Experimental Study on Permeability Characteristics of Compacted Backfill Body after Gangue Grouting and Backfilling in the Mining Space

Abstract

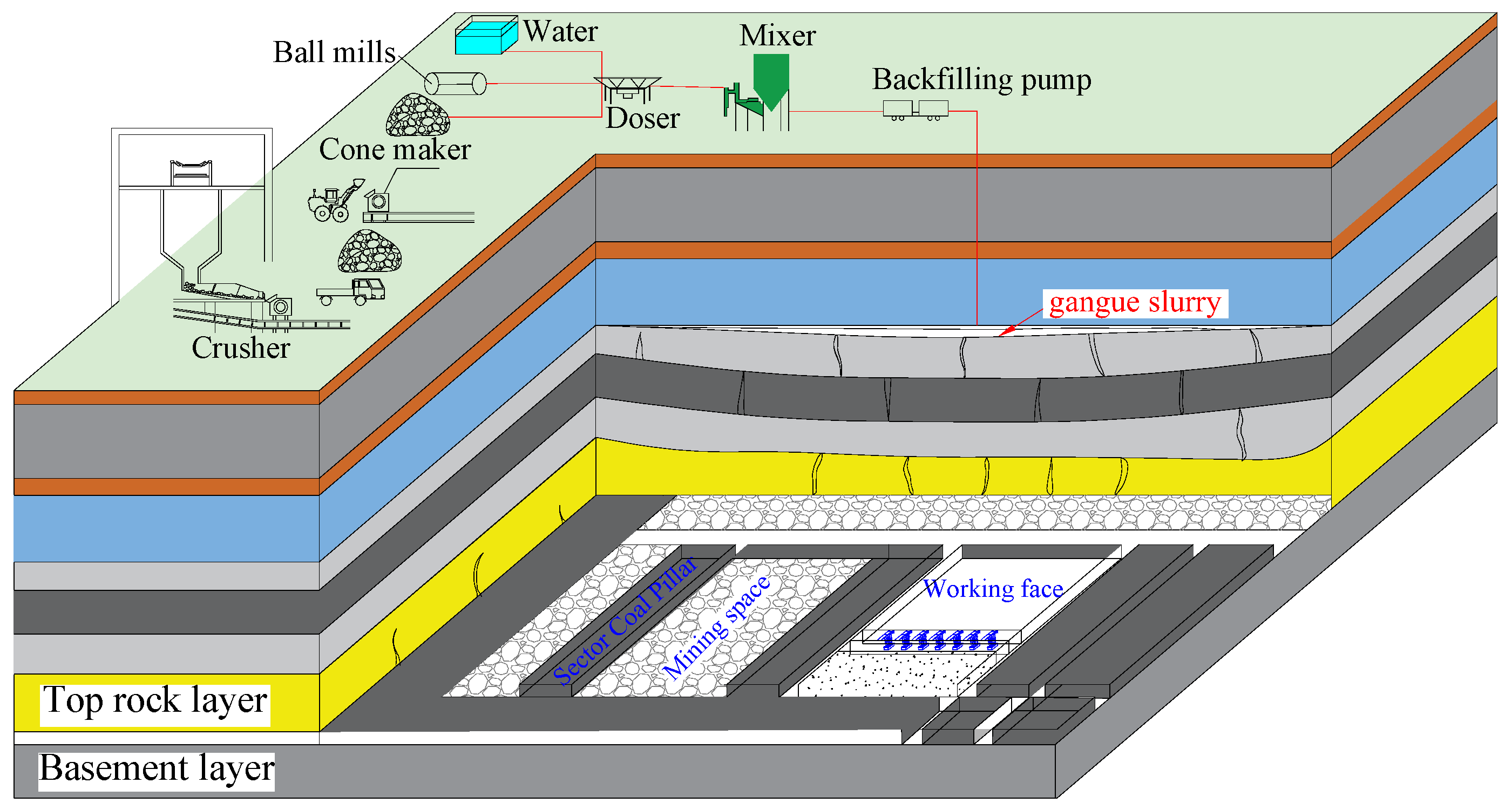

:1. Introduction

2. Materials and Methods

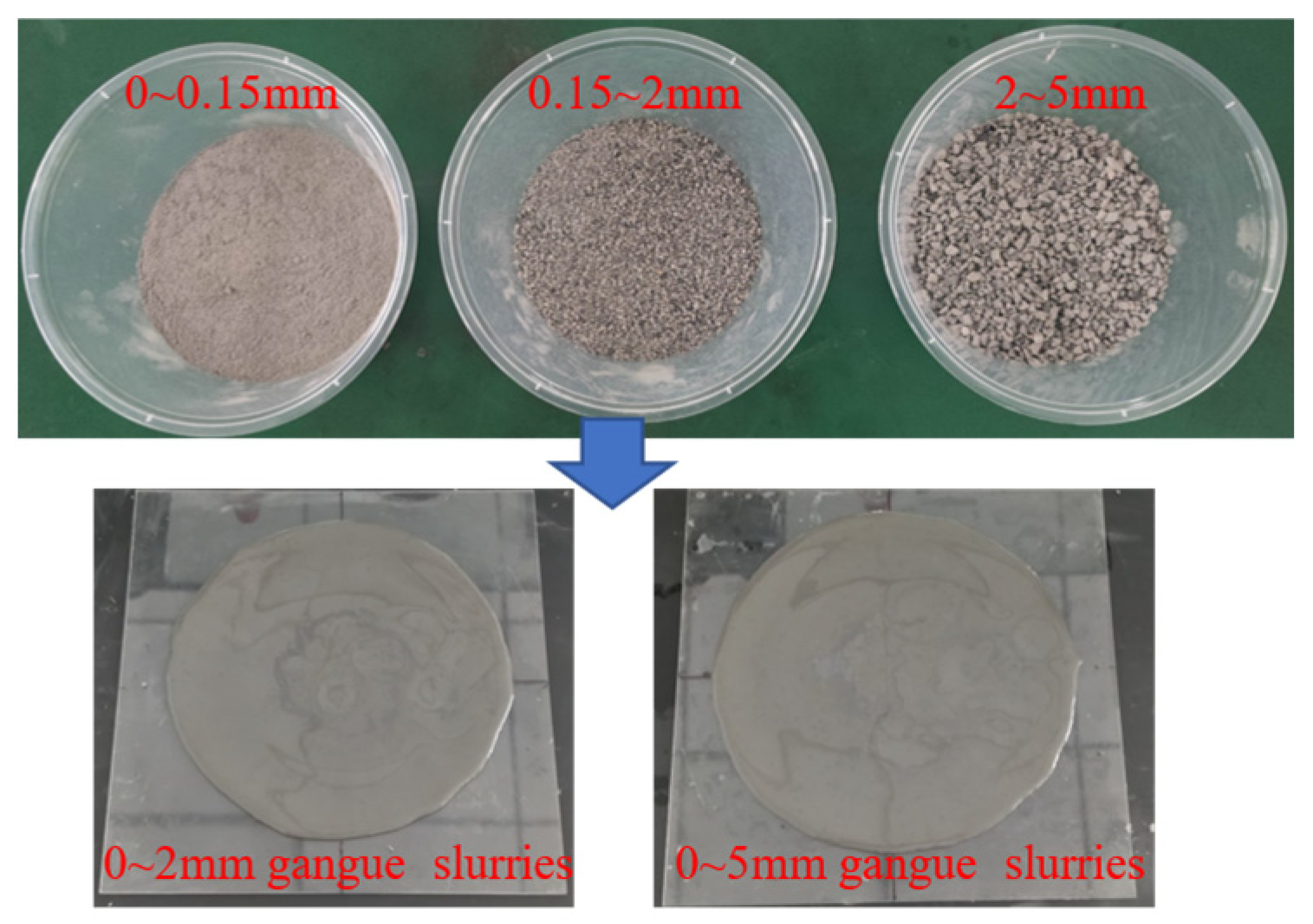

2.1. Test Materials

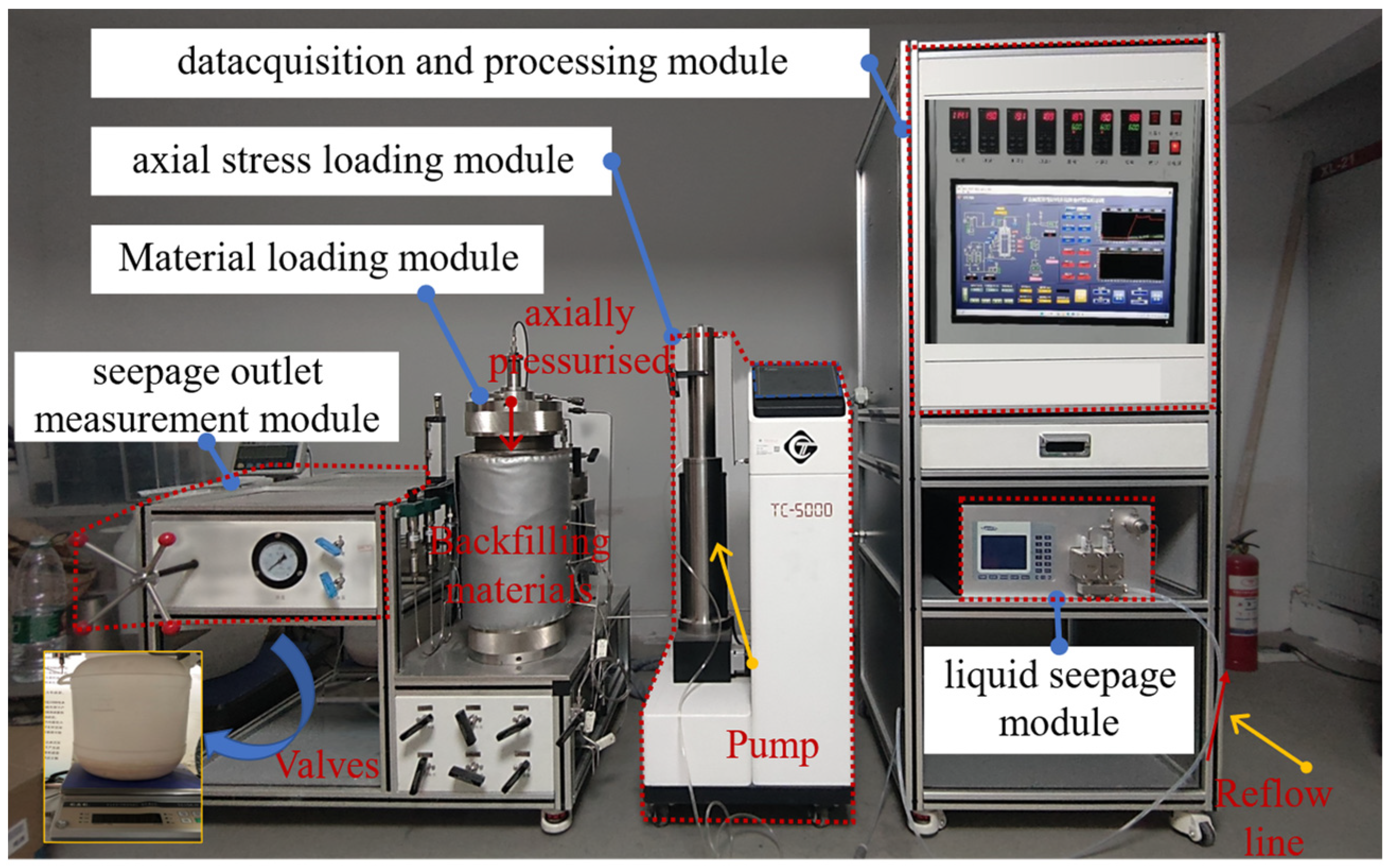

2.2. Multi-Field Coupled Seepage Test System for Backfill Materials

- (1)

- Material loading module

- (2)

- Axial stress loading module

- (3)

- Liquid seepage module

- (4)

- Seepage outlet metering module

- (5)

- Data collection and processing module

2.3. Testing Method for Permeability Characteristics of the CBB

2.3.1. Preparation Method for the CBB

2.3.2. Principle of Permeability Tests

2.3.3. Permeability Characteristic Test

2.3.4. Procedures of Seepage Test

- (1)

- Pipeline inspection and system debugging. The connections of equipment pipelines were confirmed, the valves of the axial stress loading module and liquid seepage module were checked, and the integrity of all accessories was verified. The key module was initiated, and the corresponding testing software was debugged.

