Dynamic Modeling and Optimization of Tension Distribution for a Cable-Driven Parallel Robot

Abstract

:1. Introduction

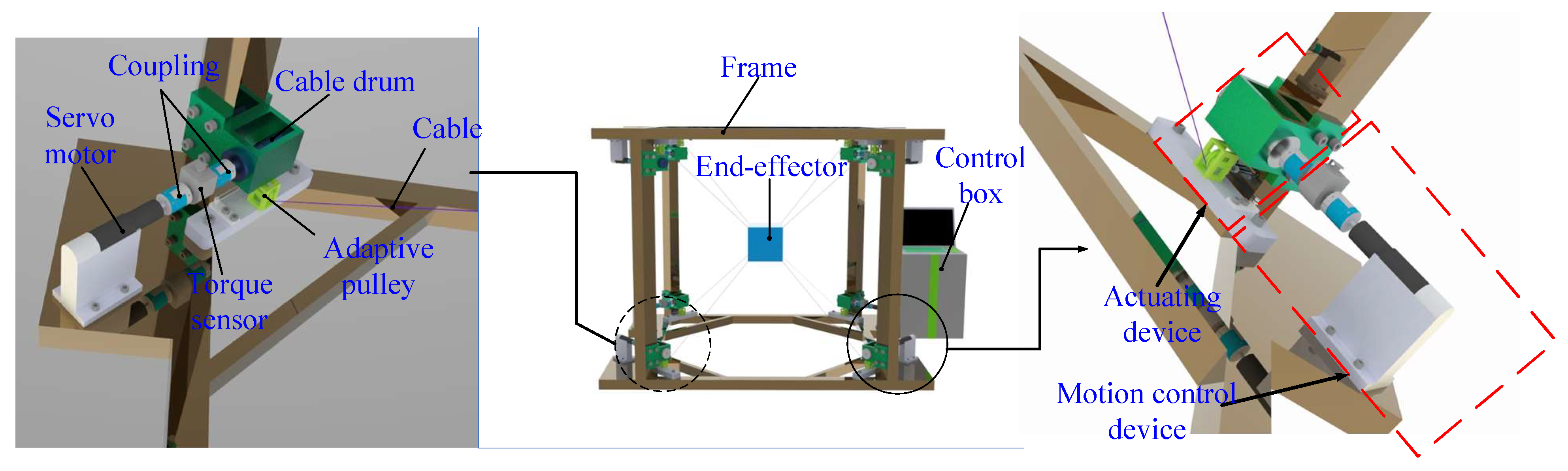

2. Design of Parallel Robot

2.1. Constraint Classification of Parallel Mechanism

2.2. Overall Structural Design

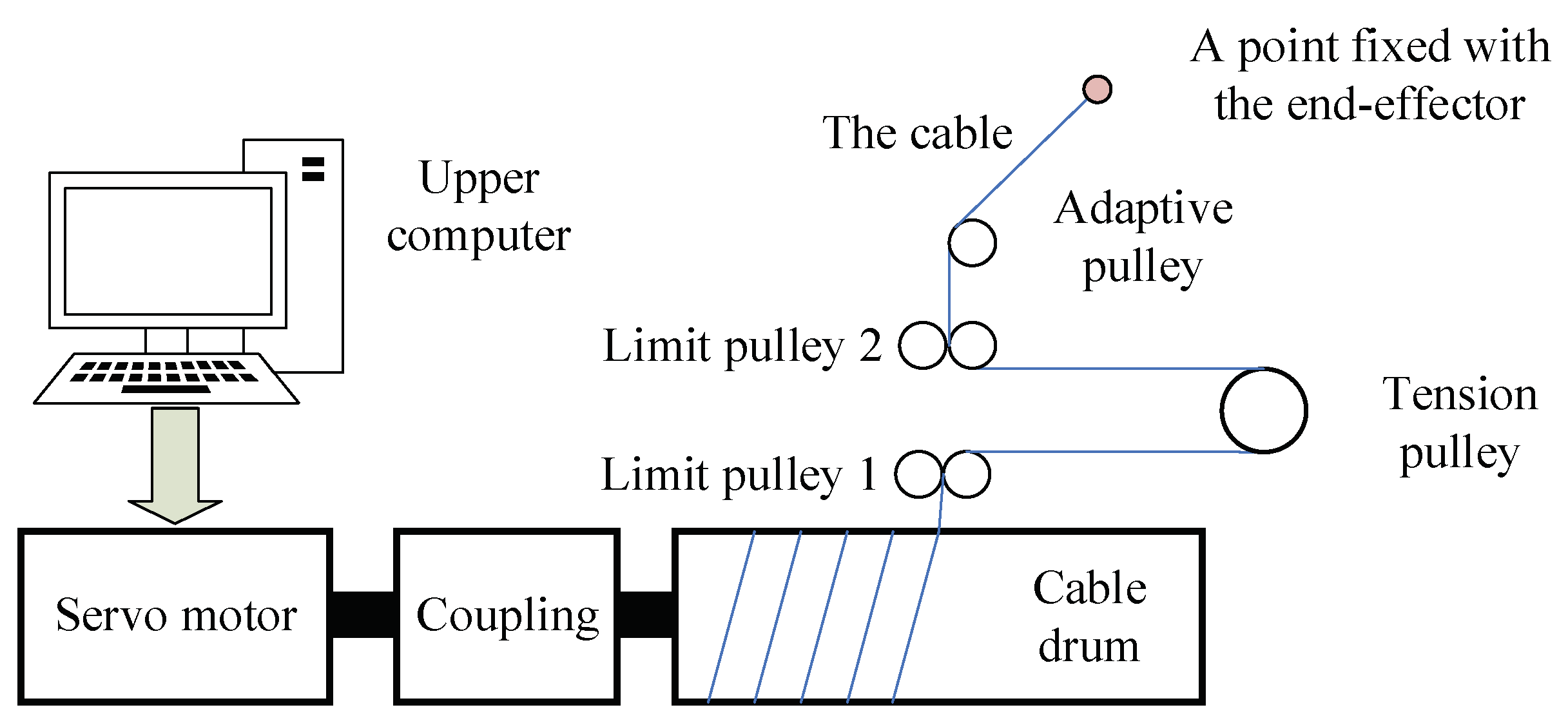

2.3. Principle of Working for the Robot

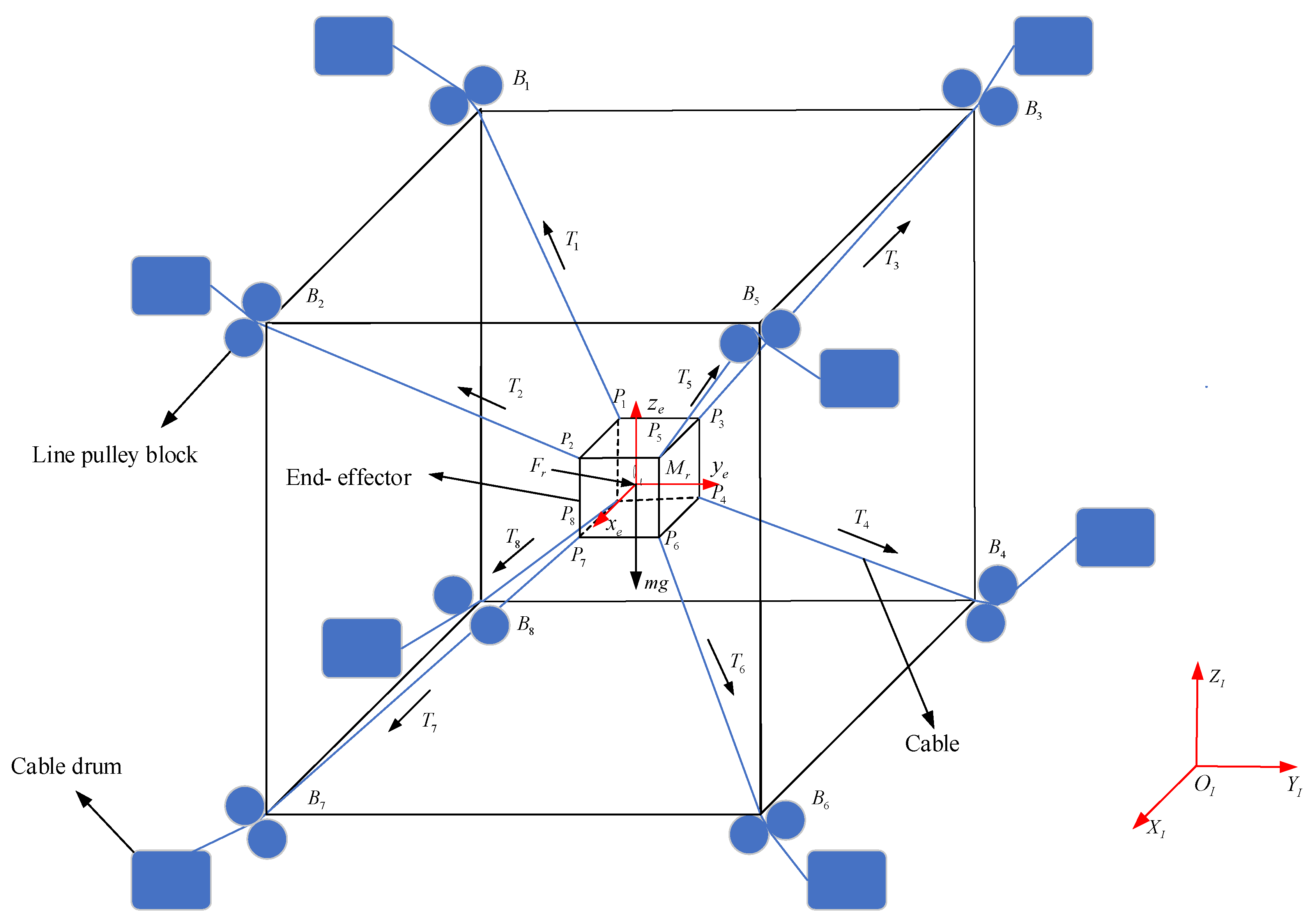

3. Dynamics Model of the Robot

3.1. Force Analysis of the End-Effector

- (a)

- The weight of the cable in the coordinate system oe − xeyeze is fixed on the center of the end-effector. The coordinate system OI − XIYIZI is an inertial system denoted by ∑I. For the convenience of dynamics modeling, two assumptions are as follows: is not considered in dynamics modeling due to the tiny mass of the cable;

- (b)

