Management Solutions and Stabilization of a Pre-Existing Concealed Goaf Underneath an Open-Pit Slope

Abstract

:1. Introduction

2. Engineering Background

2.1. Mine Geological Condition

2.2. Mine Production Status

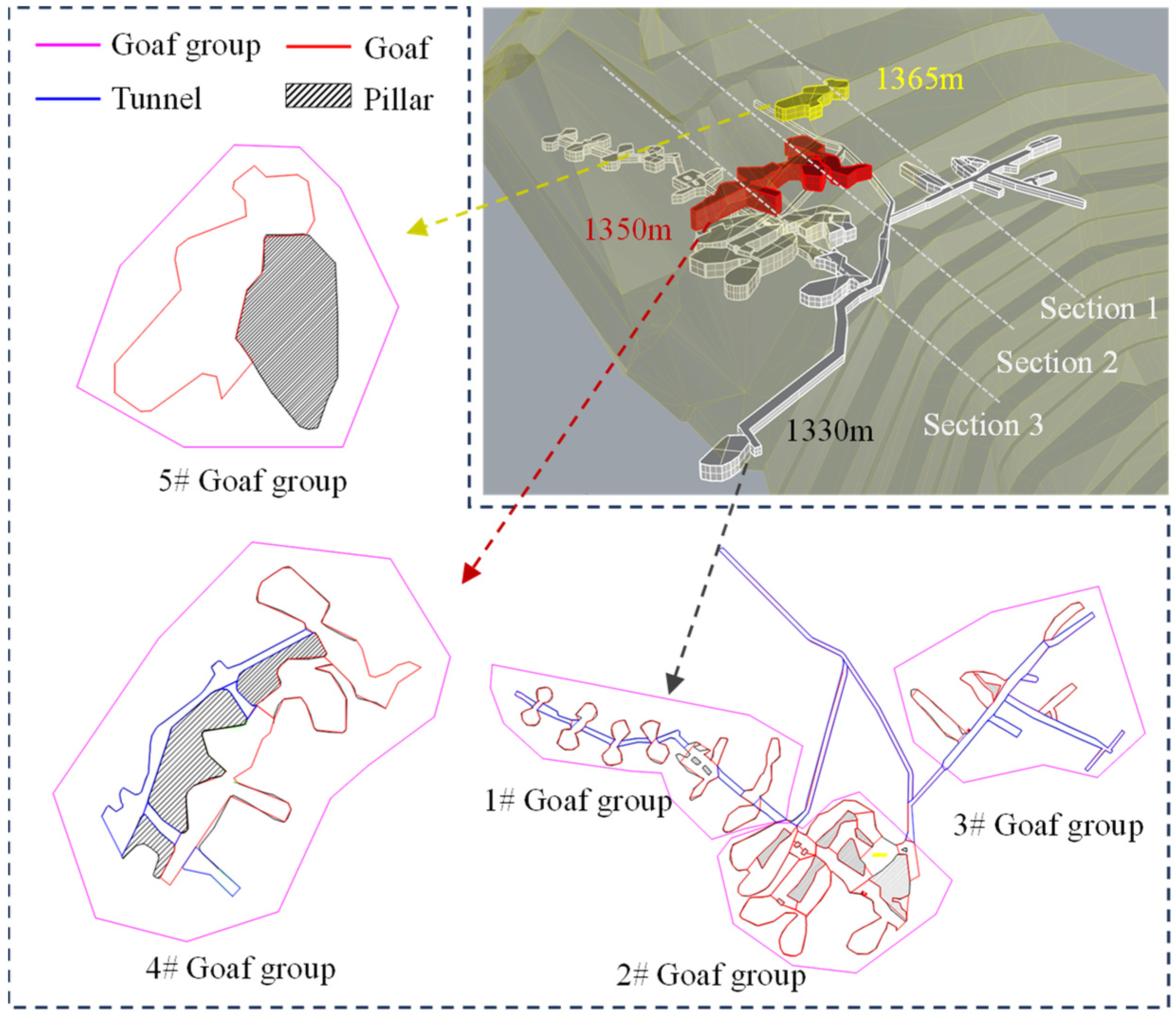

2.3. Goaf Distribution

3. Goaf Group Risk Classification

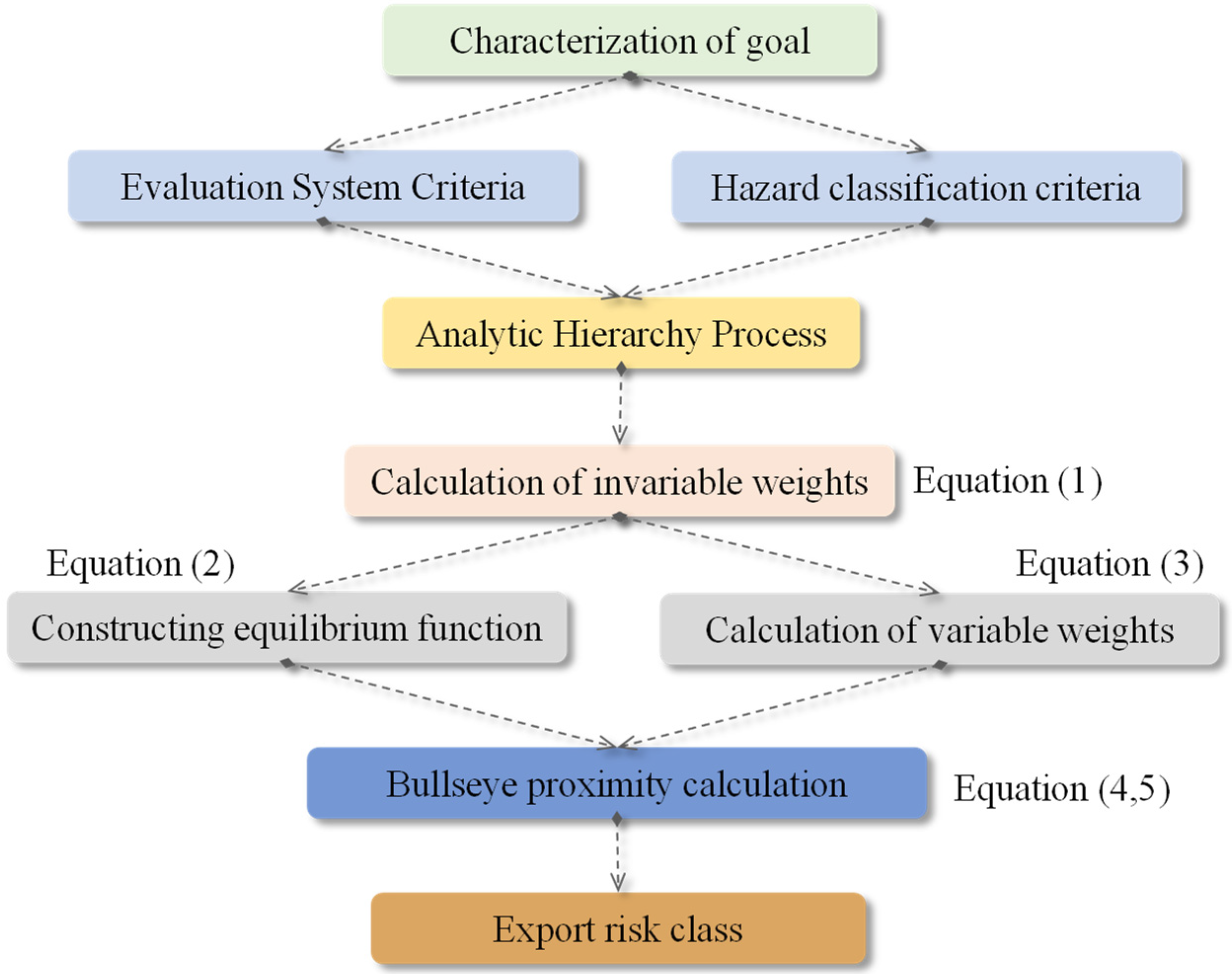

3.1. Methodology

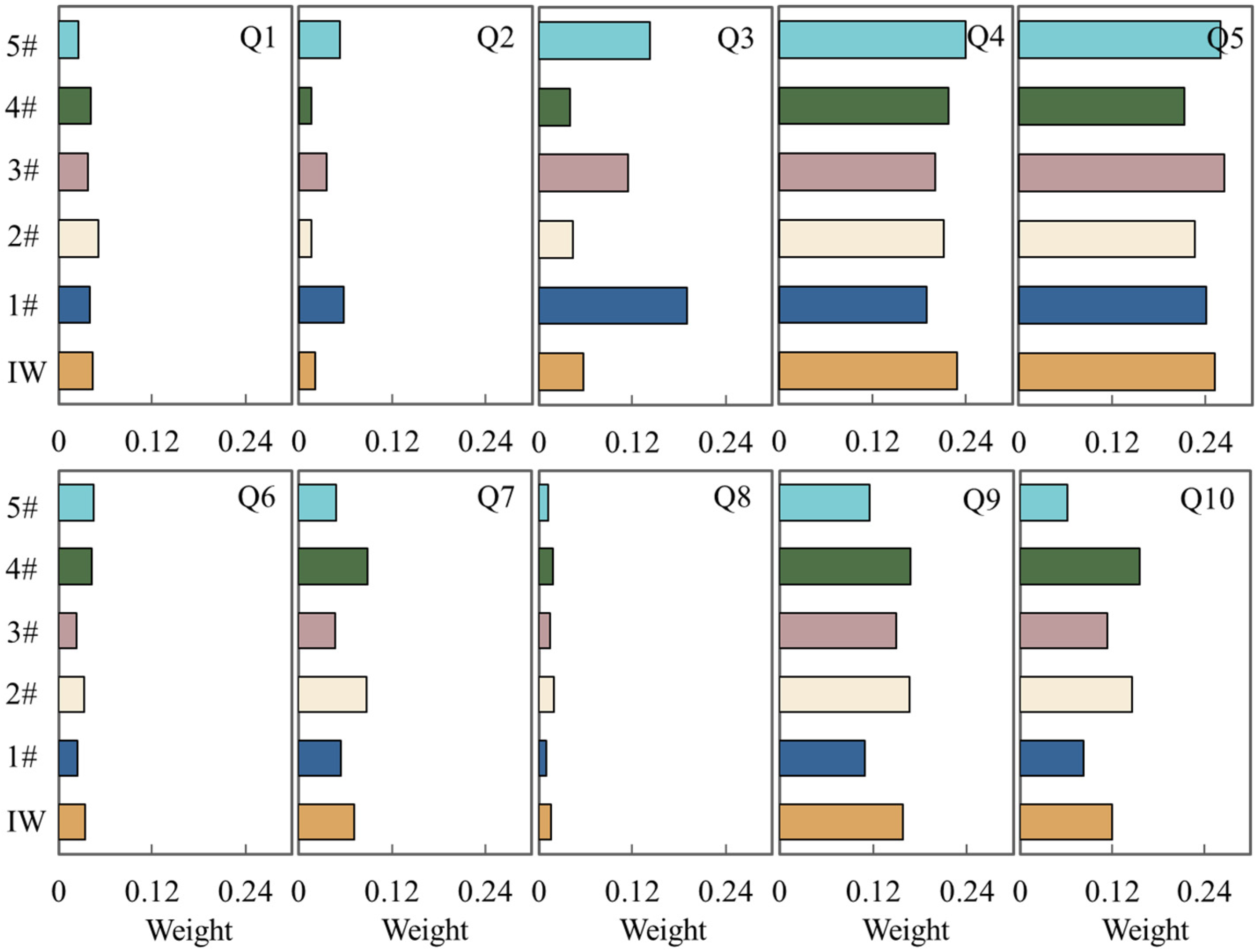

3.2. Evaluation of Quantitative Grading Standards

3.3. Computation for Target Approaching

4. Key Parameters of the PCO-Goaf Treatment Scheme

4.1. Safe Thickness of the Overlying Rock in PCO-Goafs

4.2. Backfill Strength

5. Analysis of Slope Stability

5.1. Basic Parameters of the Model

5.2. Setting of the Blasting Vibration Conditions