- (2)

- Loading and sealing inspection. Firstly, a sealing inspection was performed; then, the material loading container was filled with gangue slurry, and the surface of the material flat was scraped with a distance of 8 cm from the upper port. Finally, the pipeline was connected, and the airtightness was rechecked.

- (3)

- Axial stress loading. The axial stress loading module provides axial stress through water pressure. A constant-speed and -pressure pump and related valves were opened to absorb and pressurize pure water, and axial pressure can be increased through multiple repetitions of liquid suction and injection. The preparation of the CBB was carried out by using a graded loading and pressure retention method.

- (4)

- Seepage pressure gradient loading. An advection pump was used to pressurize the bottom inlet of the material loading container. The top outlet pressure of the material loading container was 0, so the pressure gradient of the material was the inlet pressure. The inlet pressure was gradually increased, and after the water stabilized in the CBB, the permeability test switch was opened. The system automatically recorded the pressure gradient and seepage data, and the permeability of the CBB was calculated.

- (5)

- Test termination. The test equipment was cleaned, and the test data were saved.

3. Results and Discussion

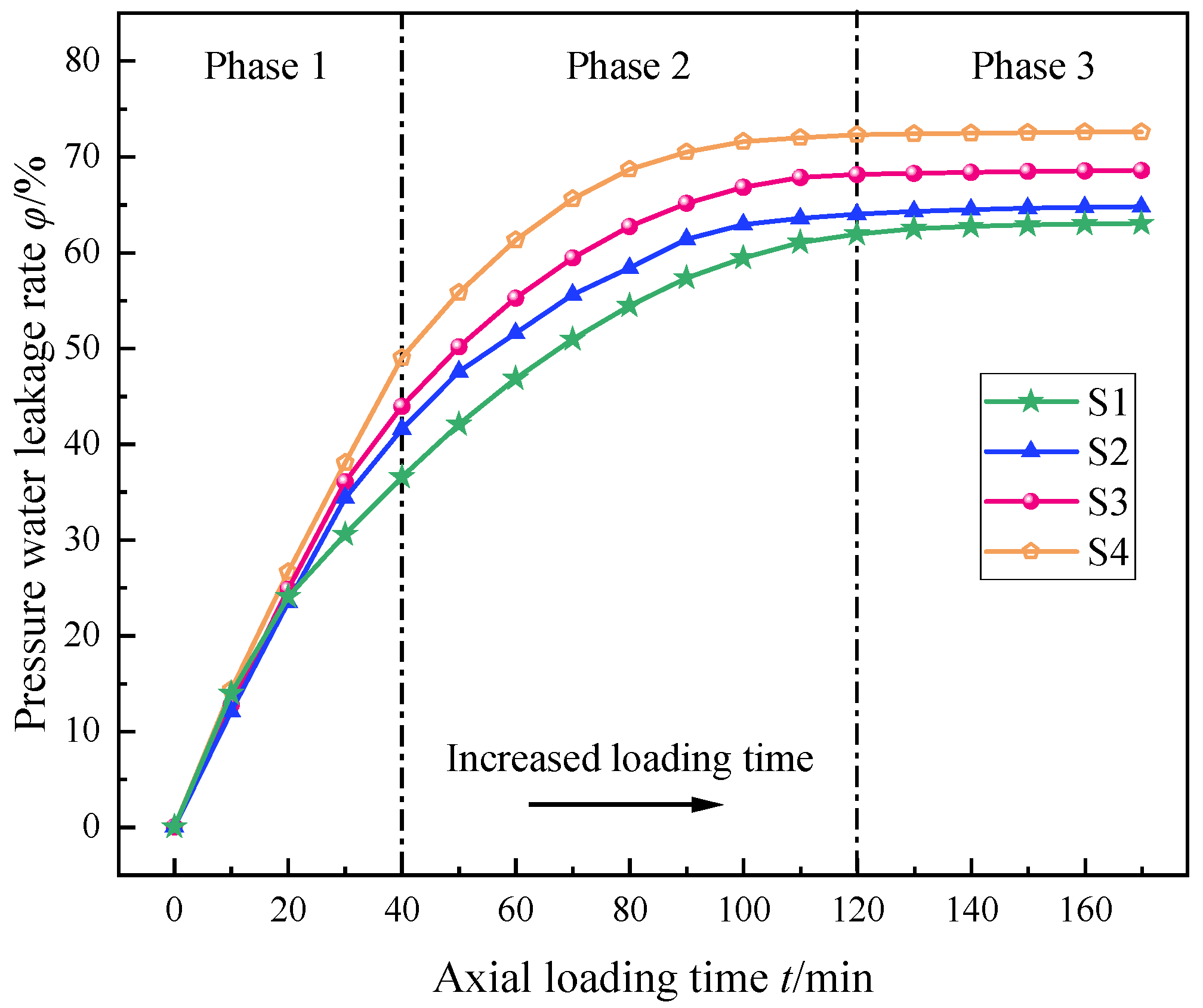

3.1. Staged Pressure Bleeding Characteristics of Gangue Slurry

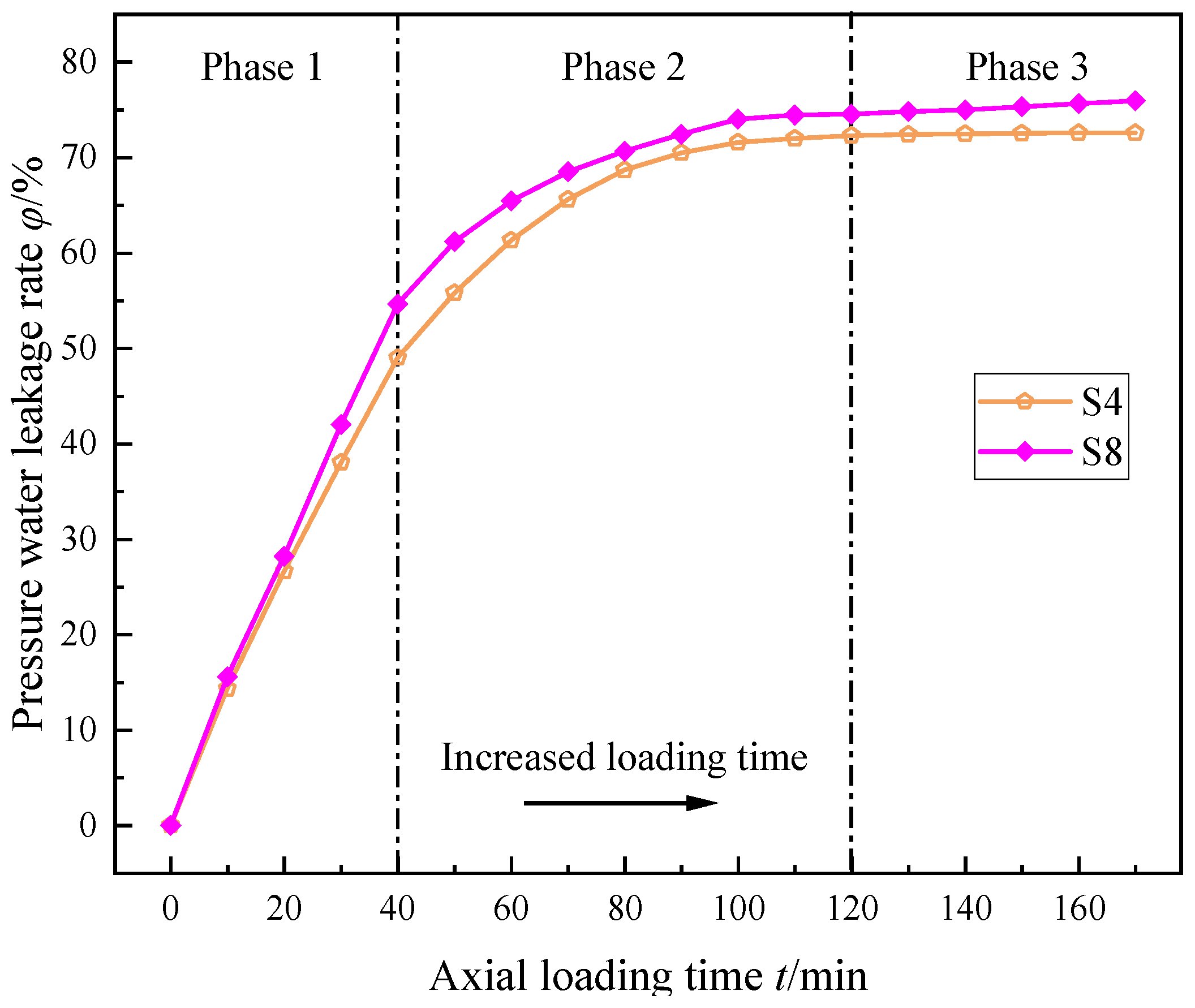

- (1)

- Phase 1. The pressure bleeding rate shows a linear increasing trend with loading time. At this stage, the gangue slurry is in a supersaturated state, with large particle spacing and more free water in the slurry. Under pressure, free water flows out uniformly from the seepage channel. However, when the gangue