The Noise Exposure of Urban Rail Transit Drivers: Hazard Classification, Assessment, and Mitigation Strategies

Abstract

:1. Introduction

2. Literature Review

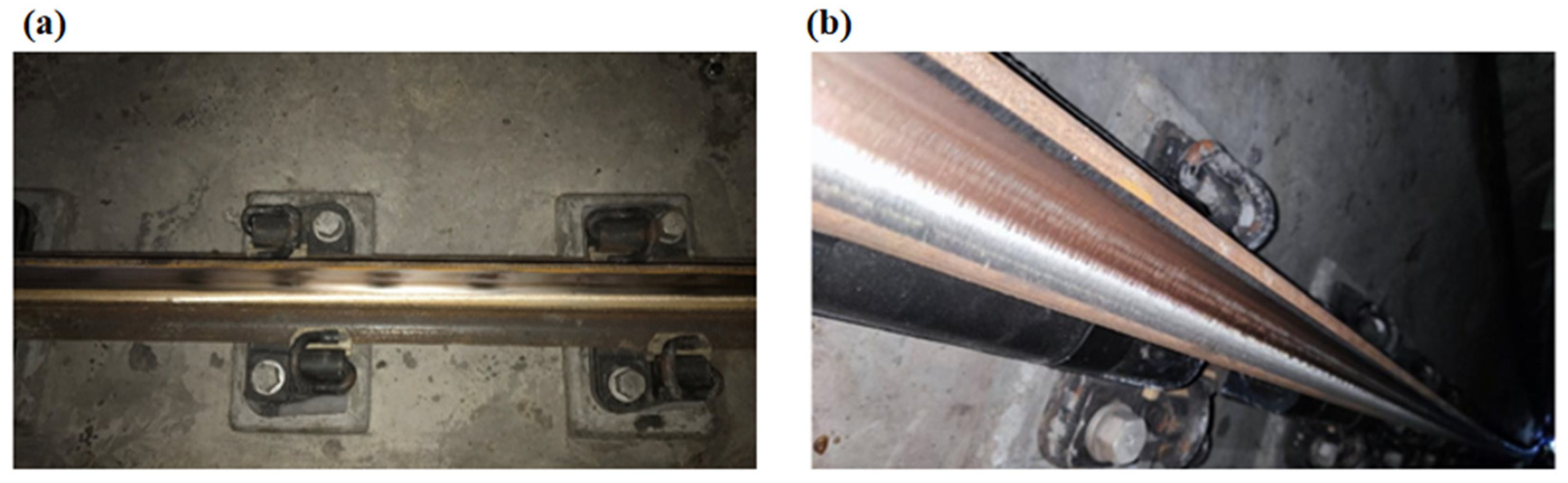

2.1. Mechanisms of Urban Rail Transit Noise

2.2. Urban Rail Transit Noise Assessment and Control

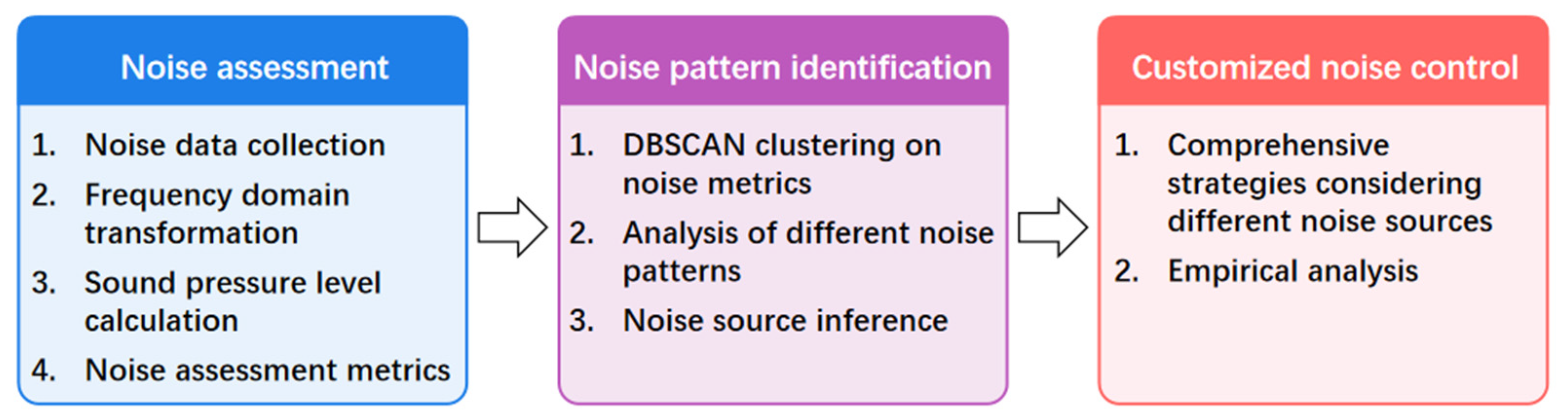

3. Methodology

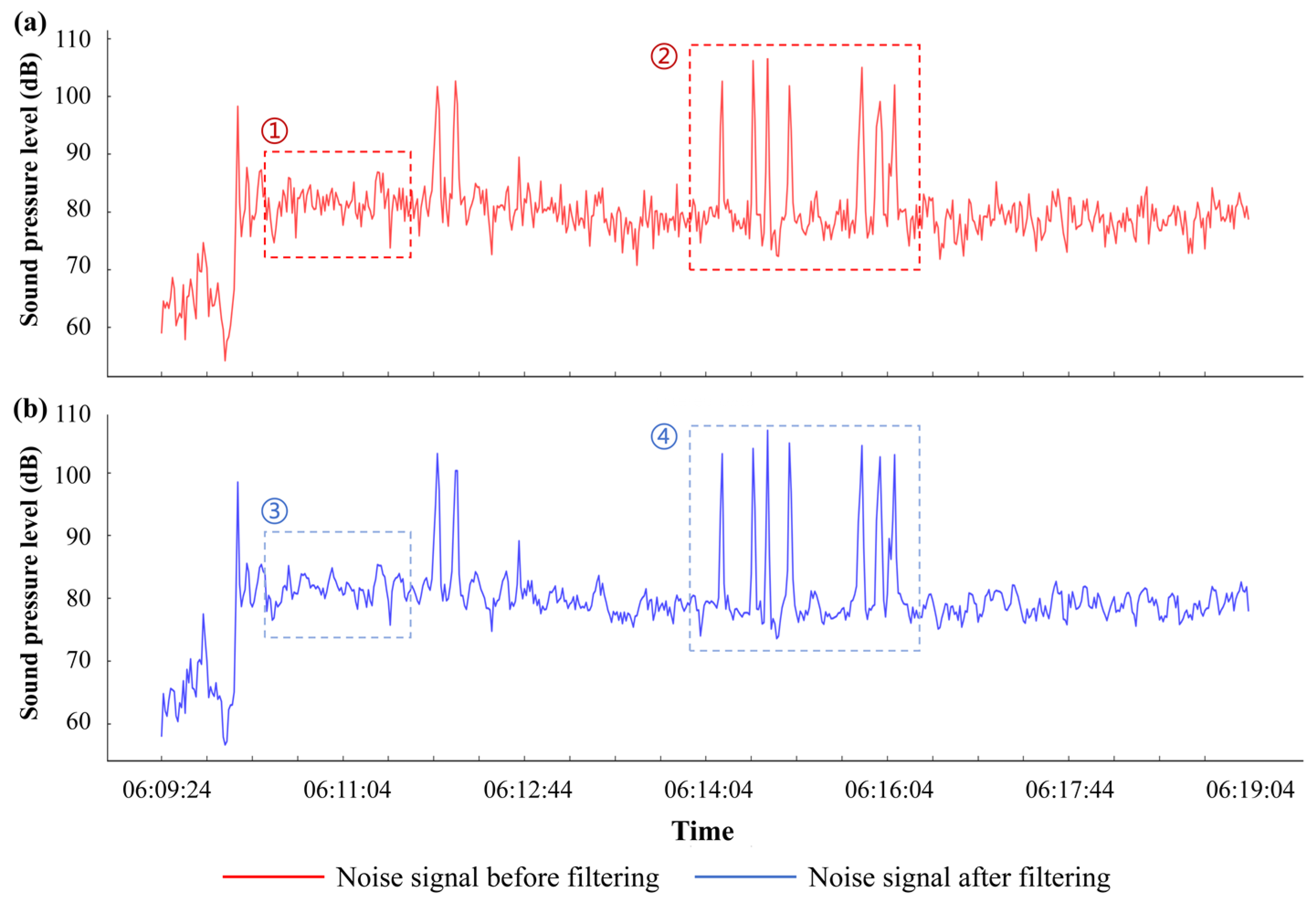

3.1. Noise Signal Processing and Assessment

3.2. Noise Pattern Identification

| Algorithm 1: Pseudocode for the noise pattern identification DBSCAN algorithm |

| Input: Dataset (D), neighborhood radius (ε), minimum points (minPts) |

| Output: Clusters of different noise patterns |

| 1: clusterID = 0 2: for each unvisited signal Sig in dataset D do 3: mark Sig as visited 4: NeighborSignals = regionQuery(Sig, ε) 5: if size of(NeighborSignals) < minPts then 6: mark Sig as noise 7: else 8: clusterID = clusterID + 1 9: expandCluster(Sig, NeighborSignals, clusterID, ε, minPts) 10: end if 11: end for 12: function expandCluster(Sig, NeighborSignals, clusterID, ε, minPts) 13: add Sig to cluster clusterID 14: for each signal Sig′ in NeighborSignals do 15: if Sig′ is not visited then 16: mark Sig′ as visited 17: NeighborSignals′ = regionQuery(Sig′, ε) 18: if sizeof(NeighborSignals′) ≥ minPts then 19: NeighborSignals ± NeighborSignals′ 20: end if 21: end if 22: if Sig′ is not yet part of any cluster then 23: add Sig′ to cluster clusterID 24: end if 25: end for 26: end function 27: function regionQuery(Sig, ε) 28: NeighborSignals = [] 29: for each signal Sig′ in dataset D do 30: if signalDistance(Sig, Sig′) ≤ ε and signalSimilarity(Sig, Sig′) then 31: NeighborSignals.add(Sig′) 32: end if 33: end for 34: return NeighborSignals 35: end function 36: function signalDistance(Sig, Sig′) 37: return sqrt((Sig.x − Sig′.x)2 + (Sig.y − Sig′.y)2 + (Sig.frequency − Sig′.frequency)2) 38: end function 39: function signalSimilarity(Sig, Sig′) 40: return four types of similarity metrics 41: end function 42: function soundPressureLevelSimilarity(Sig, Sig′) 43: return abs(Sig.SPL − Sig′.SPL) ≤ ε_SPL 44: end function 45: function mainFrequencyComponentSimilarity(Sig, Sig′) 46: return abs(Sig.MF − Sig′.MF) ≤ ε_MF 47: end function 48: function timeAccumulationOfEnergySimilarity(Sig, Sig′) 49: return abs(Sig.TE − Sig’.TE) ≤ ε_TE 50: end function 51: function eventsExceedingSpecificSoundPressureLevelsSimilarity(Sig, Sig′) 52: return abs(Sig.NE − Sig′.NE) ≤ ε_NE 53: end function |