- The cable is an ideal, flexible body that does bending or shearing force. Based on the above assumptions and the Newton–Euler Equation, the dynamics model of the end-effector is given as follows:

3.2. The Driving Device’s Dynamics Model

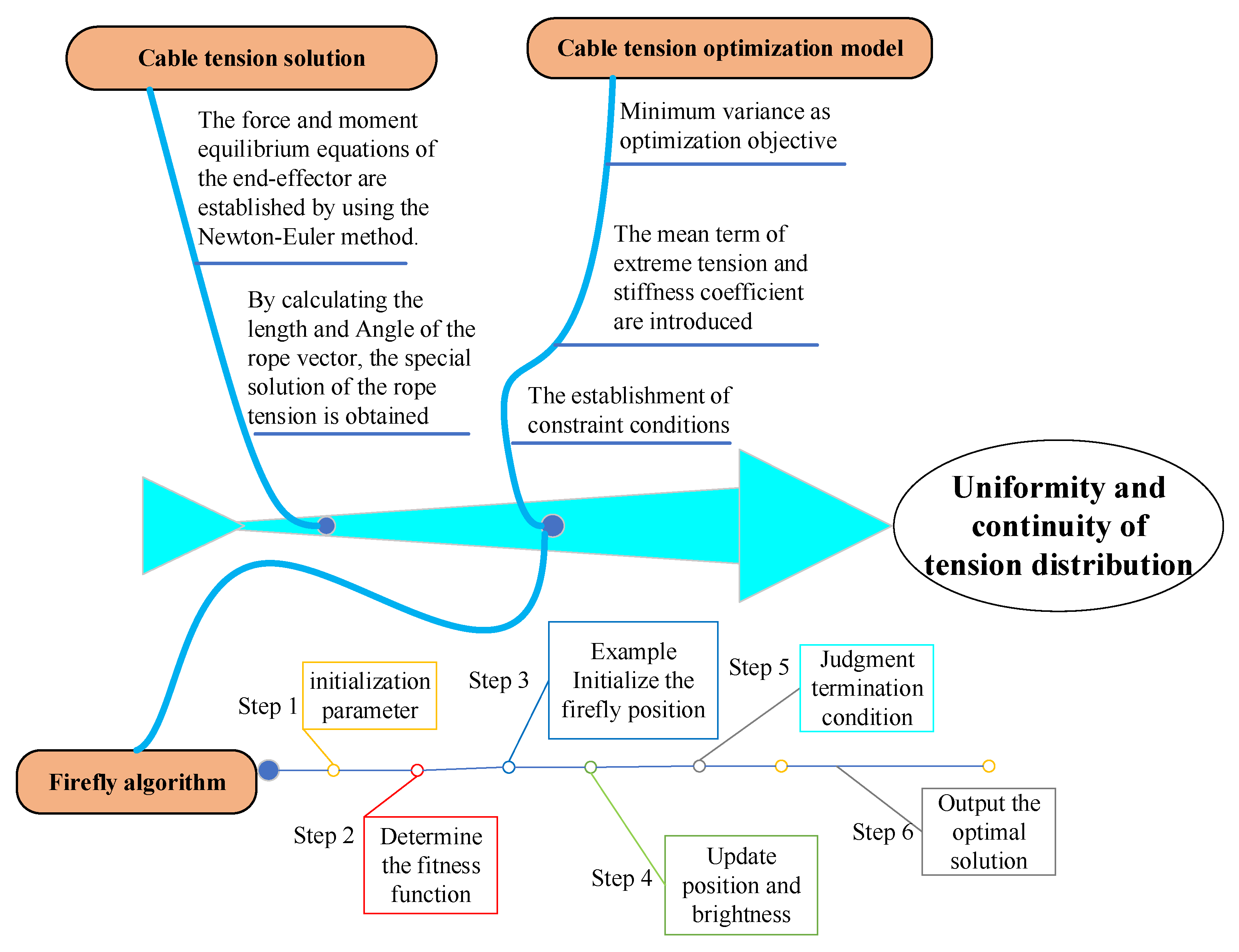

4. Optimization Algorithm of Tension Distribution

4.1. Cable Tension Optimization Process

4.2. Cable Tension Optimization Model

4.3. The Solution of Cable Tension

4.3.1. Calculation for Angle θi

4.3.2. The Determination of the Angle ϕi

4.4. Optimization Algorithm Design

- (1)

- Initialize parameters. First of all, the initial parameters are set, such as the robot structure parameters and time parameters. The robot parameters are the vertex coordinate and the end effector vertex . And the maximum iteration parameter is in the time parameters.

- (2)

- Set the FA algorithm parameters. These are the population size , the attraction parameter γ = 1.0, and the initial attraction .

