An Investigation on the Pore Structure Characterization of Sandstone Using a Scanning Electron Microscope and an Online Nuclear Magnetic Resonance System

Abstract

:1. Introduction

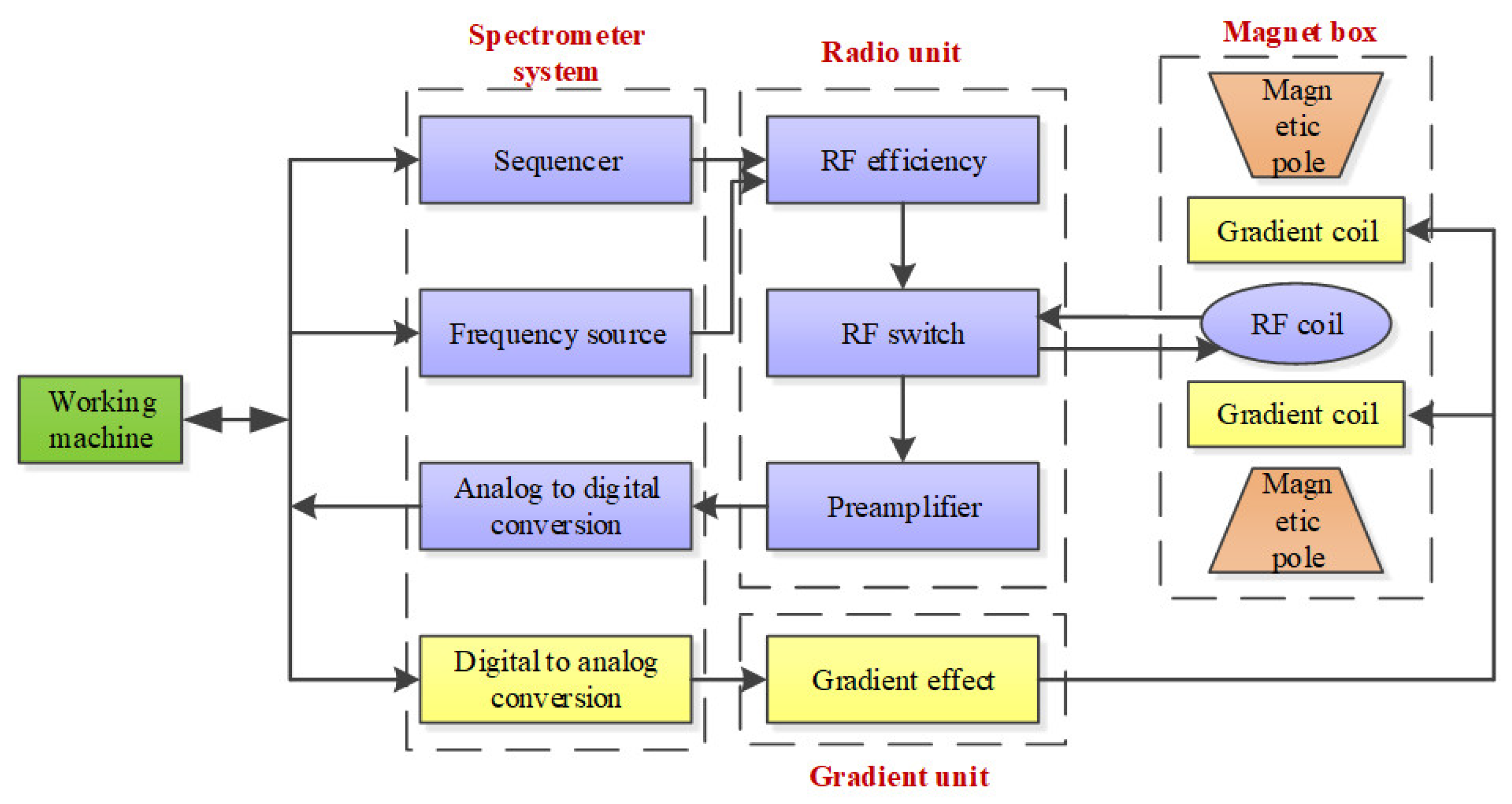

2. The Principle of NMR Method

3. Materials and Methods

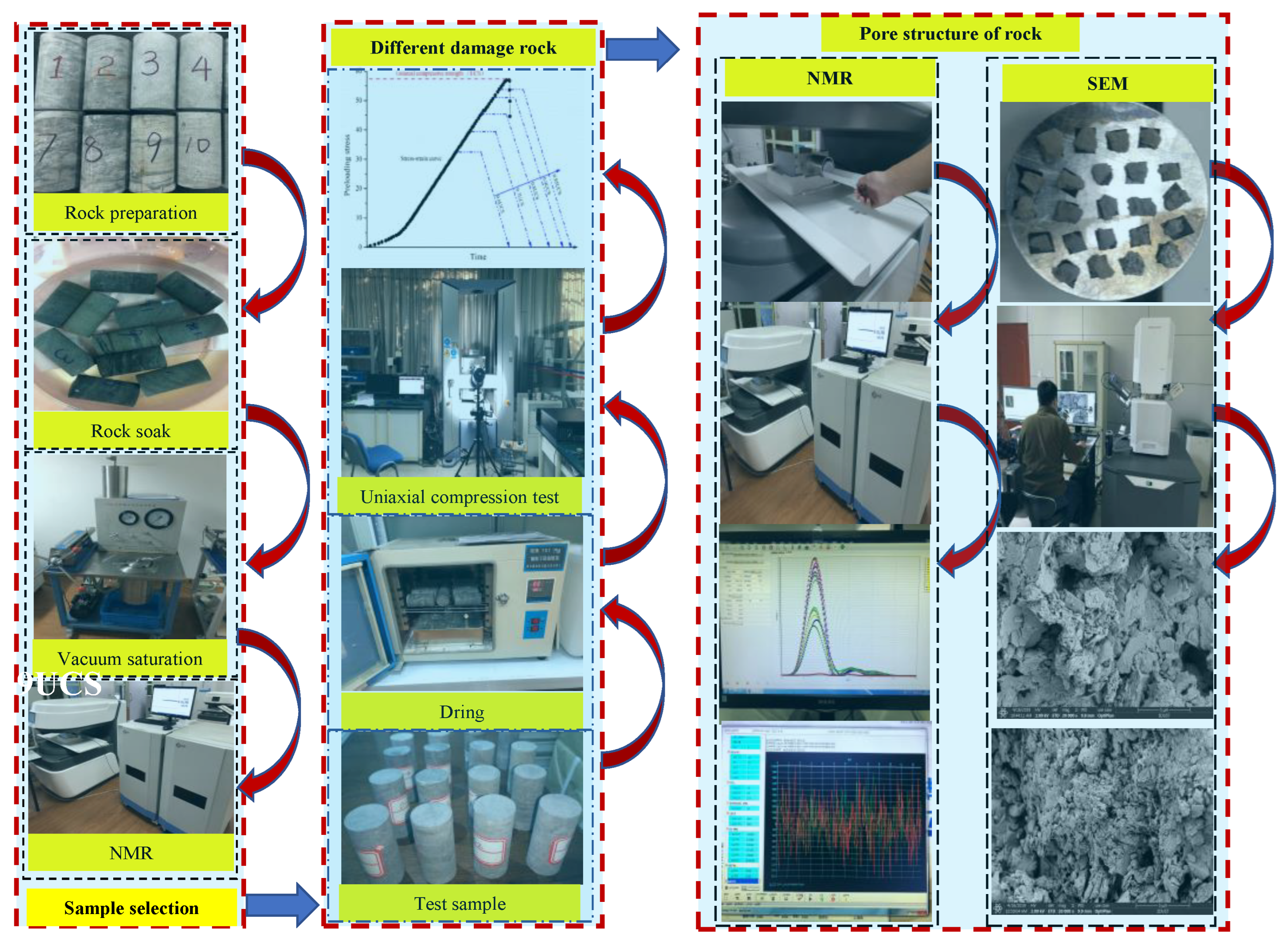

