Analysis of Longitudinal Braking Stability of Lightweight Liquid Storage Mini-Track Vehicles

Abstract

1. Introduction

2. Analysis of LBS

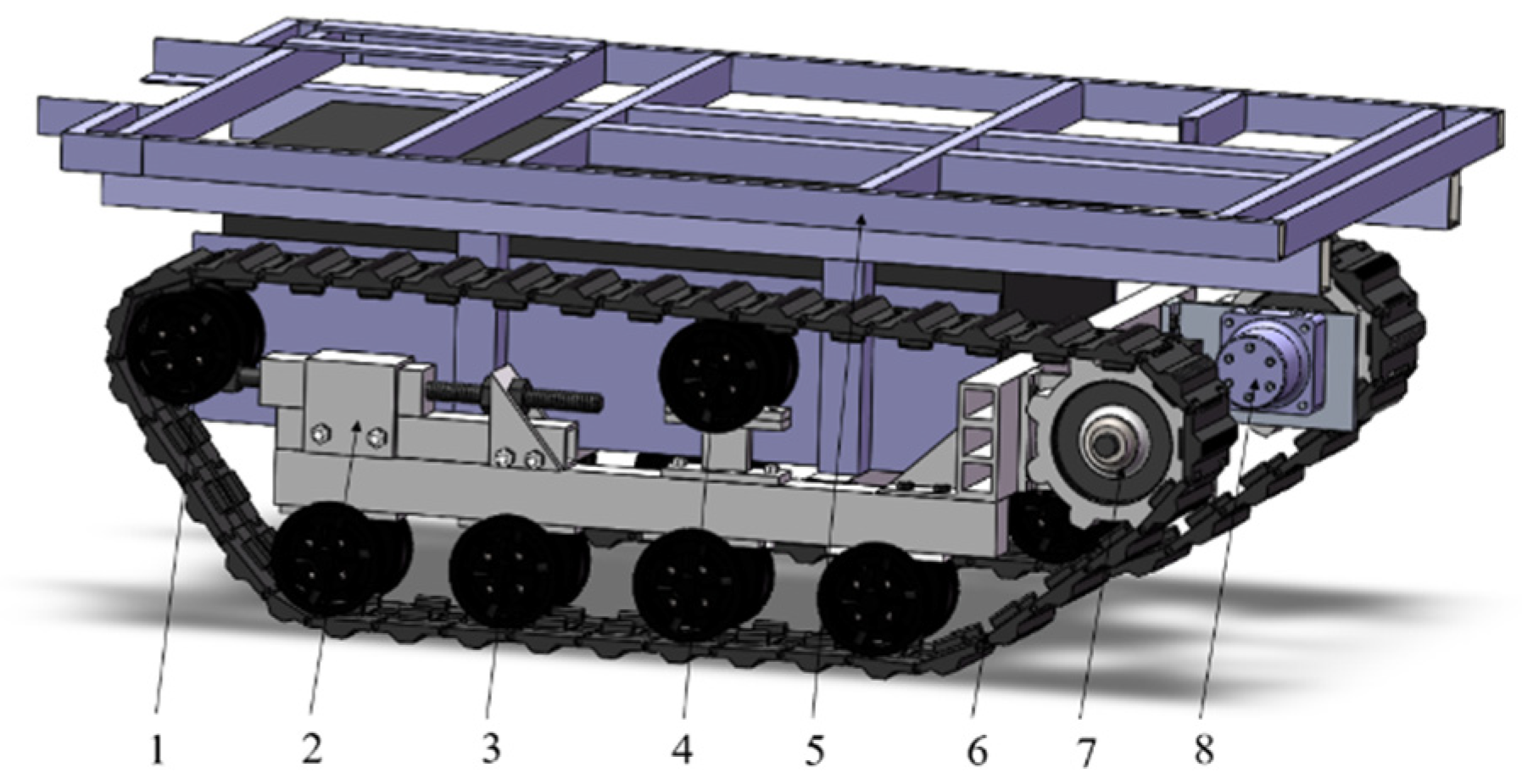

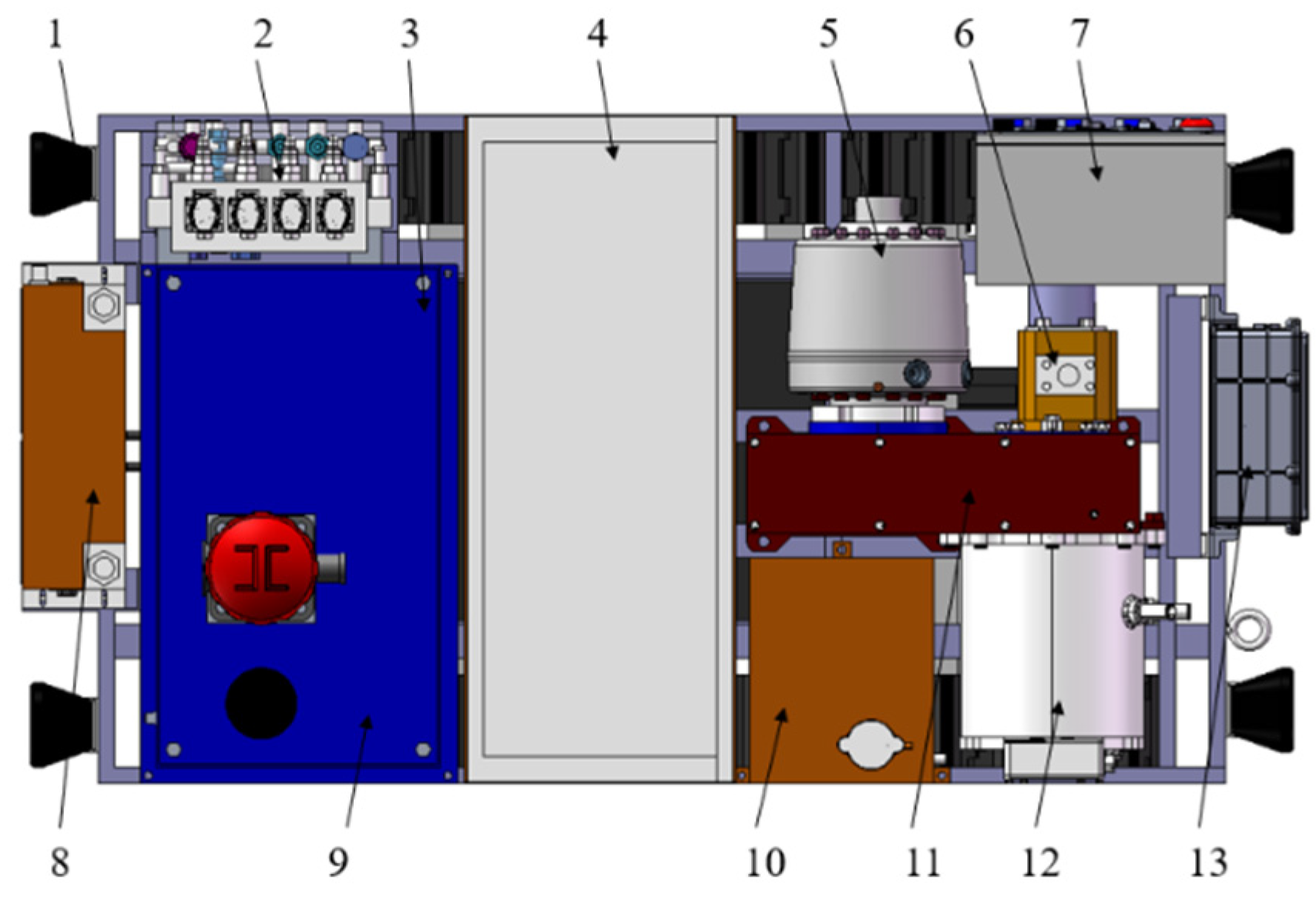

2.1. Tracked Vehicle Structure and Onboard Layout

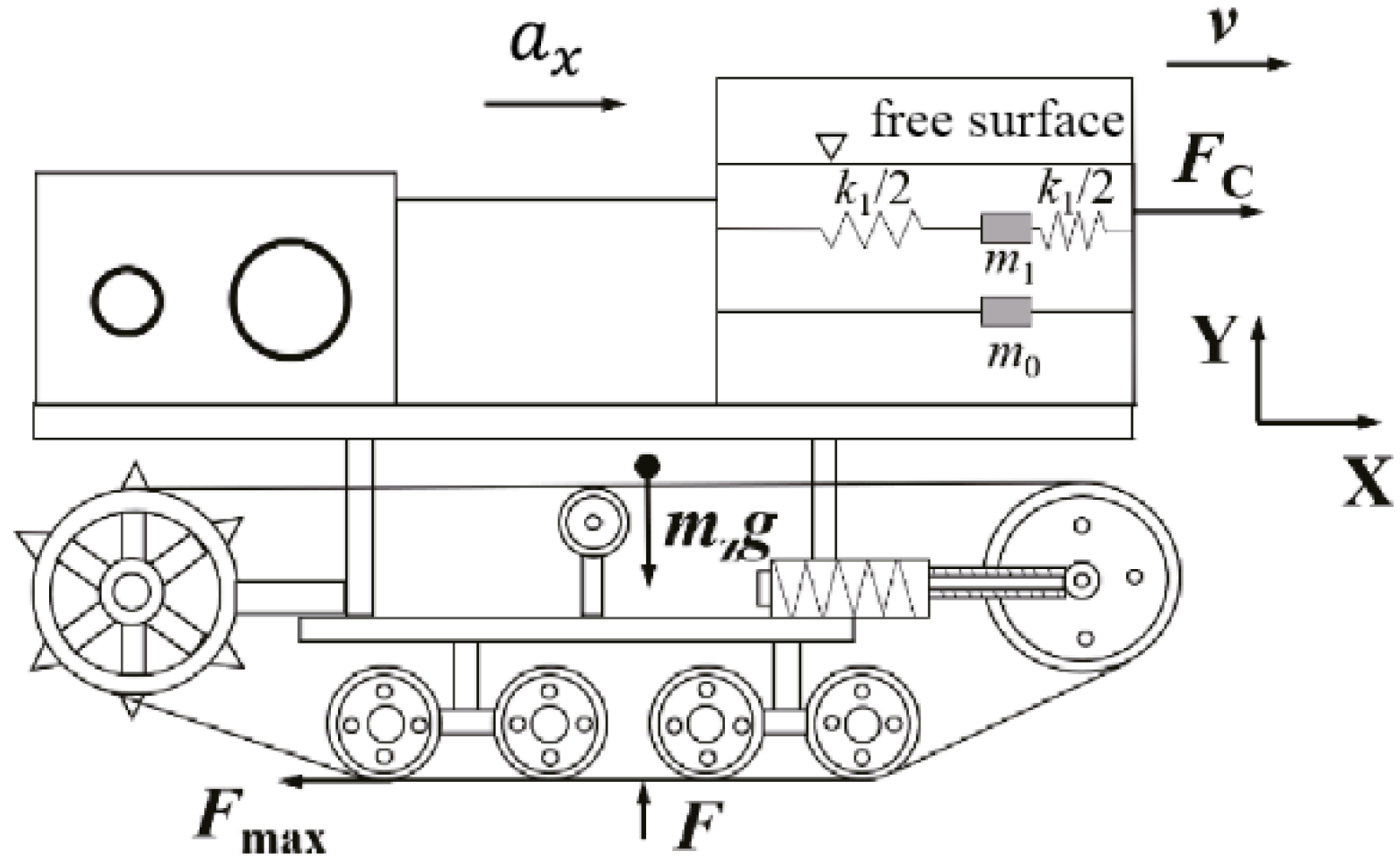

2.2. Mathematical Modeling

2.3. Theoretical Solution of the Longitudinal Impact Force of Tank Liquid According to a Literature Study [4]

- Continuity equation:

- Momentum conservation equation:

