Experimental and Theoretical Study of Heat Transfer in a Chilled Ceiling System

Abstract

1. Introduction

2. Experimental Methodology

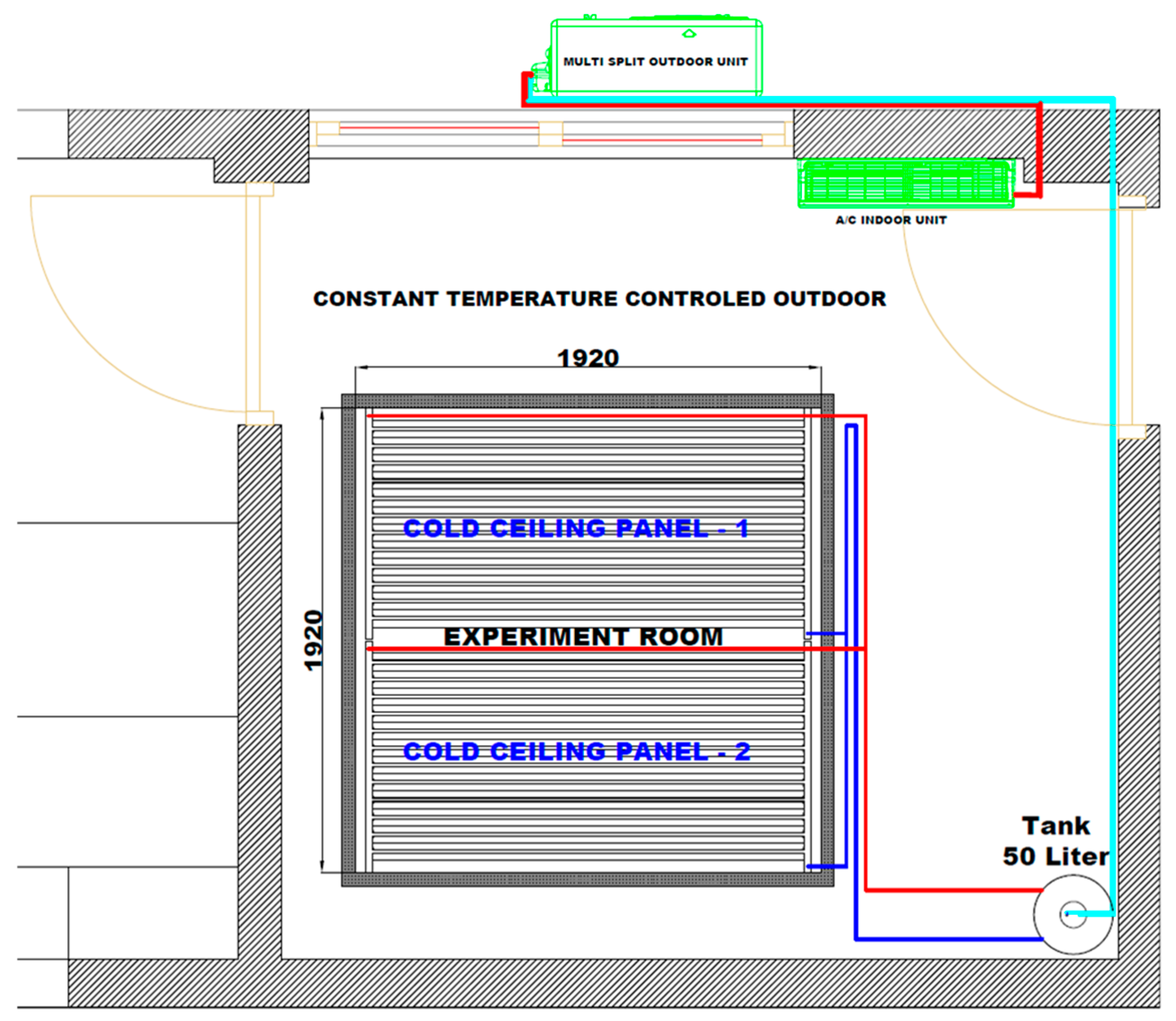

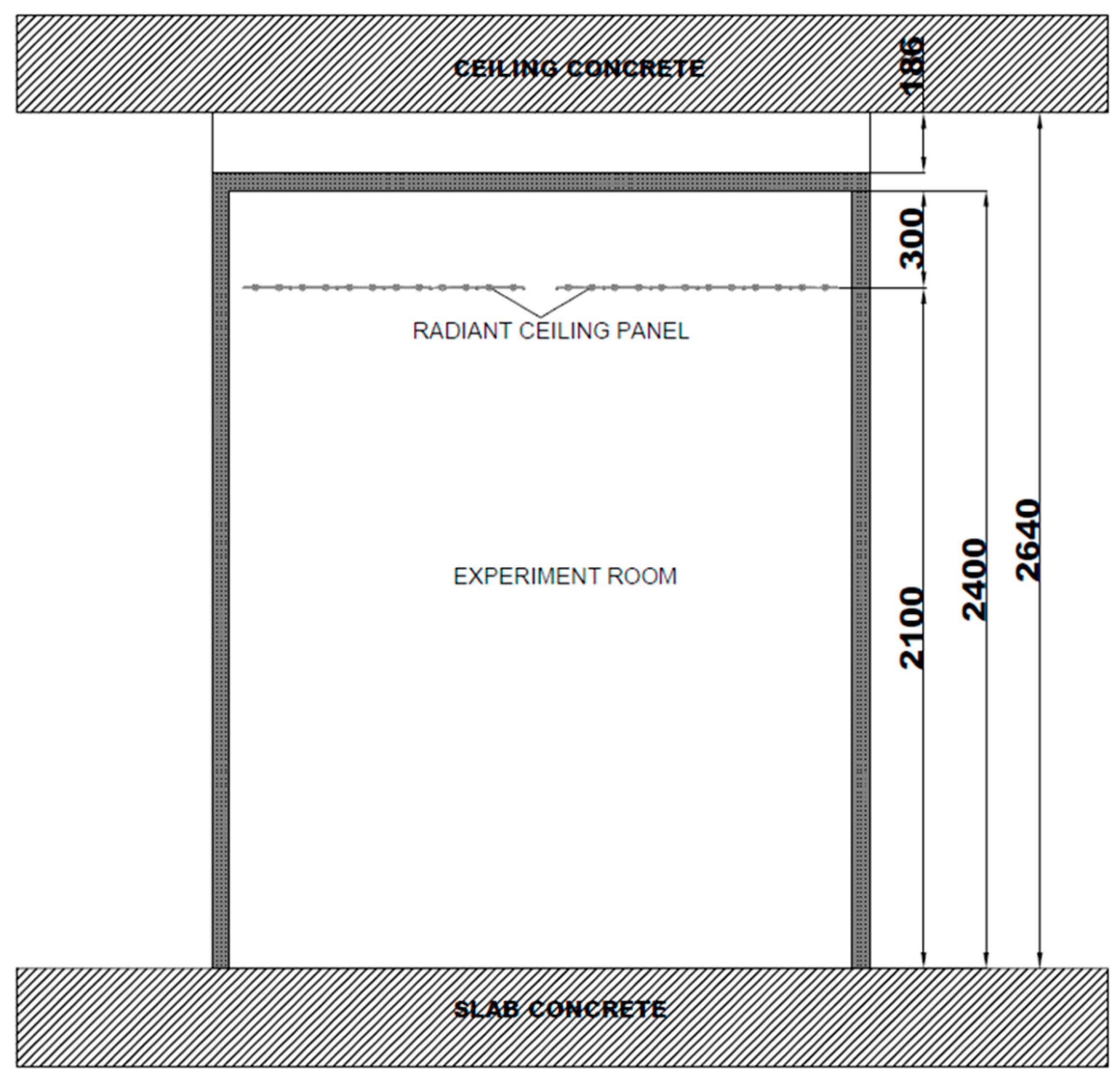

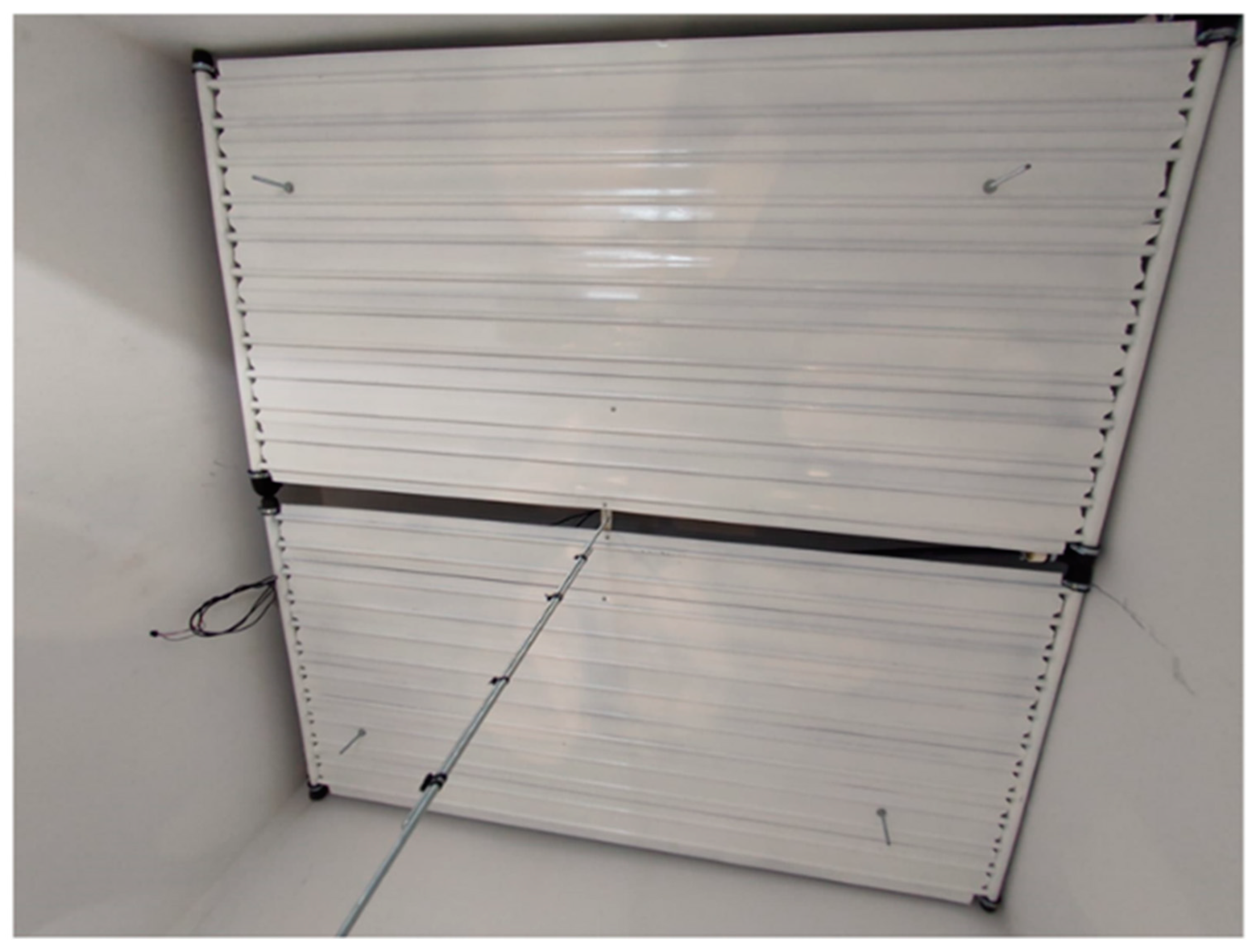

