Efficiency of Maintenance Activities in Aggregate Quarries: A Case Study of Wear Parts on Loaders and Excavators

Abstract

:1. Introduction

- Secondary and tertiary rock crushing–sorting flow, consisting of Sandvik H4800 Secondary Crusher, Sandvik UH420 Tertiary Crusher, Chieftain 2100 Sorting Station, Volvo L220 E Front Loader;

- The rock loading–transport flow, consisting of excavator Caterpillar 345 CL and dumper Volvo A35D.

2. Materials and Methods

2.1. Reliability Distribution Law Types

- Discrete: binomial or Bernoulli, polynomial, Poisson, hypergeometric, etc.;

- Continuous: uniform, normal, lognormal, exponential, gamma, Rayleigh, Weibull, etc.;

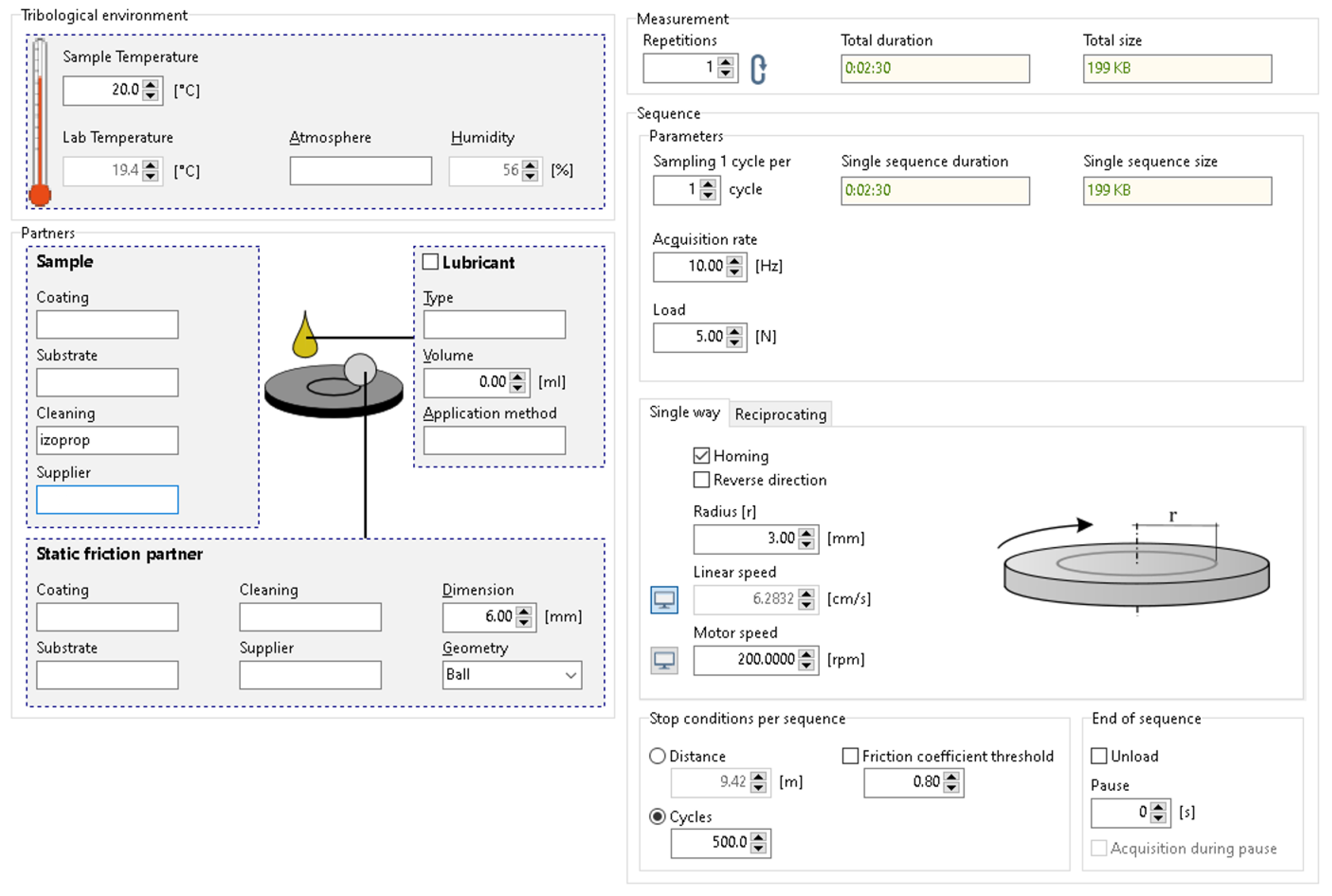

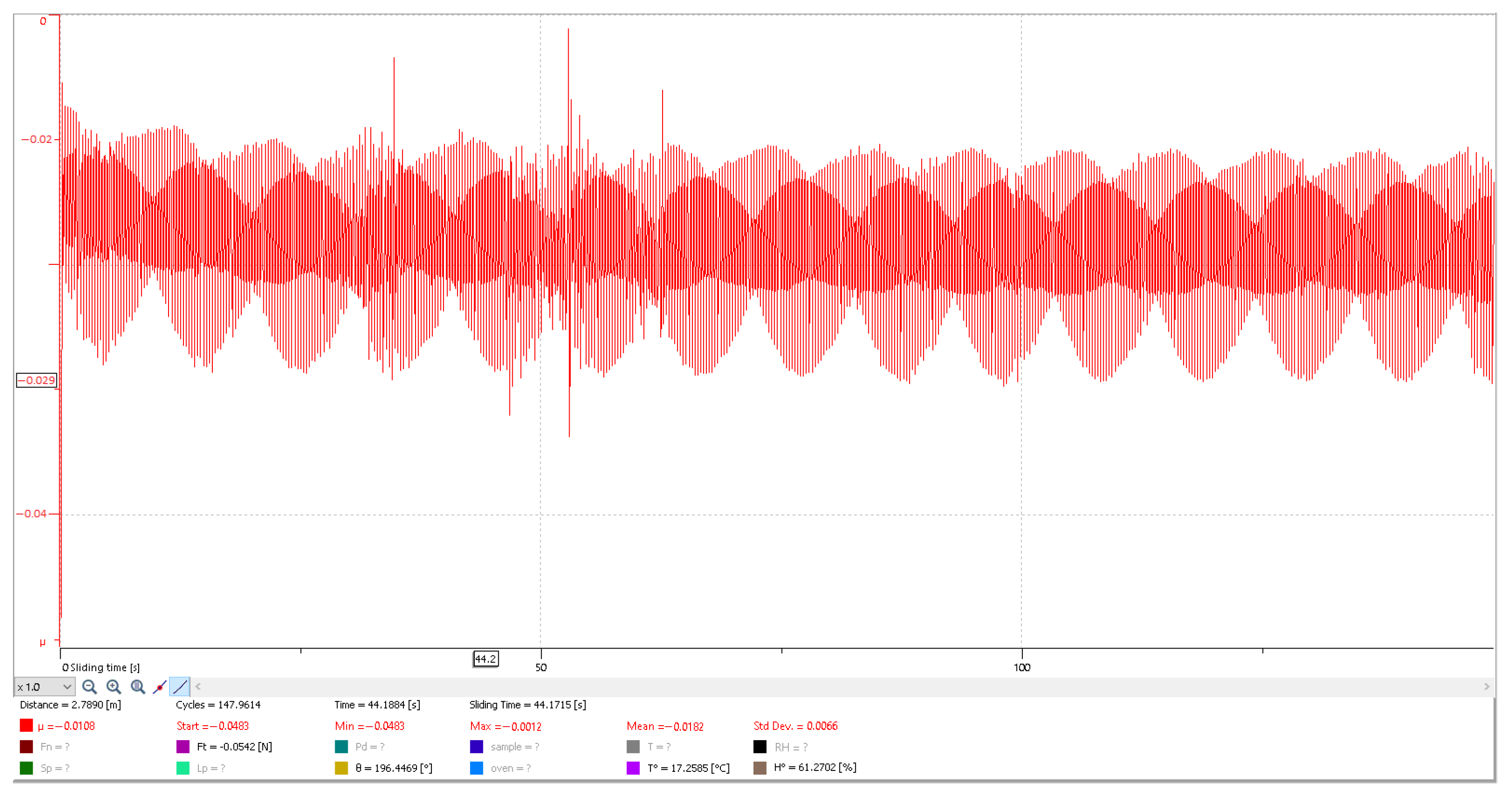

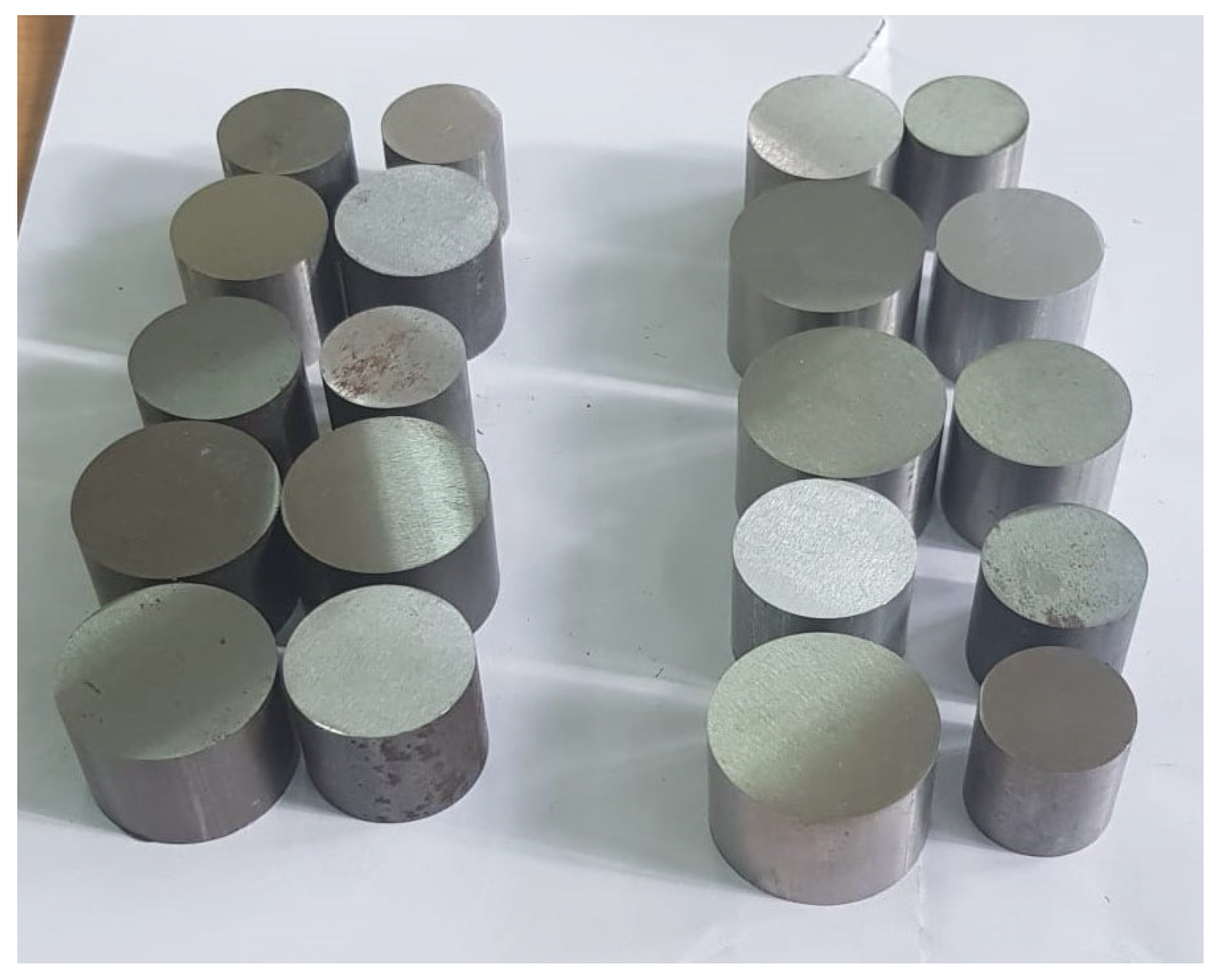

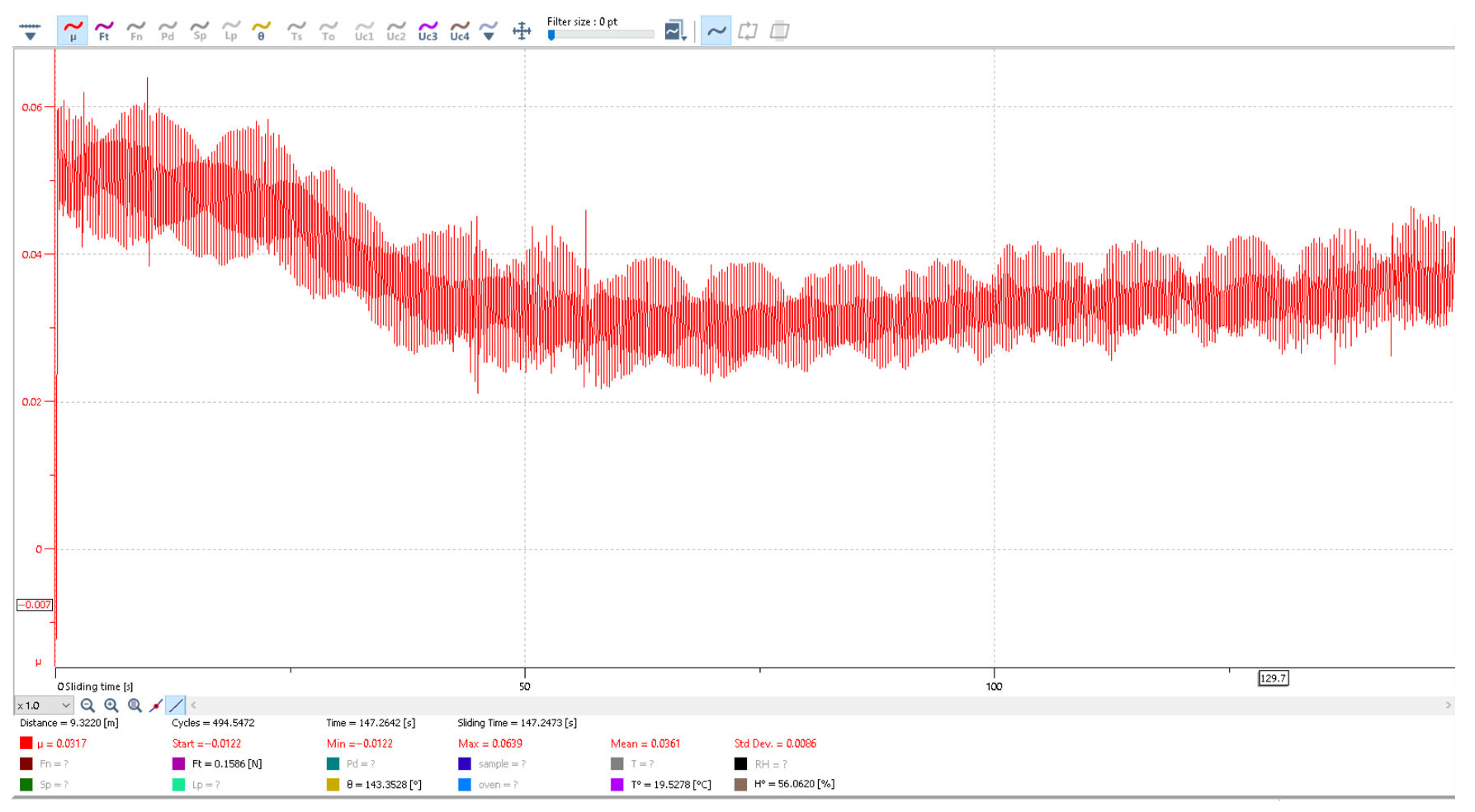

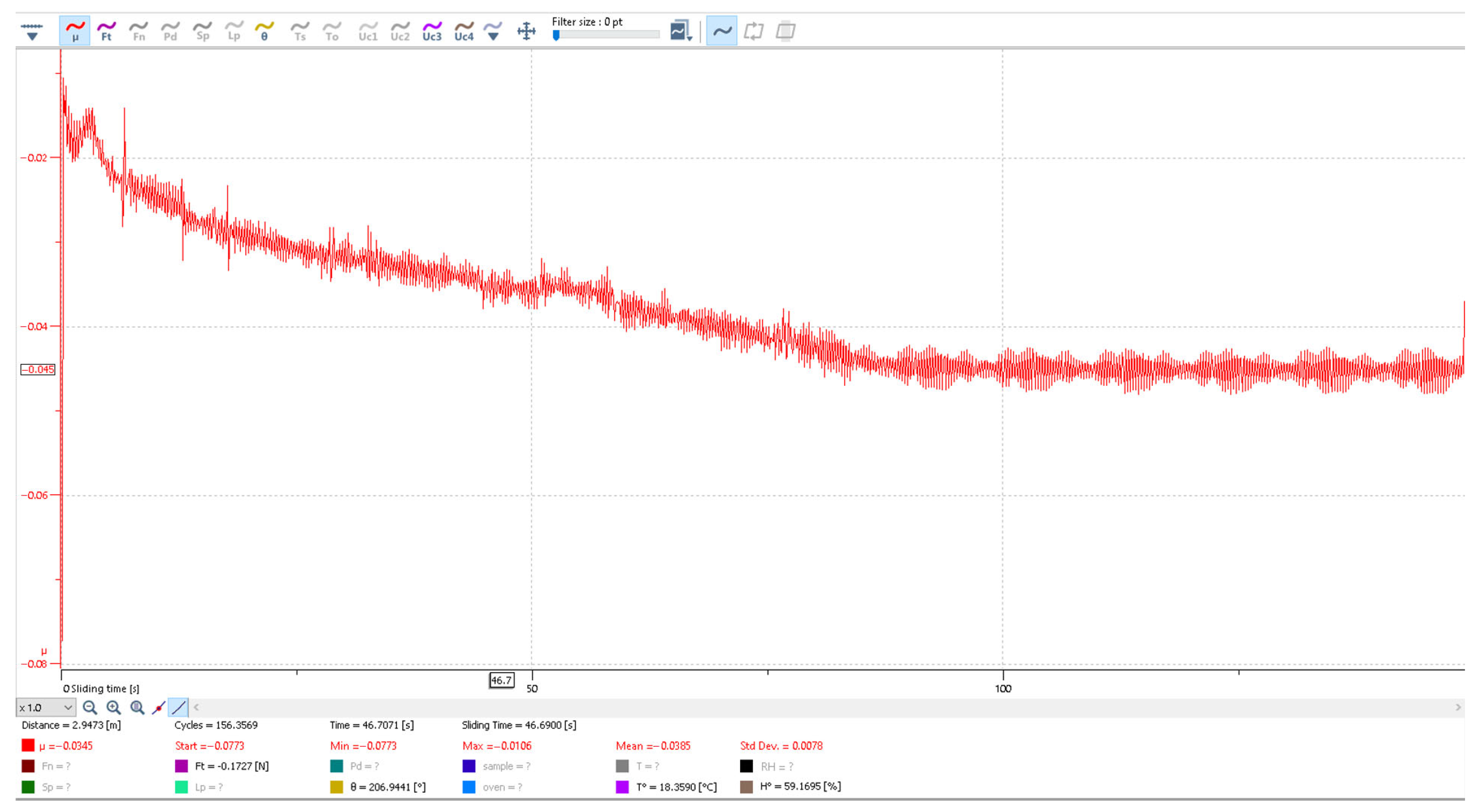

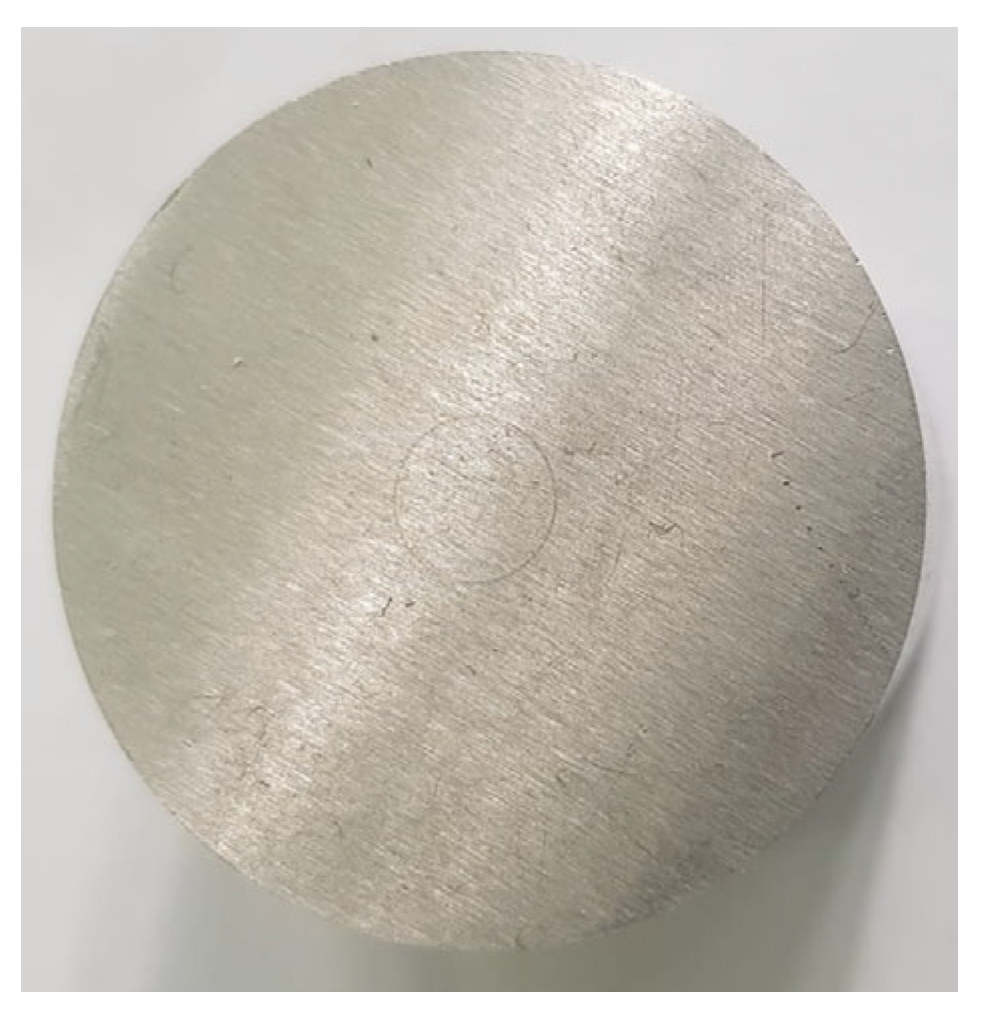

2.2. Laboratory Simulation Methodology for the Phenomenon of Wear at the Contact of Metal–Rock Surfaces

2.3. Maintenance Types

- Fault detection, identification, and isolation. Fault indicators and symptoms should be clearly defined through maintainability design to attract the operator’s attention for isolation. Testing equipment, usually incorporated into “hot spots”, and well-trained personnel are necessary;

- Accessibility. System elements with a high failure rate should be easily accessible, a condition that must be considered and provided for from the design phase;