4. Results Analysis

4.1. Noise Data Collection and Assessment

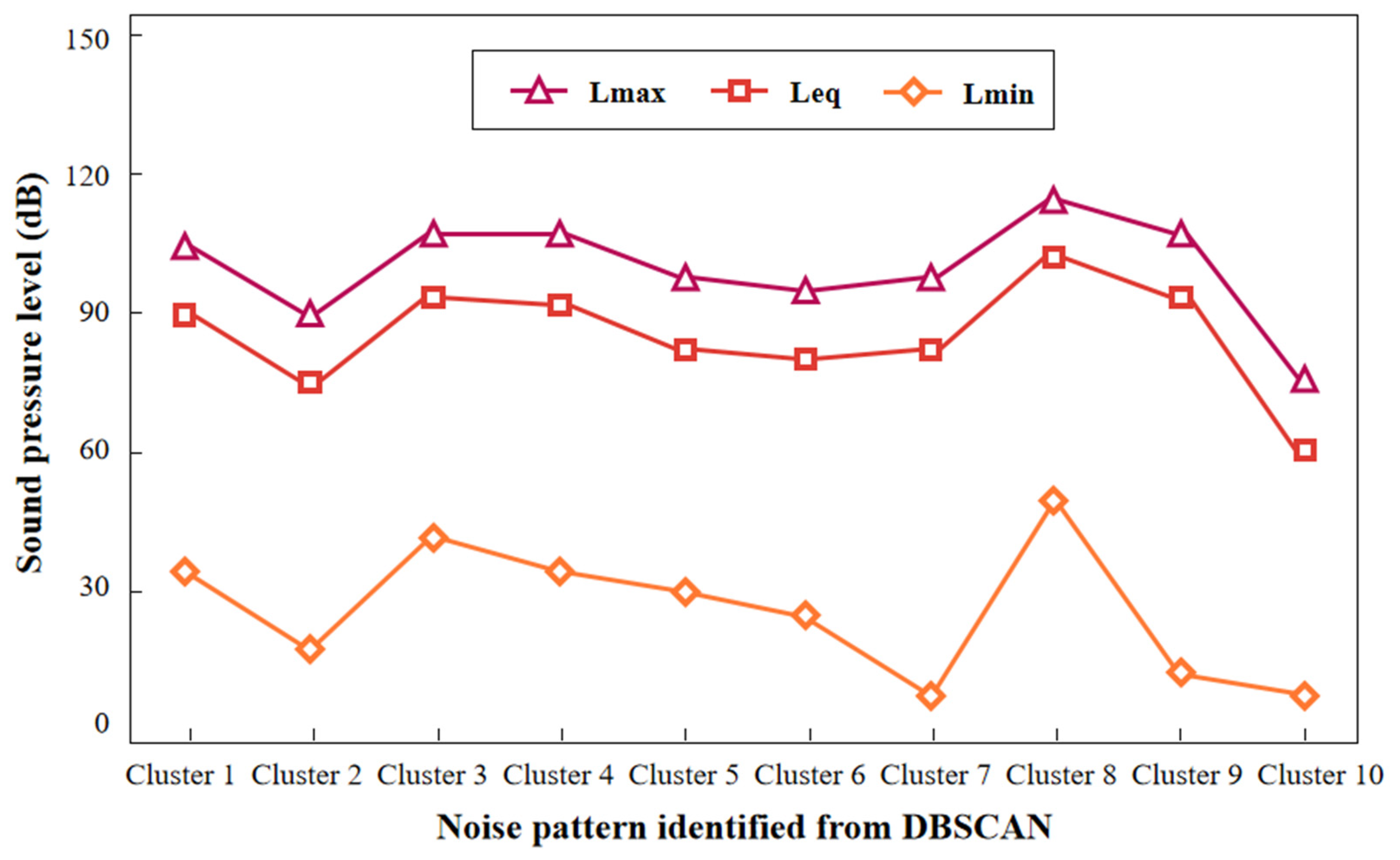

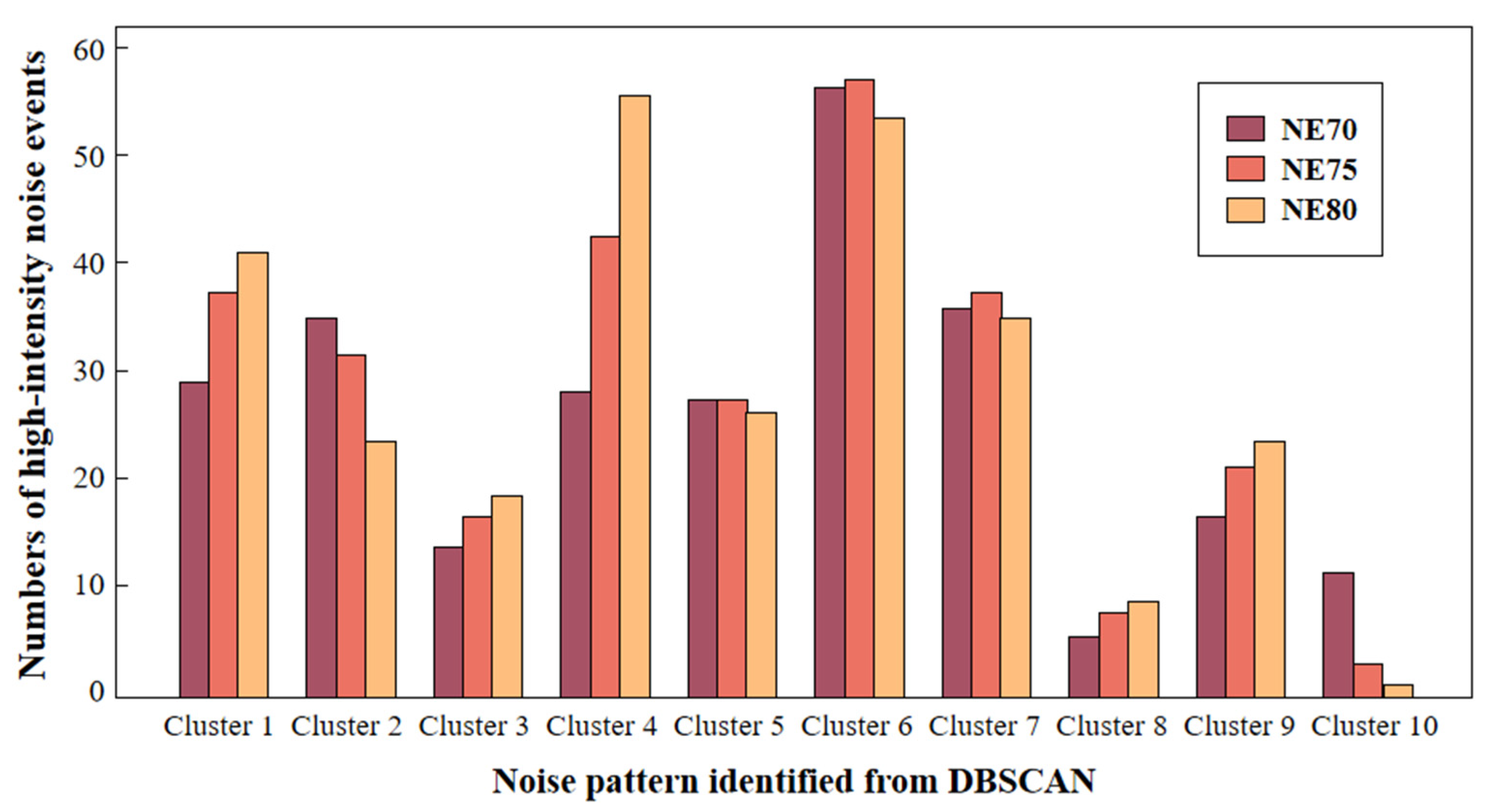

4.2. Noise Pattern Analysis

5. Discussion of the Noise Control Strategies

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Equipment | Model/Type | Application and Specifications |

|---|---|---|

| Sound Level Meter | 2270-S | The 2270-S is a Type 1 dual-channel sound level meter that integrates the features of models 2250-S and 2250-W. It is capable of simultaneous measurements using two microphones, two accelerometers, or one of each, allowing for efficient data collection. This meter complies with ISO 7196:1995 and ANSI S1.42-2001 (R2011) standards for infrasonic measurements. |

| Microphone | Bruel & Kjaer 4189-A-021 | The Bruel & Kjaer 4189-A-021 is a high-sensitivity, precision free-field microphone designed for accurate sound measurements. It features a sensitivity of 50 mV/Pa, a frequency range of 6.3 Hz to 20 kHz, a dynamic range of 14.6 to 146 dB, and can operate in temperatures ranging from −30 to +150 °C (−22 to +302 °F). |

| Acoustic Calibrator | 4231 | The 4231 Acoustic Calibrator is a portable sound source used for calibrating sound level meters and other acoustic measurement instruments. It meets the specifications of EN/IEC 60942 Class LS and Class 1, as well as ANSI S1.40-1984, ensuring reliable and precise calibration. |

