, and repurposed, fostering sustainable consumption patterns, and contributing to long-term environmental stewardship.

Due to the lack of long-term sustainability, in terms of the low circularity of materials, short durability/lifespan, obsolescence issues (some even planned), and low preparedness for extension of lifecycles, for many current products, the need for change has been highlighted by, for instance, the European Union’s (EU) emerging update of Ecodesign for sustainable products regulation (https://commission.europa.eu/energy-climate-change-environment/standards-tools-and-labels/products-labelling-rules-and-requirements/sustainable-products/ecodesign-sustainable-products-regulation_en (accessed on 20 March 2024)), research programs such as Mistra REES (https://mistrarees.se/home/ (accessed on 20 March 2024)) and Faste Laboratory (https://www.ltu.se/en/research/research-subjects/machine-design/project/project/2023-12-07-vinn-excellence-center-faste-laboratory (accessed on 1 July 2024)) in Sweden, existing and emerging standards such as ISO-14006/BS 8001:2017/ISO 59004 research [3,4,5], and reports [6,7]. In recent years, due to new research discoveries and increasing attention, companies have started to act with more responsibility, with requirements originating from consumer awareness and public policy development. The EU Ecodesign regulation and requirements pose several existing and emerging existential design aspects on general products, and the products can be hard, impossible, or even illegal to continue to develop, support, market, and sell, if these regulations and requirements are not fulfilled. Further, the environmental impact of the increased consumption of products, services, and fossil fuels seems to have a correlation with, for instance, global warming and pollution according to COP28 (https://www.cop28.com/en/ (accessed on 20 March 2024)) and its predecessors, although the COP concept has been criticized by many due to its contentless and politized outcomes. In addition, for digital/connected products, cybersecurity, and the ability to keep the cybersecurity level (c.f. EU’s current and emerging Cyber Resilience Act, Cyber Security Act, RED, GDPR, NIS2, CER, etc. Other parts of the world may have similar or different laws and regulations pertaining to cybersecurity in digital/connected products or similar offerings) up to date, as well as to comply with any additional digital legal/regulatory requirements and other origin-related issues, etc., further existential design aspects are required to keep the lifecycle going or else it can be abruptly halted or terminated (at least for new sales). Thus, it is not easy to foresee the future and what requirements will change or emerge; however, there needs to be an attentive mind and willingness to adapt to stay current with time and create value while also achieving increased sustainability, profitability, and competitiveness. In addition, if the notion of the term sustainability varies within a large product provider, in a cooperative value chain or network, it can be a problem and cause non-optimal results [6].

Currently, there is significant interest in circularity and how it can be achieved. One of the key elements in the product lifecycle is the product design. The biggest struggle manufacturers face in the context of implementing circularity is the design of the product. Therefore, the current paper aims at identifying and analyzing all the crucial design aspects that, if neglected, can halt a product’s lifecycle, or even hinder future sales. The paper is based on a participatory research effort, including an evaluation and initial verification of the resulting model through workshops with providers of general products as well as digital/connected products.

2. Related Work

Circular product design is a sustainable approach to creating products that consider their entire lifecycle, aiming to minimize waste, maximize resource efficiency and usage potential, and create products that can be reused, repaired, or recycled. This design philosophy is an integral part of the circular economy, which contrasts with the traditional linear economy of “take, make, and dispose”. There are existing design methods, models, or concepts pertaining to almost any general product.

2.1. Current Design Methods, Models, or Concepts for Enabling Circularity

Below is a selection of such related to long and extendable lifecycles that are of interest for the initial model crafted later in this paper:

- Circularity—depending on the location in the world, there are various notions, ideas, and requirements to improve the circularity, potential disassembly and reverse logistics of products, components, and material flows [3,4,5,8].

- Long/extendable lifecycles—as the wear and tear concept of short-lived products is questioned, the idea of products having long and extendable lifecycles is raising interest [4,5] based on the selection of durable raw materials/components and being increasingly maintainable/repairable in various ways. Further, durable hardware combined with new software and optimizing the operation can also affect the useful life of products and provide significant financial gains (https://www.datacenterfrontier.com/cloud/article/11427600/sturdier-servers-cloud-platforms-say-servers-living-longer-saving-billions (accessed on 20 March 2024)). In addition, the use of plus-1 strategies, or similar ideas, can be used to prolong the life of a product model by, e.g., performing exterior facelifts every other year and updating hardware, software, and service content [9].

- Elliptical lifecycles—this idea involves extending the usage phase for products/components with only one lifecycle expectancy prior to the re-use of components and recycling of materials [10].

- 5R (Reuse, Repair, Re-manufacturing, Re-processing, and Recycling)—the 5 Rs are a natural part of the above three bullet points [6] to extend a product’s lifecycle. Further, there are additional Rs, such as Re-purposing (fixing up with potential extensions/modifications and finding new contexts or areas to continue the usage within) and Re-conditioning (updating any software, cleaning and buffing up to continue use in another context extending the remaining useful lifetime, e.g., cars, computers/servers, and cell phones) [2,9].

