Application of Explosive Equivalency Approach in Blast-Induced Seismic Effect Prediction Using EXPLO5 Thermochemical Code

Abstract

1. Introduction

2. Materials and Methods

Thermochemical Calculations

3. Results and Discussion

4. Conclusions

- (a)

- The results have shown that the equivalency approach is a potential tool in the assessment of the blast-induced seismic effect. It is especially useful in the situation when the type of explosive is changed within a single project;

- (b)

- It was demonstrated that the best results are obtained when the equivalent weight of the studied explosive is calculated as a ratio of detonation velocities of studied and reference explosives;

- (c)

- Analysis of experimental results has shown that the measurement uncertainty is quite high. This may be attributed to the fact that the weight of the explosives used in the tests was too small (15–75 g). To validate the approach, it is necessary to improve the accuracy of experimental measurements, which can be achieved by using larger samples, including the amounts required for mass blasting at open pits;

- (d)

- The advantage of the approach is that EMEe is determined using detonation velocity, the parameter that is relatively easy to measure experimentally;

- (e)

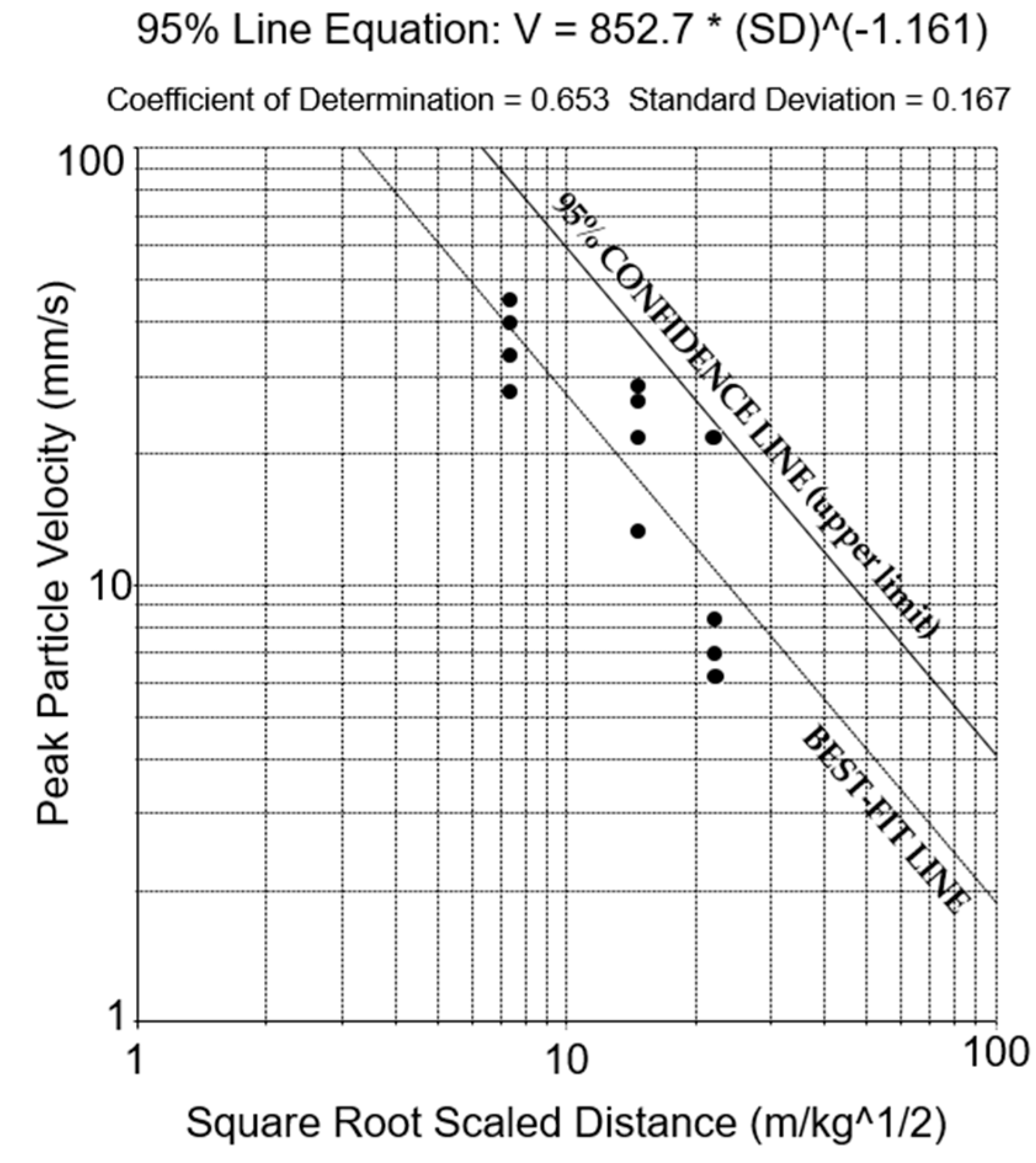

- Experimental PPV-SD data in this study are analyzed using Blastware 10.74 (Instantel application) and Curve Expert 1.4, however, any other software capable of performing regression analysis may be used.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Resende, R.; Lamas, L.; Lemos, J.; Calçada, R. Stress Wave Propagation Test and Numerical Modelling of an Underground Complex. Int. J. Rock Mech. Min. Sci. 2014, 72, 26–36. [Google Scholar] [CrossRef]