| Cloud Intelligence Acquisition System | INV3062A | The INV3062A is a versatile cloud intelligence acquisition system that supports remote measurement and monitoring via LAN and internet connectivity. It allows for external USB connections and features GPS/Beidou and IEEE1588 synchronization. |

| Sound Pressure (dB) | Effects on Human Health |

|---|---|

| 30 | Very quiet, suitable for restful sleep; little to no health impact. |

| 40 | Quiet, comfortable sound level; no significant health effects. |

| 50 | Moderate noise, suitable for a normal conversation; no health issues. |

| 60 | Normal conversation level; prolonged exposure can be annoying. |

| 70 | Above this level, prolonged exposure may cause stress and hearing discomfort. |

| 80 | Long-term exposure can lead to increased risk of hearing damage and stress. |

| 85 | Prolonged exposure without protection can cause hearing damage. |

| 90 | Hearing protection recommended for prolonged exposure; risk of hearing loss. |

| 100 | Hearing loss risk increases significantly without protection; uncomfortable. |

| 110 | Regular exposure can lead to permanent hearing loss. |

| 120 | Threshold of pain; immediate harm to hearing possible. |

References

- Yu, C.; Deng, Y.; Qin, Z.; Yang, C.; Yuan, Q. Traffic volume and road network structure: Revealing transportation-related factors on PM2.5 concentrations. Transp. Res. Part D Transp. Environ. 2023, 124, 103935. [Google Scholar] [CrossRef]

- Yang, C.; Yu, C.; Dong, W.; Yuan, Q. Substitutes or complements? Examining effects of urban rail transit on bus ridership using longitudinal city-level data. Transp. Res. Part A Policy Pract. 2023, 174, 103728. [Google Scholar] [CrossRef]