- Digital twins with simulations—to use collected intelligence/information as an input to model and simulate future changes, and emerging general as well as compliance requirements before implementing such [5,11]. It may be hard to simulate some requirements, and these may need to be analyzed differently.

Further, there are problems that can have a large long-term effect on product value chains/networks, leading to significant problems related to the initial production/manufacturing phase or later maintenance/repair/overhaul phase as there is a shortage of raw materials, parts, or components, etc. In recent years, this problem has been accentuated by the squeezes caused by stressed supply chains (e.g., sourcing issues from the Covid pandemic (https://www.oecd-ilibrary.org/economics/efficiency-and-risks-in-global-value-chains-in-the-context-of-covid-19_3e4b7ecf-en (accessed on 20 March 2024)) with following limited production of a wide variety of necessary components and electronic chips) and shipping/logistics issues (due to, for instance, the war in Ukraine, geopolitical problems in Asia, closed harbors due to the COVID-19 pandemic, and Panama and Suez Canal problems, with the complementary attacks on vessels in the Red Sea) [12,13]. These problems can lead to short-term as well as long-term problems for product providers, especially if customers start to buy the products from more agile competitors. There may also be effects on global sourcing, with more consideration given to local or regional options combined with political interventions to achieve increased sovereignty (EU Chips Act—https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/europe-fit-digital-age/european-chips-act_en (accessed on 20 March 2024) and US Chips and Science Act—https://www.whitehouse.gov/briefing-room/statements-releases/2022/08/09/fact-sheet-chips-and-science-act-will-lower-costs-create-jobs-strengthen-supply-chains-and-counter-china/ (accessed on 20 March 2024)).

Pertaining to further advanced offerings, such as products with integrated services, subscriptions or leasing (with retained ownership), product–service systems [14,15], or functions [16,17], there is a need to uphold a sustainable win–win situation [18] while managing the parallel technical lifecycles [19] of the main constituents (e.g., hardware, software, services/support, management of operations) to keep the lifecycle going. These further advanced offerings have inherent properties of sustainability and recyclability as part of their foundational business models/logic.

2.2. Current Design Aspects for Circular Products with Long/Extendable Lifecycles

Concerning existential design aspects for both general and digital/connected products, there are common ones for both as well as additional ones for digital/connected products:

- Design aspects for general products in terms of applicable design-for-Xs [6,8,20]:

- ○

- Design-for-recyclability and design-for-disassembly—with reverse logistics for closing-the-loops.

- ○

- Design-for-long life—to achieve wanted durability/reparability/reusability as well as general maintainability/upgradability/modularity of all main constituents in the product.

- ○

- Design-for-stable/robust and safe function—to achieve wanted levels of availability/reliability and safety.

- Additional design aspects for digital/connected products:

- ○

- Remote/fleet management—including necessary asset monitoring, predictive maintenance, diagnostics, the possibility to clean/wipe secret and sensitive data/information/configurations and user accounts (including encryption keys and revocation of certificates), etc. [9,21,22].

- ○

- Cybersecurity (and privacy)—providing through-lifecycle upgradability/maintainability of software and hardware necessary for cybersecurity functionality and resilience (or else the lifecycle for digital/connected products will end) [9,21,22]. In addition, there will for some products and contexts also be requirements on having a secure product development lifecycle (SPDLC). Such SPDLC includes a secure development environment/process and matters that affect cybersecurity through the lifecycle requiring processes, structures, and tools (e.g., key/certificate management, secure distribution of (security) updates with relevant documentation, in-depth defense within and around, security hardening, and incident response management/recovery) (for more information, see, for instance, IEC62443 3-3 and 4-1 [23].

- ○

- Known and true “content” in products and the origin/influences on such—if there are untrue/false declarations (or even unawareness about circumstances such as impact/influence from hostile countries/regimes), this can cause security issues and force the usage and removal of the product to stop. Examples of this are export-controlled components without a license, electronic components/open-source code with unclear origin/influences or additions (https://www.cert.europa.eu/publications/security-advisories/2024-032/ accessed on 20 March 2024)), prohibited components/raw materials, etc. [9].

Thus, there is a growing set of design aspects that can all be existentially significant if not properly addressed and adequately cared for in the required engineering and following design. The set needs to be kept updated over time for the product to be in focus.