3.1. Materials and Experiment Procedure

3.2. Experiment Equipment and Method

3.2.1. Loading and Unloading Tests

3.2.2. SEM Analysis

3.2.3. NMR Analysis

4. Experimental Results and Discussion

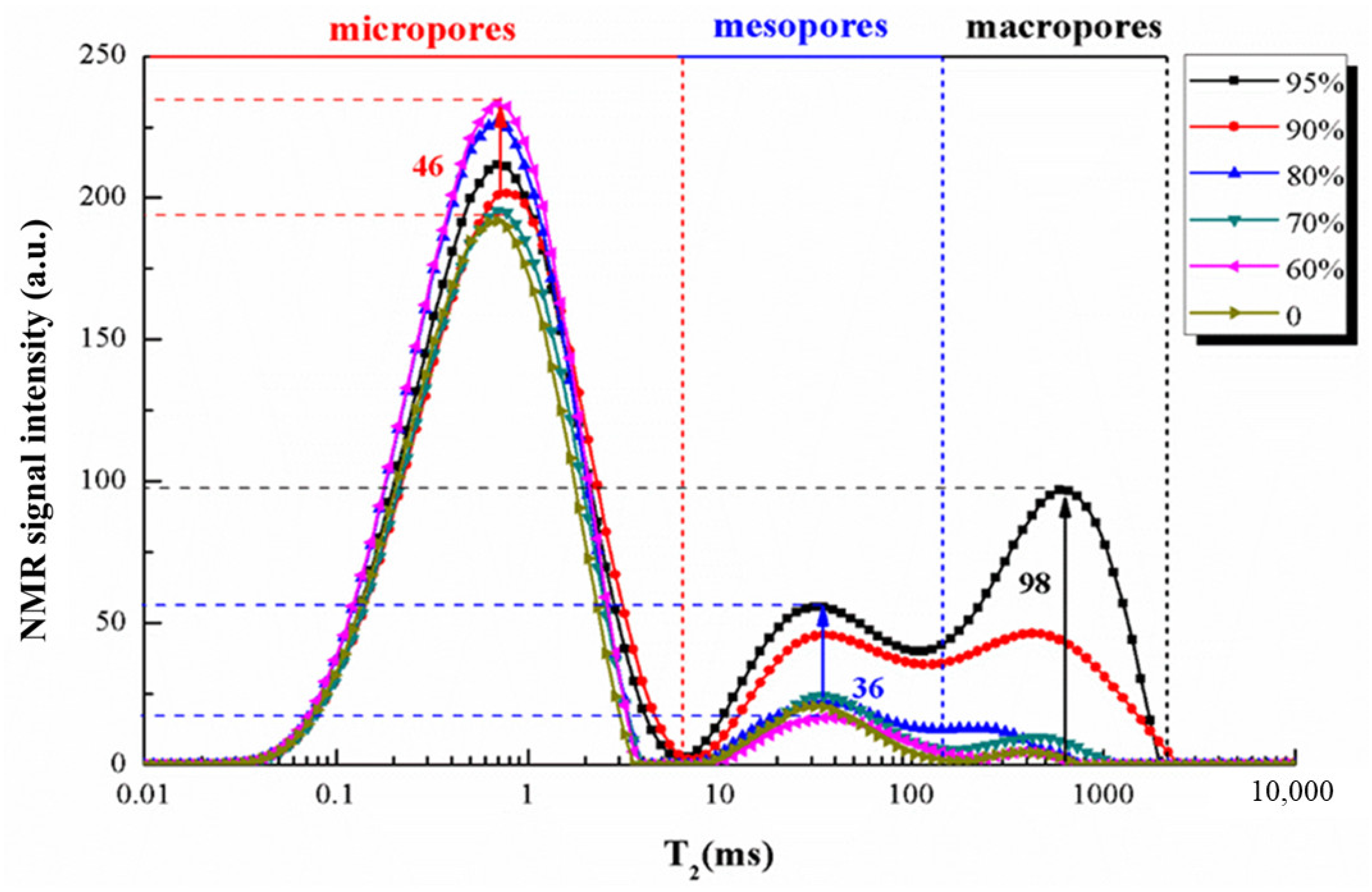

4.1. T2 Spectrum Distribution Curves

- (1)

- Change in the T2 spectrum distribution curves

- (2)