particles are in contact with each other, the first stage of gangue slurry pressure seepage ends immediately, so the time is shorter than the second stage. By comparing the slope of the first stage of the S1–S4 curve, it can be found that the pressure bleeding rate of the gangue slurry increases almost uniformly at the beginning of compression and rarely changes with the axial pressure. However, as shown in Figure 5, the greater the axial pressure on the slurry of the same proportion, the shorter the duration of the first stage and the earlier the transition to the second stage. Figure 6 shows the variation curves of the pressure bleeding rate of gangue slurry in the S4 and S8 groups. Under the same axial pressure, the linear growth rate of gangue slurry with particle sizes ranging from 0 to 5 mm in the first stage is significantly higher than that of the gangue slurry with particle sizes ranging from 0 to 2 mm. This is because there are more small-sized gangues in the gangue slurry with particle sizes ranging from 0 to 2 mm, and some of them follow the bleeding of the free water, thereby affecting the water bleeding rate.

- (2)

- Phase 2. At this stage, the pressure bleeding rate gradually slows down with the increase in loading time. Under axial stress loading, the distance between gangue particles gradually decreases. Through the processes of sliding, rotation, and fragmentation, gangue particles gradually assume a bearing role. The compression effect exerted on the gangue particles and the container’s side walls can lead to an increased number of smaller-sized gangue. Since the small-sized gangue has a larger specific surface and can adsorb more bound water, the pressure bleeding rate gradually decreases. The second stage is the main stage of gangue slurry bleeding and has the longest duration.