- Parametric equation of turbulence model

3. Simulation of LBS

3.1. Simulation Parameters

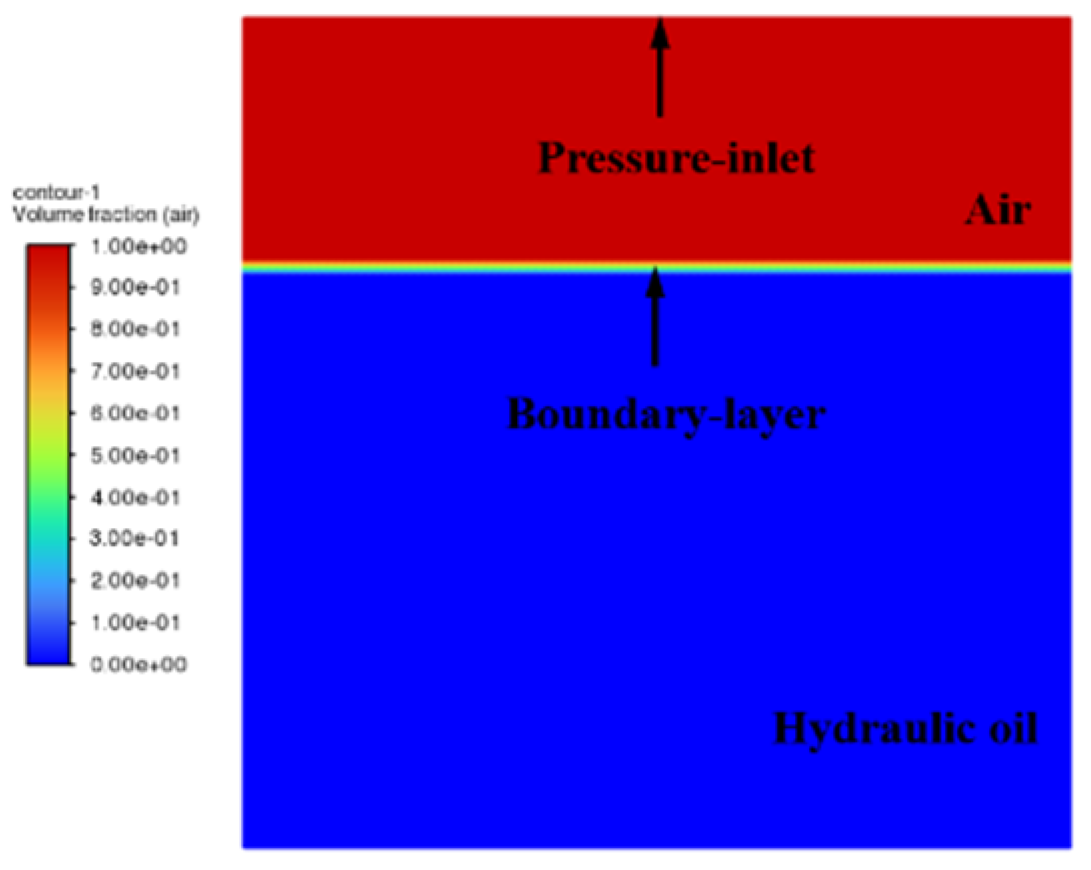

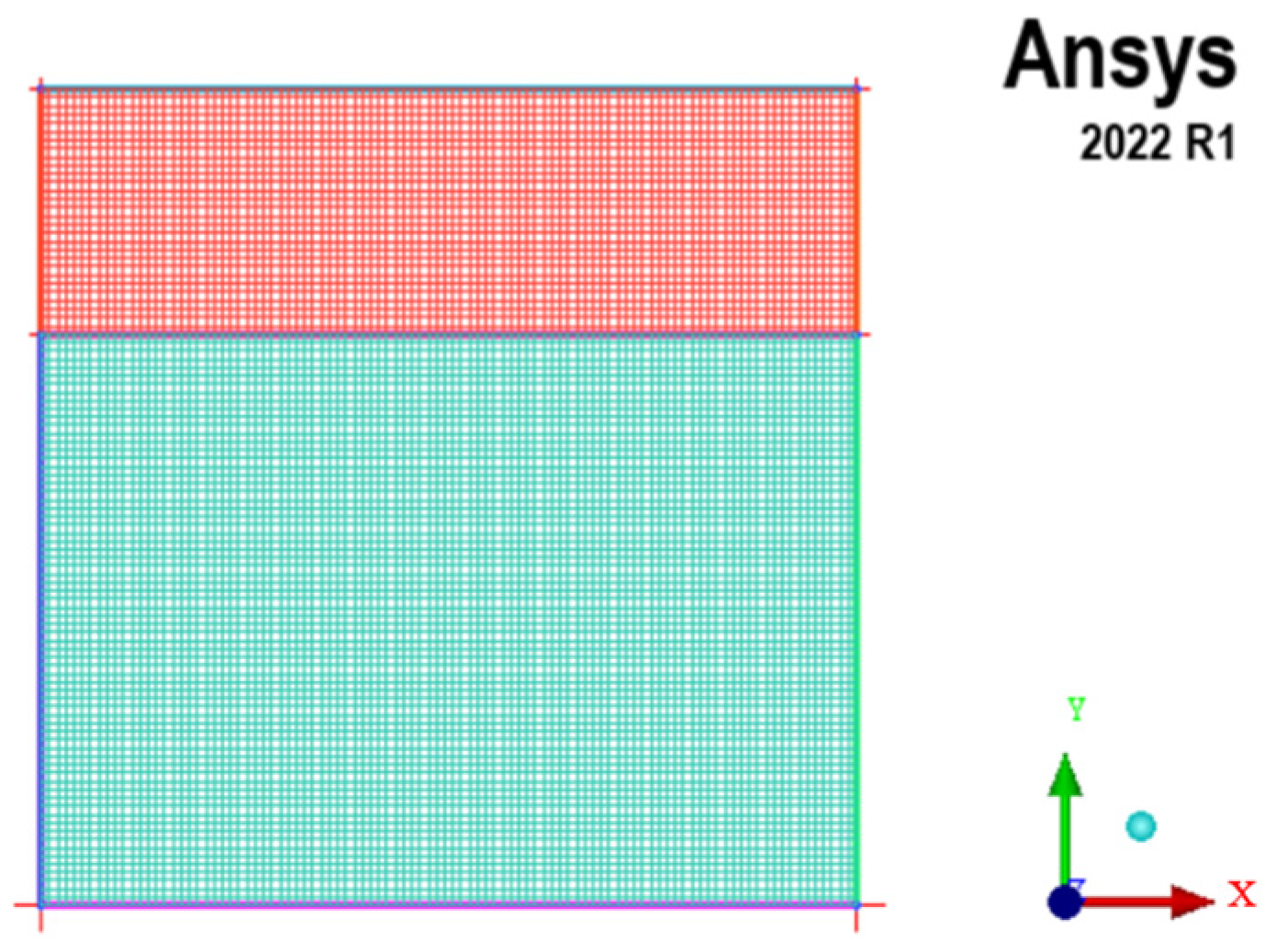

3.1.1. Liquid Tank Model and Boundary Conditions

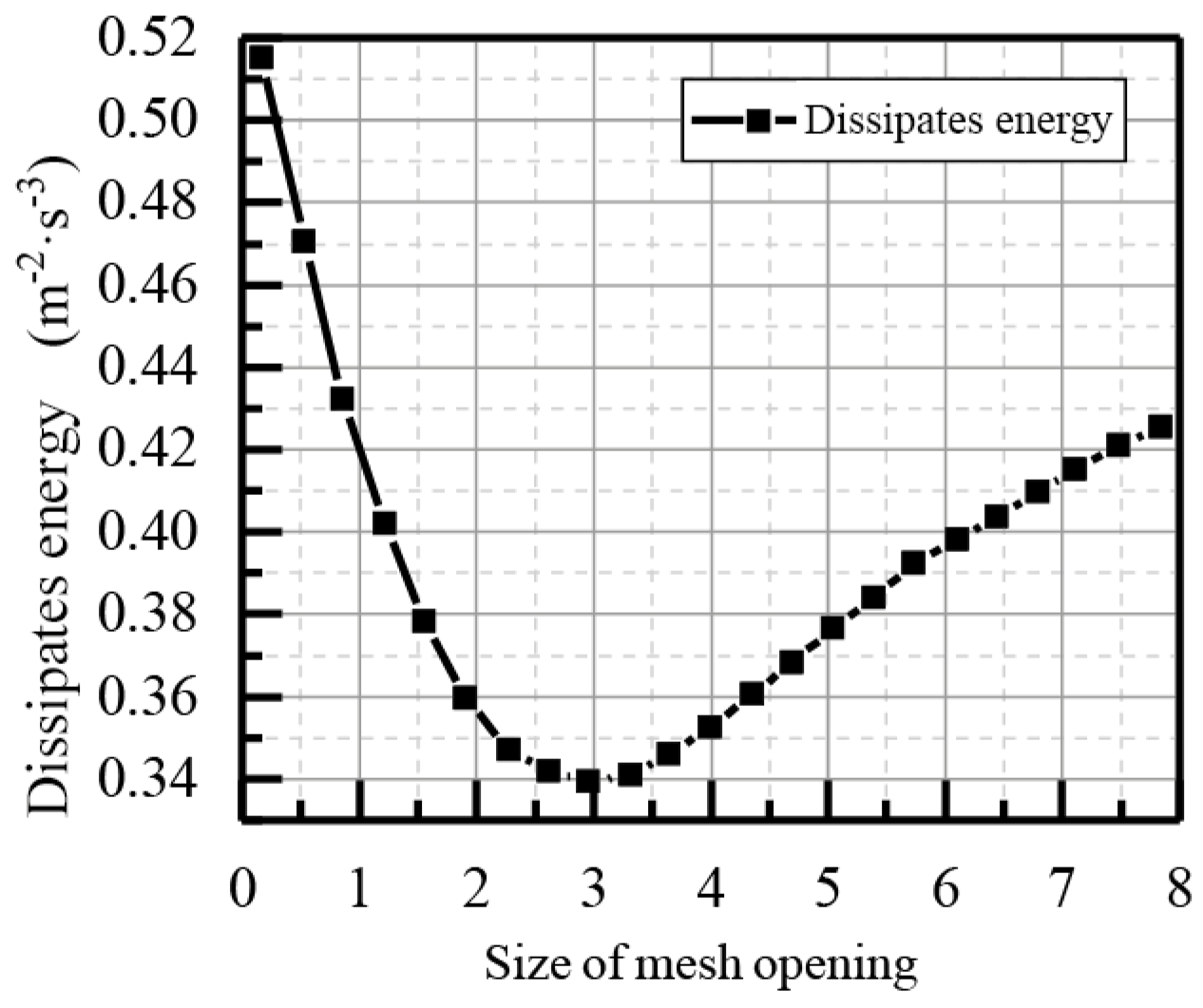

3.1.2. Mesh Precision Design and Mesh Division

3.1.3. Setting of the Key Parameters

3.1.4. Simulation Experimental Data

3.2. Influence of TLR on Stability

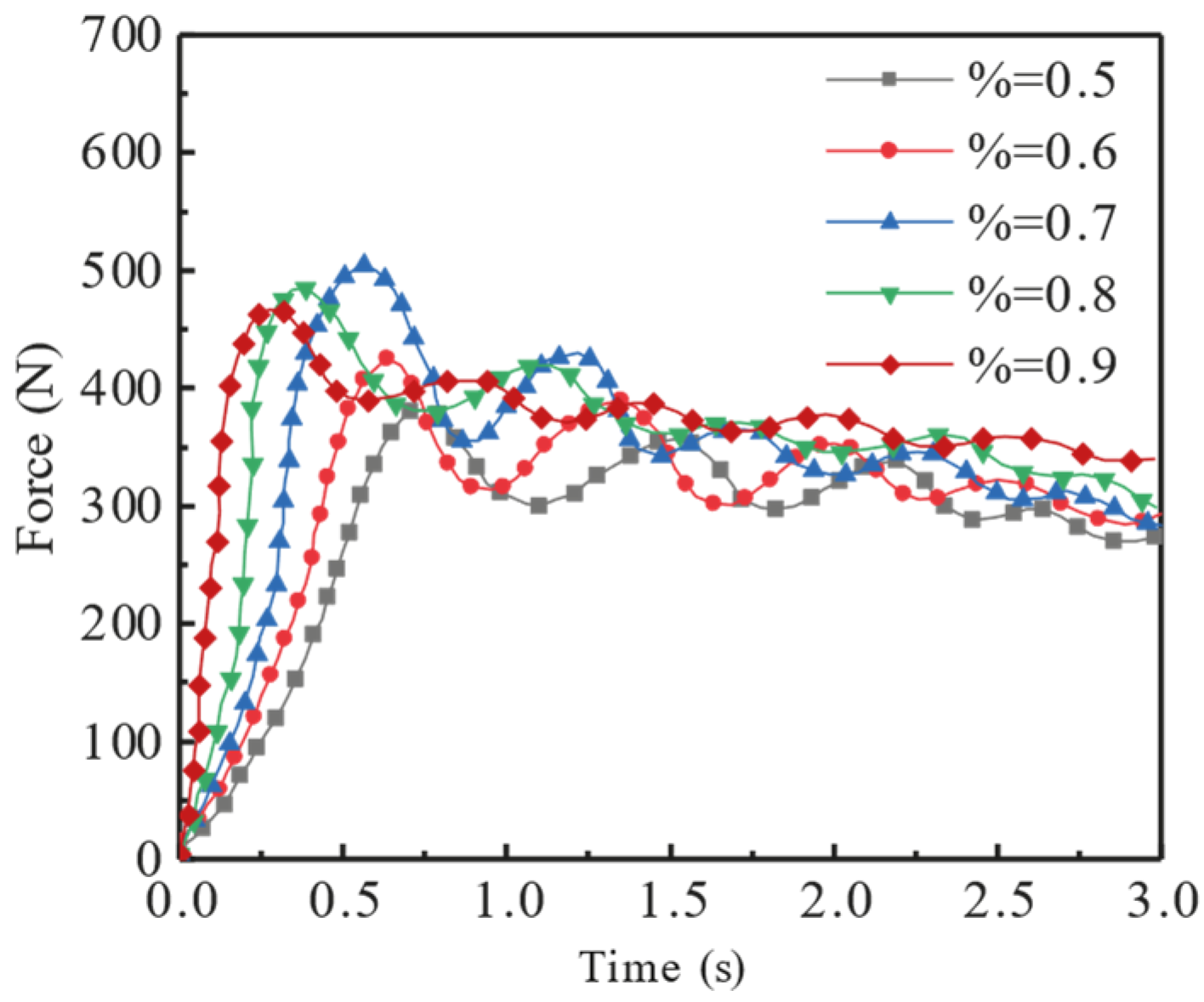

3.2.1. Influence of the TLR on the Longitudinal Impact Force

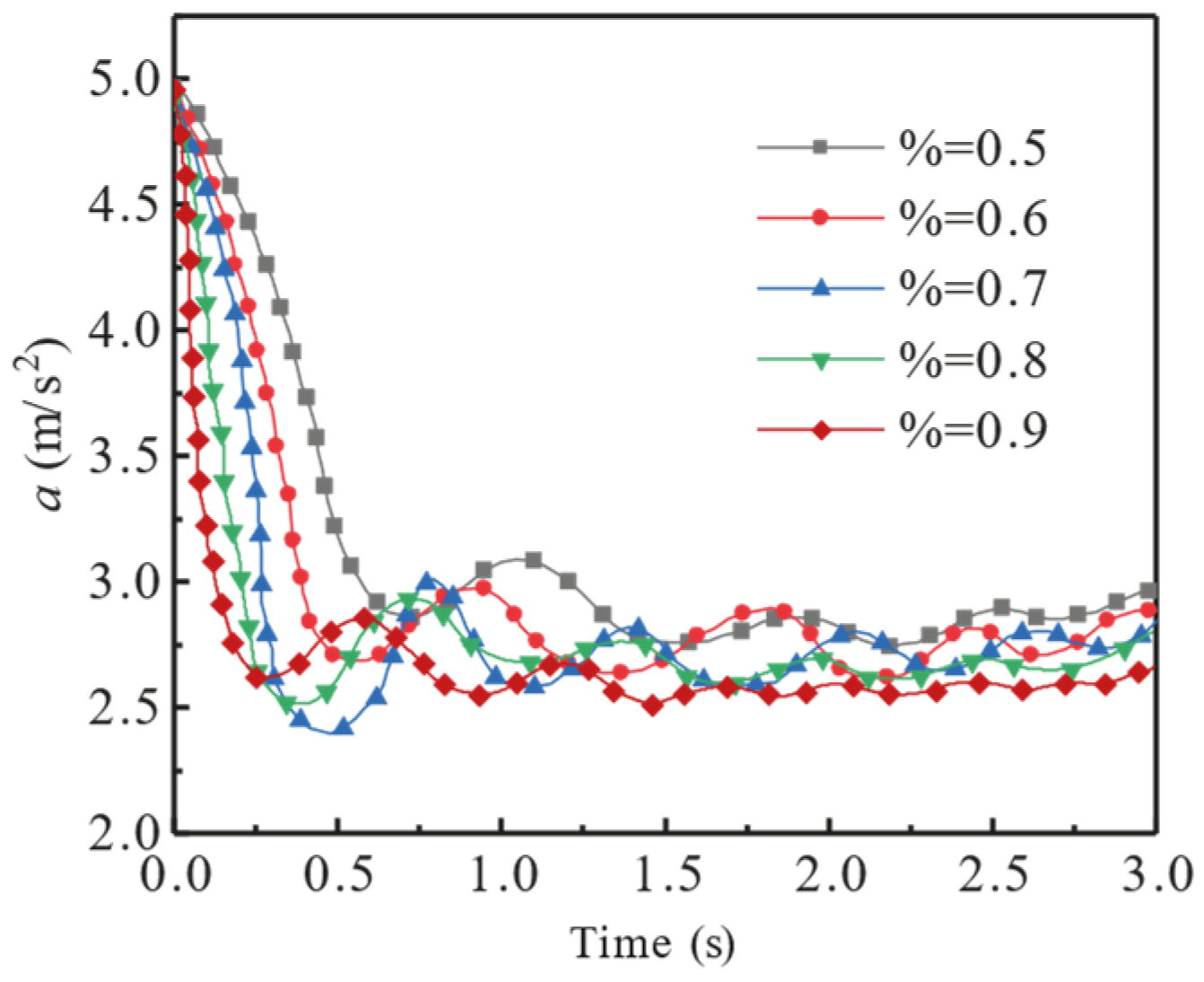

3.2.2. The Effect of TLR on the Effective Braking Deceleration

3.2.3. Analysis of LBS for Different TLRs

3.3. Influence of IV on Stability

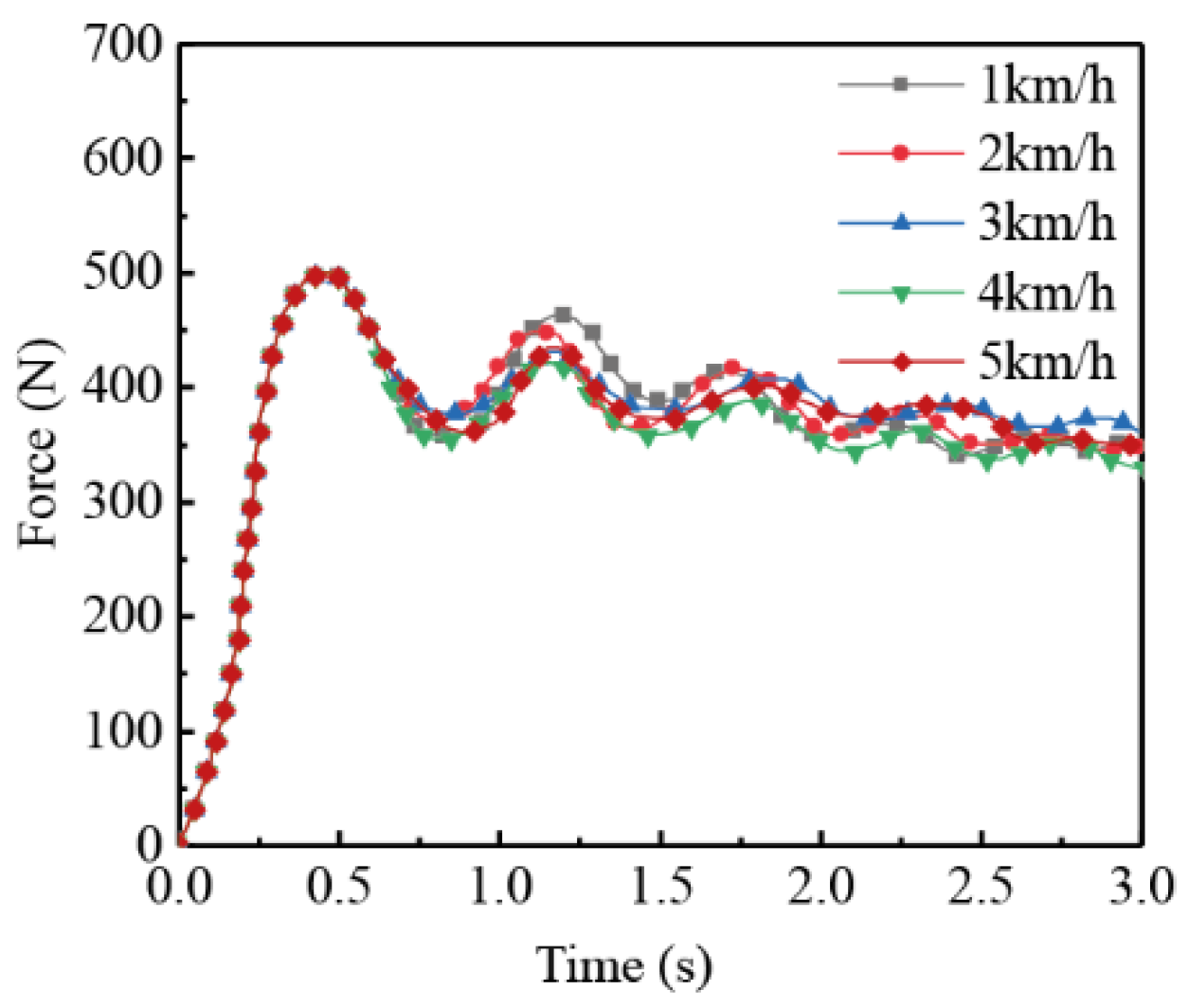

3.3.1. Influence of IV on the Longitudinal Impact Force

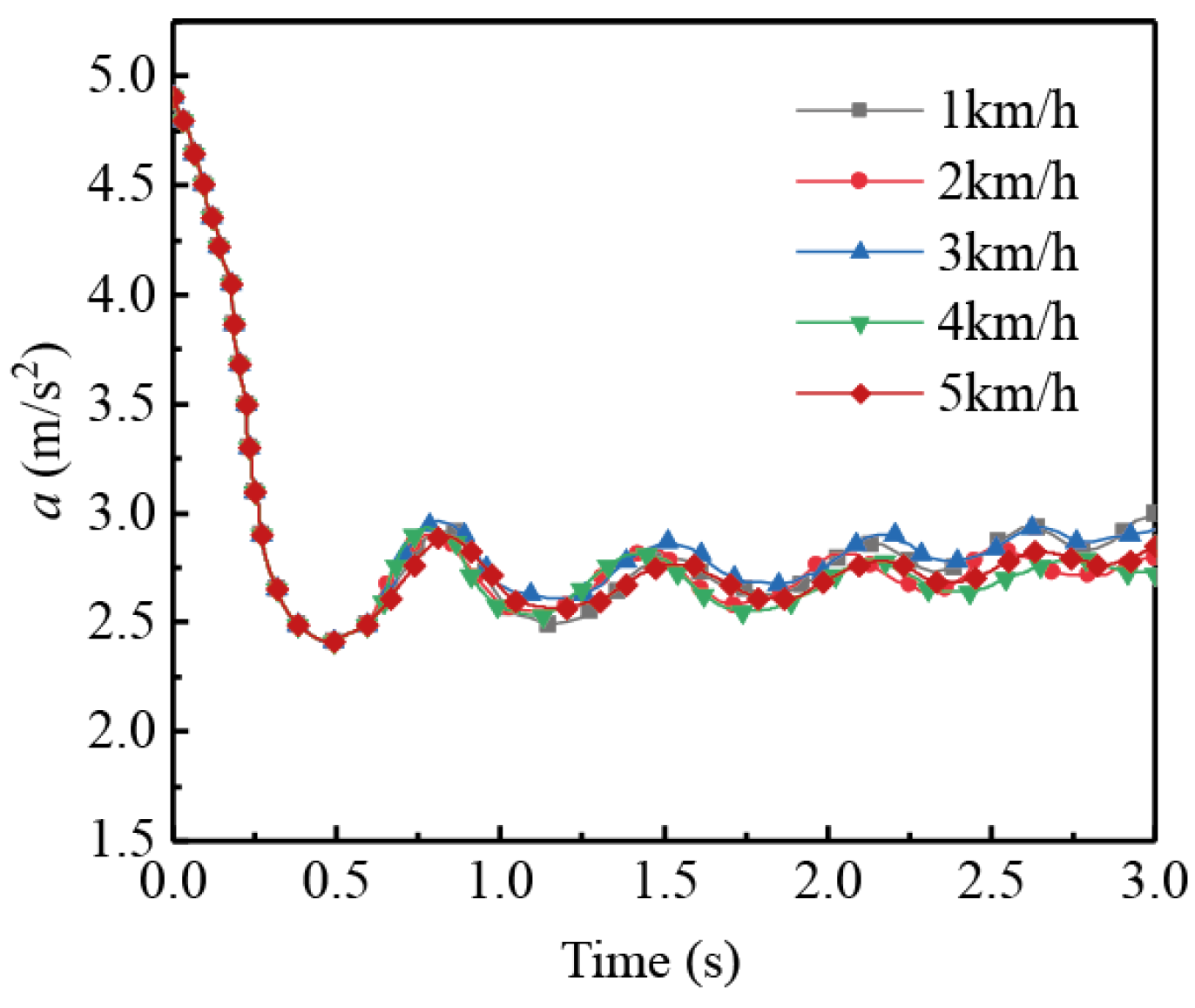

3.3.2. The Influence of IV on the Effective Braking Deceleration

3.3.3. Analysis of the LBS at Various IVs

3.4. Influence of IBD on Stability

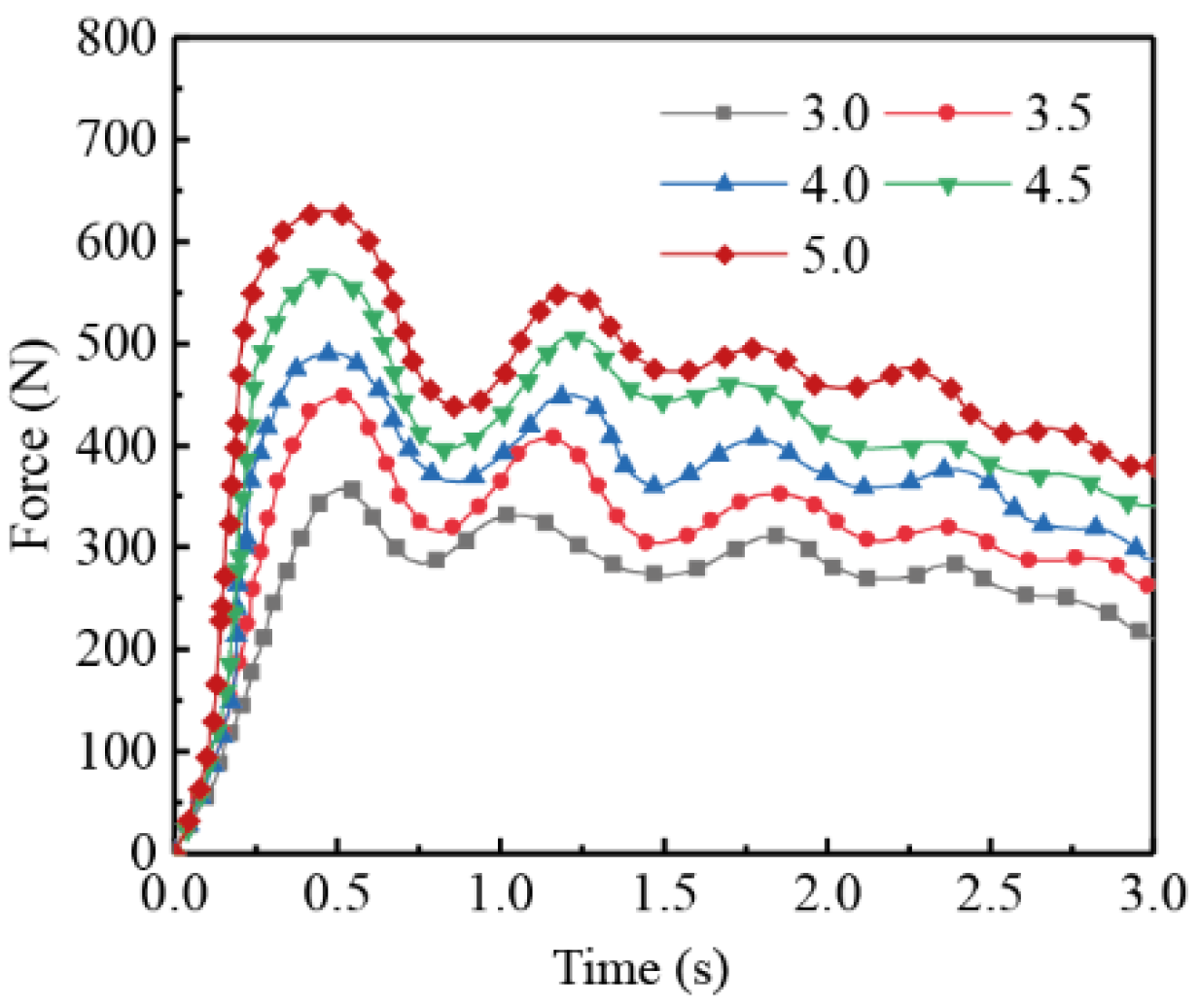

3.4.1. Influence of IBD on the Longitudinal Impact Force

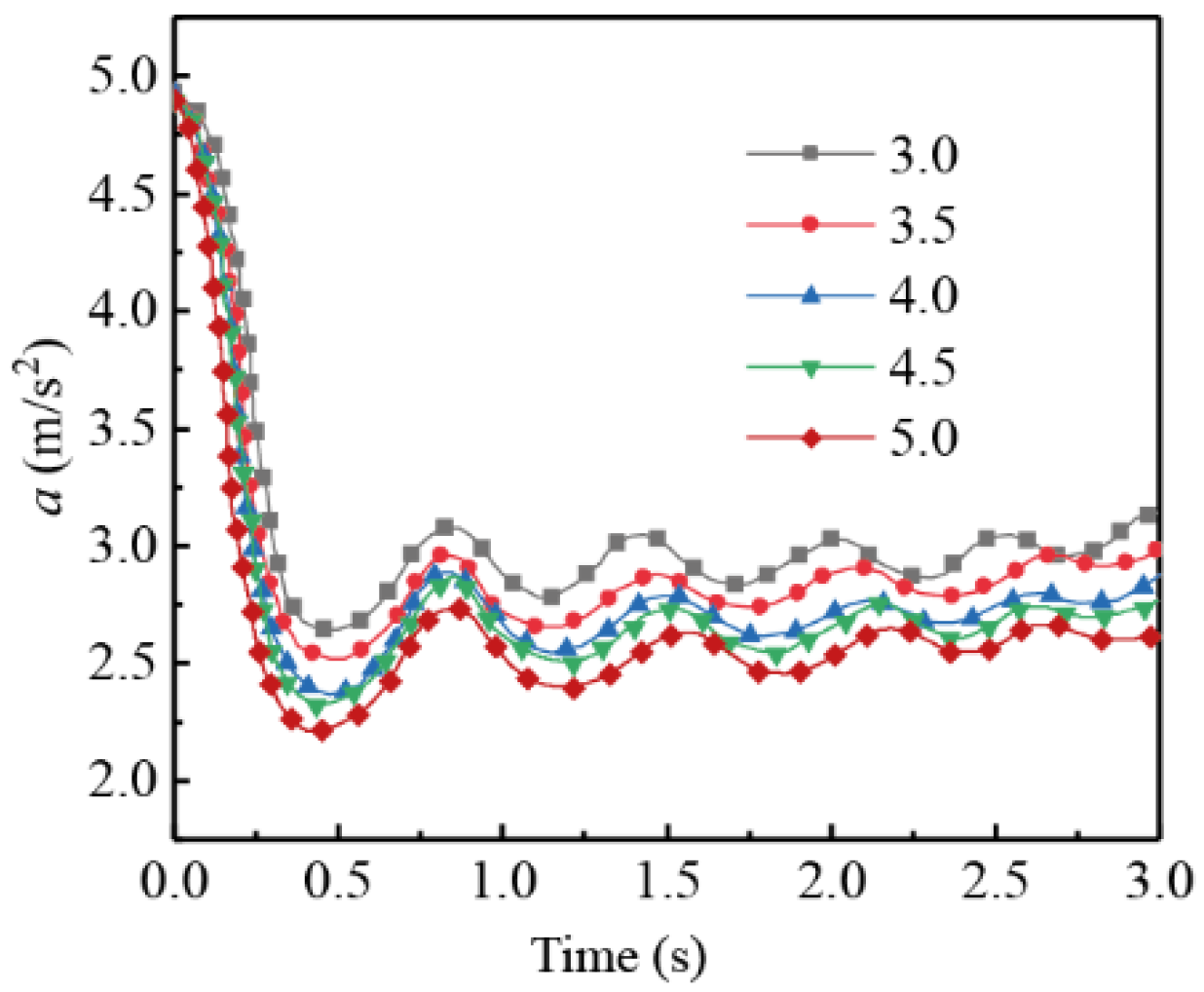

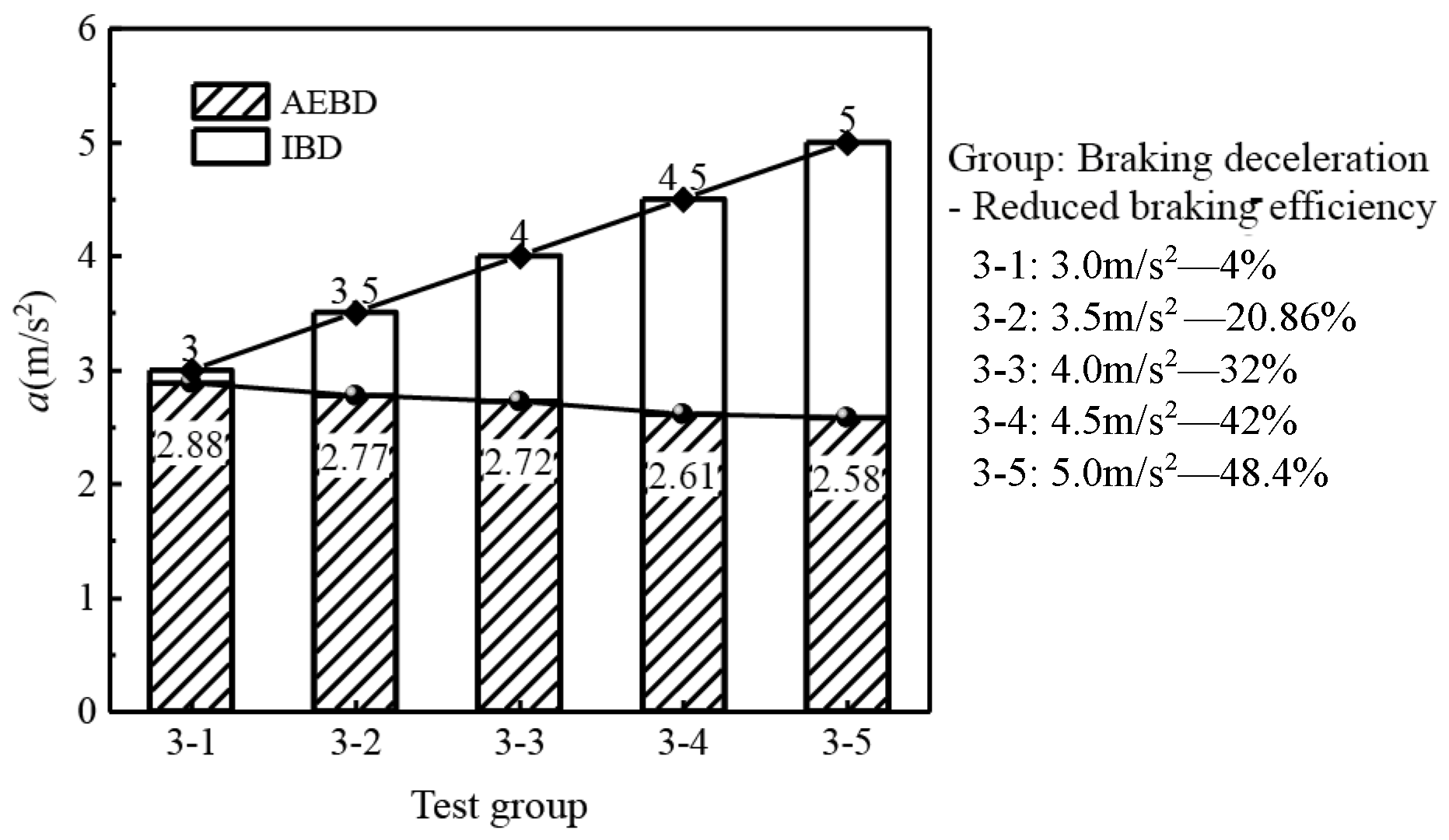

3.4.2. The Influence of IBD on the Effective Braking Deceleration

3.4.3. Analysis of LBS at Different IBDs

4. Road Experiment