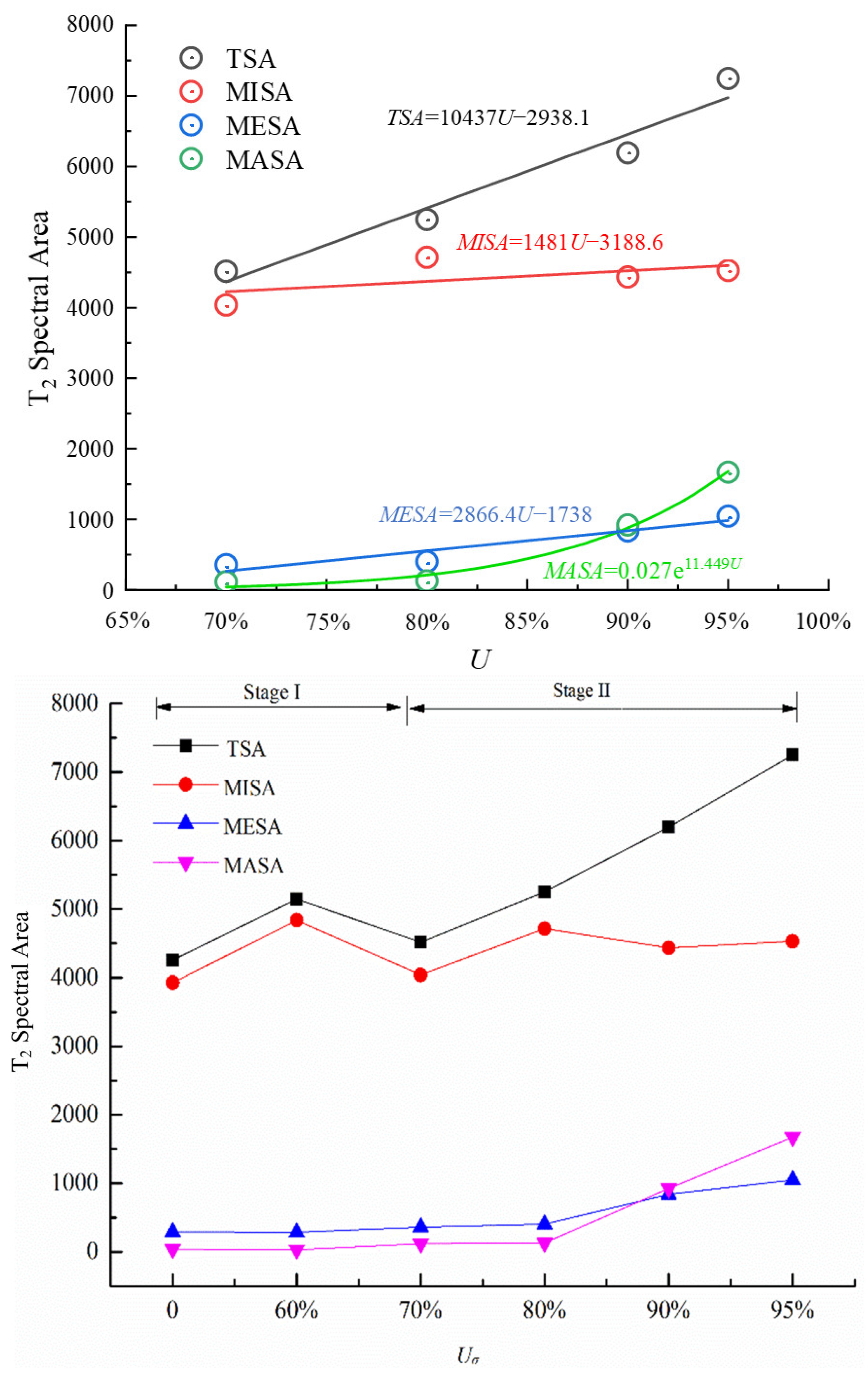

- Analysis of T2 spectral area

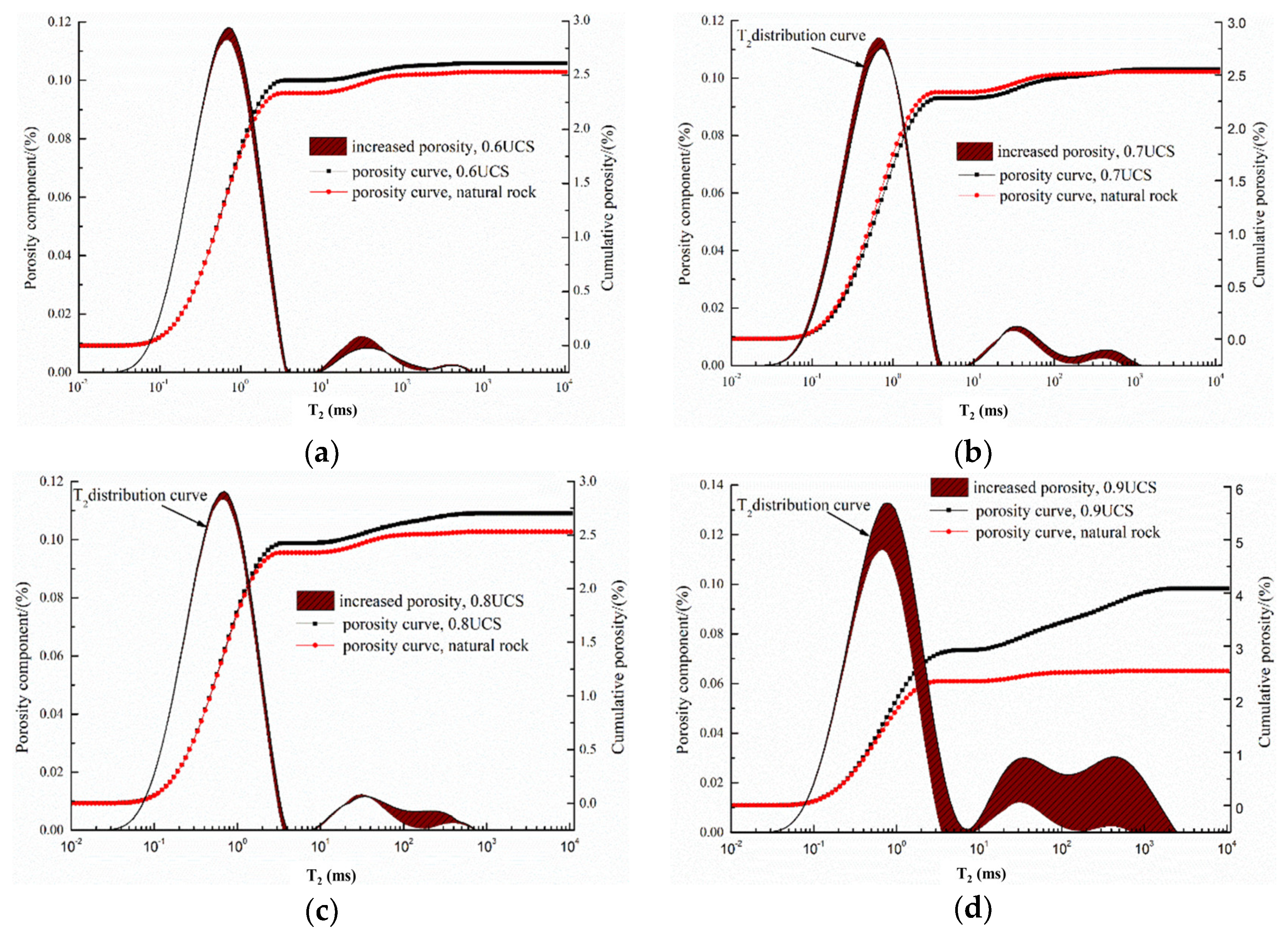

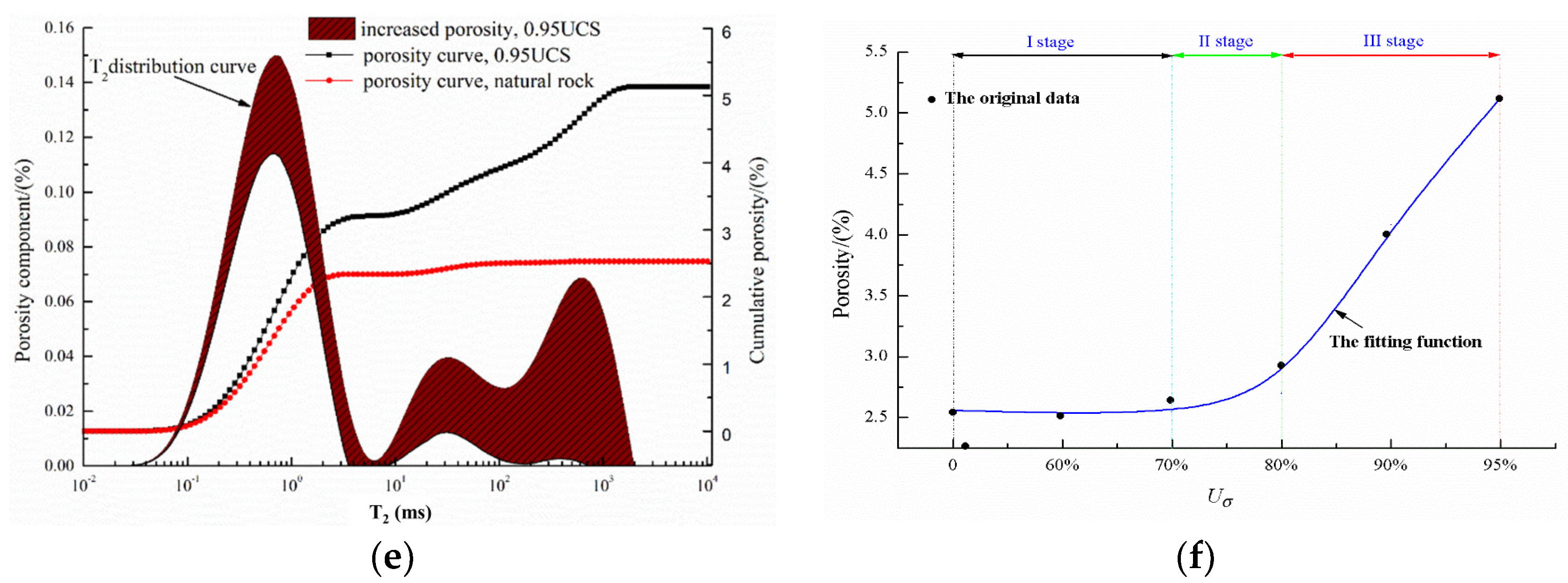

4.2. Porosity