- Dowding, C.H. Blast Vibration Monitoring and Control; Prentice Hall, Inc.: Englewood Cliffs, NJ, USA, 1985; ISBN 0-9644313-0-0. [Google Scholar]

- Kumar, R.; Choudhury, D.; Bhargava, K. Determination of Blast-Induced Ground Vibration Equations for Rocks Using Mechanical and Geological Properties. J. Rock Mech. Geotech. Eng. 2016, 8, 341–349. [Google Scholar] [CrossRef]

- Ozer, U. Environmental Impacts of Ground Vibration Induced by Blasting at Different Rock Units on the Kadikoy-Kartal Metro Tunnel. Eng. Geol. 2008, 100, 82–90. [Google Scholar] [CrossRef]

- Hopler, R. Blasters’ Handbook; International Society of Explosives Engineers: Cleveland, OH, USA, 1998; ISBN 978-1892396006. [Google Scholar]

- Ak, H.; Iphar, M.; Yavuz, M.; Konuk, A. Evaluation of Ground Vibration Effect of Blasting Operations in a Magnesite Mine. Soil Dyn. Earthq. Eng. 2009, 29, 669–676. [Google Scholar] [CrossRef]

- Nicholson, R.F. Determination of Blast Vibrations Using Peak Particle Velocity at Bengal Quarry, in St Ann, Jamaica Determination of Blast Vibrations Using Peak A Case Study. Master’s Thesis, Department of Civil Environmental and Natural Resources Engineering, Luleå University of Technology, Luleå, Sweden, 2005. Volume 1. pp. 51–53. [Google Scholar]

- Badal, K.K. Blast Vibration Studies in Surface Mines. Ph.D. Thesis, National Institute of Technology, Rourkela, India, 2010; p. 41. [Google Scholar]

- Mesec, J.; Kovač, I.; Soldo, B. Estimation of Particle Velocity Based on Blast Event Measurements at Different Rock Units. Soil Dyn. Earthq. Eng. 2010, 30, 1004–1009. [Google Scholar] [CrossRef]

- Zeng, Y.; Li, H.; Xia, X.; Liu, B.; Zuo, H.; Jiang, J. Blast-Induced Rock Damage Control in Fangchenggang Nuclear Power Station, China. J. Rock Mech. Geotech. Eng. 2018, 10, 914–923. [Google Scholar] [CrossRef]

- Agrawal, H.; Mishra, A.K. Modified Scaled Distance Regression Analysis Approach for Prediction of Blast-Induced Ground Vibration in Multi-Hole Blasting. J. Rock Mech. Geotech. Eng. 2019, 11, 202–207. [Google Scholar] [CrossRef]

- Hasanipanah, M.; Faradonbeh, R.S.; Amnieh, H.B.; Armaghani, D.J.; Monjezi, M. Forecasting Blast-Induced Ground Vibration Developing a CART Model. Eng. Comput. 2017, 33, 307–316. [Google Scholar] [CrossRef]

- Monjezi, M.; Ahmadi, M.; Sheikhan, M.; Bahrami, A.; Salimi, A.R. Predicting Blast-Induced Ground Vibration Using Various Types of Neural Networks. Soil Dyn. Earthq. Eng. 2010, 30, 1233–1236. [Google Scholar] [CrossRef]

- Rodríguez, R.; García de Marina, L.; Bascompta, M.; Lombardía, C. Determination of the Ground Vibration Attenuation Law from a Single Blast: A Particular Case of Trench Blasting. J. Rock Mech. Geotech. Eng. 2021, 13, 1182–1192. [Google Scholar] [CrossRef]

- ISEE. ISEE Field Practice Guidelines for Blasting Seismographs 2020; International Society of Explosives Engineers: Cleveland, OH, USA, 2020; 11p. [Google Scholar]

