Mechanical Properties of Cement Concrete with Waste Rubber Powder

Abstract

:1. Introduction

2. Materials and Methods

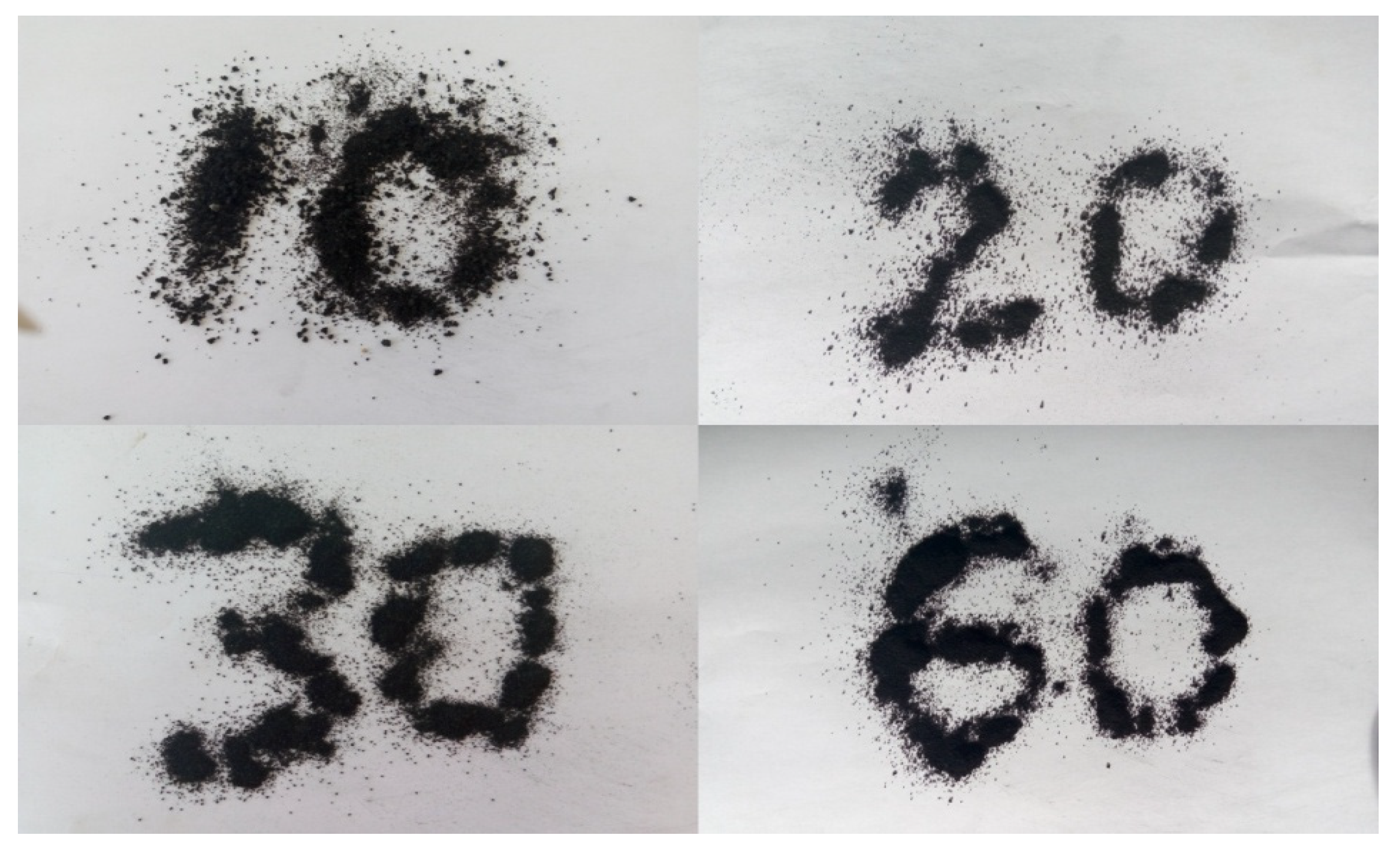

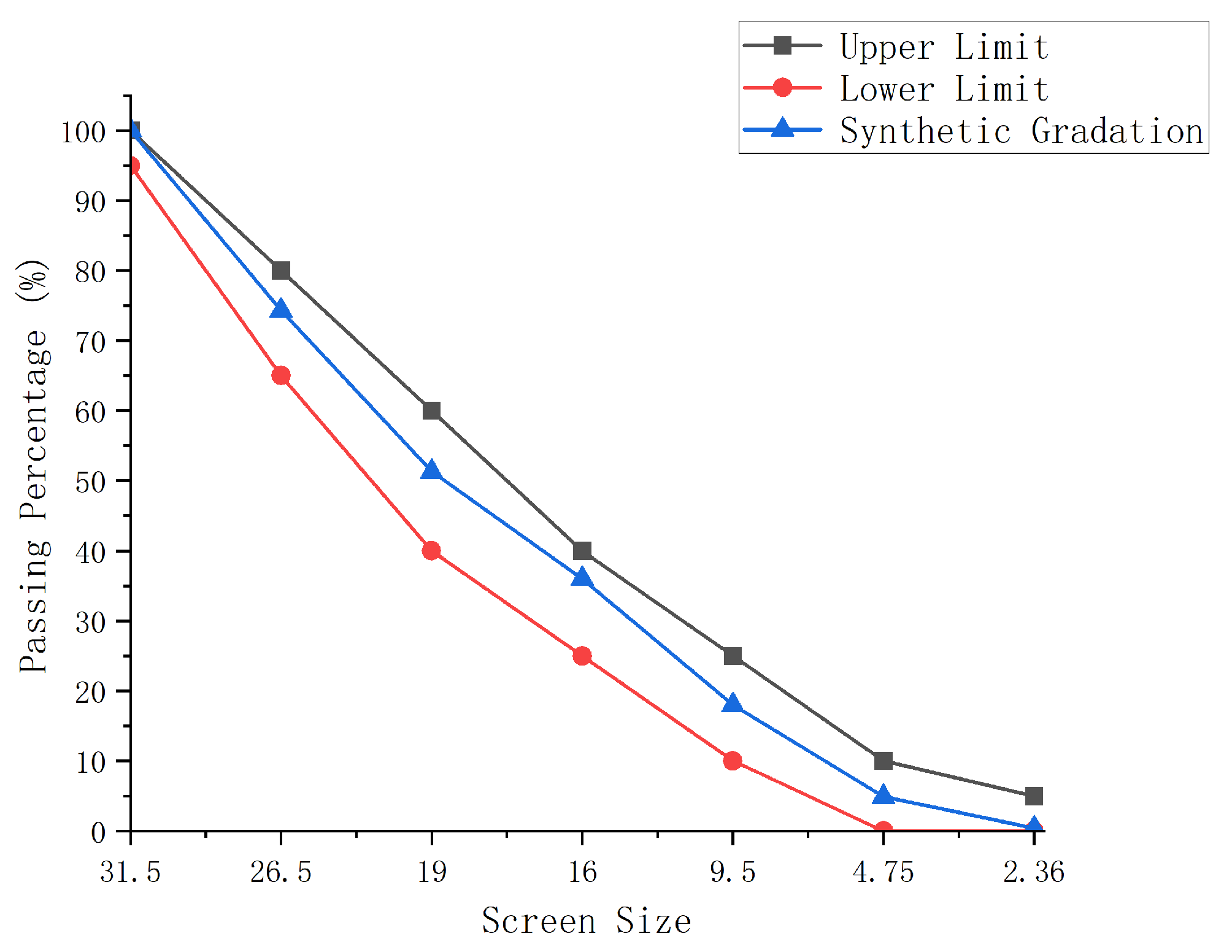

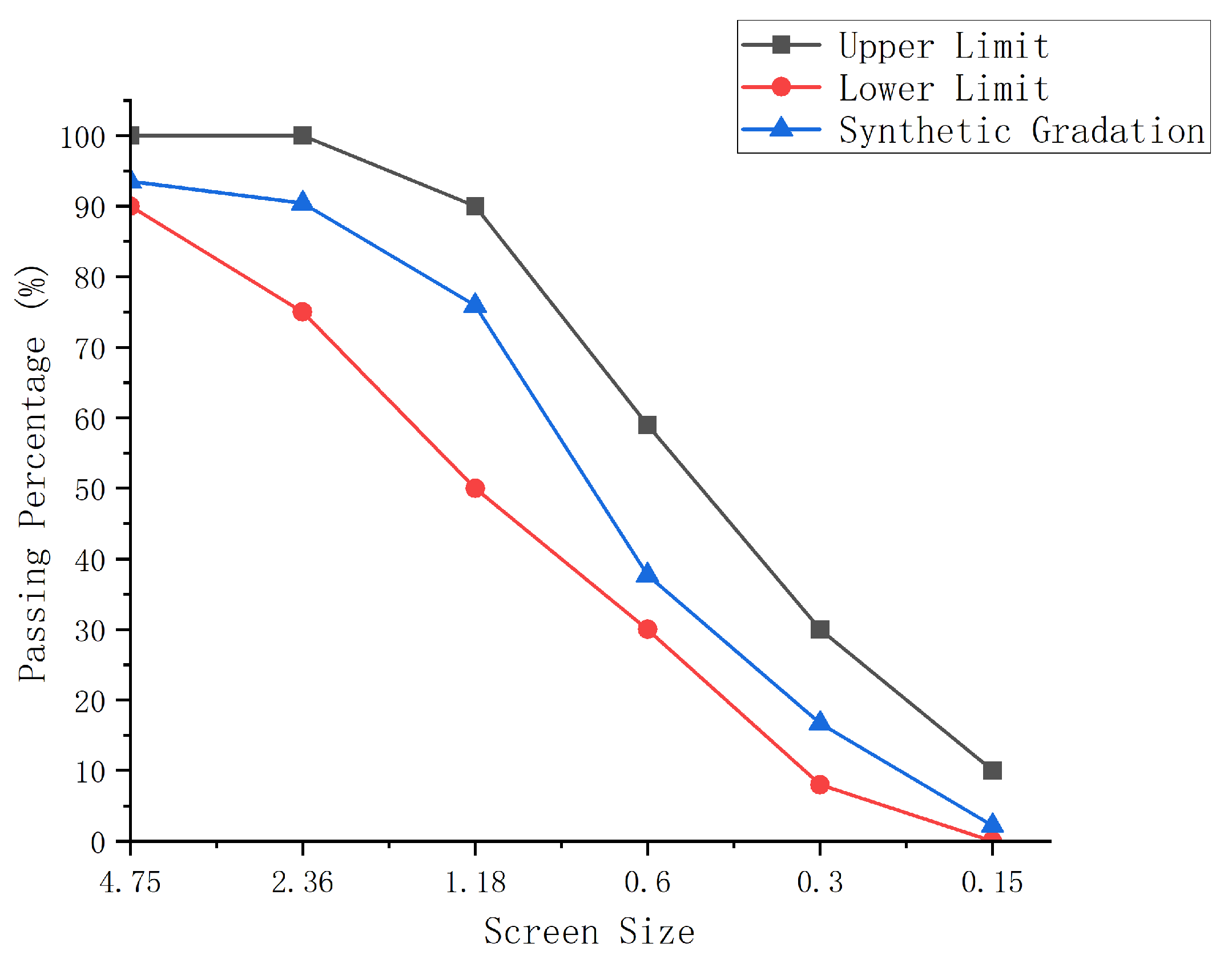

2.1. Materials

2.2. Response Surface Methodology (RSM)

2.3. Methods

2.3.1. Specimens Preparation

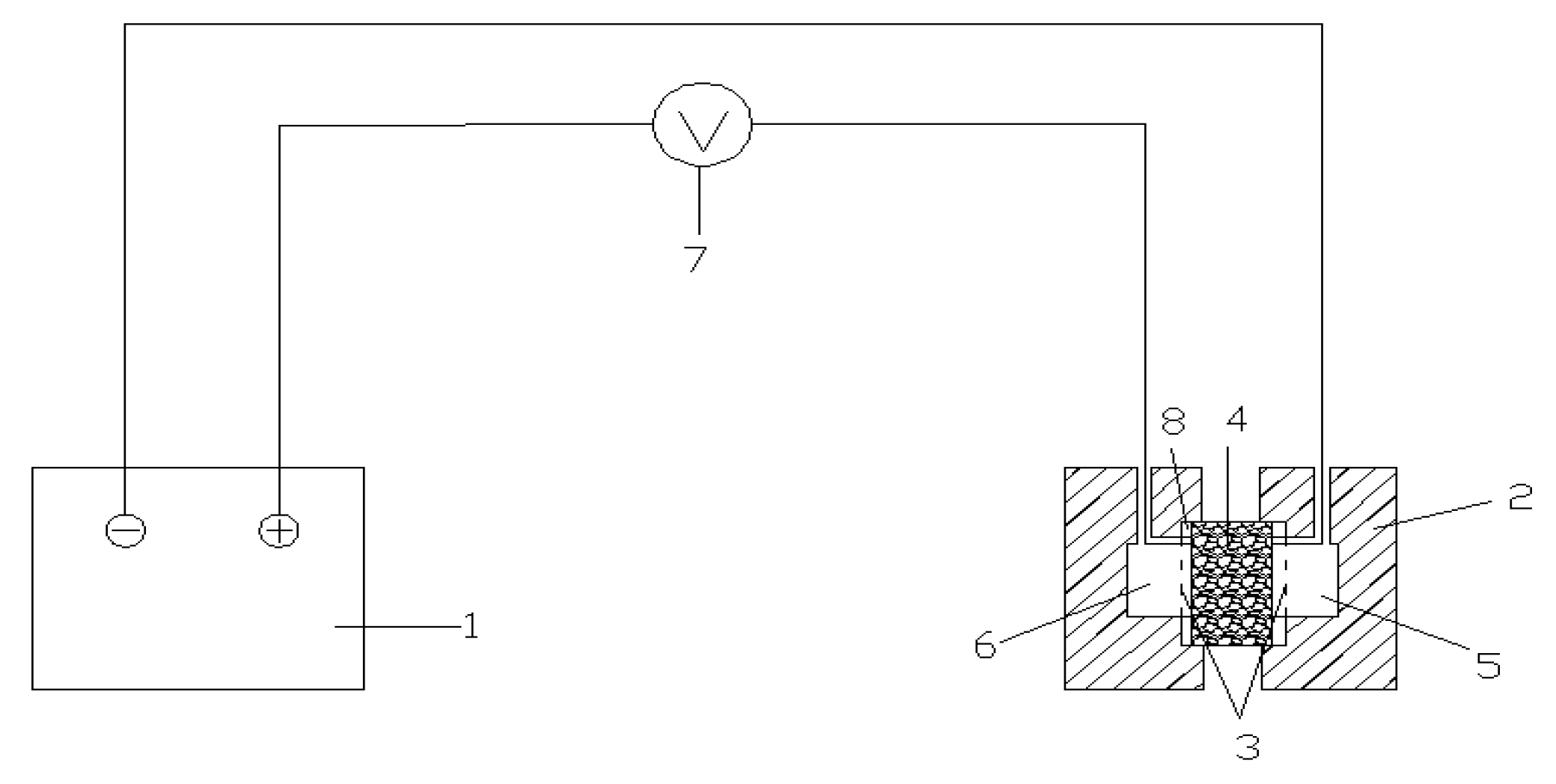

2.3.2. Impact Resistance

2.3.3. Noise Reduction

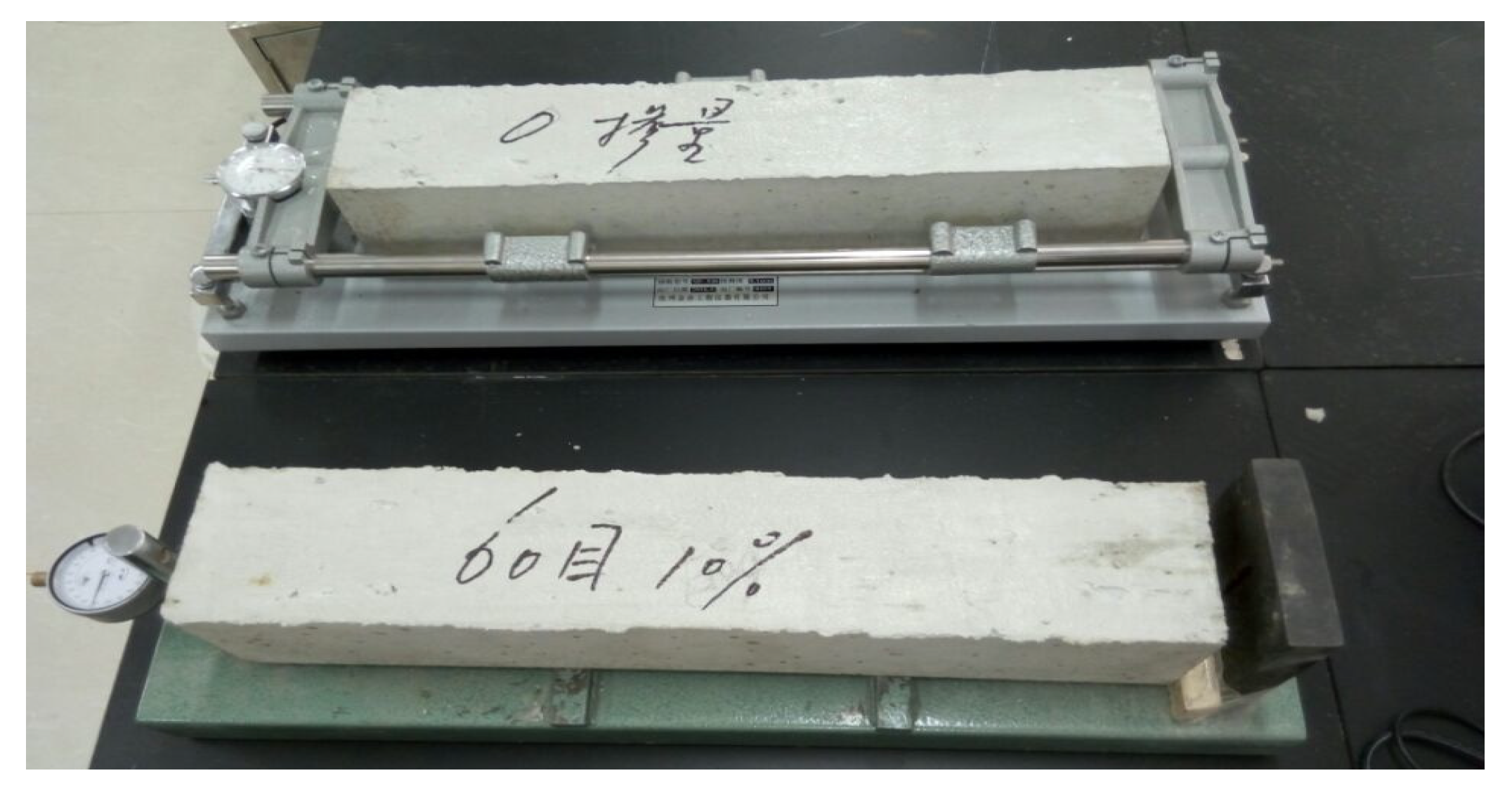

2.3.4. Shrinkage

2.3.5. Impermeability

2.3.6. Freezing Resistance

3. Results and Discussion

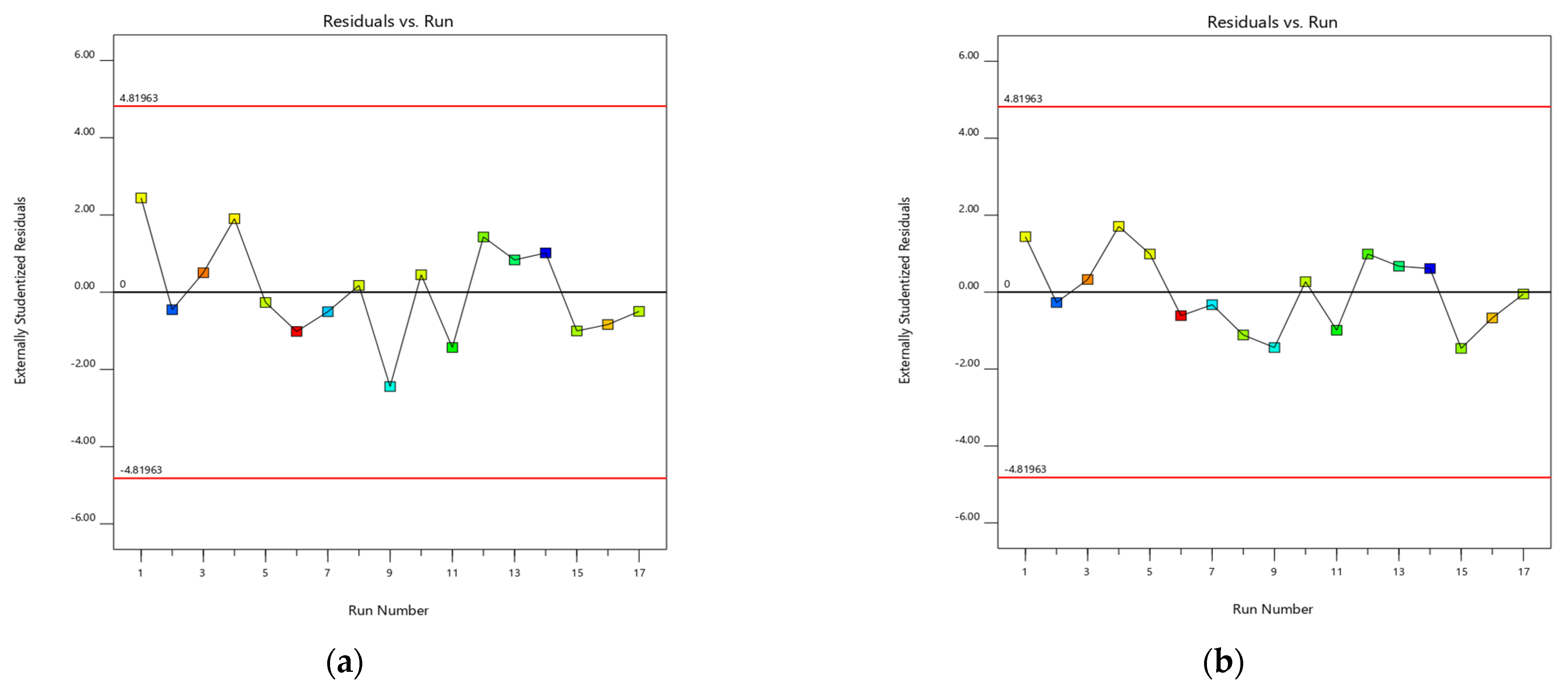

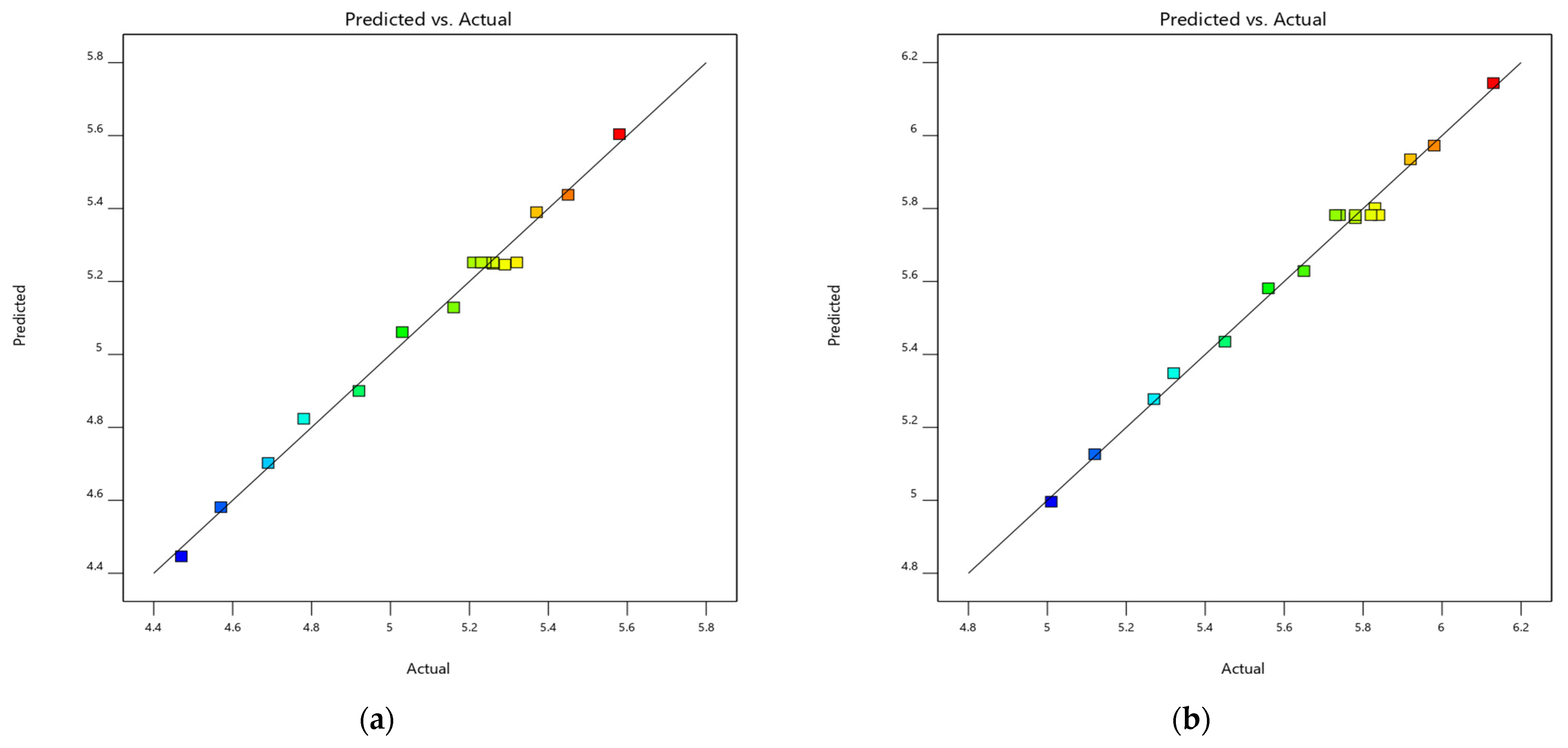

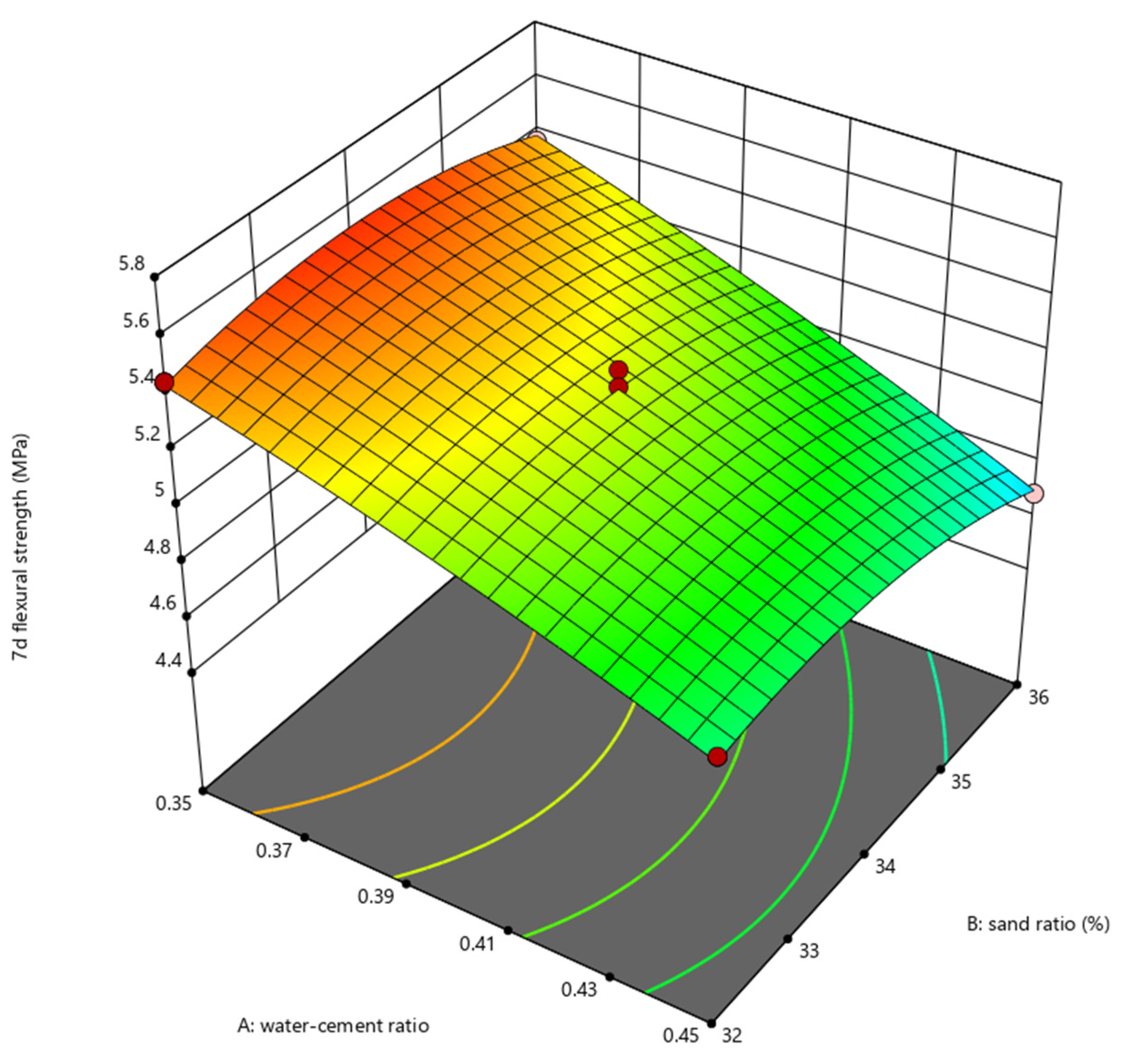

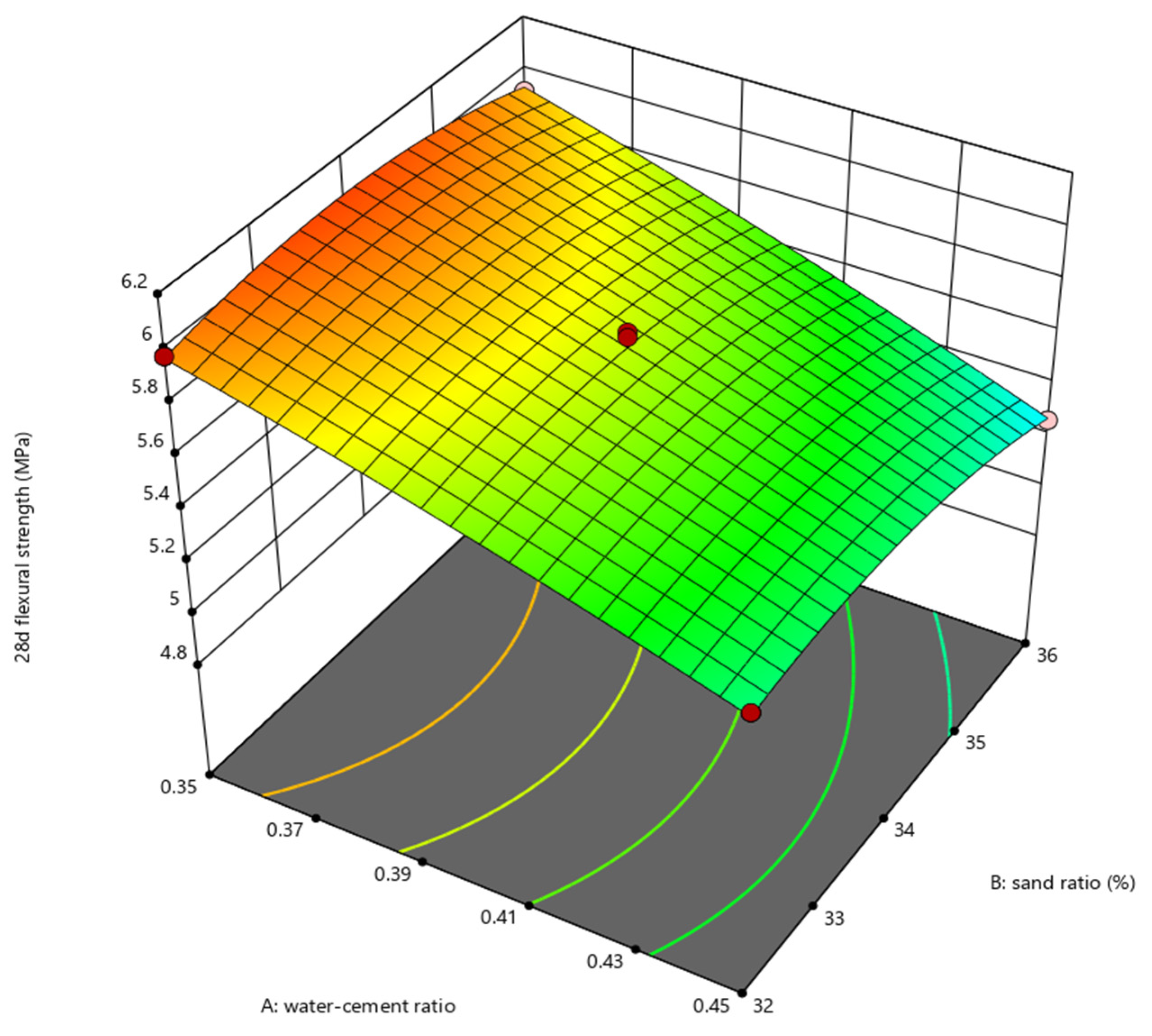

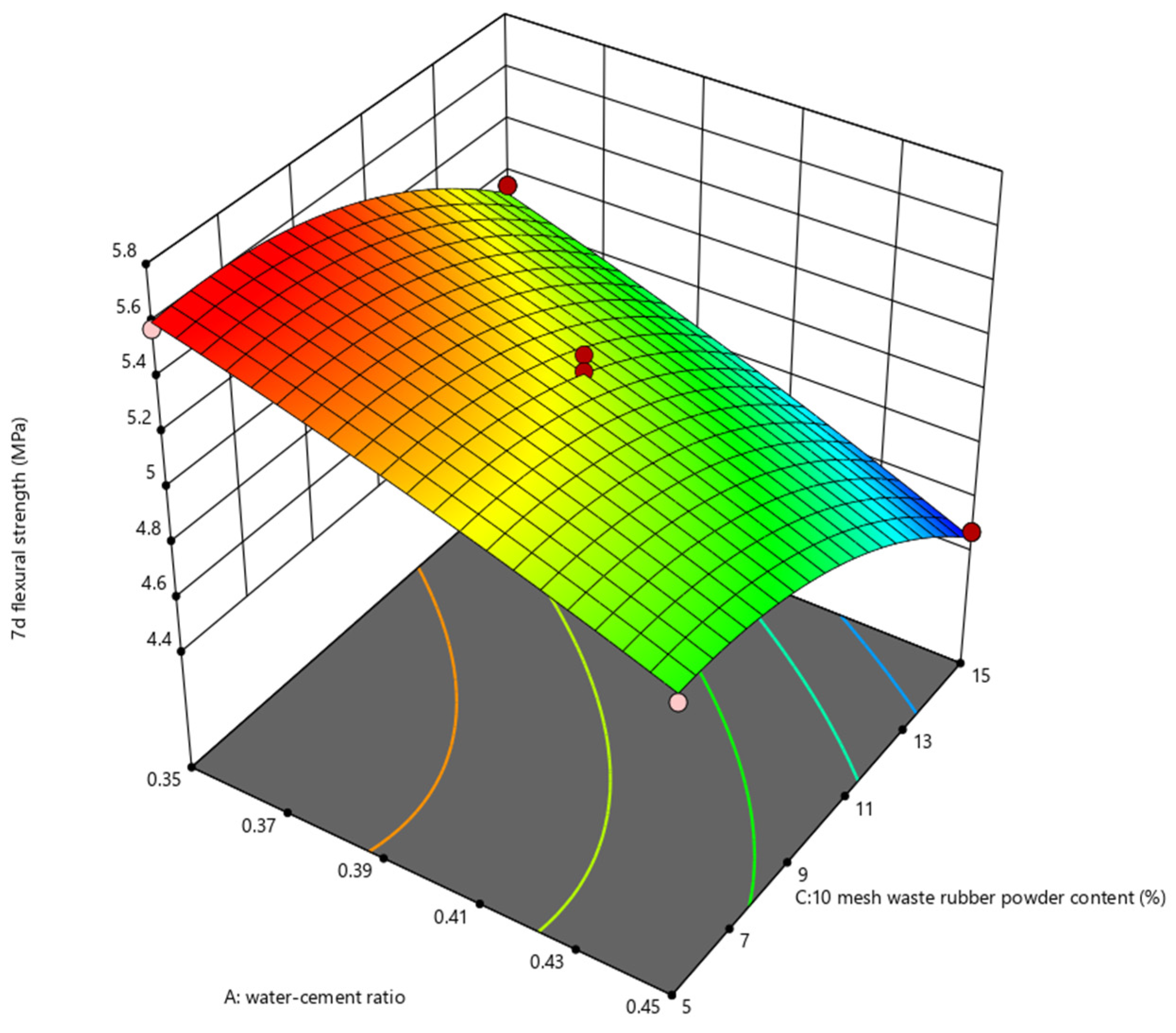

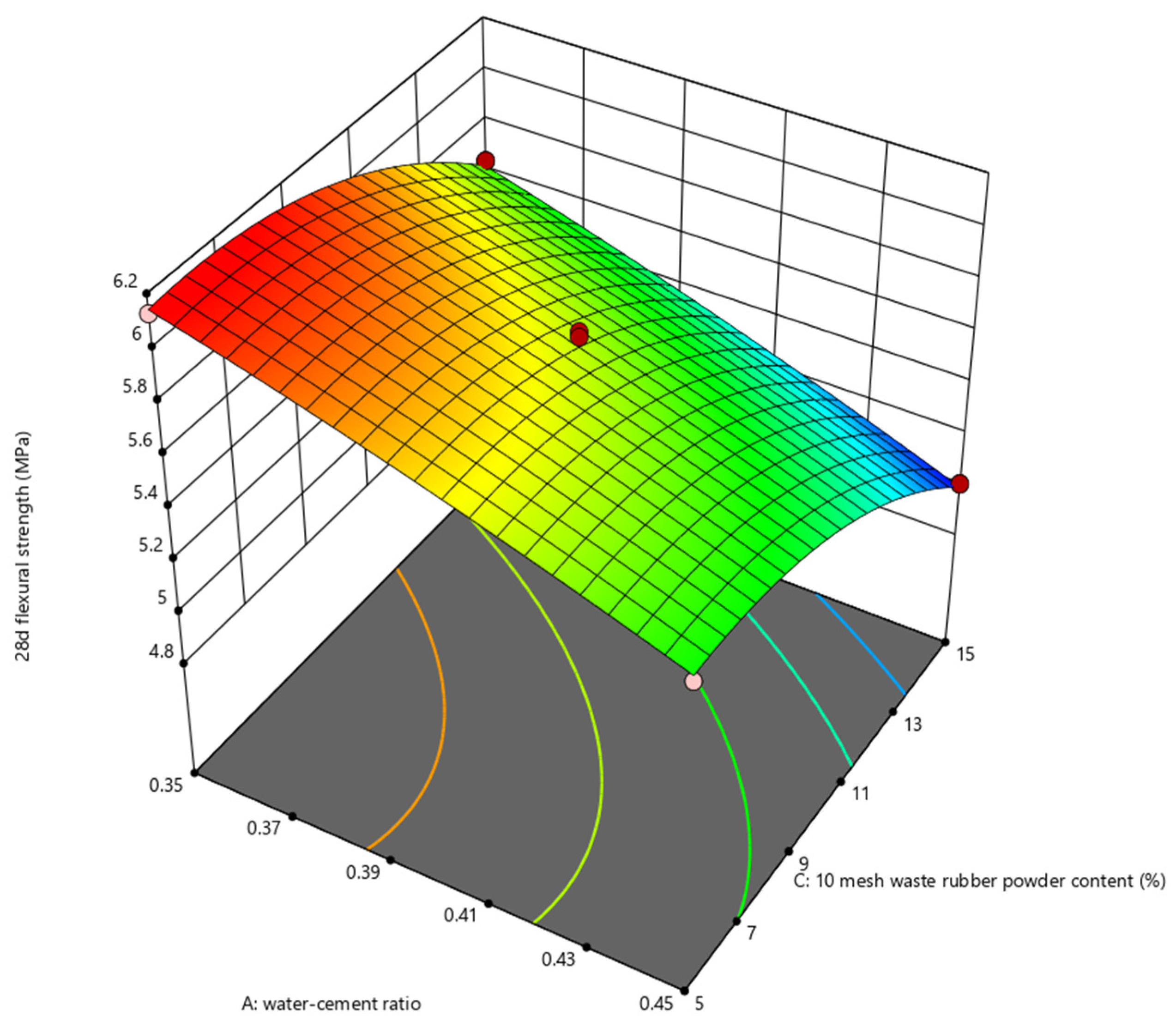

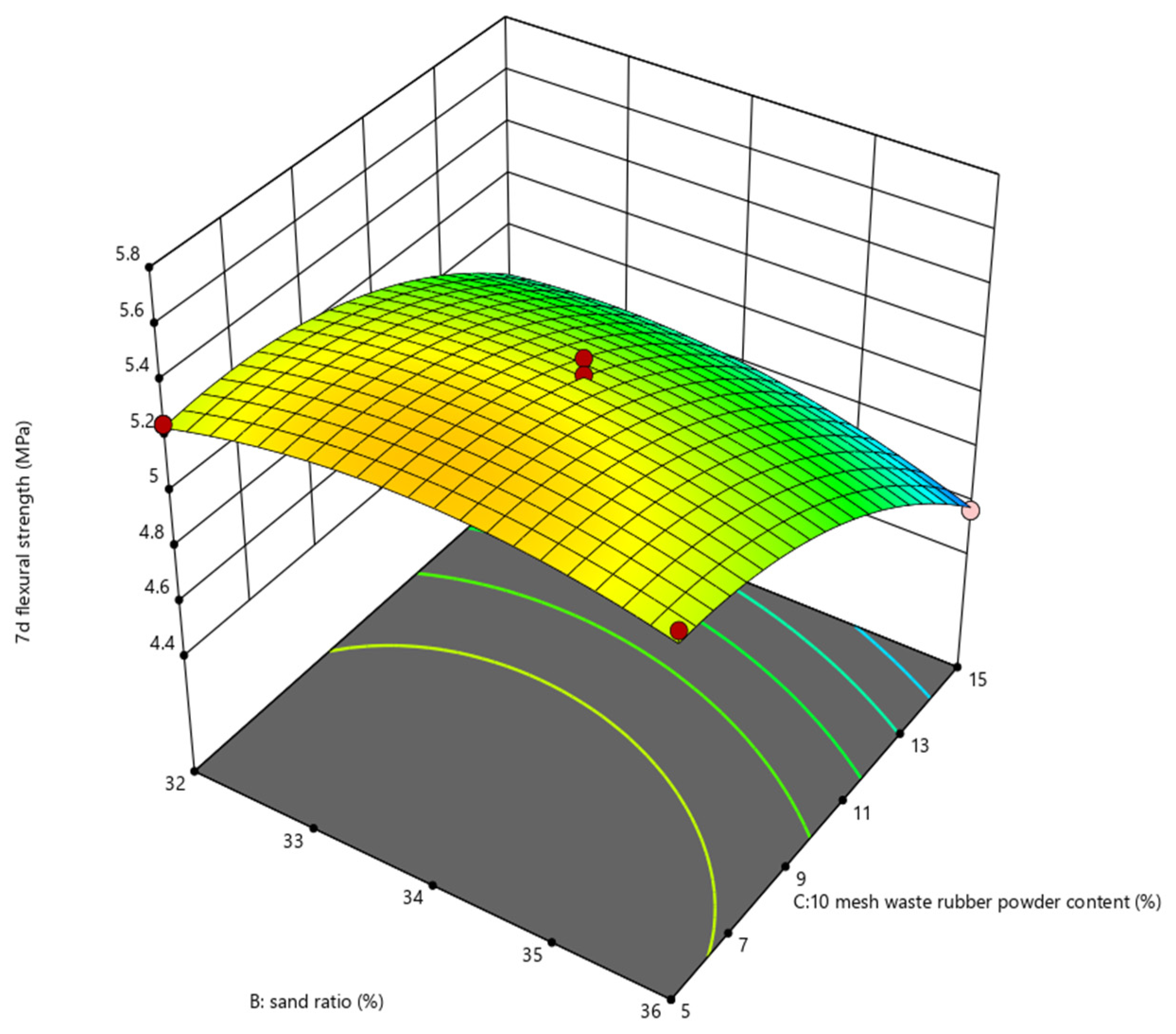

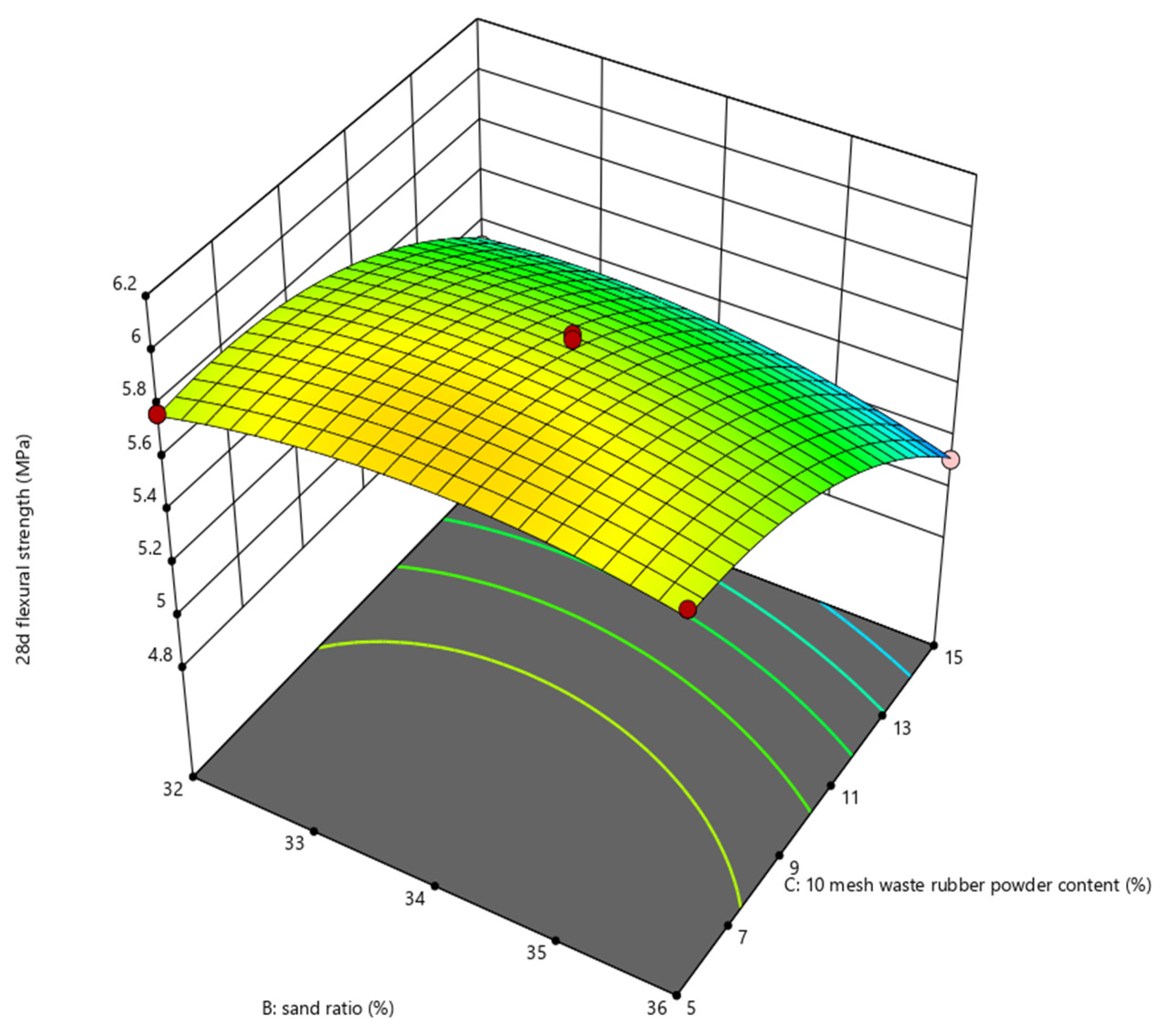

3.1. Optimal Design Based on the Mix Design of the RSM

3.2. Influence of Waste Rubber Powder Concrete Composition Materials

