Shape Optimization of Structures by Biological Growth Method

Abstract

1. Introduction

2. Materials and Methods

2.1. Growth Optimization Method—CAO Method 1

- -

- uniform stress distribution for all load conditions;

- -

- minimum weight.

2.2. Shape Optimization—CAO Method 2

- Create an FEA model with an initial design proposal.

- Cover the model with a thin layer of finite elements that have a much smaller Young’s modulus value than the original elements.

- Apply a load to the model, thereby elastically modifying both the surface layer and the underlying structure.

- Multiply the incremental displacements by an appropriate factor to obtain visible shape corrections. The multiplied displacements shall be added to the coordinates of the nodal points on the grid surface.

- Subsequently, the inner edge of the surface layer is displaced outward so that the thickness of the surface layer is constant throughout. It is also possible to move the nodal points further inward to avoid strong deformations of the mesh.

- Repeat step 3 but with the new FEM model optimized according to step 5.

- Perform elastic control cycles to determine the degree of optimization with a high value of Young’s modulus (also on a surface layer that was previously soft).

- Stop the optimization procedure if the stress concentrators are sufficiently reduced or if there are dimensional design constraints [6].

2.3. Topological Optimization—SKO Method

- Compute the stresses within the selected design area for given loads. The design has a constant Young’s modulus over the entire area.

- The values of the Young’s modulus across the surface vary as a function of stress.

- Compute the new stress distribution over the whole given area under the same load but already with a locally different distribution of the Young’s modulus [25].