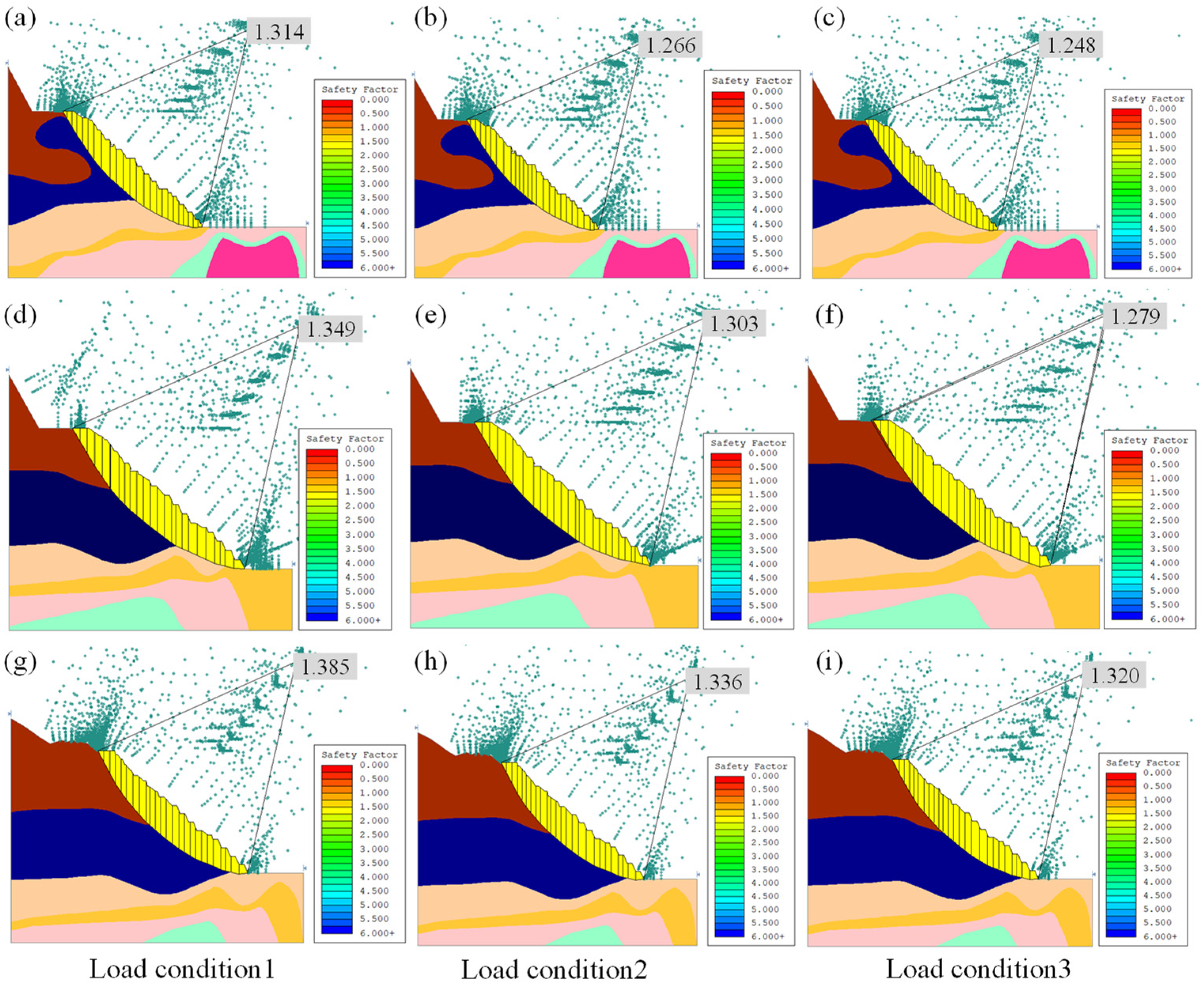

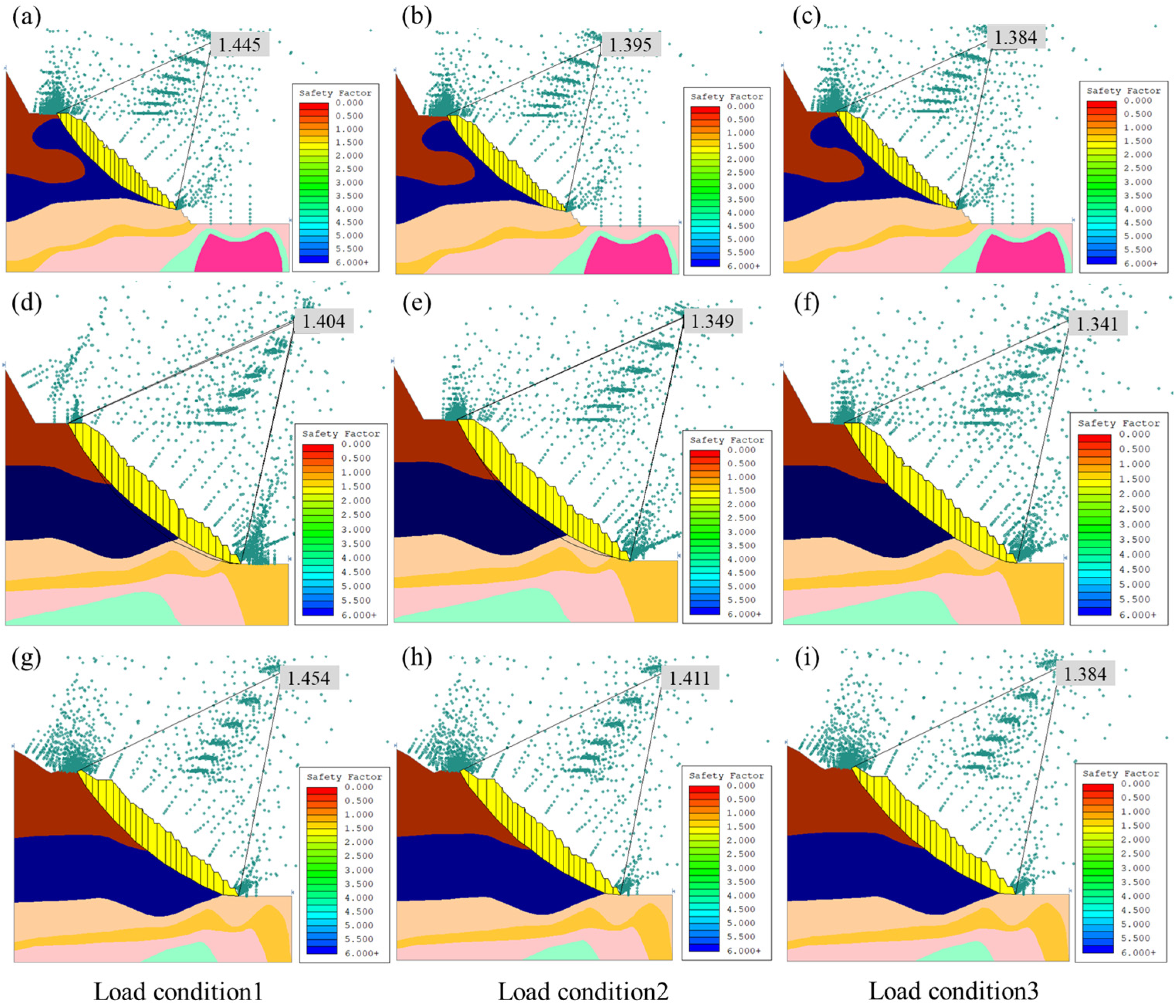

5.3. Calculation of the Safety Factor for the Slope

6. Conclusions

- The slope stability is divided into four hazard classes, and the PCO-goaf groups are classified using the variable weight and bullseye approach methods. There is one Grade I PCO-goaf group, two Grade II PCO-goaf groups, and two Grade III PCO-goaf groups.

- The balance beam theory and the Pratt arch theory are used to calculate the safety thickness of the roof over the goaf, and the safe thickness of the roof is 10.5–41 m when the goaf span is 15–50 m. The strength of the designed backfill is 1.2 MPa.