- Functional and physical interchangeability, which facilitates the disassembly and replacement of components, reduces downtime, and has a positive impact on the need for spare parts and inventory;

- Redundant elements. If technical and economic considerations allow, the design should provide for standby components to avoid system downtime and enable maintenance operations to be performed with adequate quality.

- (A)

- The system of periodic functional maintenance of the planned preventive type

- Avoiding equipment degradation and extending their life;

- Maintaining the functional parameters as close as possible to the initial ones;

- Elimination of accidental stops;

- Reduction in maintenance costs;

- Increasing safety in operation;

- Creation of important sectors of parts reconditioning.

- (B) The system of technical reviews and planned preventive repairs

- Anticipated preparation of interventions to the prescribed quality. Thus, the drawings of the spare parts, their production, and their storage until the intervention; the purchase of specific spare parts (bearings, belts, sealing materials, etc.); and the replacement machines and equipment for the period of repairs are prepared;

- Carrying out the interventions on time, simultaneously with the assessment of the real technical condition of the equipment. It is necessary to take the decision on carrying out the interventions at the planned term, respectively, carrying out the interventions for some machines and postponing them for others, without affecting the production process. In parallel, the measuring and control devices are being prepared, namely the tools, devices, and verifiers necessary for the interventions;

- Modernization of equipment during capital repairs. The introduction of automatic drives, programming commands, operation limiters, etc., can be considered;

- Increasing the yield of machines and equipment. The mechanization of some technological operations, the automation of specific works, the provision of automatic work, and control and handling devices are considered.

- Maintaining or increasing the reliability of the equipment between two interventions by ensuring spare parts and carrying out interventions of good quality, while the operation is carried out according to the technological specifications;

- Reducing repair costs by reconditioning and reusing used parts, typing and standardizing parts, and reducing accidental stops;

- Optimum use of the labor force is possible through the nomination of concrete tasks, the control of their realization, and the material stimulation of employees;

- Reducing the consumption of energy, fuel, and lubricants by determining the consumption of cars and their judicious management, as well as removing any form of squandering.