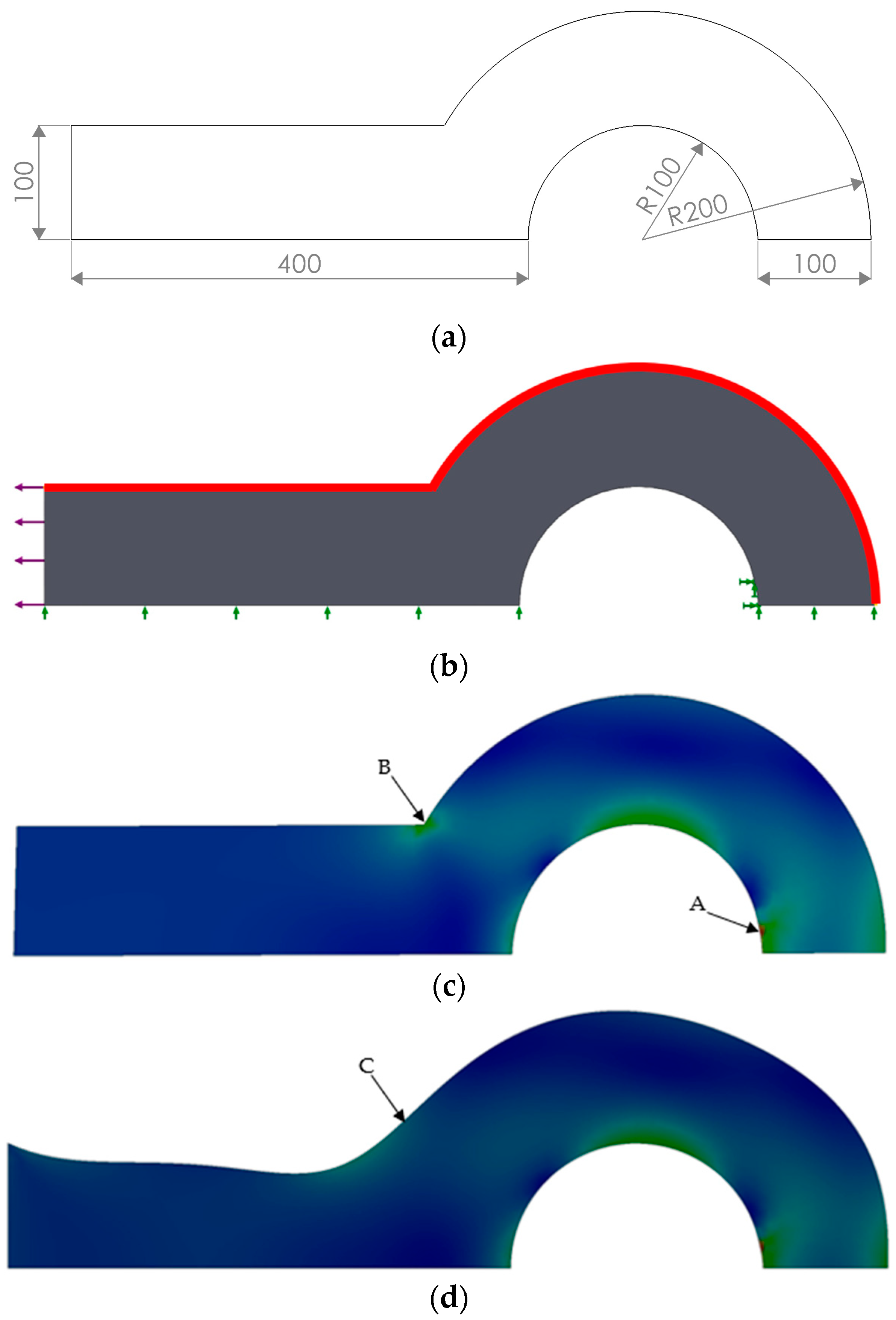

2.4. Application of the SKO and CAO Method for Optimization of 2D Structural Element

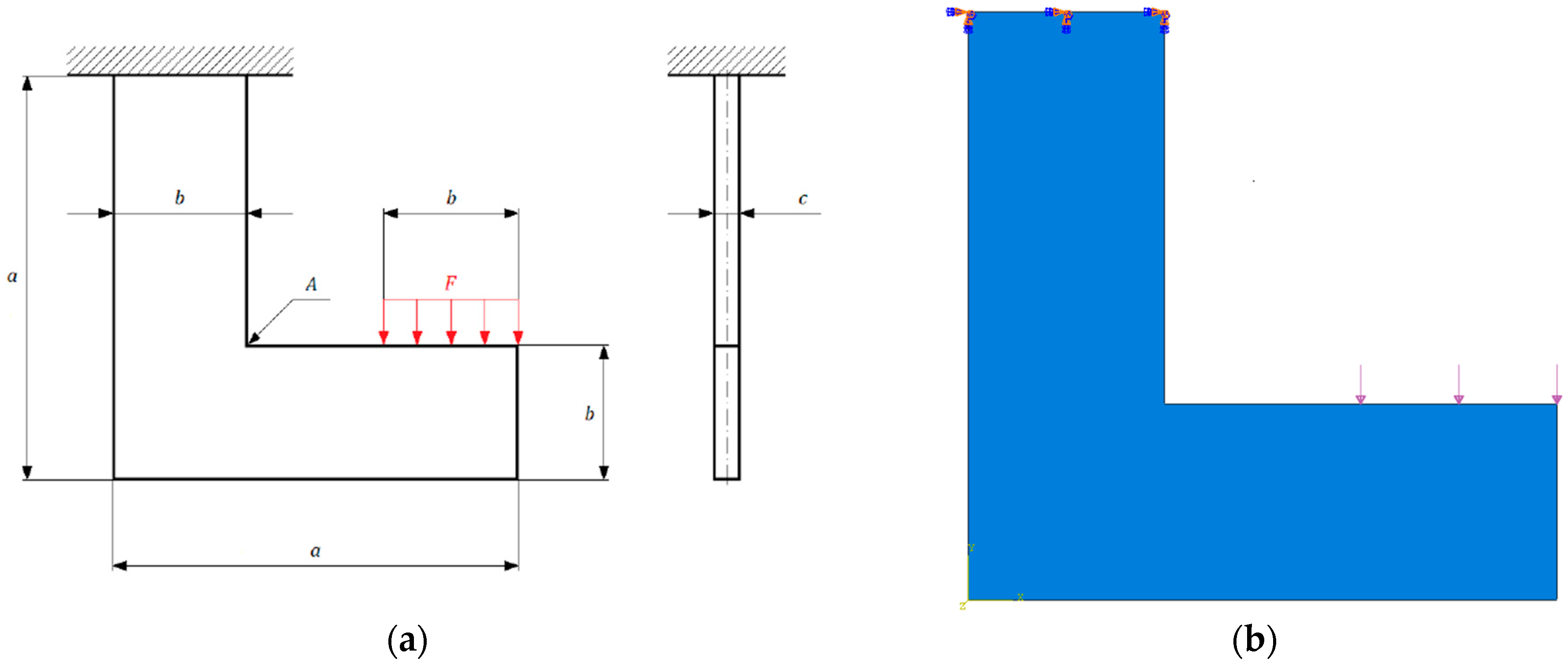

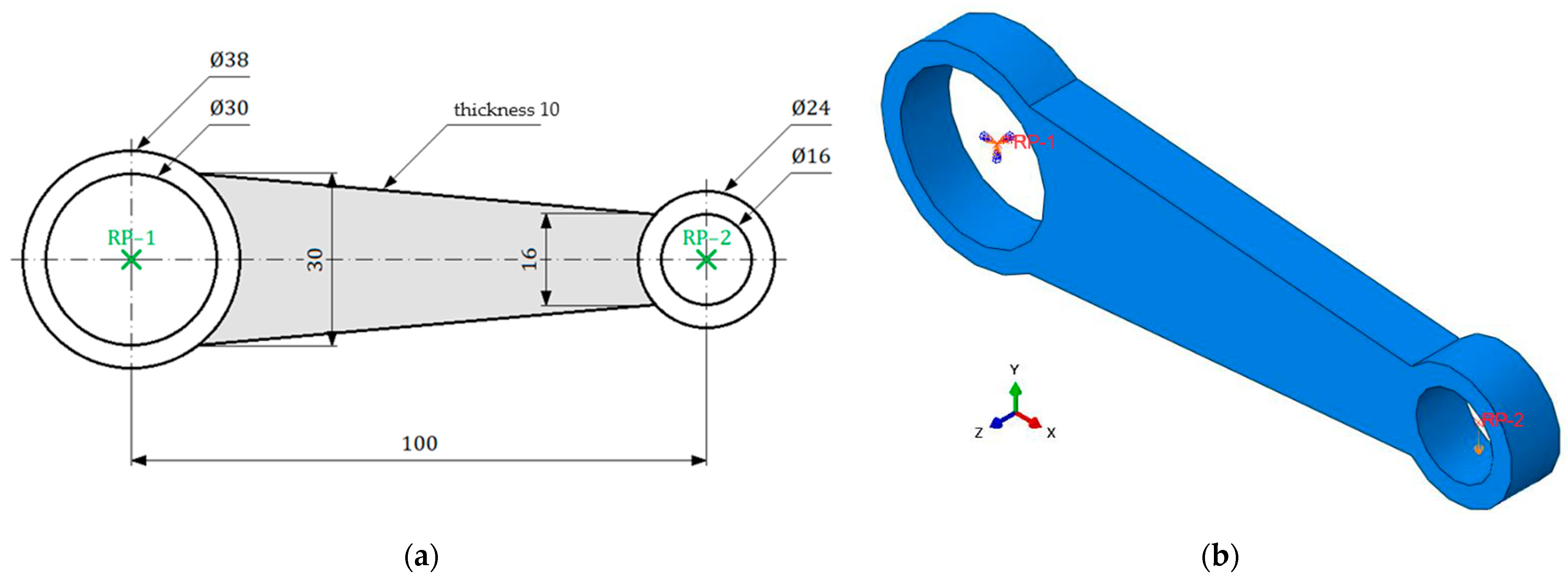

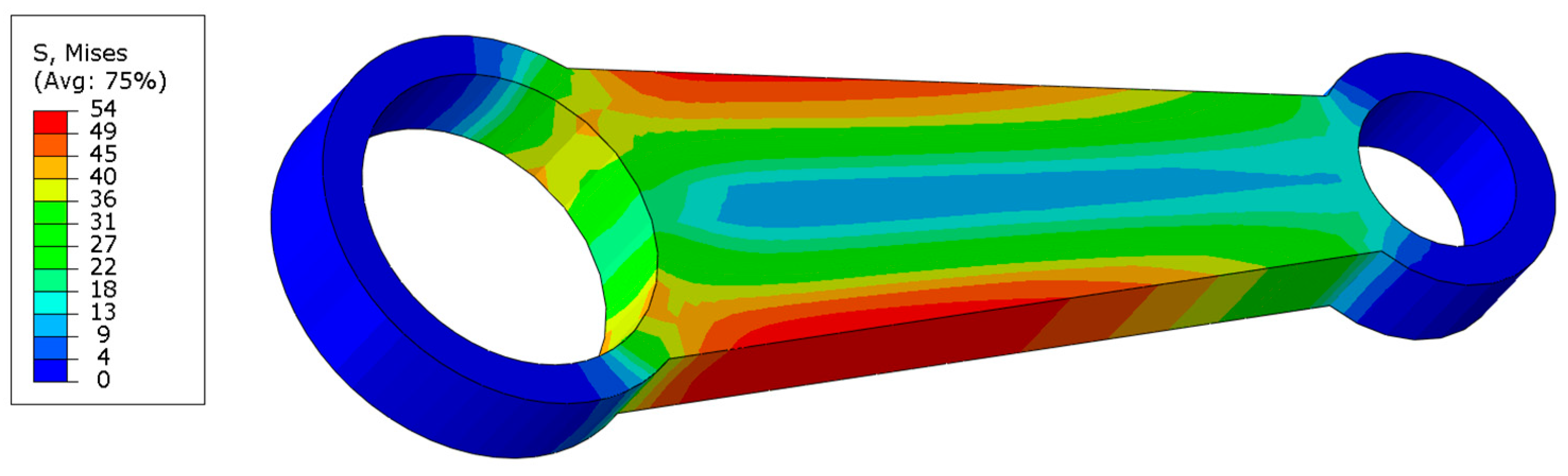

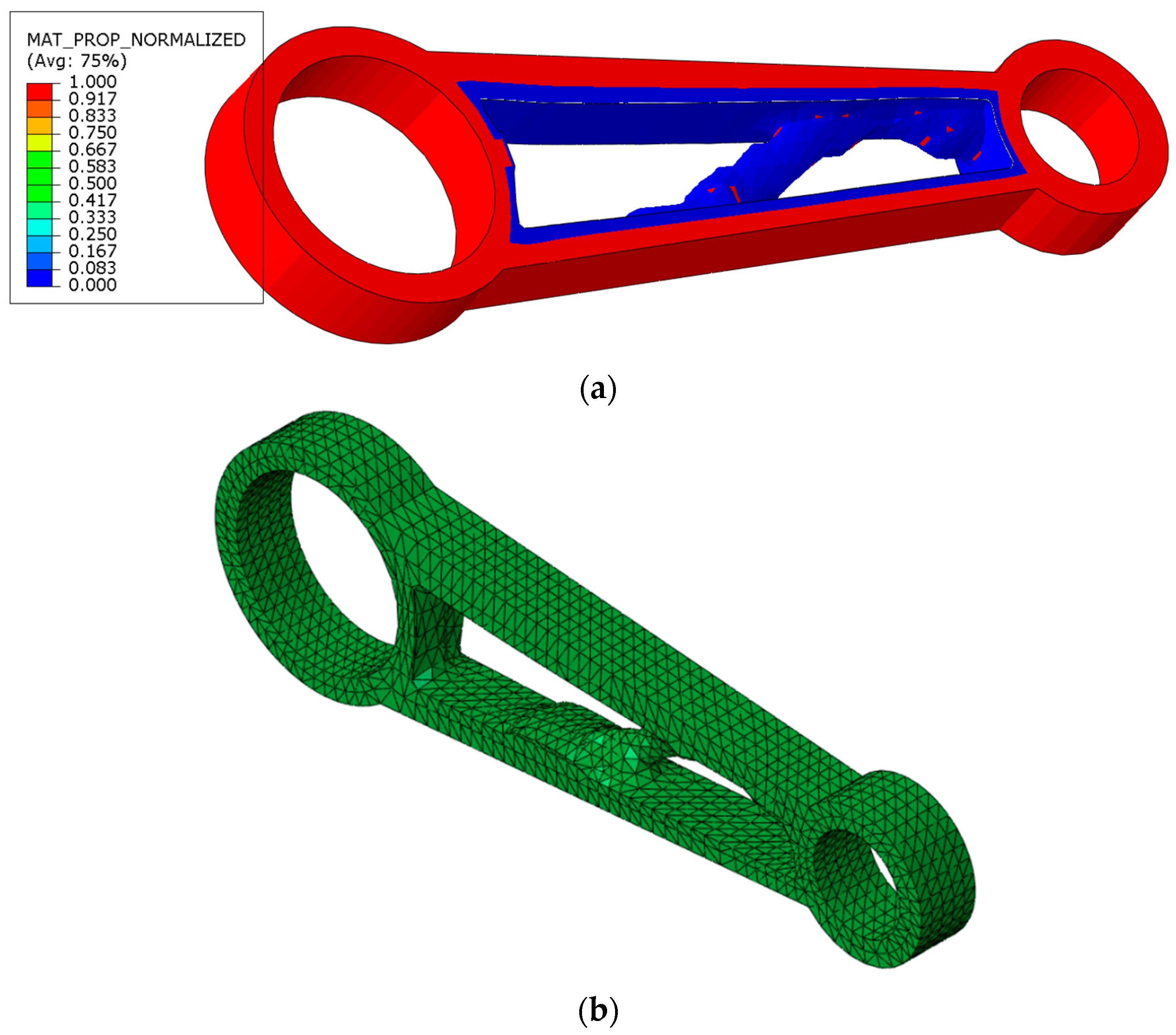