- After the PCO-goaf groups are treated separately, Slide software was used to analyze the stability of the slope. The minimum safety factor of the PCO-goaf groups is 1.248 under the three load conditions, which is greater than the safety factor of 1.2. This shows that the goaf classification and treatment plan are reliable, and the slopes are in a stable state.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Azhari, A.; Ozbay, U. Investigating the effect of earthquakes on open pit mine slopes. Int. J. Rock Mech. Min. Sci. 2017, 100, 218–228. [Google Scholar] [CrossRef]

- Jiang, S.; Li, J.; Zhang, S.; Gu, Q.; Lu, C.; Liu, H. Landslide risk prediction by using GBRT algorithm: Application of artificial intelligence in disaster prevention of energy mining. Process Saf. Environ. Prot. 2022, 166, 384–392. [Google Scholar] [CrossRef]

- Lu, Y.; Jin, C.; Wang, Q.; Han, T.; Chen, L. Modeling Study on Cumulative Damage Effects and Safety Control Criterion of Open-Pit Final Slope Under Blasting. Rock Mech. Rock Eng. 2024, 57, 2081–2101. [Google Scholar] [CrossRef]

- Tolovkhan, B.; Demin, V.; Amanzholov, Z.; Smagulova, A.; Tanekeyeva, G.; Zairov, S.; Krukovskyi, O.; Cabana, E. Substantiating the rock mass control parameters based on the geomechanical model of the Severny Katpar deposit, Kazakhstan. Min. Miner. Depos. 2022, 16, 123–133. [Google Scholar] [CrossRef]

- Dick, G.J.; Eberhardt, E.; Cabrejo-Liévano, A.G.; Stead, D.; Rose, N.D. Development of an early-warning time-of-failure analysis methodology for open-pit mine slopes utilizing ground-based slope stability radar monitoring data. Can. Geotech. J. 2015, 52, 515–529. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Q.; Dai, B.; Wang, D. Guidance and review: Advancing mining technology for enhanced production and supply of strategic minerals in China. Green Smart Min. Eng. 2024, 1, 2–11. [Google Scholar] [CrossRef]

- Dintwe, T.K.M.; Sasaoka, T.; Shimada, H.; Hamanaka, A.; Moses, D.N.; Peng, M.; Meng, F.; Liu, S.; Ssebadduka, R.; Onyango, J.A. Numerical Simulation of Crown Pillar Behaviour in Transition from Open Pit to Underground Mining. Geotech. Geol. Eng. 2022, 40, 2213–2229. [Google Scholar] [CrossRef]

- Jiang, N.; Zhou, C.; Lu, S.; Zhang, Z. Propagation and prediction of blasting vibration on slope in an open pit during underground mining. Tunn. Undergr. Space Technol. 2017, 70, 409–421. [Google Scholar] [CrossRef]