3. Methodology

Problems related to the realization and formulation of the following development of an initial model were made and iterated while participating in 6 sequential development projects at a global manufacturing company related to IoT products, enabling unconnected products to be connected during 2021–2024. The involvement in the development projects comprised discussions with customers and internal business units about requirements and, in particular, cybersecurity ones. Further, several customers’ requests for information (RFI), often involving 50–300 cybersecurity-related questions, have been answered, and initial requirements and design aspects, such as design-for-Xs related to achieving long, sustainable, and secure lifecycles of the products, were analyzed, iterated, and, finally, formulated into testable and verifiable product requirements. The requirements were, in some cases, improved during later development iterations as more information was made available. After development and test activities, some of the resulting connected products were certified according to international cybersecurity standards. The certification efforts were led or supported by one of the researchers. In addition, the SPDLC and secure supply chain have continuously been further refined and implemented. The research was based on a participatory research approach [24,25] combined with a literature review. Participatory research encompasses action-oriented research activities wherein ordinary people address common needs and, as a result of that process, generate new knowledge. Key aspects include the involvement of people who share the same problems, formulate the problems, decide which problems to tackle, and plan as well as execute change activities to achieve the knowledge or change needed [25]. The use of sequential action and evaluation, using local priorities and perspectives, drives the research to be relevant and enhances its effectiveness [24]. The research question was as follows: “how can a product lifecycle include existential design aspects and ensure they are adequately incorporated into the resulting product outcome?”. In this research effort, the researchers have acted as experts or consultants, having had the role of project leader or sub-project leader and been involved in the participating companies’ requirement engineering and design, development, and test teams. It would have been possible to use other research approaches, such as action research [26] or sequential case studies [27]. However, the use of participatory research gave more flexibility as an initial model, and neither organizational change nor a study of an organizational or social unit was the intended result at this stage. Further, the literature review covered approximately 200 articles using Google Scholar and led to snowballing when publications of interest were found. The search strings used were as follows: design aspects; sustainability; circularity; sustainability + business model; supply chains + problems; value chains + value networks + problems; and compliance problems.

Open unstructured interviews [28,29,30] with snowballing were used to evaluate and obtain feedback and improvement possibilities as well as to verify the validity at the finalization of the initial model. The evaluation interviews were conducted with the following anonymized companies offering various types of digital/connected products:

- Micro-SME #1—offering IoT products comprising hardware, software, and cloud services (or on-premises server) for industrial and mining use—Chief Technical Officer (CTO) as respondent.

- Micro-SME #2—offering cybersecurity digital/connected appliances for use in any type of organization—CTO as respondent.

- Global manufacturing company—offering IoT products, digital/connected automation solutions, and related services—Quality Assurance and Support Manager as respondent.

- Multi-national large provider of IT products and services—offering a variety of hardware and software products together with software and related services including consulting, cloud services, and hosting—Cybersecurity Manager (in middle management of service operations) as respondent.

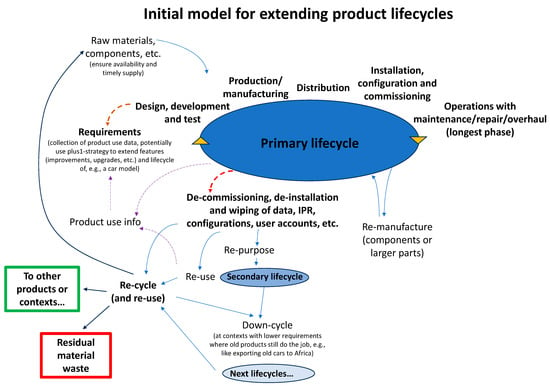

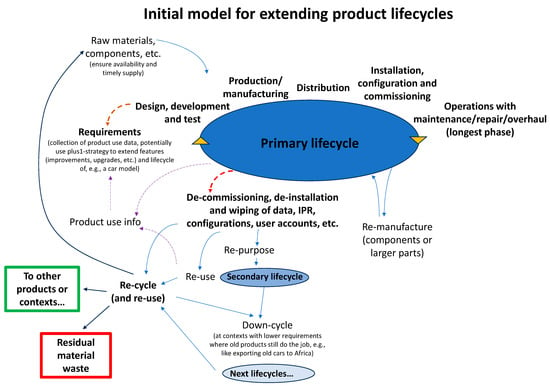

To analyze the feedback and verifications collected during the evaluation interviews, a table and pattern matching [31] were used. The collected feedback and verifications have been shared and verified with the interviewees to ensure correctness and accuracy, which increases the validity of the research further. Finally, the feedback from the evaluations was then used to improve the draft initial model into the final initial one (see Figure 1), which was also reviewed by the interviewees after the interviews.

4. Extending Product Lifecycles—An Initial Model Using New and Emerging Existential Design Aspects for Long and Extendable Lifecycles

The initial model in Figure 1, regarding extending product lifecycles to achieve long and extendable lifecycles in the light of new and emerging existential design aspects, is based on insights from the participatory research and the following literature:

- Design methods and lifecycle models for circularity [2,3,4,5,8,10,18,19].

- Practical problems concerning for instance stressed value chains/networks and related issues regarding sourcing, shipping, and logistics [14,15,21].

- Applicable design-for-Xs and additional existential design aspects including cybersecurity for long, sustainable, and secure lifecycles [1,6,7,8,9,21,22].

The initial model draws on ideas regarding design methods and lifecycle models for circularity with long and extendable lifecycles including disassembly and reverse logistics [2,3,4,5,8,10,18,19]. Further, the number of design aspects [1,5,6,7,8], whereof some may need to be translated into requirements, may require some loops between requirements engineering and design to form the set of requirements and following design into an integrated design. Some of this may be possible to solve by iterations in agile settings; however, if there are holistic design aspects, this can have a great impact on software and hardware architectures as well as on the selection of available raw materials, components, open-source software/frameworks, etc. Further, to be able to test adequately, the requirements and design aspects need to be properly documented and communicated regarding quality assurance, documentation, support, continuing engineering teams, etc., or else there is a risk of poor quality or untested parts of the products. In addition, if the availability of key raw materials, components, external software, etc., varies and is unreliable, stocking up or other measures may be required to keep the installed and commissioned products operating at the agreed-upon level with customers. However, stocks bind capital, and, in general, stock levels are kept as low as possible depending on the expected average time to refill, for instance, raw materials and components. The recent major problems in value chains/networks [14,15] may lead to changes lessening the need for long transport through dangerous or adventurous passages as well as avoiding production or transit in countries with non-democratic ruling.