3. The 3D Structural Element Optimization

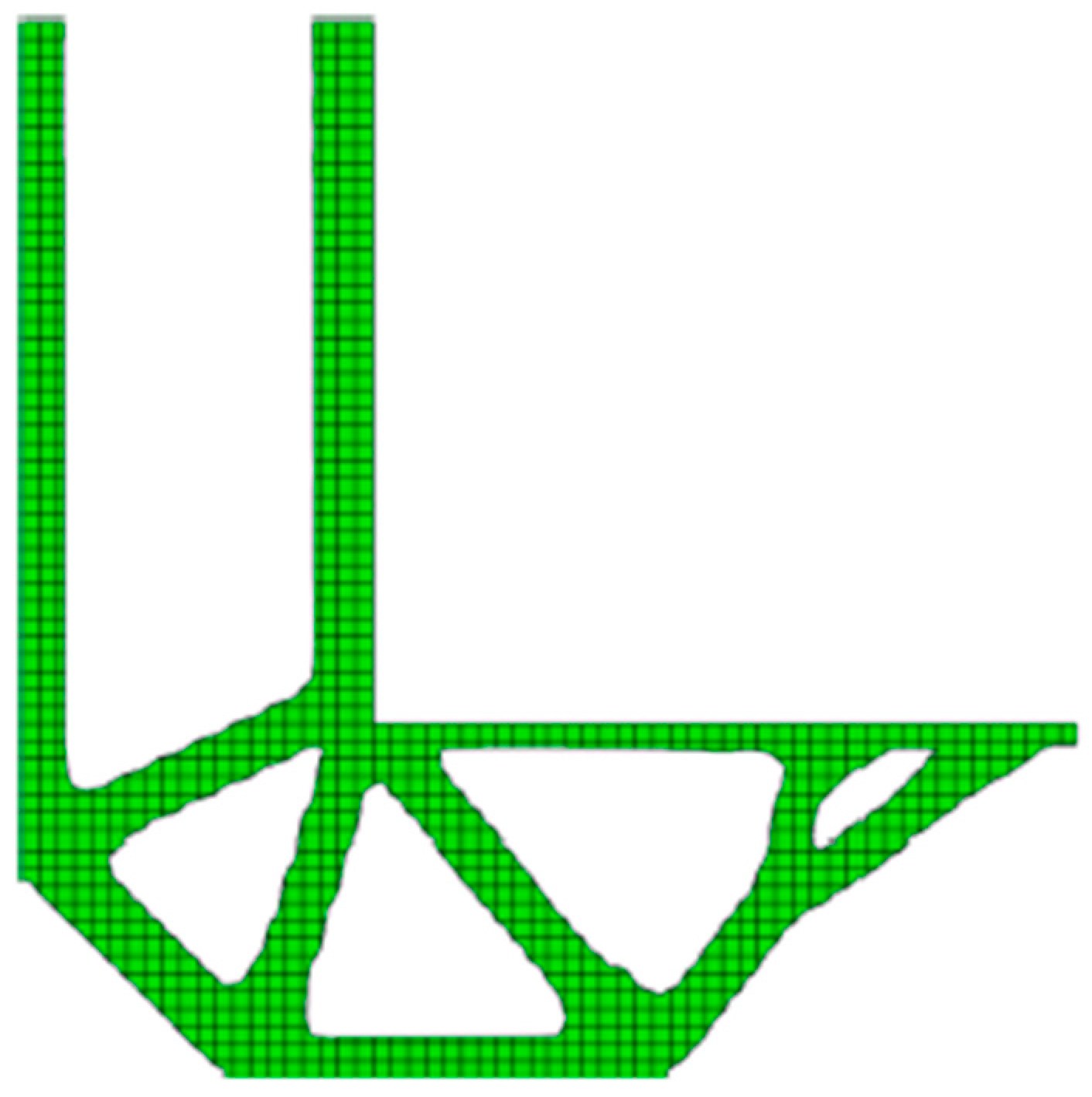

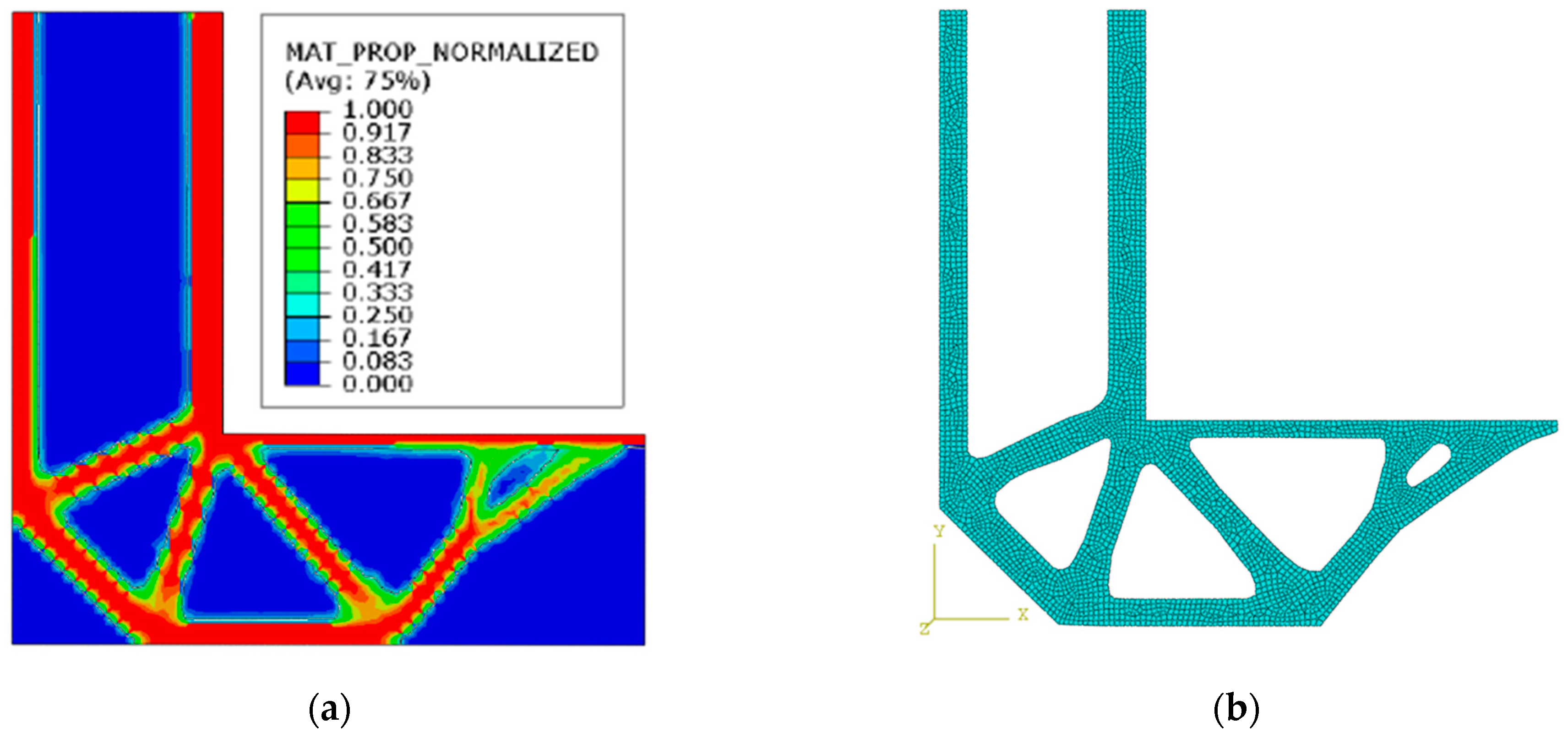

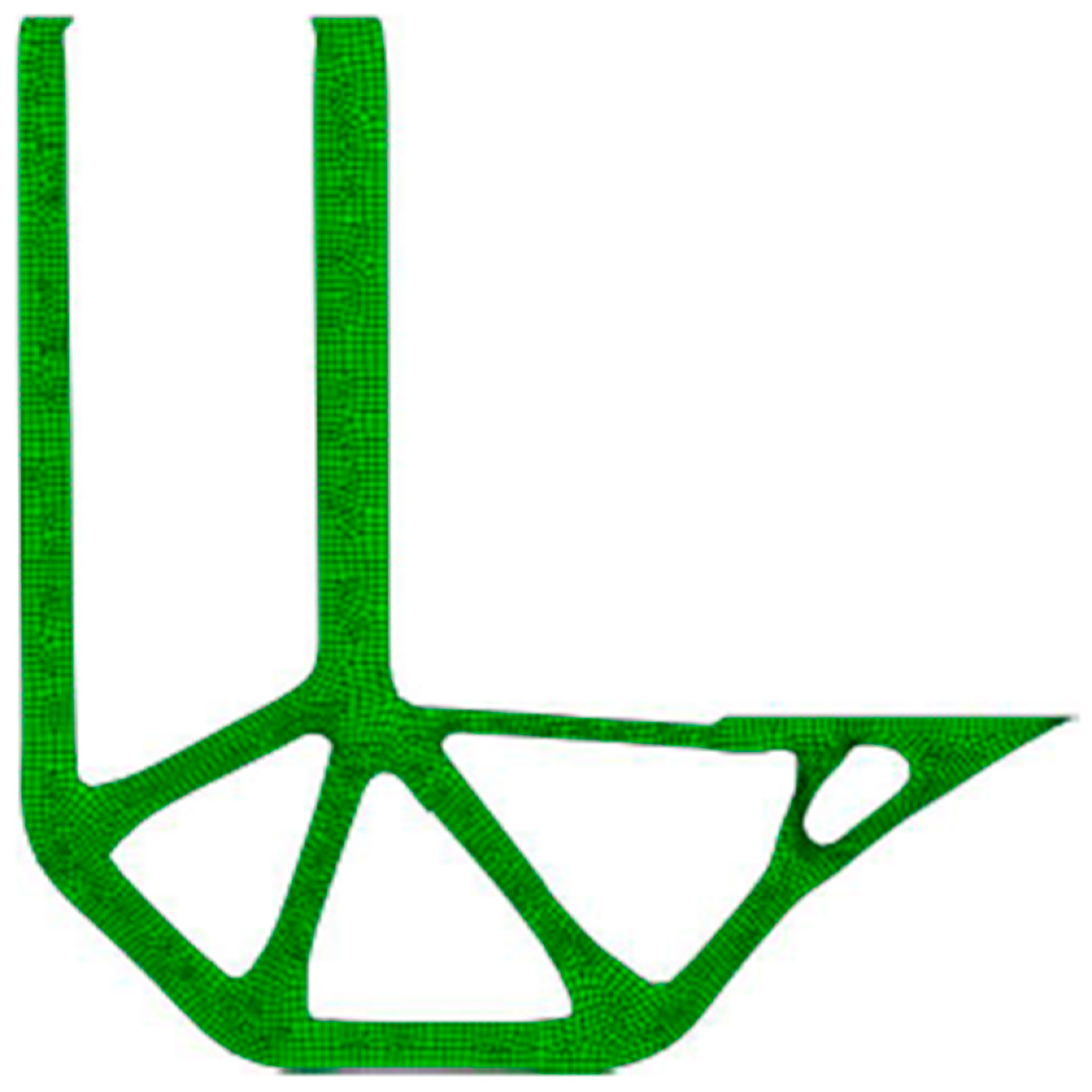

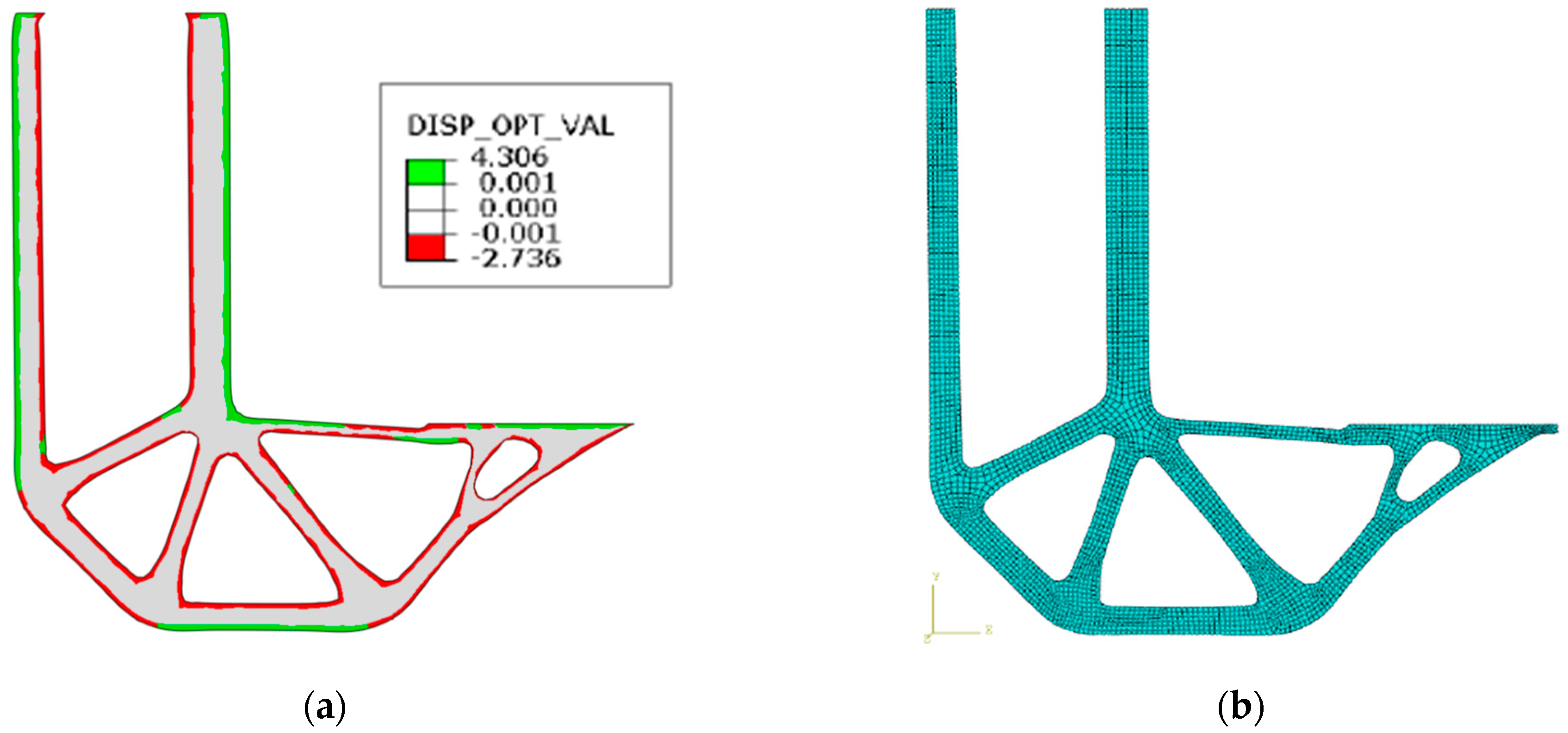

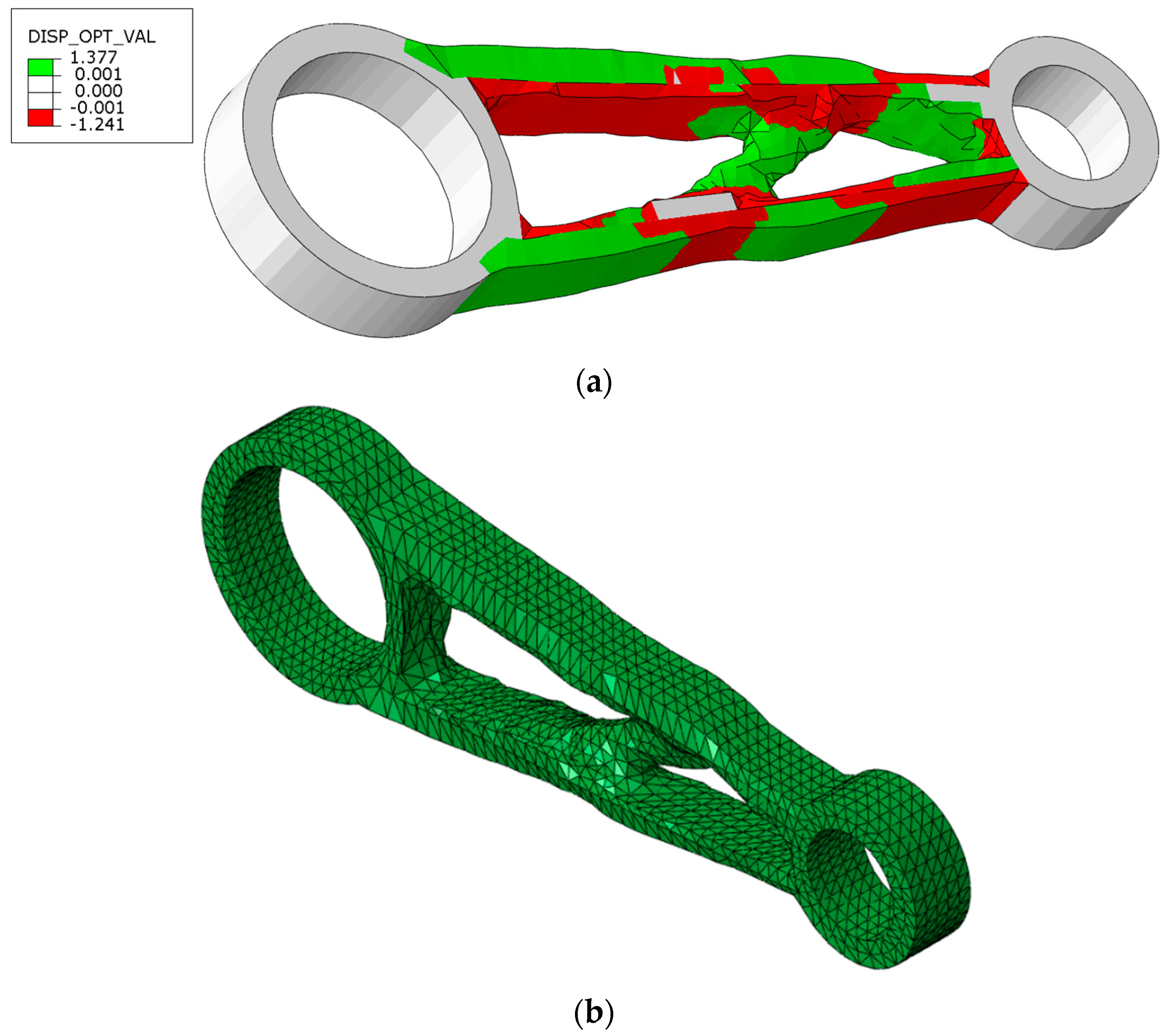

