Effect of Aging Treatment on the Microstructure and Mechanical Properties of Ti-3Al-8V-6Cr-4Mo-4Zr Alloy

Abstract

:1. Introduction

2. Experimental Section

3. Results and Discussion

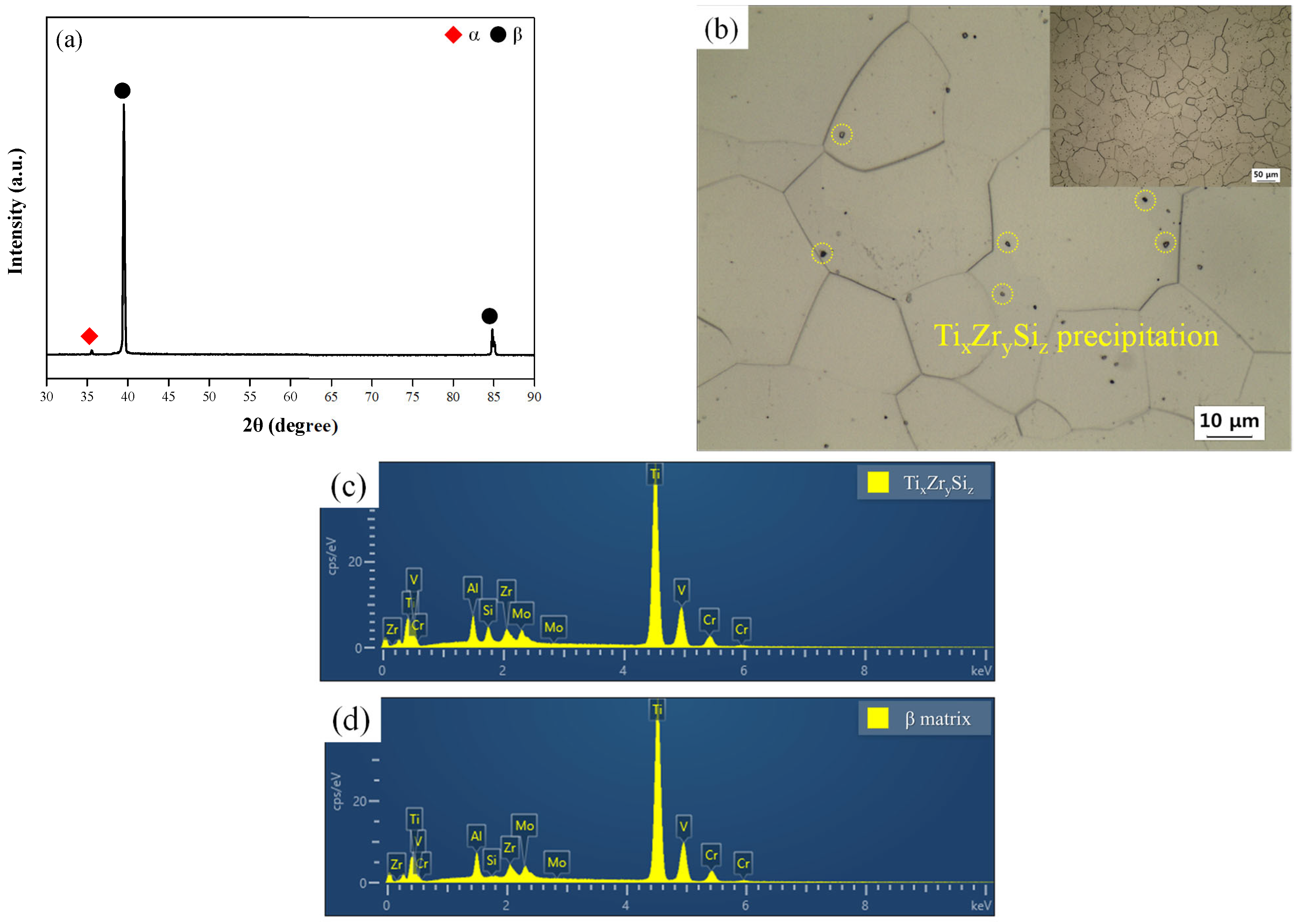

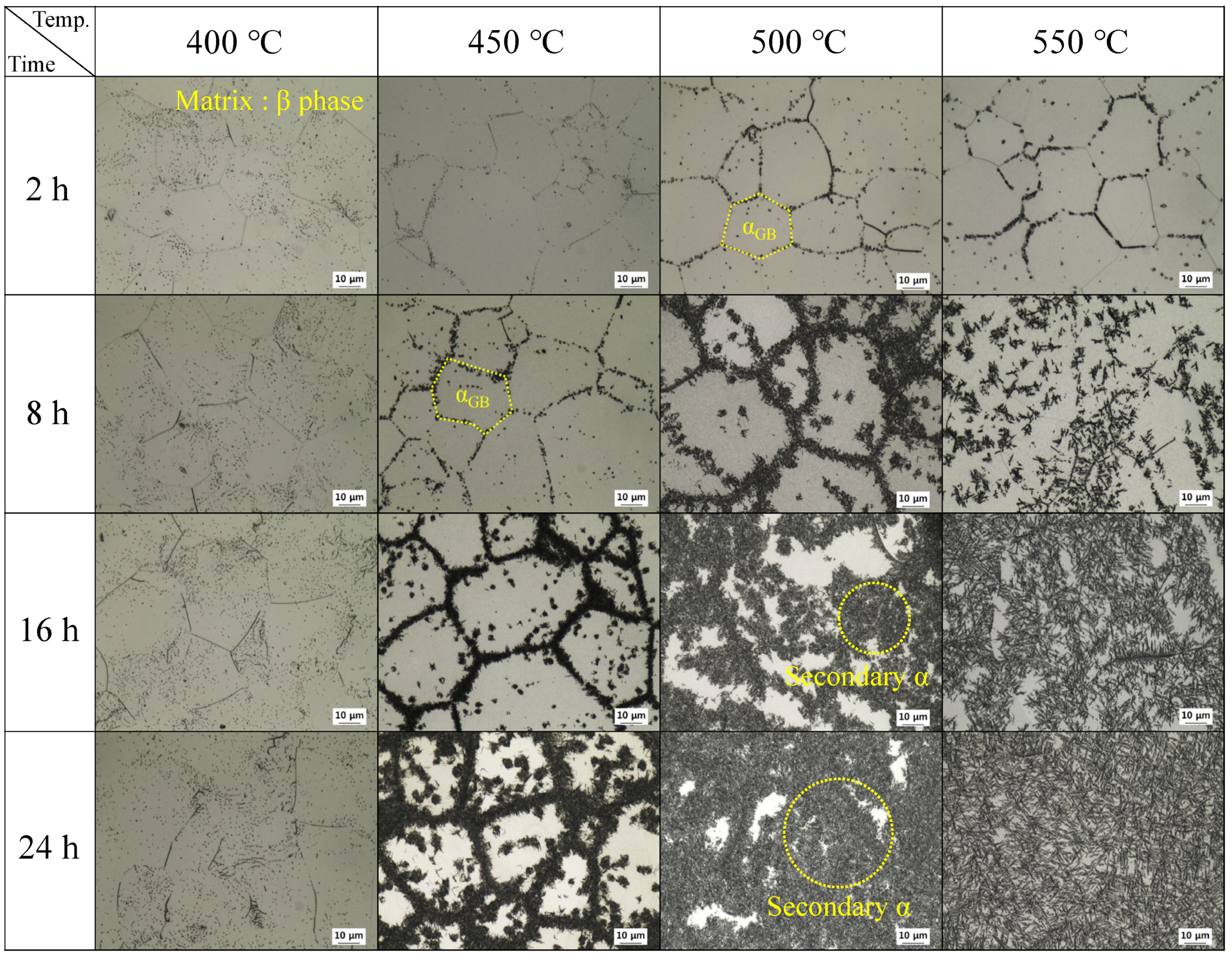