- Burdzik, R.; Konieczny, Ł.; Figlus, T. Concept of On-Board Comfort Vibration Monitoring System for Vehicles. In Proceedings of the Activities of Transport Telematics, Katowice, Poland, 23–26 October 2013; Mikulski, J., Ed.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 418–425. [Google Scholar]

- Figlus, T.; Gnap, J.; Skrúcaný, T.; Szafraniec, P. Analysis of the influence of different means of transport on the level of traffic noise. Sci. J. Silesian Univ. Technology. Ser. Transp. 2017, 97, 27–38. [Google Scholar]

- Zhu, Z.; Zhu, S.; Sun, L.; Mardan, A. Modelling changes in travel behaviour mechanisms through a high-order hidden Markov model. Transp. A Transp. Sci. 2022, 20, 2130731. [Google Scholar] [CrossRef]

- Wang, A.L.; Bista, S.; Can, A.; Chaix, B. Personal noise exposure during daily commutes and subjectively reported stress: A trip stage level analysis of MobiliSense data. J. Transp. Health 2023, 30, 11. [Google Scholar] [CrossRef]

- Yan, L.; Chen, Z.; Zou, Y.F.; He, X.H.; Cai, C.Z.; Yu, K.H.; Zhu, X.J. Field Study of the Interior Noise and Vibration of a Metro Vehicle Running on a Viaduct: A Case Study in Guangzhou. Int. J. Environ. Res. Public Health 2020, 17, 2807. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Thompson, D.; Squicciarini, G.; Liu, X.W.; Rissmann, M.; Bouvet, P.; Denia, F.D.; Baeza, L.; Jarillo, J.M.; García-Loygorri, J.M. A framework to predict the airborne noise inside railway vehicles with application to rolling noise. Appl. Acoust. 2021, 179, 108064. [Google Scholar] [CrossRef]

- Kowalczyk, K.; Opala, M. Commuter Experience: An Assessment of Metro-Train Comfort Amidst Operational Vibroacoustic Conditions. Appl. Sci. 2024, 14, 6137. [Google Scholar] [CrossRef]

- Peng, H.; Yao, Y.; Cai, X.; Zhong, Y.; Sun, T. Field Measurement Analysis and Control Measures Evaluation of Metro Vehicle Noise Caused by Rail Corrugation. Appl. Sci. 2021, 11, 11190. [Google Scholar] [CrossRef]

- Yu, B.; Chai, Y.; Wang, C. Effect of the Exterior Traffic Noises on the Sound Environment Evaluation in Office Spaces with Different Interior Noise Conditions. Appl. Sci. 2024, 14, 3017. [Google Scholar] [CrossRef]

- Golmohammadi, R.; Darvishi, E.; Faradmal, J.; Poorolajal, J.; Aliabadi, M. Attention and short-term memory during occupational noise exposure considering task difficulty. Appl. Acoust. 2020, 158, 9. [Google Scholar] [CrossRef]

- Liu, X.L.; Han, J.; Liu, M.K.; Wang, J.N.; Xiao, X.B.A.; Wen, Z.F. Rail Roughness Acceptance Criterion Based on Metro Interior Noise. Chin. J. Mech. Eng. 2022, 35, 12. [Google Scholar] [CrossRef]

- Lázaro, J.; Costa, P.A.; Godinho, L. Experimental Light Rail Traffic Noise Assessment in a Metropolitan Area. Appl. Sci. 2024, 14, 969. [Google Scholar] [CrossRef]

- Cao, X.; Yang, L.; Li, P.; Xu, J.; Zhang, X. Influence of Fastener Stiffness and Damping on Vibration Transfer Characteristics of Urban Railway Bridge Lines Using Vibration Power Flow Method. Appl. Sci. 2023, 13, 12543. [Google Scholar] [CrossRef]

- Garg, N.; Sharma, O.; Maji, S. Noise impact assessment of mass rapid transit systems in Delhi city. Indian J. Pure Appl. Phys. 2011, 49, 257–262. [Google Scholar]

- Tao, Z.Y.; Wang, Y.M.; Zou, C.; Li, Q.; Luo, Y. Assessment of ventilation noise impact from metro depot with over-track platform structure on workers and nearby inhabitants. Environ. Sci. Pollut. Res. 2019, 26, 9203–9218. [Google Scholar] [CrossRef]

- Zou, C.; Wang, Y.M.; Wang, P.; Guo, J.X. Measurement of ground and nearby building vibration and noise induced by trains in a metro depot. Sci. Total Environ. 2015, 536, 761–773. [Google Scholar] [CrossRef] [PubMed]

- Hsu, W. Structure-borne noise of steel and concrete box girders in an urban metro system: A hybrid evaluation and parametric study. J. Low Freq. Noise Vib. Act. Control 2023, 42, 1560–1577. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Li, L.; Li, H.X. Interior Noise Prediction of Metro Train in a Tunnel Caused by Wheel/Rail Rolling. Acoust. Aust. 2024, 52, 161–173. [Google Scholar] [CrossRef]

- Zhao, C.Y.; Ping, W. Minimizing noise from metro viaduct railway lines by means of elastic mats and fully closed noise barriers. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2018, 232, 1828–1836. [Google Scholar] [CrossRef]

- Liu, X.B.; Jiang, Z.C.; Wang, X.F.; Li, D.K. Noise distribution law of air-conditioning ducts for metro vehicles. Noise Control Eng. J. 2020, 70, 376–383. [Google Scholar]

- Li, X.M.; Chen, Y.K.; Zou, C.; Wang, H.; Zheng, B.K.; Chen, J.L. Building structure-borne noise measurements and estimation due to train operations in tunnel. Sci. Total Environ. 2024, 926, 16. [Google Scholar] [CrossRef]