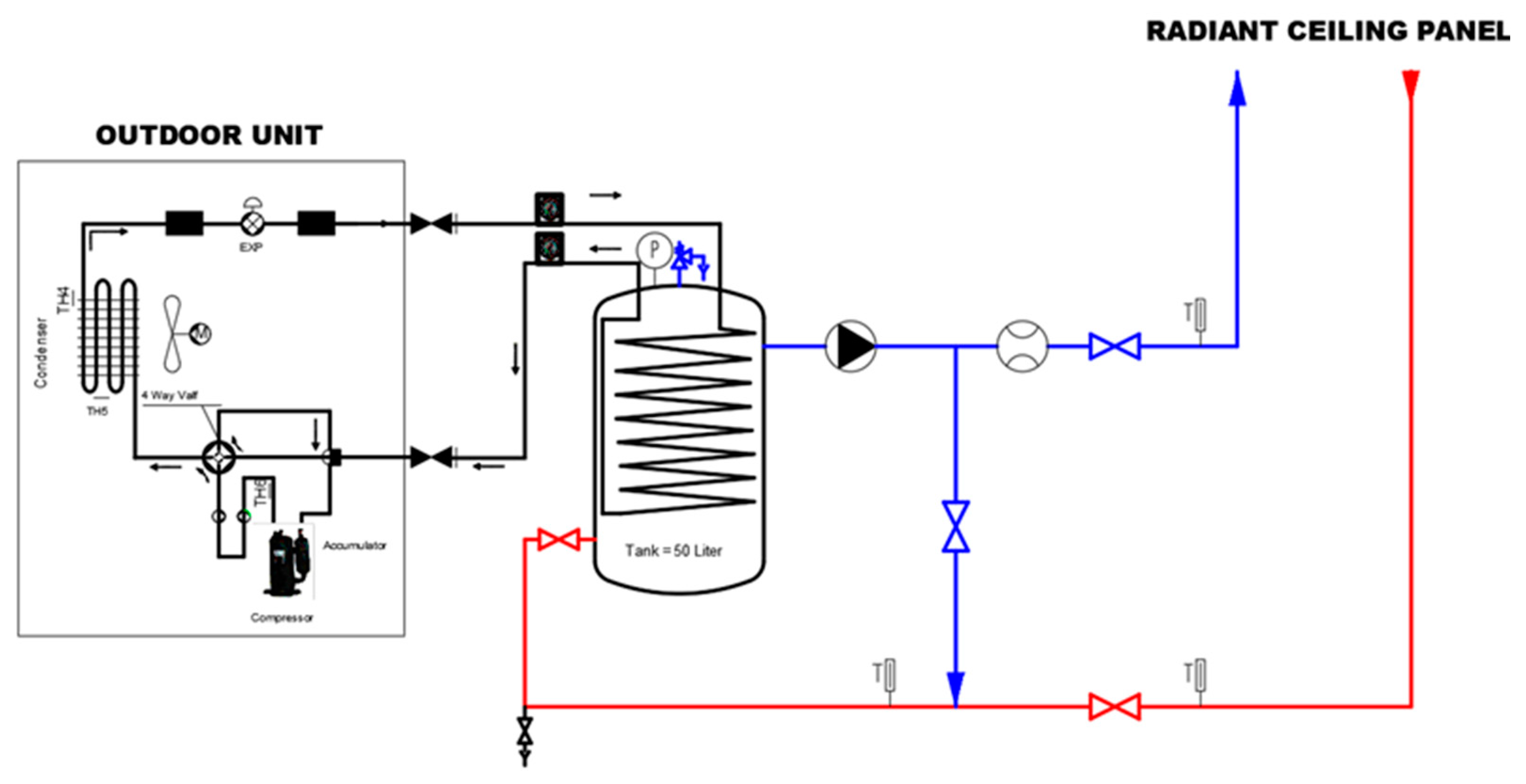

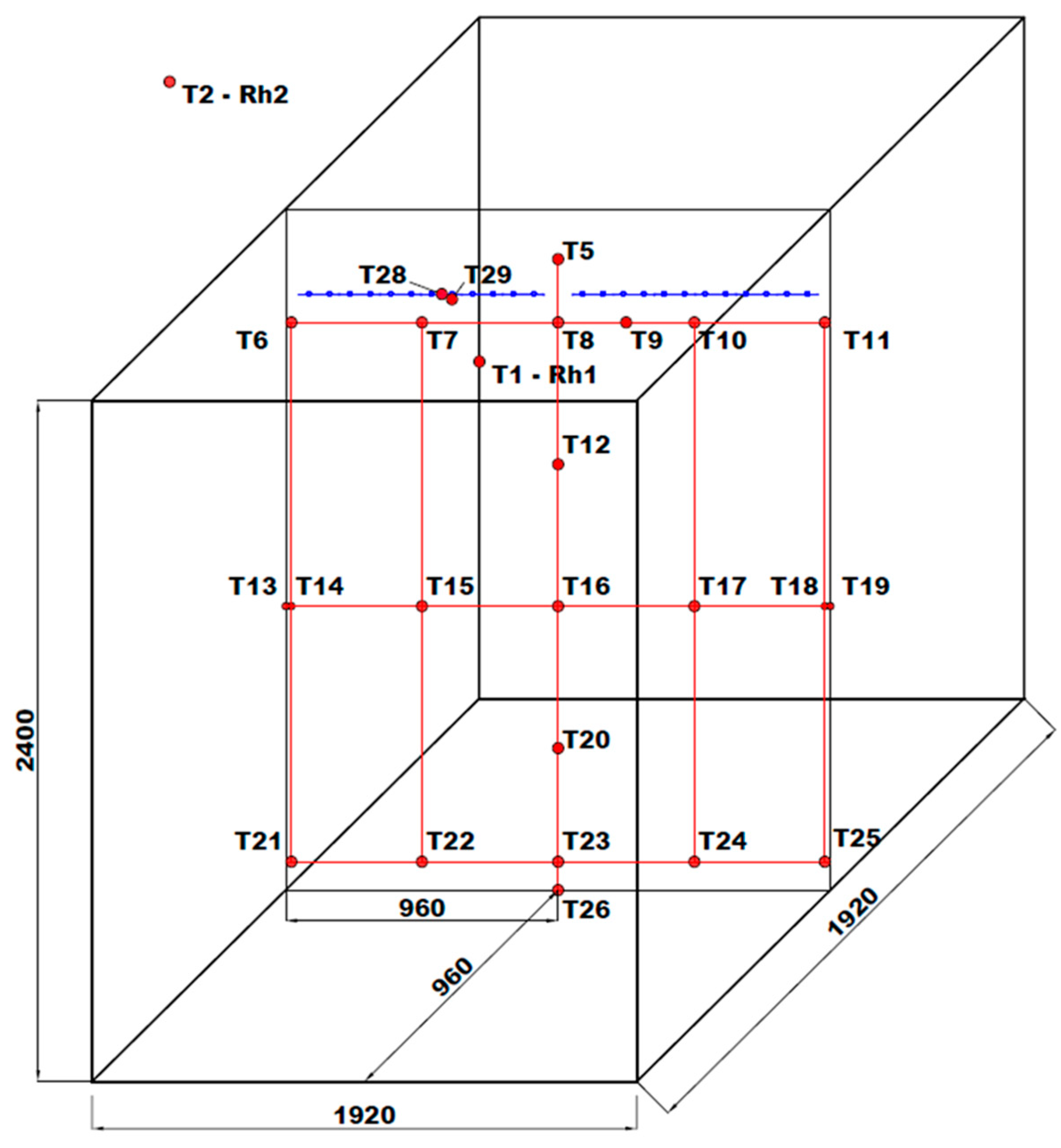

2.1. Experimental Setup