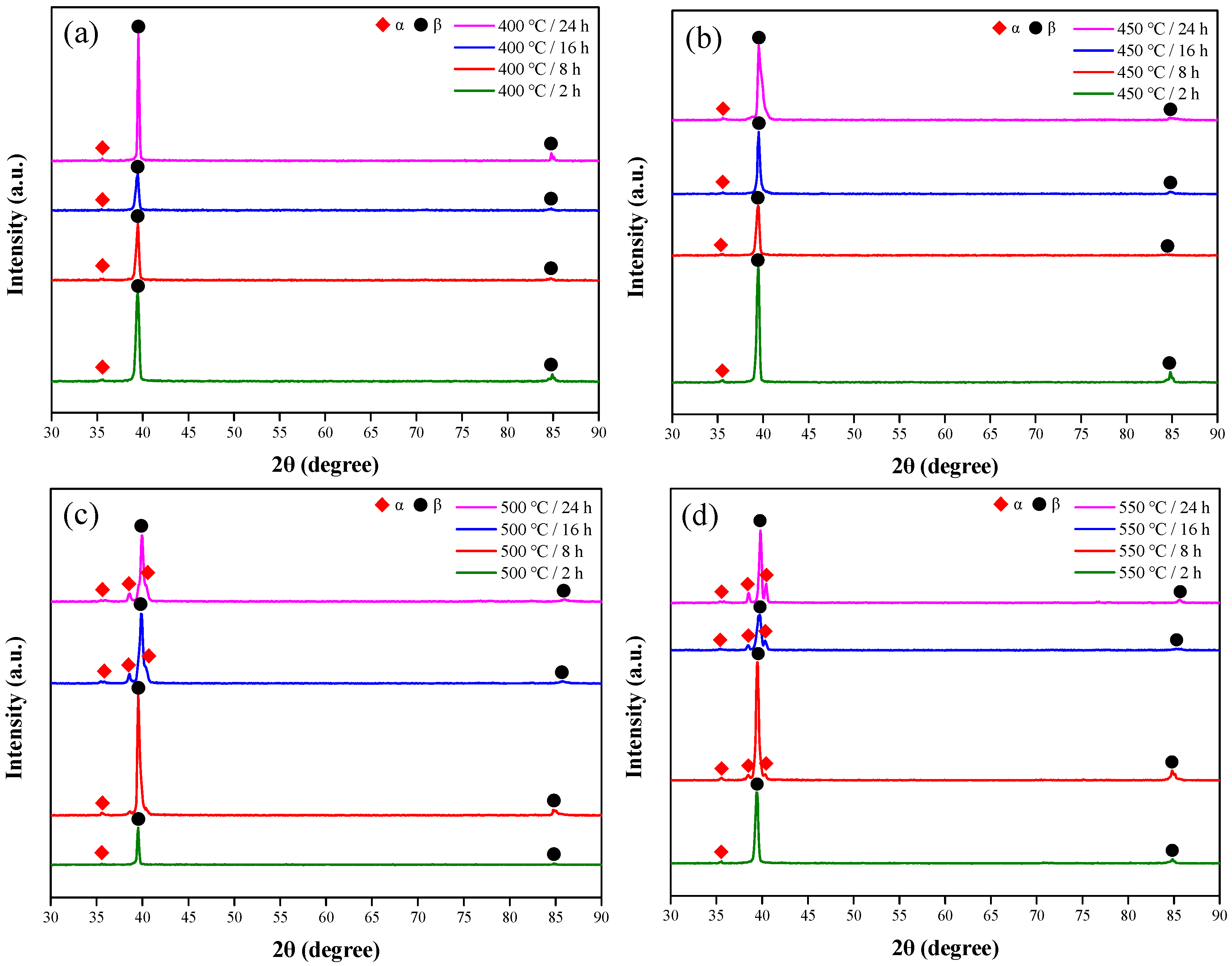

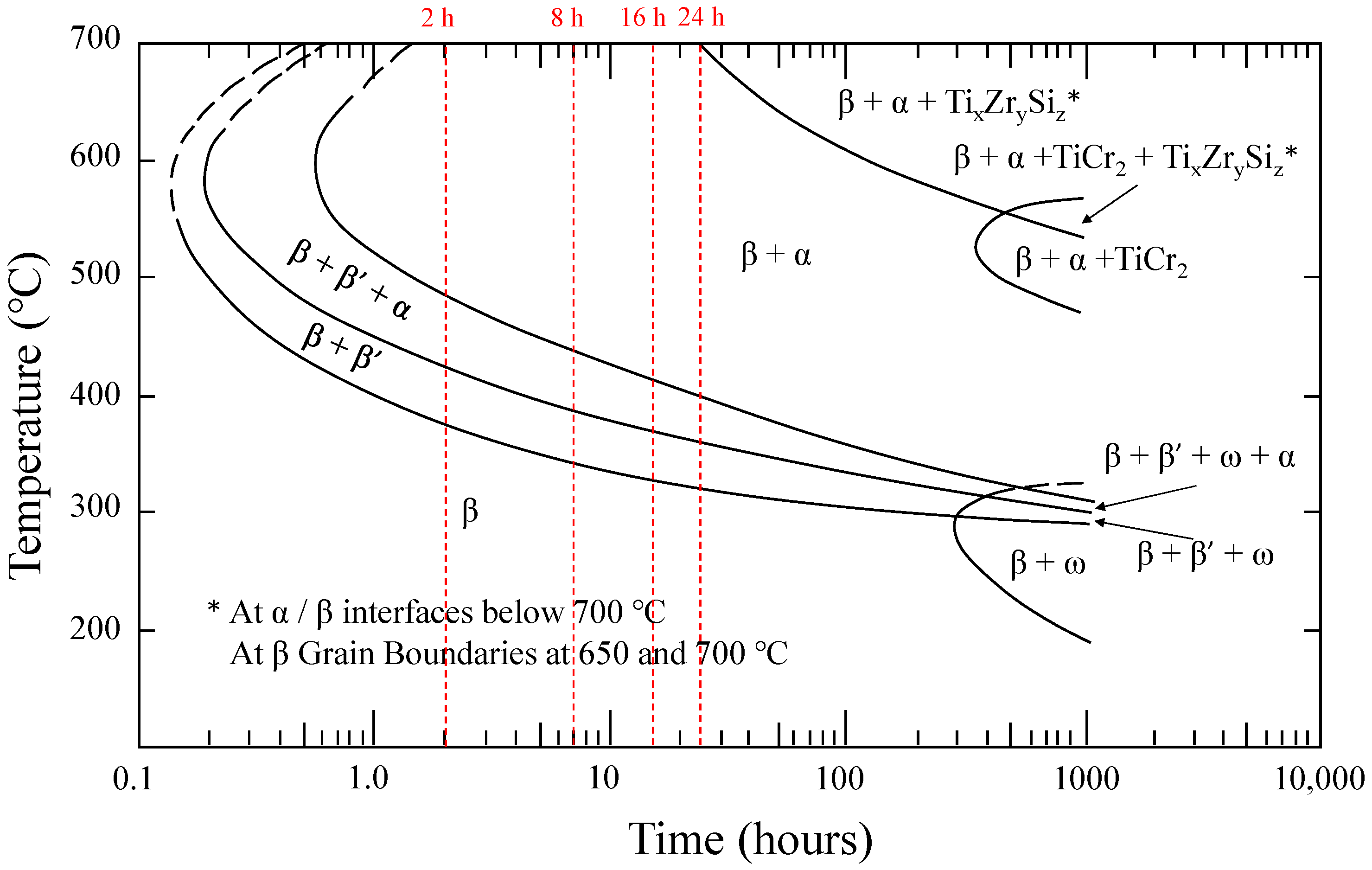

3.1. Microstructure Changes for Different Aging Conditions

3.2. Evaluation of Mechanical Properties Changes

4. Conclusions

- (1)

- The metastable β-titanium Ti-3Al-8V-6Cr-4Mo-4Zr alloy was subjected to stress-relief heat treatment at 950 °C for 25 s, and a fine TixZrySiz phase was precipitated in the β-base owing to the rapid cooling rate. Subsequent aging treatments at 400 °C to 550 °C for 2 h, 8 h, 16 h, and 24 h resulted in the generation of a secondary α phase, preferentially on the β grain boundary, in all specimens except that treated at 400 °C, where the driving force for precipitation was low. The secondary α phase precipitated inside the β matrix as the aging time increased.

- (2)

