Comparative Analysis of Tribological Behavior of 45 Steel under Intensive Quenching-High-Temperature Tempering and Queenching-Tempering Process

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

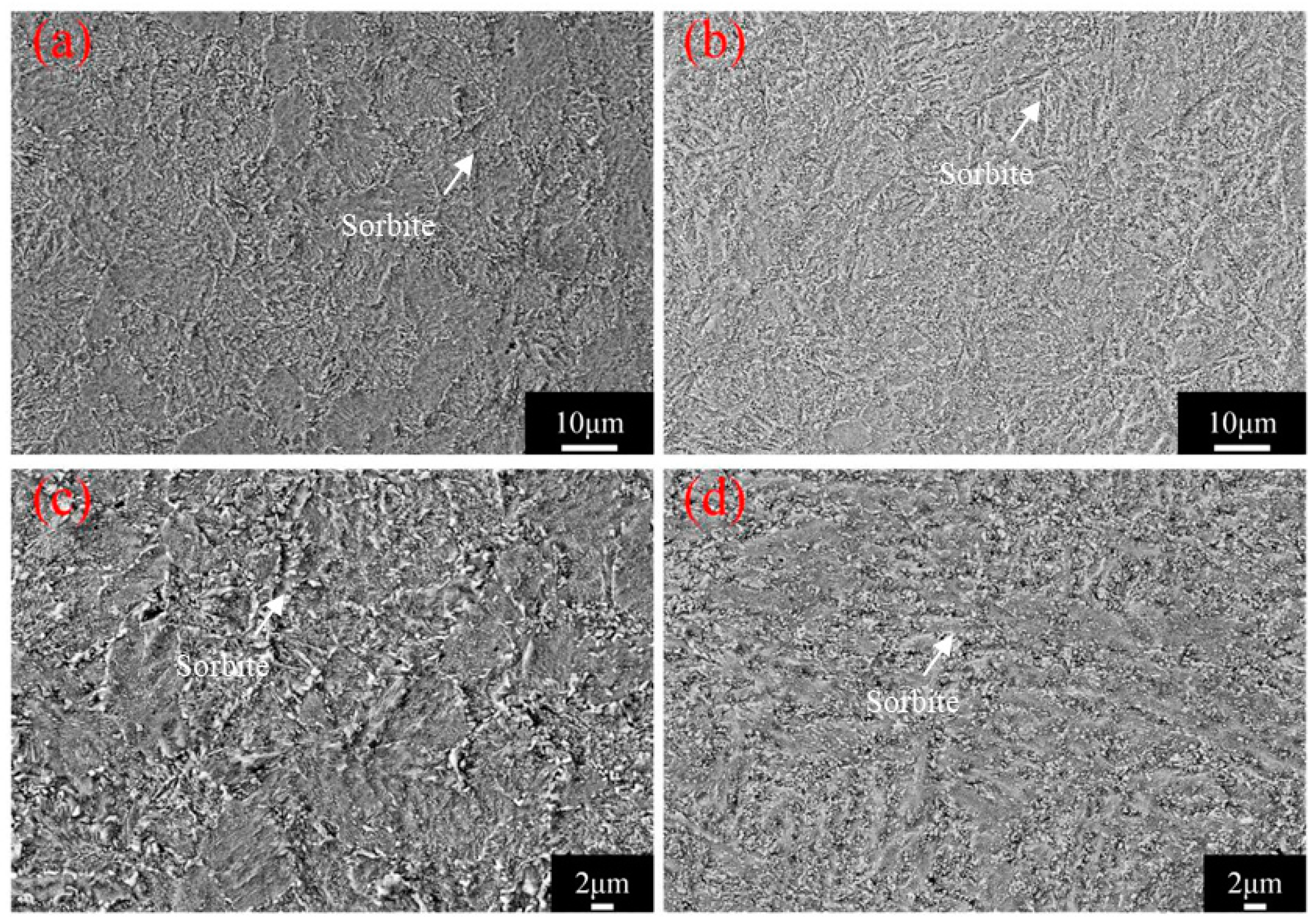

3.1. Microstructure

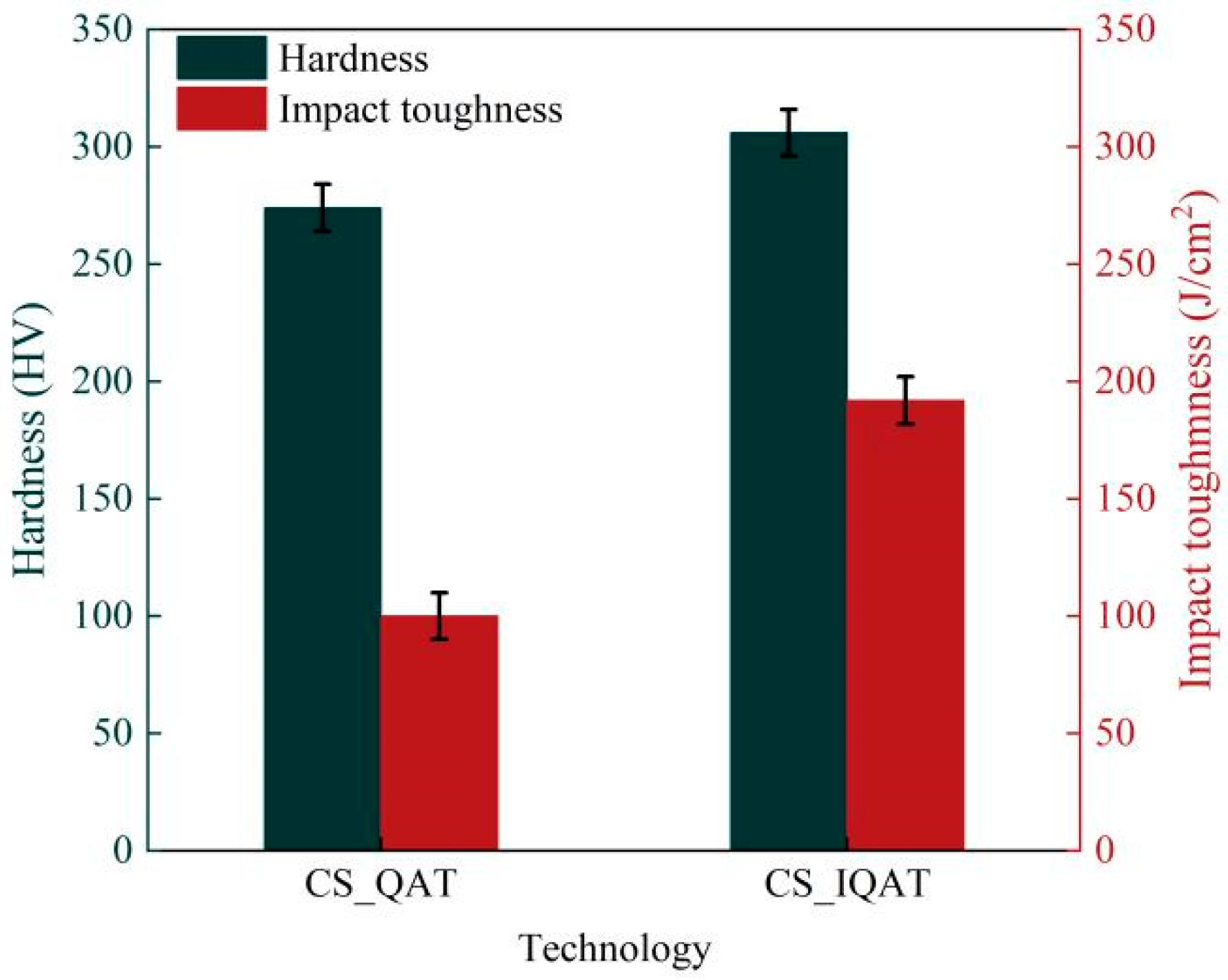

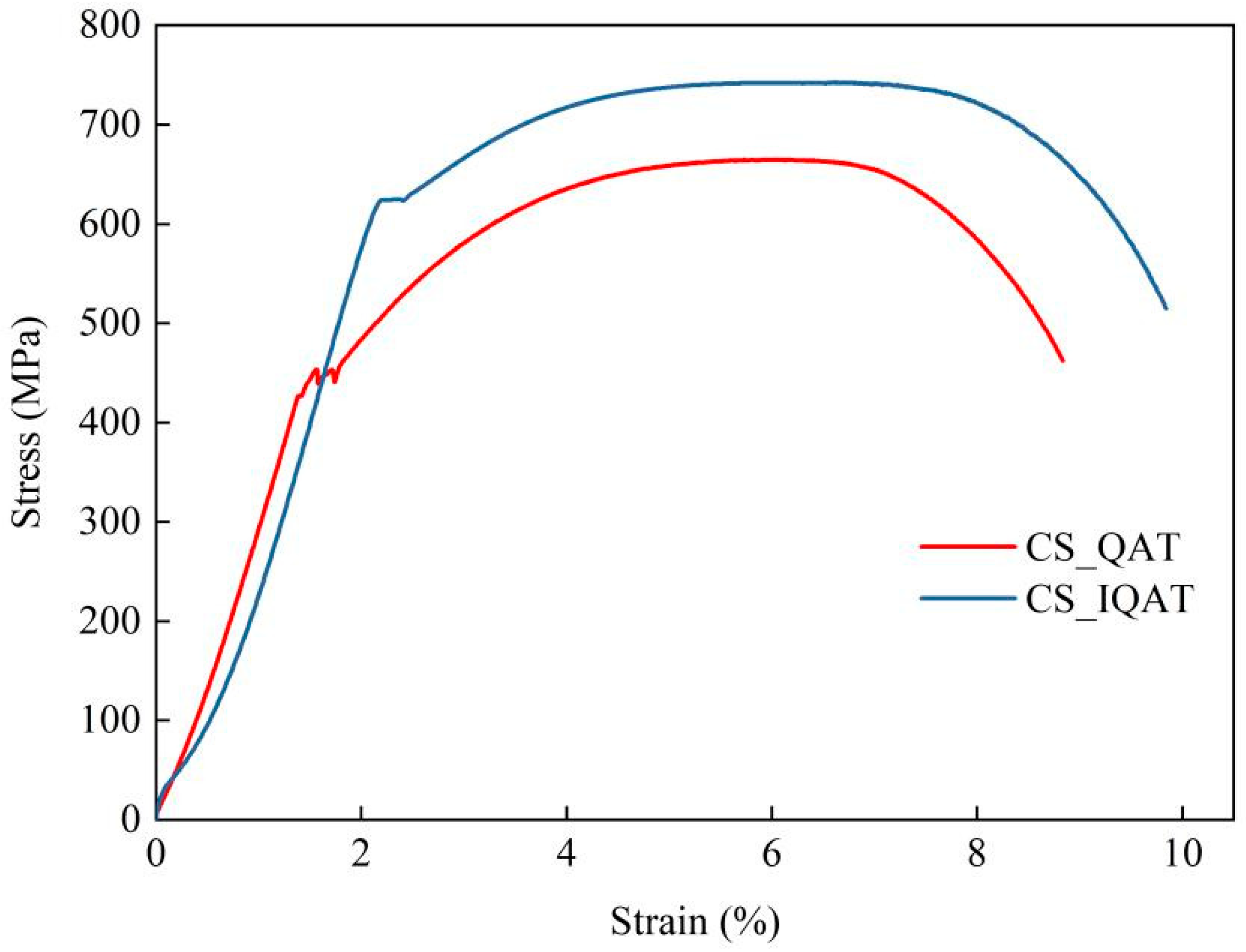

3.2. Mechanical Properties

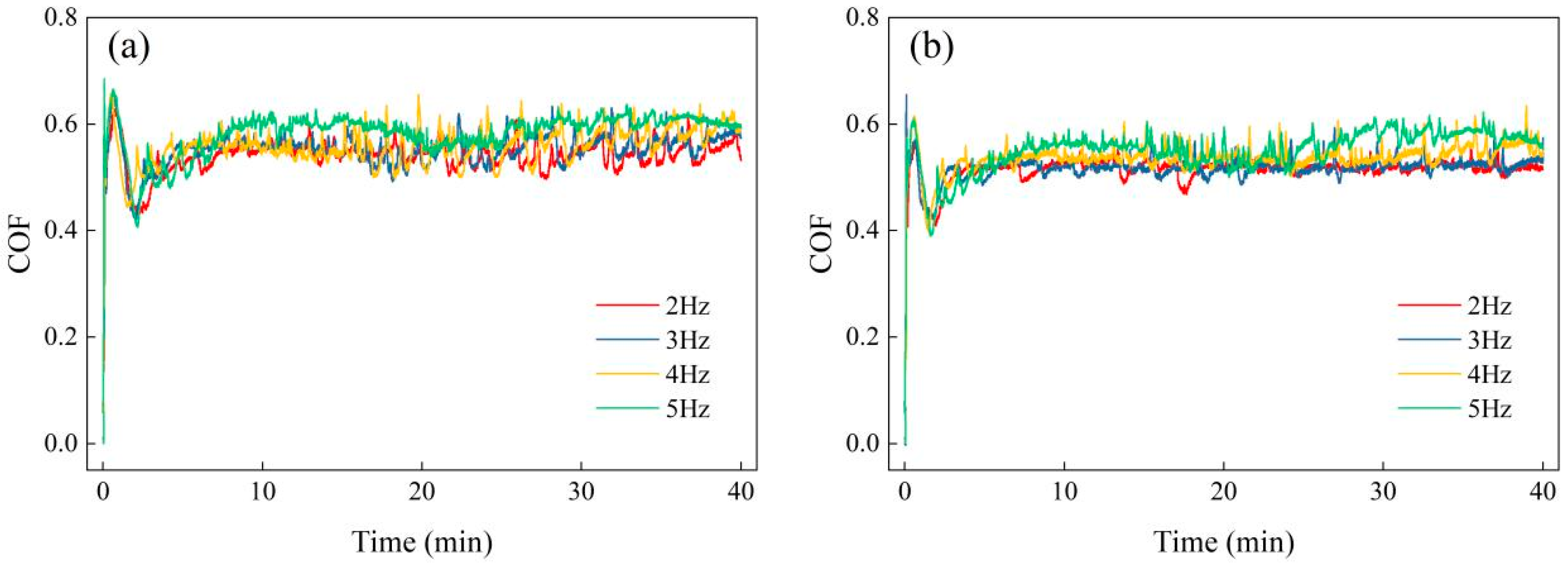

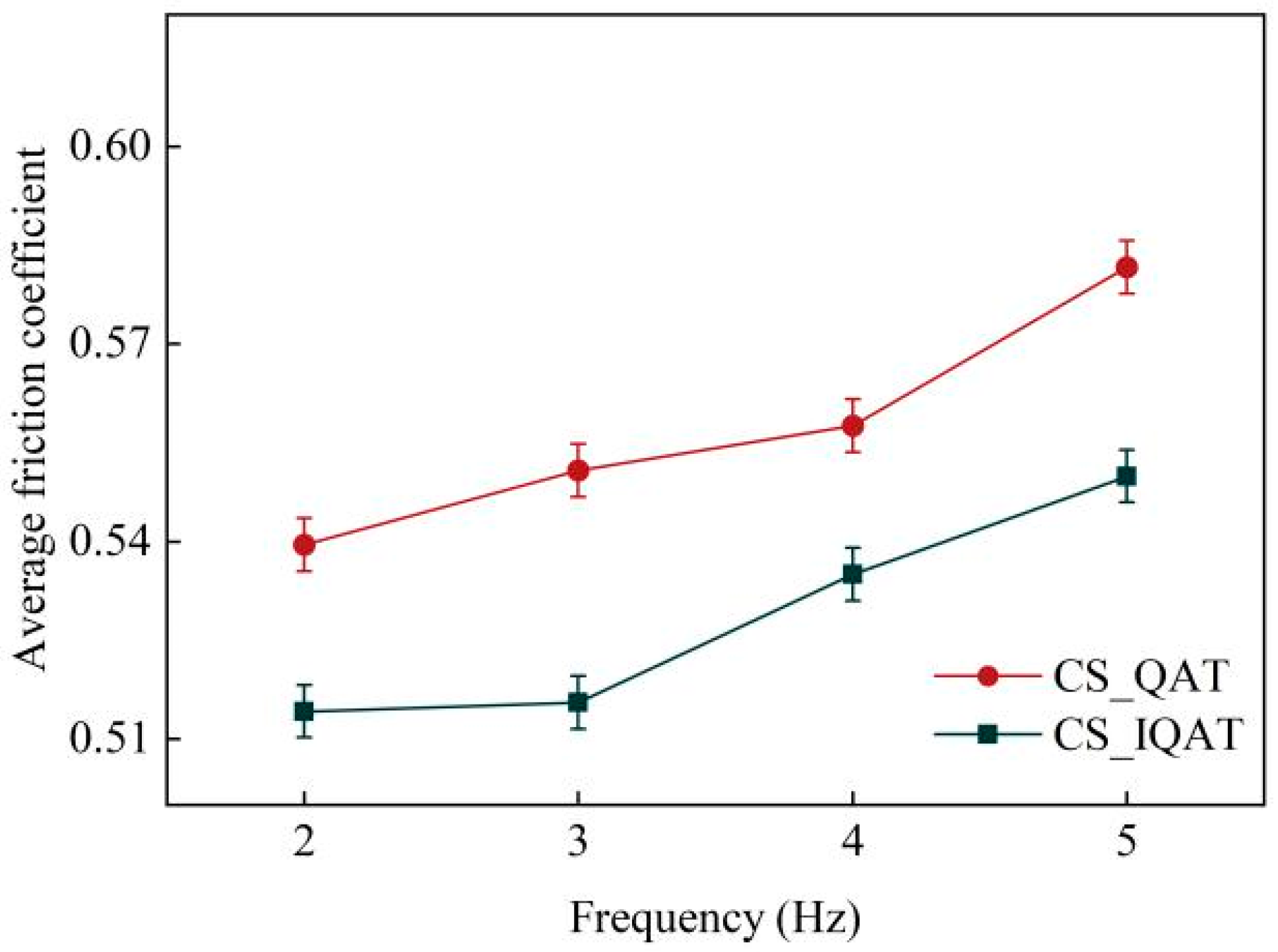