2.2. The Measurement Apparatus

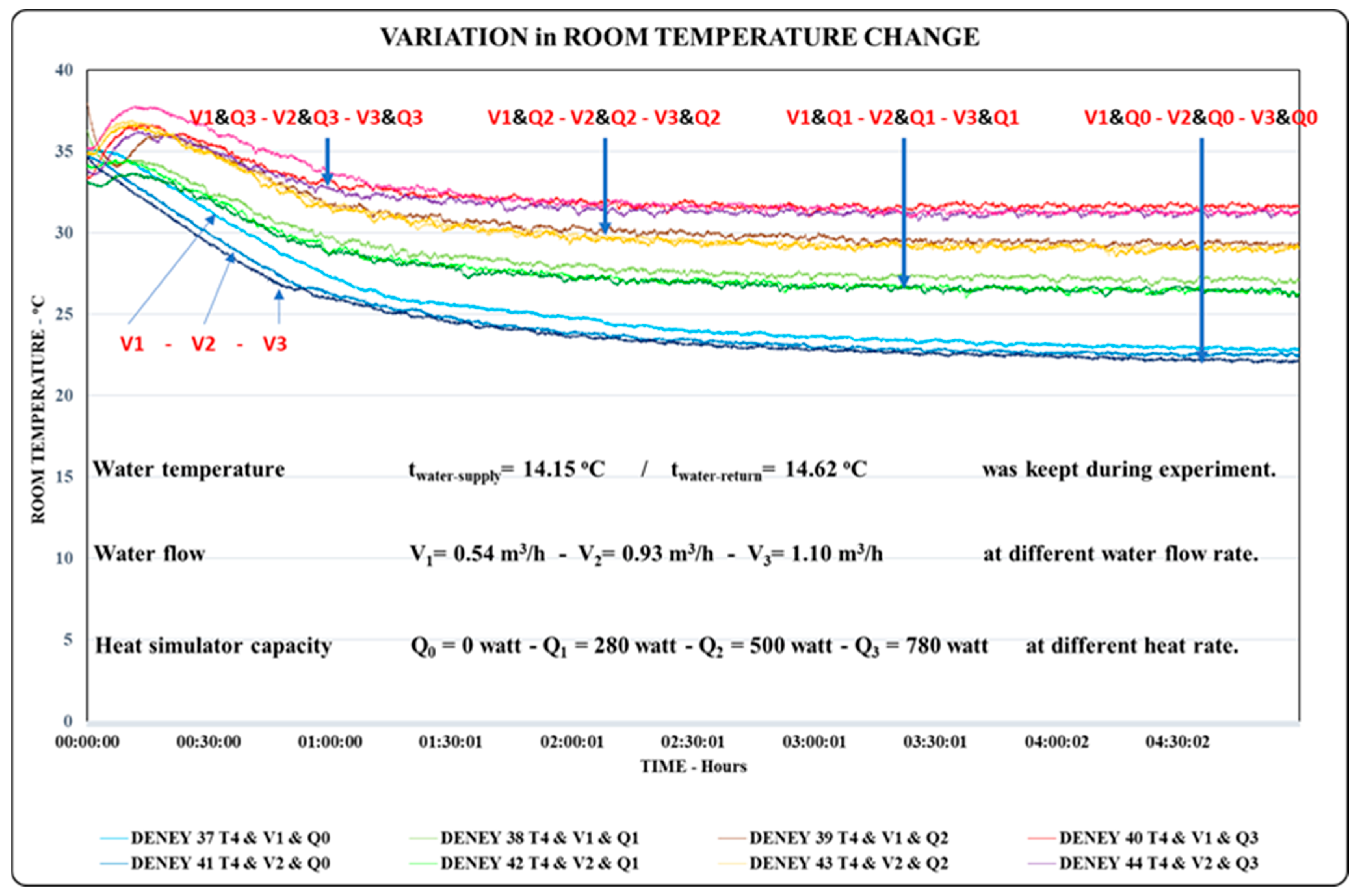

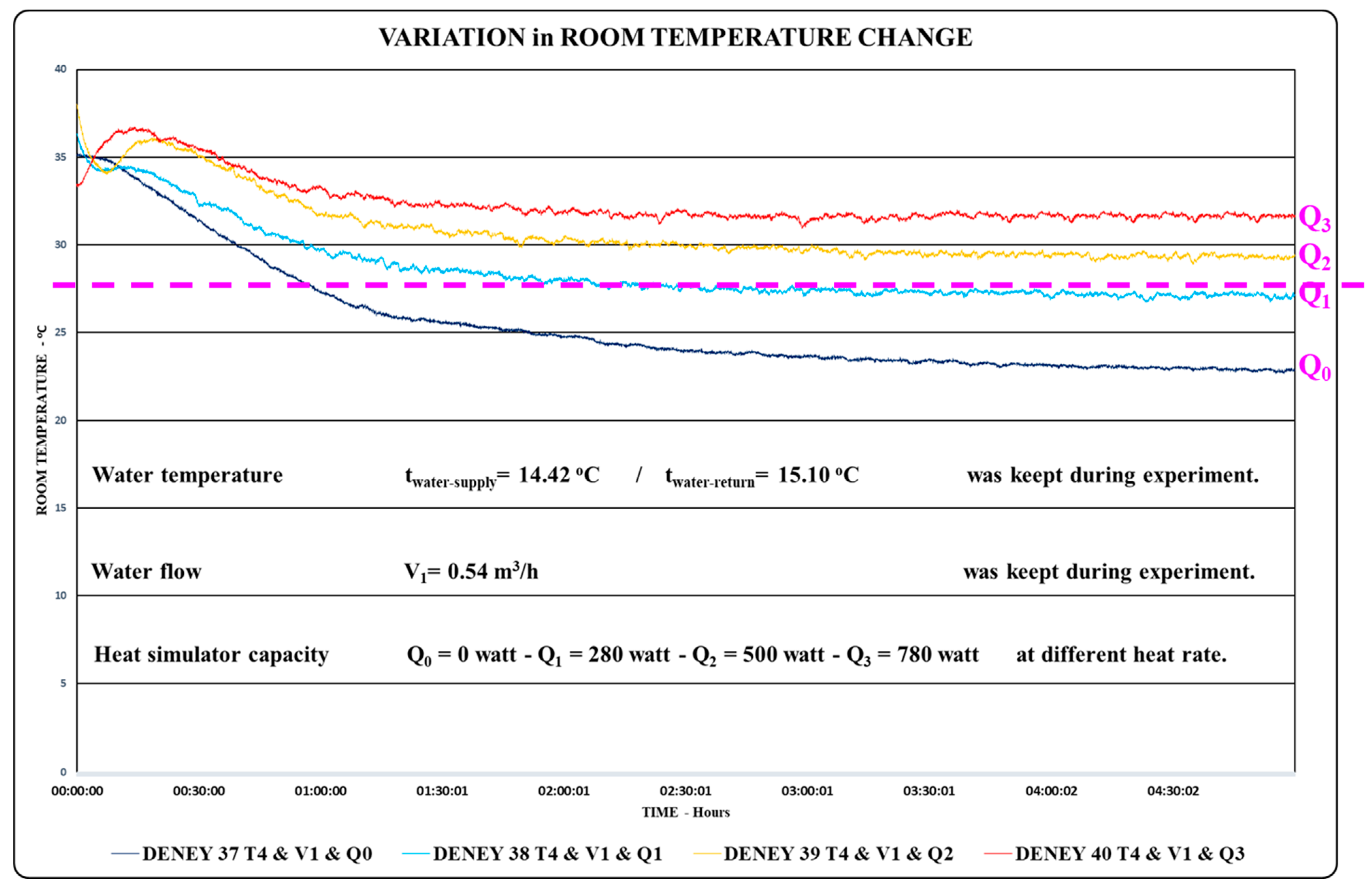