- (3)

- Randomly initialize the firefly position. The positions of individual fireflies are randomly initialized, and each firefly corresponds to a tension distribution solution. The initial brightness is calculated from the fitness function, assuming that the initial tension value is randomly distributed between the preset minimum tension and the maximum tension .

- (4)

- Determine the fitness function. The fitness function is the objective function of the optimization problem. The objective of the optimization is to minimize the variance of the cable tension distribution and introduce the stiffness coefficient to make the tension distribution more uniform and continuous. The objective function is Equation (16).

- (5)

- The introduction of force and moment equation constraints. When calculating the fitness function, it is necessary to ensure that the cable tension satisfies the balance equation of force and moment. The force and moment balance equation of the cable robot is shown in Equation (32). In the fitness function calculation, a penalty term should be introduced to constrain these conditions:

- (6)

- Position update: update the position of fireflies according to step (4) and recalculate the brightness of fireflies according to Equation (14).where is the distance between firefly and firefly , is the random parameter, and rand is the random number between them.

- (7)

- Judge the termination condition: check whether the error of the solution is less than the given precision or whether the number of iterations is greater than the maximum number of iterations. If the conditions are met, the optimal solution is output, and optimization is completed; otherwise, return to Step 5 to continue the iteration.

- (8)

- Output the globally optimal solution to tension and complete the optimization.