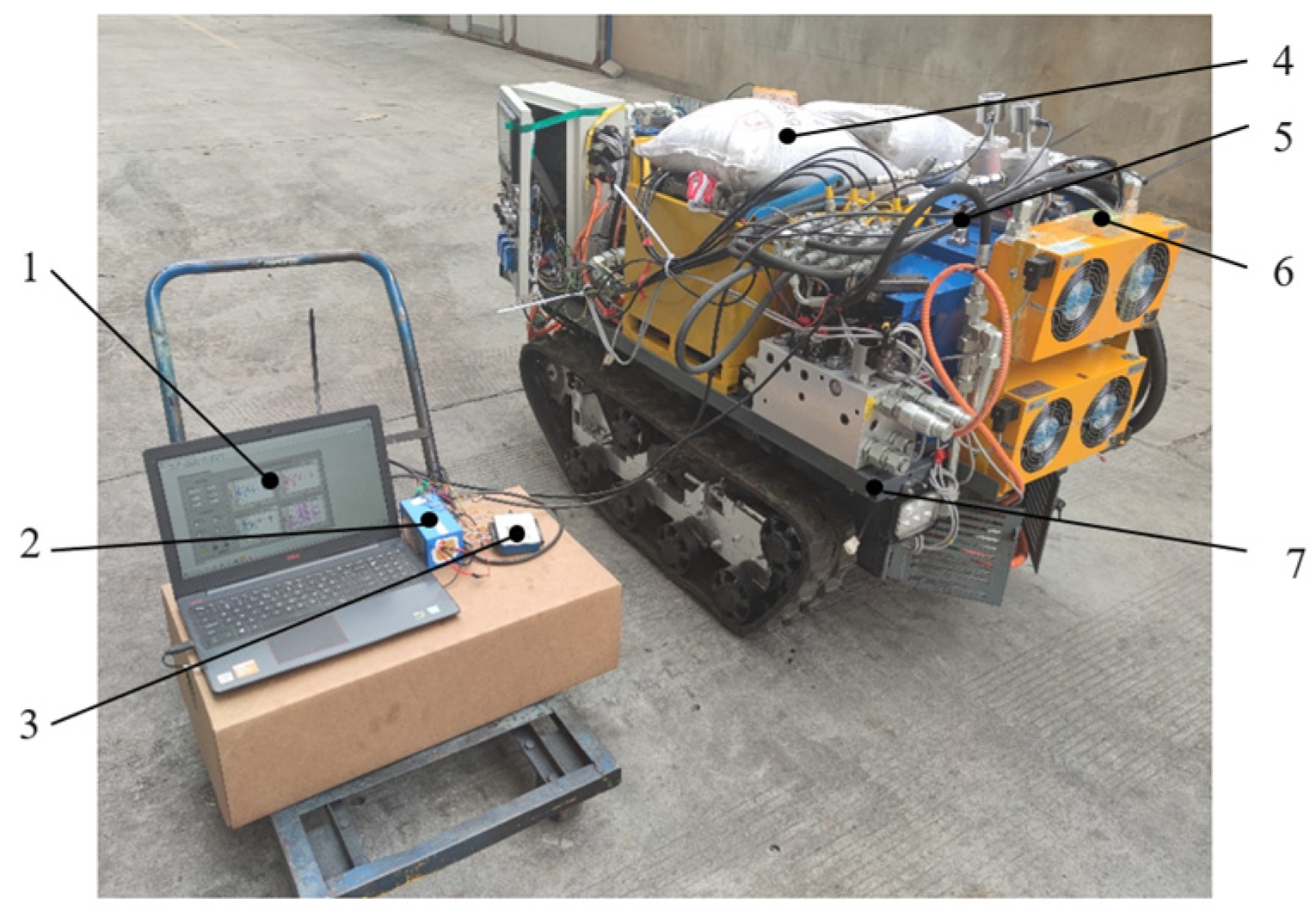

4.1. Dynamic Stability Experiment Device

4.2. Dynamic Stability Experiment

4.2.1. Experimental Conditions and Scheme

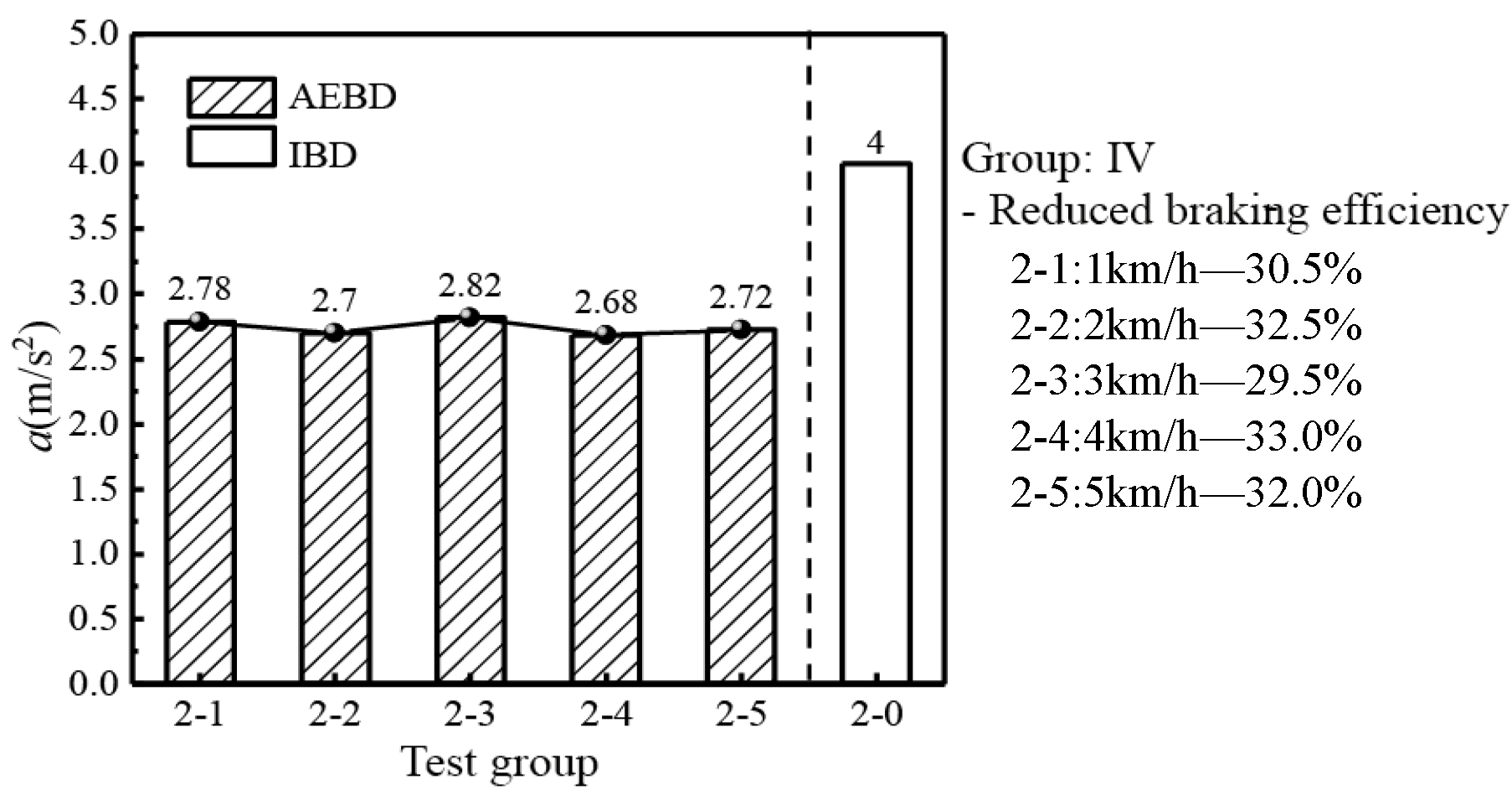

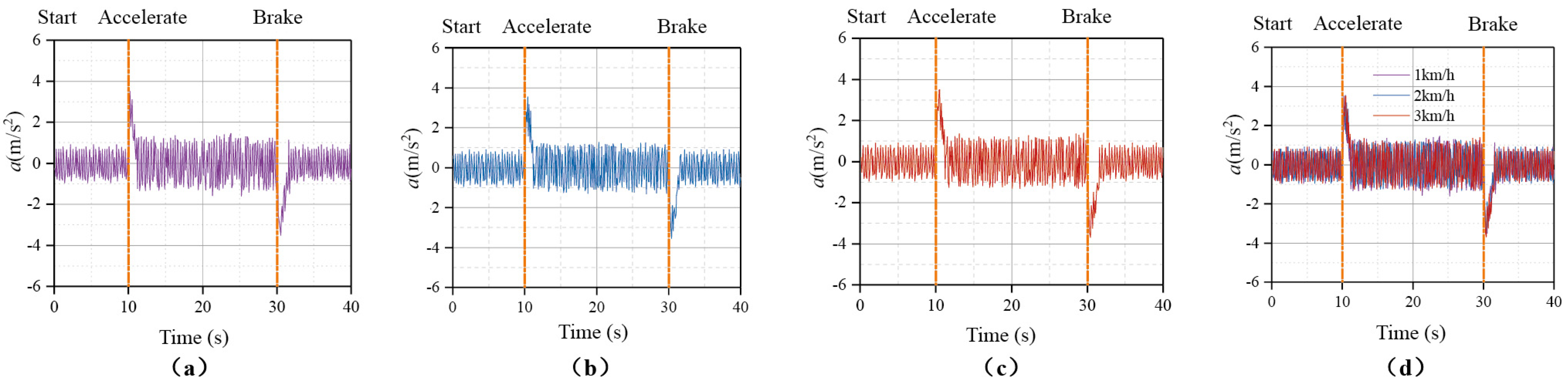

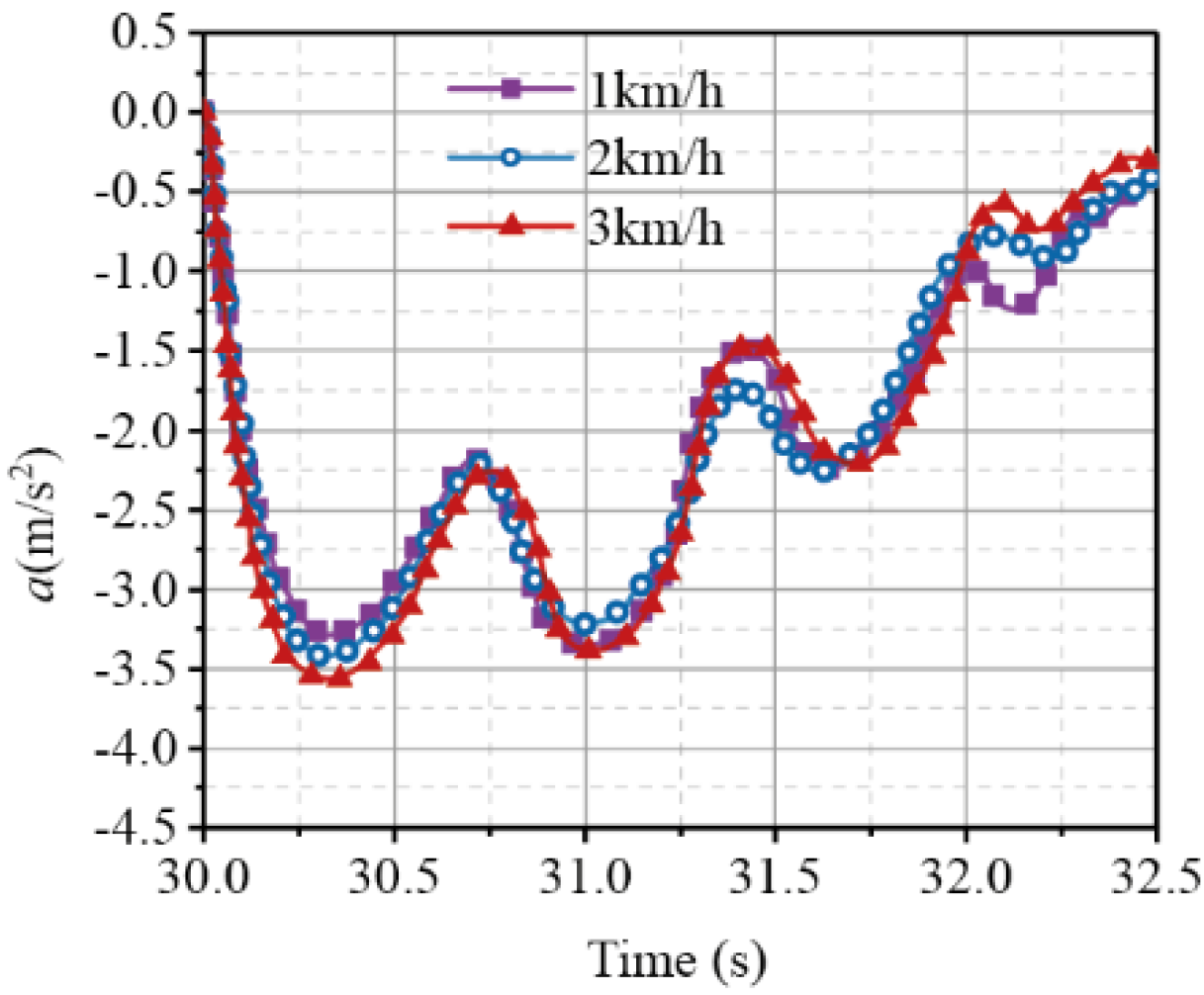

4.2.2. Influence of IV on the Effective Braking Deceleration

4.2.3. Influence of the IV on the Longitudinal Angular Displacement

5. Conclusions

- The braking dynamics model of the lightweight mini-track vehicle was established. According to the model, the effective braking speed reduction was positively correlated with the total mass of the tracked vehicle when the tracked vehicle was impacted by the liquid tank during running. Furthermore, it was negatively correlated with the longitudinal impact force of the liquid oscillation. In other words, the smaller the tracked vehicle mass, the greater the longitudinal impact force. Moreover, smaller vehicle mass also corresponds to a smaller effective braking deceleration, inferior longitudinal stability, and longer braking time.

- Based on the fluid motion equation applied to the liquid tank and the theoretical model of longitudinal impact force, the influences of the TLR, IV, and IBD on the longitudinal stability of the observed vehicle were analyzed. It is noteworthy that the control