3. Results and Discussion

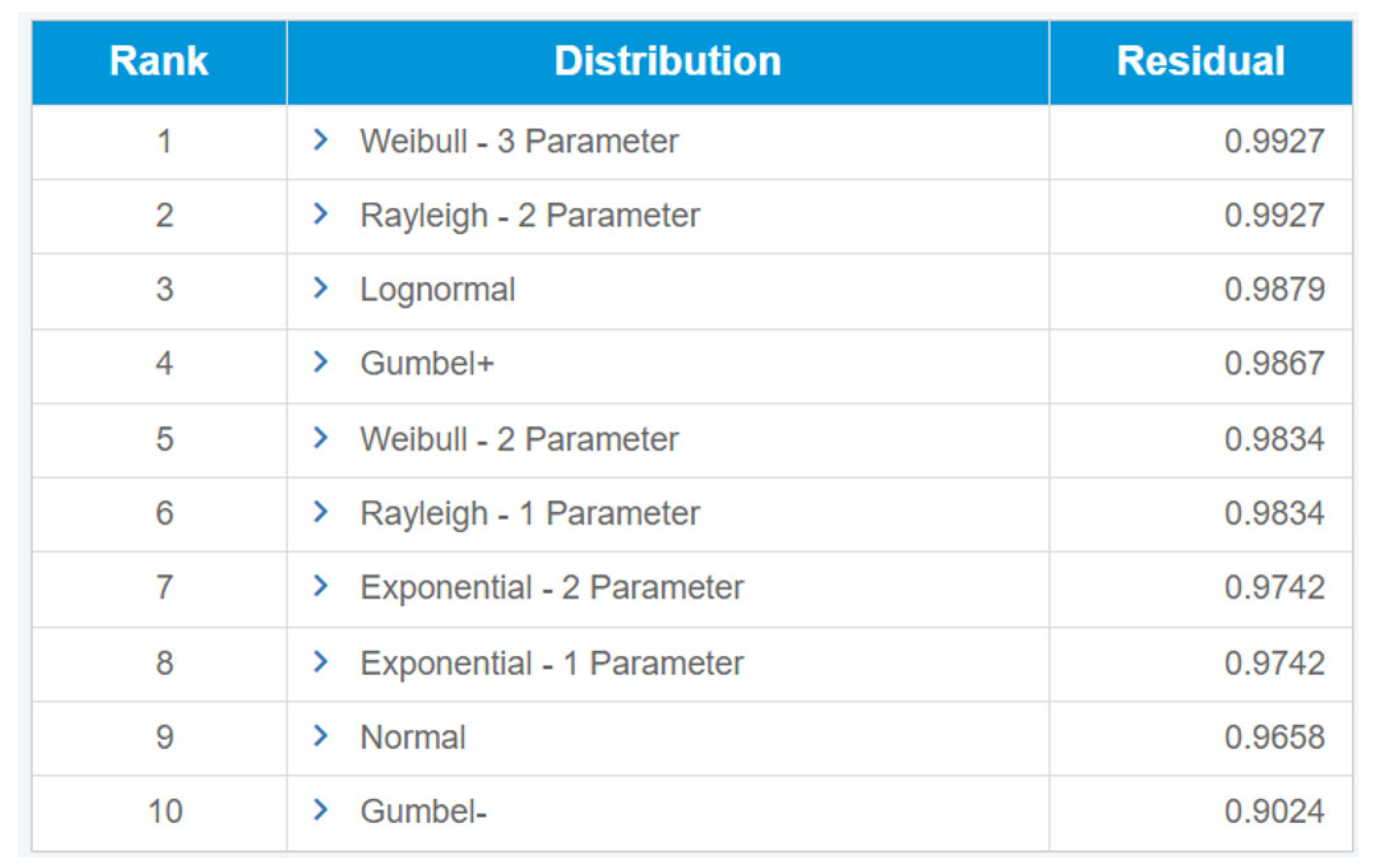

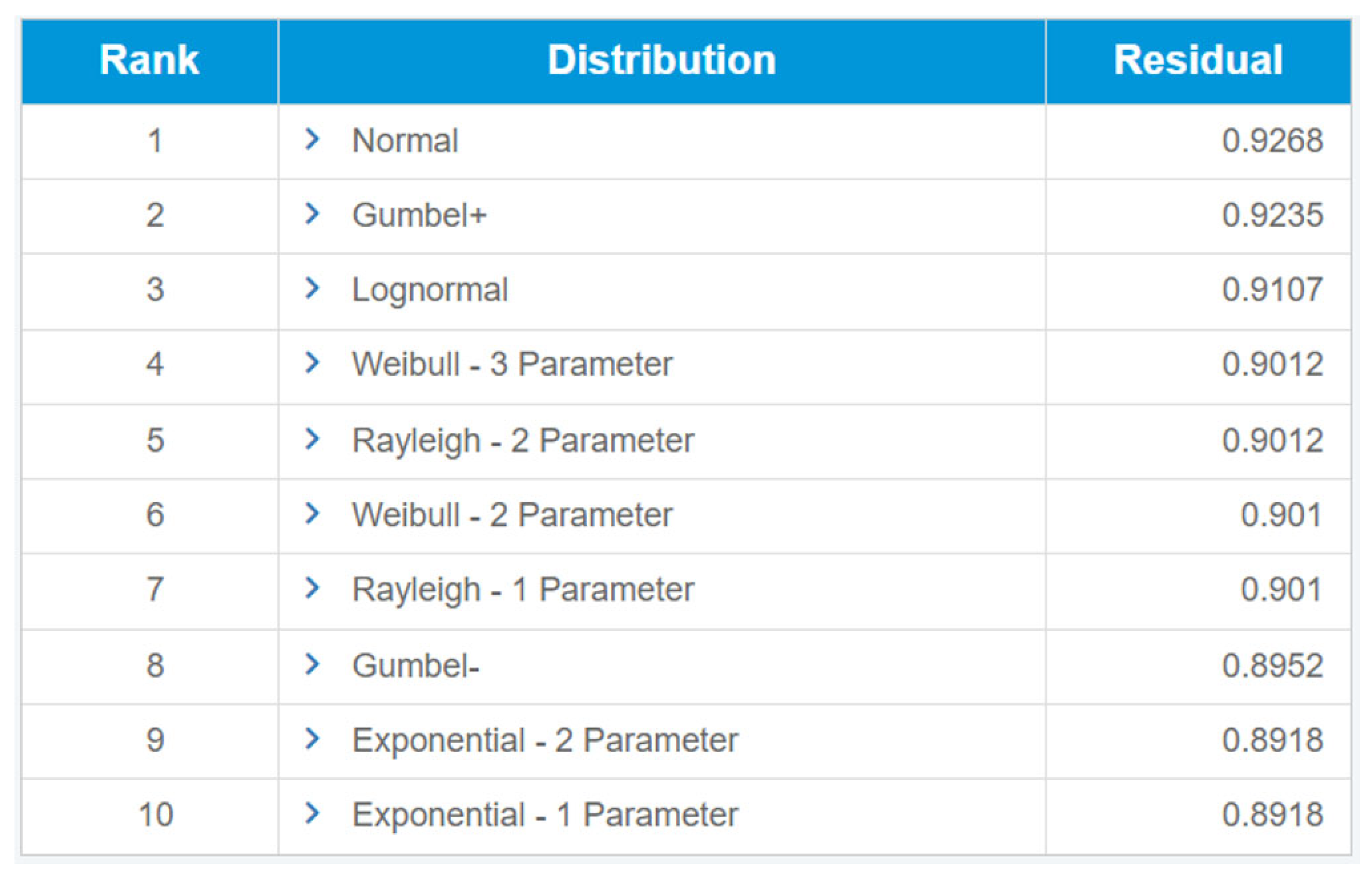

3.1. Reliability Analysis of the Components That Have the Most Defects

- By adopting the 3-Parameter Weibull distribution law (Figure 6) for the operating times between two failures of the Liebherr 944 L excavator’s bucket teeth, we were able to assess the evolution of failure times. Similarly, we used the Normal distribution law (Figure 7) to analyze the evolution of repair times for the teeth;