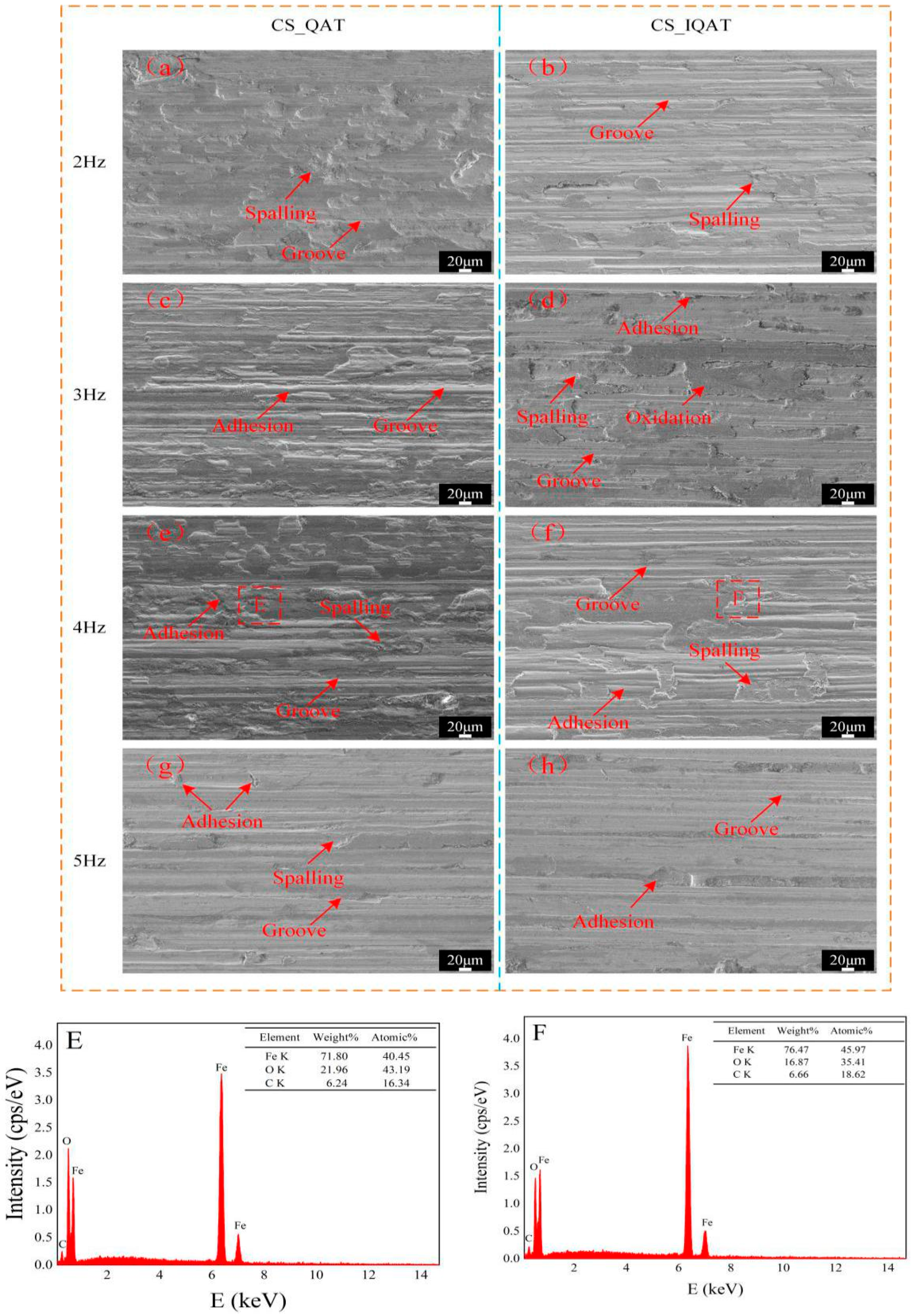

3.3. Tribological Behavior

4. Conclusions

- The microstructure of 45 steel obtained by the CS_IQAT process is more detailed and homogeneous, and its hardness and yield strength are significantly increased. The impact toughness is enhanced by nearly 1.9 times compared with the traditional CS_QAT specimens. This improvement significantly optimizes the overall mechanical properties of the material and is expected to significantly extend the service life of the workpiece.