- (3)

- Phase 3. The pressure bleeding rate gradually stabilizes, and all free water in the gangue slurry has already been secreted. The maximum value of the pressure bleeding rate φmax can be used to describe the bleeding characteristics of the gangue slurry and the moisture dosage of the CBB. At the beginning of the third stage, there is already less free water in the gangue slurry. Under pressure, it can soon be secreted, so the duration of the third stage is significantly shorter than the second stage. The variation curve of φmax with respect to the axial pressure of the gangue slurry in S1–S8 groups can be drawn. As shown in Figure 7, as the axial pressure increases, the φmax of the gangue slurry with the same ratio gradually increases. When the axial pressure increases from 2 MPa to 8 MPa, the φmax of the gangue slurry increases by 15.16% to 16.63%. The φmax of the gangue slurry with particle sizes ranging from 0 to 2 mm is significantly greater than that with particle sizes ranging from 0 to 5 mm, which is also related to the water retention capacity of small-sized gangue particles. The static bleeding rate of the gangue slurry is about 15%, and after being subjected to continuous pressure, the bleeding rate can reach about 70%.

3.2. Permeability Variation Law of the CBB

3.2.1. The Influence of Axial Compression on the Permeability of the CBB

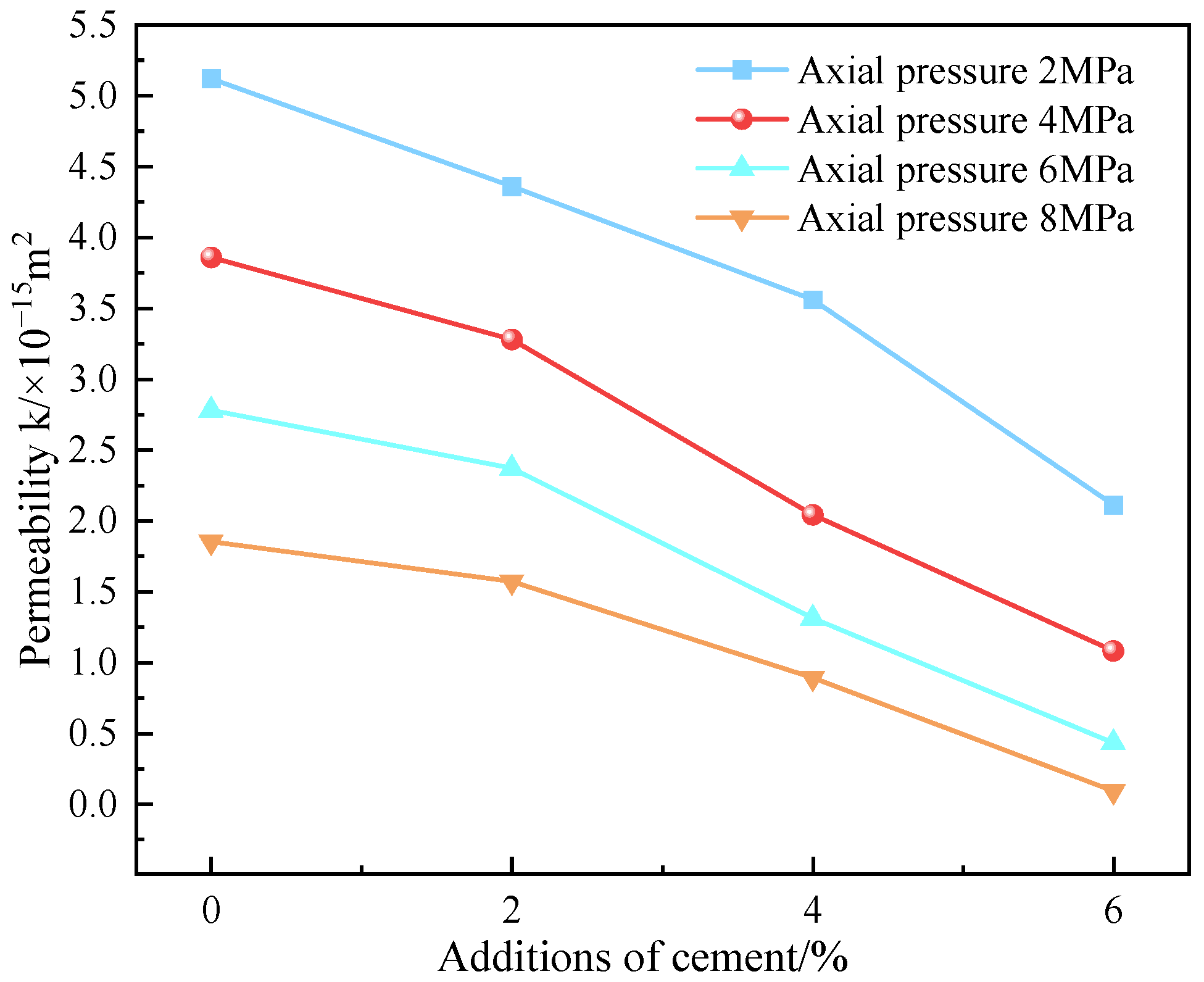

- (1)

- The permeability of the CBB shows an exponential decreasing trend with the increasing axial pressure, and the fitting degree of the fitting curve is good, with an R2 above 0.99. When 4% and 6% cement is added to the CBB with a 0–5 mm particle size, permeability decreases by one order of magnitude with an increase in axial pressure from 2 MPa to 8 MPa. This indicates that the sensitivity of the permeability of the CBB to axial pressure was improved after adding the cement to the gangue slurry.

- (2)

- When 0% and 2% cement dosage is added to gangue slurry with particle sizes ranging from 0 to 5 mm, the permeability of the CBB is almost linearly negatively correlated with axial pressure. When 4% and 6% cement dosage is added to gangue slurry with particle sizes ranging from 0 to 5 mm, the permeability of the CBB decreases with the increasing axial pressure. It indicates that as the cement dosage increases, the permeability of the CBB transitions from linear to nonlinear, and a cement dosage of 2% is the critical value. The permeability variation in the CBB with a particle size range of 0–2 mm also exhibits nonlinear characteristics, indicating that the reduction in particle size has the same effect as the addition of cement. As the curve illustrates in Figure 8, when the axial pressure is the same, the permeability of the CBB with a particle size range of 0–2 mm is equivalent to adding 2–4% cement in the CBB with a particle size range of 0–5 mm.