3.1. Topological Optimization of a 3D Structural Element (SKO Method)

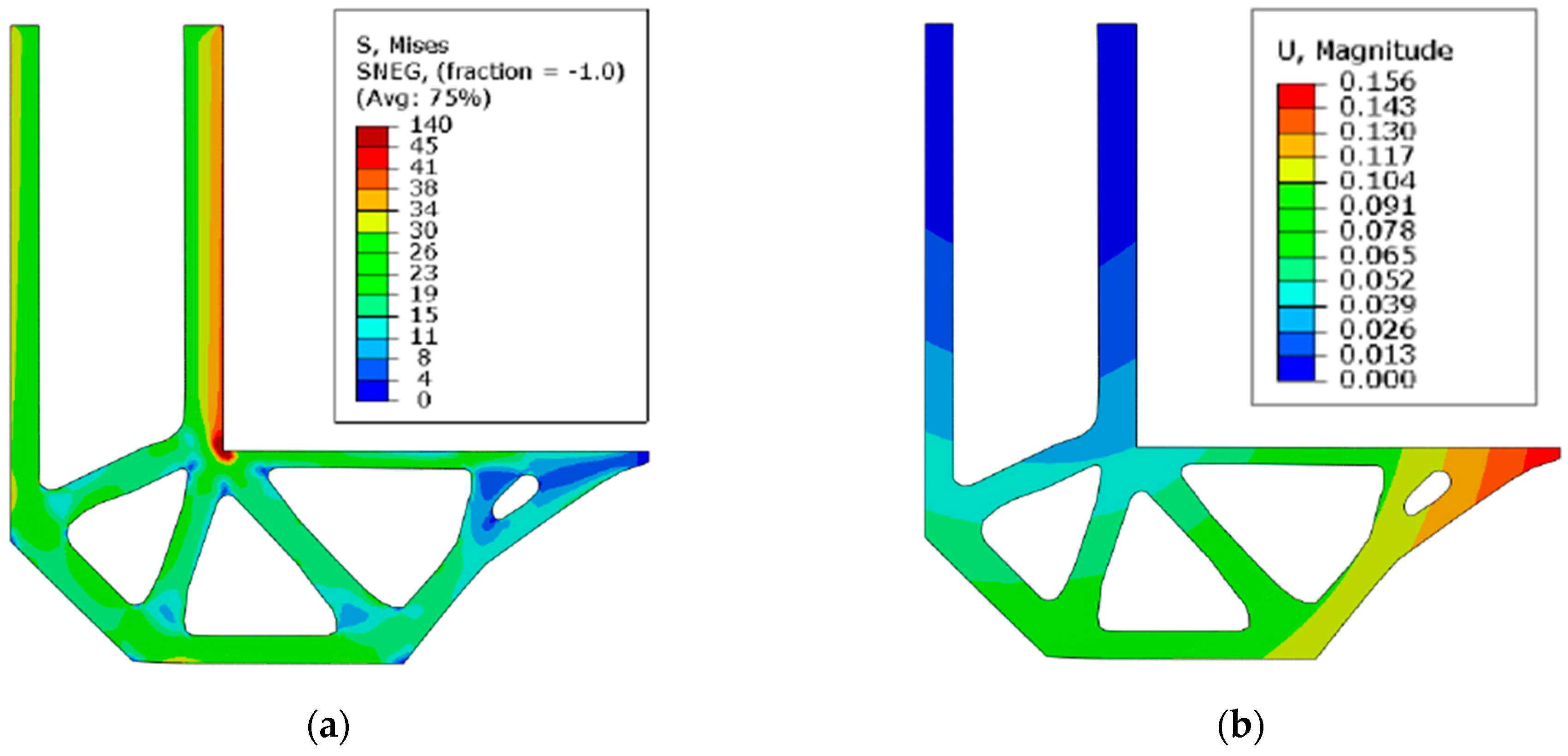

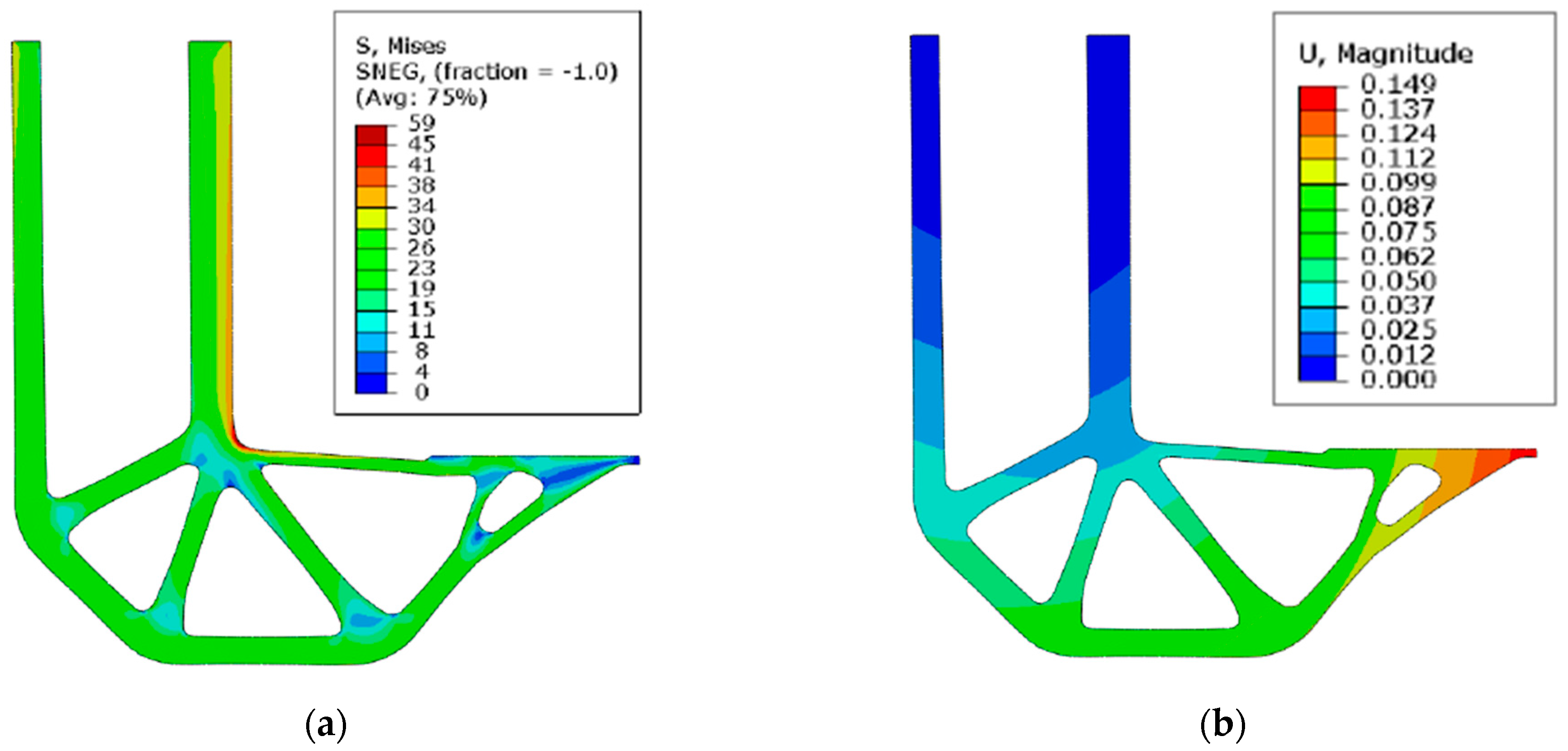

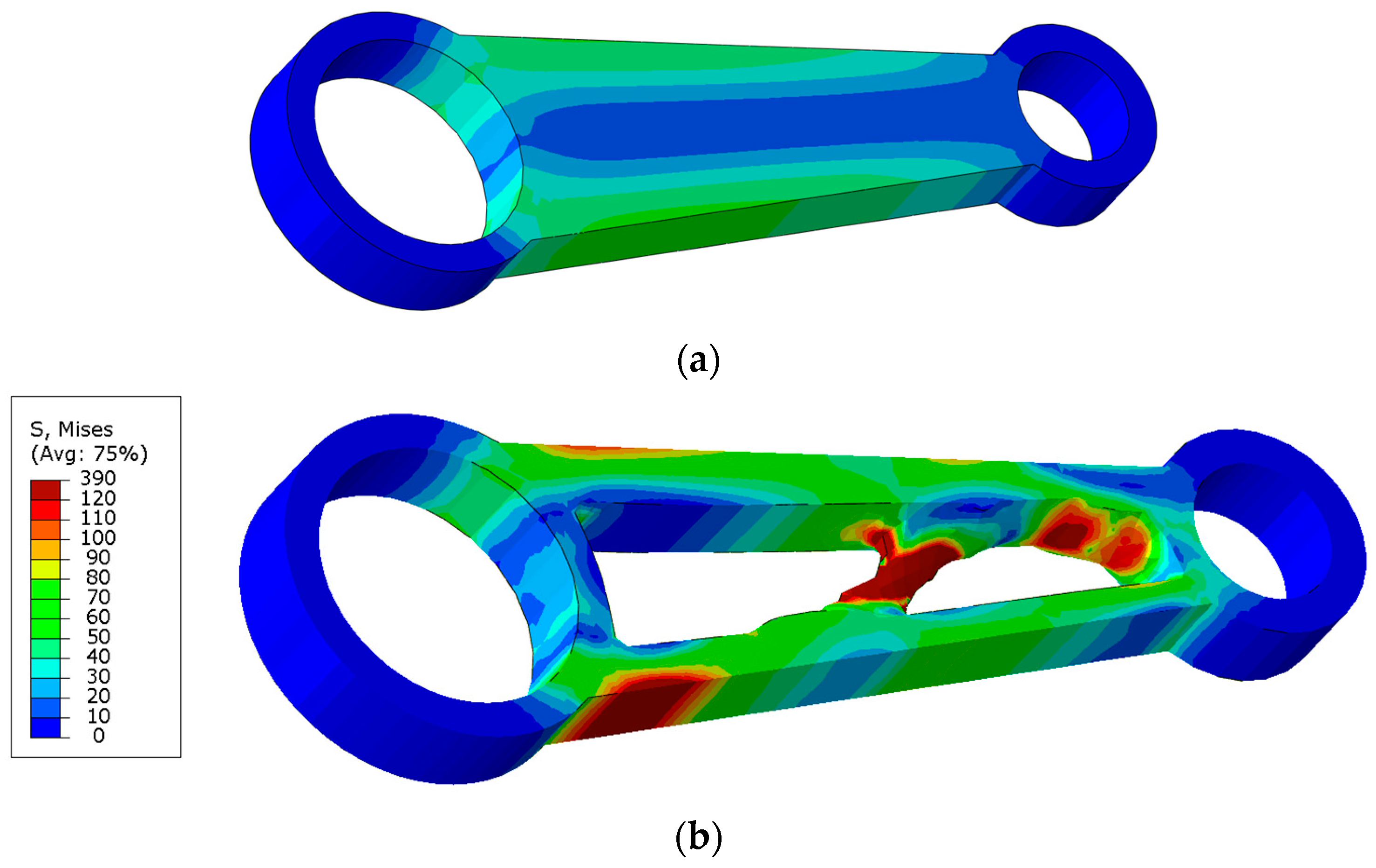

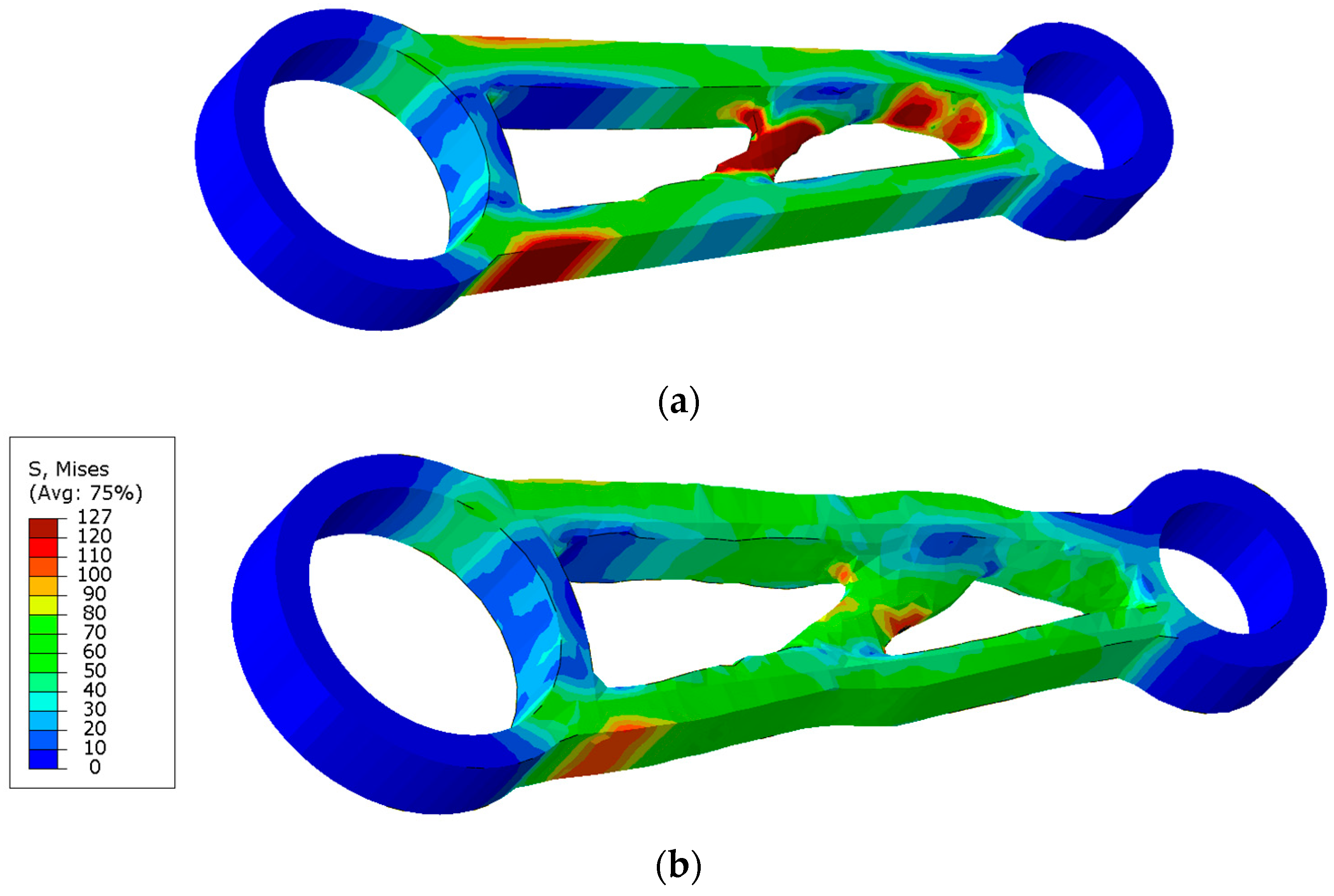

3.2. Shape Optimization of 3D Structural Element (CAO Method)

4. Discussion of Optimization Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Michell, A.G.M. LVIII. The limits of economy of material in frame-structures. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1904, 8, 589–597. [Google Scholar] [CrossRef]

- Lewiński, T.; Sokół, T.; Graczykowski, C. Michell Structures; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Christensen, P.W.; Klarbring, A. An Introduction to Structural Optimization; Springer Science & Business Media: Dordrecht, The Netherlands, 2008. [Google Scholar]

- Tang, J.; Fu, C.; Mi, C.; Liu, H. An interval sequential linear programming for nonlinear robust optimization problems. Appl. Math. Model. 2022, 107, 256–274. [Google Scholar] [CrossRef]

- Goldberg, D.E. Genetic Algorithms in Search, Optimization and Machine Learning, 1st ed.; Pearson: London, UK, 1989. [Google Scholar]