- In terms of wear resistance, specimens from the CS_IQAT process show lower average coefficients of friction and relative wear rates than those from CS_QAT, especially at high frequencies, where the relative wear rate is only 58 to 72 percent of that of CS_QAT specimens, and the wear surface is much flatter. This finding indicates that the CS_IQAT process can effectively replace the conventional process and significantly improve the wear resistance of the workpiece.

- Comparison of the two processes revealed that the main wear mechanism shifted from adhesive wear to abrasive wear, and that the effect of abrasive wear on part life became more pronounced as the frequency of testing increased. The revelation of this mechanism is of great significance for the optimization of process parameters and improvement of part design.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hao, W.; Ping, C.; Yang, L.; Tianshou, M. Effect of Axial Vibration on Sliding Frictional Force between Shale and 45 Steel. Shock Vib. 2018, 2018, 4179312. [Google Scholar] [CrossRef]

- Singh, S.; Samir, S.; Kumar, K.; Thapa, S. Effect of heat treatment processes on the mechanical properties of AISI 1045 steel. Mater. Today Proc. 2021, 45, 5097–5101. [Google Scholar] [CrossRef]

- Rogante, M. Wear characterization and tool performance of sintered carbide inserts during automatic machining of AISI 1045 steel. J. Mater. Process Technol. 2009, 209, 4776–4783. [Google Scholar] [CrossRef]

- Lesyk, D.A.; Mordyuk, B.N.; Martinez, S.; Iefimov, M.O.; Dzhemelinskyi, V.V.; Lamikiz, A. Influence of combined laser heat treatment and ultrasonic impact treatment on microstructure and corrosion behavior of AISI 1045 steel. Surf. Coat. Technol. 2020, 401, 126275. [Google Scholar] [CrossRef]