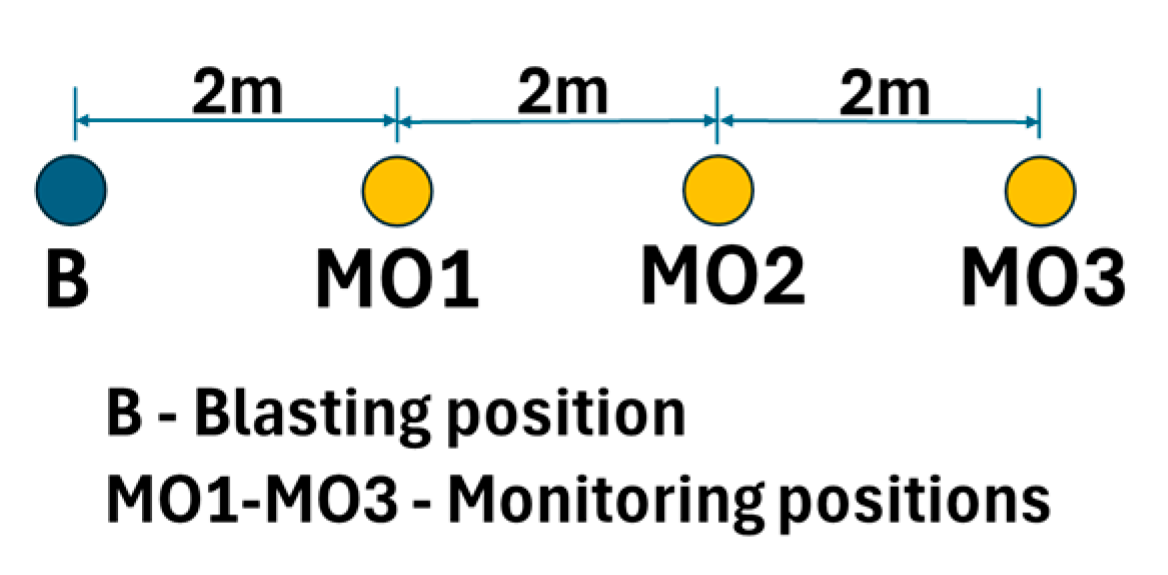

- Stanković, S.; Dobrilović, M.; Bohanek, V. Novi Pristup Mjerenju Brzine Oscilacija Tla. Rud. Geol. Naft. Zb. 2017, 32, 55–61. [Google Scholar] [CrossRef]

- Stanković, S.; Dobrilović, M.; Škrlec, V. Optimal Positioning of Vibration Monitoring Instruments and Their Impact on Blast-Induced Seismic Influence Results. Arch. Min. Sci. 2019, 64, 591–607. [Google Scholar] [CrossRef]

- Stanković, S.; Katalinić, M.; Kuhinek, D.; Bohanek, V. Detecting Atypical Values and Their Influence on Blast-Induced Seismic Measurement Results. Appl. Sci. 2022, 12, 5820. [Google Scholar] [CrossRef]

- Tripathy, G.R.; Shirke, R.R.; Kudale, M.D. Safety of Engineered Structures against Blast Vibrations: A Case Study. J. Rock Mech. Geotech. Eng. 2016, 8, 248–255. [Google Scholar] [CrossRef]

- Cooper, P.W. Comments on TNT Equivalence. In Proceedings of the 20th International Pyrotechnics Seminar, Colorado Springs, CO, USA, 24–29 July 1994; pp. 215–226. [Google Scholar]

- Formby, S.A.; Wharton, R.K. Blast Characteristics and TNT Equivalence Values for Some Commercial Explosives Detonated at Ground Level. J. Hazard. Mater. 1996, 50, 183–198. [Google Scholar] [CrossRef]

- Panowicz, R.; Konarzewski, M.; Trypolin, M. Analysis of Criteria for Determining a TNT Equivalent. Stroj. Vestnik/J. Mech. Eng. 2017, 63, 666–672. [Google Scholar] [CrossRef]

- Locking, P.M. The Trouble with TNT Equivalence. In Proceedings of the 26th International Symposium on Ballistics, Miami, FL, USA, 12–16 September 2011. [Google Scholar]

- Dobrilovic, I.; Dobrilovic, M.; Suceska, M. Revisiting the Theoretical Prediction of the Explosive Performance Found by the Trauzl Test. Def. Technol. 2023, 36, 163–174. [Google Scholar] [CrossRef]

- Karlos, V.; Solomos, G. Calculation of Blast Loads for Application to Structural Components. Administrative Arrangement No JRC 32253-2011 with DG-HOME Activity A5-Blast Simulation Technology Development; Publications Office of the European Union: Luxembourg, 2013; ISBN 9789279351587. [Google Scholar]

- Shin, J.; Whittaker, A.S.; Cormie, D. TNT Equivalency for Overpressure and Impulse for Detonations of Spherical Charges of High Explosives. Int. J. Prot. Struct. 2015, 6, 567–579. [Google Scholar] [CrossRef]

- Wharton, R.K.; Formby, S.A.; Merrifield, R. Airblast TNT Equivalence for a Range of Commercial Blasting Explosives. J. Hazard. Mater. 2000, 79, 31–39. [Google Scholar] [CrossRef]

- Maienschein, J.L. Estimating Equivalency Of Explosives Through A Thermochemical Approach. In Proceedings of the 12th International Conference Symposium, San Diego, CA, USA, 11–16 August 2002. [Google Scholar]

- Jeremić, R.; Bajić, Z. An Approach to Determining the TNT Equivalent of High Explosives. Sci. Rev. 2006, LVI, 58–62. [Google Scholar]

- Škrlec, V.; Dobrilović, M.; Tumara, B.Š.; Bohanek, V. The Effect of Blasting Using Low-Density Emulsion Explosives. J. Sustain. Min. 2024, 23, 10–19. [Google Scholar] [CrossRef]

- Siskind, D.E. Vibrations from Blasting; International Society of Explosives Engineers: Cleveland, OH, USA, 2000. [Google Scholar]

- Suceska, M.; Stimac Tumara, B.; Künzel, M. Using Thermochemical Code EXPLO5 to Predict the Performance Parameters of Explosives. Mater. Wysokoenergetyczne/High Energy Mater. 2021, 13, 17–27. [Google Scholar] [CrossRef] [PubMed]