3.2.2. The Influence of Particle Size Range on the Permeability of the CBB

- (1)

- The permeability of the CBB with the particle sizes ranging from 0 to 5 mm generally shows a linear decreasing trend. When the axial pressure increases from 2 MPa to 8 MPa, the permeability decreases from 5.12 × 10−15 m2 to 1.85 × 10−15 m2, with a decrease of 63.9%. The permeability of the CBB with a particle size ranging from 0 to 2 mm decreases nonlinearly with the increase in axial pressure, and the decreasing rate gradually diminishes.

- (2)

- When the same axial pressure is applied, the permeability of the CBB with a particle size range of 0–5 mm is greater than that of 0–2 mm. This is because there are more coarse gangue particles in the CBB with a particle size range of 0–5 mm, leading to higher porosity. In addition, as the axial pressure increases, the difference in permeability between the two CBBs first increases and then decreases. This is because as the axial pressure increases, the coarse-grained gangue in the CBB with a particle size range of 0–5 mm is compressed and crushed into small particle size gangue by extrusion and friction and fills the void. Consequently, the voidage of the CBB with a particle size range of 0–5 mm decreases, resulting in a greater drop in permeability.

3.2.3. The Influence of Cement Dosage on the Permeability of the CBB

3.3. Determination Method for Permeability Level of the CBB

4. Conclusions

- (1)

- The developed multi-field coupled seepage test system for backfill materials mainly consists of five parts: material loading module, axial stress loading module, liquid seepage module, seepage outlet measurement module, and data acquisition and processing module. With a maximum axial pressure of 30 MPa and a maximum seepage pressure of 15 MPa, this system can monitor and collect key parameters, such as stress, displacement seepage flow rate, and water pressure, in real time during the experiment.

- (2)

- After being injected into the mining space, the gangue slurry is subjected to pressure and local stress from the overburden, resulting in a pressure bleeding phenomenon. After the free water is completely drained, the CBB is formed. A laboratory preparation method for the CBB is proposed, and the waterproof performance of the gangue grouting backfill materials is evaluated by testing the permeability of the CBB.

- (3)

- The pressure bleeding of the gangue slurry exhibits obvious phased characteristics. In the first stage, it shows a linear growth trend with axial loading time. In the second stage, the increasing amplitude of pressure bleeding gradually weakens. In the third stage, pressure bleeding gradually stabilizes and finally stops. Moreover, the second stage has a significantly longer duration compared to the first and third stages.

- (4)

- The permeability of the CBB decreases exponentially with the increasing axial pressure. After adding cement to the gangue slurry, the permeability of the CBB exhibits a higher sensitivity to axial stress. As the cement dosage increases, the permeability change in the CBB transfers from linear to nonlinear, and the cement dosage of 2% is the turning point of the linear to nonlinear transition. With the same axial stress, the permeability of the CBB with a particle size range of 0–5 mm is greater than that of 0–2 mm. This is because there is a higher porosity in the CBB with a particle size range of 0–5 mm. As the cement dosage increases, the permeability of the CBB with a particle size range of 0–5 mm gradually decreases, and the addition of cement reduces the permeability of the CBB by 1–2 orders of magnitude.

- (5)

- The permeability level of the CBB of gangue slurry is within the range of poor permeability and extremely poor permeability. After entering the mining space, the gangue slurry has a good water-blocking effect. Increasing the axial stress on the gangue slurry and adding cement can both improve the permeability level of the CBB and improve its waterproof performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, N.; Zhang, J.X.; Ouyang, S.Y.; Deng, X.J.; Dong, C.W.; Du, E.B. Feasibility Study and Performance Optimization of Sand-Based Cemented Paste Backfill Materials. J. Clean. Prod. 2020, 259, 120798. [Google Scholar] [CrossRef]

- Zhu, D.F.; Yu, B.B.; Wang, D.Y.; Zhang, Y.J. Fusion of finite element and machine learning methods to predict rock shear strength parameters. J. Geophys. Eng. 2024, gxae064. [Google Scholar] [CrossRef]

- Upadhyay, A.; Laing, T.; Kumar, V.; Dora, M. Exploring Barriers and Drivers to the Implementation of Circular Economy Practices in the Mining Industry. Resour. Policy 2021, 72, 102037. [Google Scholar] [CrossRef]

- Xie, S.R.; Pan, H.; Gu, W.Z.; Zhu, L.; Yue, D.; Chen, D.D.; Song, T.Q.; Jiang, Z.S. Technology and Engineering Test of Filling Goaf with Coal Gangue Slurry. Sci. Rep. 2023, 13, 20536. [Google Scholar] [CrossRef] [PubMed]

- Zong, T.C.; Zhu, G.L.; Zhang, Q.; Yang, K.; Wang, Y.B.; Han, Y.; Lv, H.N.; Cao, J.M. Solid Backfilling Efficiency Optimization in Coal Mining: Spatiotemporal Linkage Analysis and Case Study. Appl. Sci. 2023, 13, 12298. [Google Scholar] [CrossRef]

- Zhang, D.S.; Fan, G.W.; Liu, Y.D.; Ma, L.Q. Field Trials of Aquifer Protection in Longwall Mining of Shallow Coal Seams in China. Int. J. Rock Mech. Min. Sci. 2010, 47, 908–914. [Google Scholar] [CrossRef]

- Zhu, L.; Song, T.Q.; Gu, W.Z.; Xu, K.; Liu, Z.C.; Qiu, F.Q.; Zhang, X.F. Study on Layered-Backfill-Based Water Protection Technology of Thick Coal Seam in the Ecologically Fragile Mining Area in Western China. Geofluids 2022, 2022, 3505176. [Google Scholar] [CrossRef]

- Li, L.N.; Li, W.P.; Wang, Q.Q. Prediction and Zoning of the Impact of Underground Coal Mining on Groundwater Resources. Process Saf. Environ. Prot. 2022, 168, 454–462. [Google Scholar] [CrossRef]