- Lu, S.; Miao, B.; Song, L.; Song, R.; Wei, K.; Hu, J. Enhancement of wear resistance of AISI 1045 steel by a two-step plasma treatment. Vacuum 2017, 145, 153–157. [Google Scholar] [CrossRef]

- Pereira, D.; Gandra, J.; Pamies-Teixeira, J.; Miranda, R.M.; Vilaça, P. Wear behaviour of steel coatings produced by friction surfacing. J. Mater. 2014, 214, 2858–2868. [Google Scholar] [CrossRef]

- Li, J.; Cao, Z.; Liu, L.; Liu, X.; Peng, J. Effect of microstructure on hardness and wear properties of 45 steel after induction hardening. Steel Res. Int. 2002, 92, 2000540. [Google Scholar] [CrossRef]

- Fortini, A.; Bertarelli, E.; Cassola, M.; Merlin, M. An Industrial-Scale Study of the Hardness and Microstructural Effects of Isothermal Heat Treatment Parameters on EN 100CrMo7 Bearing Steel. Appl. Sci. 2024, 14, 737. [Google Scholar] [CrossRef]

- Arana, M.; Ukar, E.; Rodriguez, I.; Aguilar, D.; Alvarez, P. Influence of deposition strategy and heat treatment on mechanical properties and microstructure of 2319 aluminium WAAM components. Mater. Design 2022, 221, 110974. [Google Scholar] [CrossRef]

- Burton, J.; Love, H.; Richards, K.; Burton, C.; Summers, S.; Pitman, J.; Easterbrook, E.; Davies, K.; Spencer, P.; Roberts, A.D.; et al. The effect of heat-treatment on SARS-CoV-2 viability and detection. J. Virol. Methods 2021, 290, 114087. [Google Scholar] [CrossRef]

- Zhang, H.; Xie, Z.; Zhu, X.; Cheng, H.; Ma, H.; Lv, Z.; Wang, G. Optimization of heat treatment process of 34CrNi3MoV steel case. Met. Heat Treat. 2023, 48, 224–228. [Google Scholar] [CrossRef]

- Liu, H. Comparison of tribological properties between 45~# steel and 40Cr steel under different heat treatment conditions. Lubr. Oil 2007, 7, 129–131. [Google Scholar]

- Zhang, J.; Zhao, M.-C.; Tian, Y.; Zhang, J.; Wang, Z.; Zhao, Y.-C.; Peng, L. Simultaneous Enhancement of Strength and Sulfide Stress Cracking Resistance of Hot-Rolled Pressure Vessel Steel Q345 via a Quenching and Tempering Treatment. Materials 2024, 17, 1636. [Google Scholar] [CrossRef]

- Kuznetsov, A.A.; Rudnev, V.I. Causes of Cracking in Quenching of the Parts Made of Steels and Cast Iron and Recommendations for Their Removal: A Review. Russ. Metall. 2017, 2017, 1125–1130. [Google Scholar] [CrossRef]

- Cai, W.; Meng, F.; Gao, X.; Hu, J. Effect of QPQ nitriding time on wear and corrosion behavior of 45 carbon steel. Appl. Surf. Sci. 2012, 261, 411–414. [Google Scholar] [CrossRef]

- Kruthiventi, S.; Basavakumar, K.G.; Nambala, S.; Subramanyacharyulu, G. Influence of Heat Treatment on Microstructural and Mechanical Properties of Nodular Cast Iron. J. Inst. Eng. Ser. D 2014, 95, 75–79. [Google Scholar] [CrossRef]

- Yim, S.; Bian, H.; Aoyagi, K.; Chiba, A. Effect of multi-stage heat treatment on mechanical properties and microstructure transformation of Ti–48Al–2Cr–2Nb alloy. Mat. Sci. Eng. A Struct. 2021, 816, 141321. [Google Scholar] [CrossRef]

- Kobasko, N.I.; Aronov, M.A.; Powell, J.A.; Canale, L.C.F.; Totten, G.E. Intensive quenching process classification and applications. Heat Treat. Met. 2004, 31, 51–58. [Google Scholar] [CrossRef]

- Kobasko, N.I. Quench Process and Steel Chemistry Optimization to Prevent Quench Cracking during Hardening of Splined Semi—Axles. Eur. J. Appl. Phys. 2021, 3, 23–28. [Google Scholar] [CrossRef]