4.5. Factors Affecting Minimum Cable Tension

4.5.1. Cable Preload

4.5.2. Strength Limitation of Cable Material

4.5.3. Cable Length Changes

4.5.4. Stiffness Coefficient

5. Simulation Study

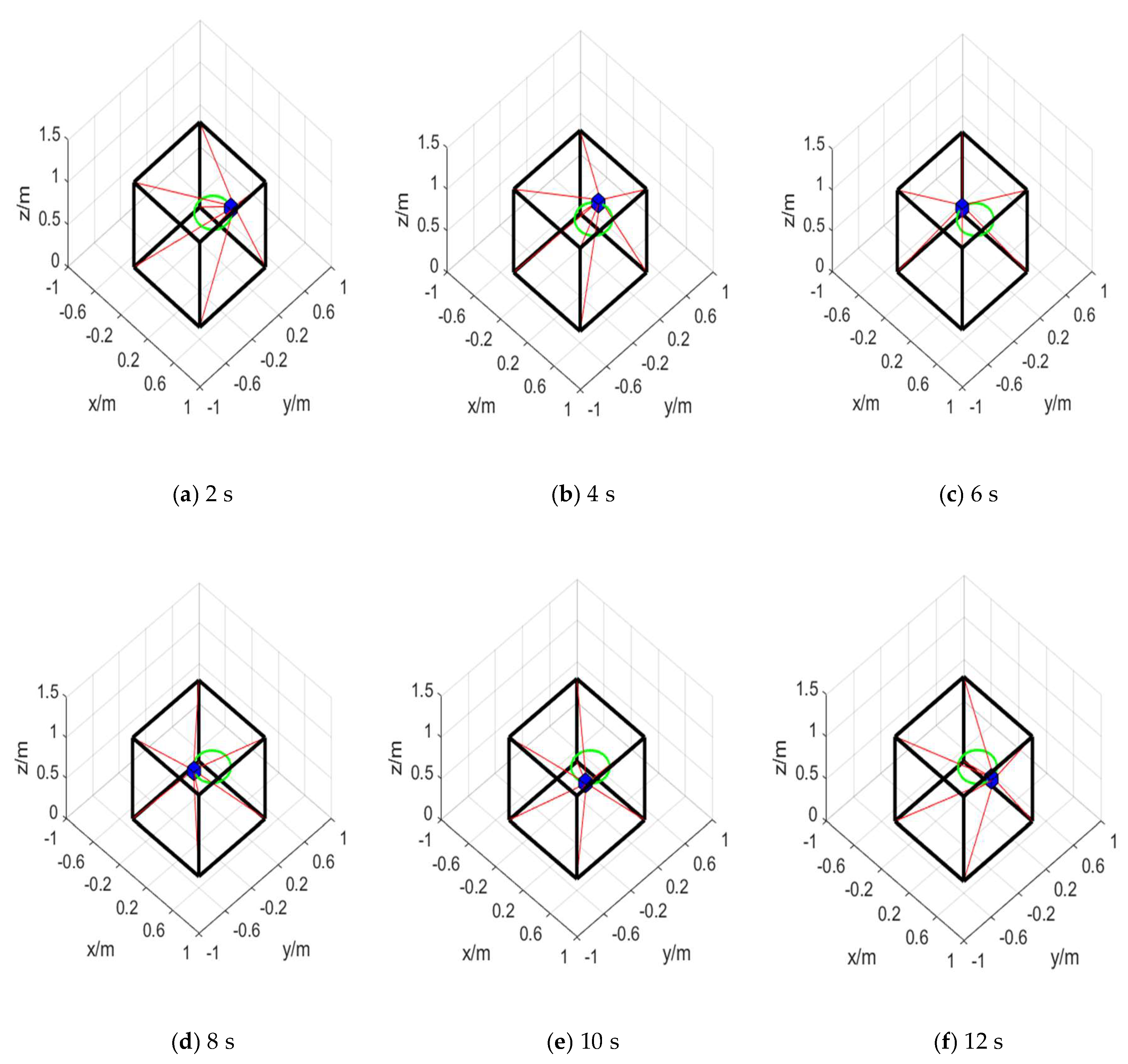

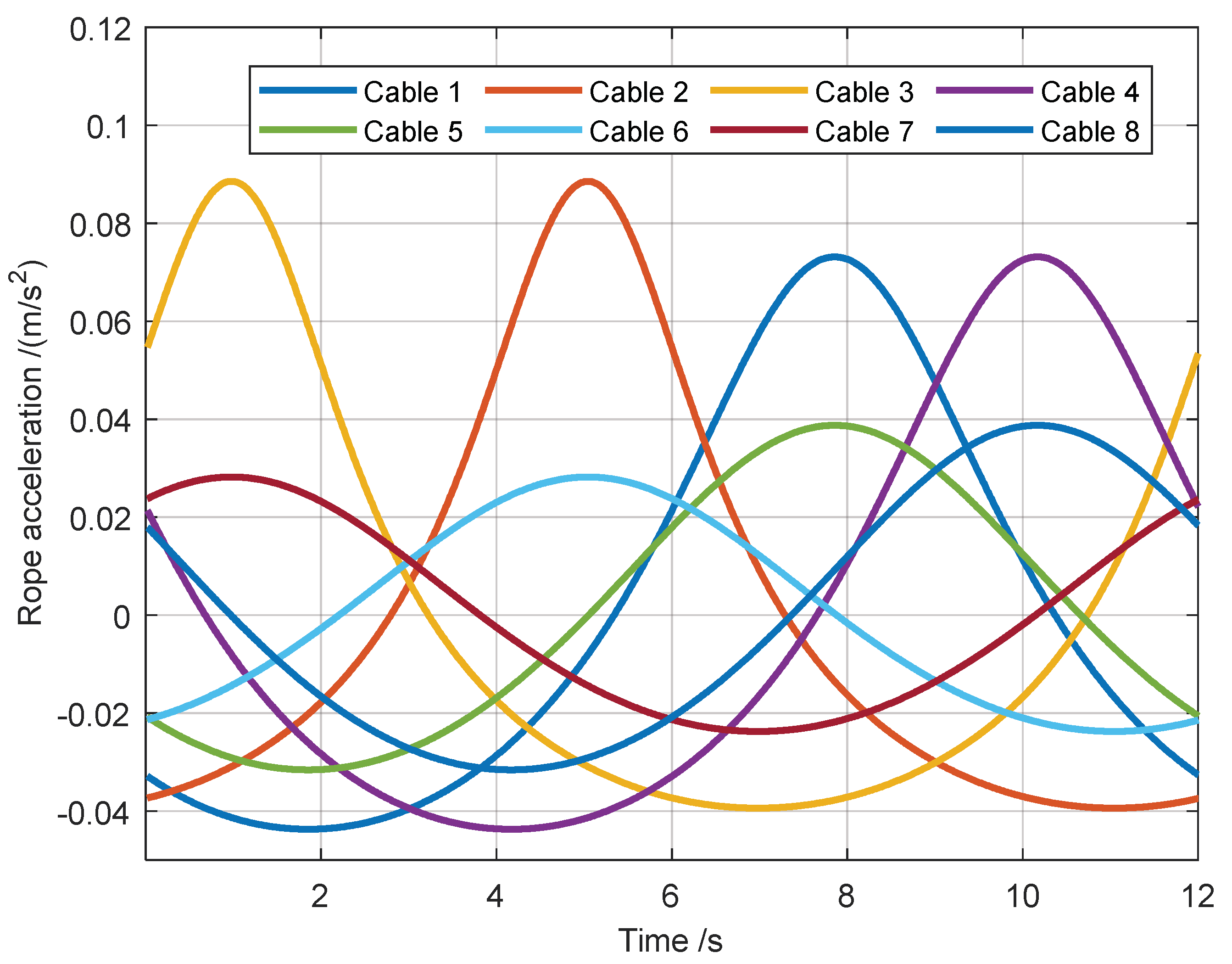

5.1. The Simulation for the End-Effector’s Motion

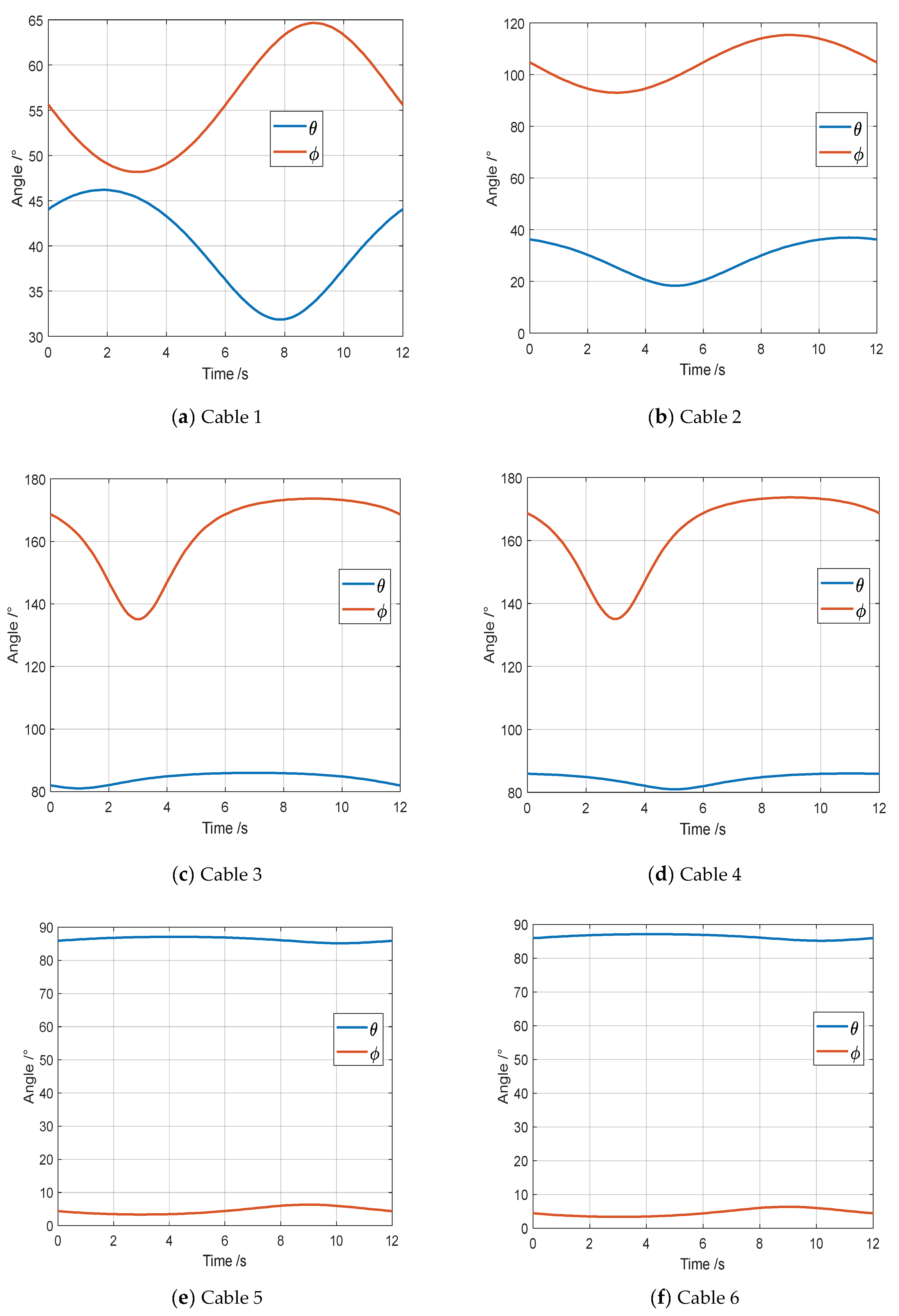

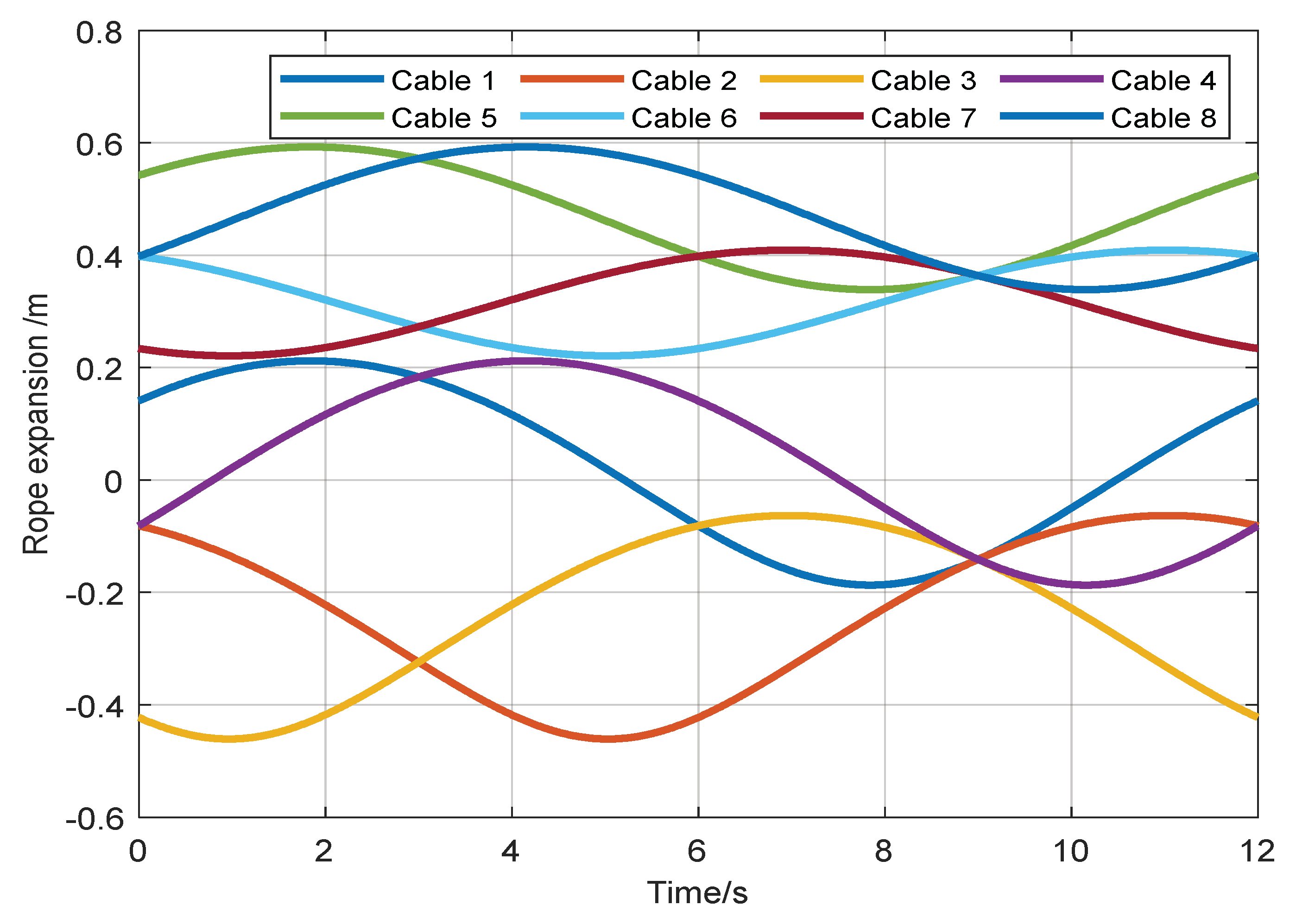

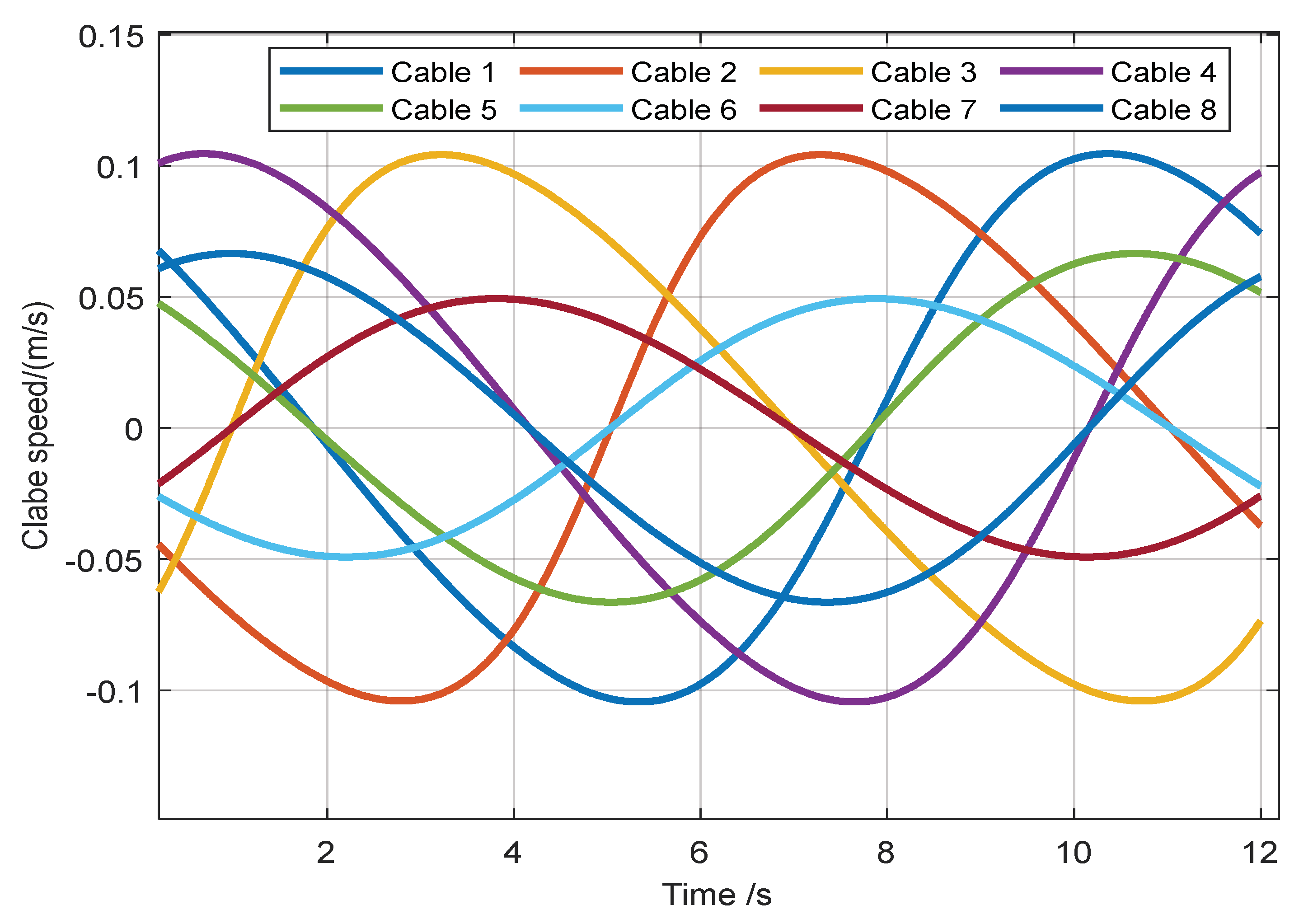

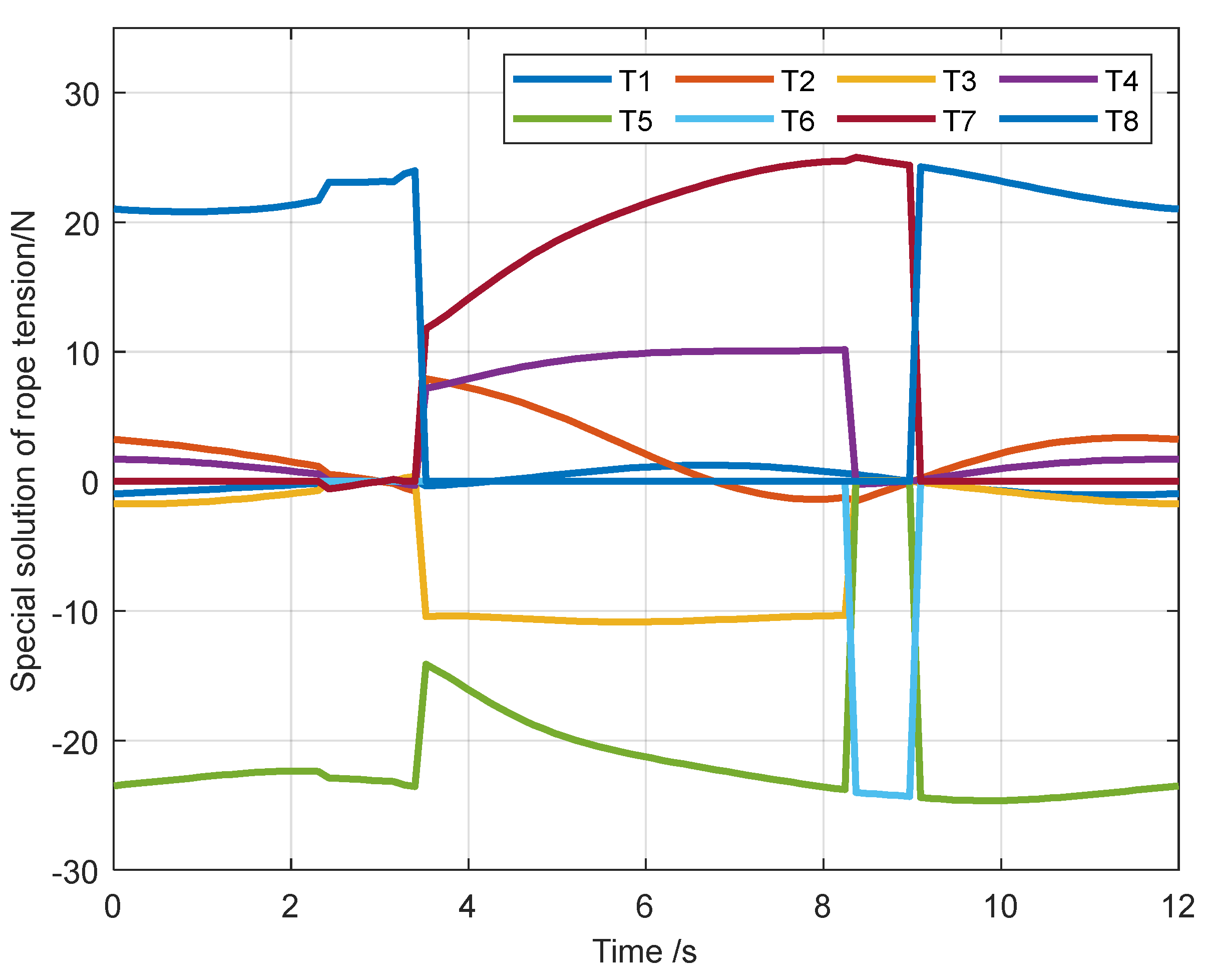

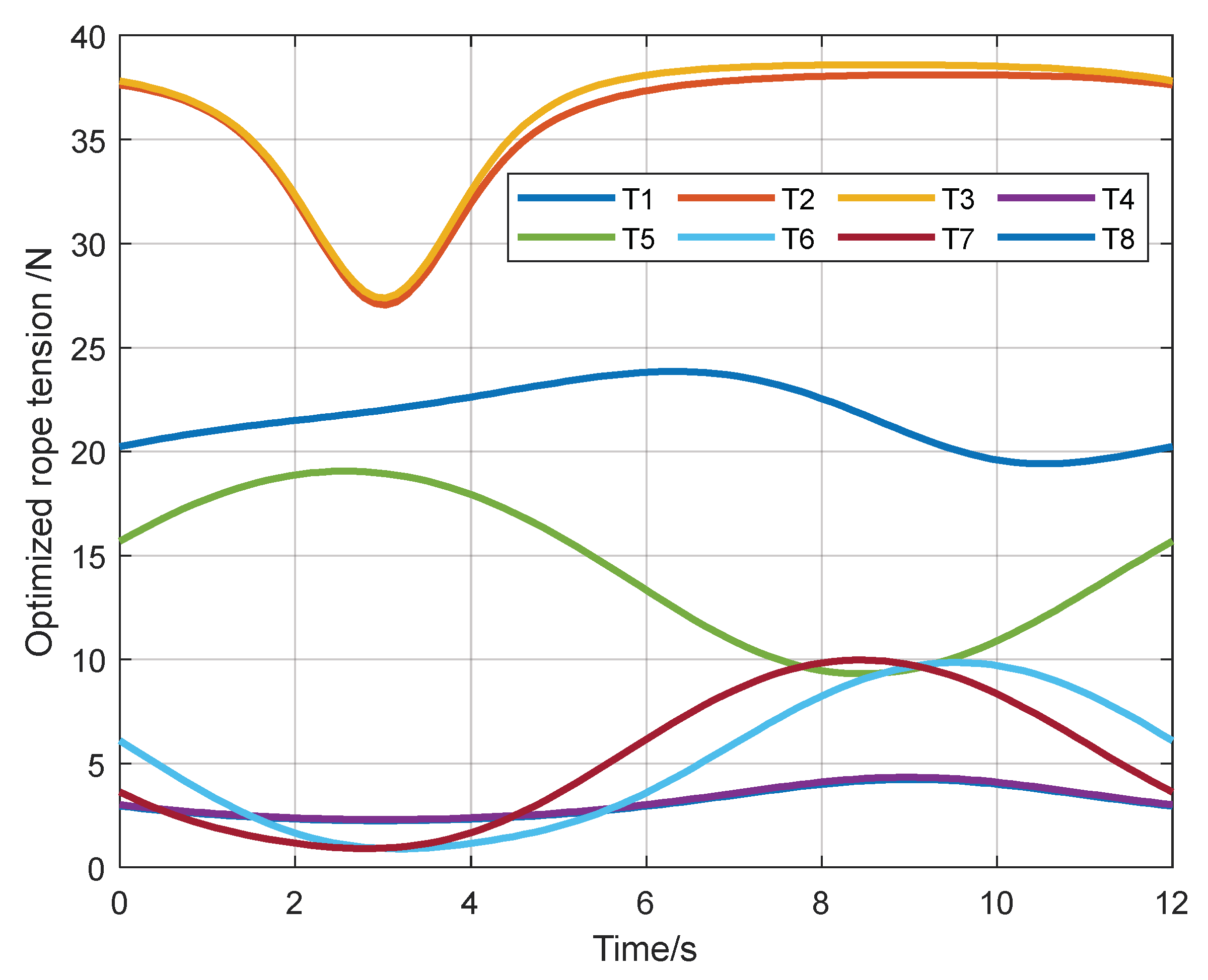

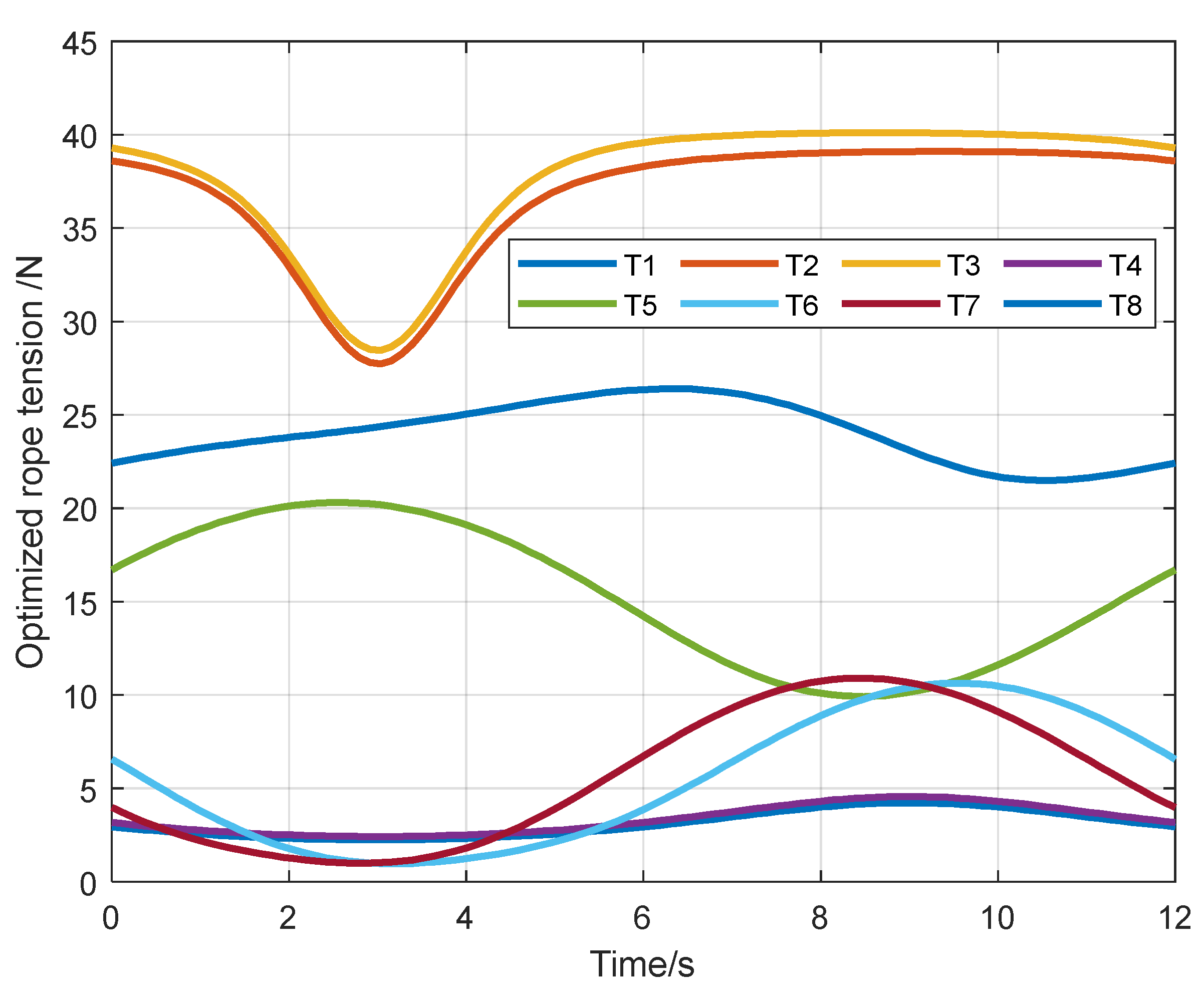

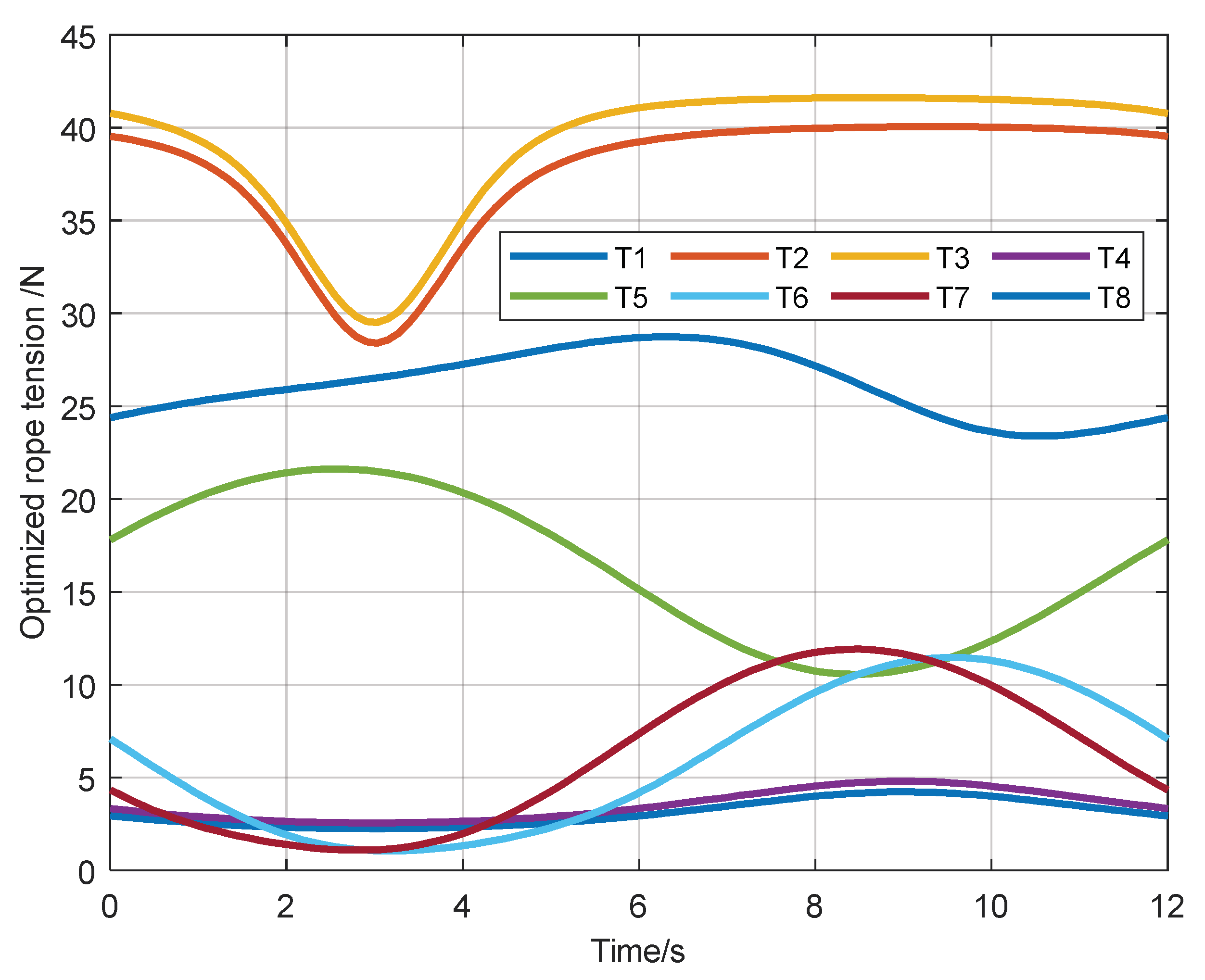