To achieve increased sustainability, profitability, and competitiveness, the proposed solution is to plan for and implement advanced cybersecure fleet management functionality to improve the efficiency of operations, enable the monitoring of digital/connected products, and lessen the need for physical visits to support and maintain software or services while hardware service, maintenance, or repairs may still require a physical presence on-site [9,21,22]. The fleet management functionality may cover:

- Installation, configuration, and commissioning phase—support installations of software, set up, and initial configuration (potentially using secure plug-and-play, including pre-decided configurations fetched when and where appropriate).

- Operations phase—secure remote management of changes related to configurations, software, cybersecurity, or networks, as well as the secure updating of software. Obtaining information and data about wear and tear as well as information about any problems occurring and potentially also have functionality for actions related to the degradation or stopping of operations or safety before an imminent breakdown of the hardware.

- De-commissioning, de-installation, and wiping phase—wiping/erasing of secret data, information, recipes, process settings, network, and security configurations, sensitive info such as user manuals and how to set up cybersecurity, software or other IPR, and encryption keys and revoke certificates prior to potential continued usage in a new setting or a next lifecycle

- Product use information—the ability to collect how the products are used (and if they deviate from what is expected), maintained, and if there is a need for maintenance, as well as to keep track of which versions of hardware, software, etc., are used in each installation. Further, this information and data should be analyzed to find systemic and common problems and possibilities for improvements (i.e., new or changed requirements) to store in the technical debt repository until the next design, development, and test iteration.

It is important to remember that the fleet management functionality [5,9,22] may require openings in the firewalls of standalone or Internet-exposed IoT products, or to organizations’ network firewalls to enable needed connections. If such openings are not possible, it can be expected that the cost of support and maintenance will be substantially higher. Thus, the fleet management functionality must itself be cybersecure to not open for vulnerabilities and threats.

Due to the expected increasing level of cybersecurity requirements imposed by the EU and other parts of the world’s legal and regulatory developments, software related to applications, operating systems, firmware, open-source software, and software frameworks used must be updatable and upgradable in a secure manner to stay current [8,20,21]. Further, the hardware used may also need to be updatable and upgradable if cybersecurity requires that and issues cannot be fixed via, for instance, firmware, operating system, or additional cybersecurity software controls. In addition, the products must have clearly stated content and origin, as well as factors influencing them, along with documented availability of service, support, and spare parts, etc. (c.f., EU’s Digital Product Passports (DPP) (https://commission.europa.eu/energy-climate-change-environment/standards-tools-and-labels/products-labelling-rules-and-requirements/sustainable-products/ecodesign-sustainable-products-regulation_en (accessed on 20 March 2024)) and [32], which, hopefully, will become compliant with international trade rules to not cause expensive and unnecessary difficulties).

The evaluation results with feedback and verification, regarding the draft initial model, were collected during interviews with the following four companies:

- Micro-SME #1—during the primary lifecycle, if an IoT product is returned from a customer or after a short-term test, we commonly recondition/re-manufacture the hardware by swapping out the plastic cover and doing a cleaning if needed prior to re-packaging and continued operation in either the primary or a secondary lifecycle. Further, we are currently considering changing our business model from selling products with integrated services to either a leasing or subscription setup to enable extending the length of the economic lifecycle (as long as the technical lifecycle is viable) or enabling the following lifecycles. If we get our IoT products back, we do not only delete/remove all data, etc., but make a full erase of all memory/disks and data in cloud services, etc., and then re-install a fresh operating system, firmware, and applications.

- Micro-SME #2—as we have used partly open-source code to base our software solution on, we have learned that it is of utmost importance to select a viable/popular open-source code base to ensure that is continuously further developed and bugs fixed. Further, as we have an appliance with hardware and software, we have learned that it is important to retain ownership to be able to extend the lifecycle as well as enable secondary or next ones following due to the fact that we can get the appliance back, recondition it, and, if needed, also change the metal cover. Thus, a subscription business model is what we have ended up with, which also has an improvement in profitability compared to using a product with a support-based business model.

- Global manufacturing company—to tackle the problem early in the lifecycle and be able to get the requirements formulated and listed so that they are also tested later, it would be good to use more feasibility and impact analysis on a continuous basis involving different groups of stakeholders who have adequate knowledge. Further, long-term management of maintenance will become increasingly important. Prior to starting a new product or offering, there should be collective thinking and consideration of all important factors and involved stakeholders, which may be put into a project charter or similar as a guide for later work.