variable method and the fluid simulation software FLUENT 2023 were used. The results show that the TLR significantly impacted the braking efficiency of the tracked vehicle. The braking effect was the weakest for the filling ratio of 0.7, and the braking efficiency decreased by 32% compared to its initial value. Changing only the IV exhibited a limited effect on the longitudinal stability of the tracked vehicle. Further, the braking efficiency was also reduced by about 30% compared with the IBD. When the IBD was changed, the braking efficiency reduction rate was positively correlated with it. Finally, when the IBD speed was increased to 5 m⋅s−2, the braking efficiency decreased by more than 48%.

- The dynamic stability experimental platform of the lightweight mini-tracked vehicle was built. The limit conditions of the TLR of 0.7 and effective braking deceleration of 4 m⋅s−2 were selected for the experimental case. The longitudinal stability of the tracked vehicle during the starting, accelerating, walking, and emergency braking at IVs of 1, 2, and 3 km⋅h−1 was evaluated. Based on the results, the following conclusions were drawn: when the TLR and effective braking deceleration were constant, the change in the IV exhibited a limited effect on the effective braking deceleration. Compared to the simulation results, the AEBD obtained in the experiment was smaller. This was due to the sudden acceleration or braking of the tracked vehicle during the road experiment, which caused forced vibration of its motor, gearbox, and pump, among other components. The forced vibration led to a further increase in the longitudinal force of the liquid, thus reducing effective braking deceleration.

- When the tracked vehicle accelerated and braked under extreme conditions, the front and rear tilt angles were approximately 4°. This value is below 5°, which indicates that the stability requirements are met.

- Owing to time and resource constraints, only the longitudinal stability of the tracked vehicle during the braking was studied. However, the road conditions of the tracked vehicle during the rescue were harsh. Therefore, it might be valuable to systematically examine the lateral rollover stability and longitudinal stability of the tracked vehicle under various working conditions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wan, Y.; Zhao, W.Q.; Zong, C.F.; Zheng, H.Y.; Li, Z.Y. Modelling and Analysis of the Influences of Various Liquid Sloshing Characteristics on Tank Truck Dynamics. Int. J. Heavy Veh. Syst. 2019, 26, 463–493. [Google Scholar] [CrossRef]