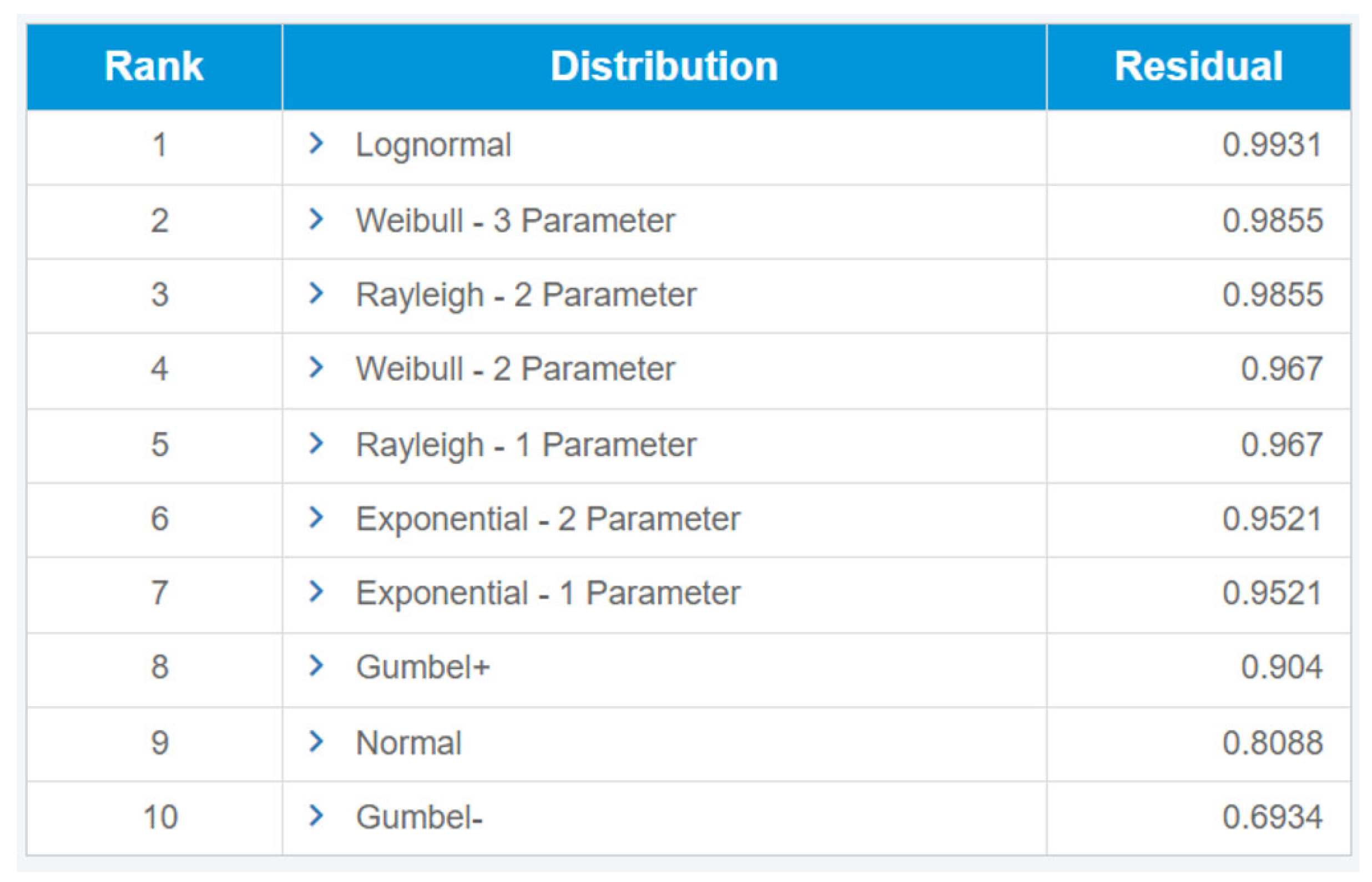

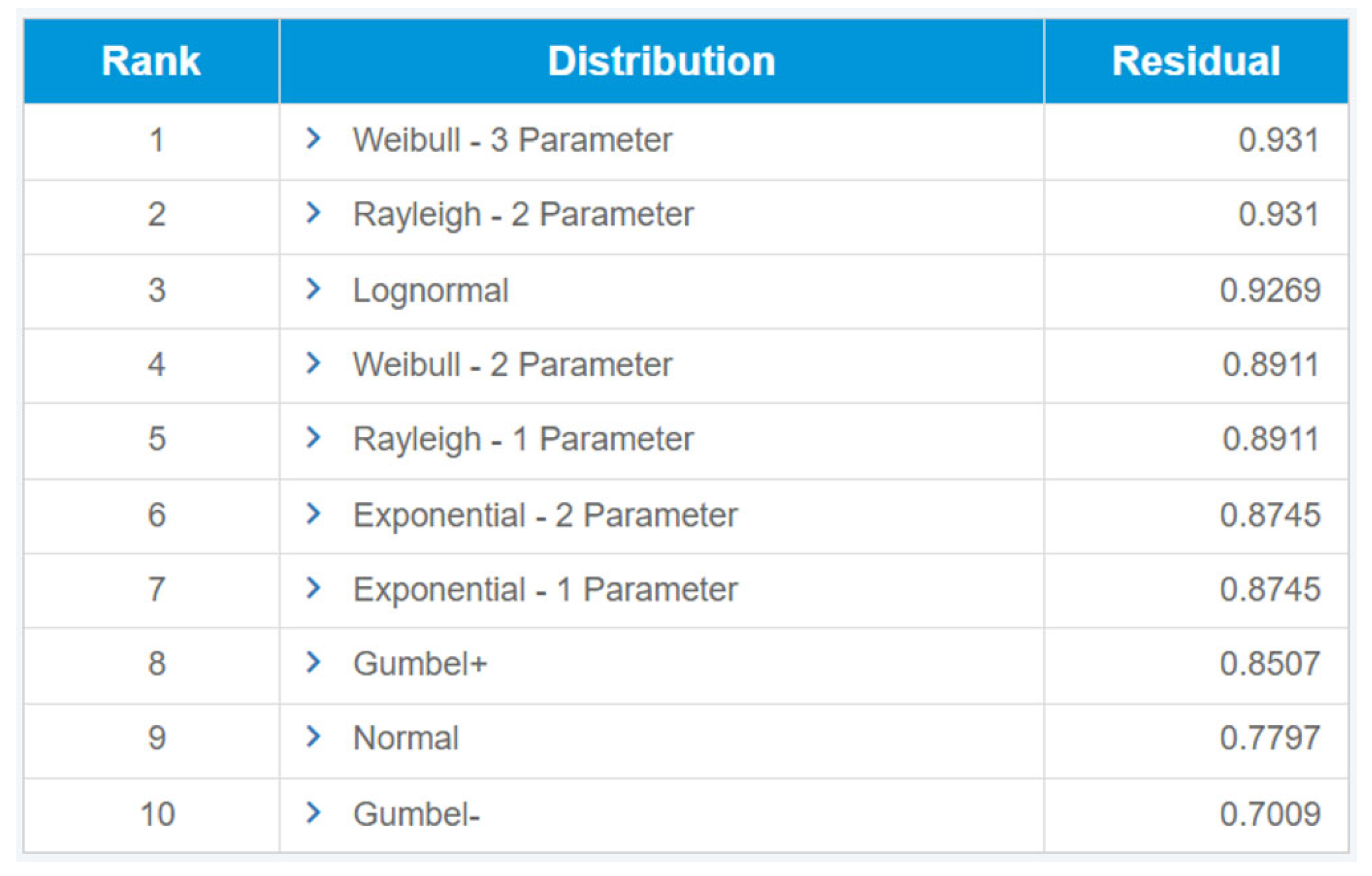

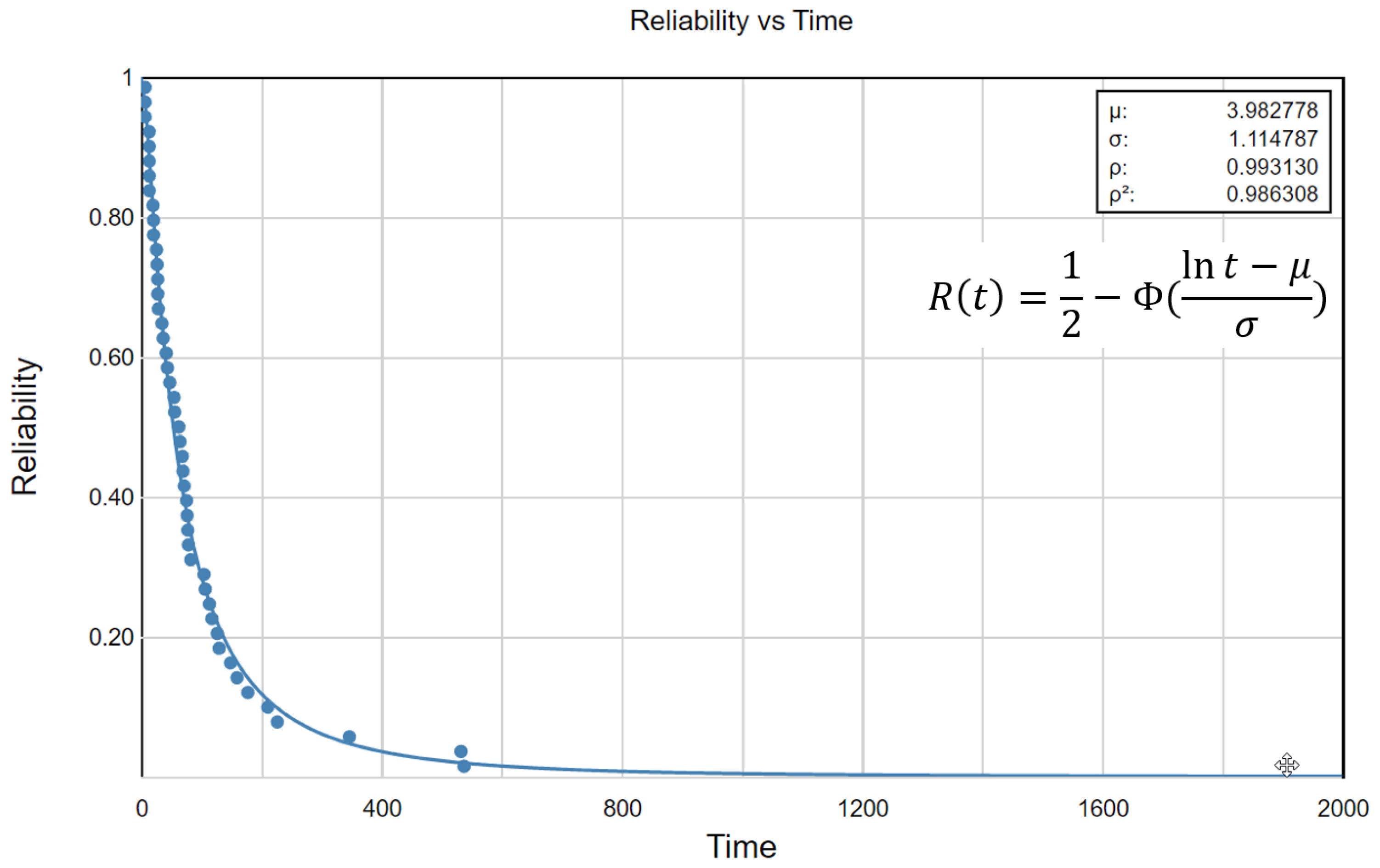

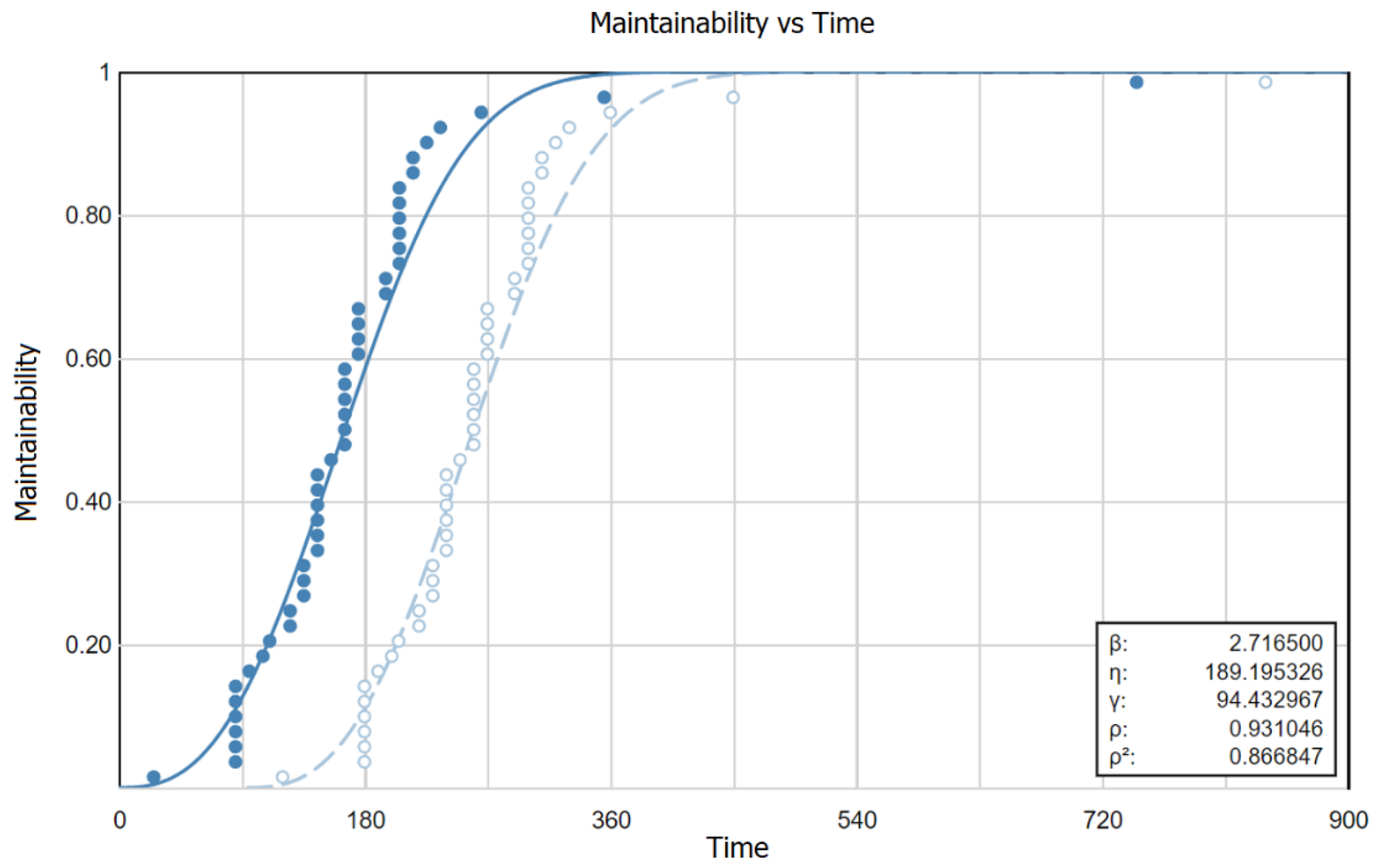

- By adopting the Lognormal distribution law (Figure 8) for the operating times between two failures of the Volvo L220 E front loader’s bucket teeth, we were able to assess the evolution of failure times. Similarly, we used the 3-Parameter Weibull distribution law (Figure 9) to analyze the evolution of repair times for the teeth.