- Freborg, A.M.; Ferguson, B.L.; Aronov, M.A.; Kobasko, N.I.; Powell, J.A. Intensive quenching theory and application for imparting high residual surface compressive stresses in pressure vessel components. J. Press. Vess. Technol. 2003, 125, 188–194. [Google Scholar] [CrossRef]

- Amatanweze, K.T.; Buchely, M.F.; Athavale, V.A.; Bartlett, L.N.; O’Malley, R.J.; Suzuki, T. Residual Stress Distribution, Distortion, and Crack Initiation in Conventional and Intensive Quench Practices. J. Mater. Eng. Perform. 2024, 33, 3838–3848. [Google Scholar] [CrossRef]

- Samuel, A.; Prabhu, K.N. Residual stress and distortion during quench hardening of steels: A review. J. Mater. Eng. Perform. 2022, 31, 5161–5188. [Google Scholar] [CrossRef]

- Huang, B.; Xu, H.; Jiang, N.; Wang, M.; Huang, J.; Guan, L. Tensile-Strained RuO2 Loaded on Antimony-Tin Oxide by Fast Quenching for Proton-Exchange Membrane Water Electrolyzer. Adv. Sci. 2022, 9, 2201654. [Google Scholar] [CrossRef]

- Chen, X.; Zhu, Y.; Wu, Y.; Hao, J.; Ma, X.; Lu, P. Modeling of fast ionization waves in pure nitrogen at moderate pressure. Plasma Sources Sci. Technol. 2021, 30, 065002. [Google Scholar] [CrossRef]

- Lowrie, J.; Pang, H.; Ngaile, G. Weight reduction of heavy-duty truck components through hollow geometry and intensive quenching. J. Manuf. Process. 2017, 28, 523–530. [Google Scholar] [CrossRef]

- Yang, D.; Zhu, X.; Bo, Y.; Maimaiti, A. Intensive quenching + tempering treatment of 40Cr steel. Met. Heat Treat. 2023, 48, 117–123. [Google Scholar] [CrossRef]

- Peng, S.; Wang, Z.; Li, J.; Fang, Q.; Wei, Y. Beyond Orowan hardening: Map the four distinct mechanisms associated with dislocation-precipitate interaction. Int. J. Plast. 2023, 169, 103710. [Google Scholar] [CrossRef]

| Chemical Element | C | Cr | Mn | Ni | P | S | Si | Fe |

|---|---|---|---|---|---|---|---|---|

| Content | 0.42~ 0.50 | 0.001~ 0.25 | 0.50~ 0.80 | 0.001~ 0.25 | 0.001~ 0.035 | 0.001~ 0.035 | 0.17~ 0.37 | excess |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, X.; Zhu, X.; Fu, Y.; Xiao, S.; Liu, Y. Comparative Analysis of Tribological Behavior of 45 Steel under Intensive Quenching-High-Temperature Tempering and Queenching-Tempering Process. Appl. Sci. 2024, 14, 5942. https://doi.org/10.3390/app14135942

Su X, Zhu X, Fu Y, Xiao S, Liu Y. Comparative Analysis of Tribological Behavior of 45 Steel under Intensive Quenching-High-Temperature Tempering and Queenching-Tempering Process. Applied Sciences. 2024; 14(13):5942. https://doi.org/10.3390/app14135942

Chicago/Turabian StyleSu, Xiyang, Xiaoshuo Zhu, Yudong Fu, Shichen Xiao, and Yuchao Liu. 2024. "Comparative Analysis of Tribological Behavior of 45 Steel under Intensive Quenching-High-Temperature Tempering and Queenching-Tempering Process" Applied Sciences 14, no. 13: 5942. https://doi.org/10.3390/app14135942

APA StyleSu, X., Zhu, X., Fu, Y., Xiao, S., & Liu, Y. (2024). Comparative Analysis of Tribological Behavior of 45 Steel under Intensive Quenching-High-Temperature Tempering and Queenching-Tempering Process. Applied Sciences, 14(13), 5942. https://doi.org/10.3390/app14135942