- White, W.B.; Johnson, S.M.; Dantzig, G.B. Chemical Equilibrium in Complex Mixtures. J. Chem. Phys. 1958, 28, 751–755. [Google Scholar] [CrossRef]

- Mader, C.L. Numerical Modeling of Explosives and Propellants; CRC Press: Boca Raton, FL, USA, 2007; ISBN 9780429150500. [Google Scholar]

- Suceska, M.; Chan, S.; How-Ghee, A. Can the Accuracy of BKW EOS Be Improved? In Proceedings of the 15th International Detonation Symposium, San Francisco, CA, USA, 21 July 2014. [Google Scholar]

- Sućeska, M. Evaluation of Detonation Energy from EXPLO5 Computer Code Results. Propellants Explos. Pyrotech. 1999, 24, 280–285. [Google Scholar] [CrossRef]

- Suceska, M.; Ang, H.; Serene Chan, H.Y. Study of the Effect of Covolumes in BKW Equation of State on Detonation Properties of CHNO Explosives. Propellants Explos. Pyrotech. 2013, 38, 103–112. [Google Scholar] [CrossRef]

- Sućeska, M. Calculation of Detonation Parameters by EXPLO5 Computer Program. Mater. Sci. Forum 2004, 465–466, 325–330. [Google Scholar] [CrossRef]

- Marshall, A. Explosives, Vol II: Properties and Tests; J & A Churchill: London, UK, 1917. [Google Scholar]

- Instantel Inc. Blastware Operator Manual; Instantel: Kanata, ON, Canada, 2004. [Google Scholar]

- DIN 4150; Vibracije u Građevinama--3. Dio: Djelovanje Na Konstrukcije. Croatian Standards Institute: Zagreb, Croatia, 2011.

| Diabase Rock | ||

|---|---|---|

| Compressive strength | 200–400 | MPa |

| Density | 2.85–3.15 | g/cm3 |

| Water absorption | 0.2–1 | % mass |

| Spatial mass | 2.8–3.1 | g/cm3 |

| Porosity | 0.1–1 | % volume |

| Explosive | Volume Ratio (%) | Density (g/cm3) | Dexpt. * (m/s) | Calculated Detonation Parameters | ||||

|---|---|---|---|---|---|---|---|---|

| D (m/s) | pCJ (GPa) | Q (kJ/kg) | E0 (kJ/cm3) | T (K) | ||||

| Emulsion explosive (EME) | 100 | 1.175 | 5534 | 5559 | 8.03 | 2779.78 | 3.68 | 2217 |

| EMM/EPS (50/50) | 50/50 | 0.627 | 3051 | 3413 | 2.16 | 2645.42 | 1.91 | 2261 |

| EMM/EPS (40/60) | 40/60 | 0.437 | 2491 | 2785 | 1.06 | 2469.27 | 1.26 | 2138 |

| EMM/EPS (30/70) | 30/70 | 0.302 | 2089 | 2399 | 0.59 | 2284.85 | 0.81 | 2012 |

| EMM/EPS (20/80) | 20/80 | 0.218 | 1710 | 2137 | 0.36 | 1974.69 | 0.52 | 1804 |

| Explosive | Density (g/cm3) | EME Equivalent (%) | ||||

|---|---|---|---|---|---|---|

| Equation (4) | Equation (5) | Equation (6) | Equation (7) | Equation (8) | ||

| Emulsion explosive (EME) | 1.175 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