- Shi, H.L.; Wang, L.; Nicolsen, B.; Shabana, A.A. Integration of Geometry and Analysis for the Study of Liquid Sloshing in Railroad Vehicle Dynamics. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2017, 231, 608–629. [Google Scholar] [CrossRef]

- Wu, W.J.; Gao, C.N.; Yue, B.Z.; Deng, M.L. Experimental Study and Dynamic Characteristic Analysis of Nonlinear Steady State Sloshing of Liquid in a Cylindrical Tank. J. Astronaut. 2021, 42, 1078–1089. [Google Scholar]

- Li, X. Research on the Longitudinal Stability of Tank Vehicles on Liquid Sloshing. Master’s Thesis, Jilin University, Changchun, China, 2016; pp. 10–12. [Google Scholar]

- Azadi, S.; Jafari, A.; Samadian, M. Effect of Parameters on Roll Dynamic Response of an Articulated Vehicle Carrying Liquids. J. Mech. Sci. Technol. 2020, 28, 837–848. [Google Scholar] [CrossRef]

- Zhou, F.X. Study on Handling Dynamics and Stability of Heavy-duty Vehicles with Storage Tank. Master’s Thesis, Guangxi University Science Technology, Liuzhou, China, 2020; pp. 33–36. [Google Scholar]

- Wang, L. Research on Anti-Rollover Stability of Tank Semi-Trailer Considering Vehicle-Liquid Coupling. Master’s Thesis, Harbin Institute Technology, Harbin, China, 2021; pp. 31–35. [Google Scholar]

- Zheng, X.L.; Li, X.S.; Ren, Y.Y. Rollover Stability Analysis of Tank Vehicle Impacted by Transient Liquid Sloshing. J. Jilin Univ. (Eng. Technol. Ed.) 2014, 44, 61–64. [Google Scholar]