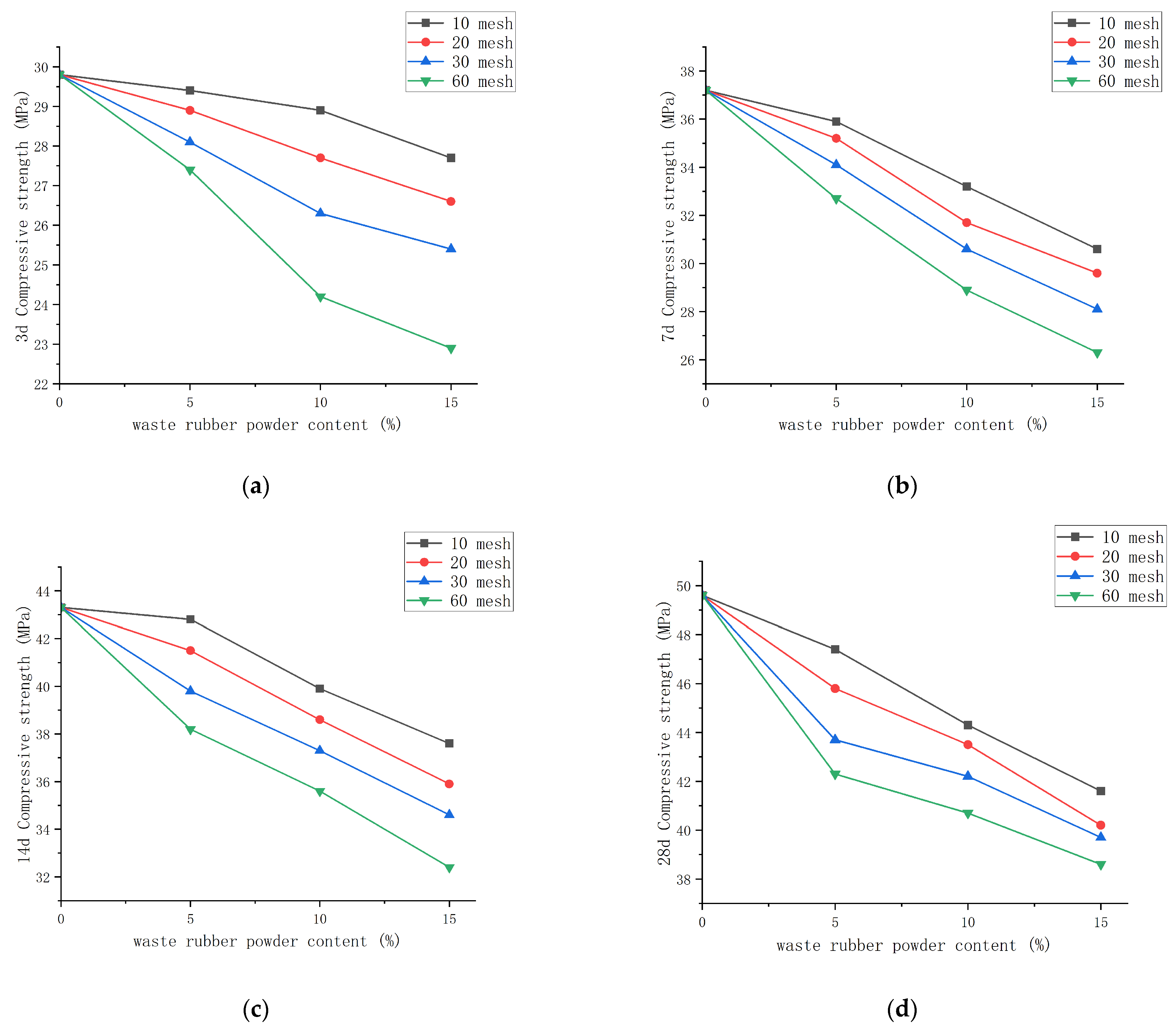

3.3. Compressive Strength

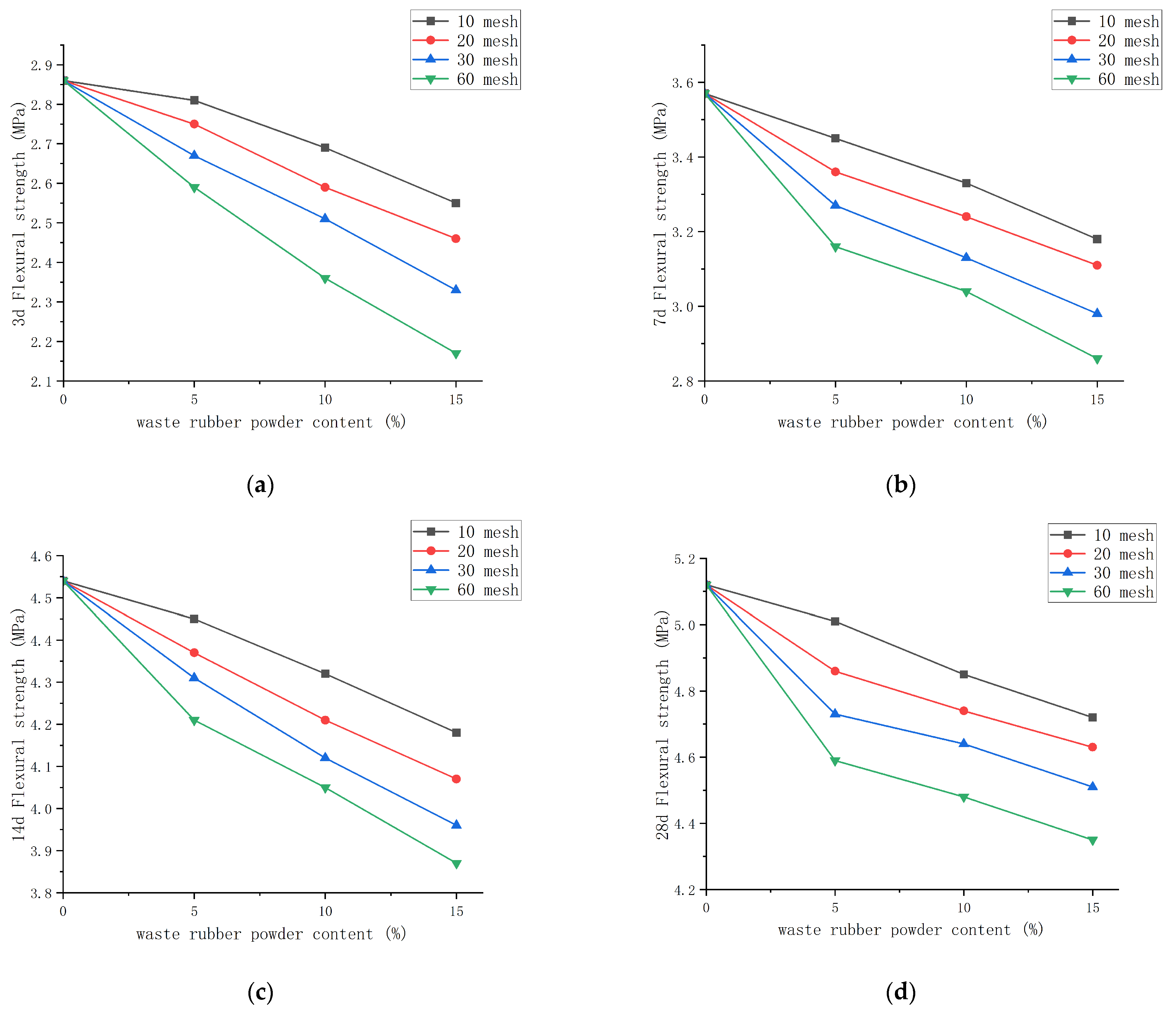

3.4. Flexural Strength

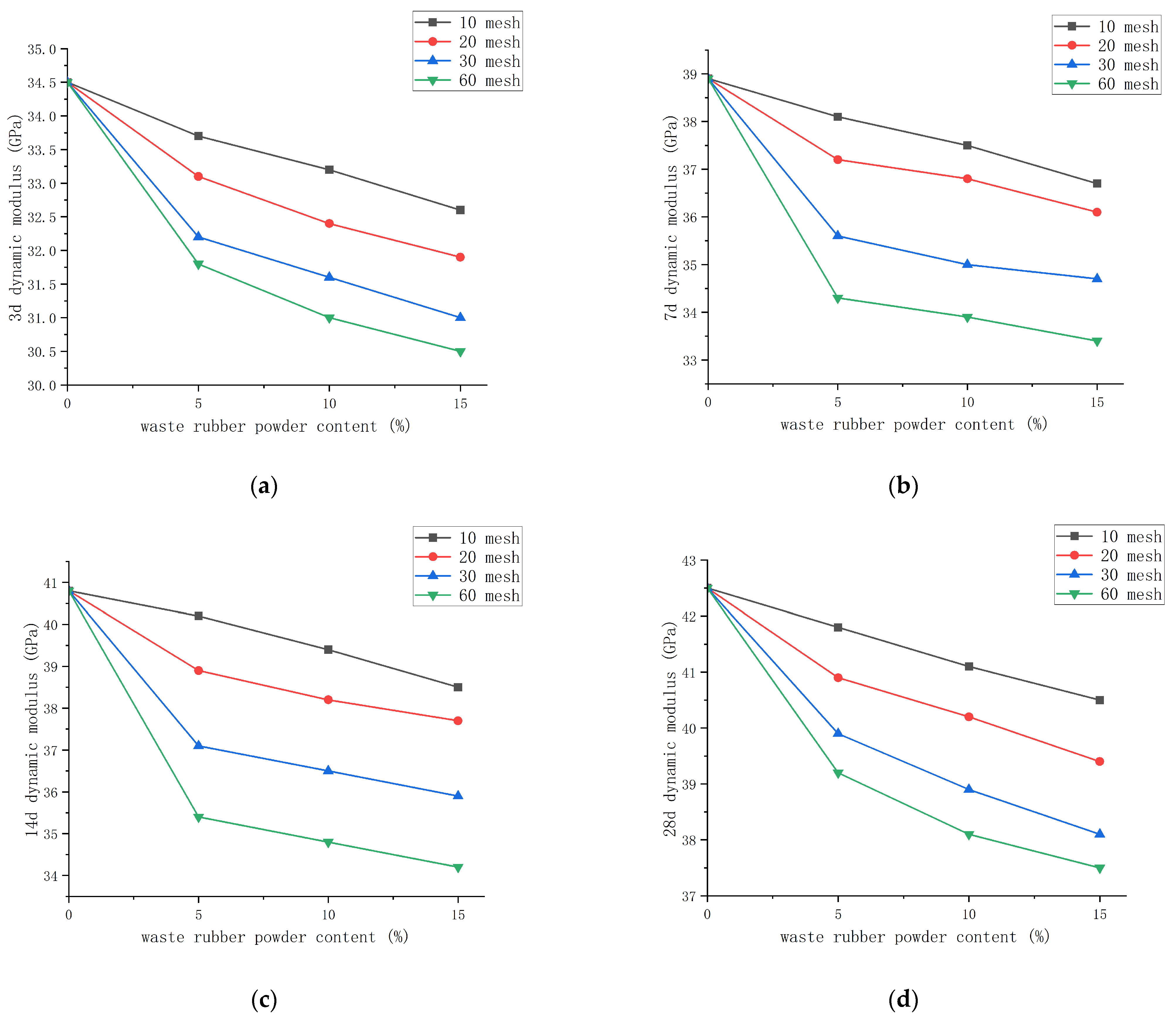

3.5. Dynamic Modulus

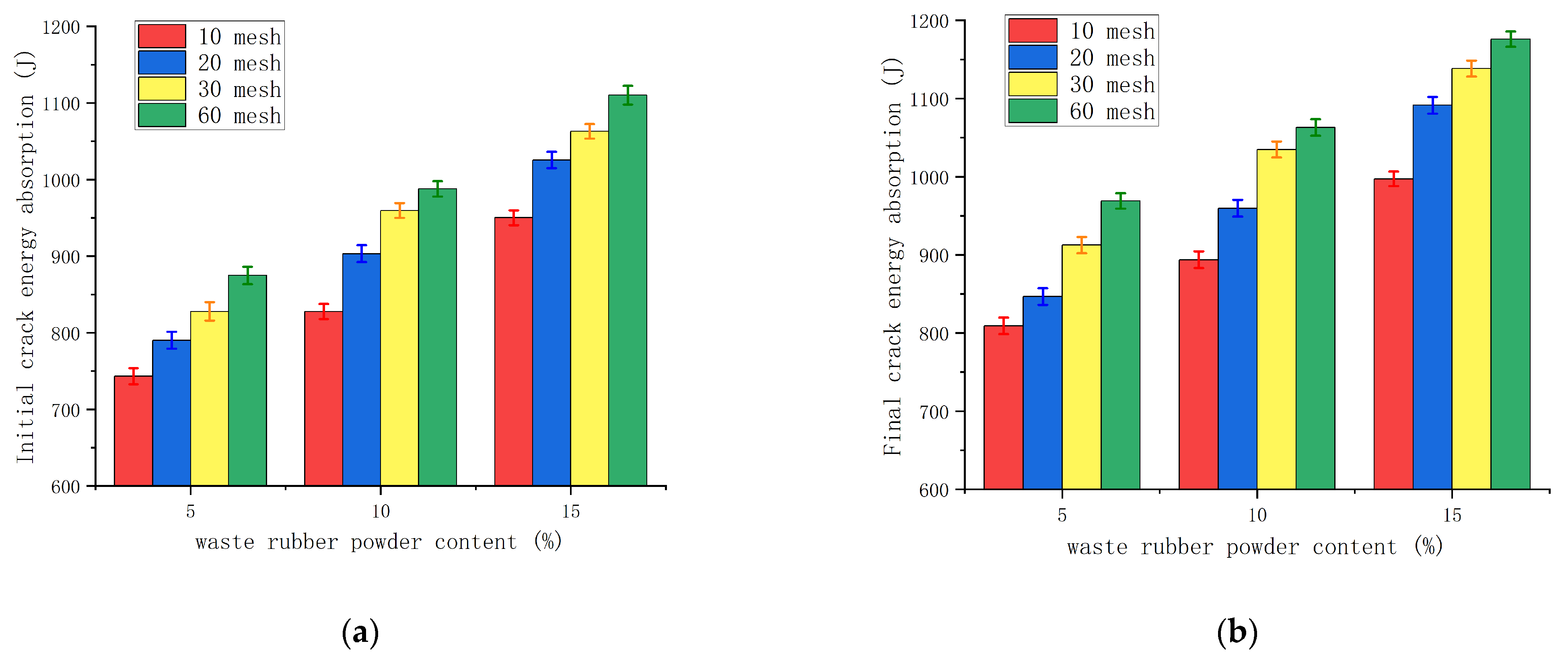

3.6. Impact Resistance

3.7. Noise Reduction

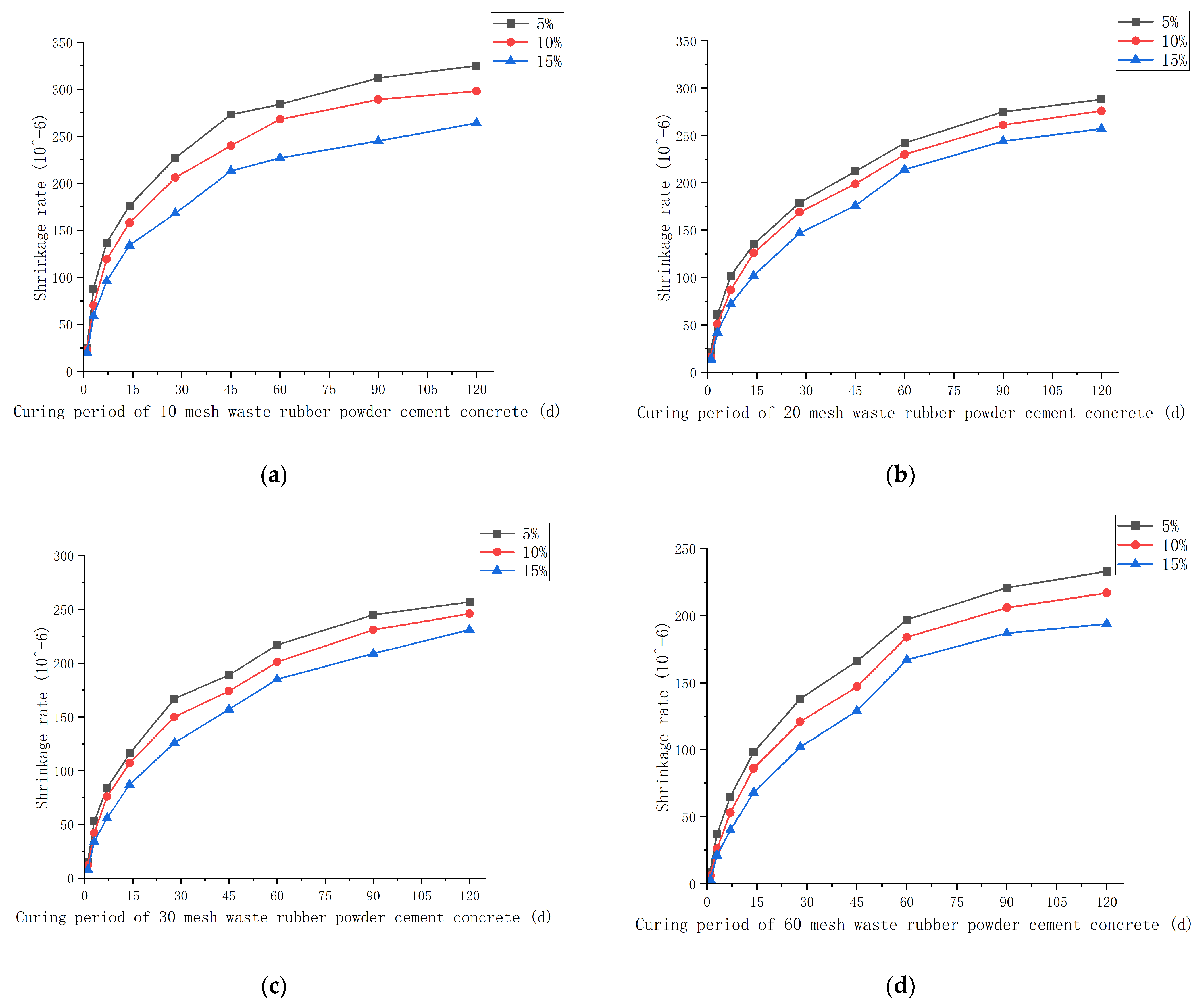

3.8. Shrinkage

3.9. Impermeability

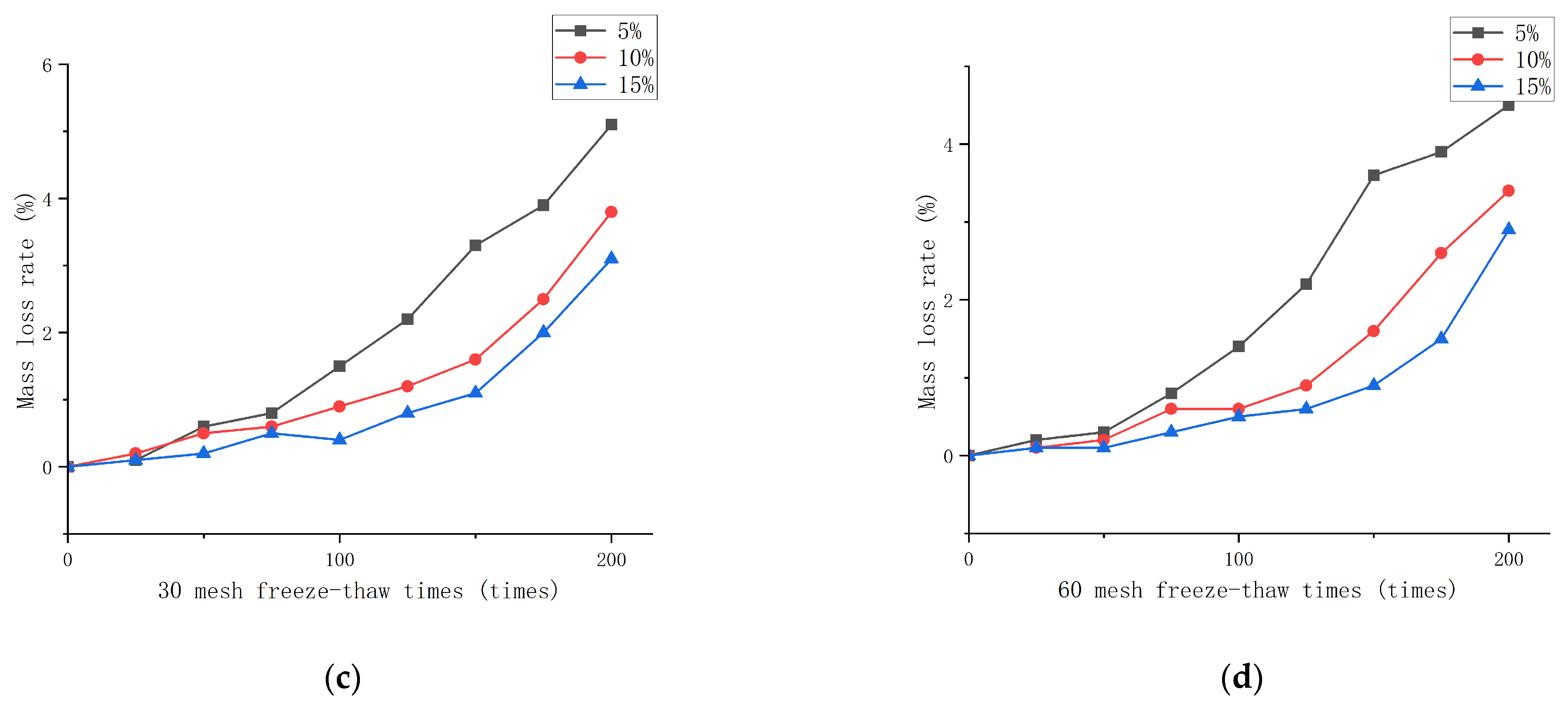

3.10. Freezing Resistance

4. Conclusions

- (1)

- Among the three influencing factors—the water–cement ratio, sand ratio, and waste rubber powder content—the optimization design results indicate that when the water-cement ratio was held constant and the sand ratio was maintained between 33% and 36%, the waste rubber powder content should not exceed 10%. Additionally, it was observed that the water–cement ratio exerted the most significant influence on the flexural strength of cement concrete, whereas the sand ratio had the least impact.

- (2)