| EMM/EPS (50/50) | 0.627 | 95.17 | 98.46 | 96.98 | 26.87 | 61.39 |

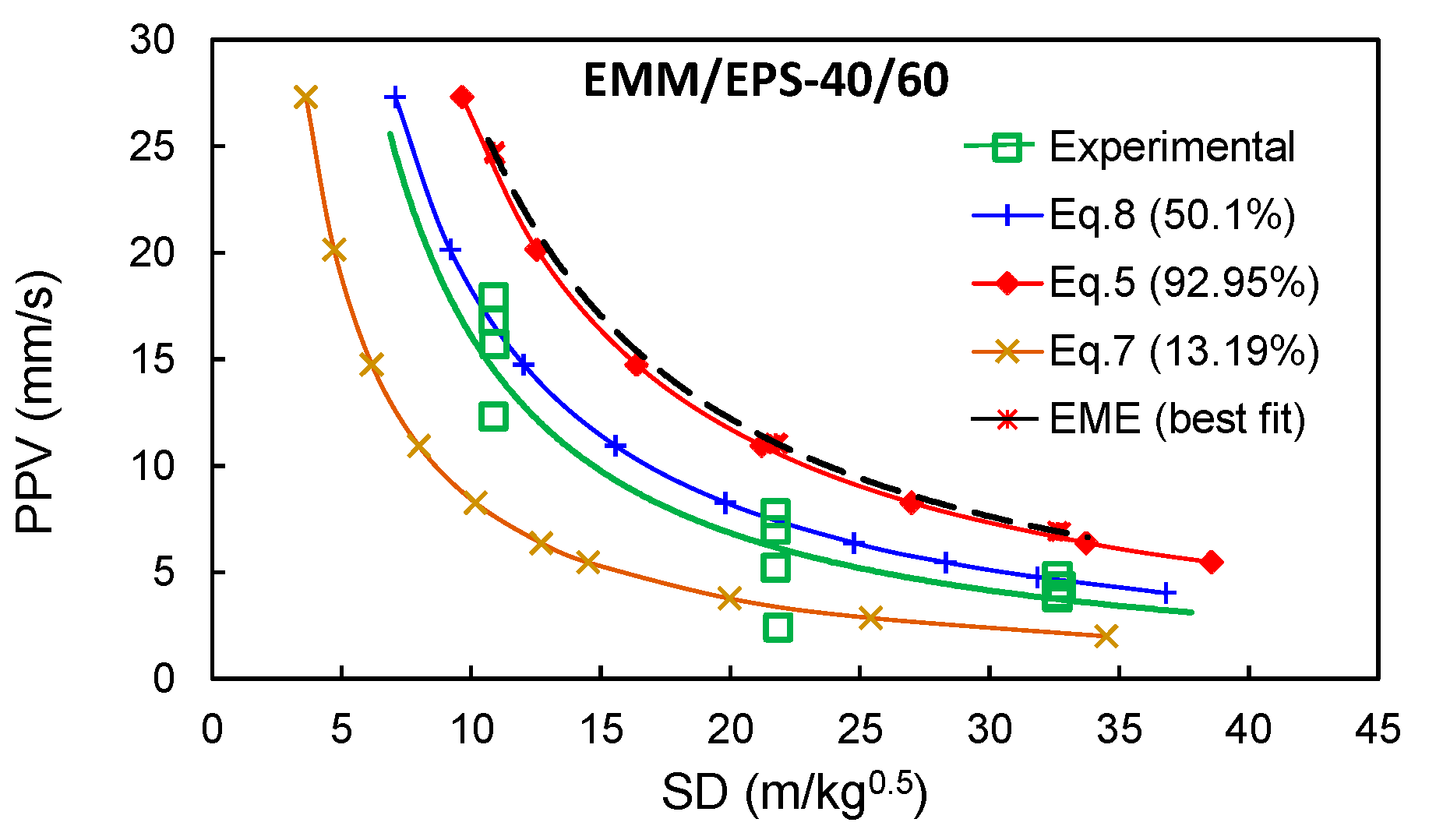

| EMM/EPS (40/60) | 0.437 | 88.83 | 92.95 | 91.94 | 13.19 | 50.10 |

| EMM/EPS (30/70) | 0.302 | 82.20 | 87.24 | 85.89 | 7.33 | 43.16 |

| EMM/EPS (20/80) | 0.218 | 71.04 | 76.61 | 75.83 | 4.44 | 38.45 |

| Explosive | W (g) | R (m) | SD (m/kg0.5) | PPV (mm/s) |

|---|---|---|---|---|

| EME | 73.24 | 2 | 7.390 | 33.3 |

| 4 | 14.780 | 26.3 | ||

| 6 | 22.171 | 21.8 | ||

| 72.36 | 2 | 7.435 | 27.3 | |

| 4 | 14.870 | 21.7 | ||

| 6 | 22.305 | 8.25 | ||

| 73.11 | 2 | 7.397 | 39.6 | |

| 4 | 14.794 | 28.6 | ||

| 6 | 22.190 | 6.98 | ||

| 73.18 | 2 | 7.393 | 44.8 | |

| 4 | 14.786 | 13.3 | ||

| 6 | 22.180 | 6.22 |

| Explosive | EMEe/100 (Equation (8)) | Experimental Data | Calculated Equivalent Weight and Scaled Distance | ||||

|---|---|---|---|---|---|---|---|

| W (g) | R (m) | PPV (mm/s) | SD(W, R) (m/kg0.5) | We (g) | SD(We, R) (m/kg0.5) | ||