- Han, J.; Xiao, X.B.; Wu, Y.; Wen, Z.F.; Zhao, G.T. Effect of rail corrugation on metro interior noise and its control. Appl. Acoust. 2018, 130, 63–70. [Google Scholar] [CrossRef]

- Wang, Q.C.; Hongwei, W.; Yang, C.X.; Zhang, G.Y. Developing multivariate models for predicting the levels of multi- dimensional critical perceptions due to metro noise inside buildings. Appl. Acoust. 2022, 200, 14. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Li, L.; Zhu, Q. Structure-borne Noise Differences of Metro Vehicle Running on Different Tracks. KSCE J. Civ. Eng. 2023, 27, 3861–3871. [Google Scholar] [CrossRef]

- Song, X.; Yin, L.; Xiong, W.; Wu, H.; Cai, C.S.; Li, X. Underwater noise prediction and control of a cross-river subway tunnel: An experimental and numerical study. Int. J. Environ. Sci. Technol. 2024, 21, 4045–4062. [Google Scholar] [CrossRef]

- Zhu, W.Z.; Shi, S.G.; Luo, L.; Sun, J.W. A novel adaptive state detector-based post-filtering active control algorithm for Gaussian noise environment with impulsive interference. Appl. Sci. 2019, 9, 1176. [Google Scholar] [CrossRef]

- Zhang, L.B.; Kang, J.; Luo, H.B.; Zhong, B.T. Drivers’ physiological response and emotional evaluation in the noisy environment of the control cabin of a shield tunneling machine. Appl. Acoust. 2018, 138, 1–8. [Google Scholar] [CrossRef]

- Bal Kocyigit, F.; Kocyigit, A. Sound control in mass transit stations: With case study from Central Anatolia. J. Acoust. Soc. Am. 2010, 128 (Suppl. S4), 2296. [Google Scholar] [CrossRef]

- Laffitte, P.; Sodoyer, D.; Tatkeu, C.; Girin, L. Deep neural networks for automatic detection of screams and shouted speech in subway trains. In Proceedings of the 2016 IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP), Shanghai, China, 20–25 March 2016; pp. 6460–6464. [Google Scholar]

- Ghotbi, M.R.; Monazzam, M.R.; Baneshi, M.R.; Asadi, M.; Fard, S.M.B. Noise pollution survey of a two-storey intersection station in Tehran metropolitan subway system. Environ. Monit. Assess. 2012, 184, 1097–1106. [Google Scholar] [CrossRef]

- Yao, C.M.K.L.; Ma, A.K.; Cushing, S.L.; Lin, V.Y.W. Noise exposure while commuting in Toronto—A study of personal and public transportation in Toronto. J. Otolaryngol. Head Neck Surg. 2017, 46, 62. [Google Scholar] [CrossRef]

- Jiang, S.; Zou, Y.F.; He, X.H.; Cai, C.Z.; Zhai, L.H.; Nong, X.Z. Wind Tunnel Study on Aerodynamic Characteristics of the Train on Viaducts with a New Type of Wind-Noise Barrier under Cross Wind. Int. J. Struct. Stab. Dyn. 2022, 22, 23. [Google Scholar] [CrossRef]

- Lee, D.; Kim, G.; Han, W. Analysis of Subway Interior Noise at Peak Commuter Time. J. Audiol. Otol. 2017, 21, 61–65. [Google Scholar] [CrossRef]

- He, X.H.; Yu, K.H.; Cai, C.Z.; Zou, Y.F. Dynamic Responses of the Metro Train’s Bogie Frames: Field Tests and Data Analysis. Shock Vib. 2020, 2020, 10. [Google Scholar] [CrossRef]

- Aly, M.E. Noise assessment inside the second-line of the Greater Cairo Underground Metro. Sadhana-Acad. Proc. Eng. Sci. 2005, 30, 47–55. [Google Scholar] [CrossRef]

- Bhattacharya, S.K.; Bandyopadhyay, P.; Kashyap, S.K. Calcutta metro: Is it safe from noise pollution hazards? Ind. Health 1996, 34, 45–50. [Google Scholar] [CrossRef]

- Li, X.M.; Hu, Z.H.; Zou, C. Noise annoyance and vibration perception assessment on passengers during train operation in Guangzhou Metro. Environ. Sci. Pollut. Res. 2022, 29, 4246–4259. [Google Scholar] [CrossRef]

- Wang, Q.C.; Wang, H.W.; Cai, J.L.; Zhang, L. The multi-dimensional perceptions of office staff and non-office staff about metro noise in commercial spaces. Acta Acust. 2022, 6, 14. [Google Scholar] [CrossRef]

- Ma, M.; Li, M.H.; Qu, X.Y.; Zhang, H.G. Effect of passing metro trains on uncertainty of vibration source intensity: Monitoring tests. Measurement 2022, 193, 19. [Google Scholar] [CrossRef]

- Wang, J.P.; Ren, C.L.; Liu, Z.; Mao, M.Y. Research on Direct Drive Technology of the Permanent Magnet Synchronous Motor for Urban Rail Vehicles. Math. Probl. Eng. 2022, 2022, 13. [Google Scholar] [CrossRef]

- Tao, Y.H.; Chai, Y.W.; Kou, L.R.; Kwan, M.P. Understanding noise exposure, noise annoyance, and psychological stress: Incorporating individual mobility and the temporality of the exposure-effect relationship. Appl. Geogr. 2020, 125, 14. [Google Scholar] [CrossRef]

- Vogiatzis, K.; Vanhonacker, P. Noise reduction in urban LRT networks by combining track based solutions. Sci. Total Environ. 2016, 568, 1344–1354. [Google Scholar] [CrossRef] [PubMed]