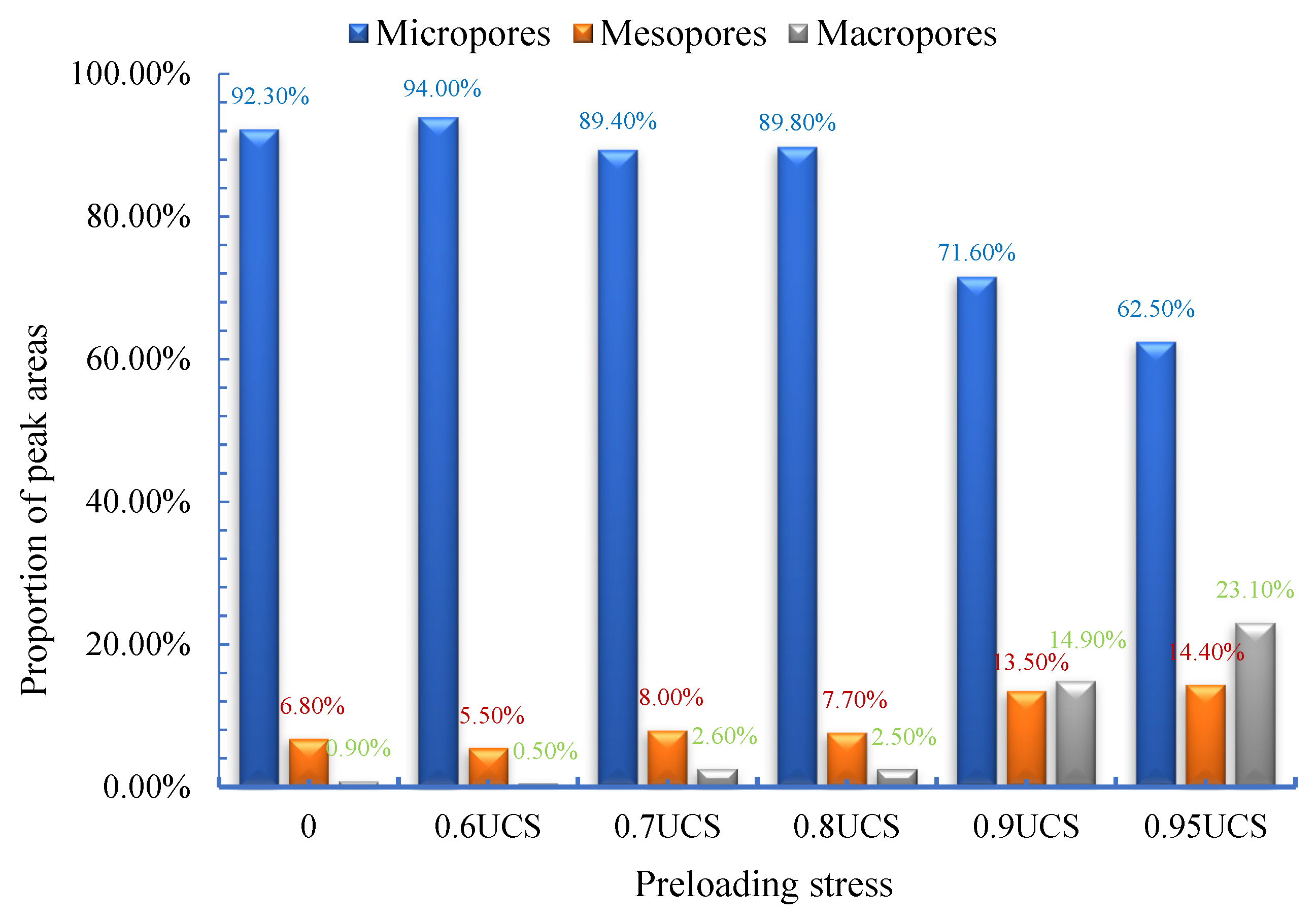

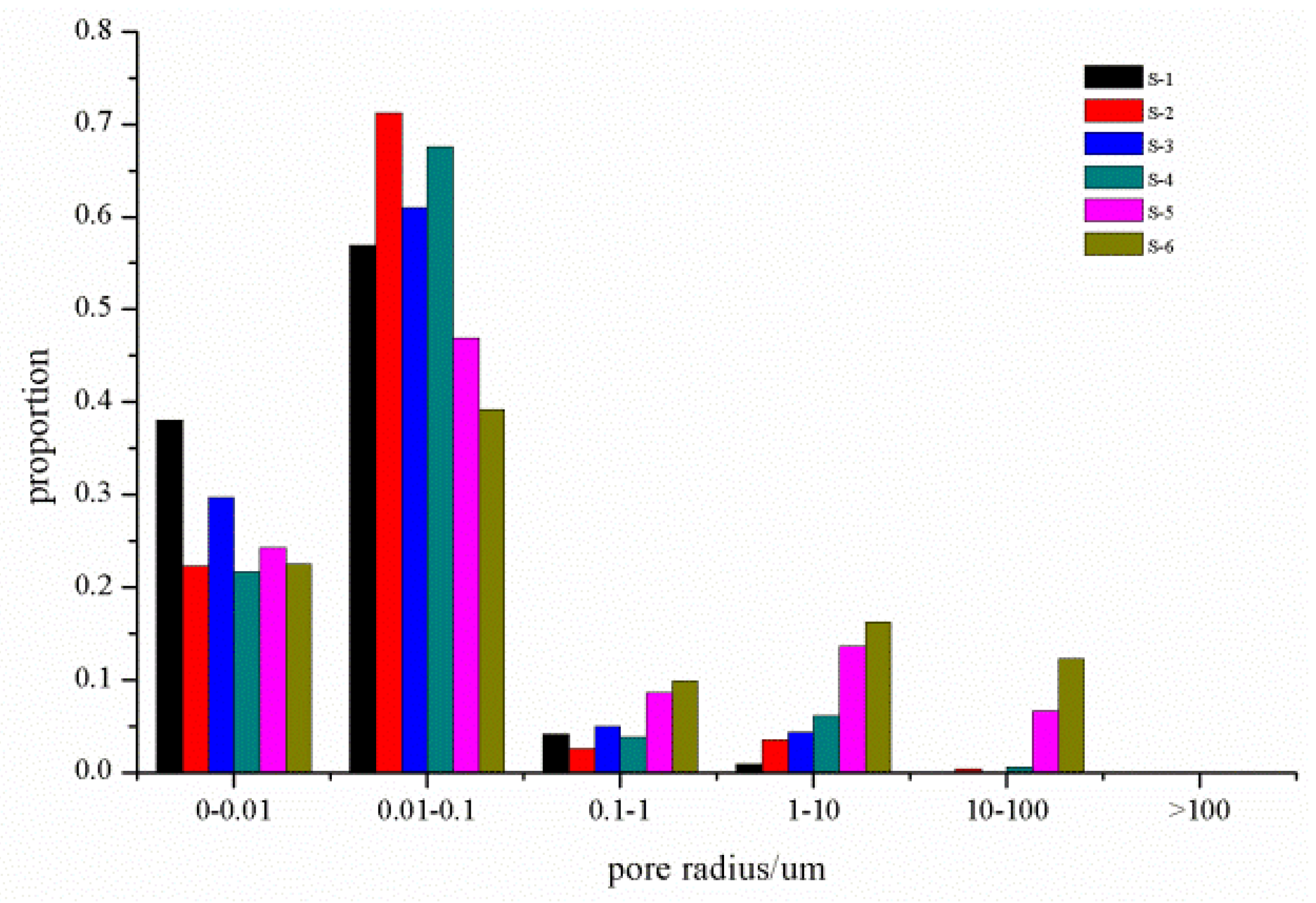

4.3. Analysis of Pore Size Distribution

5. Discussion

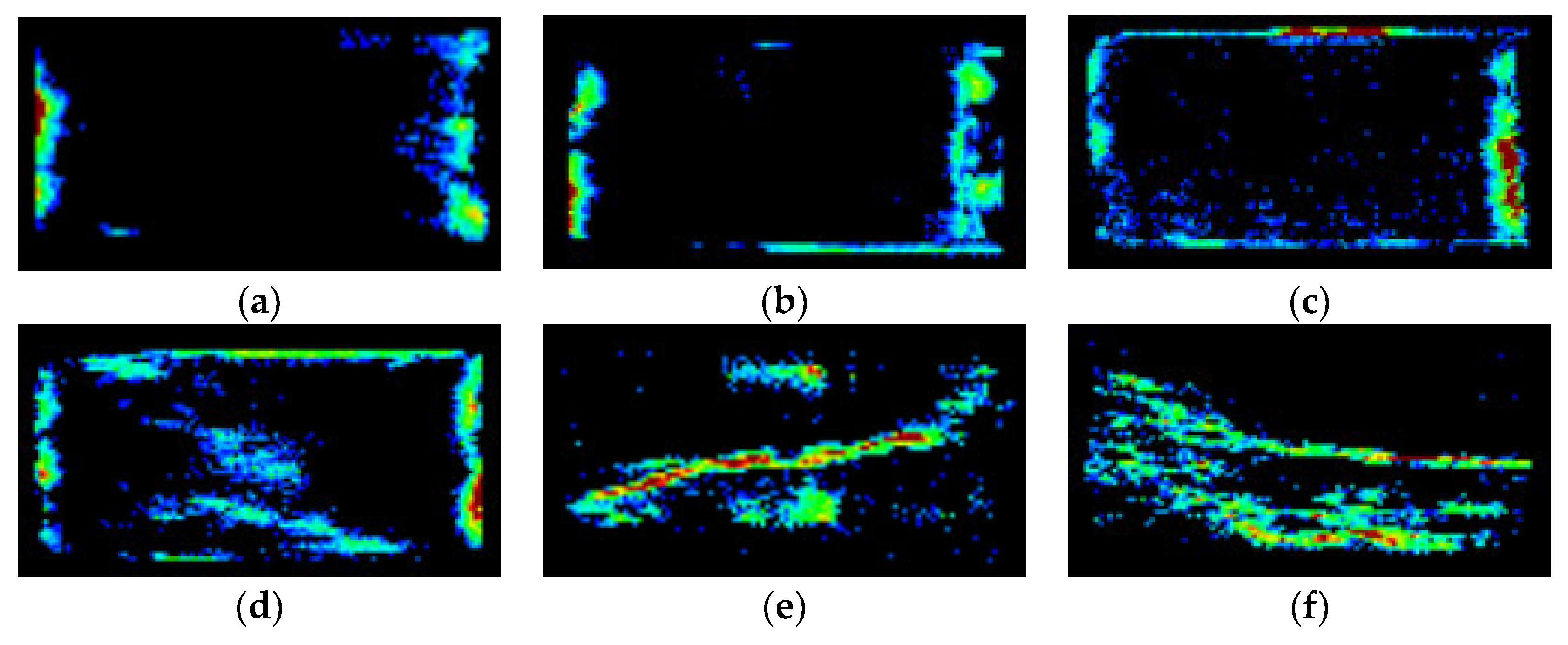

- (1)

- NMR images of S-1, S-2, and S-3: The NMR images of the rock specimen are generally dark, with bright spots concentrated at the ends of the sample. Overall, the distribution is a point shape at the ends. This color distribution indicates that there are no apparent cracks throughout the sample before an external load is applied.