2.3. Determination of Experimental Parameters

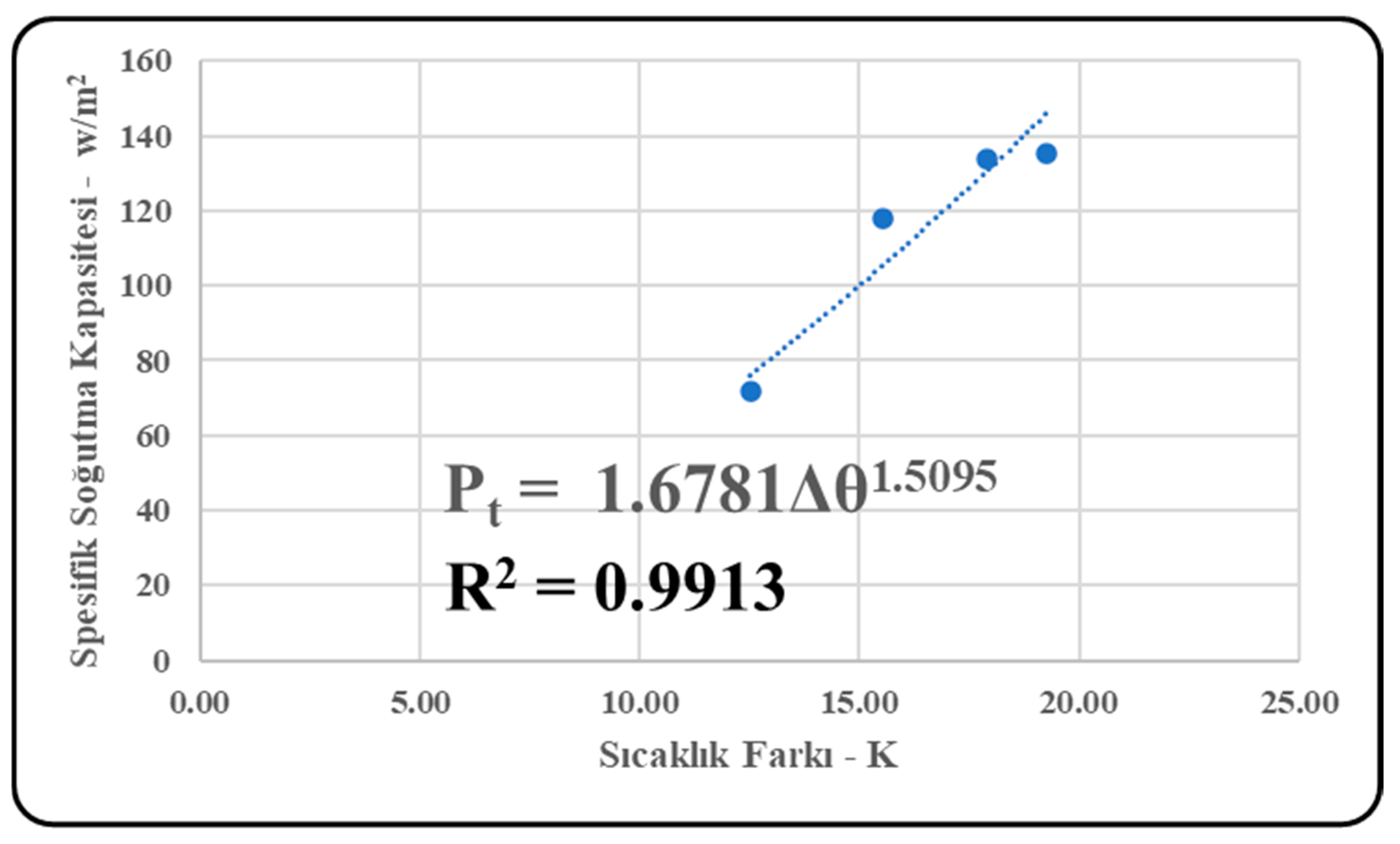

3. Calculation Method

4. Uncertainty Analysis

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| A | Surface area of the heating/cooling panel, m2 |