5.2. The Simulation for the Tension Optimization

6. Conclusions

- (1)

- The cable tension optimization method introduced by minimum variance is adopted so that the optimized cable tension is evenly distributed near the average value of the preset extreme tension, and the optimization range of the tension is determined by the extreme tension value.

- (2)

- Taking the improved minimum variance of the correlation force as the optimization objective and using the improved minimum variance method to optimize the cable tension, the change in cable tension by the proposed method is smoother than that of the traditional method. In addition to this, all cable tension curves are continuous. Nevertheless, they are discontinuous for traditional methods.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zarebidoki, M.; Dhupia, J.S.; Xu, W. A review of cable-driven parallel robots: Typical configurations, analysis techniques, and control methods. IEEE Robot. Autom. Mag. 2022, 29, 89–106. [Google Scholar] [CrossRef]

- Mishra, U.A.; Caro, S. Forward kinematics for suspended under-actuated cable-driven parallel robots with elastic cables: A neural network approach. J. Mech. Robot. 2022, 14, 041008. [Google Scholar] [CrossRef]

- Liu, Q.; Ye, L. Design and Research for Industrial Robot Using Goods Sorting in Warehouse. In Proceedings of the 2022 WRC Symposium on Advanced Robotics and Automation (WRC SARA), Beijing, China, 20 August 2022; IEEE: Piscataway, NJ, USA, 2022. [Google Scholar]

- Zaccaria, F.; Idá, E.; Briot, S.; Carricato, M. Workspace computation of planar continuum parallel robots. IEEE Robot. Autom. Lett. 2022, 7, 2700–2707. [Google Scholar] [CrossRef]

- Hou, S.H.; Tang, X.Q.; Cao, L.; Cui, Z.-W.; Sun, H.-H.; Yan, Y.-W. Research on end-force output of 8-cable driven parallel manipulator. Int. J. Autom. Comput. 2020, 17, 378–389. [Google Scholar] [CrossRef]