- Mattheck, C.; Burkhardt, S. A New Method of Structural Shape Optimization Based on Biological Growth. Int. J. Fatigue 1990, 12, 185–190. [Google Scholar] [CrossRef]

- Delyová, I.; Frankovský, P.; Bocko, J.; Trebuňa, P.; Živčák, J.; Schürger, B.; Janigová, S. Sizing and Topology Optimization of Trusses Using Genetic Algorithm. Materials 2021, 14, 715. [Google Scholar] [CrossRef] [PubMed]

- Kaveh, A.; Zaerreza, A. Structural Optimization Using Shuffled Shepherd Meta-Heuristic Algorithm: Extensions and Applications; Springer Nature: Cham, Switzerland, 2023. [Google Scholar]

- Xie, Y.M.; Steven, G.P. Evolutionary Structural Optimization; Springer: London, UK, 1997; ISBN 13:978-1-4471-1250-1. [Google Scholar]

- Mattheck, C.; Kubler, H. Wood—The Internal Optimization of Trees; Springer: Berlin/Heidelberg, Germany, 1997. [Google Scholar]

- Huang, X.; Xie, M. Evolutionary Topology Optimization of Continuum Structures: Methods and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Zhu, J.; Gao, T. Topology Optimization in Engineering Structure Design; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Querin, O.M.; Victoria, M.; Gordoa, C.A.; Ansola, R.; Martí, P. Topology Design Methods for Structural Optimization; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Gao, J.; Gao, L.; Xiao, M. Isogeometric Topology Optimization. Methods, Applications and Implementations; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Li, Y.; Chang, T.; Kong, W.; Wu, F.; Kong, X. Topological Optimization of Bi-Directional Progressive Structures with Dynamic Stress Constraints under Aperiodic Load. Appl. Sci. 2024, 14, 322. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhan, K.; Xia, J.; Zhao, M. Topology Optimization for Minimum Compliance with Material Volume and Buckling Constraints under Design-Dependent Loads. Appl. Sci. 2023, 13, 646. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, H.; Wang, W.; Zhang, Q. Topology Optimization Based on SA-BESO. Appl. Sci. 2023, 13, 4566. [Google Scholar] [CrossRef]

- Pham-Truong, T.; Kawamura, Y.; Okada, T. Bisection Constraint Method for Multiple-Loading Conditions in Structural Topology Optimization. Appl. Sci. 2023, 13, 13005. [Google Scholar] [CrossRef]

- Fu, Y.; Li, L.; Hu, Y. An Efficient and Robust Topology Optimization Method for Thermoelastically Damped Microresonators. Appl. Sci. 2023, 13, 8811. [Google Scholar] [CrossRef]

- Polak, J.; Nowak, M. From Structural Optimization Results to Parametric CAD Modeling—Automated, Skeletonization-Based Truss Recognition. Appl. Sci. 2023, 13, 5670. [Google Scholar] [CrossRef]

- Yago, D.; Cante, J.; Lloberas-Valls, O.; Oliver, J. Topology Optimization Methods for 3D Structural Problems: A Comparative Study. Arch. Comput. Methods Eng. 2022, 29, 1525–1567. [Google Scholar] [CrossRef]

- Ambrosi, D.; Amar, B.M.; Cyron, C.J.; De Simone, A.; Goriely, A.; Humphrey, J.D.; Kuhl, E. Growth and Remodelling of Living Tissues: Perspectives, Challenges and Opportunities. J. R. Soc. Interface 2019, 16, 20190233. [Google Scholar] [CrossRef] [PubMed]

- Hu, T.; Ding, X.; Shen, L.; Zhang, H. Improved Adaptive Growth Method of Stiffeners for Three-dimensional Box Structures with Respect to Natural Frequencies. Comput. Struct. 2020, 239, 106330. [Google Scholar] [CrossRef]

- Dong, X.H.; Ding, X.H.; Xiong, M. Optimal Layout of Internal Stiffeners for Threedimensional Box Structures Based on Natural Branching Phenomena. Eng. Optim. 2018, 51, 590–607. [Google Scholar] [CrossRef]

- Baumgartner, A.; Harzheim, L.; Mattheck, C. SKO (soft kill option): The Biological Way to Find an Optimum Structure Topology. Int. J. Fatigue 1992, 14, 387–393. [Google Scholar] [CrossRef]

- Mattheck, C.; Bethge, K. The Structural Optimization of Trees. Naturwissenschaften 1998, 85, 1–10. [Google Scholar] [CrossRef]

- Mattheck, C.; Bethge, K. Mechanical Optimization in Nature, Principles of. In Encyclopedia of Materials: The Science and Technology; Elsevier: Amsterdam, The Netherlands, 2001; pp. 5247–5250. Available online: https://www.sciencedirect.com/science/article/abs/pii/B0080431526009141 (accessed on 23 November 2023).

- Corriou, J.-P. Numerical Methods of Optimization. Numer. Methods Optim. 2021, 187, 505–574. [Google Scholar]

- Mattheck, C.; Teschner, M.; Schӓfer, J. Mechanical Control of Root Growth: A Computer Simulation. J. Theor. Biol. 1997, 184, 261–269. [Google Scholar] [CrossRef]

- Mattheck, C. Teacher Tree: The Evolution of Notch Shape Optimization from Complex to Simple. Eng. Fract. Mech. 2006, 73, 1732–1742. [Google Scholar] [CrossRef]

- Quint, M. Introduction to Shape (CAO) & Topology (SKO) Optimization Derived from the Growing of Trees. Adaptive Biological Growth. NAFEMS-Seminar: 2001. Available online: http://www.xperteez.de/publikationen/docs/NAFEMS/NAFEMS_2001.pdf (accessed on 20 November 2023).

- Kara, A.; Eksin, I.; Mugan, A. Parameter and Topology Optimization of Structures in the Frequency Domain under Nevanlinna–Pick Interpolation Constraints. Appl. Sci. 2024, 14, 1278. [Google Scholar] [CrossRef]

- İnce, E.G.; Özkal, F.M. Optimization of Structural Steel Used in Concrete-Encased Steel Composite Columns via Topology Optimization. Appl. Sci. 2024, 14, 1170. [Google Scholar] [CrossRef]

| Parameters of the Design Element | The Difference | The Difference in % | |

|---|---|---|---|

| Before Topological Optimization | After Topological Optimization | ||

| Parameters of the Design Element | The Difference | The Difference in % | |

|---|---|---|---|

| Before Shape Optimization | After Shape Optimization | ||

| Parameters of the Design Element | The Difference | The Difference in % | |

|---|---|---|---|

| Before BGM Optimization | After BGM Optimization | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bocko, J.; Delyová, I.; Kostka, J.; Sivák, P.; Fiľo, M. Shape Optimization of Structures by Biological Growth Method. Appl. Sci. 2024, 14, 6245. https://doi.org/10.3390/app14146245

Bocko J, Delyová I, Kostka J, Sivák P, Fiľo M. Shape Optimization of Structures by Biological Growth Method. Applied Sciences. 2024; 14(14):6245. https://doi.org/10.3390/app14146245

Chicago/Turabian StyleBocko, Jozef, Ingrid Delyová, Ján Kostka, Peter Sivák, and Milan Fiľo. 2024. "Shape Optimization of Structures by Biological Growth Method" Applied Sciences 14, no. 14: 6245. https://doi.org/10.3390/app14146245

APA StyleBocko, J., Delyová, I., Kostka, J., Sivák, P., & Fiľo, M. (2024). Shape Optimization of Structures by Biological Growth Method. Applied Sciences, 14(14), 6245. https://doi.org/10.3390/app14146245