| AUST | Average unheated (uncooled) surface temperature, °C |

| cp | Specific heat capacity, J/(kg K) |

| Convective heat transfer coefficient, W/(m2 K) | |

| Radiant heat transfer coefficient, W/(m2 K) | |

| Total heat transfer coefficient, W/(m2 K) | |

| mw | Water mass flow, kg/s |

| Natural convective heat flux, W/m2 | |

| Heat losses due to transmission, W/m2 | |

| Radiation heat flux, W/m2 | |

| Heat flux density, W/m2 | |

| Indoor air dry-bulb temperature, °C | |

| Outdoor (outside the test chamber) air dry-bulb temperature, °C | |

| Internal surface temperature, °C | |

| Mean radiant temperature, °C | |

| Indoor operative temperature, °C | |

| Water temperature, °C | |

| Radiant ceiling surface temperature, °C | |

| Δθ | Difference between reference room temperature and mean cooling water temperature, °C |

| Greeks | |

| ϵ | Emissivity |

| σ | Stefan–Boltzmann constant |

References

- Deng, Y.; Ding, Y.; Chen, S.; Li, J.; Zhou, C. Study on radiant heat exchange between human body and radiant surfaces under asymmetric radiant cooling environments. Therm. Sci. Eng. Prog. 2023, 37, 101617. [Google Scholar] [CrossRef]

- Junasová, B.; Krajčík, M.; Šikula, O.; Arıcı, M.; Šimko, M. Adapting the construction of radiant heating and cooling systems for building retrofit. Energy Build. 2022, 268, 112228. [Google Scholar] [CrossRef]

- Koca, A.; Karakoyun, Y.; Acikgoz, O.; Dogu, M.; Dalkilic, A.S. An experimental investigation on the radiant cooled wall’s heat transfer characteristics in a fully conditioned real-sized living environment. Energy Build. 2022, 277, 112578. [Google Scholar] [CrossRef]

- Camci, M.; Karakoyun, Y.; Acikgoz, O.; Dalkilic, A.S. An experimental study on the heat transfer characteristics over a radiant cooled wall exposed to mixed and forced convection driven by displacement ventilation. Int. Commun. Heat Mass Transf. 2022, 135, 106122. [Google Scholar] [CrossRef]

- Koca, A. Experimental examination of heat transfer coefficients in hydronic radiant wall cooling Systems. J. Build. Eng. 2022, 60, 105209. [Google Scholar] [CrossRef]

- Chen, Q.; Li, N. Model predictive control for energy-efficient optimization of radiant ceiling cooling systems. Build. Environ. 2021, 205, 108272. [Google Scholar] [CrossRef]

- Jin, W.; Jing, J.; Jia, L.; Wang, Z. The dynamic effect of supply water flow regulation on surface temperature changes of radiant ceiling panel for cooling operation. Sustain. Cities Soc. 2020, 52, 101765. [Google Scholar] [CrossRef]

- Shinoda, J.; Kazanci, O.B.; Tanabe, S.; Olesen, B.W. A review of the surface heat transfer coefficients of radiant heating and cooling systems. Build. Environ. 2019, 159, 106156. [Google Scholar] [CrossRef]

- Shin, M.S.; Rhee, K.N.; Park, S.H.; Yeo, M.S.; Kim, K.W. Enhancement of cooling capacity through open-type installation of cooling radiant ceiling panel systems. Build. Environ. 2019, 148, 417–432. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhang, X.; Zhou, X. Simplified correlations for heat transfer coefficient and heat flux density of radiant ceiling panels. Sci. Technol. Built Environ. 2017, 23, 251–263. [Google Scholar] [CrossRef]

- Andres-Chicote, M.; Tejero-Gonzalez, A.; Velasco-Gomez, E.; Javier Rey-Martinez, F.J. Experimental study on the cooling capacity of a radiant cooled ceiling system. Energy Build. 2012, 54, 207–214. [Google Scholar] [CrossRef]

- Causone, F.; Corgnati, S.P.; Filippi, M.; Olesen, B.W. Experimental evaluation of heat transfer coefficients between radiant ceiling and room. Energy Build. 2009, 41, 622–628. [Google Scholar] [CrossRef]

- Diaz, F.N.; Lebrun, J.; André, P. Experimental study and modelling of cooling ceiling systems using steady-state analysis. Int. J. Refrig. 2010, 33, 793–805. [Google Scholar] [CrossRef]

- Cheng, Q.; Gomez, S.; Hu, G.; Abaalkhail, A.; Beasley, J.; Zhang, P. A Zigzag Wall with Asymmetric Emissivity for Radiative Cooling Building Envelope. engrXiv, 2023; preprint. [Google Scholar] [CrossRef]

- Cheng, Q.; Tang, C.; Luo, D.; Park, M.; Tian, S.; Yang, Y. A dynamic wall design with tunable angular emissivity for all-season thermal regulation. Cell Rep. Phys. Sci. 2024, 5, 101934. [Google Scholar] [CrossRef]

- BS EN 12975-2:2006; BRITISH Standard: Thermal Solar Systems and Components. Solar Collectors—Test Methods. British Standards Institution (BSI): London, UK, 2006.