- Li, H. Fluid-Structure Coupling Stress Analysis of Tank for Tank Truck and Study of Internal Fluid Sloshing. Master’s Thesis, Northeastern University, Shenyang, China, 2018; pp. 42–46. [Google Scholar]

- Chen, J.M. Analysis on Characteristics of Liquid Sloshing in Automobile Fuel Tank under Multiple Operating Condition. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2019; pp. 24–41. [Google Scholar]

- Feng, C.Q. Study on Longitudinal Sloshing of Liquid Tank Car and Vehicle Dynamics Model. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2020; pp. 67–82. [Google Scholar]

- Zhang, J.W.; Wang, W.Y.; Peng, Y.H.; Li, X.D. A Study on Turning-braking Stability of a Tanker. Automot. Eng. 2019, 2, 118–123. [Google Scholar]

- Yu, Z.S. Automobile Theory, 6th ed.; China Machine Press: Beijing, China, 2018. [Google Scholar]

- Ranganathan, R.; Rakheja, S.; Sankar, S. Steady Turning Stability of Partially Filled Tank Vehicles with Arbitrary Tank Geometry. J. Dyn. Sys., Meas. Control 2019, 111, 481–489. [Google Scholar] [CrossRef]

- Zhang, E.H.; He, R.; Su, W.D. Numerical Analysis of Oil Liquid Sloshing Characteristics in fuel tank with different baffle structure. J. Jilin Univ. (Eng. Technol. Ed.) 2021, 1, 83–95. [Google Scholar]