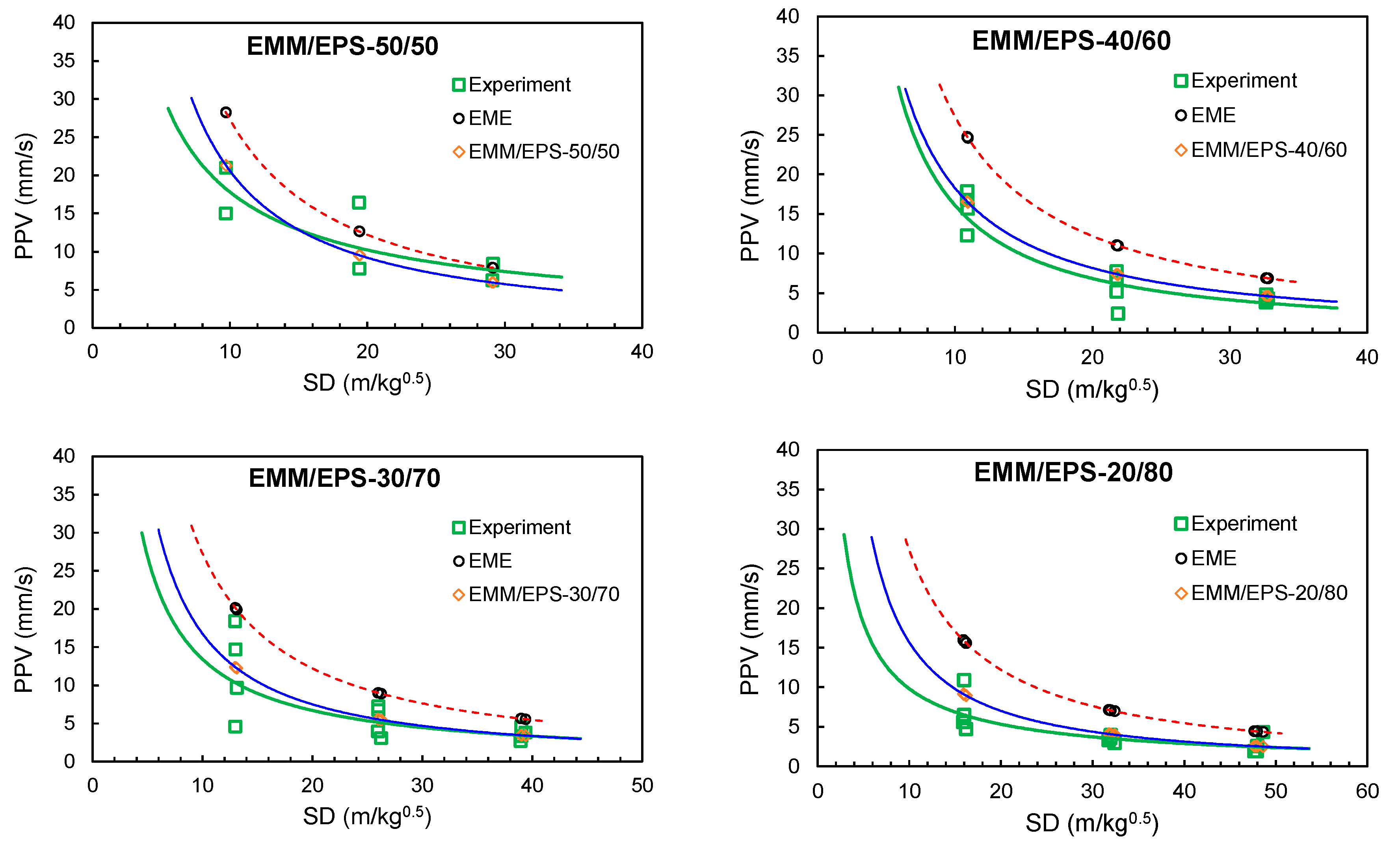

| EMM/EPS-50/50 | 0.614 | 42.40 | 2 | 21 | 9.713 | 26.03 | 12.395 |

| 0.614 | 42.40 | 4 | 7.75 | 19.426 | 26.03 | 24.791 | |

| 0.614 | 42.40 | 6 | 8.38 | 29.139 | 26.03 | 37.186 | |

| 0.614 | 42.54 | 2 | 15 | 9.697 | 26.12 | 12.375 | |

| 0.614 | 42.54 | 4 | 16.4 | 19.394 | 26.12 | 24.750 | |

| 0.614 | 42.54 | 6 | 6.22 | 29.091 | 26.12 | 37.125 | |

| EMM/EPS-40/60 | 0.501 | 33.79 | 2 | 17.9 | 10.880 | 16.93 | 15.372 |

| 0.501 | 33.79 | 4 | 7.75 | 21.760 | 16.93 | 30.743 | |

| 0.501 | 33.79 | 6 | 3.94 | 32.641 | 16.93 | 46.115 | |

| 0.501 | 33.79 | 2 | 16.8 | 10.880 | 16.93 | 15.372 | |

| 0.501 | 33.79 | 4 | 5.21 | 21.760 | 16.93 | 30.743 | |

| 0.501 | 33.79 | 6 | 4.83 | 32.641 | 16.93 | 46.115 | |

| 0.501 | 33.81 | 2 | 12.3 | 10.877 | 16.94 | 15.367 | |

| 0.501 | 33.81 | 4 | 6.98 | 21.754 | 16.94 | 30.734 | |

| 0.501 | 33.81 | 6 | 3.81 | 32.631 | 16.94 | 46.101 | |

| 0.501 | 33.51 | 2 | 15.7 | 10.926 | 16.79 | 15.436 | |

| 0.501 | 33.51 | 4 | 2.41 | 21.851 | 16.79 | 30.871 | |

| 0.501 | 33.51 | 6 | 4.32 | 32.777 | 16.79 | 46.307 | |

| EMM/EPS-30/70 | 0.432 | 23.64 | 2 | 14.7 | 13.008 | 10.21 | 19.791 |

| 0.432 | 23.64 | 4 | 6.73 | 26.016 | 10.21 | 39.582 | |

| 0.432 | 23.64 | 6 | 3.3 | 39.024 | 10.21 | 59.373 | |

| 0.432 | 23.65 | 2 | 4.57 | 13.005 | 10.22 | 19.787 | |

| 0.432 | 23.65 | 4 | 7.24 | 26.010 | 10.22 | 39.573 | |

| 0.432 | 23.65 | 6 | 4.57 | 39.015 | 10.22 | 59.360 | |

| 0.432 | 23.72 | 2 | 18.4 | 12.986 | 10.25 | 19.757 | |

| 0.432 | 23.72 | 4 | 3.94 | 25.972 | 10.25 | 39.515 | |

| 0.432 | 23.72 | 6 | 2.67 | 38.958 | 10.25 | 59.272 | |