- He, L.; Feng, B. Fundamentals of Measurement and Signal Analysis; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar] [CrossRef]

- Tuzlukov, V. Signal Processing Noise; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Fahy, F.; Walker, J. Advanced Applications in Acoustics, Noise and Vibration; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Havelock, D.I.; Kuwano, S.; Vorländer, M. Handbook of Signal Processing in Acoustics; Springer: Berlin/Heidelberg, Germany, 2008; Volume 1. [Google Scholar]

- Amami, R.; Smiti, A. An incremental method combining density clustering and support vector machines for voice pathology detection. Comput. Electr. Eng. 2017, 57, 257–265. [Google Scholar] [CrossRef]

- Kim, S.K. Improvements for reduction of the brake squeal noise at Seoul metro rolling stock on tracks. J. Mech. Sci. Technol. 2009, 23, 2206–2214. [Google Scholar] [CrossRef]

- Yu, C.; Qin, Z.; Lu, Y.; Lin, H.; Yang, C.; Yuan, Q.; Wu, Q. Integrated strategies for road transportation-related multi-pollutant control: A cross-departmental policy mix. Transp. Res. Part D Transp. Environ. 2024, 132, 104257. [Google Scholar] [CrossRef]

- Yu, C.; Lin, H.; Chen, Y.; Yang, C.; Yin, A.; Yuan, Q. Creating most needed customized bus services: A collaborative analysis of user-route dynamics. Transp. Res. Part D Transp. Environ. 2024, 133, 104312. [Google Scholar] [CrossRef]

- Shi, Z.; Xu, M.; Song, Y.; Zhu, Z. Multi-Platform dynamic game and operation of hybrid Bike-Sharing systems based on reinforcement learning. Transp. Res. Part E Logist. Transp. Rev. 2024, 181, 103374. [Google Scholar] [CrossRef]

- Song, Y.; Luo, K.; Shi, Z.; Zhang, L.; Shen, Y. Nonlinear Influence and Interaction Effect on the Imbalance of Metro-Oriented Dockless Bike-Sharing System. Sustainability 2024, 16, 349. [Google Scholar]

- Song, Y.; Zhang, L.; Luo, K.; Wang, C.; Yu, C.; Shen, Y.; Yu, Q. Self-loop analysis based on dockless bike-sharing system via bike mobility chain: Empirical evidence from Shanghai. Transportation 2024. [Google Scholar] [CrossRef]

| Research | Target | Empirical Case | Conclusions (Mitigation Measures) |

|---|---|---|---|

| Zhao et al., (2018) [21] | Minimizing noise from urban rail transit viaduct railway lines using elastic mats and noise barriers | Hangzhou Urban Rail Transit Line 1 | Elastic mats reduce bridge-borne noise; fully enclosed barriers control wheel–rail noise |

| Liu et al., (2020) [22] | Noise distribution in air-conditioning ducts for urban rail transit vehicles | Air-conditioning ducts in urban rail transit vehicles | The exponential increase inside hole area ensures uniform air supply; focus on the front end for noise control |

| Wang et al., (2022) [25] | Direct drive technology for permanent magnet synchronous motors in urban rail vehicles | Suzhou Urban Rail Transit Line 3 | Hollow shaft structure reduces vibration and noise; optimized mass distribution improves performance |

| Zhang et al., (2023) [26] | Structure-borne noise differences of urban rail transit vehicles on various tracks | Field measurements and numerical simulation | Floating-slab track increases noise; recommendations include track condition monitoring and design adjustments |

| Zhang et al., (2024) [20] | Low-frequency noise inside urban rail transit: contribution analysis and noise control | Urban rail transit vehicle interior | Identifying essential elements contributing to low-frequency noise; damping optimization reduces noise peaks |

| Hsu, (2023) [19] | Structure-borne noise in steel and concrete box girders in urban rail transit systems | Urban rail transit systems | Pre-stressed concrete box girders are recommended for lower noise levels; optimize track conditions and train speed |

| Song et al., (2024) [27] | Underwater noise prediction and control for a cross-river urban rail transit tunnel | Nanjing Urban Rail Transit Line 10 | Lower stiffness rail fasteners reduce underwater noise, mitigating impact on aquatic species |

| Tao et al., (2019) [17] | Ventilation noise impact from urban rail transit depot with over-track platform structure | Guangzhou Urban Rail Transit Line 6 | Noise control measures for ventilation systems; traditional methods insufficient for low-frequency noise |

| Liu et al., (2022) [13] | Rail roughness acceptance criterion based on urban rail transit interior noise | Urban rail transit interior noise analysis | Rail roughness control limits based on interior noise; combined test and simulation method used |

| Zhu et al., (2019) [28] | Adaptive state detector-based active control algorithm for Gaussian noise with impulsive interference | Urban rail transit air-conditioner systems | The new algorithm enhances noise control performance; effective for varying impulsive noise |

| Peng et al., (2021) [10] | Analysis and evaluation of urban rail transit vehicle noise caused by rail corrugation | Urban rail transit vehicle interior noise | Rail grinding and increasing track stiffness reduce interior noise significantly |

| Zhang et al., (2018) [29] | Drivers’ physiological and emotional responses to noisy environments in shield tunneling machine cabins | Urban rail transit systems | Addressing driver stress and emotional impact due to noise; recommendations for noise reduction measures |

| Han et al., (2018) [24] | Impact of rail corrugation on urban rail transit interior noise and its mitigation | Urban rail transit trains in tunnels | Rail grinding standards based on interior noise limits; addressing short-wavelength corrugations |