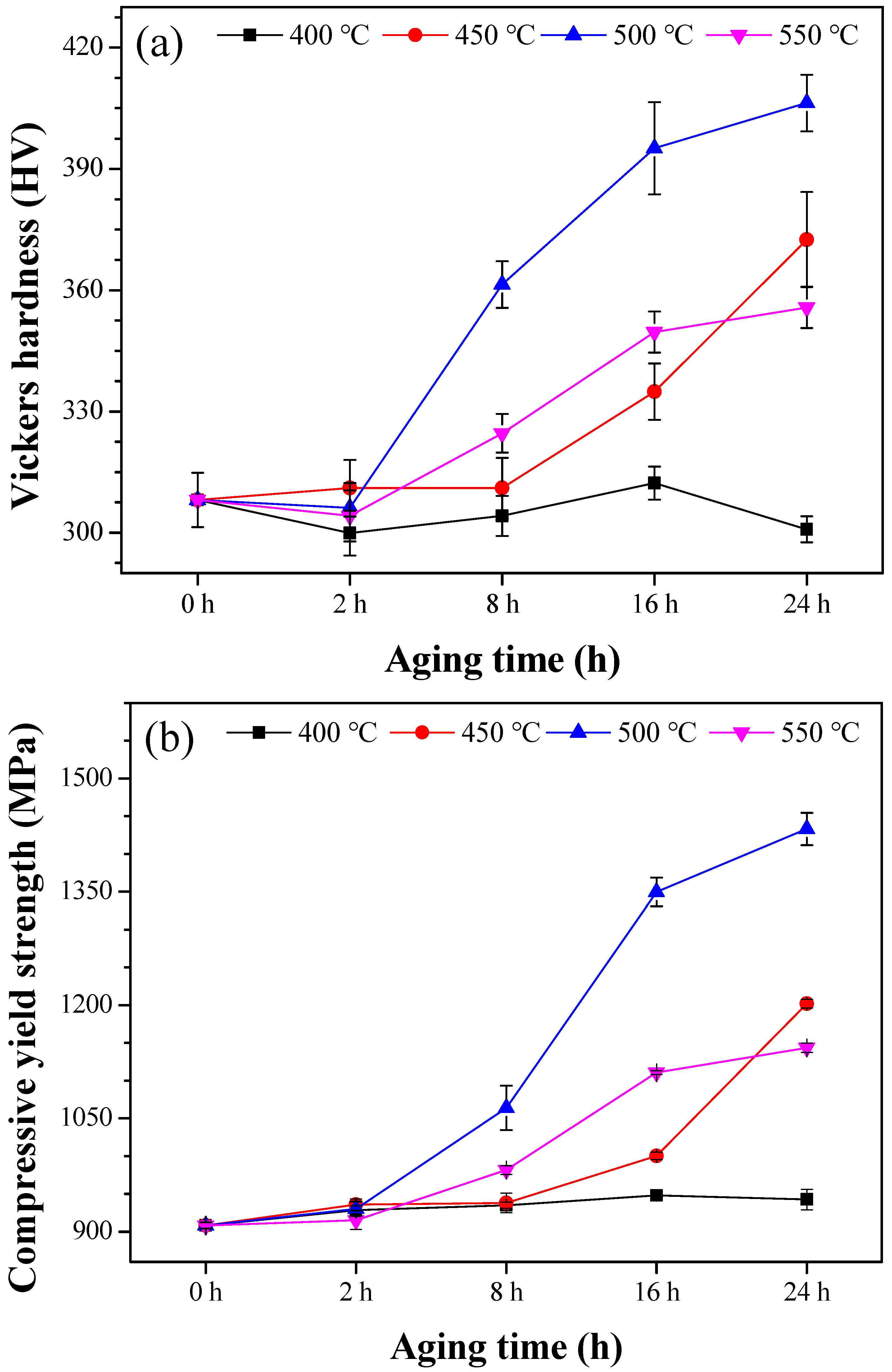

- At aging temperatures below 500 °C, the aging time significantly contributed to the amount of secondary α phase precipitated, which increased with increasing aging time. This improved the hardness and compressive yield strength. At 550 °C, the β′ phase, which acted as a nucleation site for the secondary α phase, rapidly underwent phase separation from β → β + β′, which accelerated the phase transformation to the secondary α phase, resulting in the coarsening of the secondary α phase. The softening phenomenon reduced the hardness and compressive yield strength and increased the compressive elongation.

- (3)

- The best mechanical properties (406.3 HV and 1433.2 MPa) were obtained at 500 °C/24 h because of the increase in the α/β interfacial area as a large amount of fine secondary α phase was generated. This condition was confirmed to be the optimal process condition.

- (4)

- The correlation between the distribution of precipitation phases and mechanical properties during the aging treatment of the Ti-3Al-8V-6Cr-4Mo-4Zr alloy was confirmed, and optimal aging process conditions were derived to secure the mechanical properties required for springs and aircraft structural materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Han, B.S.; Kim, S.H.; Shin, J.H.; Kim, J.P.; Kim, D.O.; Seong, S.Y. Automotive Technology Trends and Lightweighting Technologies. J. Korea Foundry Society 2022, 42, 97–104. [Google Scholar]

- Kim, Y.W.; Jo, Y.H.; Lee, Y.S.; Kim, H.W.; Lee, J.I. Effect of Dissolution of η′ Precipitates on Mechanical Properties of A7075-T6 Alloy. Korean J. Met. Mater. 2022, 60, 83–93. [Google Scholar] [CrossRef]

- Takahashi, K.; Mori, K.; Takebe, H. Application of titanium and its alloys for automobile parts, MATEC web of conferences. EDP Sci. 2020, 321, 02003. [Google Scholar]

- Yoon, B.H.; Kim, S.H.; Chang, W.S. Recent Trends of Welding Technology for Ti and Ti Alloys. J. Weld. Join. 2007, 25, 22–28. [Google Scholar]

- Lei, X.; Dong, L.; Zhang, Z.; Liu, Y.; Hao, Y.; Yang, R.; Zhang, L.C. Microstructure, Texture Evolution and Mechanical Properties of VT3-1 Titanium Alloy Processed by Multi-Pass Drawing and Subsequent Isothermal Annealing. Metals 2017, 7, 131. [Google Scholar] [CrossRef]

- Hwang, H.W.; Park, J.H.; Lee, D.G. Effect of Molybdenum Content on Microstructure and Mechanical Properties of Ti-Mo-Fe Alloys by Powder Metallurgy. Appl. Sci. 2022, 12, 7257. [Google Scholar] [CrossRef]