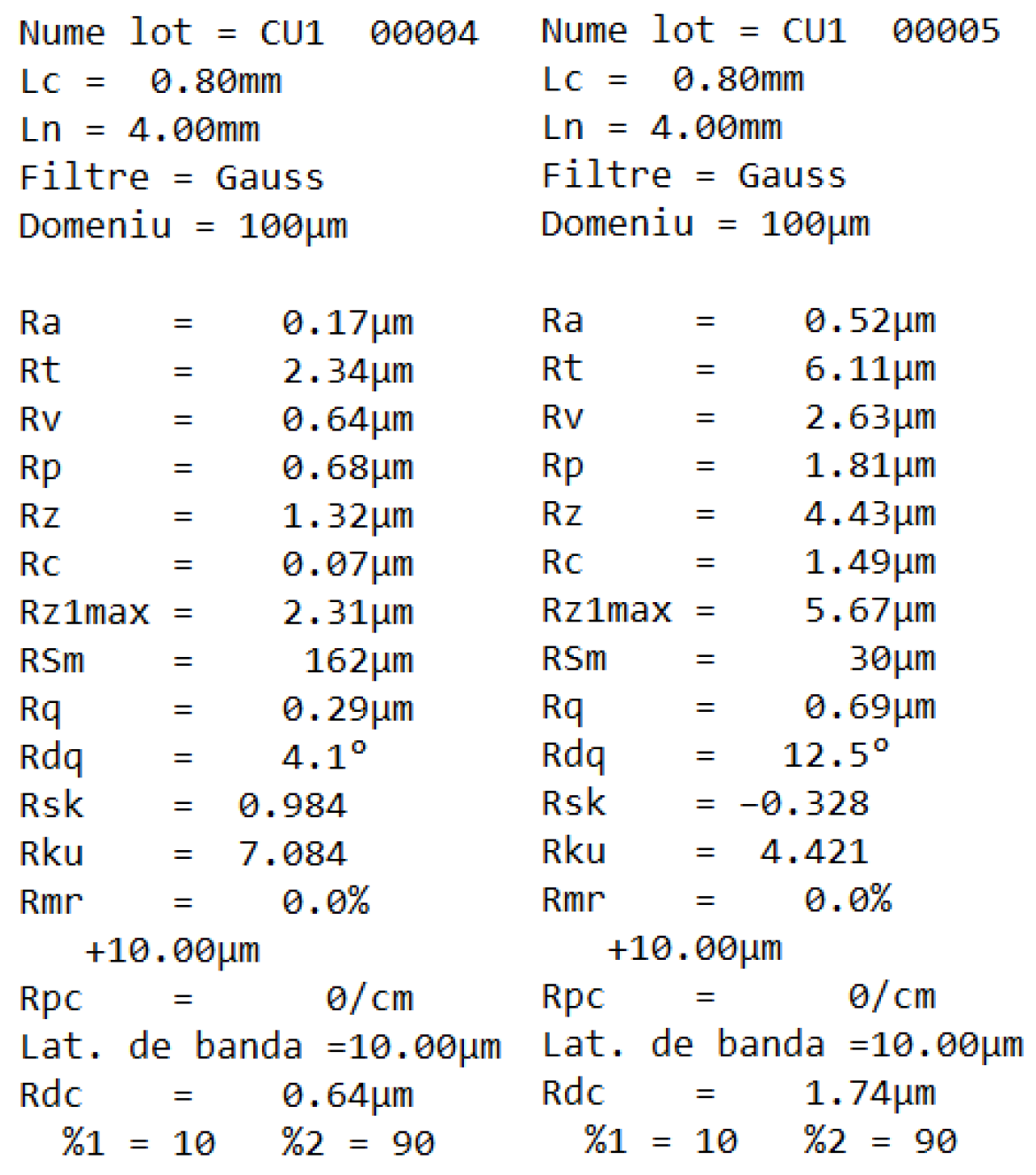

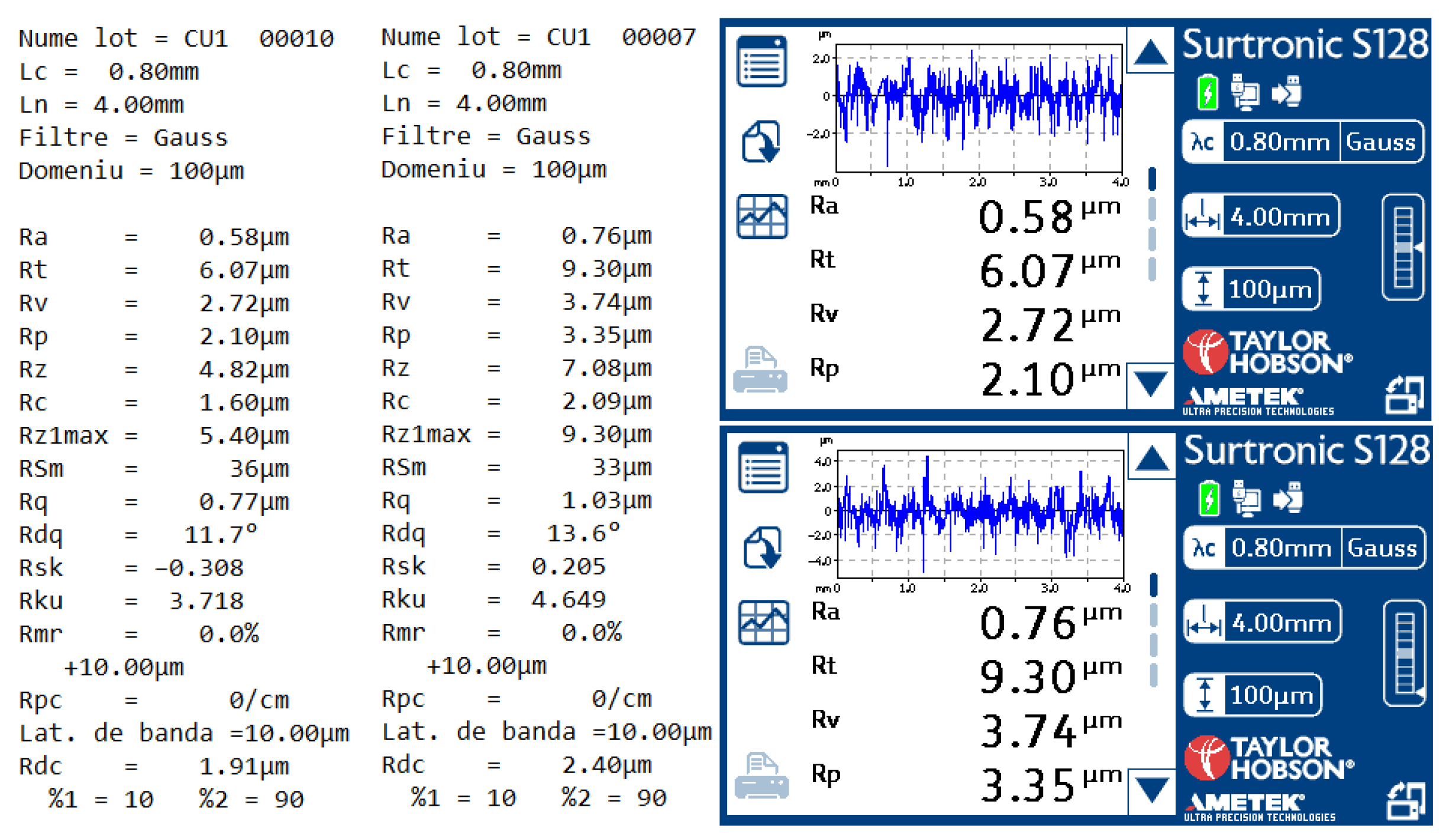

3.2. Tribological Test Results of the Benchmarks Showing the Greatest Wear

3.3. Establishing the Solutions to Make the Career Maintenance Plan More Efficient

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Teera-achariyakul, N.; Rerkpreedapong, D. Optimal Preventive Maintenance Planning for Electric Power Distribution Systems Using Failure Rates and Game Theory. Energies 2022, 15, 5172. [Google Scholar] [CrossRef]

- Cheng, G.Q.; Zhou, B.H.; Li, L. Integrated production, quality control and condition-based maintenance for imperfect production systems. Reliab. Eng. Syst. Saf. 2018, 175, 251–264. [Google Scholar] [CrossRef]

- Jaturonnatee, J.; Murthy, D.N.P.; Boondiskulchok, R. Optimal preventive maintenance of leased equipment with corrective minimal repairs. Eur. J. Oper. Res. 2006, 174, 201–215. [Google Scholar] [CrossRef]

- Ruschel, E.; Alves, E.; Santos, P.; De Freitas, E.; Loures, R. Industrial maintenance decision-making: A systematic literature review. J. Manuf. Syst. 2017, 45, 180–194. [Google Scholar] [CrossRef]

- Fakher, H.B.; Nourelfath, M.; Gendreau, M. Integrating production, maintenance and quality: A multi-period multi-product profit-maximization model. Reliab. Eng. Syst. Saf. 2018, 170, 191–201. [Google Scholar] [CrossRef]

- Chen, Y.C. An optimal production and inspection strategy with preventive maintenance error and rework. J. Manuf. Syst. 2013, 32, 99–106. [Google Scholar] [CrossRef]

- Pacana, A.; Siwiec, D. Method of Determining Sequence Actions of Products Improvement. Materials 2022, 15, 6321. [Google Scholar] [CrossRef]

- Wei, S.; Nourelfath, M.; Nahas, N. Analysis of a production line subject to degradation and preventive maintenance. Reliab. Eng. Syst. Saf. 2023, 230, 108906. [Google Scholar] [CrossRef]

- Melani, A.H.A.; Murad, C.A.; Netto, A.C.; de Souza, G.F.M.; Nabeta, S.I. Criticality-based maintenance of a coal-fired power plant. Energy 2018, 147, 767–781. [Google Scholar] [CrossRef]

- Dangal, S.; Faludi, J.; Balkenende, R. Design Aspects in Repairability Scoring Systems: Comparing Their Objectivity and Completeness. Sustainability 2022, 14, 8634. [Google Scholar] [CrossRef]

- Iheukwumere-Esotu, L.O.; Yunusa-Kaltungo, A. Knowledge Management and Experience Transfer in Major Maintenance Activities: A Practitioner’s Perspective. Sustainability 2022, 14, 52. [Google Scholar] [CrossRef]

- Dhillon, B.S. Mining Equipment Reliability, Maintainability and Safety; Springer/Verlag London Limited: London, UK, 2008; Available online: http://books.google.ro/books?id=sJ7gd3uB_QoC&printsec=frontcover&dq=DHILLON+Mining+Equipment&source (accessed on 15 January 2024).

- Ishikawa, K. Controlul de Calitate; Editura Tehnică: București, Romania, 1973. [Google Scholar]

- Birolini, A. Reliability Engineering. Theory and Practice, 6h ed.; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- Weibull, W. A Statistical Theory of the Strength of Materials; The Royal Swedish Institute for Engineering Research: Stockholm, Sweden, 1939; p. 151. Available online: https://scholar.google.com/scholar_lookup?title=A+Statistical+Theory+of+the+Strength+of+Materials&author=Weibull,+W.&publication_year=1939 (accessed on 6 February 2024).