| 0.432 | 23.20 | 2 | 9.65 | 13.131 | 10.02 | 19.978 | |

| 0.432 | 23.20 | 4 | 3.05 | 26.261 | 10.02 | 39.955 | |

| 0.432 | 23.20 | 6 | 3.81 | 39.392 | 10.02 | 59.933 | |

| EMM/EPS-20/80 | 0.385 | 15.23 | 2 | 4.7 | 16.206 | 5.86 | 26.119 |

| 0.385 | 15.23 | 4 | 2.92 | 32.412 | 5.86 | 52.237 | |

| 0.385 | 15.23 | 6 | 4.32 | 48.618 | 5.86 | 78.356 | |

| 0.385 | 15.64 | 2 | 6.48 | 15.992 | 6.02 | 25.774 | |

| 0.385 | 15.64 | 4 | 3.94 | 31.985 | 6.02 | 51.548 | |

| 0.385 | 15.64 | 6 | 2.54 | 47.977 | 6.02 | 77.322 | |

| 0.385 | 15.84 | 2 | 5.59 | 15.891 | 6.10 | 25.611 | |

| 0.385 | 15.84 | 4 | 3.3 | 31.782 | 6.10 | 51.221 | |

| 0.385 | 15.84 | 6 | 1.9 | 47.673 | 6.10 | 76.832 | |

| 0.385 | 15.67 | 2 | 10.9 | 15.977 | 6.03 | 25.749 | |

| 0.385 | 15.67 | 4 | 3.56 | 31.954 | 6.03 | 51.499 | |

| 0.385 | 15.67 | 6 | 1.9 | 47.931 | 6.03 | 77.248 | |

| Line | Type of Structure | Vibration at the Foundation at a Frequency of | Vibration at Horizontal Plane of Highest Floor at All Frequencies | ||

|---|---|---|---|---|---|

| 1 Hz to 10 Hz | 10 Hz to 50 Hz | 50 Hz to 100 Hz *) | |||

| 1 | Buildings used for commercial purposes, industrial buildings, and buildings of similar design | 20 mm/s | 20–40 mm/s | 40–50 mm/s | 40 mm/s |

| 2 | Dwellings and buildings of similar design and/or occupancy | 5 mm/s | 5–15 mm/s | 15–20 mm/s | 15 mm/s |

| 3 | Structures that, because of their particular sensitivity to vibration, cannot be classified under lines 1 and 2 and are of great intrinsic value (e.g., listed buildings under preservation order) | 3 mm/s | 3–8 mm/s | 8–10 mm/s | 8 mm/s |