- Li, C.L.; Mi, X.J.; Ye, W.J.; Hui, S.X.; Lee, D.G.; Lee, Y.T. Influence of heat treatment on microstructure and tensile property of a new high strength beta alloy Ti–2Al–9.2Mo–2Fe. Mater. Sci. Eng. A 2013, 581, 250–256. [Google Scholar] [CrossRef]

- Wang, K.; Wu, D.; Wang, D.; Deng, Z.; Tian, Y.; Zhang, L.; Liu, L. Influence of cooling rate on ω phase precipitation and deformation mechanism of a novel metastable β titanium alloy. Mater. Sci. Eng. A 2022, 829, 142151. [Google Scholar] [CrossRef]

- Li, L.; Xu, Q.; Yang, H.; Ying, Y.; Cao, Z.; Guo, D.; Ji, V. Design and Rate Control of Large Titanium Alloy Springs for Aerospace Applications. Aerospace 2024, 11, 514. [Google Scholar] [CrossRef]

- Nakamura, Y.; Nambum, K.; Akahori, T.; Shimizu, T.; Kikuchi, S. Effect of Fine Particle Peening Using Hydroxyapatite Particles on Rotating Bending Fatigue Properties of β-Type Titanium Alloy. Appl. Sci. 2021, 11, 4307. [Google Scholar] [CrossRef]

- An, J.J.; Lee, D.G.; Lim, K.R.; Kim, T.Y.; Lee, Y.T.; Yoon, S.Y. Effect of Boron on Mechanical Properties of Ti-12.1Mo-1Fe-xB System. Korean J. Met. Mater. 2015, 53, 380–388. [Google Scholar]

- Kwon, H.J.; Lim, K.R.; Lee, Y.T.; Lee, D.G.; Lee, J.H.; Kim, S.E. Effect of Aging Time and Temperature on Microstructure and Mechanical Properties of Ti-39Nb-6Zr Alloy. Korean J. Met. Mater. 2016, 54, 925–930. [Google Scholar]

- Boyer, R.R.; Rosenberg, H.W. (Eds.) Beta Titanium Alloys in the 80’s; The Metallurgical Society of AIME: Warrendale, PA, USA, 1984; pp. 295–305. [Google Scholar]

- Jung, Y.C.; Kim, C.J.; Sohn, S.M. Effects of Solution Treatment Temperature and Microstructures on the Mechanical Properties and Fatigue Limit of Ti-3Al-8V-6Cr-4Mo-4Zr (β-C) Alloy. Korean J. Met. Mater. 1998, 36, 310–319. [Google Scholar]

- Lee, J.W.; Kim, C.J.; Sohn, S.M. Effect of α Phase Precipitation on Tensile Properties and Fatigue Limit in Ti-3Al-8V-6Cr-4Mo-4Zr (β-C) Alloy. Korean J. Met. Mater. 1997, 35, 807–815. [Google Scholar]

- Li, C.; Lee, D.G.; Mi, X.; Ye, W.; Hui, S.; Lee, Y.T. Phase transformation and age hardening behavior of new Ti–9.2Mo–2Fe alloy. J. Alloys Compd. 2013, 549, 152–157. [Google Scholar] [CrossRef]

- Kolli, R.P.; Devaraj, A. A Review of Metastable Beta Titanium Alloys. Metals. 2018, 8, 506. [Google Scholar] [CrossRef]

- Hendl, J.; Daubner, S.; Marquardt, A.; Stepien, L.; Lopez, E.; Brückner, F.; Leyens, C. In Situ CT Tensile Testing of an Additively Manufactured and Heat-Treated Metastable ß-Titanium Alloy (Ti-5Al-5Mo-5V-3Cr). Appl. Sci. 2021, 11, 9875. [Google Scholar] [CrossRef]

- Rhodes, C.G.; Paton, N.E. The Influence of Microstructure on Mechanical Properties in Ti-3AI-8V-6Cr-4Mo-4Zr (Beta-C). Metall. Trans. A 1977, 8, 1749–1761. [Google Scholar] [CrossRef]

- Salvador, C.A.F.; Opini, V.C.; Lopes, E.S.N.; Caram, R. Microstructure evolution of Ti–30Nb–(4Sn) alloys during classical and step-quench aging heat treatments. Mater. Sci. Technol. 2017, 33, 400–407. [Google Scholar] [CrossRef]

- Ba, H.B.; Dong, L.M.; Zhang, Z.Q.; Lei, X. Effects of Trace Si Addition on the Microstructures and Tensile Properties of Ti-3Al-8V-6Cr-4Mo-4Zr Alloy. Metals 2017, 7, 286. [Google Scholar] [CrossRef]

- Lee, B.H.; Choe, B.H.; Choi, J.H.; Kim, S.E.; Kim, S.J.; Lee, Y.T. Aging Behavior and Phase Transformation in the β-C Titanium Alloy. Korean J. Met. Mater. 2000, 38, 1304–1308. [Google Scholar]