- Irfan, A.; Umar Muhammad, M.; Omer, A.; Mohd, A. Optimization and estimation in system reliability allocation problem. Reliab. Eng. Syst. Saf. 2021, 212, 107620. [Google Scholar] [CrossRef]

- Băjenescu, I.T. Reliability of Technical Systems; Matrix Rom Publishing House: Bucharest, Romania, 2003. (In Romanian) [Google Scholar]

- Kuźnar, M.; Lorenc, A.; Kaczor, G. Pantograph Sliding Strips Failure—Reliability Assessment and Damage Reduction Method Based on Decision Tree Model. Materials 2021, 14, 5743. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, S.; Hou, X.; Dong, H.; Cui, C.; Li, Y. Reliability Modeling and Analysis of a Diesel Engine Design Phase Based on 4F Integration Technology. Appl. Sci. 2022, 12, 6513. [Google Scholar] [CrossRef]

- Ateya, S.F.; Alghamdi, A.S.; Mousa, A.A.A. Future Failure Time Prediction Based on a Unified Hybrid Censoring Scheme for the Burr-X Model with Engineering Applications. Mathematics 2022, 10, 1450. [Google Scholar] [CrossRef]

- Yusufa, K.; Hadiy, S.; Olanipekuns, A. Sources of failures of engineering systems. Villanova J. Sci. Technol. Manag. 2019, 1, 69–76. Available online: https://acjol.org/index.php/vjstm/article/view/vjstm_v1n1_7/269 (accessed on 9 February 2024).

- Chen, Y.; Ma, X.; Wei, F.; Yang, L.; Qiu, Q. Dynamic Scheduling of Intelligent Group Maintenance Planning under Usage Availability Constraint. Mathematics 2022, 10, 2730. [Google Scholar] [CrossRef]

- Kowalski, S.; Pexa, M.; Aleš, Z.; Čedík, J. Failure Analysis and the Evaluation of Forced-in Joint Reliability for Selected Operation Conditions. Coatings 2021, 11, 1305. [Google Scholar] [CrossRef]

- Pavelescu, D. Tribotehnica; Editura tehnică: București, Romania, 1983. [Google Scholar]

- Olaru, D. Tribologie. Available online: https://mec.tuiasi.ro/wp-content/uploads/2020/09/DUMITRU-OLARU_TRIBOLOGIE-CURSURI-CU-APLICATII.pdf (accessed on 11 October 2023).

- Chang, X.-D.; Peng, Y.-X.; Zhu, Z.-C.; Zou, S.-Y.; Gong, X.-S.; Xu, C.-M. Evolution Properties of Tribological Parameters for Steel Wire Rope under Sliding Contact Conditions. Metals 2018, 8, 743. [Google Scholar] [CrossRef]

- Teringl, A.; Ales, Z.; Legat, V. Dependability characteristics—Indicators for maintenance performance measurement of manufacturing technology. Manuf. Technol. 2015, 15, 456–461. [Google Scholar] [CrossRef]

- Florea, V.A. Mentenanța Echipamentelor Industriale; Editura Universitas: Petroșani, România, 2020; Available online: https://scholar.google.com/citations?view_op=view_citation&hl=ro&user=wQviz9gAAAAJ&citation_for_view=wQviz9gAAAAJ:ZeXyd9-uunAC (accessed on 9 February 2024).

- Jimenez-Cortadi, A.; Irigoien, I.; Boto, F.; Sierra, B.; Rodriguez, G. Predictive maintenance on the machining process and machine tool. Appl. Sci. 2020, 19, 224. [Google Scholar] [CrossRef]

- Erozan, I. A fuzzy decision support system for managing maintenance activities of critical components in manufacturing systems. J. Manuf. Syst. 2019, 52, 110–120. [Google Scholar] [CrossRef]

- García, F.J.Á.; Salgado, D.R. An Approach for Predictive Maintenance Decisions for Components of an Industrial Multistage Machine That Fail before Their MTTF: A Case Study. Systems 2022, 10, 175. [Google Scholar] [CrossRef]

- García, F.J.Á.; Salgado, D.R. Analysis of the Influence of Component Type and Operating Condition on the Selection of Preventive Maintenance Strategy in Multistage Industrial Machines: A Case Study. Machines 2022, 10, 385. [Google Scholar] [CrossRef]

- Ertugrul, G.; Hälsig, A.; Hensel, J.; Buhl, J.; Härtel, S. Efficient Multi-Material and High Deposition Coating including Additive Manufacturing by Tandem Plasma Transferred Arc Welding for Functionally Graded Structures. Metals 2022, 12, 1336. [Google Scholar] [CrossRef]

- Tihanov-Tănăssache, D.; Binchiciu, E.F.; Florea, C.; Geanta, V.; Binchiciu, H. Research regarding wear protection in sever exploitation condition of crusher jaws. Adv. Mater. Res. 2015, 1128, 390–393. [Google Scholar] [CrossRef]

- Bachchhav, B.D.; Chaitanya, S.V.; Salunkhe, S.; Chandrakumar, P.; Pagáč, M.; Nasr, E.A. Wear Performance of Cu–Cd, Cu–Be and Cu–Cr–Zr Spot Welding Electrode Materials. Lubricants 2023, 11, 291. [Google Scholar] [CrossRef]

- Lavrys, S.; Pohrelyuk, I.; Padgurskas, J.; Shliakhetka, K. Improving Wear Resistance of Highly Porous Titanium by Surface Engineering Methods. Coatings 2023, 13, 1714. [Google Scholar] [CrossRef]

- Khalil, J.; Saad, S.M.; Gindy, N. An integrated cost optimisation maintenance model for industrial equipment. J. Qual. Maint. Eng. 2009, 15, 106–118. [Google Scholar] [CrossRef]

| No. | Characteristics | |

|---|---|---|

| 1 | Color | Gray |

| 2 | Appearance | Homogeneous |

| 3 | Fracture | Angled, slightly irregular prismatic shapes |

| 4 | Texture | Compact, weakly vacuolated |

| 5 | Structure | Porphyric |

| 6 | Density | 2.94 g/cm2 |

| 7 | Compactness | 93.5% |

| 8 | Appearance | 1.08% |

| 9 | Appearance | 6.5% |

| 10 | Compression strength | 147 N/mm2 |

| 11 | Friction wear resistance (at 440 rpm) in dry state | 0.07 g/cm2 |

| Time | Value | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Operating times between two failures (hours) | 18 | 24 | 35 | 36 | 37 | 42 | 43 | 48 | 64 | 65 |

| 66 | 67 | 72 | 73 | 78 | 96 | 108 | 120 | 126 | 138 | |

| 140 | 162 | 168 | 174 | 198 | 222 | |||||

| Repair times (minutes) | 40 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| 60 | 60 | 60 | 65 | 65 | 65 | 70 | 70 | 75 | 75 | |

| 80 | 80 | 80 | 80 | 85 | 85 | |||||

| Time | Value | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Operating times between two failures (hours) | 7 | 7 | 7 | 14 | 14 | 14 | 14 | 14 | 20 | 21 |

| 21 | 26 | 27 | 28 | 28 | 29 | 35 | 37 | 42 | 44 | |

| 48 | 55 | 56 | 63 | 65 | 69 | 70 | 72 | 76 | 77 | |

| 78 | 79 | 83 | 105 | 107 | 114 | 118 | 127 | 130 | 149 | |

| 160 | 178 | 211 | 227 | 347 | 533 | 538 | ||||

| Repair times (minutes) | 120 | 180 | 180 | 180 | 180 | 180 | 180 | 190 | 200 | 205 |

| 220 | 220 | 230 | 230 | 230 | 240 | 240 | 240 | 240 | 240 | |

| 240 | 250 | 260 | 260 | 260 | 260 | 260 | 260 | 270 | 270 | |

| 270 | 270 | 290 | 290 | 300 | 300 | 300 | 300 | 300 | 300 | |

| 310 | 310 | 320 | 330 | 360 | 450 | 840 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Florea, V.A.; Toderaș, M. Efficiency of Maintenance Activities in Aggregate Quarries: A Case Study of Wear Parts on Loaders and Excavators. Appl. Sci. 2024, 14, 7649. https://doi.org/10.3390/app14177649

Florea VA, Toderaș M. Efficiency of Maintenance Activities in Aggregate Quarries: A Case Study of Wear Parts on Loaders and Excavators. Applied Sciences. 2024; 14(17):7649. https://doi.org/10.3390/app14177649

Chicago/Turabian StyleFlorea, Vlad Alexandru, and Mihaela Toderaș. 2024. "Efficiency of Maintenance Activities in Aggregate Quarries: A Case Study of Wear Parts on Loaders and Excavators" Applied Sciences 14, no. 17: 7649. https://doi.org/10.3390/app14177649