| Zhang et al., (2024) [20] | Prediction of interior noise in urban rail transit trains due to wheel/rail rolling in tunnels | Urban rail transit trains in tunnels | SEA model predicts interior noise; noise control treatment on tunnel walls reduces interior noise |

| Kocyigit et al., (2010) [30] | Sound control in mass transit stations | Ankara Metro System | The use of sound-absorbing materials on ceilings and sidewalls is confirmed as important for metro noise control |

| Laffitte et al., (2016) [31] | Automatic detection of screams and shouts in subway trains | Paris Metro, France | Recommend to implement real-time audio monitoring systems that use deep neural networks to detect abnormal sounds such as screams and shouts |

| Ghotbi et al., (2012) [32] | Noise pollution in Tehran metro station | Imam Khomeini Station, Tehran | Noise levels ranged from 68.35 to 79.54 dB(A), exceeding limits; recommended improved design and materials to reduce noise exposure |

| Yao et al., (2017) [33] | Noise exposure in urban transportation | Toronto Mass Transit system | Mean average noise levels are within safe limits, but peak noise exposures, especially on public transit routes, pose a risk for noise-induced hearing loss |

| This study | Noise assessment and mitigation in driver cab | Urban rail transit systems | Tailored strategies such as optimizing the train’s deceleration process, installing vibration dampers and elastic fasteners, regularly grinding the rails, and covering air conditioning and certain equipment with sound-absorbing materials are effective |

| Metric | Description |

|---|---|

| Leq | Average sound pressure level over a specific period |

| Lmax | Maximum sound pressure level over a specific period |

| Lmin | Minimum sound pressure level over a specific period |

| L10 | Sound pressure level exceeded 10% of the time |

| L25 | Sound pressure level exceeded 25% of the time |

| L50 | Sound pressure level exceeded 50% of the time |

| L75 | Sound pressure level exceeded 75% of the time |

| L90 | Sound pressure level exceeded 90% of the time |

| LR | Difference between the maximum (Lmax) and minimum (Lmin) sound pressure levels |

| MF | Dominant frequency component over a specific period |

| TE | The total energy of the signal over a specific period |

| NE70 | Number of events exceeding a specific sound level (70 dB) |

| NE75 | Number of events exceeding a specific sound level (75 dB) |

| NE80 | Number of events exceeding a specific sound level (80 dB) |

| Metric | Mean | Std | Max | Min |

|---|---|---|---|---|

| Leq | 87.12 | 8.52 | 117.33 | 53.43 |

| Lmax | 101.11 | 8.15 | 132.05 | 67.98 |

| Lmin | 29.54 | 14.21 | 78.78 | 0.00 |

| L10 | 96.72 | 8.39 | 126.05 | 63.01 |

| L25 | 93.71 | 8.41 | 124.24 | 59.83 |

| L50 | 89.19 | 8.51 | 119.74 | 55.34 |

| L75 | 82.87 | 8.71 | 115.76 | 48.73 |

| L90 | 74.97 | 8.95 | 110.14 | 40.68 |

| LR | 71.57 | 11.88 | 124.87 | 36.32 |

| MF | 24.68 | 20.26 | 100.00 | 10.00 |

| TE | 7,753,212.22 | 1,480,296.53 | 13,831,022.73 | 2,948,416.30 |

| NE70 | 27.76 | 15.81 | 97.00 | 0.00 |

| NE75 | 30.72 | 16.43 | 99.00 | 0.00 |

| NE80 | 30.97 | 17.90 | 109.00 | 0.00 |

| Cluster | L10 | LR | MF | TE | Noise Type |

|---|---|---|---|---|---|

| 1 | 100.04 | 69.98 | 14.47 | 8,219,631.64 | Wheel–rail noise during acceleration |

| 2 | 85.39 | 70.91 | 17.60 | 5,813,206.67 | Air conditioning system noise |

| 3 | 103.39 | 65.31 | 15.76 | 8,963,234.54 | Wind noise and track noise |

| 4 | 101.50 | 71.56 | 69.70 | 8,539,070.76 | Braking system noise |

| 5 | 92.61 | 65.99 | 17.18 | 6,983,686.88 | Train noise at low speeds |

| 6 | 90.57 | 70.14 | 34.10 | 6,637,823.11 | Mechanical noise |

| 7 | 91.98 | 87.82 | 20.13 | 6,837,665.92 | Train noise at low speeds |

| 8 | 110.74 | 65.38 | 18.78 | 10,475,325.30 | Wind noise and track noise |

| 9 | 103.68 | 94.10 | 17.89 | 8,900,800.27 | Railway track crossing noise |

| 10 | 71.00 | 67.50 | 19.33 | 3,859,957.45 | Other noise |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, L.; Sun, Z.; Yu, C.; Zhang, Y.; Yan, B. The Noise Exposure of Urban Rail Transit Drivers: Hazard Classification, Assessment, and Mitigation Strategies. Appl. Sci. 2024, 14, 7388. https://doi.org/10.3390/app14167388

Huang L, Sun Z, Yu C, Zhang Y, Yan B. The Noise Exposure of Urban Rail Transit Drivers: Hazard Classification, Assessment, and Mitigation Strategies. Applied Sciences. 2024; 14(16):7388. https://doi.org/10.3390/app14167388

Chicago/Turabian StyleHuang, Lu, Zhiqiang Sun, Chengcheng Yu, Yuliang Zhang, and Bing Yan. 2024. "The Noise Exposure of Urban Rail Transit Drivers: Hazard Classification, Assessment, and Mitigation Strategies" Applied Sciences 14, no. 16: 7388. https://doi.org/10.3390/app14167388