- Yolton, C.F.; Froes, F.H.; Malone, R.F. Alloying Element Effects in Metastable Beta Titanium Alloys. Metall. Trans. A 1979, 10, 132–134. [Google Scholar] [CrossRef]

- Zhang, K.; Kan, W.H.; Zhu, Y.; Lim, S.C.V.; Gao, X.; Sit, C.K.; Bai, C.; Huang, A. Achieving ultra-high strength rapidly in Ti-3Al-8V-6Cr-4Mo-4Zr alloy processed by directed energy deposition. Mater. Des. 2022, 224, 111325. [Google Scholar] [CrossRef]

- Cao, S.; Zhou, X.; Lim, C.V.S.; Boyer, R.R.; Williams, J.C.; Wu, X. A strong and ductile Ti-3Al-8V-6Cr-4Mo-4Zr (Beta-C) alloy achieved by introducing trace carbon addition and cold work. Scr. Mater. 2020, 178, 124–128. [Google Scholar] [CrossRef]

- Wagner, L.; Gregory, J.K. Improvement of mechanical behavior in Ti-3Al-8V-6Cr-4Mo-4Zr by duplex aging. In Beta Titanium Alloys in the 1990’s, TMS: Warrendale, PA, USA, 1993; pp. 199–209.

- ASTM E9-09; Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature. ASTM International: West Conshohocken, PA, USA, 2018.

- Ba, H.B.; Dong, L.M.; Zhang, Z.Q.; Xu, D.S.; Yang, R. Effects of Zr Content on the Microstructures and Tensile Properties of Ti–3Al–8V–6Cr–4Mo–xZr Alloys. Acta Metall. 2016, 29, 722–726. [Google Scholar] [CrossRef]

- Headley, T.J.; Rack, J. Phase transformations in Ti-3AI-8V-6Cr-4Zr-4Mo. Metall. Trans. A 1979, 10, 909–920. [Google Scholar] [CrossRef]

- Youn, C.S.; Park, Y.K.; Kim, J.H.; Lee, S.C.; Lee, D.G. Aging Treatment Optimization of Ti-3Al-8V-6Cr-4Mo-4Zr Alloy for Spring Application. J. Kor. Soc. Heat Treatment 2017, 30, 279–284. [Google Scholar]

- Ankem, S.; Banerjee, D.; Mcneeish, D.J.; Williams, J.C.; Seagle, S.R. Silicide Formation in Ti-3Al-8V-6Cr-4Zr-4Mo. Metall. Trans. A 1987, 18, 2015–2025. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, C.; Zhou, G.; Zhang, S.; Chen, L. Dependence of strength and ductility on secondary α phase in a novel metastable-β titanium alloy. J. Mater. Res. Technol. 2022, 18, 5257–5266. [Google Scholar] [CrossRef]

- Liu, C.M.; Wang, H.M.; Tian, X.J.; Tang, H.B. Subtransus triplex heat treatment of laser melting deposited Ti–5Al–5Mo–5V–1Cr–1Fe near β titanium alloy. Mater. Sci. Eng. A 2014, 590, 30–36. [Google Scholar] [CrossRef]

- Yumak, N.; Aslantas, K. A review on heat treatment efficiency in metastable β titanium alloys: The role of treatment process and parameters. J. Mater. Res. Technol. 2020, 9, 15360–15380. [Google Scholar] [CrossRef]

- Du, Z.; Xiao, S.; Xu, L.; Tian, J.; Kong, F.; Chen, Y. Effect of heat treatment on microstructure and mechanical properties of a new β high strength titanium alloy. Mater. Des. 2014, 55, 183–190. [Google Scholar] [CrossRef]

- Tandon, V.; Park, K.S.; Khatirkar, R.; Gupta, A.; Choi, S.H. Evolution of Microstructure and Crystallographic Texture in Deformed and Annealed BCC Metals and Alloys: A Review. Metals 2024, 14, 149. [Google Scholar] [CrossRef]