- Multi-national large provider of IT products and services—we have a lot of end-of-lived equipment from other vendors, whose technical lifecycles could be extended, which unfortunately is hard/impossible to use due to the fact that our customers will not accept that. Our fully developed products are re-used or largely re-cycled, and, in particular, software products can usually be used for a very long time if managed properly for multiple purposes (i.e., requires that functionality is adapted for more than one context). Thus, retaining the ownership of hardware is important for the extendibility of lifecycles.

The feedback from the evaluation interviews provided insights that led to an addition in the de-commission where potentially all software, configurations, data, etc., can be completely erased and replaced with a fresh setup prior to a potential continuation of the primary lifecycle or transition to a secondary or next following lifecycle. Further, it became clear that if the product has a viable economic and technical lifecycle, i.e., there is a residual value to capture while there are no legal or end-of-life cycle issues concerning the operating system or other supporting frameworks, then the choice of business model can have a large impact on the possibility for the provider to make any changes and to reset software, etc. This is due to who owns the “product”, and thus also those who can capture the residual value in at least the hardware part. If it is someone else than the provider, it complicates the continuation of the life for the “product”. For more on the business model selection, see the discussion and conclusion sections. Further, the global manufacturing company emphasized a thorough preparation as part of their engineering requirements and design/development/test phases, considering all important factors and involving all relevant stakeholders. The final initial model can be viewed in Figure 1.

Figure 1.

Initial model concerning extending product lifecycles to achieve long and extendable lifecycles in the light of new and emerging existential design aspects.

5. Findings

Based on the interviews conducted with the four companies of different sizes, the initial model has been evaluated and improved. The findings of the evaluated initial model in Figure 1 are summarized below. The initial model provides an overview of primary, secondary, and next lifecycles, which can be used for the long-term planning of product lifecycle management, including considering several new and emerging existential design aspects. The additional key findings, part of the initial model, are highlighted below:

- There may be a need for iterations between the requirements and design, development, and test phases to sort out the requirements and make design aspects, such as design-for-X, translated into actual and testable requirements. Otherwise, there is a risk that many design aspects are not formally tested or properly documented as (detailed) requirements:

- ○

- Digital/connected products should be designed to be updatable and upgradable regarding software and partly hardware in combination, preferably using advanced cybersecure fleet management functionality. Concerning non-connected or regular products, these may need a lot of similar functionality but may require manual measures to update, upgrade, maintain, check wear and tear, as well as monitor the need for maintenance, etc. These properties are needed to maintain an adequate cybersecurity level throughout the products’ lifecycles and to comply with, for instance, the EU’s new and emerging legal and regulatory requirements. Other regions in the world will likely pose similar, or in the worst case quite different, legal and regulatory requirements; therefore, if one is a global provider of products, a lot of surveying is necessary.

- ○

- Connected or not, at the end of the primary lifecycle or any of the following ones, erasing and wiping of data, information, IPR, software, etc., should be made to not provide any IPR to competitors or clues to hackers (enabling attacks toward the environment where the product was installed).

- Availability of key raw materials, components, external software, etc., used needs to be ensured. This will likely result in significant changes in the structure of value chains/networks to avoid the same problems as experienced during the recent COVID-19 pandemic with political decisions, Suez and Panama Canal problems, as well as war and terrorist activities, such as in Ukraine and the Red Sea, which had a grave impact on supply and availability. Further, the new and emerging existential design aspects may also impact the availability of software and hardware at least until providers have adapted or new ones need to be sourced. Thus, the expected availability should be investigated if not already made, and actions should be taken to minimize risks related to the availability of raw materials, components, and external software.

- The selection of a business model is key for long and extendable product lifecycles. Business models enabling the provider to retain the ownership, such as subscriptions, leasing, product–service systems, or functions, provide the possibility for better control and management of the product and possibilities to efficiently maintain, service, and support the product in operations until the very end of the last lifecycle.

To summarize the findings, design methods, development processes/models, or lifecycle models, etc., used to manage a product’s lifecycle and, in particular, the interaction between the requirements and design, development, and test phases may need to be adjusted, and iterations should be added in between to be able to capture all necessary and existential design aspects so that these are formally included into the design, functional, and test specifications. Otherwise, there will be no traceability, and compliance requirements may be hard to verify in practice. The timely availability of key raw materials, components, external software, etc., must be ensured and may require substantial re-modeling of the value chain/network structure and actors involved. The selection of an adequate business model, where ownership is retained by the provider, is key for cyclic management of products with expected long and extendable lifecycles.