- Both the particle size and content of waste rubber powder significantly influenced the mechanical properties of cement concrete. Specifically, under consistent mesh sizes, increasing content led to a decline in compressive strength, flexural strength, and dynamic elastic modulus; conversely, at constant content levels, larger mesh sizes corresponded to lower compressive strength, flexural strength, and dynamic elastic modulus. Furthermore, impact resistance tests revealed that higher content and smaller particle sizes of waste rubber powder enhanced the concrete’s crack resistance. Statistical analysis utilizing the two-parameter Weibull distribution can be employed to assess the initial crack impact number (N1) and final crack impact number (N2) of waste rubber powder cement concrete.

- (3)

- Among the waste rubber powders, the 10-mesh variant exhibited the most pronounced noise reduction effect, whereas the 20-mesh, 30-mesh, and 60-mesh varieties showed comparable noise reduction effects in concrete. Moreover, an increase in waste rubber powder content correlated with improved noise reduction capability.

- (4)

- Waste rubber powder addition resulted in decreased drying shrinkage of cement concrete. Moreover, larger content and mesh size led to reduced drying shrinkage. Conversely, under constant content, impermeability increased with higher mesh sizes of waste rubber powder; meanwhile, with consistent mesh size, impermeability rose with increasing content, although the impact on concrete impermeability was more pronounced. Additionally, the mass loss rate of waste rubber powder cement concrete decreased with greater mesh size of waste rubber powder, and higher content correlated with lower mass loss rates.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ming, X.; Cao, M. Development of Eco-Efficient Cementitious Composites with High Fire Resistance and Self-Healing Abilities-a Review. Resour. Conserv. Recycl. 2020, 162, 105017. [Google Scholar] [CrossRef]

- Bhardwaj, B.; Kumar, P. Waste Foundry Sand in Concrete: A Review. Constr. Build. Mater. 2017, 156, 661–674. [Google Scholar] [CrossRef]