- ASHRAE Handbook—Fundamentals 2021; ASHRAE: Peachtree Corners, GA USA, 2021; ISBN 978-1-947192-90-4.

- BS EN ISO 7730:2005; ISO Standard: Ergonomics of the Thermal Environment. Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. ISO: Geneva, Switzerland, 2005.

- ANSI/ASHRAE 55:2010; ASHRAE Standard: Thermal Environmental Conditions for Human Occupancy. American Society of Heating, Refrigerating and Air-Conditioning Engineers Inc.: Atlanta, GA, USA, 2010.

- BS EN 14240:2004; BRITISH Standard: Ventilation for Buildings—Chilled Ceilings—Testing and Rating. ASTM International: West Conshohocken, PA, USA, 2004.

- Kline, S.J.; ve McClintock, F.A. Describing Uncertainties in Single-Sample Experiments. Mech. Eng. 1953, 75, 3–8. [Google Scholar]

| Supply Water—°C | Return Water—°C | Number of Experiments | |||||

|---|---|---|---|---|---|---|---|

| Explanation | Min | Max | Avg | Min | Max | Avg | |

| Water temp. Step 1 | 17.55 | 18.04 | 17.77 | 17.62 | 18.76 | 18.25 | 12 |

| Water temp. Step 2 | 16.36 | 16.97 | 16.62 | 16.89 | 17.87 | 17.21 | 12 |

| Water temp. Step 3 | 15.31 | 15.87 | 15.61 | 15.50 | 16.77 | 16.12 | 17 |

| Water temp. Step 4 | 13.76 | 14.63 | 14.11 | 13.94 | 15.44 | 14.64 | 15 |

| Pump Flow—m3/h | Number of Experiments | |||

|---|---|---|---|---|

| Explanation | Min | Max | Avg | |

| Pump Flow Step 1 | 0.52 | 0.58 | 0.54 | 18 |

| Pump Flow Step 2 | 0.90 | 0.94 | 0.93 | 18 |

| Pump Flow Step 3 | 1.07 | 1.13 | 1.10 | 20 |

| Explanation | Capacity W | Qty. | Total Capacity W |

|---|---|---|---|

| Heat Simulator—Closed | 0 | 4 | 0 |

| Heat Simulator—Step 1 | 70 | 4 | 280 |

| Heat Simulator—Step 2 | 55 + 70 | 4 | 500 |

| Heat Simulator—Step 3 | 70 + 55 + 70 | 4 | 780 |

| LAYER—WALL | Thickness | Thermal Conductivity Calculation Value | d/kh, 1/h | Thermal Conductivity Coefficient |

|---|---|---|---|---|

| U | ||||

| d (m) | kh (W/mK) | (m2K/W) | (W/m2K) | |

| 1/hi | 0.130 | |||

| Interior Plaster (gypsum mortar) | 0.001 | 0.700 | 0.001 | |

| Gypsum board—800 kg/m3 | 0.012 | 0.250 | 0.048 | |

| Thermal Insulation Material | 0.030 | 0.047 | 0.644 | |

| Gypsum board—800 kg/m3 | 0.012 | 0.250 | 0.048 | |

| Outer Plaster (gypsum mortar) | 0.001 | 0.250 | 0.004 | |

| 1/hd | 0.040 | |||

| 0.916 | 1.092 |

| LAYER—FLOOR | Thickness | Thermal Conductivity Calculation Value | d/kh, 1/h | Thermal Conductivity Coefficient |

|---|---|---|---|---|

| U | ||||

| d (m) | kh (W/mK) | (m2K/W) | (W/m2K) | |

| 1/hi | 0.130 | |||

| Ceramic Tile | 0.001 | 1.650 | 0.001 | |

| Cement mortar screed—2000 kg/m3 | 0.080 | 1.400 | 0.057 | |

| Concrete—2400 kg/m3 | 0.100 | 2.500 | 0.040 | |

| Outer Plaster (cement mortar) | 0.002 | 0.250 | 0.008 | |

| 1/hd | 0.040 | |||

| 0.276 | 3.626 |

| Explanation | ||

|---|---|---|

| Literature values–[W/m2K] | 3.1–4.1 | 5.50 |

| Calculated values–[W/m2K] | 4.02 | 5.49 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Küheylan, C.D.; Özkan, D.B. Experimental and Theoretical Study of Heat Transfer in a Chilled Ceiling System. Appl. Sci. 2024, 14, 5908. https://doi.org/10.3390/app14135908

Küheylan CD, Özkan DB. Experimental and Theoretical Study of Heat Transfer in a Chilled Ceiling System. Applied Sciences. 2024; 14(13):5908. https://doi.org/10.3390/app14135908

Chicago/Turabian StyleKüheylan, Cüneyt Deniz, and Derya Burcu Özkan. 2024. "Experimental and Theoretical Study of Heat Transfer in a Chilled Ceiling System" Applied Sciences 14, no. 13: 5908. https://doi.org/10.3390/app14135908

APA StyleKüheylan, C. D., & Özkan, D. B. (2024). Experimental and Theoretical Study of Heat Transfer in a Chilled Ceiling System. Applied Sciences, 14(13), 5908. https://doi.org/10.3390/app14135908