| Explosive | Best-Fit Line Equation | SD (PPV = 20 mm/s) (m/kg1/2) |

|---|---|---|

| EME | σ = 7.306 mm/s, r = 0.8357 | 13.07 |

| EMM/EPS (50/50) | σ = 3.929 mm/s, r = 0.8014 | 8.65 |

| EMM/EPS (40/60) | σ = 7.306 mm/s, r = 0.9439 | 8.40 |

| EMM/EPS (30/70) | σ = 3.504 mm/s, r = 0.7448 | 6.76 |

| EMM/EPS (20/80) | σ = 1.65 mm/s, r = 0.7751 | 4.46 |

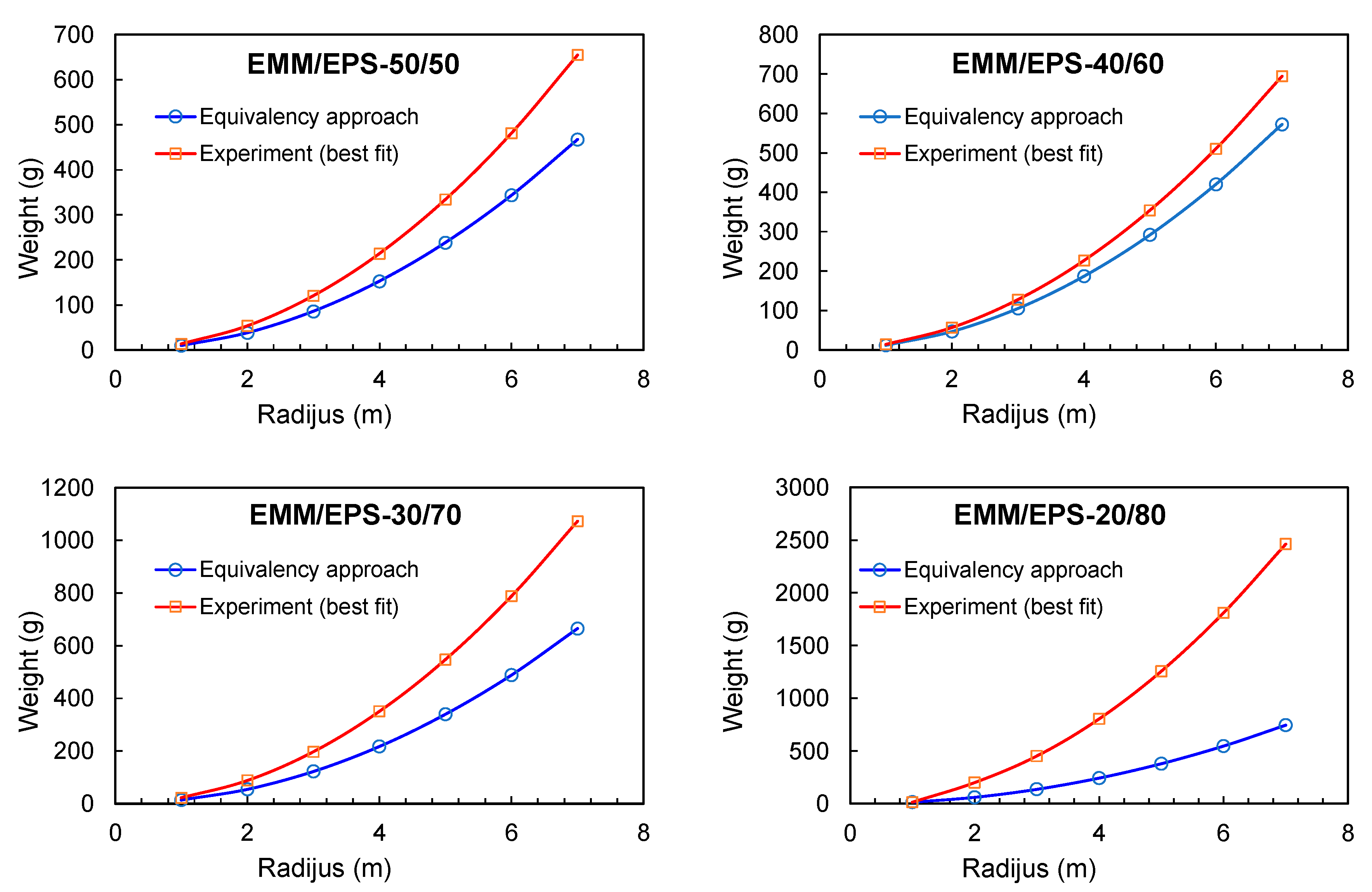

| R (m) | EME | EMM/EPS (50/50) | EMM/EPS (40/60) | EMM/EPS (30/70) | EMM/EPS (20/80) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| WEP (g) | Wfit (g) | WEP (g) | Wfit (g) | WEP (g) | Wfit (g) | WEP (g) | Wfit (g) | WEP (g) | Wfit (g) | |

| 1 | 5.85 | 5.85 | 9.54 | 13.36 | 11.68 | 14.17 | 13.56 | 21.88 | 15.22 | 50.27 |

| 2 | 23.42 | 23.42 | 38.14 | 53.46 | 46.74 | 56.69 | 54.25 | 87.53 | 60.90 | 201.09 |

| 3 | 52.69 | 52.69 | 85.82 | 120.28 | 105.16 | 127.55 | 122.07 | 196.95 | 137.02 | 452.45 |

| 4 | 93.66 | 93.66 | 152.57 | 213.84 | 186.95 | 226.76 | 217.01 | 350.13 | 243.60 | 804.36 |

| 5 | 146.35 | 146.35 | 238.39 | 334.12 | 292.11 | 354.31 | 339.08 | 547.07 | 380.62 | 1256.81 |

| 6 | 210.74 | 210.74 | 343.28 | 481.14 | 420.64 | 510.20 | 488.28 | 787.79 | 548.09 | 1809.81 |

| 7 | 286.84 | 286.84 | 467.25 | 654.88 | 572.54 | 694.44 | 664.60 | 1072.27 | 746.02 | 2463.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stanković, S.; Olivani, J.; Dobrilović, I.; Sućeska, M. Application of Explosive Equivalency Approach in Blast-Induced Seismic Effect Prediction Using EXPLO5 Thermochemical Code. Appl. Sci. 2024, 14, 7408. https://doi.org/10.3390/app14167408

Stanković S, Olivani J, Dobrilović I, Sućeska M. Application of Explosive Equivalency Approach in Blast-Induced Seismic Effect Prediction Using EXPLO5 Thermochemical Code. Applied Sciences. 2024; 14(16):7408. https://doi.org/10.3390/app14167408

Chicago/Turabian StyleStanković, Siniša, Josip Olivani, Ivana Dobrilović, and Muhamed Sućeska. 2024. "Application of Explosive Equivalency Approach in Blast-Induced Seismic Effect Prediction Using EXPLO5 Thermochemical Code" Applied Sciences 14, no. 16: 7408. https://doi.org/10.3390/app14167408

APA StyleStanković, S., Olivani, J., Dobrilović, I., & Sućeska, M. (2024). Application of Explosive Equivalency Approach in Blast-Induced Seismic Effect Prediction Using EXPLO5 Thermochemical Code. Applied Sciences, 14(16), 7408. https://doi.org/10.3390/app14167408