| Experiment Group 1 | Experiment Group 2 | Experiment Group 3 | ||||||

|---|---|---|---|---|---|---|---|---|

| Filling Ratio | IV/(km⋅h−1) | IBD/(m⋅s−2) | IV/(km⋅h−1) | IBD/(m⋅s−1) | Filling Ratio | IBD/(m⋅s−1) | IV/(km⋅h−1) | Filling Ratio |

| 0.5 | 5 | 4 | 1 | 4 | 0.7 | 3 | 5 | 0.7 |

| 0.6 | 2 | 3.5 | ||||||

| 0.7 | 3 | 4 | ||||||

| 0.8 | 4 | 4.5 | ||||||

| 0.9 | 5 | 5 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Cao, X.; Xu, L.; Wang, Y.; He, Y.; Liu, X. Analysis of Longitudinal Braking Stability of Lightweight Liquid Storage Mini-Track Vehicles. Appl. Sci. 2024, 14, 7780. https://doi.org/10.3390/app14177780

Zhang C, Cao X, Xu L, Wang Y, He Y, Liu X. Analysis of Longitudinal Braking Stability of Lightweight Liquid Storage Mini-Track Vehicles. Applied Sciences. 2024; 14(17):7780. https://doi.org/10.3390/app14177780

Chicago/Turabian StyleZhang, Cuihong, Xuepeng Cao, Lijia Xu, Yan Wang, Yutian He, and Xiaohui Liu. 2024. "Analysis of Longitudinal Braking Stability of Lightweight Liquid Storage Mini-Track Vehicles" Applied Sciences 14, no. 17: 7780. https://doi.org/10.3390/app14177780

APA StyleZhang, C., Cao, X., Xu, L., Wang, Y., He, Y., & Liu, X. (2024). Analysis of Longitudinal Braking Stability of Lightweight Liquid Storage Mini-Track Vehicles. Applied Sciences, 14(17), 7780. https://doi.org/10.3390/app14177780