- (2)

- NMR images of S-4: Compared with the first three samples, the NMR images of S-4 are brighter overall, and the areas that were bright in S-1, S-2, and S-3 are now brighter in this image after an external load has been applied. Bright patches also appear in the center of the rock in a patchy pattern. This indicates the generations of cracks in the rock, and micropores are continuously expanding into macropores and cracks.

- (3)

- NMR images of S-5: Compared to the previous images, S-5 is significantly brighter overall, and the brightness covers a much larger area. There are significant bright spots in multiple sections of the sample, especially an obvious bright strip in the diagonal position of the sample, which is regarded as a large crack. This indicates that a large number of cracks interconnected to form even larger cracks.

- (4)

- NMR images of S-6: the brightness of the NMR image is significantly brightened, with two bright crack channels clearly seen in the center of the rock.

6. Conclusions

- (1)

- When the axial compression ratio is less than 80%, the rock interior mainly contains micropores, and the growth of the mesopores and macropores is low. The variation rate of mesopores and macropores shows a significant increase when the predefined stress is more than 0.8 UCS, which is due to the rapid generation, expansion and transgression of pores. There is a critical value in the process of rock damage (0.8 UCS), and when it is less than this critical value, the microstructure in the rock is mainly composed of pores and micro-cracks, and the length is generally less than 5 μm. When it exceeds this value, there are obvious cracks or even groups of cracks inside the rock.

- (2)

- The variation in porosity can be divided into three stages, with an overall “√” shape tendency in porosity growth. The growth trend is mostly flat when the axial compression ratio is between 0% and 70%, which is mainly because the interior of the rock is dominated by micropores, and the growth of macropores and mesopores is low. The porosity in sandstone increases with an increasing axial compression ratio; however, due to the small size and number of macropores and mesopores, the porosity growth rate is very low; the variation rate shows a significant increase when the axial compression ratio reaches the damage threshold.

- (3)

- The pore structure of a rock can be visually presented using SEM and NMR imaging. The distribution mode of pores changes from separated points to thick patches and finally to connected networks with an increase in predefined stress.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Han, T.; Shi, J.; Chen, Y.; Cao, X. Quantifying Microstructural Damage of Sandstone after Hydrochemical Corrosion. Int. J. Geomech. 2018, 18, 04018121. [Google Scholar] [CrossRef]

- Li, W.; Liu, H.; Song, X. Influence of Fluid Exposure on Surface Chemistry and Pore-Fracture Morphology of Various Rank Coals: Implications for Methane Recovery and CO2 Storage. Energy Fuels 2017, 31, 12552–12569. [Google Scholar] [CrossRef]

- Alam, M.M.; Hjuler, M.L.; Christensen, H.F.; Fabricius, I.L. Petrophysical and rock-mechanics effects of CO2 injection for enhanced oil recovery: Experimental study on chalk from South Arne field, North Sea. J. Pet. Sci. Eng. 2014, 122, 468–487. [Google Scholar] [CrossRef]

- Zhu, H.; Ju, Y.; Qi, Y.; Huang, C.; Zhang, L. Impact of tectonism on pore type and pore structure evolution in organic-rich shale: Implications for gas storage and migration pathways in naturally deformed rocks. Fuel 2018, 228, 272–289. [Google Scholar] [CrossRef]

- Wang, L.; Fu, Y.; Li, J.; Sima, L.; Wu, Q.; Jin, W.; Wang, T. Mineral and pore structure characteristics of gas shale in Longmaxi formation: A case study of Jiaoshiba gas field in the southern Sichuan Basin, China. Arab. J. Geosci. 2016, 9, 733. [Google Scholar] [CrossRef]

- Tan, M.; Mao, K.; Song, X.; Yang, X.; Xu, J. NMR petrophysical interpretation method of gas shale based on core NMR experiment. J. Pet. Sci. Eng. 2015, 136, 100–111. [Google Scholar] [CrossRef]

- Sigal, R.F.; Odusina, E. Laboratory NMR Measurements on Methane Saturated Barnett Shale Samples. Petrophysics 2011, 52, 32–49. [Google Scholar]

- Hosseini, M.; Tavakoli, V.; Nazemi, M. The effect of heterogeneity on NMR derived capillary pressure curves, case study of Dariyan tight carbonate reservoir in the central Persian Gulf. J. Pet. Sci. Eng. 2018, 171, 1113–1122. [Google Scholar] [CrossRef]

- Gao, H.; Wang, C.; Cao, J.; He, M.; Dou, L. Quantitative study on the stress sensitivity of pores in tight sandstone reservoirs of Ordos basin using NMR technique. J. Pet. Sci. Eng. 2019, 172, 401–410. [Google Scholar] [CrossRef]

- Feng, S.; Chai, J.; Xu, Z.; Qin, Y. Evaluating the Mesostructural Changes of Laboratory Created Soil-Rock Mixtures Using a Seepage Test Based on NMR Technology. J. Test. Eval. 2018, 46, 879–891. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, H.; Wang, W.; Cheng, W.; Xin, L. Experimental Study on the Pore Structure Fractals and Seepage Characteristics of a Coal Sample Around a Borehole in Coal Seam Water Infusion. Transp. Porous Media 2018, 125, 289–309. [Google Scholar] [CrossRef]