- Zhu, L.; Gu, W.Z.; Ouyang, Y.B.; Qiu, F.Q. Grouting Mechanism and Experimental Study of Goaf Considering Filtration Effect. PLoS ONE 2023, 18, e0282190. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.Q.; Zhou, N.; Li, M.; Wang, Y.B. Analysis of Characteristics of Diffusion Tortuosity of Fine-Grained Gangue Slurry in Coal Mine Caving Zone. Environ. Sci. Pollut. Res. 2023, 30, 108201–108211. [Google Scholar] [CrossRef]

- Feng, C.Y.; Yang, X.D.; Afshan, S.; Irfan, M. Can Renewable Energy Technology Innovation Promote Mineral Resources’ Green Utilization Efficiency? Novel Insights from Regional Development Inequality. Resour. Policy 2023, 82, 103449. [Google Scholar] [CrossRef]

- Li, M.; Zhang, J.X.; Li, A.L.; Zhou, N. Reutilisation of Coal Gangue and Fly Ash as Underground Backfill Materials for Surface Subsidence Control. J. Clean. Prod. 2020, 254, 120113. [Google Scholar] [CrossRef]

- Wang, X.Z.; Xie, J.L.; Xu, J.L.; Zhu, W.B.; Wang, L.M. Effects of Coal Mining Height and Width on Overburden Subsidence in Longwall Pier-Column Backfilling. Appl. Sci. 2021, 11, 3105. [Google Scholar] [CrossRef]

- Du, X.J.; Feng, G.R.; Zhang, M.; Wang, Z.H.; Liu, W.H. Influence of Backfilling Rate on the Stability of the “Backfilling Body-Immediate Roof” Cooperative Bearing Structure. Int. J. Min. Sci. Technol. 2022, 32, 1197–1206. [Google Scholar] [CrossRef]

- Wang, Y.M.; Huang, Y.C.; Hao, Y.X. Experimental Study and Application of Rheological Properties of Coal Gangue-Fly Ash Backfill Slurry. Processes 2020, 8, 284. [Google Scholar] [CrossRef]

- Song, W.J.; Zhang, J.X.; Li, M.; Yan, H.; Zhou, N.; Yao, Y.N.; Guo, Y.B. Underground Disposal of Coal Gangue Backfill in China. Appl. Sci. 2022, 12, 12060. [Google Scholar] [CrossRef]

- Li, W.; Yue, L.; Liu, Y.; Li, S.C.; Ma, L.Q.; Wang, J.T. Study on Mechanical Properties of Coal Gangue and Fly Ash Mixture as Backfill Material Based on Fractal Characteristics. Environ. Sci. Pollut. Res. 2023, 30, 111936–111946. [Google Scholar] [CrossRef] [PubMed]

- Janjuhah, H.T.; Alansari, A.; Gámez Vintaned, J.A. Quantification of Microporosity and Its Effect on Permeability and Acoustic Velocity in Miocene Carbonates, Central Luconia, Offshore Sarawak, Malaysia. J. Pet. Sci. Eng. 2019, 175, 108–119. [Google Scholar] [CrossRef]

- Chen, Y.L.; Yu, B.Y.; Zhang, K.; Zhang, M.W.; Xu, G.; Chen, Z.Q. Permeability Evolution and Particle Size Distribution of Saturated Crushed Sandstone under Compression. Geofluids 2018, 2018, 6043420. [Google Scholar] [CrossRef]

- Qiu, H.F.; Zhang, F.S.; Sun, W.B.; Liu, L.; Zhao, Y.J.; Huan, C. Experimental Study on Strength and Permeability Characteristics of Cemented Rock-Tailings Backfill. Front. Earth Sci. 2022, 10, 802818. [Google Scholar] [CrossRef]

- He, W.; Liu, L.; Fang, Z.Y.; Gao, Y.H.; Sun, W.J. Effect of Polypropylene Fiber on Properties of Modified Magnesium-Coal-Based Solid Waste Backfill Materials. Constr. Build. Mater. 2023, 362, 129695. [Google Scholar] [CrossRef]

- Zhou, N.; Xu, J.F.; Zhang, J.X.; Yan, H.; Zhu, C.L.; Li, M. An Experimental Study of the Permeability of Sand-Based Cemented Backfill under the Influence of Multi-Factor Interaction. Environ. Earth Sci. 2022, 81, 320. [Google Scholar] [CrossRef]

- Liu, Y.; Deng, H.W. Study on Permeability Performance of Cemented Tailings Backfill Based on Fractal Characteristics of Pore Structure. Constr. Build. Mater. 2023, 365, 130035. [Google Scholar] [CrossRef]

- Zhu, C.L.; Zhang, J.X.; Zhou, N.; Li, M.; Guo, Y.B. Permeability of Sand-Based Cemented Backfill under Different Stress Conditions: Effects of Confining and Axial Pressures. Geofluids 2021, 2021, 6657662. [Google Scholar] [CrossRef]

- GB/T 8077-2012; Methods for Testing Uniformity of Concrete Admixture. Available online: https://www.chinesestandard.net/PDF/English.aspx/GBT8077-2012 (accessed on 9 July 2024).