6. Analysis of Findings and Selected Research Approach

Besides what is commonly perceived as necessary product design aspects, e.g., product quality in terms of long life and recyclability, there are additional design aspects which in the worst case potentially can/will abruptly stop, or even kill, a product’s lifecycle (or at least any new sales as well as requiring a re-call of not yet sold but distributed products). The existential product design aspects found in the research relate to circularity, cybersecurity, and availability (which is part of designing the structure of actors participating in the value chain/network and thus a very critical part of the planning for the whole lifecycle of products). Thus, extensive knowledge, understanding, and the ability to plan for a whole lifecycle are needed to successfully bring products to market and then be able to create and capture value for many years to follow. This includes the selection of one or more adequate business models supporting cyclic, sustainable, long, and extendable product lifecycles. If the products are not prepared (i.e., designed) for the future, unnecessary and unanticipated risks may become of an existential nature instead of a problem or issue to resolve. Designs for long and extendable lifecycles will likely have a higher initial cost as, for instance, hardware components may be more expensive but profitability, competitiveness, and ecological and societal sustainability will be better in the long run. Besides the hardware aspect, there is the need for further detailed design and the selection of manufacturing and assembly operations. In particular, assembly design is of vital importance in the implementation of circular products. This is due to the fact that the re-using and re-purposing of a product is always the first step to try, prior to disassembly, to conduct any necessary maintenance or upgrades. Thus, there is a need to shift management thinking towards total lifecycle cost and apply a whole lifecycle perspective as the requirements and design, development, and test phases are just a small part of the lifecycle and, in fact, are just the start of the lifecycle.

Concerning the problem, i.e., “the issue of identifying crucial design aspects that, if neglected, can halt a product’s lifecycle or hinder future sales”, it has been initially addressed, and several existential design aspects have been highlighted. Further, regarding the research question, i.e., “how can a product lifecycle include existential design aspects and ensure they are adequately incorporated into the resulting product outcome?”, an initial model has been crafted ensuring the transformation of existential design aspects into actual requirements through iterations between the requirements and design, development, and test phases.

Pertaining to the choice of research approach, the participatory research well supported the crafting of the initial model. Other possible choices would have been action research or sequential case studies. To continue the research towards achieving changes and further development with the verification of the model in the target organizations, action research will likely be used instead of participatory research as the action research approach targets achieving change (as well as further refinements of models).

7. Discussion

This paper contributes to the literature with an initial model, concerning extending product lifecycles to achieve long and extendable lifecycles in light of new and emerging existential design aspects, ensuring that existential design aspects are included and transformed into actual requirements for the design, development, and test phase in Figure 1 through any necessary number of iterations. Several such existential design aspects have been highlighted, and the set of such needs to be kept updated over time. Further, the paper contributes to the practice by including the need to ensure the availability of key raw materials, components, external software, etc., as part of the initial model and its sourcing and reverse logistics of raw materials and components. In addition, the managerial contribution of the paper is the importance of selecting a business model which supports long and extendable lifecycles as it will be a lot easier if the ownership of the product is retained by the provider. Otherwise, it will be hard to obtain full circularity, the possibility to add secondary and any next lifecycles following, maintaining, and supporting the product, as well as keeping the whole lifecycle cybersecure, including at the end-of-life stage.

The resulting initial model, seen from a high level, needed to consider whole lifecycle management, access to products remotely or only on-site, end-of-life or extension into new lifecycles, etc., at as early a stage as possible. This is in line with [5,6], who outlined the need to plan for efficiency, reliability, robustness, and availability to obtain circularity and sustainable products with high quality and long, durable, and extendable life. Further, the need for circularity and to close the loop is also an efficient disassembly of products and reverse logistics, which is highlighted in the initial model proposed as well as in [8]. Such considerations and planning need to cover the whole value chain or value network and not just range the own corporation. Since maintaining the ownership of the product and all its constituents may infer an extended exposure to financial risks, digital twins can be used to simulate and predict problems but also to realize and act upon opportunities (including the existential design aspects) [5,8,11]. However, it is an effort to build a digital twin already at the planning stage. Further, a digital twin could also include disturbances and problems, such as stressed value chains/networks, transport route issues, and war as outlined in [14,15]. In addition, an increasing compliance burden, at least within the EU, will require a substantial effort from all product providers. Thus, the most relevant question is how much effort must be spent on collecting information on future developments and compliance requirements to not encounter serious problems as well as be able to start making necessary changes in due time. Finally, the highlighted business models, deemed suitable as they support circularity and sustainability at the same time as they enable the provider to efficiently manage and maintain the product over time, align along with what [3,4] outlined, although are more specific here.

Regarding our future research, we plan to find opportunities to implement, further develop, and evaluate the initial model with corporations involved in the product development of preferably digital/connected products.

Issues with untrue or false product declarations regarding contents, raw materials, origins, or the use of components or open-source code of unclear origin and management can create trust and confidence issues leading to stopped lifecycles and thus be an existential design aspect too. The EU’s forthcoming DPPs, also facilitating repairs by indicating where service outlets and spare parts can be found, may be a step to prevent this. The DPPs should also guide the public authorities’ efforts concerning performing controls and check-ups of digital/connected products. An open question is how much DPPs will be transferred to and affect the secondary and next following lifecycles (wherein public authorities’ controls and check-ups may also occur). Today, this seems like a challenge unless it is tied to the cybersecure fleet management functionality (with the potential to temporarily invite public authorities, in a cybersecure manner, for controls or check-ups), which, in many cases, likely could be used after the primary lifecycle until the very end-of-life. Long and extendable lifecycles for products will likely need cybersecure fleet management functionality, or else it will be very challenging to achieve efficient long-term management of the lifecycles of advanced digital/connected products and offerings. Thus, an adequate cybersecurity level is a must in most contexts, and it is necessary to continuously keep updated.