- Aprianti, S.E. A Huge Number of Artificial Waste Material Can Be Supplementary Cementitious Material (SCM) for Concrete Production—A Review Part II. J. Clean. Prod. 2017, 142, 4178–4194. [Google Scholar] [CrossRef]

- Marinelli, S.; Marinello, S.; Lolli, F.; Gamberini, R.; Coruzzolo, A.M. Waste Plastic and Rubber in Concrete and Cement Mortar: A Tertiary Literature Review. Sustainability 2023, 15, 7232. [Google Scholar] [CrossRef]

- Marques, B.; António, J.; Almeida, J.; Tadeu, A.; de Brito, J.; Dias, S.; Pedro, F.; Sena, J.D. Vibro-Acoustic Behaviour of Polymer-Based Composite Materials Produced with Rice Husk and Recycled Rubber Granules. Constr. Build. Mater. 2020, 264, 120221. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z.; Majdi, A.; Alqurashi, M.; Deifalla, A.F. Overview of Concrete Performance Made with Waste Rubber Tires: A Step toward Sustainable Concrete. Materials 2022, 15, 5518. [Google Scholar] [CrossRef]

- Nasir, N.A.M.; Bakar, N.B.; Safiee, N.A.; Aziz, F.N.A.A.; Archnaah, N. Mechanical Properties of Blended-Rubberized Concrete. J. Phys. Conf. Ser. 2023, 2521, 012016. [Google Scholar] [CrossRef]

- Wu, Y.-F.; Kazmi, S.M.S.; Munir, M.J.; Zhou, Y.; Xing, F. Effect of Compression Casting Method on the Compressive Strength, Elastic Modulus and Microstructure of Rubber Concrete. J. Clean. Prod. 2020, 264, 121746. [Google Scholar] [CrossRef]

- Soren, A.K. A Laboratory Study of Use of Crumb Rubber as Partial Replacement of Fine Aggregate in Concrete. Int. J. Res. Appl. Sci. Eng. Technol. 2023, 11, 1631–1651. [Google Scholar] [CrossRef]

- Chicoma, A.; Quiroz, R.; Muñoz, S.; Villena, L. Influence of the Physical and Mechanical Properties of Concrete by Adding Rubber Powder and Silica Fume. J. Sustain. Archit. Civ. Eng. 2023, 32, 205–223. [Google Scholar] [CrossRef]

- Lakhiar, M.T.; Kong, S.Y.; Bai, Y.; Susilawati, S.; Zahidi, I.; Paul, S.C.; Raghunandan, M.E. Thermal and Mechanical Properties of Concrete Incorporating Silica Fume and Waste Rubber Powder. Polymers 2022, 14, 4858. [Google Scholar] [CrossRef]

- Zhai, S.; Liu, C.; Liu, G.; Pang, B.; Zhang, L.; Liu, Z.; Liu, L.; Zhang, Y. Effect of Modified Rubber Powder on the Mechanical Properties of Cement-Based Materials. J. Mater. Res. Technol. 2022, 19, 4141–4153. [Google Scholar] [CrossRef]

- Zhu, H.; Liang, J.; Xu, J.; Bo, M.; Li, J.; Tang, B. Research on Anti-Chloride Ion Penetration Property of Crumb Rubber Concrete at Different Ambient Temperatures. Constr. Build. Mater. 2018, 189, 42–53. [Google Scholar] [CrossRef]

- Han, Q.; Wang, N.; Zhang, J.; Yu, J.; Hou, D.; Dong, B. Experimental and Computational Study on Chloride Ion Transport and Corrosion Inhibition Mechanism of Rubber Concrete. Constr. Build. Mater. 2021, 268, 121105. [Google Scholar] [CrossRef]

- Si, R.; Guo, S.; Dai, Q. Durability Performance of Rubberized Mortar and Concrete with NaOH-Solution Treated Rubber Particles. Constr. Build. Mater. 2017, 153, 496–505. [Google Scholar] [CrossRef]