- Ozdogan, M.V.; Deliormanli, A.H. Determination of possible failure surfaces in an open-pit slope caused by underground production. Boll. Di Geofis. Teor. Ed Appl. 2020, 61, 199–218. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, Z.; Bao, M.; Nian, G.; Zhou, Z.; Zhu, T. Stability analysis and movement process determination of rock masses under open-pit to underground mining conditions. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 1–19. [Google Scholar] [CrossRef]

- Chen, Q.; Niu, Y.; Xiao, C. Study on the influence of wet backfilling in open pit on slope stability. Sustainability 2023, 15, 12492. [Google Scholar] [CrossRef]

- Hu, Y.; Ren, F.; Ding, H.; Fu, Y.; Tan, B. Study on the Process and Mechanism of Slope Failure Induced by Mining under Open Pit Slope: A Case Study from Yanqianshan Iron Mine, China. Adv. Civ. Eng. 2019, 2019, 6862936. [Google Scholar] [CrossRef]

- Vyazmensky, A.; Stead, D.; Elmo, D.; Moss, A. Numerical Analysis of Block Caving-Induced Instability in Large Open Pit Slopes: A Finite Element/Discrete Element Approach. Rock Mech. Rock Eng. 2010, 43, 21–39. [Google Scholar] [CrossRef]

- Zhao, Q.; Yang, Z.; Jiang, Y.; Liu, X.; Cui, F.; Li, B. Discrete element analysis of deformation features of slope controlled by karst fissures under the mining effect: A case study of Pusa landslide, China. Geomat. Nat. Hazards Risk 2023, 14, 1–35. [Google Scholar] [CrossRef]

- Geng, J.; Li, Q.; Li, X.; Zhou, T.; Liu, Z.; Xie, Y. Research on the Evolution Characteristics of Rock Mass Response from Open-Pit to Underground Mining. Adv. Mater. Sci. Eng. 2021, 2021, 3200906. [Google Scholar] [CrossRef]

- Shi, S.; Guo, Z.; Ding, P.; Tao, Y.; Mao, H.; Jiao, Z. Failure Mechanism and Stability Control Technology of Slope during Open-Pit Combing Underground Extraction: A Case Study from Shanxi Province of China. Sustainability 2022, 14, 8939. [Google Scholar] [CrossRef]

- Li, X.; Li, Q.; Hu, Y.; Teng, L.; Yang, S. Evolution characteristics of mining fissures in overlying strata of stope after converting from open-pit to underground. Arab. J. Geosci. 2021, 14, 2795. [Google Scholar] [CrossRef]

- Lu, Y.; Jin, C.; Wang, Q.; Li, G.; Han, T. Deformation and failure characteristic of open-pit slope subjected to combined effects of mining blasting and rainfall infiltration. Eng. Geol. 2024, 331, 107437. [Google Scholar] [CrossRef]

- Molina, E.; Martinon, P.; Ramirez, H. Optimal control approaches for open pit planning. Optim. Eng. 2023, 24, 2887–2909. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, D.; Ma, M.; Zheng, K. Parameter inversion and location determination of evolutionary weak layer for open-pit mine slope. Int. J. Coal Sci. Technol. 2020, 7, 714–724. [Google Scholar] [CrossRef]

- Samson, A.; Bowa, V.M.; Chileshe, P.R.K.; Chinyanta, S.; Manda, E. Analytical and Numerical Modelling of the Effects of Buttressing on Slide-Head Toppling Failure. Min. Metall. Explor. 2024. [Google Scholar] [CrossRef]

- Popescu, F.D.; Radu, S.M.; Andras, A.; Brinas, I.; Marita, M.-O.; Radu, M.A.; Brinas, C.L. Stability Assessment of the Dam of a Tailings Pond Using Computer Modeling—Case Study: Coroiești, Romania. Appl. Sci. 2024, 14, 268. [Google Scholar] [CrossRef]

- Mapurang, A. Influence of Pit Wall Stability on Underground Planning and Design When Transitioning from Open Pit to Sublevel Caving; University of the Witwatersrand, Faculty of Engineering and the Built Environment: Johannesburg, South Africa, 2019. [Google Scholar]

- Tan, B.; Ren, F.; Ning, Y.; He, R.; Zhu, Q. A New Mining Scheme for Hanging-Wall Ore-Body during the Transition from Open Pit to Underground Mining: A Numerical Study. Adv. Civ. Eng. 2018, 2018, 1465672. [Google Scholar] [CrossRef]

- Li, S.; Zhao, Z.; Hu, B.; Yin, T.; Chen, G.; Chen, G. Hazard Classification and Stability Analysis of High and Steep Slopes from Underground to Open-Pit Mining. Int. J. Environ. Res. Public Health 2022, 19, 11679. [Google Scholar] [CrossRef] [PubMed]