- Chen, M.; Dai, J.; Liu, X.; Qin, M.; Pei, Y.; Wang, Z. Differences in the Fluid Characteristics between Spontaneous Imbibition and Drainage in Tight Sandstone Cores from Nuclear Magnetic Resonance. Energy Fuels 2018, 32, 10333–10343. [Google Scholar] [CrossRef]

- Zhao, Y.; Sun, Y.; Liu, S.; Wang, K.; Jiang, Y. Pore structure characterization of coal by NMR cryoporometry. Fuel 2017, 190, 359–369. [Google Scholar] [CrossRef]

- Ren, Y.; Sun, Y.; Meng, X. Multi-scale structural characteristics and the damage evolution mechanism of rock under load. Mater. Lett. 2023, 331, 133430. [Google Scholar] [CrossRef]

- Sun, Y.; Meng, X.; Ren, Y. Experimental study on the evolution of rock microstructure under dynamic water pressure. Mater. Lett. 2023, 349, 134825. [Google Scholar] [CrossRef]

- Li, H.; Zhong, Z.; Liu, X.; Sheng, Y.; Yang, D. Micro-damage evolution and macro-mechanical property degradation of limestone due to chemical effects. Int. J. Rock Mech. Min. Sci. 2018, 110, 257–265. [Google Scholar] [CrossRef]

- Blümich, B.; Casanova, F.; Perlo, J.; Anferova, S.; Anferov, V.; Kremer, K.; Goga, N.; Kupferschlager, K.; Adams, M. Advances of unilateral mobile NMR in nondestructive materials testing. Magn. Reson. Imaging 2005, 23, 197–201. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; You, L.; Zi, H.; Lan, Y.; Cui, Y.; Xu, J.; Fan, X.; Wang, G. Determination of pore size distribution in tight gas sandstones based on Bayesian regularization neural network with MICP, NMR and petrophysical logs. J. Nat. Gas Sci. Eng. 2022, 100, 104468. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.; Fan, Z.; Chen, J.; Wang, S.; Zhou, Z.; Fan, X. Insight into the Pore Structure of Tight Sandstones Using NMR and HPMI Measurements. Energy Fuels 2016, 30, 10200–10214. [Google Scholar] [CrossRef]

- Liu, D.; Ge, H.; Liu, J.; Shen, Y.; Wang, Y.; Liu, Q.; Jin, C.; Zhang, Y. Experimental investigation on aqueous phase migration in unconventional gas reservoir rock samples by nuclear magnetic resonance. J. Nat. Gas Sci. Eng. 2016, 36, 837–851. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, Y.; Liu, B.; Wu, Z.; Weng, L.; Liu, Q. Experimental investigation of strength repairing effects of chemical grouting on fractured porous sandstone under different temperature conditions. Int. J. Rock Mech. Min. Sci. 2023, 170, 105552. [Google Scholar] [CrossRef]

- Ghobadi, M.H.; Babazadeh, R. Experimental Studies on the Effects of Cyclic Freezing-Thawing, Salt Crystallization, and Thermal Shock on the Physical and Mechanical Characteristics of Selected Sandstones. Rock Mech. Rock Eng. 2015, 48, 1001–1016. [Google Scholar] [CrossRef]

- Martínez-Martínez, J.; Benavente, D.; Gomez-Heras, M.; Marco-Castaño, L.; Garcia-del-Cura, M.Á. Non-linear decay of building stones during freeze-thaw weathering processes. Constr. Build. Mater. 2013, 38, 443–454. [Google Scholar] [CrossRef]

- Meng, T.; Xiangxi, M.; Donghua, Z.; Hu, Y. Using micro-computed tomography and scanning electron microscopy to assess the morphological evolution and fractal dimension of a salt-gypsum rock subjected to a coupled thermal-hydrological-chemical environment. Mar. Pet. Geol. 2018, 98, 316–334. [Google Scholar] [CrossRef]

| Samples | Uσ | TSA | MISA | Proportion | MESA | Proportion | MASA | Proportion |

|---|---|---|---|---|---|---|---|---|

| 0 | 0 | 4256.86 | 3928.73 | 92.3% | 290.61 | 6.8% | 37.52 | 0.9% |

| S-2 | 60% | 5148.54 | 4837.07 | 94.0% | 281.51 | 5.5% | 29.96 | 0.5% |

| S-3 | 70% | 4516.69 | 4038.85 | 89.4% | 359.25 | 8.0% | 118.59 | 2.6% |

| S-4 | 80% | 5250.30 | 4714.45 | 89.8% | 404.85 | 7.7% | 131.00 | 2.5% |

| S-5 | 90% | 6196.25 | 4435.02 | 71.6% | 838.05 | 13.5% | 923.18 | 14.9% |

| S-6 | 95% | 7249.23 | 4529.59 | 62.5% | 1047.98 | 14.4% | 1671.66 | 23.1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, B.; Deng, X.; Pan, C.; Meng, X. An Investigation on the Pore Structure Characterization of Sandstone Using a Scanning Electron Microscope and an Online Nuclear Magnetic Resonance System. Appl. Sci. 2024, 14, 7063. https://doi.org/10.3390/app14167063

Tian B, Deng X, Pan C, Meng X. An Investigation on the Pore Structure Characterization of Sandstone Using a Scanning Electron Microscope and an Online Nuclear Magnetic Resonance System. Applied Sciences. 2024; 14(16):7063. https://doi.org/10.3390/app14167063

Chicago/Turabian StyleTian, Bo, Xuexiang Deng, Congwang Pan, and Xiangxi Meng. 2024. "An Investigation on the Pore Structure Characterization of Sandstone Using a Scanning Electron Microscope and an Online Nuclear Magnetic Resonance System" Applied Sciences 14, no. 16: 7063. https://doi.org/10.3390/app14167063