To be able to reach the circularity and sustainability objectives as well as compliance requirements of the future, which business models will support this best? Business models such as products with or without services are probably less suitable if the residual value of the offering is substantial after the primary lifecycle as it may be problematic to return the product in an environmentally friendly manner as well as with financial soundness (unless there are many to be returned at the same time). Thus, business models that are either designed for sustainability and long-term lifecycles (e.g., industrial product systems or functions) or allow the provider to retain at least the ownership (subscription or leasing) can be better choices to be able to keep the life ongoing for the offering. It will be a problem to continue, for instance, the integrated services of a product if the provider is not informed about the change of ownership and is able to erase all data and user accounts, etc., concerning the previous owner.

A topic of general interest concerning circularity and sustainability with durable products and long and extendable lifecycles is the expected (or planned) length of product lifecycles. As discussed in [6], this is a problem if general products seem to have a certain lifespan and if digital/connected products are planned to have rather short, supported lifecycles prior to being end-of-lived by the provider. This should be changed, and change will be required by the new and emerging EU legal and regulatory frameworks as well as policies. Further, we also need to change the attitude of customers to older hardware, etc., in terms of that if a product can do the job, it should be used (unless there are existential issues with end-of-lived support for operating systems, firmware, external software, or other components). To further support long and extendable lifecycles, this needs to be gradually implemented into public procurement requirements, as public policy development and EU legal/regulatory requirements strive towards increased circularity and sustainability. In addition, the EU Digital Markets Act (https://digital-markets-act.ec.europa.eu/index_en (accessed on 20 March 2024)) (DMA) is another legal development that affects corporations, who act as gatekeepers, to comply with this as well, in addition to those having trouble continuing to go on as such within the EU. Further, the EU AI Act will also govern a responsible use of AI which can be expected within many future digital/connected products. This will force changes within the EU, but will the rest of the world follow, and when?

8. Conclusions

The paper has outlined an initial evaluated model, considering existing and emerging existential design aspects, to design products that are circular with long/extendable lifecycles. To conclude, the combination of complex value chains, or value networks, with increasingly sophisticated (digital/connected) products requires that product providers start to evaluate and prepare for how to improve durability, long and extendable lifespans, and circularity. Further, updatability and upgradability are also required to stay current with time and create value while also achieving increased sustainability, profitability, and competitiveness. Otherwise, customers’ expectations, various legal and regulatory aspects, as well as other existential design aspects can halt, or in the worst case, terminate the product’s lifecycle. The unfortunate unrest in parts of the world and other problems with sourcing and logistics, including transfers and transport, are also factors to include in this equation. Our future research will focus on the implementation of the initial model within different industrial use cases and quantify the benefits of the model.

Author Contributions

Conceptualization, J.L., P.K. and F.P.; Methodology, J.L. and P.K.; Validation, K.A. and K.S.E.; Formal analysis, J.L.; Investigation, J.L.; Writing—original draft, J.L., P.K. and F.P.; Writing—review & editing, J.L., P.K., F.P., K.A. and K.S.E.; Visualization, J.L. and P.K. All authors have read and agreed to the published version of the manuscript.

Funding

The research has mainly been funded by the authors’ organizations themselves but has also been partially supported by the PLOOTO and CIRCULess EU H2020-projects under grant agreements No 101092008 and 101138330. The paper reflects the authors’ views, and the EU Commission is not responsible for any use that may be made of the information it contains.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

Author John Lindström was employed by the company Dielcon AB. Author Foivos Psarommatis was employed by the company Zerofect GmbH. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Langeveld, L.-H. Design with X is new in production design education. In Proceedings of the 9th International Design Conference—DESIGN 2006, Dubrovnik, Croatia, 15–18 May 2006. [Google Scholar]

- Psarommatis, F.; May, G. Achieving global sustainability through sustainable product life cycle. In Proceedings of the International Conference on Advances in Production Management Systems, Gyeongju, Republic of Korea, 25–29 September 2022; pp. 391–398. [Google Scholar]

- Bocken, N.M.P.; Short, S.W.; Rana, P.; Evans, S. A literature and practice review to develop sustainable business model archetypes. J. Clean. Prod. 2014, 65, 42–56. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Y.; Ren, S.; Yang, M.; Wang, Y.; Huisingh, D. How can smart technologies contribute to sustainable product lifecycle management? J. Clean. Prod. 2020, 249, 119423. [Google Scholar] [CrossRef]

- Lindahl, M.; Dalhammar, C. The Circular Economy: Towards a New Business Paradigm with Support from Public Policy; Stockholm+50 background Paper Series; Stockholm Environment Institute: Stockholm, Sweden, 2022; Available online: https://www.sei.org/wp-content/uploads/2022/05/circular-economy-stockholm50backgroundpaper-corrected.pdf (accessed on 19 January 2024).

- COP28. COP28 Declaration on Climate, Relief, Recovery and Peace. Available online: https://www.cop28.com/en/cop28-declaration-on-climate-relief-recovery-and-peace (accessed on 19 January 2024).