- Cao, H.; Ma, G.; Liu, P.; Qin, X.; Wu, C.; Lu, J. Multi-Factor Analysis on the Stability of High Slopes in Open-Pit Mines. Appl. Sci. 2023, 13, 5940. [Google Scholar] [CrossRef]

- Karakus, M.; Zhukovskiy, S.; Goodchild, D. Investigating the Influence of Underground Ore Productions on the Overall Stability of an Existing Open Pit. Procedia Eng. 2017, 191, 600–608. [Google Scholar] [CrossRef]

- Li, S.; Zhao, Z.; Hu, B.; Yin, T.; Chen, G.; Chen, G. Three-Dimensional Simulation Stability Analysis of Slopes from Underground to Open-Pit Mining. Minerals 2023, 13, 402. [Google Scholar] [CrossRef]

- Zhao, X.-d.; Li, L.-c.; Tang, C.-a.; Zhang, H.-x. Stability of boundary pillars in transition from open pit to underground mining. J. Cent. South Univ. 2012, 19, 3256–3265. [Google Scholar] [CrossRef]

- Kang, Q.; Wang, Y.; Zhang, S.; Pu, C.; Zhang, C. Prediction of Stope Stability Using Variable Weight and Unascertained Measurement Technique. Geofluids 2021, 2021, 8821168. [Google Scholar] [CrossRef]

- Yang, S.; Xu, Z.; Su, K. Variable Weight Matter-Element Extension Model for the Stability Classification of Slope Rock Mass. Mathematics 2021, 9, 2807. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.; Chen, Q. Using cemented paste backfill to tackle the phosphogypsum stockpile in China: A down-to-earth technology with new vitalities in pollutant retention and CO2 abatement. Int. J. Miner. Metall. Mater. 2024, 31, 1480–1499. [Google Scholar] [CrossRef]

- Library, U.; Daiyu, X.; Tianhong, Y.; String, W.; Jianjun, H. Analysis on disaster impact of concealed goaves underneath open-pit slope and its treatment. Chin. J. Nonferrous Met. 2020, 30, 2503–2512. [Google Scholar]

- Zhang, D.J.; Liu, Z.Y.; Duan, X.B.; Tuo, M.X. Research on the Mechanism of Overlying Strata Caving in Composite Goaf and its Collaborative Treatment Method. Min. Res. Dev. 2024, 44, 91–96. [Google Scholar] [CrossRef]

- He, K.; Swarbrick, G.; Sullivan, T. Numerical modelling of underground and open pit interaction in a gold mine. In Proceedings of the 2020 International Symposium on Slope Stability in Open Pit Mining and Civil Engineering. Australian Centre for Geomechanics, Perth, Australia, 12–14 May 2020; pp. 1031–1046. [Google Scholar] [CrossRef]

- Jianzhou, L. Research on Integration of Goaf Treatment and Mining in Pingshuo Dong Surface Mine. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2015. [Google Scholar]

- Tao, C. Strength Design of Upward Layered Backfill under Dynamic Load of Trackless Equipment. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2022. [Google Scholar]

- Guzzo Duz, B.; Moreira, C.A.; Hartwig, M.E.; Queiroz Miano, F.; Araújo, A.F. Groundwater identification using geophysical tools and its implications for the stability of slopes in an open pit mine. Geofísica Int. 2024, 63, 1033–1043. [Google Scholar] [CrossRef]

- GB 50771-2012; Code for Design of Nonferrous Metal Mining. Ministry of Housing and Urban-Rural Development of the People’s Republic of China, General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2012.

- GB 51016-2014; Technical Code for Non-Coal Open-Pit Mine Slope Engineering. Ministry of Housing and Urban-Rural Development of the People’s Republic of China, General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2014.

- GB 18306-2015; Seismic Ground Motion Parameters zonation Map of China. Ministry of Housing and Urban-Rural Development of the People’s Republic of China, General Administration of Quality Supervision, Standardization Administration of the People’s Republic of China: Beijing, China, 2015.

- Nandi, S.; Ghosh, P. Curvilinear Slope Profile–Based Seismic Stability for Rock Slopes Using Stress Characteristics Method and Generalized Hoek–Brown Criterion. J. Eng. Mech. 2024, 150, 04024049. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, J.; Huo, X.; Wang, J. Numerical Simulation of Dynamic Damage and Stability of a Bedding Rock Slope under Blasting Load. Shock Vib. 2019, 2019, 9616859. [Google Scholar] [CrossRef]

- Hu, Y.; Lu, W.; Chen, M.; Yan, P.; Yang, J. Comparison of Blast-Induced Damage Between Presplit and Smooth Blasting of High Rock Slope. Rock Mech. Rock Eng. 2014, 47, 1307–1320. [Google Scholar] [CrossRef]