- Wu, C.; Zhan, M. Effect of solution plus aging heat treatment on microstructural evolution and mechanical properties of near-β titanium alloy. Trans. Nonferrous Met. Soc. China 2019, 29, 997–1006. [Google Scholar] [CrossRef]

| Elements | Al | V | Cr | Mo | Zr | Si | Fe | O | C | N | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|

| wt.% | 3.38 | 8.3 | 5.82 | 4.13 | 3.92 | 0.12 | 0.06 | 0.08 | 0.007 | 0.008 | Bal. |

| Element | wt.% | at.% |

|---|---|---|

| Al | 3.09 | 5.53 |

| Si | 1.70 | 2.91 |

| Ti | 74.09 | 74.64 |

| V | 8.60 | 8.15 |

| Cr | 5.61 | 5.20 |

| Zr | 3.16 | 1.67 |

| Mo | 3.75 | 1.89 |

| Element | wt.% | at.% |

|---|---|---|

| Al | 3.06 | 5.53 |

| Si | 0.06 | 0.10 |

| Ti | 75.53 | 76.92 |

| V | 8.84 | 8.47 |

| Cr | 5.91 | 5.55 |

| Zr | 3.09 | 1.65 |

| Mo | 3.51 | 1.78 |

| Temp. (°C) | Time (h) | Vf,α(%) | Vf,β (%) |

|---|---|---|---|

| 400 | 2 | 1.45 | 98.55 |

| 8 | 2.30 | 97.70 | |

| 16 | 0.90 | 99.10 | |

| 24 | 1.17 | 98.83 | |

| 450 | 2 | 1.33 | 98.67 |

| 8 | 1.73 | 98.27 | |

| 16 | 1.76 | 98.24 | |

| 24 | 7.53 | 92.47 | |

| 500 | 2 | 0.99 | 99.01 |

| 8 | 5.41 | 94.59 | |

| 16 | 6.79 | 93.21 | |

| 24 | 23.62 | 76.38 | |

| 550 | 2 | 1.25 | 98.75 |

| 8 | 8.14 | 91.86 | |

| 16 | 20.08 | 79.92 | |

| 24 | 27.13 | 72.87 |

| Temp. (°C) | Time (h) | Compressive Yield Strength (MPa) | Compressive Strength (MPa) (at Strain 30%) |

|---|---|---|---|

| - | - | 908.1 ± 4.1 | 1378.3 ± 10.2 |

| 400 | 2 | 928.6 ± 5.4 | 1442.7 ± 6.9 |

| 8 | 935.0 ± 4.1 | 1425.5 ± 21.2 | |

| 16 | 947.7 ± 6.2 | 1492.4 ± 23.7 | |

| 24 | 942.5 ± 13.6 | 1425.0 ± 10.1 | |

| 450 | 2 | 935.6 ± 7.4 | 1386.2 ± 4.5 |

| 8 | 937.8 ± 12.9 | 1403.9 ± 47.0 | |

| 16 | 1000.3 ± 4.9 | 1476.8 ± 12.8 | |

| 24 | 1202.1 ± 5.7 | 1683.0 ± 20.6 | |

| 500 | 2 | 930.1 ± 9.6 | 1389.0 ± 67.4 |

| 8 | 1064.0 ± 29.5 | 1525.3 ± 73.1 | |

| 16 | 1349.8 ± 18.9 | 1822.0 ± 43.3 | |

| 24 | 1433.8 ± 21.5 | 1859.9 ± 11.7 | |

| 550 | 2 | 915.0 ± 12.3 | 1396.8 ± 54.4 |

| 8 | 981.5 ± 5.8 | 1488.4 ± 59.6 | |

| 16 | 1110.5 ± 2.6 | 1651.6 ± 29.3 | |

| 24 | 1143.5 ± 6.1 | 1648.6 ± 26.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.-W.; Kim, H.-M.; Lee, Y.-J.; Lee, J.-G.; Lee, D.-G. Effect of Aging Treatment on the Microstructure and Mechanical Properties of Ti-3Al-8V-6Cr-4Mo-4Zr Alloy. Appl. Sci. 2024, 14, 6192. https://doi.org/10.3390/app14146192

Lee S-W, Kim H-M, Lee Y-J, Lee J-G, Lee D-G. Effect of Aging Treatment on the Microstructure and Mechanical Properties of Ti-3Al-8V-6Cr-4Mo-4Zr Alloy. Applied Sciences. 2024; 14(14):6192. https://doi.org/10.3390/app14146192

Chicago/Turabian StyleLee, Seung-Woo, Hong-Min Kim, Yong-Jae Lee, Jae-Gwan Lee, and Dong-Geun Lee. 2024. "Effect of Aging Treatment on the Microstructure and Mechanical Properties of Ti-3Al-8V-6Cr-4Mo-4Zr Alloy" Applied Sciences 14, no. 14: 6192. https://doi.org/10.3390/app14146192

APA StyleLee, S.-W., Kim, H.-M., Lee, Y.-J., Lee, J.-G., & Lee, D.-G. (2024). Effect of Aging Treatment on the Microstructure and Mechanical Properties of Ti-3Al-8V-6Cr-4Mo-4Zr Alloy. Applied Sciences, 14(14), 6192. https://doi.org/10.3390/app14146192