- Wang, X.; Zhang, J.X.; Li, M.; Huo, B.B.; Jin, L. Experimental Study on Performance Optimization of Grouting Backfill Material Based on Mechanically Ground Coal Gangue Utilizing Urea and Quicklime. Materials 2023, 16, 1097. [Google Scholar] [CrossRef] [PubMed]

- Kang, H.P.; Gao, F.Q.; Xu, G.; Ren, H.W. Mechanical Behaviors of Coal Measures and Ground Control Technologies for China’s Deep Coal Mines—A Review. J. Rock Mech. Geotech. 2023, 15, 37–65. [Google Scholar] [CrossRef]

- Xie, J.; Gao, M.Z.; Zhang, R.; Li, S.W.; Tan, Q.; Qiu, Z.Q. Lessons Learnt from Measurements of Vertical Pressure at a Top Coal Mining Face at Datong Tashan Mines, China. Rock Mech. Rock Eng. 2016, 49, 2977–2983. [Google Scholar] [CrossRef]

- Liu, S.X.; Xu, J.F.; Zhou, N.; Zhang, Y.Z.; Dong, C.W.; Lv, Z. Study on the Self–Bearing Mechanism and Mechanical Properties of Gangue Slurry under Overburden Loading. Appl. Sci. 2024, 14, 1628. [Google Scholar] [CrossRef]

- Ma, D.; Duan, H.Y.; Zhang, J.X. Solid Grain Migration on Hydraulic Properties of Fault Rocks in Underground Mining Tunnel: Radial Seepage Experiments and Verification of Permeability Prediction. Tunn. Undergr. Space Technol. 2022, 126, 104525. [Google Scholar] [CrossRef]

- Hou, W.T.; Ma, D.; Li, Q.; Zhang, J.X.; Liu, Y.; Zhou, C.Y. Mechanical and Hydraulic Properties of Fault Rocks under Multi-Stage Cyclic Loading and Unloading. Int. J. Coal Sci. Technol. 2023, 10, 54. [Google Scholar] [CrossRef]

- Liu, K.D.; Hou, C.; Jiang, Z.B.; Cheng, B.; Yuan, K.K.; Liu, C.; Li, X.L. Gas extraction technology with L-shaped ground well drilling in mining area. J. Min. Saf. Eng. 2018, 35, 1284–1292+1300. (In Chinese) [Google Scholar]

- Huang, Z.; Jiang, Z.Q.; Sun, X.Q.; Cao, D.T.; Wang, Z.S.; Xin, B. Experimental examination of permeability of deep rock mass under high water pressure. J. Min. Saf. Eng. 2015, 32, 651–657. (In Chinese) [Google Scholar]

- Wu, J.Y.; Wong, H.S.; Yin, Q.; Ma, D. Effects of Aggregate Strength and Mass Fraction on Mesoscopic Fracture Characteristics of Cemented Rockfill from Gangue as Recycled Aggregate. Compos. Struct. 2023, 311, 116851. [Google Scholar] [CrossRef]

- Hou, W.T.; Ma, D.; Liu, X.W.; Zhang, J.X. Experimental Study on Hydraulic and Mechanical Properties of Fault Rock under the Thermal-Hydraulic-Mechanical Coupling. Geothermics 2024, 119, 102975. [Google Scholar] [CrossRef]

| Test Number | Particle Size Range/mm | Cement Dosage/% | Axial Stress/MPa | Pressure Gradient/MPa |

|---|---|---|---|---|

| S1 | 0–2 | 0 | 2 | 1, 2, 3, 4 |

| S2 | 4 | 1, 2, 3, 4 | ||

| S3 | 6 | 1, 2, 3, 4 | ||

| S4 | 8 | 1, 2, 3, 4 | ||

| S5 | 0–5 | 0 | 2 | 1, 2, 3, 4 |

| S6 | 4 | 1, 2, 3, 4 | ||

| S7 | 6 | 1, 2, 3, 4 | ||

| S8 | 8 | 1, 2, 3, 4 | ||

| S9 | 0–5 | 2 | 2 | 1, 2, 3, 4 |

| S10 | 4 | 1, 2, 3, 4 | ||

| S11 | 6 | 1, 2, 3, 4 | ||

| S12 | 8 | 1, 2, 3, 4 | ||

| S13 | 0–5 | 4 | 2 | 1, 2, 3, 4 |

| S14 | 4 | 1, 2, 3, 4 | ||

| S15 | 6 | 1, 2, 3, 4 | ||

| S16 | 8 | 1, 2, 3, 4 | ||

| S17 | 0–5 | 6 | 2 | 1, 2, 3, 4 |

| S18 | 4 | 1, 2, 3, 4 | ||

| S19 | 6 | 1, 2, 3, 4 | ||

| S20 | 8 | 1, 2, 3, 4 |

| Permeability Level | Permeability Coefficient K (cm/s) | Conversion Permeability k (10−15 m2) |

|---|---|---|

| Extremely poor permeability | K < 10−6 | k < 3.04 |

| Poor permeability | 10−6 ≤ K < 10−5 | 3.04 ≤ k < 30.4 |

| Weak permeability | 10−5 ≤ K <10−4 | 30.4 ≤ k < 304 |

| Medium permeability | 10−4 ≤ K <10−2 | 304 ≤ k < 3040 |

| Strong permeability | 10−2 ≤ K < 1 | 3040 ≤ k < 30,400 |

| Extremely strong permeability | K > 1 | k > 30,400 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Liu, S.; Wang, H.; Zhou, N.; Zhang, Y. Experimental Study on Permeability Characteristics of Compacted Backfill Body after Gangue Grouting and Backfilling in the Mining Space. Appl. Sci. 2024, 14, 6045. https://doi.org/10.3390/app14146045

Xu J, Liu S, Wang H, Zhou N, Zhang Y. Experimental Study on Permeability Characteristics of Compacted Backfill Body after Gangue Grouting and Backfilling in the Mining Space. Applied Sciences. 2024; 14(14):6045. https://doi.org/10.3390/app14146045

Chicago/Turabian StyleXu, Jianfei, Sixu Liu, Haodong Wang, Nan Zhou, and Yuzhe Zhang. 2024. "Experimental Study on Permeability Characteristics of Compacted Backfill Body after Gangue Grouting and Backfilling in the Mining Space" Applied Sciences 14, no. 14: 6045. https://doi.org/10.3390/app14146045

APA StyleXu, J., Liu, S., Wang, H., Zhou, N., & Zhang, Y. (2024). Experimental Study on Permeability Characteristics of Compacted Backfill Body after Gangue Grouting and Backfilling in the Mining Space. Applied Sciences, 14(14), 6045. https://doi.org/10.3390/app14146045