- Bo, P. Study on Instability Mechanism and Blasting Collapse Treatment of Existing Goaf in an Open-pit Mine. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2022. [Google Scholar]

- Yuan, K.; Ma, C.; Guo, G.; Wang, P. Slope Failure of Shilu Metal Mine Transition from Open-Pit to Underground Mining under Excavation Disturbance. Appl. Sci. 2024, 14, 1055. [Google Scholar] [CrossRef]

| Code | Evaluation Index | 1# | 2# | 3# | 4# | 5# |

|---|---|---|---|---|---|---|

| Q1 | Height/m | 3.8 | 5.5 | 4.1 | 6.3 | 5.5 |

| Q2 | Ratio of pillar width to height | 6.5 | 205.6 | 16.0 | 158.4 | 4.5 |

| Q3 | Pillar area/m2 | 25 | 1131 | 66 | 998 | 25 |

| Q4 | Exposed area of goaf/m2 | 2063 | 3895.6 | 1740 | 2787.8 | 724 |

| Q5 | volume of goaf/m3 | 8294.3 | 21,901.2 | 6496 | 18,908.9 | 3982 |

| Q6 | Span of goaf/m | 335.5 | 408.5 | 355 | 184 | 54 |

| Q7 | Depth/m | 108.2 | 99.9 | 141.9 | 74.8 | 76.5 |

| Q8 | Distance from slope /m | 295.9 | 181 | 132.6 | 144.7 | 120 |

| Q9 | Shape factor of goaf | 8 | 8 | 4 | 6 | 4 |

| Q10 | Status of adjacent goaf | 8 | 6 | 4 | 4 | 8 |

| Evaluation Index | Grade I | Grade II | Grade III | Grade IV |

|---|---|---|---|---|

| Q1 | 6~8 | 4~6 | 3~4 | 0~3 |

| Q2 | 0.06~0.11 | 0.03~0.06 | 0.015~0.03 | 0~0.015 |

| Q3 | 0~200 | 200~500 | 500~1000 | 1000~1500 |

| Q4 | 3000~4500 | 1500~3000 | 500~1500 | 0~500 |

| Q5 | 15,000~25,000 | 10,000~15,000 | 5000~10,000 | 0~5000 |

| Q6 | 250~450 | 100~250 | 50~100 | 0~50 |

| Q7 | 0~40 | 40~80 | 80~120 | 120~150 |

| Q8 | 0~70 | 70~140 | 140~210 | 210~300 |

| Q9 | 7~9 | 5~7 | 3~5 | 0~3 |

| Q10 | 7~9 | 5~7 | 3~5 | 0~3 |

| PCO-Goaf Group | Bullseye Proximity Degree | The Grade of PCO-Goaf Group | |||

|---|---|---|---|---|---|

| Grade I | Grade II | Grade III | Grade IV | ||

| 1# | 0.9852 | 0.9530 | 0.9134 | 0.9003 | I |

| 2# | 0.9576 | 0.9609 | 0.8701 | 0.8544 | II |

| 3# | 0.8719 | 0.9400 | 0.9969 | 0.9454 | III |

| 4# | 0.8915 | 0.9621 | 0.9366 | 0.8995 | II |

| 5# | 0.9448 | 0.9602 | 0.9609 | 0.9399 | III |

| Rock | Density (kN/m3) | Cohesive Force c (kPa) | Internal Friction Angle φ (°) |

|---|---|---|---|

| Felsic Hornstone | 26.6 | 362 | 38.41 |

| Chalcopyrite-veinlet-bearing Biotitic Felsic Hornfels | 26.6 | 338 | 38.17 |

| Biotite diopside plagioclase | 28.1 | 389 | 38.93 |

| Skarn | 32.9 | 362 | 38.97 |

| Biotite diopside plagioclase | 28.1 | 389 | 38.93 |

| Granite | 25.5 | 380 | 39.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Na, Q.; Chen, Q.; Tao, Y.; Zhang, X.; Tan, Y. Management Solutions and Stabilization of a Pre-Existing Concealed Goaf Underneath an Open-Pit Slope. Appl. Sci. 2024, 14, 6849. https://doi.org/10.3390/app14156849

Na Q, Chen Q, Tao Y, Zhang X, Tan Y. Management Solutions and Stabilization of a Pre-Existing Concealed Goaf Underneath an Open-Pit Slope. Applied Sciences. 2024; 14(15):6849. https://doi.org/10.3390/app14156849

Chicago/Turabian StyleNa, Qing, Qiusong Chen, Yunbo Tao, Xiangyu Zhang, and Yi Tan. 2024. "Management Solutions and Stabilization of a Pre-Existing Concealed Goaf Underneath an Open-Pit Slope" Applied Sciences 14, no. 15: 6849. https://doi.org/10.3390/app14156849