- Su, D.; Pang, J.; Huang, X. Experimental Study on the Influence of Rubber Content on Chloride Salt Corrosion Resistance Performance of Concrete. Materials 2021, 14, 4706. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhang, S.; Wang, R.; Dang, F. Potential Use of Waste Tire Rubber as Aggregate in Cement Concrete—A Comprehensive Review. Constr. Build. Mater. 2019, 225, 1183–1201. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Demir, A. Durability of Rubberized Mortar and Concrete. J. Mater. Civ. Eng. 2007, 19, 173–178. [Google Scholar] [CrossRef]

- Retama, J.; Ayala, A.G. Influence of Crumb-Rubber in the Mechanical Response of Modified Portland Cement Concrete. Adv. Civ. Eng. 2017, 2017, 3040818. [Google Scholar] [CrossRef]

- Tran, V.C.; Dinh, Q.T.; Nguyen, C.N. Study on using grinding products from waste rubber to replace a part of the aggregate in cement concrete production. J. Sci. Tech. Sect. Spec. Constr. Eng. 2021, 4, 37–47. [Google Scholar] [CrossRef]

- Gupta, T.; Siddique, S.; Sharma, R.K.; Chaudhary, S. Behaviour of Waste Rubber Powder and Hybrid Rubber Concrete in Aggressive Environment. Constr. Build. Mater. 2019, 217, 283–291. [Google Scholar] [CrossRef]

- Zhai, S.; Liu, G.; Pang, B.; Liu, C.; Zhang, Z.; Zhang, L.; Liu, L.; Yang, Y.; Liu, Z.; Zhang, Y. Investigation on the Influence of Modified Waste Rubber Powder on the Abrasion Resistance of Concrete. Constr. Build. Mater. 2022, 357, 129409. [Google Scholar] [CrossRef]

- Abdullah, W.A.; Muhammad, M.A.; Abdulkadir, M.R. Experimental investigation of some mechanical properties of rubberized concrete with highest possible rubber content. J. Duhok Univ. 2020, 23, 509–522. [Google Scholar] [CrossRef]

- Chen, A.; Han, X.; Wang, Z.; Guo, T. Dynamic Properties of Pretreated Rubberized Concrete under Incremental Loading. Materials 2021, 14, 2183. [Google Scholar] [CrossRef] [PubMed]

- Badawi, M.; Ahmed, A.G.; Eldamaty, T.A.; Helal, M.M. Properties of Recycled Concrete Utilizing Waste Rubber. Eng. Technol. Appl. Sci. Res. 2023, 13, 11451–11458. [Google Scholar] [CrossRef]

- Alyousef, R.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P.; Alabduljabbar, H. Potential Use of Recycled Plastic and Rubber Aggregate in Cementitious Materials for Sustainable Construction: A Review. J. Clean. Prod. 2021, 329, 129736. [Google Scholar] [CrossRef]

- Deng, L.; Cai, C.S. Bridge Model Updating Using Response Surface Method. In Earth and Space 2010: Engineering, Science, Construction, and Operations in Challenging Environments; American Society of Civil Engineers: Honolulu, HI, USA, 2010; pp. 2311–2320. [Google Scholar]

- Azizmohammadi, M.; Toufigh, V.; Ghaemian, M. Experimental and Analytical Investigation on the Interlayer of Roller Compacted Concrete. J. Mater. Civ. Eng. 2021, 33, 04021090. [Google Scholar] [CrossRef]

- Khan, A.; Do, J.; Kim, D. Experimental Optimization of High-Strength Self-Compacting Concrete Based on D-Optimal Design. J. Constr. Eng. Manag. 2017, 143, 04016108. [Google Scholar] [CrossRef]

- Kosarimovahhed, M.; Toufigh, V. Sustainable Usage of Waste Materials as Stabilizer in Rammed Earth Structures. J. Clean. Prod. 2020, 277, 123279. [Google Scholar] [CrossRef]

- Elnakar, H.; Buchanan, I. Treatment of Bypass Wastewater Using Novel Integrated Potassium Ferrate(VI) and Iron Electrocoagulation System. J. Environ. Eng. 2020, 146, 04020075. [Google Scholar] [CrossRef]

- Raychaudhuri, A.; Behera, M. Review of the Process Optimization in Microbial Fuel Cell Using Design of Experiment Methodology. J. Hazard. Toxic Radioact. Waste 2020, 24, 04020013. [Google Scholar] [CrossRef]

- Pathak, A.; Khandegar, V.; Kumar, A. Statistical Investigation in Conjunction with a Box–Behnken Design for the Removal of Dyes Using Electrocoagulation. J. Hazard. Toxic Radioact. Waste 2021, 26, 04022001. [Google Scholar] [CrossRef]

| Items | Plasticizer |

|---|---|

| Water-reducing rate (%) | 25.6 |

| Shrinking percentage | 72 |

| Chloridion content (%) | 0.01 |

| Total alkali content (%) | 0.36 |

| Sodium sulfate content (%) | 1.232 |

| PH | 7.1 |

| Items | Content |

|---|---|

| Water–cement ratio | 0.38 |

| Cement (kg/m3) | 375 |

| Water (kg/m3) | 150 |

| Sand ratio (%) | 34 |

| Aggregate quantity (kg/m3) | 1925 |

| Superplasticizer (%) | 1.28 |

| Factors | Factor Levels and Ranges | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| A water–cement ratio | 0.35 | 0.40 | 0.45 |

| B sand ratio (%) | 32 | 34 | 36 |

| C 10 mesh waste rubber powder content (%) | 5 | 10 | 15 |

| Number | Cement | Water | 5∼10 mm | 10∼20 mm | 20∼30 mm | Sand | Plasticizer | Crumb Rubber |

|---|---|---|---|---|---|---|---|---|

| 1 | 375 | 131.25 | 385 | 962.5 | 577.5 | 616 | 4.8 | 37.5 |

| 2 | 375 | 168.75 | 385 | 962.5 | 577.5 | 616 | 4.8 | 37.5 |

| 3 | 375 | 150 | 385 | 962.5 | 577.5 | 654.5 | 4.8 | 37.5 |

| 4 | 375 | 131.25 | 385 | 962.5 | 577.5 | 693 | 4.8 | 37.5 |

| 5 | 375 | 168.75 | 385 | 962.5 | 577.5 | 693 | 4.8 | 37.5 |

| 6 | 375 | 150 | 385 | 962.5 | 577.5 | 654.5 | 4.8 | 37.5 |

| 7 | 375 | 131.25 | 385 | 962.5 | 577.5 | 654.5 | 4.8 | 18.75 |

| 8 | 375 | 150 | 385 | 962.5 | 577.5 | 654.5 | 4.8 | 37.5 |

| 9 | 375 | 168.75 | 385 | 962.5 | 577.5 | 654.5 | 4.8 | 18.75 |

| 10 | 375 | 131.25 | 385 | 962.5 | 577.5 | 654.5 | 4.8 | 56.25 |

| 11 | 375 | 150 | 385 | 962.5 | 577.5 | 654.5 | 4.8 | 37.5 |

| 12 | 375 | 168.75 | 385 | 962.5 | 577.5 | 654.5 | 4.8 | 56.25 |

| 13 | 375 | 150 | 385 | 962.5 | 577.5 | 616 | 4.8 | 18.75 |

| 14 | 375 | 150 | 385 | 962.5 | 577.5 | 654.5 | 4.8 | 37.5 |

| 15 | 375 | 150 | 385 | 962.5 | 577.5 | 616 | 4.8 | 56.25 |

| 16 | 375 | 150 | 385 | 962.5 | 577.5 | 693 | 4.8 | 56.25 |

| 17 | 375 | 150 | 385 | 962.5 | 577.5 | 693 | 4.8 | 18.75 |

| Number | Water–Cement Ratio | Sand Ratio (%) | 10-Mesh Waste Rubber Powder Cement (%) | Flexural Strength (MPa) | |

|---|---|---|---|---|---|

| 7 d | 28 d | ||||

| 1 | 0.35 | 32 | 10 | 5.45 | 5.98 |

| 2 | 0.45 | 32 | 10 | 4.92 | 5.45 |

| 3 | 0.4 | 34 | 10 | 5.32 | 5.84 |

| 4 | 0.35 | 36 | 10 | 5.37 | 5.92 |

| 5 | 0.45 | 36 | 10 | 4.69 | 5.27 |

| 6 | 0.4 | 34 | 10 | 5.24 | 5.82 |

| 7 | 0.35 | 34 | 5 | 5.58 | 6.13 |

| 8 | 0.4 | 34 | 10 | 5.26 | 5.74 |

| 9 | 0.45 | 34 | 5 | 5.03 | 5.56 |

| 10 | 0.35 | 34 | 15 | 5.16 | 5.65 |

| 11 | 0.4 | 34 | 10 | 5.21 | 5.73 |

| 12 | 0.45 | 34 | 15 | 4.47 | 5.01 |

| 13 | 0.4 | 32 | 5 | 5.26 | 5.78 |

| 14 | 0.4 | 34 | 10 | 5.23 | 5.78 |

| 15 | 0.4 | 32 | 15 | 4.78 | 5.32 |

| 16 | 0.4 | 36 | 15 | 4.57 | 5.12 |

| 17 | 0.4 | 36 | 5 | 5.29 | 5.83 |

| Number | Water–Cement Ratio | Sand Ratio (%) | 10-Mesh Waste Rubber Powder Content (%) | 7 d Flexural Strength (MPa) | 28 d Flexural Strength (MPa) |

|---|---|---|---|---|---|

| 1 | 0.35 | 34 | 5 | 5.6 | 6.18 |

| 2 | 0.35 | 33 | 8 | 5.57 | 6.14 |

| 3 | 0.36 | 33 | 7 | 5.56 | 6.12 |

| 4 | 0.35 | 33 | 8 | 5.55 | 6.12 |

| 5 | 0.35 | 35 | 8 | 5.56 | 6.10 |

| 6 | 0.37 | 35 | 5 | 5.53 | 6.07 |

| 7 | 0.36 | 34 | 9 | 5.51 | 6.04 |

| 8 | 0.37 | 33 | 9 | 5.47 | 6.01 |

| 9 | 0.36 | 36 | 9 | 5.47 | 6.00 |

| 10 | 0.35 | 35 | 10 | 5.45 | 5.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Li, J.; Xu, Y.; Ma, S. Mechanical Properties of Cement Concrete with Waste Rubber Powder. Appl. Sci. 2024, 14, 6636. https://doi.org/10.3390/app14156636

Liu J, Li J, Xu Y, Ma S. Mechanical Properties of Cement Concrete with Waste Rubber Powder. Applied Sciences. 2024; 14(15):6636. https://doi.org/10.3390/app14156636

Chicago/Turabian StyleLiu, Junqin, Jiyue Li, Yanwei Xu, and Shibin Ma. 2024. "Mechanical Properties of Cement Concrete with Waste Rubber Powder" Applied Sciences 14, no. 15: 6636. https://doi.org/10.3390/app14156636

APA StyleLiu, J., Li, J., Xu, Y., & Ma, S. (2024). Mechanical Properties of Cement Concrete with Waste Rubber Powder. Applied Sciences, 14(15), 6636. https://doi.org/10.3390/app14156636