- Rodriguez-Barroso, A.; Saltaren, R. Tension planner for cable-driven suspended robots with unbounded upper cable tension and two degrees of redundancy. Mech. Mach. Theory 2020, 144, 103675. [Google Scholar] [CrossRef]

- McDonald, E.; Arsenault, M.; Beites, S. Design of a Suspended Cable-Driven Parallel Robot for The Semi-automation of Construction Tasks. In Proceedings of the Canadian Committee for the Theory of Machines and Mechanisms, Québec City, QC, Canada, 19–20 June 2023. [Google Scholar]

- Laribi, M.A.; Carbone, G.; Zeghloul, S. On the optimal design of cable driven parallel robot with a prescribed workspace for upper limb rehabilitation tasks. J. Bionic Eng. 2019, 16, 503–513. [Google Scholar] [CrossRef]

- Zhao, Y.; Liang, C.; Gu, Z.; Zheng, Y.; Wu, Q. A new design scheme for intelligent upper limb rehabilitation training robot. Int. J. Environ. Res. Public Health 2020, 17, 2948. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhang, A.; Li, E.; Guo, R. A review on the environment perception and control technologies for the hyperredundant manipulators in limited space. J. Sens. 2022, 2022, 7659012. [Google Scholar] [CrossRef]

- Qian, S.; Bao, K.; Zi, B.; Wang, N. Kinematic calibration of a cable-driven parallel robot for 3D printing. Sensors 2018, 18, 2898. [Google Scholar] [CrossRef] [PubMed]

- Jung, J. Workspace and stiffness analysis of 3D printing cable-driven parallel robot with a retractable beam-type end-effector. Robotics 2020, 9, 65. [Google Scholar] [CrossRef]

- Zhang, B.; Shang, W.; Cong, S.; Li, Z. Dual-loop dynamic control of cable-driven parallel robots without online tension distribution. IEEE Trans. Syst. Man Cybern. Syst. 2022, 52, 6555–6568. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, K.; Chai, Y.; Mo, Z. Research on mechanical optimization methods of cable-driven lower limb rehabilitation robot. Robotica 2022, 40, 154–169. [Google Scholar] [CrossRef]

- Song, D.; Zhang, L.; Xue, F. Configuration optimization and a tension distribution algorithm for cable-driven parallel robots. IEEE Access 2018, 6, 33928–33940. [Google Scholar] [CrossRef]

- Picard, E.; Caro, S.; Plestan, F.; Claveau, F. Stiffness oriented tension distribution algorithm for cable-driven parallel robots. In Advances in Robot Kinematics 2020; Springer International Publishing: Cham, Switzerland, 2021. [Google Scholar]

- Ameri, A.; Molaei, A.; Khosravi, M.A. Nonlinear observer-based tension distribution for cable-driven parallel robots. In Proceedings of the 5th International Conference on Cable-Driven Parallel Robots, Virtual, 7–9 July 2021; Springer International Publishing: Cham, Switzerland, 2021. [Google Scholar]

- Dao, C.H.K.; Tuong, P.T.; Vu, N.D.; Nguyen, M.N. On Research of Cable Tension Distribution Algorithm for Four Cables-Three DOF Planar Cable-Driven Parallel Robot. J. Tech. Educ. Sci. 2023, 18, 8–17. [Google Scholar] [CrossRef]

- Chen, Y.; Li, J.; Wang, S.; Han, G.; Sun, Y.; Luo, W. Dynamic Modeling and Robust Adaptive Sliding Mode Controller for Marine Cable-Driven Parallel Derusting Robot. Appl. Sci. 2022, 12, 6137. [Google Scholar] [CrossRef]

- Kieu, V.N.D.; Huang, S.-C. Dynamic and wrench-feasible workspace analysis of a cable-driven parallel robot considering a nonlinear cable tension model. Appl. Sci. 2021, 12, 244. [Google Scholar] [CrossRef]

- Cao, S.; Luo, Z.; Quan, C. Real-Time Tension Distribution Design for Cable-Driven Parallel Robot. Appl. Sci. 2022, 13, 10. [Google Scholar] [CrossRef]

- Pott, A.; Bruckmann, T.; Mikelsons, L. Closed-form force distribution for parallel wire robots. In Computational Kinematics, Proceedings of the 5th International Workshop on Computational Kinematics, Forsthausweg, Germany, 6–8 May 2009; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Pott, A. An improved force distribution algorithm for over-constrained cable-driven parallel robots. In Computational Kinematics: Proceedings of the 6th International Workshop on Computational Kinematics (CK2013), Barcelona, Spain, 20–22 May 2013; Springer: Dordrecht, The Netherlands, 2014. [Google Scholar]

- Gouttefarde, M.; Lamaury, J.; Reichert, C.; Bruckmann, T. A versatile tension distribution algorithm for n-DOF parallel robots driven by n + 2 cables. IEEE Trans. Robot. 2015, 31, 1444–1457. [Google Scholar] [CrossRef]

- Lim, W.B.; Yeo, S.H.; Yang, G. Optimization of tension distribution for cable-driven manipulators using tension-level index. IEEE/ASME Trans. Mechatron. 2013, 19, 676–683. [Google Scholar] [CrossRef]

- Parque, V.; Miyashita, T. Optimal Design of Cable-Driven Parallel Robots by Particle Schemes. In Proceedings of the 29th International Conference on Neural Information Processing, Virtual, 22–26 November 2022; Springer Nature: Singapore, 2022. [Google Scholar]

- Choe, W. A Design of Parallel Wire Driven Robots for Ultrahigh Speed Motion Based on Stiffiness Analysis. In Proceedings of the Japan-USA Symposium on Flexible Automation, Boston, MA, USA, 7–10 July 1996. [Google Scholar]

| Constrained Type | Establishment Condition | Example |

|---|---|---|

| Incompletely restrained positioning mechanisms | ||

| Completely restrained positioning mechanisms | ||

| Redundantly restrained positioning mechanisms |

| Technical Parameters | Value |

|---|---|

| Overall size (L·W·H)/(mm·mm·mm) | 1000 × 1000 × 1000 |

| Overall machine mass/(kg) | 30.6 |

| Drive stepper motor torque/(N·M) | 1.91 |

| Cable drum diameter/(cm) | 8 |

| Item | Value | Unit |

|---|---|---|

| The size of the end-effector | 100 × 100 × 100 | mm |

| The number of driven cables | 8 | / |

| Degree of freedom for the end-effector | 6 | / |

| Cable 1–8 | Angle Range | Angle Range |

|---|---|---|

| Cable 1 | ||

| Cable 2 | ||

| Cable 3 | ||

| Cable 4 | ||

| Cable 5 | ||

| Cable 6 | ||

| Cable 7 | ||

| Cable 8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Hu, Z.H.; Zhang, C.S.; Han, Z.W.; Deng, C.W. Dynamic Modeling and Optimization of Tension Distribution for a Cable-Driven Parallel Robot. Appl. Sci. 2024, 14, 6478. https://doi.org/10.3390/app14156478

Wang K, Hu ZH, Zhang CS, Han ZW, Deng CW. Dynamic Modeling and Optimization of Tension Distribution for a Cable-Driven Parallel Robot. Applied Sciences. 2024; 14(15):6478. https://doi.org/10.3390/app14156478

Chicago/Turabian StyleWang, Kai, Zhong Hua Hu, Chen Shuo Zhang, Zhi Wei Han, and Chao Wen Deng. 2024. "Dynamic Modeling and Optimization of Tension Distribution for a Cable-Driven Parallel Robot" Applied Sciences 14, no. 15: 6478. https://doi.org/10.3390/app14156478