- Aarikka-Stenroos, L.; Chiaroni, D.; Kaipainen, J.; Urbinati, A. Companies’ circular business models enabled by supply chain collaborations: An empirical-based framework, synthesis, and research agenda. Ind. Mark. Manag. 2022, 105, 322–339. [Google Scholar] [CrossRef]

- Lindström, J. (Ed.) Handbook for Development of Cybersecure IoT-Products; Smarter Electronic Systems, IoT Sweden, and Swedish Electronics Trade Association: Stockholm, Sweden, 2023; Available online: https://www.smartareelektroniksystem.se/handbocker/ (accessed on 27 March 2024).

- Jacobson, S.; Wiklund, U.; Hardell, J.; Larsson, R. Tribology and the case for an Elliptical economy. In Proceedings of the 24th International Conference on Wear of Materials, Banff, AB, Canada, 16–20 April 2023. [Google Scholar]

- Rojek, I.; Mikołajewski, D.; Dostatni, E. Digital Twins in Product Lifecycle for Sustainability in Manufacturing and Maintenance. Appl. Sci. 2021, 11, 31. [Google Scholar] [CrossRef]

- Zis, T.P.V. The enhanced role of canals and route choice due to disruptions in maritime operations. Marit. Bus. Rev. 2023. ahead-of-print. [Google Scholar] [CrossRef]

- Kuok, L. Asia’s Ukraine Problem. Survival 2023, 65, 43–51. [Google Scholar] [CrossRef]

- Mont, O. Introducing and Developing a Product-Service System (PSS) Concept in Sweden; The International Institute for Industrial Environmental Economics (IIIEE), Lund University: Lund, Sweden, 2001. [Google Scholar]

- Meier, H.; Roy, R.; Seliger, G. Industrial Product-Service Systems—IPS2. CIRP Ann. Manuf. Technol. 2010, 59, 607–627. [Google Scholar] [CrossRef]

- Alonso-Rasgado, T.; Thompson, G.; Elfstrom, B.-O. The design of functional (total care) products. J. Eng. Des. 2004, 15, 515–540. [Google Scholar] [CrossRef]

- Löfstrand, M.; Kyösti, P.; Reed, S.; Backe, B. Evaluating availability of functional products through simulation. Simul. Model. Pract. Theory 2014, 47, 196–209. [Google Scholar] [CrossRef]

- Lindström, J.; Dagman, A.; Karlberg, M. Functional Products Lifecycle: Governed by sustainable Win-Win Situations. Procedia CIRP 2014, 22, 163–168. [Google Scholar] [CrossRef][Green Version]

- Lindström, J.; Dagman, A.; Karlberg, M. The Functional Products Technical Lifecycle and its Four Sub-lifecycles. Procedia CIRP 2015, 38, 222–227. [Google Scholar] [CrossRef][Green Version]

- Panchal, J.H.; Grogan, P.T. Designing for Technical Behaviour. In Handbook of Engineering Systems Design; Maier, A., Oehmen, J., Vermaas, P.E., Eds.; Springer: Cham, Switzerland, 2022; pp. 1–30. [Google Scholar]

- Yousefnezhad, N.; Malhi, A.; Främling, K. Security in product lifecycle of IoT devices: A survey. J. Netw. Comput. Appl. 2020, 171, 102779. [Google Scholar] [CrossRef]

- Lindström, J.; Eliasson, J.; Hermansson, A.; Blomstedt, F.; Kyösti, P. Cybersecurity level in IPS2: A case study of two industrial internet-based SME offerings. Procedia CIRP 2018, 73, 222–227. [Google Scholar] [CrossRef]

- Available online: https://www.isa.org/standards-and-publications/isa-standards/isa-iec-62443-series-of-standards (accessed on 23 May 2024).

- Cornwall, A.; Jewkes, R. What is participatory research. Soc. Sci. 1995, 41, 1667–1676. [Google Scholar] [CrossRef] [PubMed]

- Park, P. Knowledge and Participatory Research. In Handbook of Action Research: Concise Paperback Edition; Reason, P., Bradbury, H., Eds.; Sage: London, UK, 2006; pp. 83–93. [Google Scholar]

- Reason, P.; Bradbury, H. (Eds.) Handbook of Action Research: Concise Paperback Edition; Sage: London, UK, 2006. [Google Scholar]

- Priya, A. Case Study Methodology of Qualitative Research: Key Attributes and Navigating the Conundrums in Its Application. Sociol. Bull. 2021, 70, 94–110. [Google Scholar] [CrossRef]

- Kvale, S.; Brinkmann, S. Interviews: Learning the Craft of Qualitative Research Interviewing; Sage: London, UK, 2009. [Google Scholar]

- Remenyi, D. Field Methods for Academic Research: Interviews; Academic Conferences Limited: Berkshire, UK, 2012. [Google Scholar]

- Patton, M.Q. Qualitative Evaluation and Research Methods; SAGE Publications, Inc.: Thousand Oaks, CA, USA, 1990. [Google Scholar]

- Miles, M.B.; Huberman, A.M. An Expanded Sourcebook: Qualitative Data Analysis; Sage: London, UK, 1994. [Google Scholar]

- Psarommatis, F.; May, G. Digital Product Passport: A Pathway to Circularity and Sustainability in Modern Manufacturing. Sustainability 2024, 16, 396. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).